-

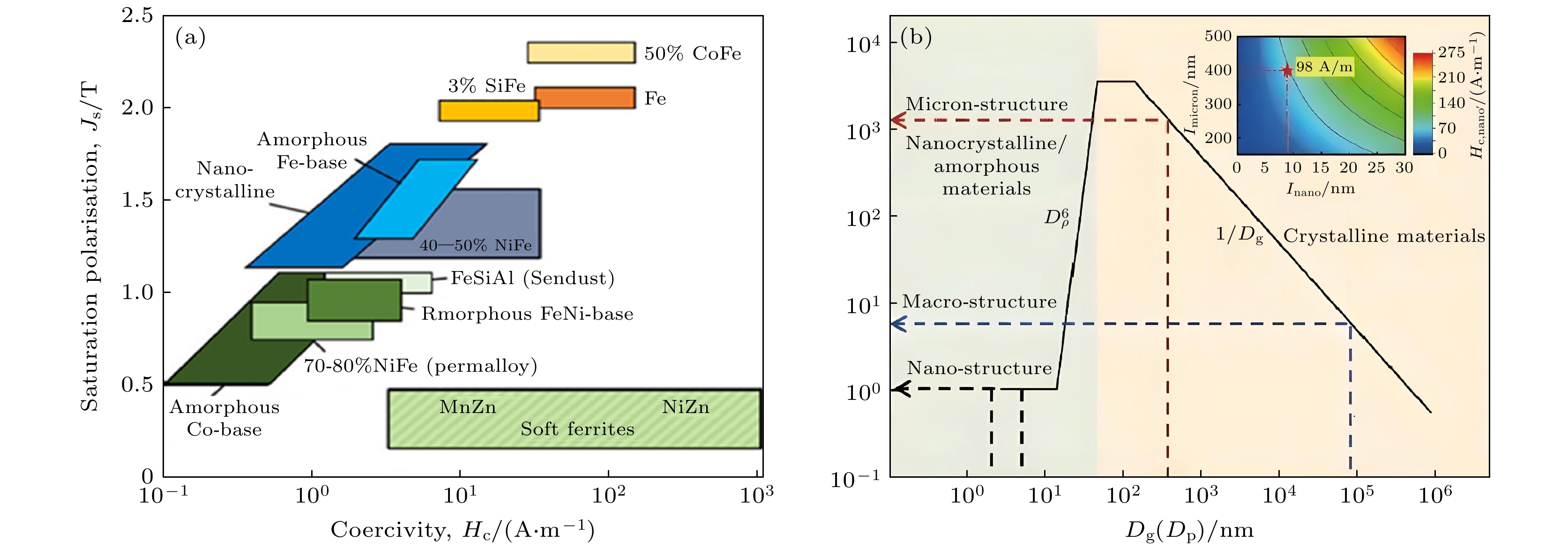

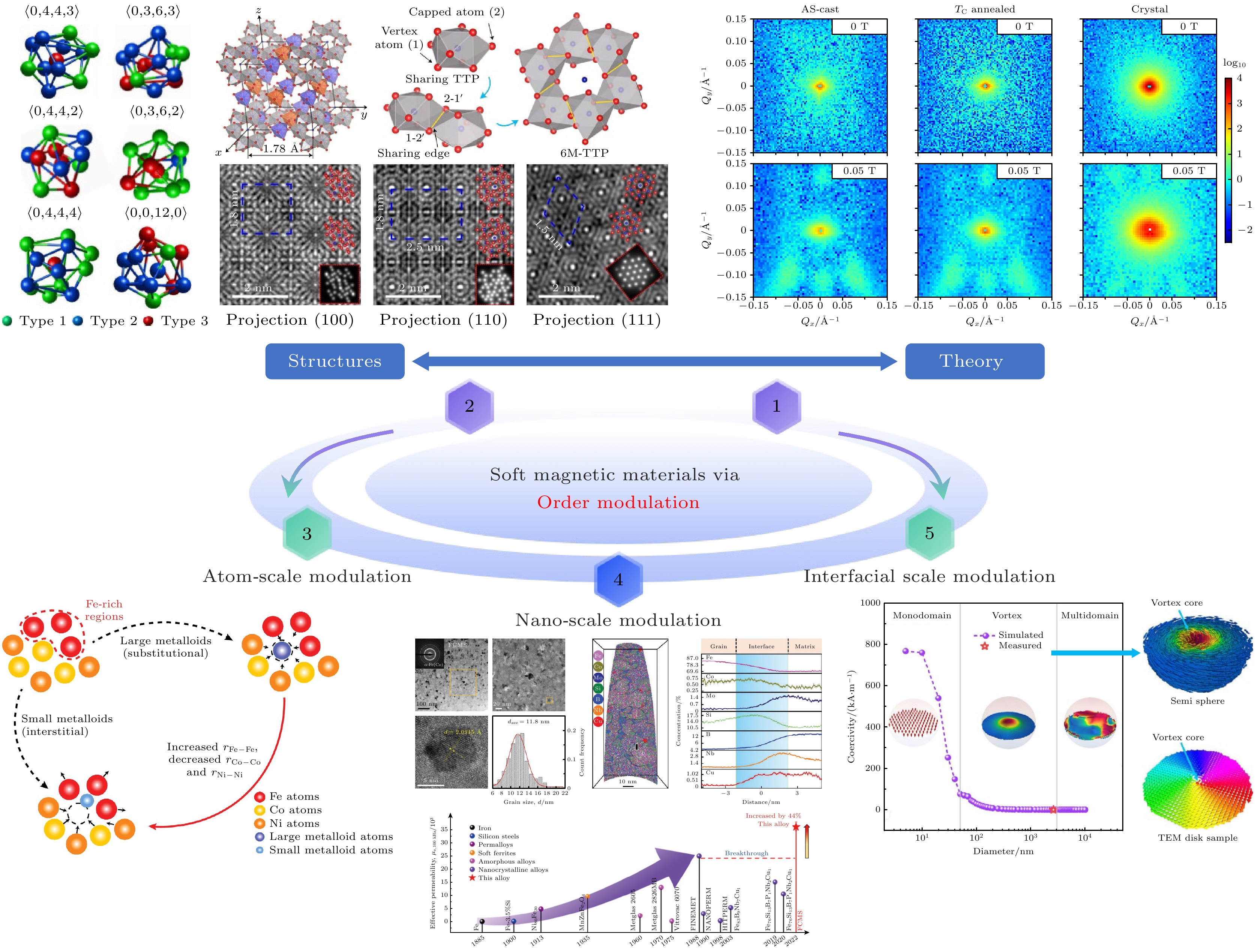

The rapid advancement of modern electronics, telecommunications, and artificial intelligence has driven an urgent demand for high-performance soft magnetic materials, particularly those compatible with third-generation semiconductors. These semiconductors, characterized by wide bandgaps, high breakdown fields, and superior thermal conductivity, enable power devices to operate at higher frequencies (> 1 MHz) and power densities. However, traditional soft magnetic materials, such as silicon steels and ferrites, face inherent trade-offs between critical properties: saturation magnetization (Bs) versus coercivity (Hc), permeability versus core loss, and mechanical strength versus magnetic “softness.” These limitations hinder their application in emerging high-frequency, high-efficiency scenarios. Amorphous soft magnetic materials, with their unique hierarchical ordered structures spanning atomic to nanoscales, offer a revolutionary platform to overcome these trade-offs. These materials exhibit rich physical properties governed by short-range order (SRO, < 0.5 nm), medium-range order (MRO, 0.5–2.0 nm), and amorphous-nanocrystalline dual-phase architectures. The concept of order modulation–strategically tailoring the intrinsic characteristics (e.g., cluster density, topological configuration) and spatial arrangements of these ordered structures–has emerged as a transformative approach to decoupling conflicting material properties. This review systematically examines the following key aspects: 1. Historical evolution of soft magnetic materials From early silicon steels and ferrites to modern amorphous and nanocrystalline alloys, the development of soft magnetic materials has paralleled advancements in power electronics. The advent of Fe-based amorphous alloys and Finemet-type nanocrystalline alloys marked milestones in achieving high Bs (>1.6 T), ultra-low Hc (< 1 A/m), and reduced core losses at high frequencies. However, performance bottlenecks persist near theoretical limits, necessitating innovative strategies. 2. Theoretical foundations of order modulation Order parameter theory: Landau’s phase transition theory and synergetics elucidate how magnetic order parameters govern macroscopic properties. In amorphous alloys, magnetic interactions are dominated by SRO clusters and their MRO arrangements. Magnetism-structure relationships: advanced techniques, such as atomic electron tomography (AET) and synchrotron pair distribution function (PDF) analysis, reveal that SRO/MRO structures directly influence exchange coupling, magnetic anisotropy, and domain wall dynamics. For instance, Fe-M (M = Si, B) clusters with dense packing enhance Bs, while MRO homogenization reduces Hc. 3. Advances in order-modulated amorphous soft magnetic materials Atomic-scale modulation: elemental doping (e.g., Co, Mo, Cu) and energy-field treatments (e.g., magnetic annealing, ultrasonic vibration) optimize local atomic configurations. For example, ultrasonic processing of Fe78Si9B13 ribbons induces stress relaxation, forming 2–3 nm Fe-M clusters that boost Bs to 183.2 emu/g while maintaining Hc at 4.2 A/m. Nanoscale dual-phase design: controlled crystallization of α-Fe(Si) nanocrystals (< 15 nm) within an amorphous matrix creates exchange-coupled nanocomposites. Co-Mo co-doping in FeSiBCuNb alloys refines grain size to 11.8 nm, achieving a permeability of 65000 at 100 kHz–44% higher than conventional Finemet alloys. Interface engineering in soft magnetic composites (SMCs): core-shell architectures (e.g., FeSiB@FeB nanoparticles) with stress-buffering interfaces reduce eddy current losses while preserving permeability. Cold sintering of vortex-domain FeSiAl powders enables GHz-range operation with stable permeability (μi = 13 at 1 GHz). 4. Future directions and challenges Machine learning-driven design: integrating high-throughput simulations and AI models (e.g., XGBoost, random forests) accelerates the discovery of optimal compositions and order parameters. Recent work predicts Bs using Fe content, mixing enthalpy, and electronegativity differences, guiding the synthesis of (Fe82Co18)85.5Ni1.5B9P3C1 alloys with Bs = 1.92 T. Novel magnetic topologies: magnetic vortex structures and skyrmion-like configurations in ultrafine powders show promise for ultra-high-frequency applications (>100 MHz). Low-stress manufacturing: innovations like ultrasonic rheoforming reduce compaction pressures by 99% (to 6.2 MPa), mitigating residual stress and enhancing SMC performance. In situ characterization: neutron scattering and grating-based imaging techniques enable real-time observation of domain dynamics under operational conditions (e.g., stress, magnetic fields). In conclusion, order modulation represents a paradigm shift in soft magnetic material design, bridging atomic-scale interactions to macroscopic performance. By leveraging multi-scale ordered structures and advanced manufacturing technologies, next-generation amorphous-based materials are poised to revolutionize high-frequency power electronics, electric vehicles, and AI-driven systems. However, challenges in scalable production, cost-effective processing, and standardized evaluation must be addressed to accelerate industrial adoption. -

Keywords:

- soft magnetic materials /

- amorphous alloy /

- order modulation /

- functional block

-

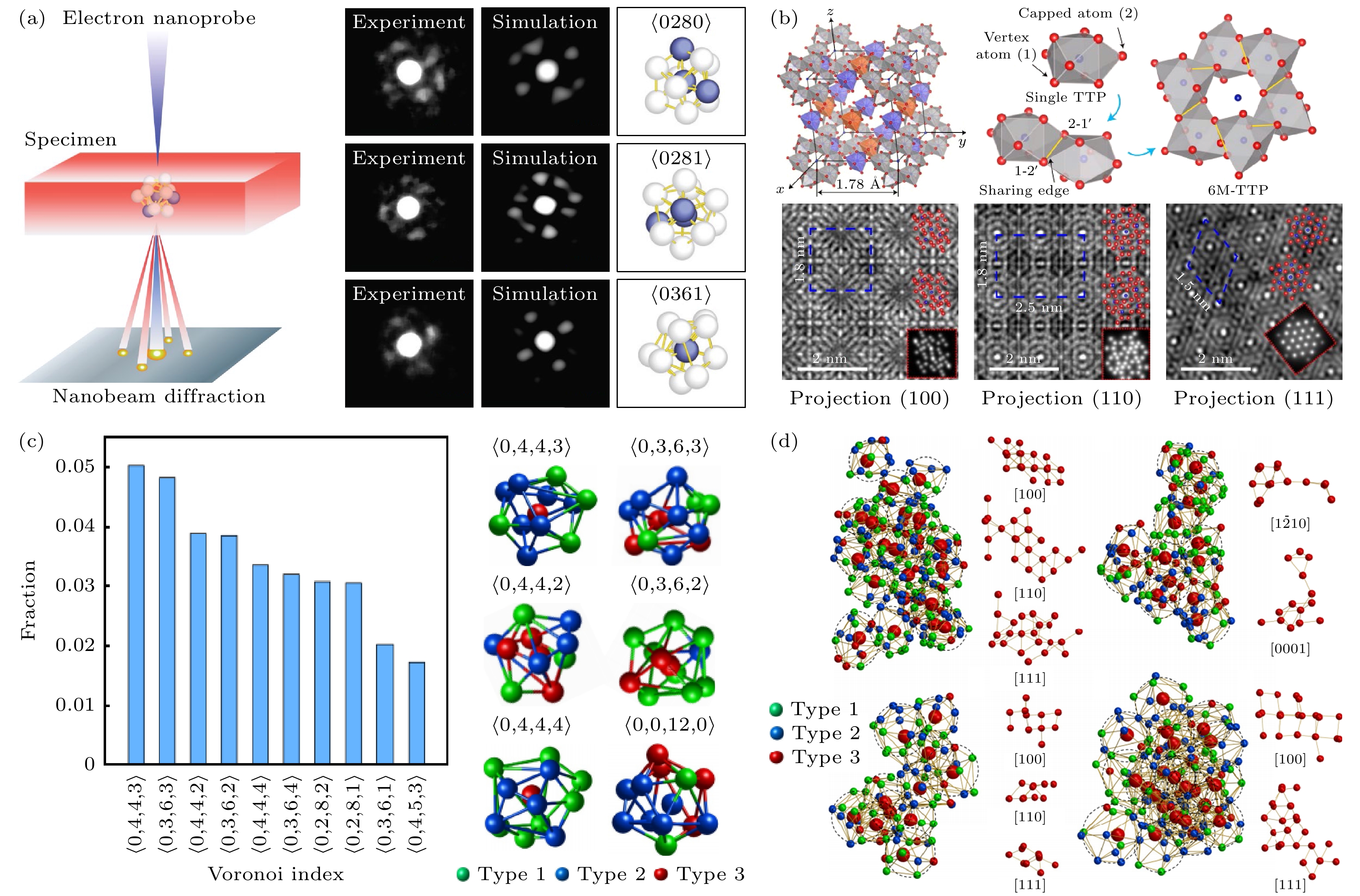

图 1 非晶合金的多尺度“序”结构 (a)利用纳米束电子衍射与从头算分子动力学模拟相结合的方法确定Zr66.7Ni33.3非晶合金的短程序结构[43]; (b) Pd41.25Ni41.25P17.5非晶合金的六元三顶三角棱柱簇(6M-TTP)手性中程序结构[36]; (c)由AET确定的非晶纳米颗粒的代表性短程序结构[44]; (d)由AET确定的非晶纳米颗粒的4种类晶状中程序结构[44]

Figure 1. Multi-scale ordered structures in amorphous alloys: (a) Short-range order (SRO) in Zr66.7Ni33.3 determined via combined nanobeam electron diffraction and ab initio molecular dynamics simulations[43]; (b) chiral medium-range order (MRO) featuring 6 M-TTP clusters in Pd41.25Ni41.25P17.5[36]; (c) representative SRO in amorphous nanoparticles revealed by atomic electron tomography (AET)[44]; (d) four crystal-like MRO configurations identified by AET[44].

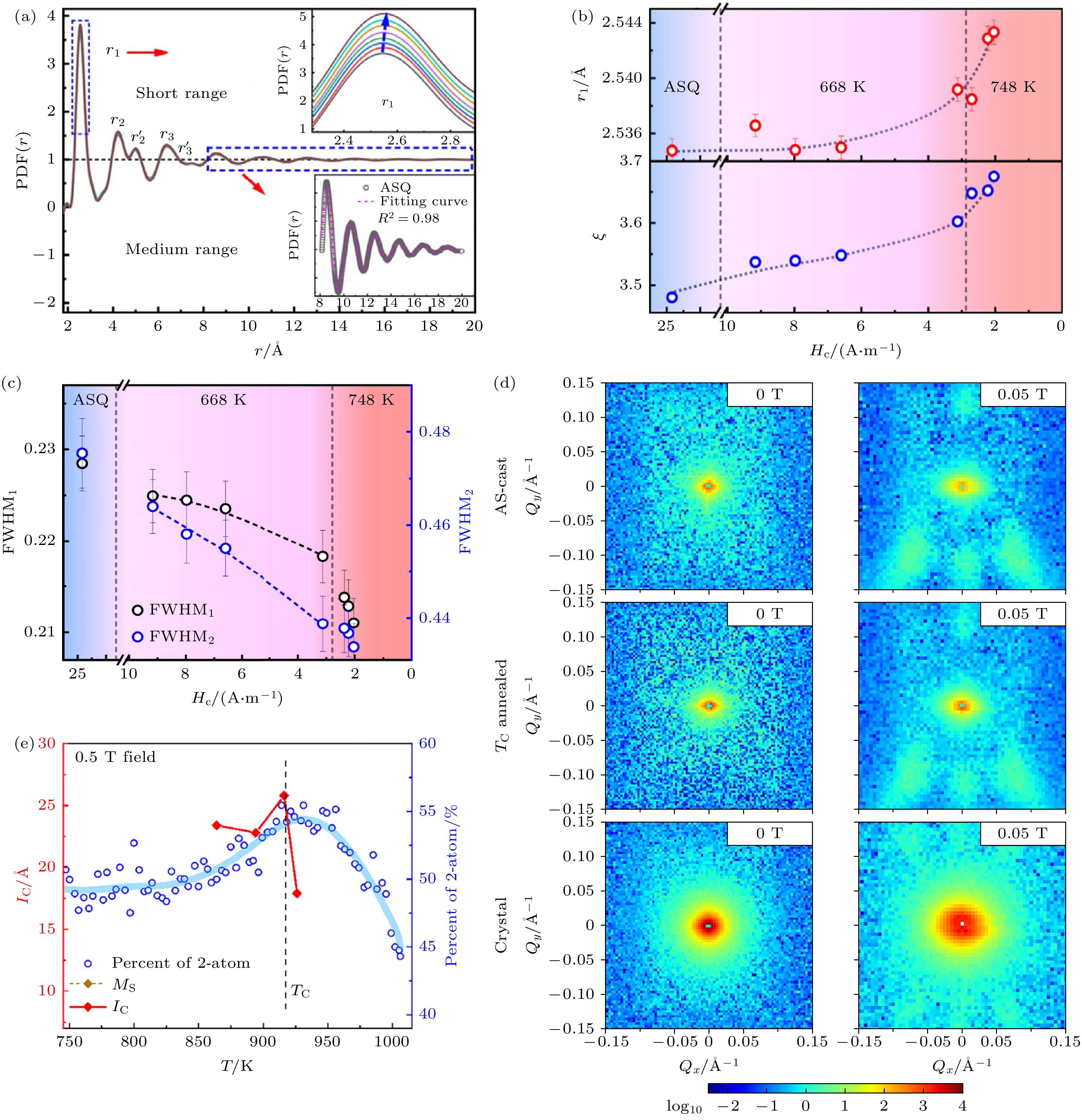

图 2 非晶合金的短/中程序结构与磁学性能的内在关联 (a)不同退火参数下非晶合金的同步辐射PDF曲线[20]; (b)矫顽力与PDF第一峰位置r1和峰强衰减指数ξ的关联[20]; (c)矫顽力与结构因子曲线第1峰和第2峰半高宽FWHM的关联[20]; (d)铸态、退火态和晶态样品在有无磁场下的小角中子散射图[46]; (e) (Fe0.71Dy0.05B0.24)96Nb4非晶合金的边共享中程序比例、饱和磁化强度、磁相关长度随温度的变化[46]

Figure 2. Short/medium-range order-magnetic property relationships in amorphous alloys: (a) Synchrotron-derived pair distribution functions (PDF) for various annealing states[20]; (b) correlations between coercive and PDF characteristics (first peak position r1, decay coefficientξ)[20]; (c) dependence of coercivity on structural disorder (FWHM of first two structure factor maxima)[20]; (d) magnetic field response of nanostructures revealed by SANS in different structural states[46]; (e) temperature-dependent medium-range ordering and magnetic characteristics (saturation magnetization, correlation lengths) in Fe-Dy-B-Nb metallic glass[46].

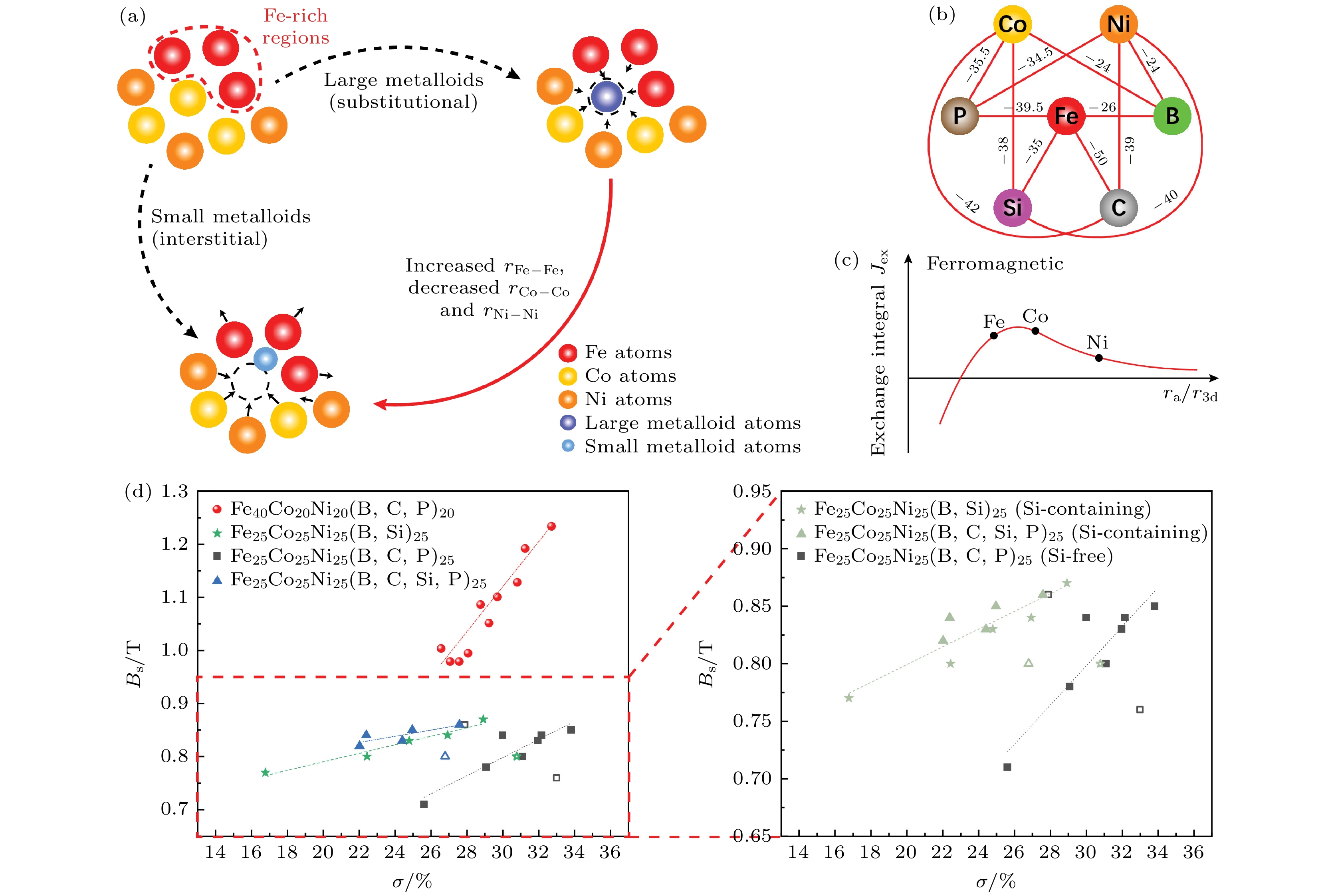

图 3 基于元素掺杂的原子尺度序调控[50] (a)“framework + fluctuation”模型示意图, 展示了不同类型非金属原子引起的结构“波动”; (b) FeCoNiBCSiP 高熵金属玻璃体系的混合焓; (c) Bethe-Slater曲线; (d)饱和磁化强度与“波动参数”σ的内在关联

Figure 3. Atomic-scale order modulation via elemental doping[50]: (a) Schematic of the “framework + fluctuation” model, illustrating structural fluctuations induced by diverse non-metal atoms; (b) mixing enthalpy of the FeCoNiBCSiP high-entropy metallic glass; (c) Bethe-Slater curve; (d) correlation between saturation magnetization and the fluctuation parameter (σ).

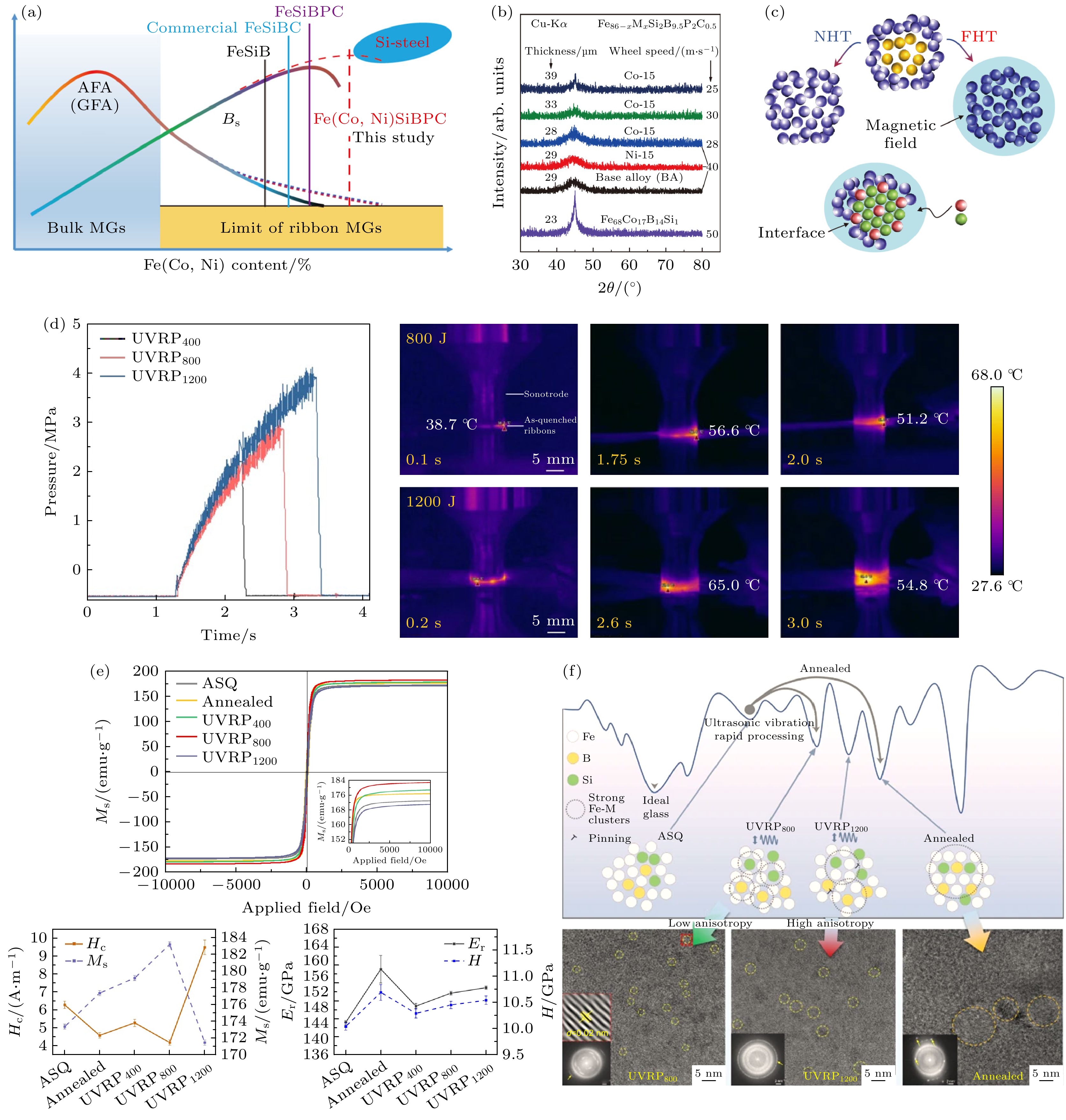

图 4 基于外加能场的原子尺度序调控 (a)不同合金系统中非晶形成能力和饱和磁感应强度对铁磁元素(Fe, Co, Ni))含量的依赖关系示意图[51]; (b)结合成分设计和磁场热处理制备的非晶合金XRD图谱[51]; (c)磁场热处理过程中, 松散区域的磁性原子在团簇界面的扩散[51]; (d)超声处理过程中, 与输入能量相关的压力和温度变化[52]; (e)超声处理对Fe78Si9B13条带的磁学、力学性能的影响[52]; (f)超声处理对非晶合金内部原子尺度结构的调控[52]

Figure 4. Atomic-scale ordering modulation via external energy fields: (a) Composition dependence of glass-forming ability and saturation magnetization in Fe/Co/Ni-based alloy systems[51]; (b) XRD patterns of compositionally optimized amorphous alloys after magnetic annealing[51]; (c) field-enhanced diffusion of magnetic atoms at cluster interfaces during magnetic annealing[51]; (d) ultrasonic-induced pressure/temperature evolution as a function of input energy[52]; (e) ultrasonic effects on magnetic/mechanical properties of Fe78Si9B13 ribbons[52]; (f) ultrasonic modulation of atomic-scale structure in amorphous alloys[52].

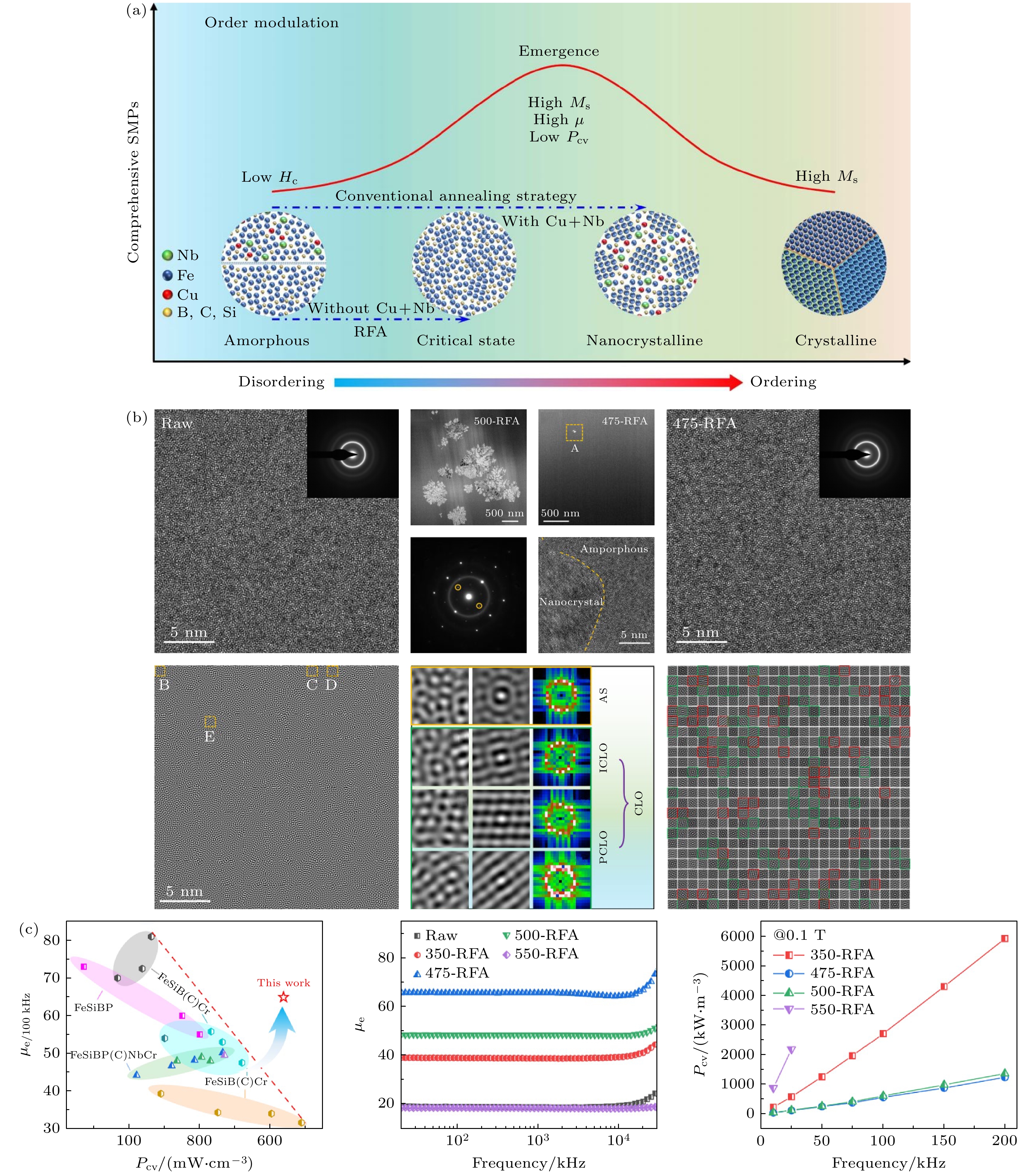

图 5 临界态序构设计突破磁导率与高频损耗的互斥关系[55] (a)序调控策略示意图; (b)磁场热处理诱导类α-Fe中程序结构的产生; (c)临界态序构软磁复合材料的性能

Figure 5. Breakthrough in permeability-loss trade-off through critical-state ordered structure design[55]: (a) Schematic of ordering modulation strategy; (b) formation of in α-Fe-like medium-ordered structure via magnetic-field annealing; (c) performance of critical-state ordered soft magnetic composites.

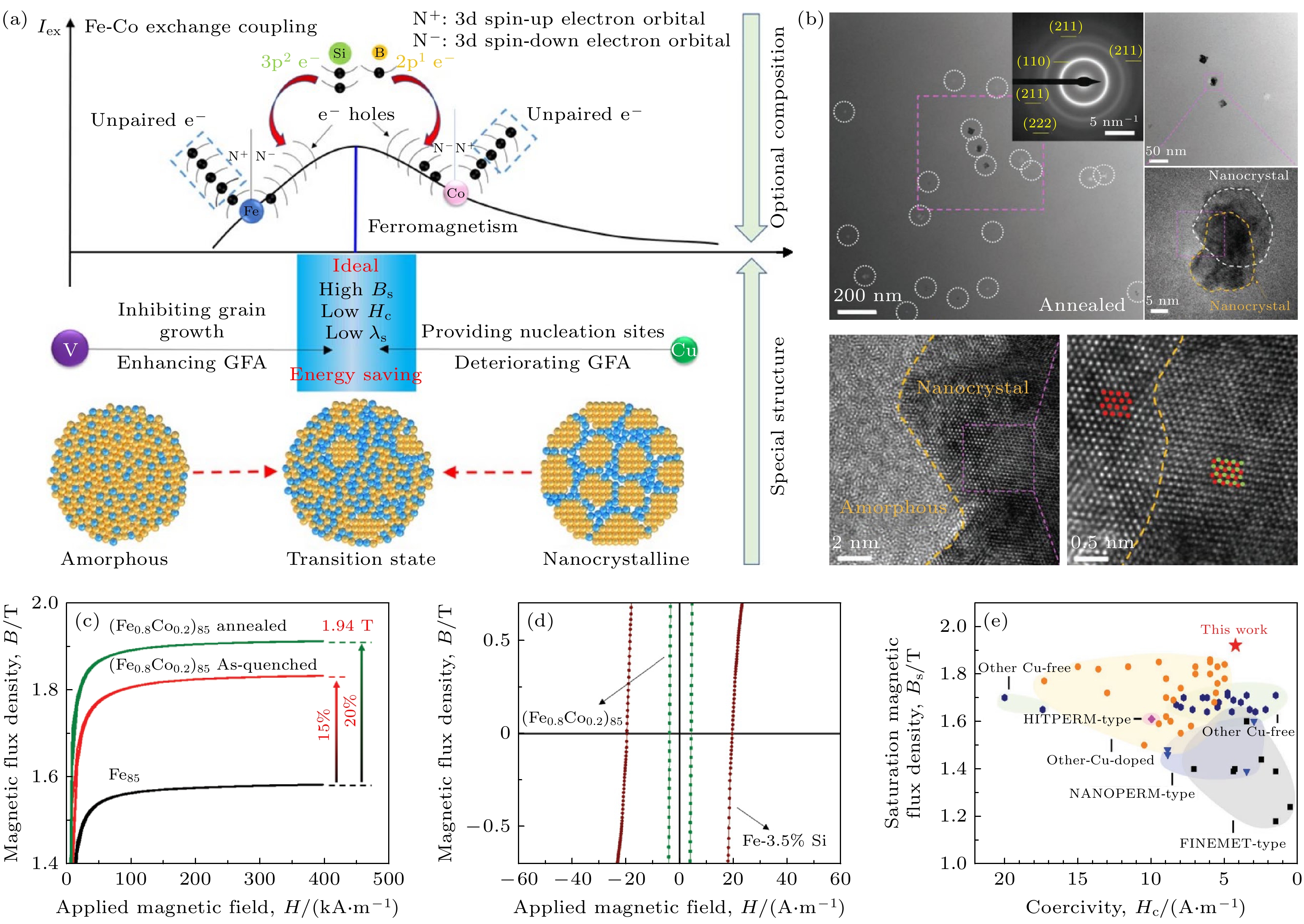

图 7 过渡态序构突破饱和磁化强度和矫顽力的互斥关系[8] (a)过渡态软磁合金设计策略; (b)少量嵌套纳米晶和类晶区分布在非晶基体内的过渡态序构; (c) B-H曲线; (d)过渡态(Fe0.8Co0.2)85合金和Fe-3.5%Si合金的放大B-H曲线; (e)性能对比

Figure 7. Transitional-state ordered structure overcoming the trade-off between saturation magnetization and coercivity[8]: (a) Design strategy for transitional-state soft magnetic alloys; (b) coherently dispersed nanocrystal/crystal-like region hybrid architecture within the amorphous matrix; (c) B-H curves; (d) comparative view of locally amplified B-H curves between transitional-state (Fe0.8Co0.2)85 alloy and conventional Fe-3.5%Si alloy; (e) performance comparison.

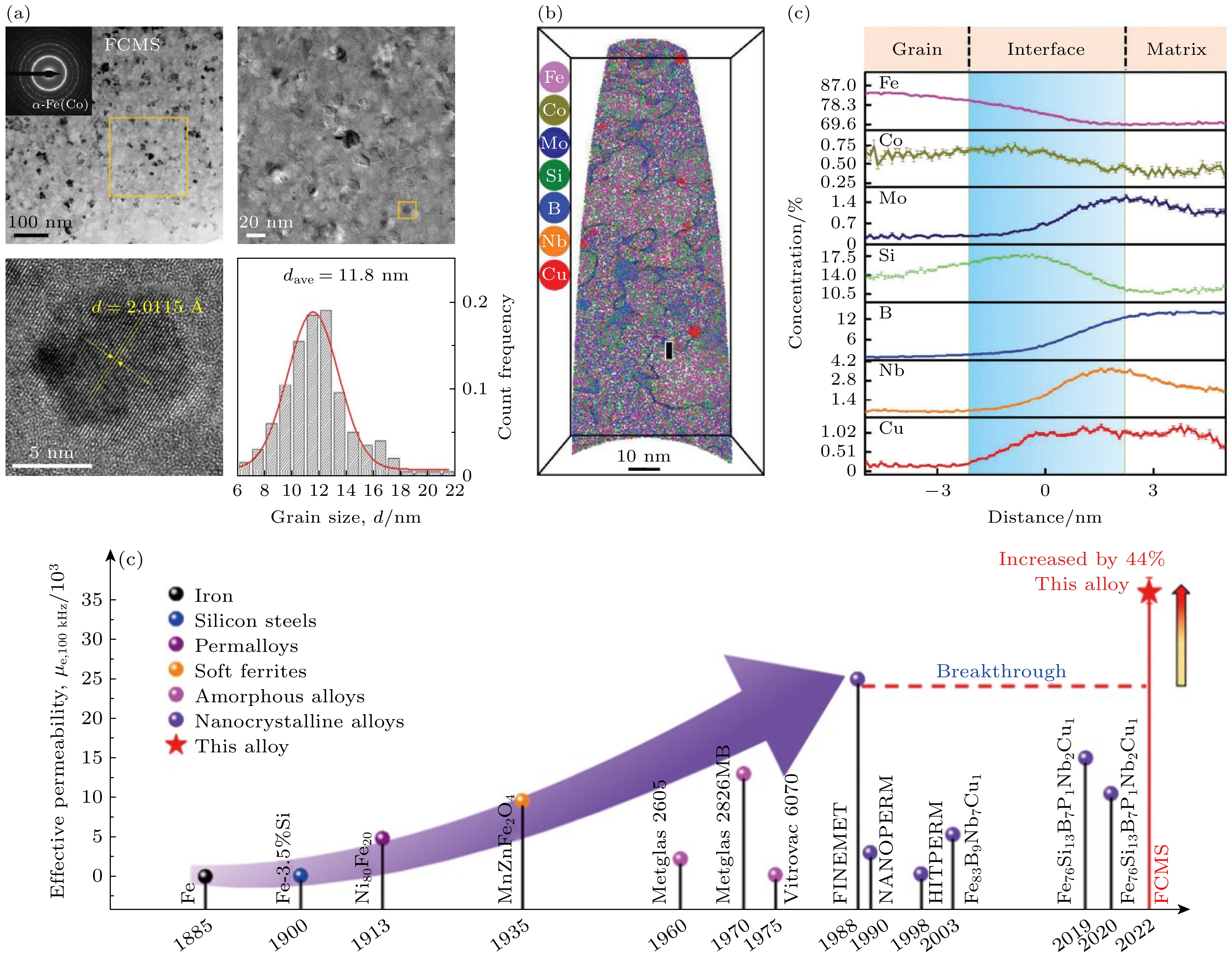

图 8 基于磁不均匀性驱动纳米晶化的新型高频高磁导率软磁材料[9] (a) Co和Mo共掺杂实现晶粒尺寸细化至11.8 nm; (b)成分分布; (c)不同年份开发的各种软磁材料在100 kHz下的磁导率

Figure 8. Magnetic inhomogeneity-driven nanocrystallization for developing high-performance soft magnetic materials with high-frequency permeability[9]: (a) Grain refinement to 11.8 nm achieved by Co-Mo co-doping; (b) composition distribution; (c) permeability at 100 kHz for various soft magnetic materials across development years.

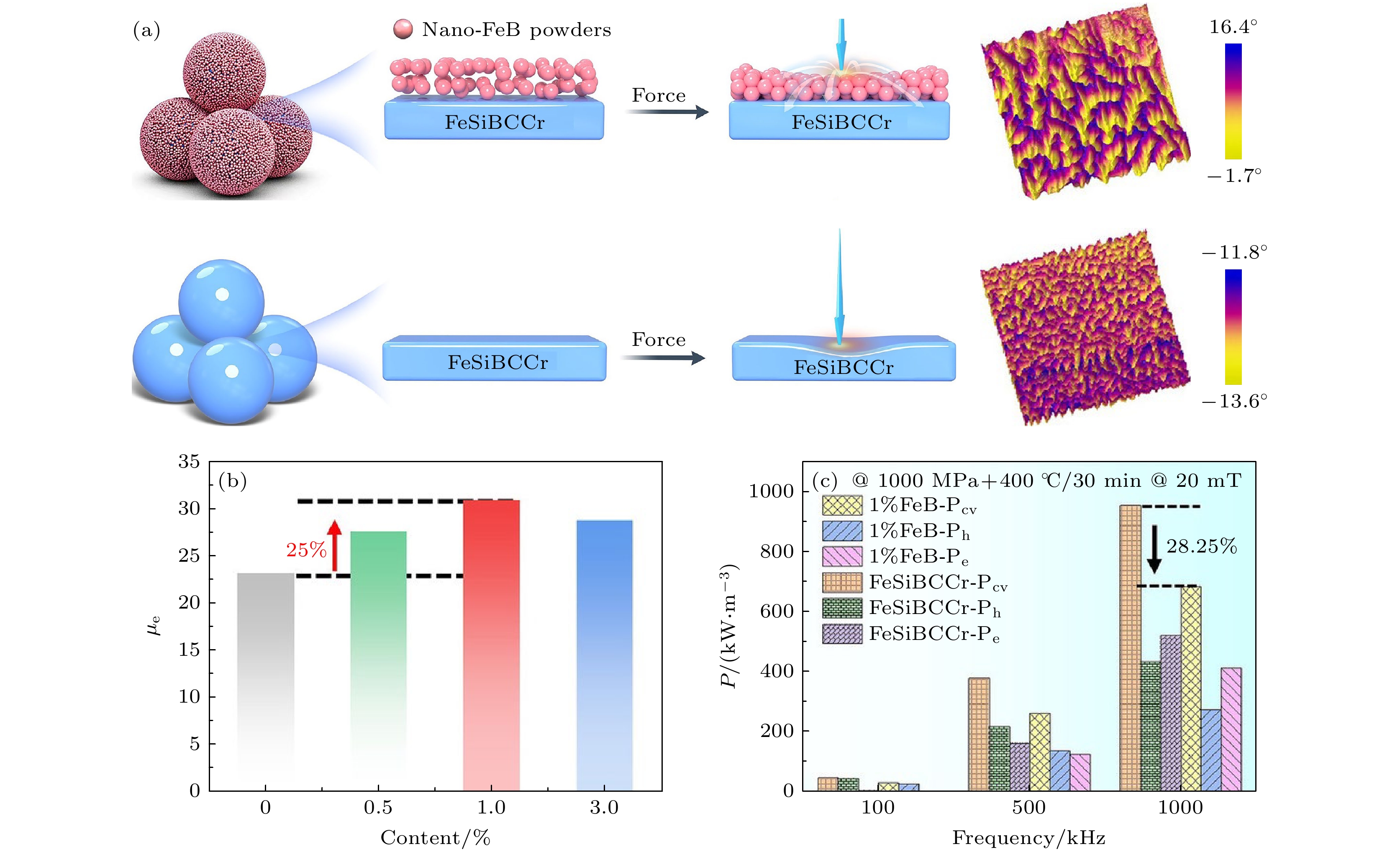

图 9 利用无序纳米颗粒作为应力缓冲界面开发综合性能优异的磁粉芯[71] (a)表面纳米工程对应力和磁畴的调控示意图; (b)磁导率; (c)高频损耗

Figure 9. Engineering high-performance magnetic powder cores through disordered nanoparticle stress-buffering interfaces[71]: (a) Schematic illustration of stress and magnetic domain regulation via surface nanoengineering; (b) permeability; (c) high-frequency loss.

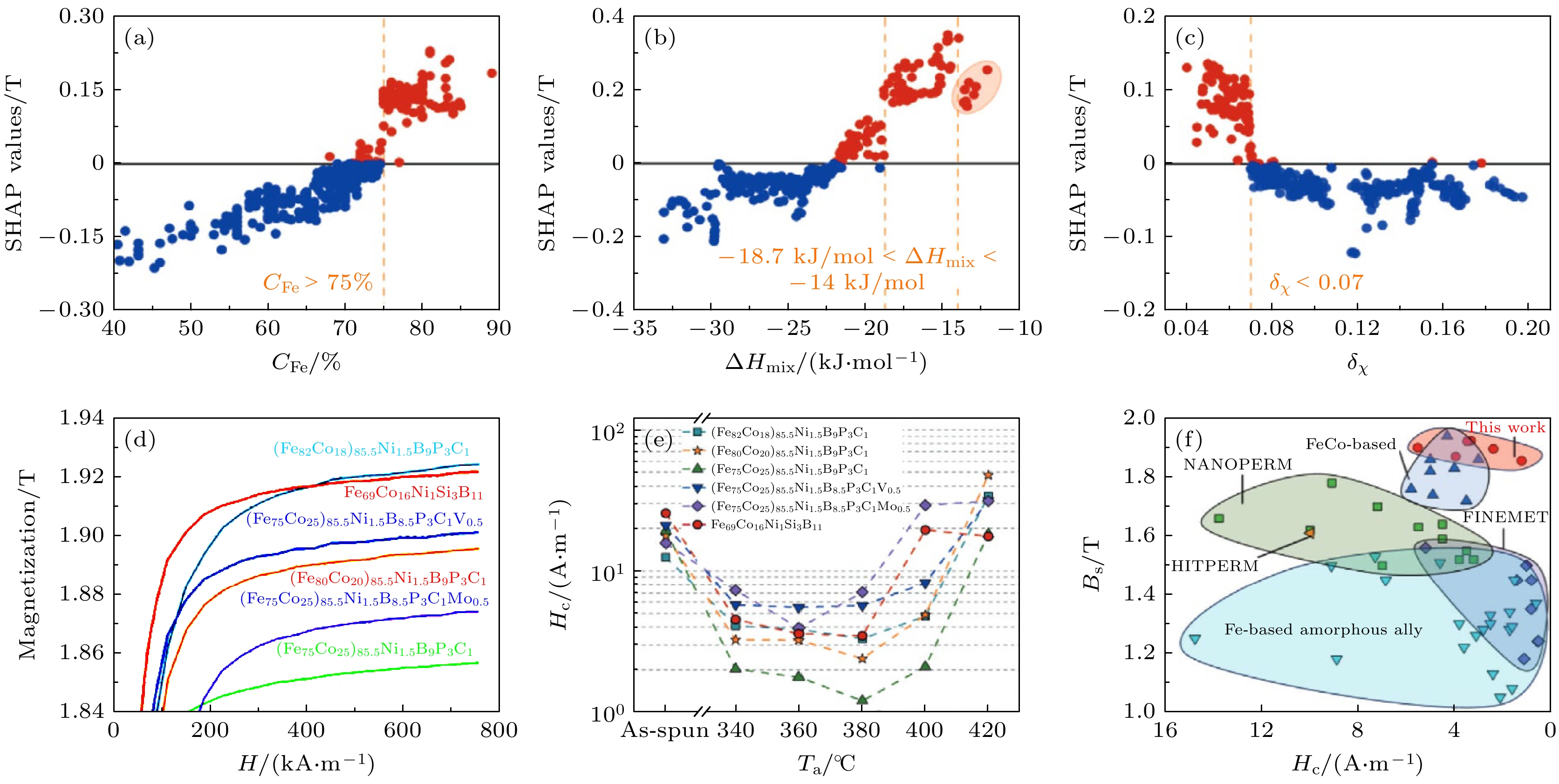

图 10 通过人工智能技术加速高性能非晶基软磁材料的研发[77] (a) Fe含量、(b)混合焓和(c)电负性差对饱和磁感应强度的影响; (d) B-H曲线; (e)矫顽力随退火温度的变化; (f)性能对比

Figure 10. AI-accelerated development of high-performance amorphous soft magnetic alloys[77]: (a) Effects of Fe content, (b) mixing enthalpy, and (c) electronegativity difference on the saturation magnetization; (d) B-H curves; (e) annealing temperature dependence of coercivity; (f) performance comparison.

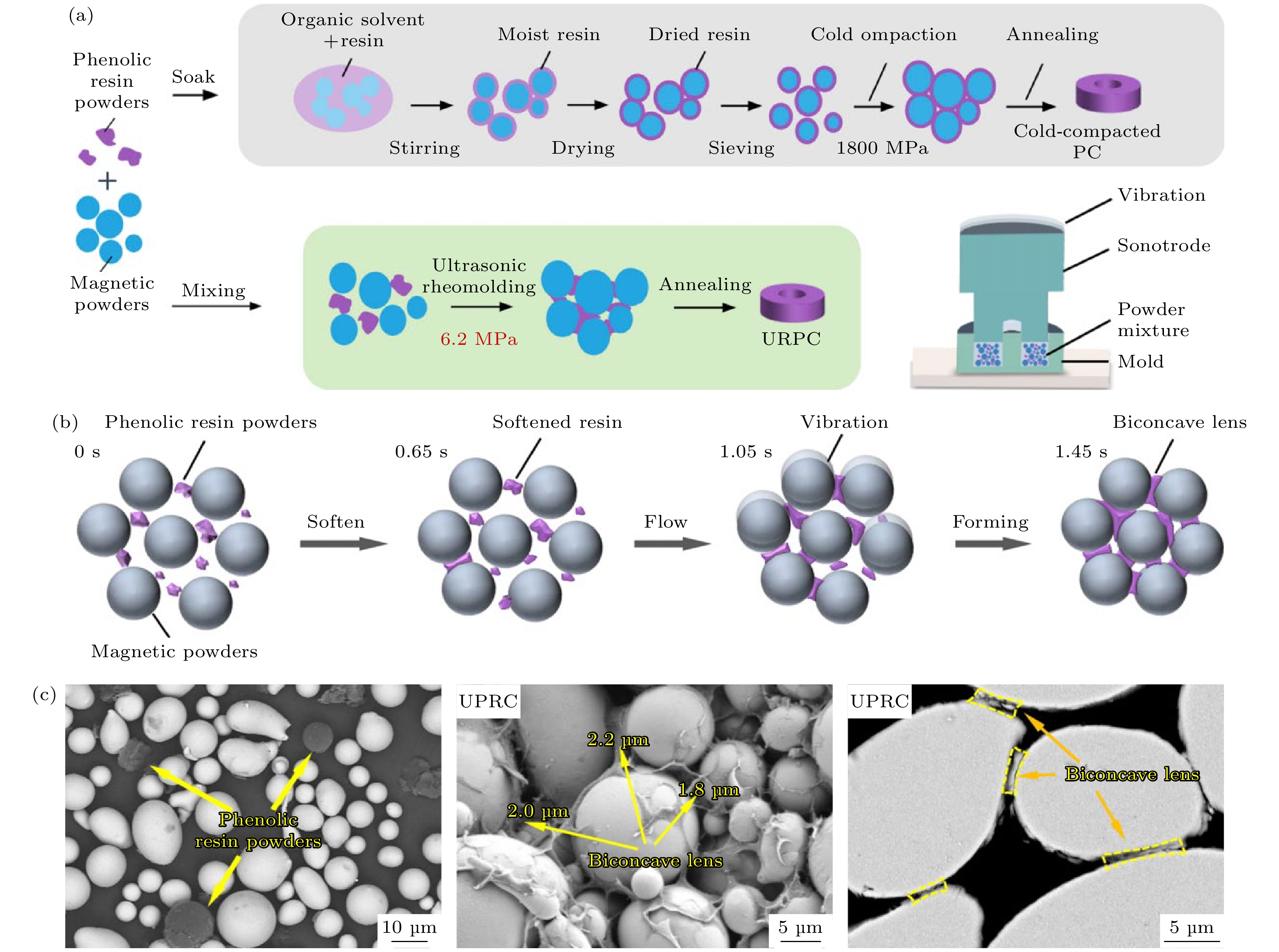

图 12 超声低应力流变成型工艺[81] (a)工艺流程示意图; (b)超声成型过程中局域自适应绝缘结构的形成; (c)软磁复合材料内部组织形貌

Figure 12. Ultrasonic-assisted low-stress rheoforming process[81]: (a) Schematic of the processing steps; (b) formation mechanism of localized adaptive insulating structures during ultrasonic forming; (c) microstructural evolution of the soft magnetic composite.

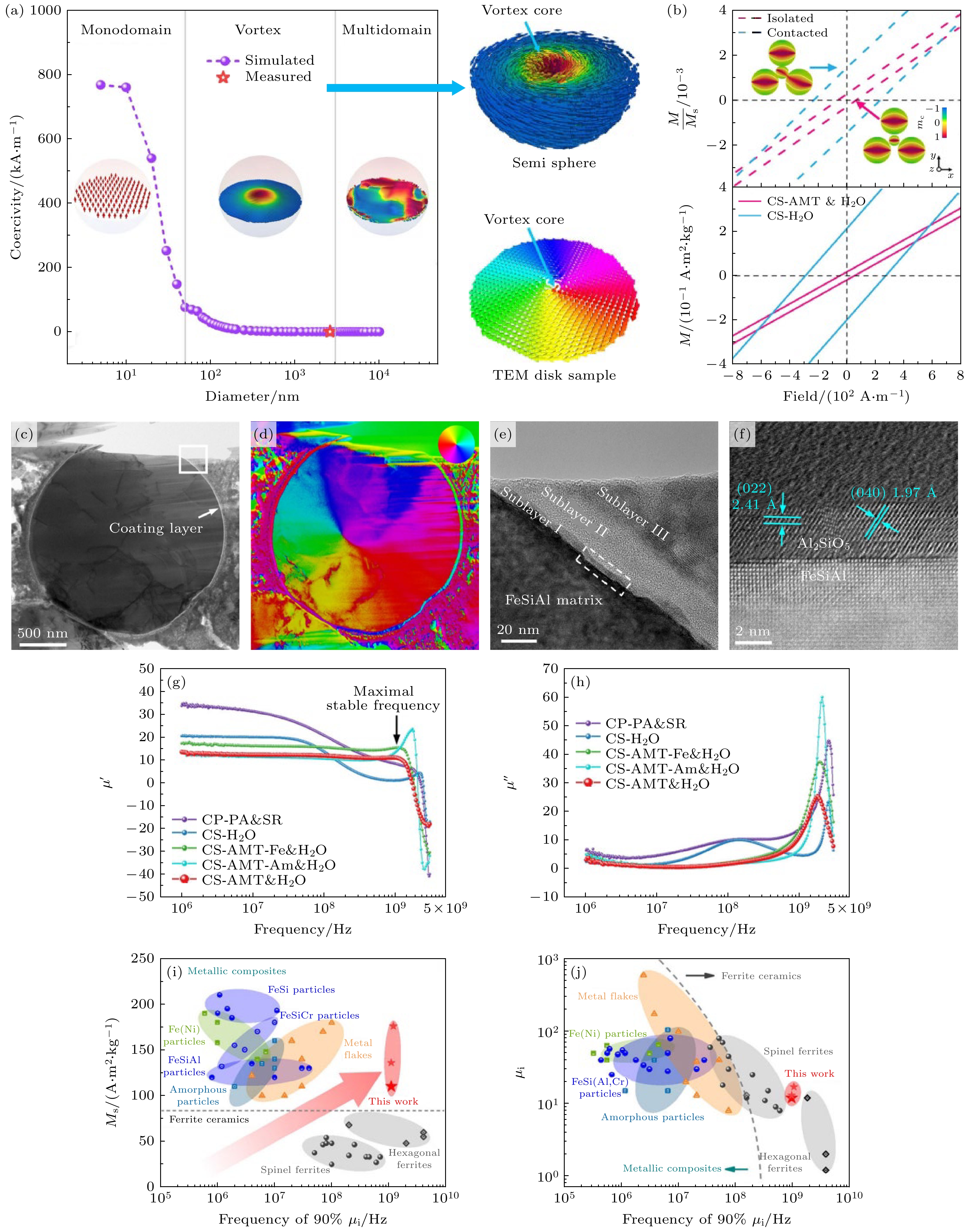

图 11 粉末尺寸效应驱动的新型磁性拓扑序构软磁复合材料[80] (a)不同直径FeSiAl颗粒的畴结构和矫顽力模拟; (b)磁绝缘结构的磁性能模拟; (c)—(f)磁涡旋结构的微观结构和畴结构; (g)—(i)磁涡旋结构的性能

Figure 11. Powder-size-engineered novel magnetic topological ordering in soft magnetic composites[80]: (a) Simulated domain structures and coercivity of FeSiAl particles with varying diameters; (b) calculated magnetic properties of the magnetic insulated architecture; (c)–(f) microstructural characteristics and domain configurations of magnetic vortex arrays; (g)–(i) properties of magnetic vortex structure.

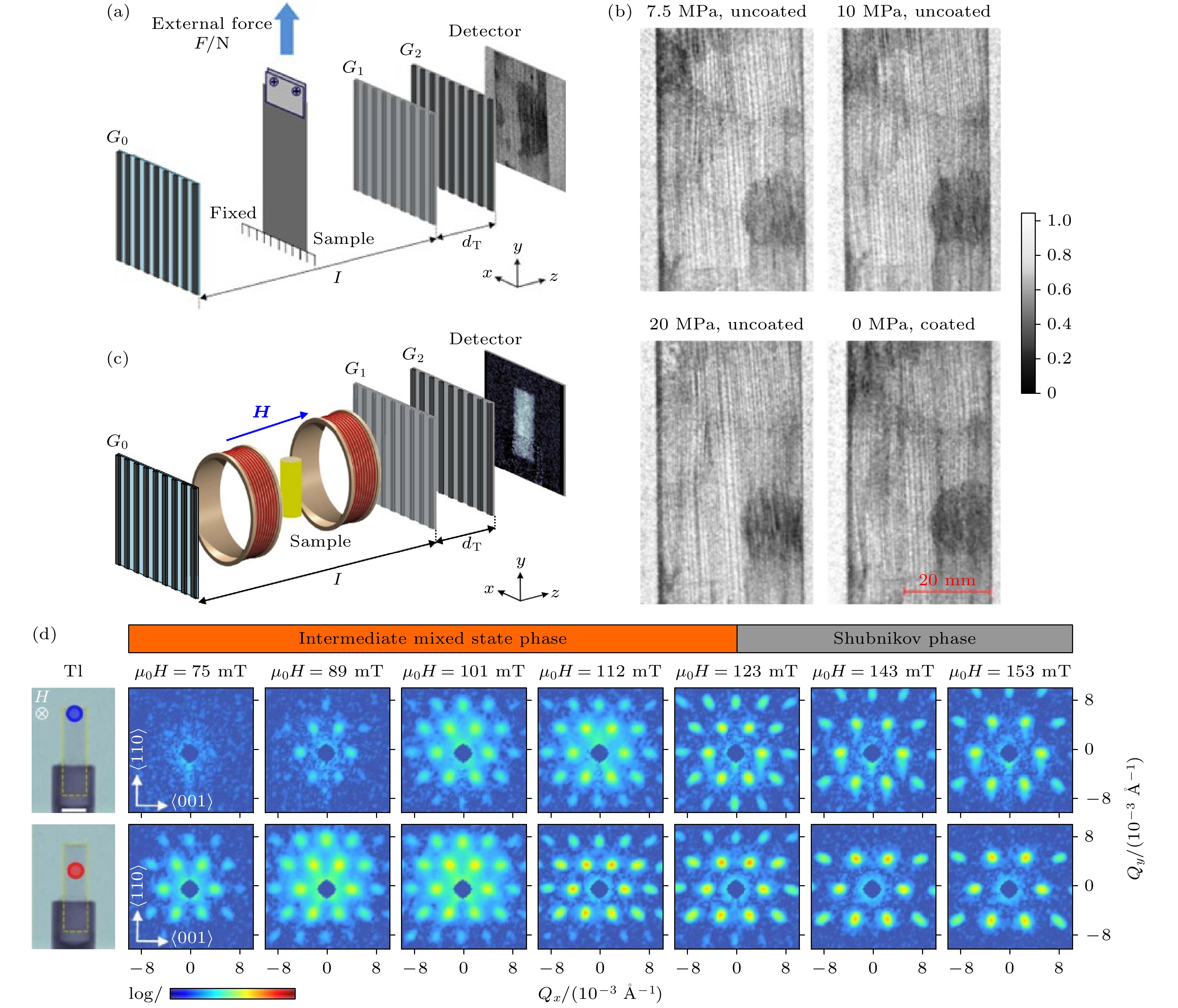

图 13 中子散射技术在磁结构研究的应用 (a)原位应力中子散射装置示意图[82]; (b)应力作用下的高磁导率钢内部磁畴演变[82]; (c)原位磁场中子散射装置示意图[83]; (d)磁场作用下的超导体Nb内部磁畴演变[83]

Figure 13. Applications of neutron scattering in magnetic structure investigations: (a) Schematic of an in-situ stress neutron scattering setup[82]; (b) stress-induced magnetic domain evolution in high-permeability steel[82]; (c) schematic of an in-situ magnetic field neutron scattering setup[83]; (d) magnetic-field-driven magnetic domain evolution in superconducting Nb[83].

-

[1] Silveyra J M, Ferrara E, Huber D L, Monson T C 2018 Science 362 eaao0195

Google Scholar

Google Scholar

[2] Yu Q 2024 HSET 81 484

Google Scholar

Google Scholar

[3] Wang H, Lamichhane T N, Paranthaman M P 2022 Mat. Today Phys. 24 100675

Google Scholar

Google Scholar

[4] Herzer G 2013 Acta Mater. 61 718

Google Scholar

Google Scholar

[5] Talaat A, Suraj M V, Byerly K, Wang A, Wang Y, Lee J K, Ohodnicki Jr P R 2021 J. Alloys Compd. 870 159500

Google Scholar

Google Scholar

[6] Rafin S S H, Ahmed R, Haque M A, Hossain M K, Haque M A, Mohammed O A 2023 Micromachines 14 2045

Google Scholar

Google Scholar

[7] Perigo E A, Weidenfeller B, Kollár P, Füzer J 2018 Appl. Phys. Rev. 5 031301

Google Scholar

Google Scholar

[8] Li X S, Zhou J, Shen L Q, Sun B A, Bai H Y, Wang W H 2023 Adv. Mater. 35 2205863

Google Scholar

Google Scholar

[9] Zhou J, Li X S, Hou X B, Ke H B, Fan X D, Luan J H, Peng H L, Zeng Q S, Lou H B, Wang J G, Liu C T, Shen B L, Sun B A, Wang W H, Bai H Y 2023 Adv. Mater. 35 2304490

Google Scholar

Google Scholar

[10] Oumsalem A, Bourezig Y, Nabi Z, Bouabdallah B 2018 Turk. J. Electr. Eng. Compu. Sci. 26 1249

[11] Zhang H T, Zhang T, Zhang X 2023 Adv. Sci. 10 2300193

Google Scholar

Google Scholar

[12] Shao L L, Luo Q, Zhang M J, Xue L, Cui J X, Yang Q Z, Ke H B, Zhang Y, Shen B L, Wang W H 2024 Nat. Commun. 15 4159

Google Scholar

Google Scholar

[13] 柯海波, 周靖, 童星, 汪卫华 2024 科技导报 42 预出版

Ke H B, Zhou J, Tong X, Wang W H 2024 Sci. Techn. Rev. 42 in press

[14] Cowley R 1980 Adv. Phys. 29 1

Google Scholar

Google Scholar

[15] Natarajan A R, Thomas J C, Puchala B, Van der Ven A 2017 Phys. Rev. B 96 134204

Google Scholar

Google Scholar

[16] Jiang Q, Wen Z, Jiang Q, Wen Z 2011 Thermodynamics of Materials (Springer) pp157-206

[17] Zhang H 2022 Models and Methods for Management Science (Springer) pp301-361

[18] Haken H 1973 Synergetics: Cooperative Phenomena in Multi-Component Systems (Springer) pp9-21

[19] Haken H 1989 Rep. Prog. Phys. 52 515

Google Scholar

Google Scholar

[20] Tong X, Zhang Y, Wang Y C, Liang X Y, Zhang K, Zhang F, Cai Y F, Ke H B, Wang G, Shen J Makino A, Wang W H 2022 J. Mater. Sci. Technol. 96 233

Google Scholar

Google Scholar

[21] Zeeman E C 1976 Sci. Am. 234 65

Google Scholar

Google Scholar

[22] Zhang E H, Zhou B K, Yang L, Li C F, Li P 2023 Trans. Soc. Min. Metall. Explor. 40 1865

[23] 任景莉, 于利萍, 张李盈 2017 66 176402

Google Scholar

Google Scholar

Ren J L, Yu L P, Zhang L Y 2017 Acta Phys. Sin. 66 176402

Google Scholar

Google Scholar

[24] Machida Y, Nakatsuji S, Onoda S, Tayama T, Sakakibara T 2010 Nature 463 210

Google Scholar

Google Scholar

[25] Laughlin D E 2019 Metall. Mater. Trans. A 50 2555

Google Scholar

Google Scholar

[26] Alonso J 2000 Chem. Rev. 100 637

Google Scholar

Google Scholar

[27] Filbet F, Xiong T, Sonnendrücker E 2018 SIAM J. Appl. Math. 78 1030

Google Scholar

Google Scholar

[28] Anderson P 1950 Phys. Rev. 79 705

Google Scholar

Google Scholar

[29] Stepanov E, Brener S, Krien F, Harland M, Lichtenstein A, Katsnelson M 2018 Phys. Rev. Lett. 121 037204

Google Scholar

Google Scholar

[30] Stöhr J, Siegmann H C 2006 Magnetism: From Fundamentals to Nanoscale Dynamics (Springer) pp479—520

[31] Hosseini M V, Askari M 2015 Phys. Rev. B 92 224435

Google Scholar

Google Scholar

[32] Kosarim A, Smirnov B 2005 J. Exp. Theor. Phys. 101 611

Google Scholar

Google Scholar

[33] Bernal J 1960 Nature 185 68

Google Scholar

Google Scholar

[34] Bernal J D 1959 Nature 183 141

Google Scholar

Google Scholar

[35] Luo W K, Sheng H W, Alamgir F M, Bai J M, He J H, Ma E 2004 Phys. Rev. Lett. 92 145502

Google Scholar

Google Scholar

[36] Lan S, Zhu L, Wu Z D, Gu L, Zhang Q H, Kong H H, Liu J Z, Song R Y, Liu S N, Sha G, Wang Y G, Liu Q, Liu W, Wang P Y, Liu C T, Ren Y, Wang X L 2021 Nat. Mater. 20 1347

Google Scholar

Google Scholar

[37] Zeng Q S, Sheng H W, Ding Y, Wang L, Yang W G, Jiang J Z, Mao W L, Mao H K 2011 Science 332 1404

Google Scholar

Google Scholar

[38] Ye J C, Lu J, Liu C T, Wang Q, Yang Y 2010 Nat. Mater. 9 619

Google Scholar

Google Scholar

[39] Miracle D B 2004 Nat. Mater. 3 697

Google Scholar

Google Scholar

[40] Sheng H, Luo W, Alamgir F, Bai J, Ma E 2006 Nature 439 419

Google Scholar

Google Scholar

[41] Ma D, Stoica A D, Wang X L 2009 Nat. Mater. 8 30

Google Scholar

Google Scholar

[42] Chen D Z, Shi C Y, An Q, Zeng Q, Mao W L, Goddard III W A, Greer J R 2015 Science 349 1306

Google Scholar

Google Scholar

[43] Hirata A, Guan P, Fujita T, Hirotsu Y, Inoue A, Yavari A R, Sakurai T, Chen M W 2011 Nat. Mater. 10 28

Google Scholar

Google Scholar

[44] Yang Y, Zhou J H, Zhu F, Yuan Y K, Chang D J, Kim D S, Pham M, Rana A, Tian X Z, Yao Y G, Osher S J, Schmid A K, Hu L B, Ercius P, Miao J W 2021 Nature 592 60

Google Scholar

Google Scholar

[45] Tang J, Xiang H P, Xu L, Qu S J, Feng A H, Li N, Ping D H 2025 Metals 15 98

Google Scholar

Google Scholar

[46] Ge J C, Gu Y, Yao Z Z, Liu S N, Ying H Q, Lu C Y, Wu Z D, Ren Y, Suzuki J, Xie Z H, Ke Y B, Zeng J R, Zhu H, Tang S, Wang X L, Lan S 2024 J. Mater. Sci. Technol. 176 224

Google Scholar

Google Scholar

[47] Bai Y W, Li J C, Zhang J, Dong B S, Li X X, Zhao X L, Cui Z H, Li T, Hu L N 2024 J. Non-Cryst. Solids 624 122705

Google Scholar

Google Scholar

[48] Tian H, Zhang C, Zhao J J, Dong C, Wen B, Wang Q 2012 Physica B 407 250

Google Scholar

Google Scholar

[49] 耿遥祥, 王英敏 2020 金属学报 56 1558

Google Scholar

Google Scholar

Geng Y X, Wang Y M 2020 Acta Metall. Sinica 56 1558

Google Scholar

Google Scholar

[50] Shi L X, Shao Y, Fan Z Y, Wang R B, Lu C Y, Yao K F 2023 Acta Mater. 254 118983

Google Scholar

Google Scholar

[51] Zhao C L, Wang A D, He A N, Chang C T, Liu C T 2021 Sci. China Mater. 64 1813

Google Scholar

Google Scholar

[52] Li H Z, Sohrabi S, Li X, Li L Y, Ma J, Peng H L, Yang C 2025 Rare Met. 44 2853

Google Scholar

Google Scholar

[53] Wang C X, Wu Z Y, Feng X M, Li Z, Gu Y, Zhang Y, Tan X H, Xu H 2020 Intermetallics 118 106689

Google Scholar

Google Scholar

[54] Lu S H, Wang M G, Zhao Z K 2023 J. Non-Cryst. Solids 616 122440

Google Scholar

Google Scholar

[55] Shao L L, Bai R S, Wu Y X, Zhou J, Tong X, Peng H L, Liang T, Li Z Z, Zeng Q S, Zhang B, Ke H B, Wang W H 2024 Mater. Futures 3 025301

Google Scholar

Google Scholar

[56] 胡玉平, 平凯斌, 闫志杰, 杨雯, 宫长伟 2011 60 107504

Hu Y P, Ping K B, Yan Z J, Yang W, Gong C W 2011 Acta Phys. Sin. 60 642

[57] Wohlfarth E P 1986 Handbook of Magnetic Materials (Vol. 2) (Elsevier

[58] Brück E H 2017 Handbook of Magnetic Materials (Vol. 26) (Elsevier

[59] Li Y H, Jia X J, Zhang W, Zhang Y, Xie G Q, Qiu Z Y, Luan J H, Jiao Z B 2021 J. Mater. Sci. Technol. 65 171

Google Scholar

Google Scholar

[60] Xi G G, Sun C, Han M H, Li H G, Cui J L, Zhang T 2024 J. Non-Cryst. Solids 633 122951

Google Scholar

Google Scholar

[61] Han M H, Sun C, Xi G G, Meng Y, Luo Q, Yu X Q, Zhang W F, Liu H, Xu H J, Zhang T 2024 Rare Met. 43 5242

Google Scholar

Google Scholar

[62] Yoshizawa Y a, Oguma S, Yamauchi K 1988 J. Appl. Phys. 64 6044

Google Scholar

Google Scholar

[63] Li H, Wang A D, Liu T, Chen P B, He A N, Li Q, Luan J H, Liu C T 2021 Mater. Today 42 49

Google Scholar

Google Scholar

[64] Duan L P, Wang K, Wang E G, Jia P 2021 Acta Metall. Sin. (English Letters) 34 1163

Google Scholar

Google Scholar

[65] Jia P, Wang E G, Han K 2016 Materials 9 899

Google Scholar

Google Scholar

[66] Chen S F, Chen C Y, Cheng C S 2015 J. Alloys Compd. 644 17

Google Scholar

Google Scholar

[67] Zhou B, Dong Y Q, Chi Q, Zhang Y Q, Chang L, Gong M J, Huang J J, Pan Y, Wang X M 2020 Ceram. Int. 46 13449

Google Scholar

Google Scholar

[68] Zhou B, Dong Y Q, Liu L, Chang L, Bi F Q, Wang X M 2019 J. Magn. Magn. Mater. 474 1

Google Scholar

Google Scholar

[69] Lu S H, Liu T, Wang M G, Zhao Z K 2025 J. Alloys Compd. 1016 178874

Google Scholar

Google Scholar

[70] Ma R, Chang L, Ye S L, Xie H Z, Xiao Q, Zhang L, Si J J, Yu P 2023 Powder Technol. 426 118639

Google Scholar

Google Scholar

[71] Bai R S, Shao L L, Ding H P, Li X S, Zhou J, Xue Z Y, Ke H B, Wang W H 2025 J. Mater. Sci. Technol. 211 82

Google Scholar

Google Scholar

[72] Zhou B, Chi Q, Dong Y Q, Liu L, Zhang Y Q, Chang L, Pan Y, He A N, Li J W, Wang X M 2020 J. Magn. Magn. Mater. 494 165827

Google Scholar

Google Scholar

[73] Chi Q, Chang L, Dong Y Q, Zhang Y Q, Zhou B, Zhang C Z, Pan Y, Li Q, Li J W, He A N, Wang X M 2021 Adv. Powder Technol. 32 1602

Google Scholar

Google Scholar

[74] Ding H P, Gong P, Chen W, Peng Z, Bu H T, Zhang M, Tang X F, Jin J S, Deng L, Xie G Q 2023 Int. J. Plast. 169 103711

Google Scholar

Google Scholar

[75] Ding H P, Bao X Q, Jamili-Shirvan Z, Jin J S, Deng L, Yao K F, Gong P, Wang X Y 2021 Mater. Des. 210 110108

Google Scholar

Google Scholar

[76] Ding H P, Bao X Q, Zhang M, Jin J S, Deng L, Yao K F, Solouk A, Gong P, Wang X Y 2023 Adv. Powder Mater. 2 100109

Google Scholar

Google Scholar

[77] Yang S Y, Zang B W, Xiang M L, Shen F Y, Song L J, Gao M, Zhang Y, Huo J T, Wang J Q 2025 Adv. Funct. Mater. 2425588

[78] Yan M, Yi S B, Fan X Y, Zhang Z H, Jin J Y, Bai G H 2021 J. Mater. Sci. Technol. 79 165

Google Scholar

Google Scholar

[79] Li W C, Han X F, Li Q, Wu J K, Li W J, Zhan H C, Ying Y, Yu J, Zheng J W, Qiao L, Li J, Che S L 2023 J. Alloys Compd. 936 168164

Google Scholar

Google Scholar

[80] Bai G H, Sun J Y, Zhang Z H, Liu X L, Bandaru S, Liu W W, Li Z, Li H X, Wang N N, Zhang X F 2024 Nat. Commun. 15 2238

Google Scholar

Google Scholar

[81] Li H Z, Yan Y Q, Cai W S, Li L Y, Yan A, Liu L H, Ma J, Ke H B, Li Q, Sun B A, Wang W H, Yang C 2024 Nat. Commun. 15 9510

Google Scholar

Google Scholar

[82] Betz B, Rauscher P, Harti R, Schäfer R, Van Swygenhoven H, Kaestner A, Hovind J, Lehmann E, Grünzweig C 2016 Appl. Phys. Lett. 108 012405

Google Scholar

Google Scholar

[83] Reimann T, Mühlbauer S, Schulz M, Betz B, Kaestner A, Pipich V, Böni P, Grünzweig C 2015 Nat. Commun. 6 8813

Google Scholar

Google Scholar

[84] Strobl M, Betz B, Harti R, Hilger A, Kardjilov N, Manke I, Gruenzweig C 2016 J. Appl. Crystallogr. 49 569

Google Scholar

Google Scholar

[85] Weiss H A, Steentjes S, Tröber P, Leuning N, Neuwirth T, Schulz M, Hameyer K, Golle R, Volk W 2019 J. Magn. Magn. Mater. 474 643

Google Scholar

Google Scholar

[86] Strobl M 2014 Sci. Rep. 4 7243

Google Scholar

Google Scholar

[87] Grünzweig C, David C, Bunk O, Dierolf M, Frei G, Kühne G, Schäfer R, Pofahl S, Rønnow H, Pfeiffer F 2008 Appl. Phys. Lett. 93 112504

Google Scholar

Google Scholar

Metrics

- Abstract views: 297

- PDF Downloads: 33

- Cited By: 0

DownLoad:

DownLoad: