-

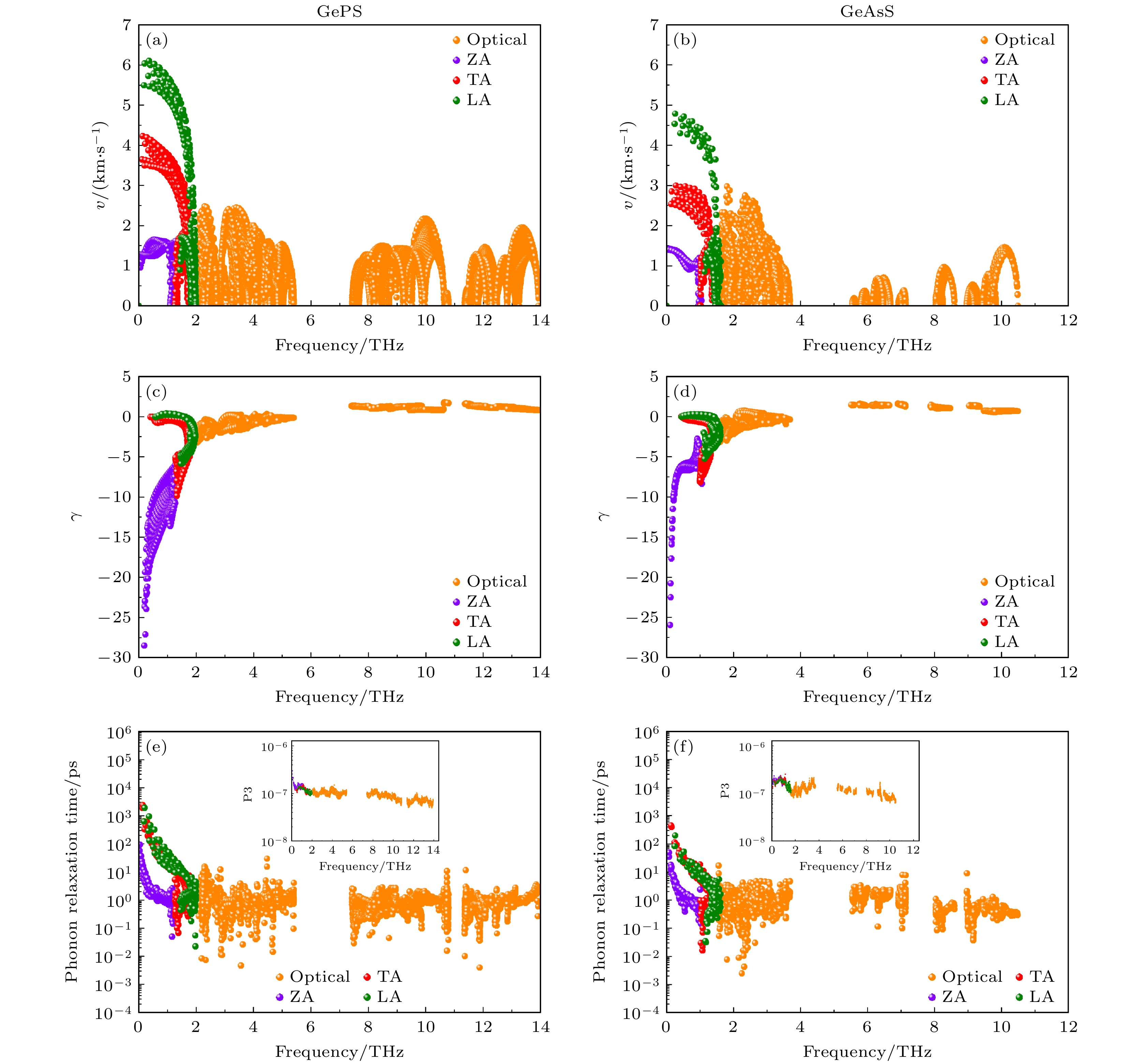

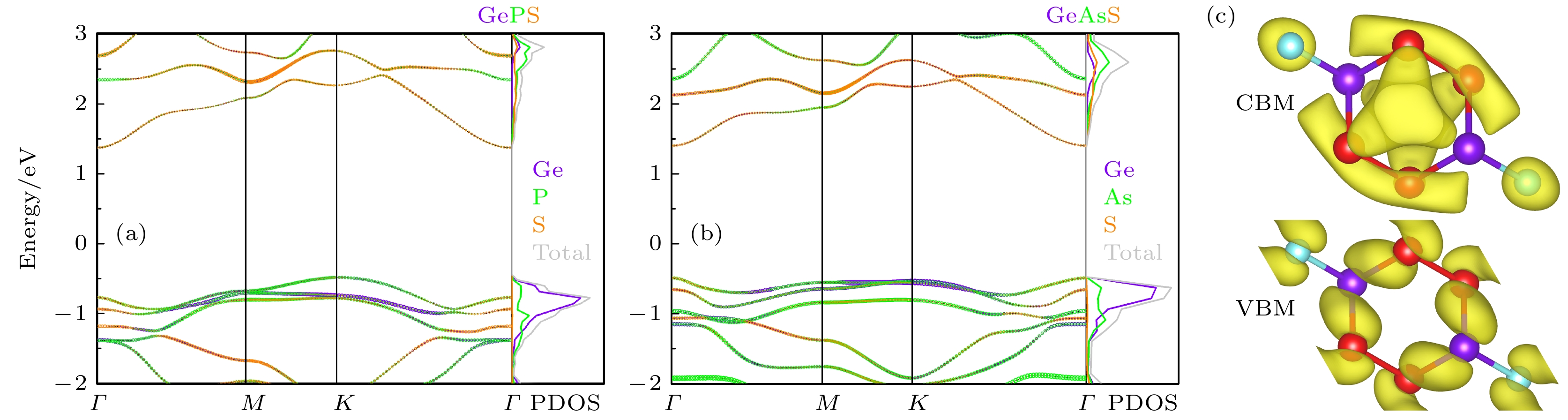

单层Ge2X4S2(X = P, As)是最近预测的一种二维层状材料, 它们不仅拥有高的光吸收系数, 同时还有较高的载流子迁移率, 这意味着它们在光电和热电领域可能有较好的应用前景. 本文通过第一性原理和玻尔兹曼输运理论系统地研究了这两种材料的热电性质. 结果表明, 单层Ge2P4S2和Ge2As4S2在室温下展现较低的晶格热导率, 沿armchair方向分别为3.93 W·m–1·K–1和3.19 W·m–1·K–1, zigzag方向分别为4.38 W·m–1·K–1和3.79 W·m–1·K–1, 这主要是由低的声子群速度、大的格林艾森参数以及小的声子弛豫时间造成的. 基于HSE06泛函计算出的能带结构表明单层Ge2As4S2是带隙值为1.21 eV的直接带隙半导体, 而单层Ge2P4S2是带隙值为1.13 eV的间接带隙半导体. 价带上明显的双重简并现象使得单层Ge2P4S2和Ge2As4S2具有较大的塞贝克系数, 其中300 K时沿armchair方向分别达到了1800 μV·K–1和2070 μV·K–1. 对于具有较小晶格热导率和较高功率因子的单层Ge2X4S2而言, 它们的热电性能是非常值得期待的. 本文计算表明, 当处于最佳的n型掺杂时, 单层Ge2P4S2和Ge2As4S2在500 K时都具有较高的热电优值, 在两个方向的最大值分别为3.06 (armchair方向)和3.51 (zigzag方向), 以及3.21 (armchair方向)和2.54 (zigzag方向), 这意味着它们在中温热电应用领域存在较大的应用价值.Monolayer Ge2X4S2 (X = P, As) are novel two-dimensional (2D) layered materials with suitable optical absorption properties in the visible range and high carrier mobility, so they possess broad application prospects in the photoelectric and thermoelectric fields. In this work, their thermoelectric properties are systematicly evaluated by using the first-principles and Boltzmann transport theory. For monolayer Ge2As4S2 and Ge2P4S2, their smaller phonon group velocities, low relaxation times and the large Grüneisen parameters result in ultra-low lattice thermal conductivities, which are 3.93 W·m–1·K–1 and 3.19 W·m–1·K–1 in the armchair direction, 4.38 W·m–1·K–1 and 3.79 W·m–1·K–1 in the zigzag directions at 300 K. Their electronic band structures reveal that the monolayer Ge2As4S2 is a semiconductor with a direct band gap of 1.21 eV, while the single-layer Ge2P4S2 owns an indirect band gap of 1.13 eV. Meanwhile, the twofold degeneracy of valence band provides a large p-type Seebeck coefficient that is 1800 μV·K–1 for Ge2P4S2 and 2070 μV·K–1 for Ge2As4S2 in the armchair direction. Obviously, monolayer Ge2X4S2 has smaller lattice thermal conductivity and higher power factor, thus it is worth exploring their thermoelectric properties. The results prove that monolayer Ge2As4S2 and Ge2P4S2 have outstanding thermoelectric performances at 500 K when they are treated by optimal n-type doping. The maximum ZT values of monolayer Ge2As4S2 and Ge2P4S2 are 3.06 (armchair direction) and 3.51 (zigzag direction), as well as 3.21 (armchair direction) and 2.54 (zigzag direction), indicating that monolayer Ge2X4S2 can be a potential candidate in the medium-temperature thermoelectric applications.

[1] Yang J, Xi L L, Qiu W J, Wu L H, Shi X, Chen L D, Yang J H, Zhang W Q, Uher C, Singh D J 2016 npj Comput. Mater. 2 1

Google Scholar

Google Scholar

[2] Ding Z D, An M, Mo S Q, Yu X X, Jin Z L, Liao Y X, Esfarjani K, Lü J T, Shiomi J, Yang N 2019 J. Mater. Chem. A 7 2114

Google Scholar

Google Scholar

[3] Hicks L D, Dresselhaus M S 1993 Phys. Rev. B 47 16631

Google Scholar

Google Scholar

[4] Hicks L D, Harman T C, Dresselhaus M S 1993 Appl. Phys. Lett. 63 3230

Google Scholar

Google Scholar

[5] Zhao L-D, Chang C, Tan G J, Kanatzidis M G 2016 Energy Environ. Sci. 9 044

[6] Liu Y C, Wang W X, Yang J, Li S 2018 Adv. Sustainable Syst. 2 1800046

Google Scholar

Google Scholar

[7] Tan Q, Zhao L D, Li J F, Wu C F, Wei T R, Xing Z B, Kanatzidis MG 2014 J. Mater. Chem. A 2 17302

Google Scholar

Google Scholar

[8] Yan X, Poudel B, Ma Y, Liu W S, Joshi G, Wang H, Lan Y C, Wang D Z, Chen G, Ren Z F 2010 Nano Lett. 10 3373

Google Scholar

Google Scholar

[9] Zhao L D, Dravid V P, Kanatzidis M G 2014 Energy Environ. Sci. 7 251

Google Scholar

Google Scholar

[10] Chhowalla M, Shin H S, Eda G, Li L J, Loh K P, Zhang H 2013 Nat. Chem. 5 263

Google Scholar

Google Scholar

[11] Xie W J, He J, Kang H J, Tang X F, Zhu S, Laver M, Wang S Y, Copley J R D, Brown C M, Zhang Q J, Tritt T M 2010 Nano Lett. 10 3283

Google Scholar

Google Scholar

[12] Dresselhaus M S, Dresselhaus G, Sun X, Zhang Z 1999 Phys. Solid State 41 679

Google Scholar

Google Scholar

[13] Rashid Z, Nissimagoudar A S, Li W 2019 Phys. Chem. Chem. Phys. 21 5679

Google Scholar

Google Scholar

[14] Snyder G J, Toberer E S 2008 Nat. Mater. 7 105

Google Scholar

Google Scholar

[15] Guo S D, Li H C 2017 Comput. Mater. Sci. 139 361

Google Scholar

Google Scholar

[16] Zare M, Rameshti B Z, Ghamsari F G, Asgari R 2017 Phys. Rev. B 95 045422

Google Scholar

Google Scholar

[17] Zhang R Q, Zhou Z Z, QI N, Zhao B, Zhang Q K, Zhang Z Y, Chen Z Q 2019 J. Mater. Chem. C 7 14986

Google Scholar

Google Scholar

[18] Ruleova P, Drasar C, Lostak P, Li C-P, Ballikaya S, Uher C 2010 Mater. Chem. Phys. 119 299

Google Scholar

Google Scholar

[19] Yu J B, Sun Q 2018 Appl. Phys. Lett. 112 053901

Google Scholar

Google Scholar

[20] Huang S, Wang Z Y, Xiong R, Yu H Y, Shi J 2019 Nano Energy 62 212

Google Scholar

Google Scholar

[21] Zhu Y L, Yuan J H, Song Y Q, Xue K H, Wang S, Lian C, Li Z N, Xu M, Cheng X M, Miao X S 2019 Int. J. Hydrogen Energy 44 21536

Google Scholar

Google Scholar

[22] Jing Y, MA Y D, LI Y F, Heine T 2017 Nano Lett. 17 1833

Google Scholar

Google Scholar

[23] Zeng B W, Long M Q, Zhang X J, Dong Y L, Li M J, Yi Y G, Duan H M 2018 J. Phys. D:Appl. Phys. 51 235302

Google Scholar

Google Scholar

[24] Zhu X L, Liu P F, Zhang J R, Zhang P, Zhou W X, Xie G F 2019 Nanoscale 11 19923

Google Scholar

Google Scholar

[25] Ouyang T, Jiang E L, Tang C, Li J, He C Y, Zhong J X 2018 J. Mater. Chem. A 6 21532

Google Scholar

Google Scholar

[26] Sun Z H, Yuan K P, Chang Z, Bi S P, Zhang X L, Tang D W 2020 Nanoscale 12 3330

Google Scholar

Google Scholar

[27] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[28] Lee K, Murray É D, Kong L Z, Lundqvist B I, Langreth D C 2010 Phys. Rev. B 82 081101

Google Scholar

Google Scholar

[29] Blöchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[30] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[31] Togo A, Oba F, Tanaka I 2008 Phys. Rev. B 78 134106

Google Scholar

Google Scholar

[32] Li W, Lindsay L, Broido D A, Stewart D A, Mingo N 2012 Phys. Rev. B 86 174307

Google Scholar

Google Scholar

[33] Li W, Carrete J, Katcho N A, Mingo N 2014 Comput. Phys. Commun. 185 1747

Google Scholar

Google Scholar

[34] Madsen G K H, Singh D J 2006 Comput. Phys. Commun. 175 67

Google Scholar

Google Scholar

[35] Heyd J, Scuseria G E, Ernzerhof M 2003 J. Chem. Phys. 118 8207

Google Scholar

Google Scholar

[36] Bardeen J, Shockley W 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[37] Chaput L, Pécheur P, Scherrer H 2007 Phys. Rev. B 75 045116

Google Scholar

Google Scholar

[38] Price P J 1981 Ann. Phys. 133 217

Google Scholar

Google Scholar

[39] Xi J Y, Long M Q, Tang L, Wanf D, Shuai Z G 2012 Nanoscale 4 4348

Google Scholar

Google Scholar

[40] Becke A D, Edgecombe K E 1990 J. Chem. Phys. 92 5397

Google Scholar

Google Scholar

[41] Nalewajski R F, Köster A M, Escalante S 2005 J. Phys. Chem. A 109 10038

Google Scholar

Google Scholar

[42] Savin A, Nesper R, Wengert S, Wengert S 1997 Angew. Chem. Int. Ed. 36 1808

Google Scholar

Google Scholar

[43] Batsanov S S 2001 Inorg. Mater. 37 871

Google Scholar

Google Scholar

[44] Gao Z B, Tao F, Ren J 2018 Nanoscale 10 12997

Google Scholar

Google Scholar

[45] Gao Z B, Zhang Z F, Liu G, Wang J S 2019 Phys. Chem. Chem. Phys. 21 26033

Google Scholar

Google Scholar

[46] Wee D, Kozinsky B, Marzari N, Fornari M 2010 Phys. Rev. B 81 045204

Google Scholar

Google Scholar

[47] Zhou Z Z, Liu H J, Fan D D, Cao G H, Sheng Y 2019 Phys. Rev. B 99 085410

Google Scholar

Google Scholar

[48] Li W, Carrete J, Mingo N 2013 Appl. Phys. Lett. 103 253103

Google Scholar

Google Scholar

[49] Peng B, Zhang H, Shao H Z, Lu H L, Zhang D W, Zhu H Y 2016 Nano Energy 30 225

Google Scholar

Google Scholar

[50] McGaughey A J H, Landry E S, Sellan D P, Amon C H 2011 Appl. Phys. Lett. 99 131904

Google Scholar

Google Scholar

[51] Xie G F, Guo Y, Wei X L, Zhang K W, Sun L Z, Zhong J X, Zhang G, Zhang Y W 2014 Appl. Phys. Lett. 104 233901

Google Scholar

Google Scholar

[52] Xie G F, Ju Z F, Zhou K K, Wei X L, Guo Z X, Cai Y Q, Zhang G 2018 npj Comput. Mater. 4 1

Google Scholar

Google Scholar

[53] Wei X L, Wang Y C, Shen Y L, Xie G F, Xiao H P, Zhong J X, Zhang G 2014 Appl. Phys. Lett. 105 103902

Google Scholar

Google Scholar

[54] Zhu L Y, Zhang G, Li B W 2014 Phys. Rev. B 90 214302

Google Scholar

Google Scholar

[55] Li W, Mingo N 2015 Phys. Rev. B 91 144304

Google Scholar

Google Scholar

[56] Pandey T, Polanco C A, Lindsay L, Parker D S 2017 Phys. Rev. B 95 224306

Google Scholar

Google Scholar

[57] Pei Y Z, Wang H, Snyder G J 2012 Adv. Mater. 24 6125

Google Scholar

Google Scholar

[58] Zhu X L, Yang H Y, Zhou W X, Wang T B, Xu N, Xie G F 2020 ACS Appl. Mater. Interfaces 12 36102

Google Scholar

Google Scholar

[59] Cai Y Q, Zhang G, Zhang Y W 2014 J. Am. Chem. Soc. 136 6269

Google Scholar

Google Scholar

[60] Zhang L C, Qin G Z, Fang W Z, Cui H J, Zheng Q R, Yan Q B, Su G 2016 Sci. Rep. 6 19830

[61] Yi W C, Chen X, Wang Z X, Ding Y C, Yang B C, Liu X B 2019 J. Mater. Chem. C 7 7352

Google Scholar

Google Scholar

[62] Heremans J P 2005 Acta Phys. Pol. A 108 609

Google Scholar

Google Scholar

[63] Jonson M, Mahan G D 1980 Phys. Rev. B 21 4223

Google Scholar

Google Scholar

-

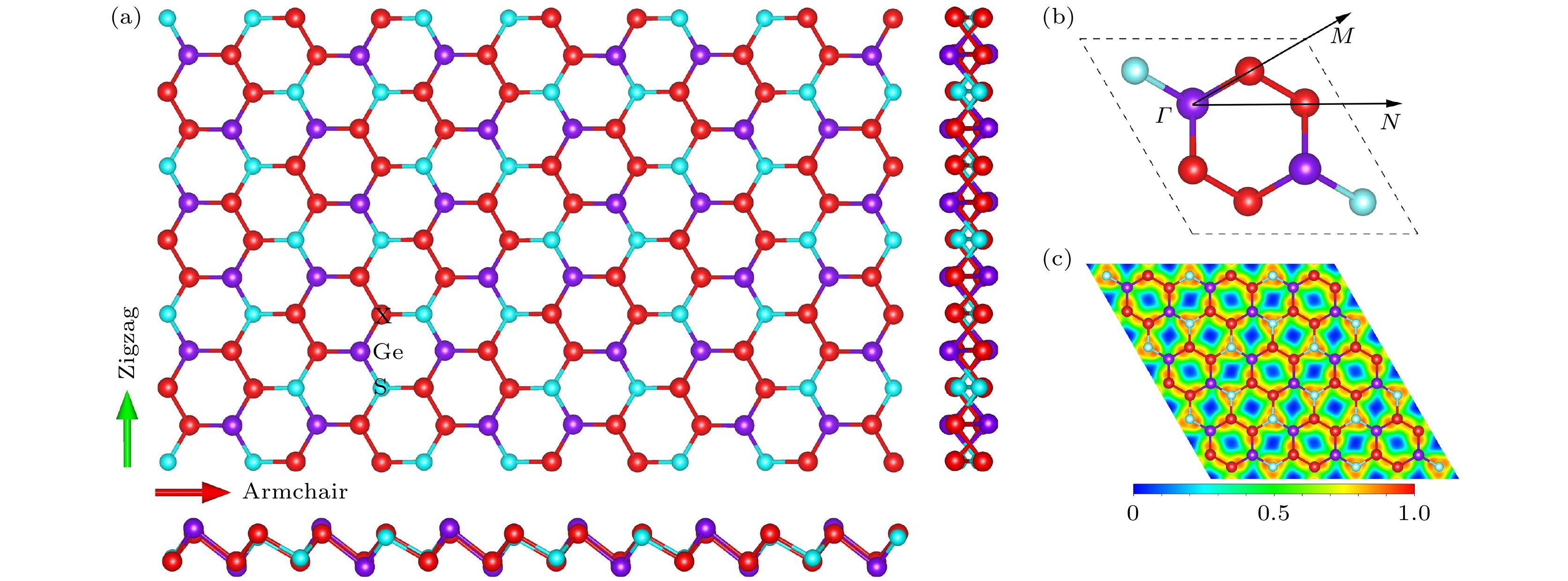

图 1 (a) 单层Ge2X4S2的几何结构; (b) 对应的布里渊区; (c) 局域电荷密度. 其中紫色、红色以及蓝色球分别是Ge原子、P(As)原子和S原子

Fig. 1. (a) The structure of monolayer Ge2X4S2; (b) schematic diagram of the Brillouin zone; (c) electron localization function, where the purple, red and blue balls are Ge atoms, P (As) atoms and S atoms, respectively.

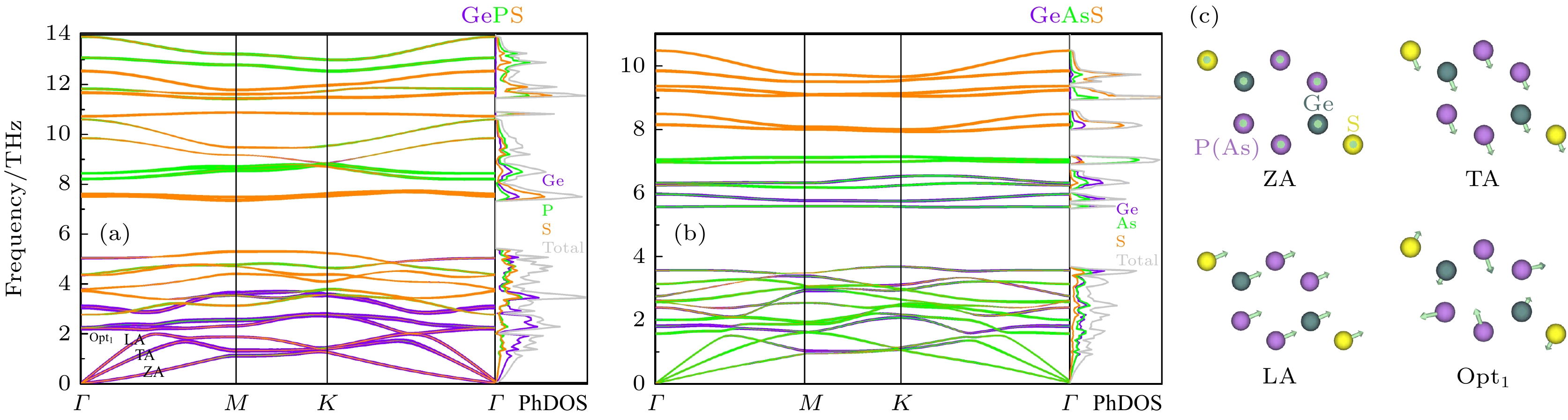

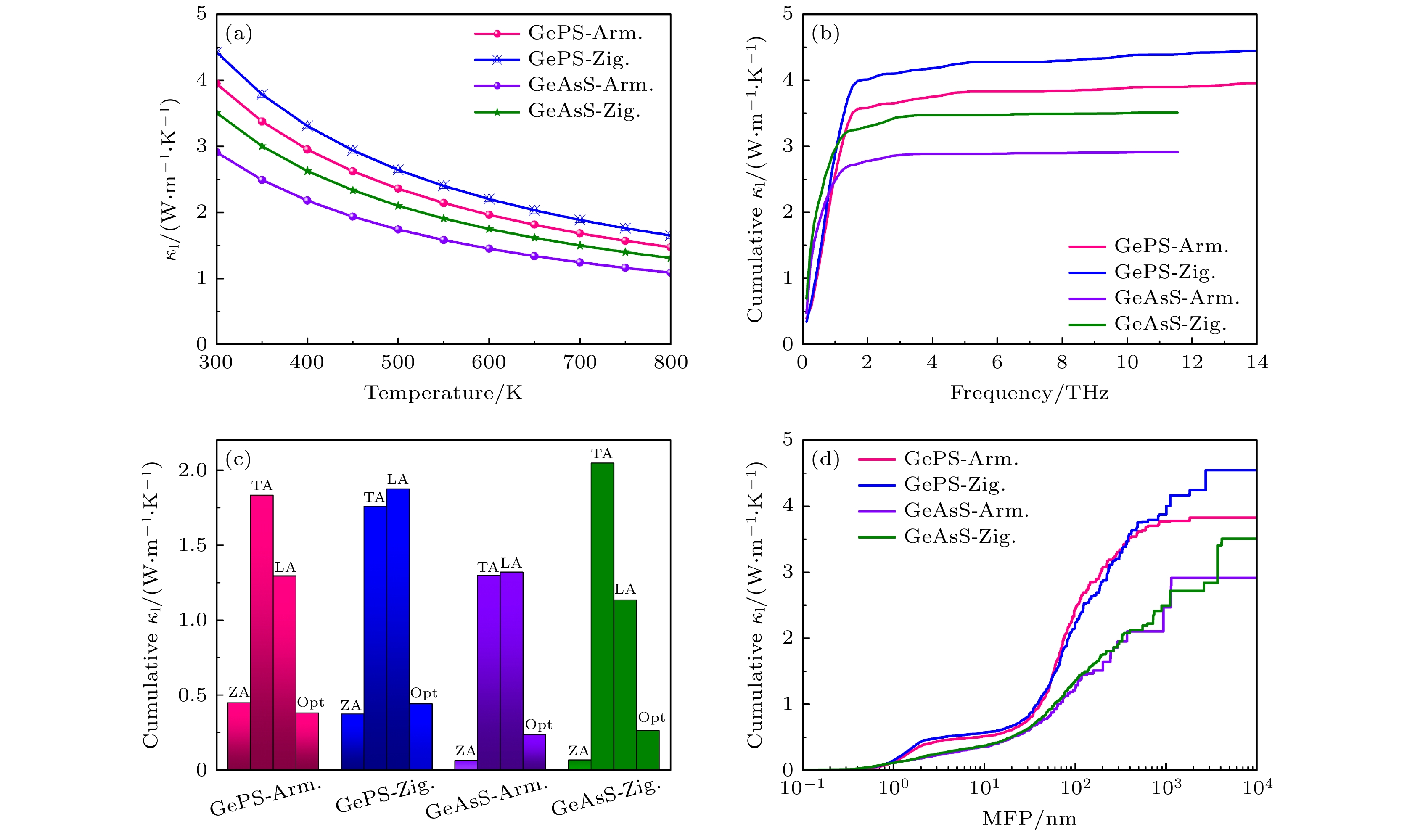

图 3 单层Ge2X4S2的晶格热导率与温度的关系(a), 累积晶格热导率与频率的关系(b), 各分支对累积晶格热导率的贡献(c), 累积晶格热导率与声子平均自由程的关系(d)

Fig. 3. (a) Lattice thermal conductively with respect to temperature, (b) cumulative lattice thermal conductivity as function of frequency, (c) the contribution of phonon acoustic mode (ZA, TA, LA) and optical modes (Opt) to the total lattice thermal conductivity, (d) cumulative lattice thermal conductivity as a function of mean free path (MFP) of monolayer Ge2X4S2.

图 4 单层Ge2X4S2的声子群速度(a), (b), 格林艾森参数(c), (d), 声子弛豫时间和三声子散射相空间(e), (f), 图 (e)和图(f)中的插图为三声子散射相空间

Fig. 4. (a), (b) The phonon group velocity, (c), (d) Grüneisen parameters, and (e), (f) phonon relaxation time of monolayer Ge2X4S2. The inset of Fgiure (e) and Figure (f) is three-phonon scattering phase space.

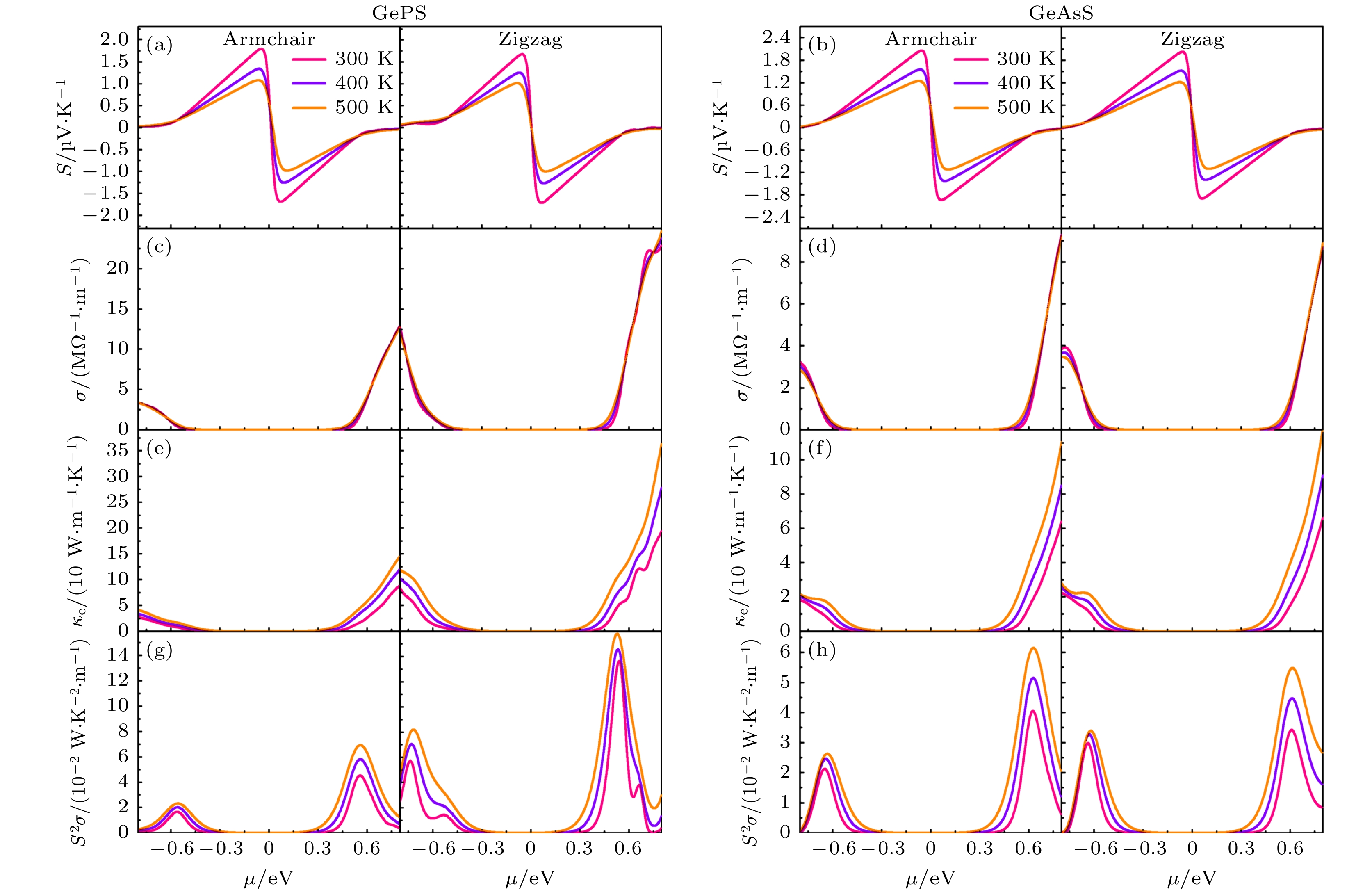

图 6 单层Ge2X4S2的电子输运参数(a), (b)塞贝克系数; (c), (d)电导率; (e), (f) 电子热导率; (g), (h) 功率因子

Fig. 6. Electronic transport parameters of monolayer Ge2X4S2 include the Seebeck coefficient ((a), (b)), electrical conductivity ((c), (d)), electronic thermal conductivity ((e), (f)), and power factor ((g), (h)) as function of the chemical potential.

表 1 弛豫后的结构参数

Table 1. The parameters of optimal structure.

晶格常数/Å 键长/Å Ge—S Ge—As (P) As—As (P—P) Ge2As4S2 7.10 2.48 2.60 2.48 Ge2P4S2 6.77 2.50 2.49 2.21 表 2 300 K下单层Ge2X4S2的弹性模量C 2D, 形变势常数El, 有效质量m*, 载流子迁移率μ和弛豫时间τ

Table 2. Calculated elastic modulus C 2D, DP constant El, effective mass m*, carrier mobility μ and scattering time τ for electron and hole in monolayer Ge2X4S2 at 300 K.

方向 类型 C 2D/(J·m–2) El /eV m* /me μ/(cm–2·V–1·s–1) τ/ps Ge2P4S2 armchair electron 55.46 2.04 0.22 3277.22 0.41 hole 55.46 3.32 0.65 131.23 0.05 zigzag electron 48.44 1.97 0.22 3676.88 0.46 hole 48.44 3.23 0.65 162.32 0.06 Ge2As4S2 armchair electron 48.94 2.30 0.19 3146.80 0.34 hole 48.94 6.56 0.24 220.71 0.03 zigzag electron 43.25 2.13 0.19 1943.61 0.21 hole 43.25 6.23 0.24 275.50 0.04 -

[1] Yang J, Xi L L, Qiu W J, Wu L H, Shi X, Chen L D, Yang J H, Zhang W Q, Uher C, Singh D J 2016 npj Comput. Mater. 2 1

Google Scholar

Google Scholar

[2] Ding Z D, An M, Mo S Q, Yu X X, Jin Z L, Liao Y X, Esfarjani K, Lü J T, Shiomi J, Yang N 2019 J. Mater. Chem. A 7 2114

Google Scholar

Google Scholar

[3] Hicks L D, Dresselhaus M S 1993 Phys. Rev. B 47 16631

Google Scholar

Google Scholar

[4] Hicks L D, Harman T C, Dresselhaus M S 1993 Appl. Phys. Lett. 63 3230

Google Scholar

Google Scholar

[5] Zhao L-D, Chang C, Tan G J, Kanatzidis M G 2016 Energy Environ. Sci. 9 044

[6] Liu Y C, Wang W X, Yang J, Li S 2018 Adv. Sustainable Syst. 2 1800046

Google Scholar

Google Scholar

[7] Tan Q, Zhao L D, Li J F, Wu C F, Wei T R, Xing Z B, Kanatzidis MG 2014 J. Mater. Chem. A 2 17302

Google Scholar

Google Scholar

[8] Yan X, Poudel B, Ma Y, Liu W S, Joshi G, Wang H, Lan Y C, Wang D Z, Chen G, Ren Z F 2010 Nano Lett. 10 3373

Google Scholar

Google Scholar

[9] Zhao L D, Dravid V P, Kanatzidis M G 2014 Energy Environ. Sci. 7 251

Google Scholar

Google Scholar

[10] Chhowalla M, Shin H S, Eda G, Li L J, Loh K P, Zhang H 2013 Nat. Chem. 5 263

Google Scholar

Google Scholar

[11] Xie W J, He J, Kang H J, Tang X F, Zhu S, Laver M, Wang S Y, Copley J R D, Brown C M, Zhang Q J, Tritt T M 2010 Nano Lett. 10 3283

Google Scholar

Google Scholar

[12] Dresselhaus M S, Dresselhaus G, Sun X, Zhang Z 1999 Phys. Solid State 41 679

Google Scholar

Google Scholar

[13] Rashid Z, Nissimagoudar A S, Li W 2019 Phys. Chem. Chem. Phys. 21 5679

Google Scholar

Google Scholar

[14] Snyder G J, Toberer E S 2008 Nat. Mater. 7 105

Google Scholar

Google Scholar

[15] Guo S D, Li H C 2017 Comput. Mater. Sci. 139 361

Google Scholar

Google Scholar

[16] Zare M, Rameshti B Z, Ghamsari F G, Asgari R 2017 Phys. Rev. B 95 045422

Google Scholar

Google Scholar

[17] Zhang R Q, Zhou Z Z, QI N, Zhao B, Zhang Q K, Zhang Z Y, Chen Z Q 2019 J. Mater. Chem. C 7 14986

Google Scholar

Google Scholar

[18] Ruleova P, Drasar C, Lostak P, Li C-P, Ballikaya S, Uher C 2010 Mater. Chem. Phys. 119 299

Google Scholar

Google Scholar

[19] Yu J B, Sun Q 2018 Appl. Phys. Lett. 112 053901

Google Scholar

Google Scholar

[20] Huang S, Wang Z Y, Xiong R, Yu H Y, Shi J 2019 Nano Energy 62 212

Google Scholar

Google Scholar

[21] Zhu Y L, Yuan J H, Song Y Q, Xue K H, Wang S, Lian C, Li Z N, Xu M, Cheng X M, Miao X S 2019 Int. J. Hydrogen Energy 44 21536

Google Scholar

Google Scholar

[22] Jing Y, MA Y D, LI Y F, Heine T 2017 Nano Lett. 17 1833

Google Scholar

Google Scholar

[23] Zeng B W, Long M Q, Zhang X J, Dong Y L, Li M J, Yi Y G, Duan H M 2018 J. Phys. D:Appl. Phys. 51 235302

Google Scholar

Google Scholar

[24] Zhu X L, Liu P F, Zhang J R, Zhang P, Zhou W X, Xie G F 2019 Nanoscale 11 19923

Google Scholar

Google Scholar

[25] Ouyang T, Jiang E L, Tang C, Li J, He C Y, Zhong J X 2018 J. Mater. Chem. A 6 21532

Google Scholar

Google Scholar

[26] Sun Z H, Yuan K P, Chang Z, Bi S P, Zhang X L, Tang D W 2020 Nanoscale 12 3330

Google Scholar

Google Scholar

[27] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[28] Lee K, Murray É D, Kong L Z, Lundqvist B I, Langreth D C 2010 Phys. Rev. B 82 081101

Google Scholar

Google Scholar

[29] Blöchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[30] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[31] Togo A, Oba F, Tanaka I 2008 Phys. Rev. B 78 134106

Google Scholar

Google Scholar

[32] Li W, Lindsay L, Broido D A, Stewart D A, Mingo N 2012 Phys. Rev. B 86 174307

Google Scholar

Google Scholar

[33] Li W, Carrete J, Katcho N A, Mingo N 2014 Comput. Phys. Commun. 185 1747

Google Scholar

Google Scholar

[34] Madsen G K H, Singh D J 2006 Comput. Phys. Commun. 175 67

Google Scholar

Google Scholar

[35] Heyd J, Scuseria G E, Ernzerhof M 2003 J. Chem. Phys. 118 8207

Google Scholar

Google Scholar

[36] Bardeen J, Shockley W 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[37] Chaput L, Pécheur P, Scherrer H 2007 Phys. Rev. B 75 045116

Google Scholar

Google Scholar

[38] Price P J 1981 Ann. Phys. 133 217

Google Scholar

Google Scholar

[39] Xi J Y, Long M Q, Tang L, Wanf D, Shuai Z G 2012 Nanoscale 4 4348

Google Scholar

Google Scholar

[40] Becke A D, Edgecombe K E 1990 J. Chem. Phys. 92 5397

Google Scholar

Google Scholar

[41] Nalewajski R F, Köster A M, Escalante S 2005 J. Phys. Chem. A 109 10038

Google Scholar

Google Scholar

[42] Savin A, Nesper R, Wengert S, Wengert S 1997 Angew. Chem. Int. Ed. 36 1808

Google Scholar

Google Scholar

[43] Batsanov S S 2001 Inorg. Mater. 37 871

Google Scholar

Google Scholar

[44] Gao Z B, Tao F, Ren J 2018 Nanoscale 10 12997

Google Scholar

Google Scholar

[45] Gao Z B, Zhang Z F, Liu G, Wang J S 2019 Phys. Chem. Chem. Phys. 21 26033

Google Scholar

Google Scholar

[46] Wee D, Kozinsky B, Marzari N, Fornari M 2010 Phys. Rev. B 81 045204

Google Scholar

Google Scholar

[47] Zhou Z Z, Liu H J, Fan D D, Cao G H, Sheng Y 2019 Phys. Rev. B 99 085410

Google Scholar

Google Scholar

[48] Li W, Carrete J, Mingo N 2013 Appl. Phys. Lett. 103 253103

Google Scholar

Google Scholar

[49] Peng B, Zhang H, Shao H Z, Lu H L, Zhang D W, Zhu H Y 2016 Nano Energy 30 225

Google Scholar

Google Scholar

[50] McGaughey A J H, Landry E S, Sellan D P, Amon C H 2011 Appl. Phys. Lett. 99 131904

Google Scholar

Google Scholar

[51] Xie G F, Guo Y, Wei X L, Zhang K W, Sun L Z, Zhong J X, Zhang G, Zhang Y W 2014 Appl. Phys. Lett. 104 233901

Google Scholar

Google Scholar

[52] Xie G F, Ju Z F, Zhou K K, Wei X L, Guo Z X, Cai Y Q, Zhang G 2018 npj Comput. Mater. 4 1

Google Scholar

Google Scholar

[53] Wei X L, Wang Y C, Shen Y L, Xie G F, Xiao H P, Zhong J X, Zhang G 2014 Appl. Phys. Lett. 105 103902

Google Scholar

Google Scholar

[54] Zhu L Y, Zhang G, Li B W 2014 Phys. Rev. B 90 214302

Google Scholar

Google Scholar

[55] Li W, Mingo N 2015 Phys. Rev. B 91 144304

Google Scholar

Google Scholar

[56] Pandey T, Polanco C A, Lindsay L, Parker D S 2017 Phys. Rev. B 95 224306

Google Scholar

Google Scholar

[57] Pei Y Z, Wang H, Snyder G J 2012 Adv. Mater. 24 6125

Google Scholar

Google Scholar

[58] Zhu X L, Yang H Y, Zhou W X, Wang T B, Xu N, Xie G F 2020 ACS Appl. Mater. Interfaces 12 36102

Google Scholar

Google Scholar

[59] Cai Y Q, Zhang G, Zhang Y W 2014 J. Am. Chem. Soc. 136 6269

Google Scholar

Google Scholar

[60] Zhang L C, Qin G Z, Fang W Z, Cui H J, Zheng Q R, Yan Q B, Su G 2016 Sci. Rep. 6 19830

[61] Yi W C, Chen X, Wang Z X, Ding Y C, Yang B C, Liu X B 2019 J. Mater. Chem. C 7 7352

Google Scholar

Google Scholar

[62] Heremans J P 2005 Acta Phys. Pol. A 108 609

Google Scholar

Google Scholar

[63] Jonson M, Mahan G D 1980 Phys. Rev. B 21 4223

Google Scholar

Google Scholar

计量

- 文章访问数: 6549

- PDF下载量: 178

- 被引次数: 0

下载:

下载: