-

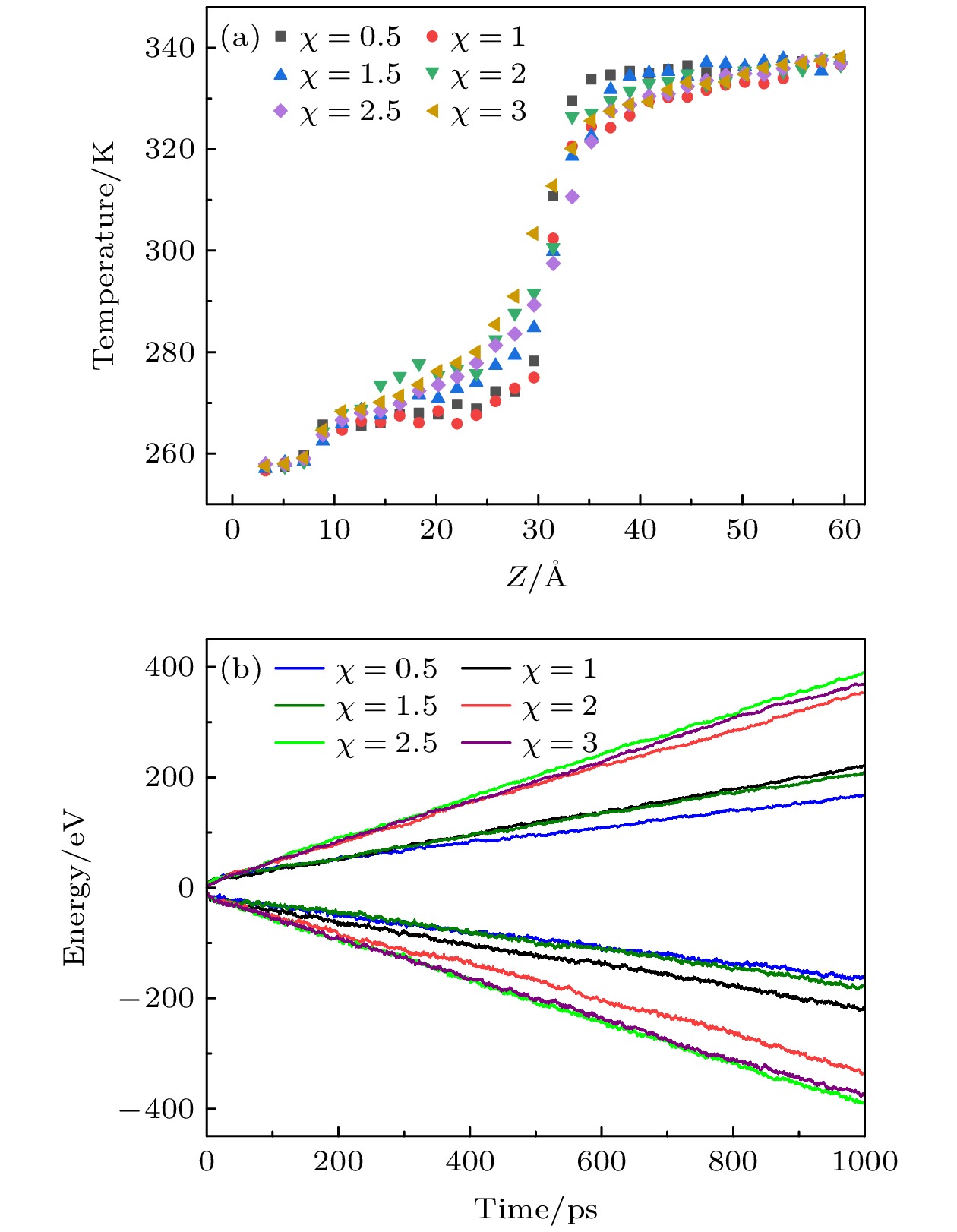

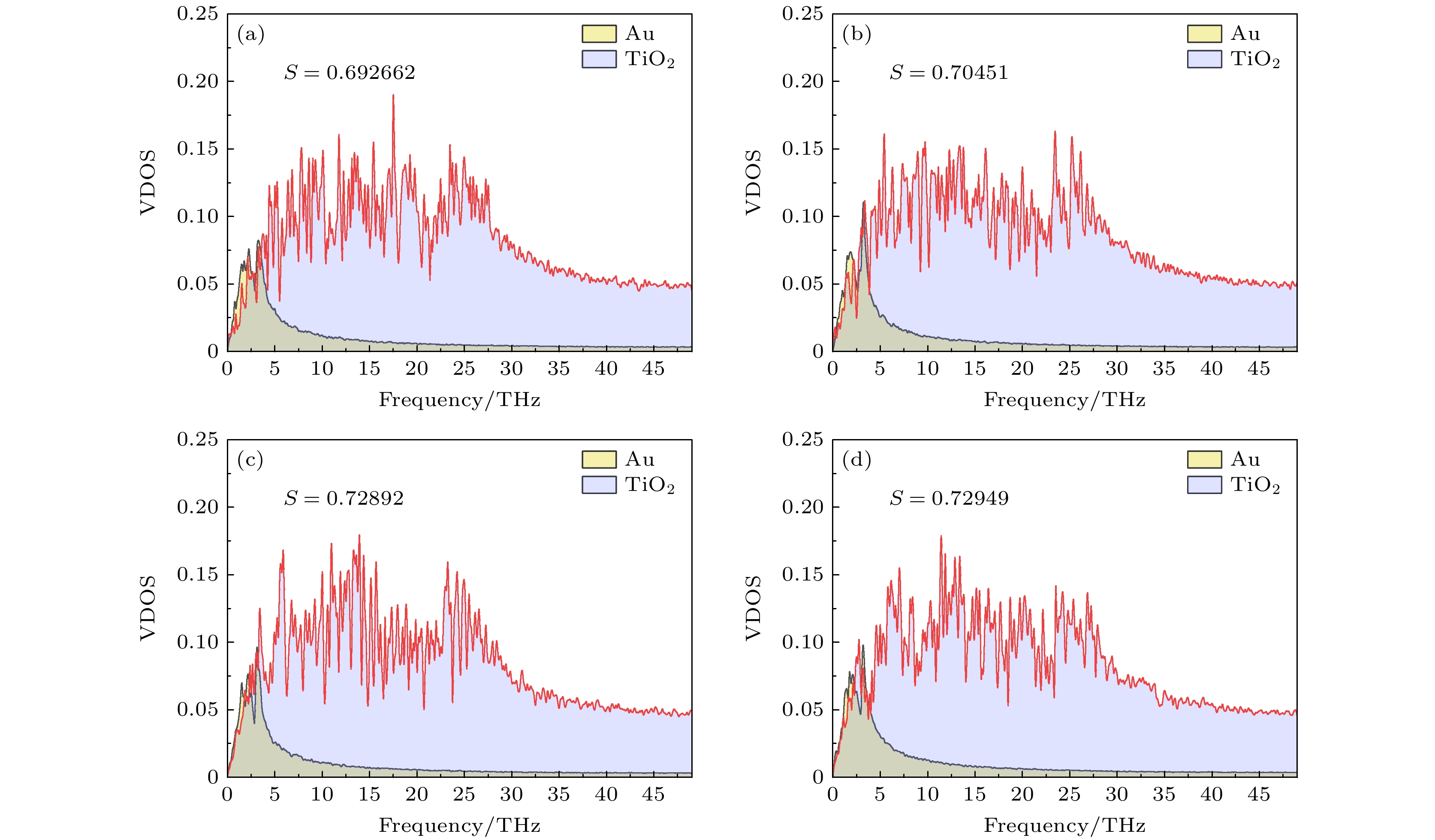

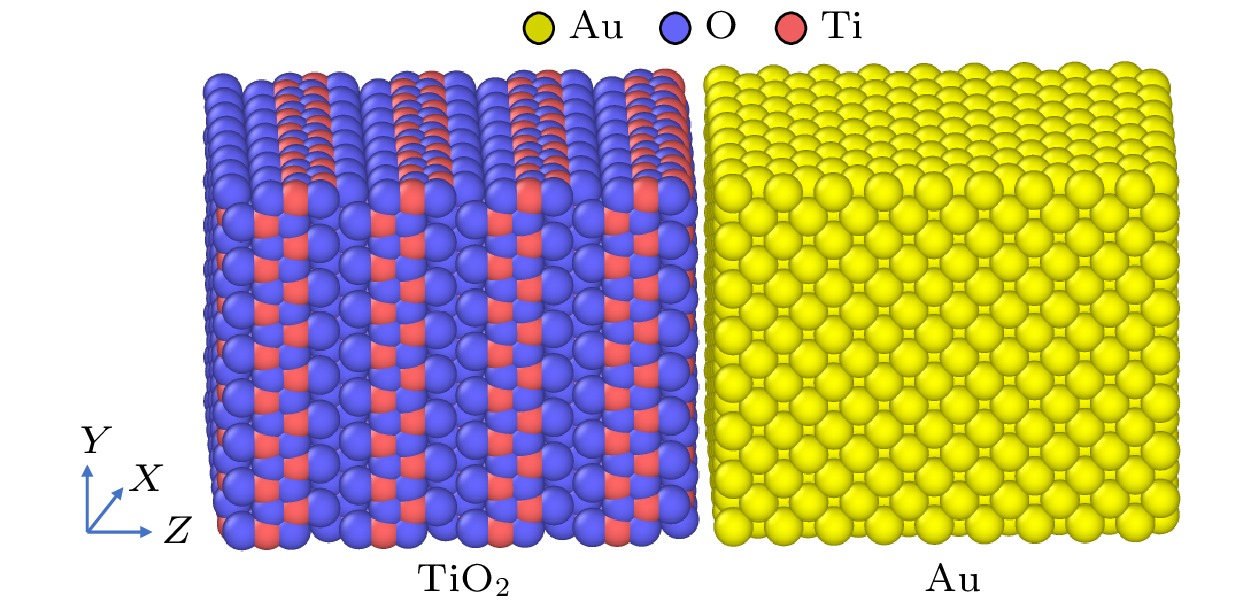

为了研究光电分解水体系中具有热等离激元效应的Au-TiO2电极的界面热输运特性, 本文采用非平衡分子动力学方法研究了温度、界面耦合强度以及添加石墨烯层对Au-TiO2界面热导的影响, 并通过声子态密度对界面热导的变化进行了分析. 研究结果表明, 当体系温度从300 K增加到800 K时, Au-TiO2界面导热系数增加了78.55%, 这与更多的低频声子参与界面热输运相关, 更多的热量传递到TiO2上可促进界面反应. 随着Au与TiO2界面耦合强度的增大, 界面热导率可通过TiO2和Au的声子态密度的重叠程度得到优化. 添加单层石墨烯可提高Au-TiO2结构的界面热导, 其中0—30 THz的低频区声子对导热贡献最大, 但添加2层和3层石墨烯, 石墨烯层与层之间的相互作用力阻碍了界面传热, 且在低频区的声子数量有所降低, 不利于热量在Au和TiO2之间进行传递.Thermoplasmonics originating from the relaxation process of plasmon resonances in nanostructures can be utilized as an efficient and highly localized heat source in solar-hydrogen conversion, but there have been few researches on the interfacial heat transport properties of photoelectrode with the thermoplasmonics effect in a photoelectrochemical water splitting system. In this work, the effects of temperature, interfacial coupling strength and the addition of graphene layers on the interfacial thermal conductance of Au-TiO2 electrodes are investigated by the non-equilibrium molecular dynamics simulation, and the variation of interfacial thermal conductance is analyzed by the phonon density of states. The results show that the interfacial thermal conductivity is increased by 78.55% when the temperature increases from 300 to 800 K. This is related to the fact that more low-frequency phonons participate in the interface heat transport, allowing more heat to be transferred to TiO2 to promote the interface reaction. As the coupling strength of the Au-TiO2 interface increases, the interfacial thermal conductivity of the electrode increases and then tends to stabilize. The interfacial thermal conductivity can be optimized by increasing the degree of overlap of the phonon state densities of Au and TiO2. The addition of a single layer of graphene can increase the interfacial thermal conductivity to 98.072 MW⋅m–2⋅K–1, but the addition of 2 and 3 layers of graphene can hinder interfacial heat transfer in Au and TiO2 due to the interaction between the layers of graphene. When adding graphene layer, medium-frequency phonons and high-frequency phonons are stimulated to participate in the interfacial heat transfer, but with the increase of the graphene layers, the number of low-frequency phonons in a range of 0—30 THz decreases, and these low-frequency phonons make the greatest contribution to the interfacial thermal conductivity. The obtained results are useful in regulating the thermal transport properties of the photoelectrode interface, which can provide new insights into and theoretical basis for the design and construction of composite photoelectrodes.

-

Keywords:

- Au-TiO2 /

- interfacial thermal conductivity /

- phonon density of states /

- molecular dynamics

[1] Cavigli L, Milanesi A, Khlebtsov B N, Centi S, Ratto F, Khlebtsov N G, Pini R 2020 J. Colloid Interface Sci. 578 358

Google Scholar

Google Scholar

[2] Czelej K, Colmenares J C, Jabłczyńska K, Ćwieka K, Werner L, Gradoń L 2021 Catal. Today 380 156

Google Scholar

Google Scholar

[3] Nie J L, Schneider J, Sieland F, Zhou L, Xia S W, Bahnemann D W 2018 RSC Adv. 8 25881

Google Scholar

Google Scholar

[4] Kunthakudee N, Puangpetch T, Ramakul P, Serivalsatit K, Hunsom M 2022 Int. J. Hydrogen Energy 47 23570

Google Scholar

Google Scholar

[5] Zhao Y, Sang L X, Wang C 2023 Sol. Energy Mater. Sol. Cells 255 112306

Google Scholar

Google Scholar

[6] Sang L X, Wang C, Zhao Y, Ren Z Y 2023 J. Phys. Chem. C 127 14666

Google Scholar

Google Scholar

[7] Wu K P, Zhang L, Wang D B, Li F Z, Zhang P Z, Sang L W, Liao M Y, Tang K, Ye J D, Gu S L 2022 Sci. Rep. 12 19907

Google Scholar

Google Scholar

[8] Swartz E T, Pohl R O 1989 Rev. Mod. Phys. 61 605

Google Scholar

Google Scholar

[9] Sadasivam S, Waghmare U V, Fisher T S 2015 J. Appl. Phys. 117 134502

Google Scholar

Google Scholar

[10] Wu B Y, Zhou M, Xu D J, Liu J J, Tang R J, Zhang P 2022 Surf. Interfaces 32 102119

Google Scholar

Google Scholar

[11] Meng H, Maruyama S, Xiang R, Yang N 2021 Int. J. Heat Mass Transfer 180 121773

Google Scholar

Google Scholar

[12] Qiu L, Zhu N, Feng Y H, Zhang X X, Wang X T 2020 Int. J. Heat Mass Transfer 152 119565

Google Scholar

Google Scholar

[13] Wu J X, Wen H, Shi H Z, Chen C P, Huang B, Wei Y F, Li M 2019 Superlattices Microstruct. 130 258

Google Scholar

Google Scholar

[14] Lu C C, Li Z H, Li S C, Li Z, Zhang Y Y, Zhao J H, Wei N 2023 Carbon 213 118250

Google Scholar

Google Scholar

[15] Chen G F, Chen J, Wang Z L 2020 Int. J. Thermophys. 41 48

Google Scholar

Google Scholar

[16] Wang B C, Shao W, Cao Q, Cui Z 2022 Int. J. Heat Mass Transfer 191 122850

Google Scholar

Google Scholar

[17] Roodbari M, Abbasi M, Arabha S, Gharedaghi A, Rajabpour A 2022 J. Mol. Liq. 348 118053

Google Scholar

Google Scholar

[18] Yang L, Wang C Z, Lin S W, Chen T H, Cao Y, Zhang P, Liu X H 2019 J. Phys. Condens. Matter 31 055302

Google Scholar

Google Scholar

[19] 于泽沛, 冯妍卉, 冯黛丽, 张欣欣 2020 化工学报 71 1822

Google Scholar

Google Scholar

Yu Z P, Feng Y H, Feng D L, Zhang X X 2020 CIESC J. 71 1822

Google Scholar

Google Scholar

[20] Zhang Y J, Wang Z Y, Li N, Sun F Y, Hao J P, Wu H J, Zhang H L 2023 Appl. Surf. Sci. 638 158001

Google Scholar

Google Scholar

[21] 宗志成, 潘东楷, 邓世琛, 万骁, 杨哩娜, 马登科, 杨诺 2023 72 034401

Google Scholar

Google Scholar

Zong Z C, Pan D K, Deng S C, Wang X, Yang L N, Ma D K, Yang N 2023 Acta Phys. Sin. 72 034401

Google Scholar

Google Scholar

[22] 刘东静, 周福, 陈帅阳, 胡志亮 2023 72 157901

Google Scholar

Google Scholar

Liu D J, Zhou F, Chen S Y, Hu Z L 2023 Acta Phys. Sin. 72 157901

Google Scholar

Google Scholar

[23] Aksoy M M, AlHosani M, Bayazitoglu Y 2021 Int. J. Thermophys. 42 87

Google Scholar

Google Scholar

[24] Liu Y, Wu W H, Yang S X, Yang P 2022 Surf. Interfaces 28 101640

Google Scholar

Google Scholar

[25] Hong Y, Zhang J C, Zeng X C 2016 Nanoscale 8 19211

Google Scholar

Google Scholar

[26] Matsui M, Akaogi M 1991 Mol. Simul. 6 239

Google Scholar

Google Scholar

[27] Heyhat M M, Abbasi M, Rajabpour A 2021 J. Mol. Liq. 333 115966

Google Scholar

Google Scholar

[28] Ding Z W, Pei Q X, Jiang J W, Huang W X, Zhang Y W 2016 Carbon 96 888

Google Scholar

Google Scholar

[29] Yang N, Luo T F, Esfarjani K, Henry A, Tian Z T, Shiomi J, Chalopin Y, Li B W, Chen G 2015 J. Comput. Theor. Nanosci. 12 168

Google Scholar

Google Scholar

[30] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[31] Zong Z C, Deng S C, Qin Y J, Wan X, Zhan J H, Ma D K, Yang N 2023 Nanoscale 15 16472

Google Scholar

Google Scholar

[32] Huang H, Zhong Y H, Cai B, Wang J F, Liu Z X, Peng Q 2023 Surf. Interfaces 37 102736

Google Scholar

Google Scholar

[33] Liang Z, Hu M 2018 J. Appl. Phys. 123 191101

Google Scholar

Google Scholar

[34] Wu X, Han Q 2021 ACS Appl. Mater. Interfaces 13 32564

Google Scholar

Google Scholar

[35] Mitra D, Howli P, Das B K, Das N S, Chattopadhyay P, Chattopadhyay K K 2020 J. Mol. Liq. 302 112499

Google Scholar

Google Scholar

[36] Momenzadeh L, Moghtaderi B, Belova I V, Murch G E 2018 Comput. Condens. Matter 17 e00342

Google Scholar

Google Scholar

[37] Chow P K, Cardona Quintero Y, O’Brien P, Hubert Mutin P, Lane M, Ramprasad R, Ramanath G 2013 Appl. Phys. Lett. 102 201605

Google Scholar

Google Scholar

[38] Hatam-Lee S M, Jabbari F, Rajabpour A 2022 Nanoscale Microscale Thermophys. Eng. 26 40

Google Scholar

Google Scholar

[39] Bao W L, Wang Z L, Tang D W 2022 Int. J. Heat Mass Transfer 183 122090

Google Scholar

Google Scholar

[40] Zou H Y, Feng Y H, Qiu L, Zhang X X 2022 Int. J. Heat Mass Transfer 183 122216

Google Scholar

Google Scholar

[41] Wilson B A, Nielsen S O, Randrianalisoa J H, Qin Z P 2022 J. Chem. Phys. 157 054703

Google Scholar

Google Scholar

[42] Farahani H, Rajabpour A, Khanaki M, Reyhani A 2018 Comput. Mater. Sci. 142 1

Google Scholar

Google Scholar

[43] 安盟, 孙旭辉, 陈东升, 杨诺 2022 71 166501

Google Scholar

Google Scholar

An M, Sun X H, Chen D S, Yang N 2022 Acta Phys. Sin. 71 166501

Google Scholar

Google Scholar

[44] Hu M, Sergei S, Pawel K 2007 Appl. Phys. Lett. 91 241910

Google Scholar

Google Scholar

[45] Kan Y J, Hong F, Wei Z Y, Bi K D 2020 Mater. Res. Express 7 095602

Google Scholar

Google Scholar

[46] Wei Z Y, Ni Z H, Bi K D, Chen M H, Chen Y F 2011 Carbon 49 2653

Google Scholar

Google Scholar

[47] Cao H Y, Guo Z X, Xiang H J, Gong X G 2012 Phys. Lett. A 376 525

Google Scholar

Google Scholar

[48] Namsani S, Singh J K 2018 J. Phys. Chem. C 122 2113

Google Scholar

Google Scholar

[49] Pei Q X, Guo J Y, Suwardi A, Zhang G 2023 J. Phys. Chem. C 127 19796

Google Scholar

Google Scholar

[50] Wu X, Han Q 2022 Int. J. Heat Mass Transfer 191 122829

Google Scholar

Google Scholar

-

表 1 Matsui-Akaogi力场的Buckingham势函数参数[28]

Table 1. Parameters of the Buckingham potential function for the Matsui-Akaogi force field[28].

Aij/(kcal·mol–1) Bij/(kcal·mol–1·Å6) ρij/Å Ti—Ti 717650 121.10 0.155 Ti—O 391050 290.42 0.195 O—O 271720 696.95 0.235 表 2 L-J势函数参数

Table 2. L-J potential function parameter.

σ/Å ε0/(kcal·mol–1) Ti—Au 2.488 1.62018 O—Au 3.092 0.81932 Ti—C 2.930 0.24029 Au—C 3.455 0.64085 O—C 3.529 0.12158 -

[1] Cavigli L, Milanesi A, Khlebtsov B N, Centi S, Ratto F, Khlebtsov N G, Pini R 2020 J. Colloid Interface Sci. 578 358

Google Scholar

Google Scholar

[2] Czelej K, Colmenares J C, Jabłczyńska K, Ćwieka K, Werner L, Gradoń L 2021 Catal. Today 380 156

Google Scholar

Google Scholar

[3] Nie J L, Schneider J, Sieland F, Zhou L, Xia S W, Bahnemann D W 2018 RSC Adv. 8 25881

Google Scholar

Google Scholar

[4] Kunthakudee N, Puangpetch T, Ramakul P, Serivalsatit K, Hunsom M 2022 Int. J. Hydrogen Energy 47 23570

Google Scholar

Google Scholar

[5] Zhao Y, Sang L X, Wang C 2023 Sol. Energy Mater. Sol. Cells 255 112306

Google Scholar

Google Scholar

[6] Sang L X, Wang C, Zhao Y, Ren Z Y 2023 J. Phys. Chem. C 127 14666

Google Scholar

Google Scholar

[7] Wu K P, Zhang L, Wang D B, Li F Z, Zhang P Z, Sang L W, Liao M Y, Tang K, Ye J D, Gu S L 2022 Sci. Rep. 12 19907

Google Scholar

Google Scholar

[8] Swartz E T, Pohl R O 1989 Rev. Mod. Phys. 61 605

Google Scholar

Google Scholar

[9] Sadasivam S, Waghmare U V, Fisher T S 2015 J. Appl. Phys. 117 134502

Google Scholar

Google Scholar

[10] Wu B Y, Zhou M, Xu D J, Liu J J, Tang R J, Zhang P 2022 Surf. Interfaces 32 102119

Google Scholar

Google Scholar

[11] Meng H, Maruyama S, Xiang R, Yang N 2021 Int. J. Heat Mass Transfer 180 121773

Google Scholar

Google Scholar

[12] Qiu L, Zhu N, Feng Y H, Zhang X X, Wang X T 2020 Int. J. Heat Mass Transfer 152 119565

Google Scholar

Google Scholar

[13] Wu J X, Wen H, Shi H Z, Chen C P, Huang B, Wei Y F, Li M 2019 Superlattices Microstruct. 130 258

Google Scholar

Google Scholar

[14] Lu C C, Li Z H, Li S C, Li Z, Zhang Y Y, Zhao J H, Wei N 2023 Carbon 213 118250

Google Scholar

Google Scholar

[15] Chen G F, Chen J, Wang Z L 2020 Int. J. Thermophys. 41 48

Google Scholar

Google Scholar

[16] Wang B C, Shao W, Cao Q, Cui Z 2022 Int. J. Heat Mass Transfer 191 122850

Google Scholar

Google Scholar

[17] Roodbari M, Abbasi M, Arabha S, Gharedaghi A, Rajabpour A 2022 J. Mol. Liq. 348 118053

Google Scholar

Google Scholar

[18] Yang L, Wang C Z, Lin S W, Chen T H, Cao Y, Zhang P, Liu X H 2019 J. Phys. Condens. Matter 31 055302

Google Scholar

Google Scholar

[19] 于泽沛, 冯妍卉, 冯黛丽, 张欣欣 2020 化工学报 71 1822

Google Scholar

Google Scholar

Yu Z P, Feng Y H, Feng D L, Zhang X X 2020 CIESC J. 71 1822

Google Scholar

Google Scholar

[20] Zhang Y J, Wang Z Y, Li N, Sun F Y, Hao J P, Wu H J, Zhang H L 2023 Appl. Surf. Sci. 638 158001

Google Scholar

Google Scholar

[21] 宗志成, 潘东楷, 邓世琛, 万骁, 杨哩娜, 马登科, 杨诺 2023 72 034401

Google Scholar

Google Scholar

Zong Z C, Pan D K, Deng S C, Wang X, Yang L N, Ma D K, Yang N 2023 Acta Phys. Sin. 72 034401

Google Scholar

Google Scholar

[22] 刘东静, 周福, 陈帅阳, 胡志亮 2023 72 157901

Google Scholar

Google Scholar

Liu D J, Zhou F, Chen S Y, Hu Z L 2023 Acta Phys. Sin. 72 157901

Google Scholar

Google Scholar

[23] Aksoy M M, AlHosani M, Bayazitoglu Y 2021 Int. J. Thermophys. 42 87

Google Scholar

Google Scholar

[24] Liu Y, Wu W H, Yang S X, Yang P 2022 Surf. Interfaces 28 101640

Google Scholar

Google Scholar

[25] Hong Y, Zhang J C, Zeng X C 2016 Nanoscale 8 19211

Google Scholar

Google Scholar

[26] Matsui M, Akaogi M 1991 Mol. Simul. 6 239

Google Scholar

Google Scholar

[27] Heyhat M M, Abbasi M, Rajabpour A 2021 J. Mol. Liq. 333 115966

Google Scholar

Google Scholar

[28] Ding Z W, Pei Q X, Jiang J W, Huang W X, Zhang Y W 2016 Carbon 96 888

Google Scholar

Google Scholar

[29] Yang N, Luo T F, Esfarjani K, Henry A, Tian Z T, Shiomi J, Chalopin Y, Li B W, Chen G 2015 J. Comput. Theor. Nanosci. 12 168

Google Scholar

Google Scholar

[30] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[31] Zong Z C, Deng S C, Qin Y J, Wan X, Zhan J H, Ma D K, Yang N 2023 Nanoscale 15 16472

Google Scholar

Google Scholar

[32] Huang H, Zhong Y H, Cai B, Wang J F, Liu Z X, Peng Q 2023 Surf. Interfaces 37 102736

Google Scholar

Google Scholar

[33] Liang Z, Hu M 2018 J. Appl. Phys. 123 191101

Google Scholar

Google Scholar

[34] Wu X, Han Q 2021 ACS Appl. Mater. Interfaces 13 32564

Google Scholar

Google Scholar

[35] Mitra D, Howli P, Das B K, Das N S, Chattopadhyay P, Chattopadhyay K K 2020 J. Mol. Liq. 302 112499

Google Scholar

Google Scholar

[36] Momenzadeh L, Moghtaderi B, Belova I V, Murch G E 2018 Comput. Condens. Matter 17 e00342

Google Scholar

Google Scholar

[37] Chow P K, Cardona Quintero Y, O’Brien P, Hubert Mutin P, Lane M, Ramprasad R, Ramanath G 2013 Appl. Phys. Lett. 102 201605

Google Scholar

Google Scholar

[38] Hatam-Lee S M, Jabbari F, Rajabpour A 2022 Nanoscale Microscale Thermophys. Eng. 26 40

Google Scholar

Google Scholar

[39] Bao W L, Wang Z L, Tang D W 2022 Int. J. Heat Mass Transfer 183 122090

Google Scholar

Google Scholar

[40] Zou H Y, Feng Y H, Qiu L, Zhang X X 2022 Int. J. Heat Mass Transfer 183 122216

Google Scholar

Google Scholar

[41] Wilson B A, Nielsen S O, Randrianalisoa J H, Qin Z P 2022 J. Chem. Phys. 157 054703

Google Scholar

Google Scholar

[42] Farahani H, Rajabpour A, Khanaki M, Reyhani A 2018 Comput. Mater. Sci. 142 1

Google Scholar

Google Scholar

[43] 安盟, 孙旭辉, 陈东升, 杨诺 2022 71 166501

Google Scholar

Google Scholar

An M, Sun X H, Chen D S, Yang N 2022 Acta Phys. Sin. 71 166501

Google Scholar

Google Scholar

[44] Hu M, Sergei S, Pawel K 2007 Appl. Phys. Lett. 91 241910

Google Scholar

Google Scholar

[45] Kan Y J, Hong F, Wei Z Y, Bi K D 2020 Mater. Res. Express 7 095602

Google Scholar

Google Scholar

[46] Wei Z Y, Ni Z H, Bi K D, Chen M H, Chen Y F 2011 Carbon 49 2653

Google Scholar

Google Scholar

[47] Cao H Y, Guo Z X, Xiang H J, Gong X G 2012 Phys. Lett. A 376 525

Google Scholar

Google Scholar

[48] Namsani S, Singh J K 2018 J. Phys. Chem. C 122 2113

Google Scholar

Google Scholar

[49] Pei Q X, Guo J Y, Suwardi A, Zhang G 2023 J. Phys. Chem. C 127 19796

Google Scholar

Google Scholar

[50] Wu X, Han Q 2022 Int. J. Heat Mass Transfer 191 122829

Google Scholar

Google Scholar

计量

- 文章访问数: 6017

- PDF下载量: 93

- 被引次数: 0

下载:

下载: