-

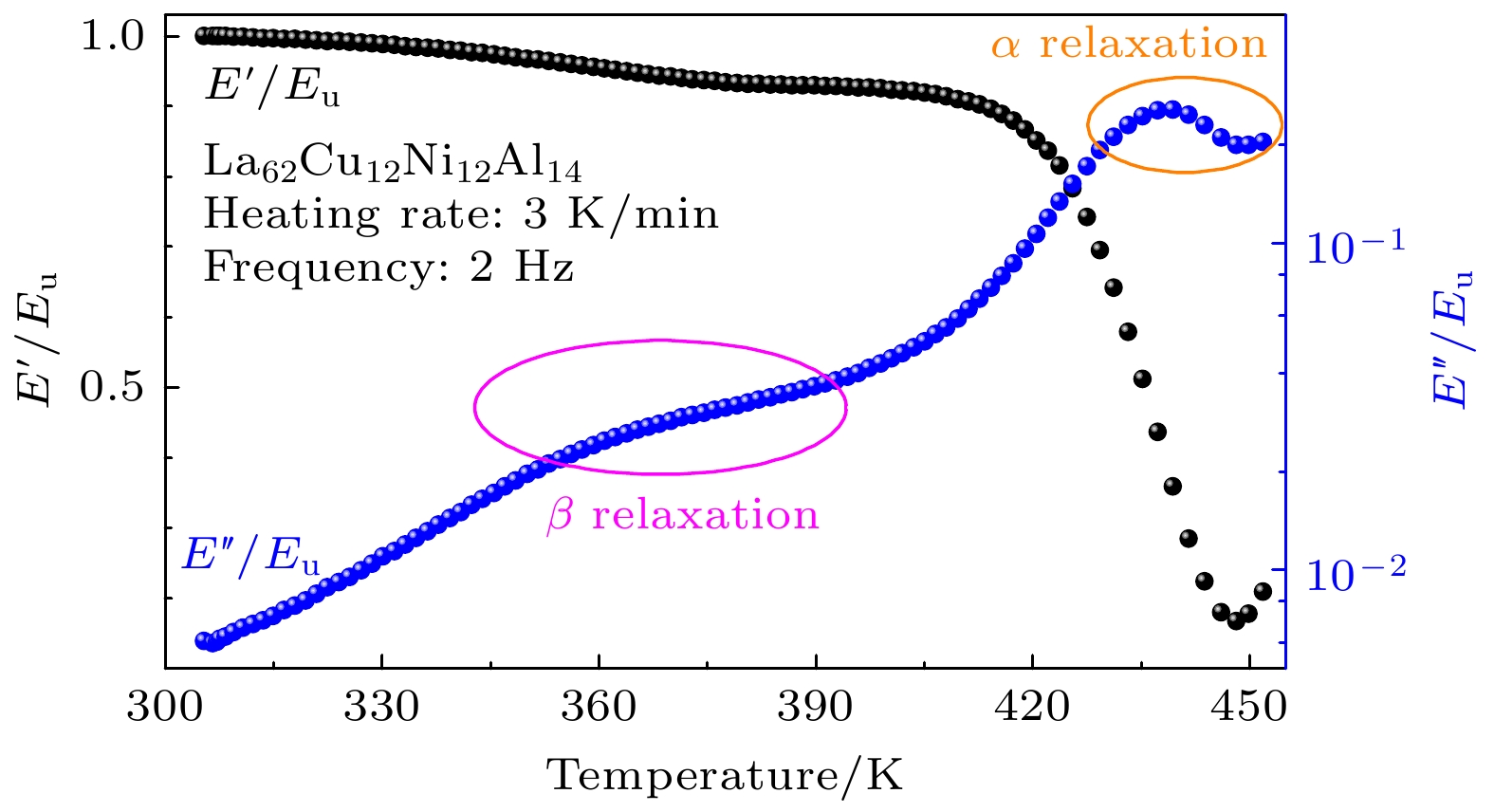

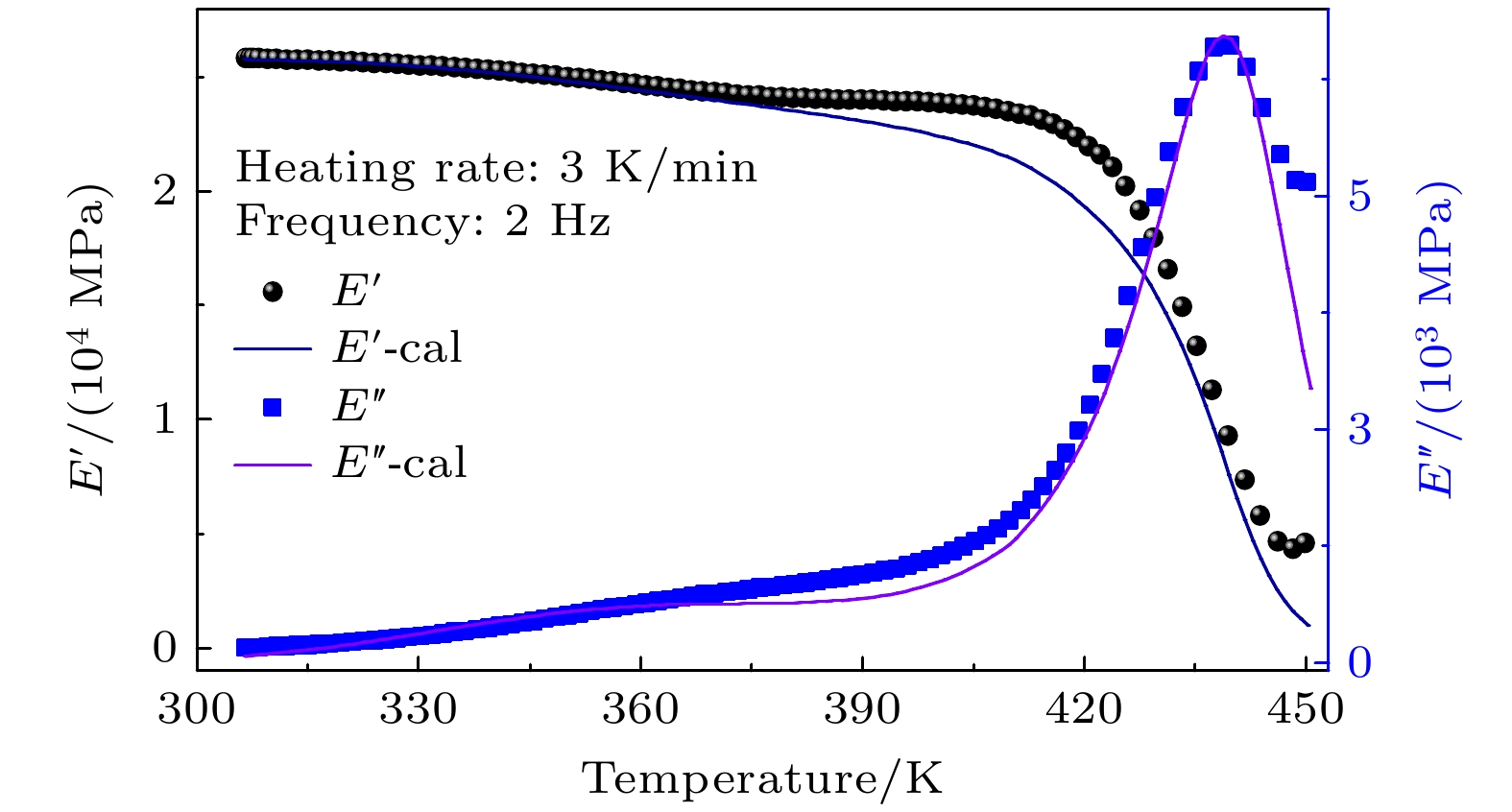

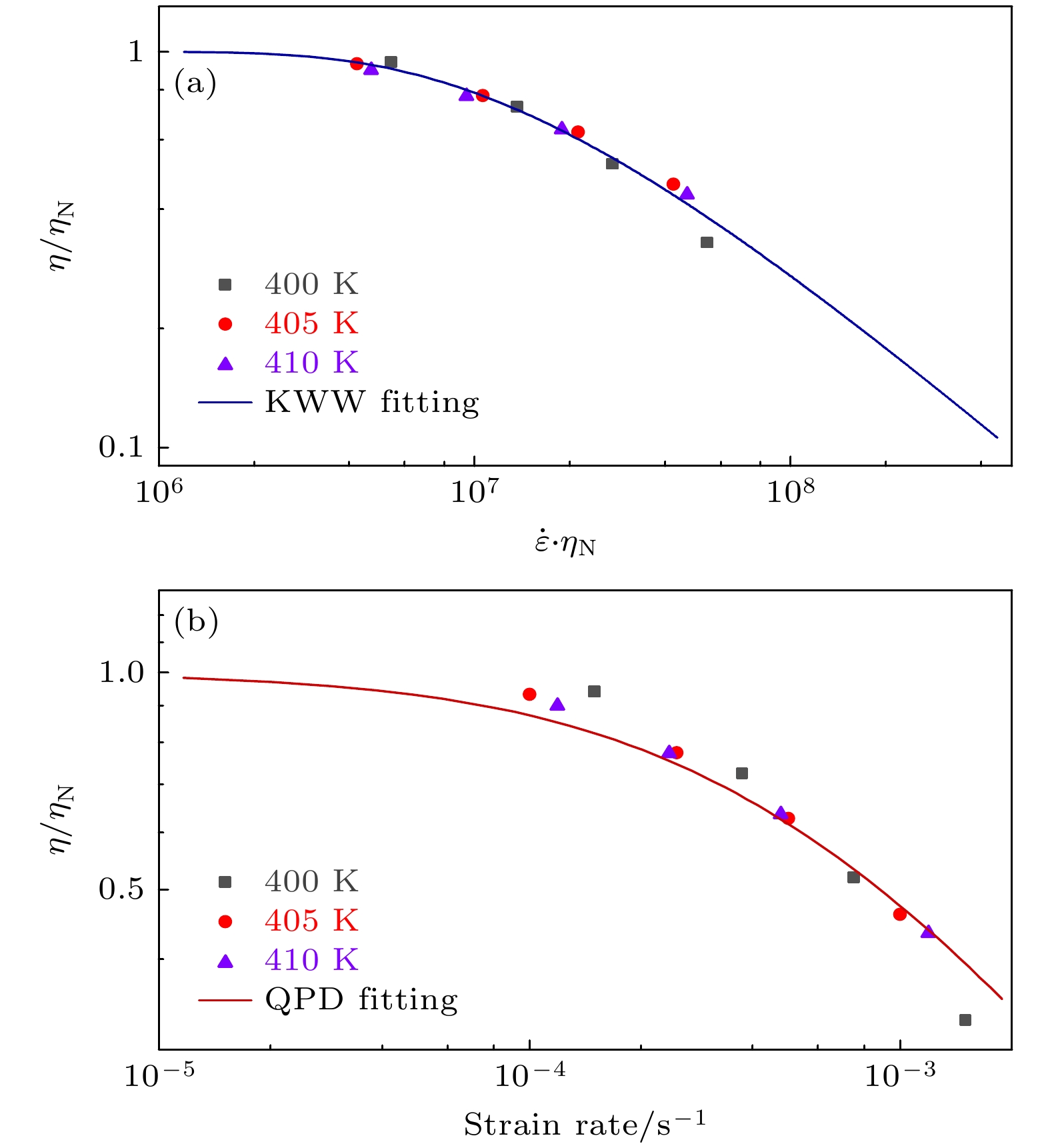

非晶合金力学行为与其微观结构非均匀性之间本征关联, 是固体力学研究领域至今未能很好解决的重要科学问题之一. 单一力学激励形式并不能有效地描述非晶合金微观结构非均匀性, 特别是结构与动力学的关联. 如何探索非晶合金结构信息, 须将诸多因素综合, 在不同力学激励下研究非晶合金微观结构非均匀性与变形机理. 本研究以La62Cu12Ni12Al14非晶合金为模型体系, 利用动态力学分析仪研究非晶合金动态弛豫行为. 基于准点缺陷模型, 对模型合金体系α弛豫和β弛豫进行了分离. 借助于拉伸应变率跳实验, 探索非晶合金高温流变行为. 确定非晶合金塑性流变过程中弹性、滞弹性以及塑性变形的贡献. 本研究从非晶合金动态力学弛豫行为和宏观塑性流变行为出发, 尝试揭示微观非均匀性对非晶合金在不同激励形式中缺陷的激活、扩展和融合的物理本质.The intrinsic structural heterogeneity of amorphous alloy is closely related to the thermodynamics and dynamical behavior, such as relaxation/crystallization, glass transition and plastic deformation. However, the structural information is submerged into the meta-stable disordered long-range structure, which makes it very difficult to explore the structural heterogeneity of amorphous alloy. A mechanical excitation factor is insufficient to effectively describe the heterogeneity of the microstructure in amorphous alloy, particularly the correlation between structure and dynamics. To explore the essence of the structure in amorphous alloy, it is necessary to consider the different mechanical stimuli. La62Cu12Ni12Al14 amorphous alloy is selected as the model system, dynamic mechanical process is probed by dynamic mechanical analyzer (DMA). The contributions of α relaxation process and β relaxation process are described in the framework of the quasi-point defect theory. Based on the quasi-point defect theory, the α-relaxation and β-relaxation in the La-based amorphous alloy are separated. Tensile strain rate jump measurements are conducted to study the high temperature rheological behavior of amorphous alloy. The contributions of elasticity, anelasticity, and plastic deformation during the homogeneous flow of amorphous alloy are determined within the framework of quasi-point defect theory. The present work aims to reveal the structural heterogeneities of amorphous alloys under the action of dynamics on various temporal scales. The physical background of the activation, propagation and coalescence of defects in amorphous alloy under different mechanical stimuli are reviewed.

-

Keywords:

- amorphous alloys /

- microstructural heterogeneity /

- dynamic mechanical relaxation /

- high-temperature flow /

- quasi-point defects theory

[1] Sun B A, Wang W H 2015 Prog. Mater. Sci. 74 211

Google Scholar

Google Scholar

[2] Greer A L 1995 Science 267 1947

Google Scholar

Google Scholar

[3] Wang W H 2012 Prog. Mater. Sci. 57 487

Google Scholar

Google Scholar

[4] Qiao J C, Wang Q, Pelletier J M, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y 2019 Prog. Mater. Sci. 104 250

Google Scholar

Google Scholar

[5] 乔吉超, 张浪渟, 童钰, 吕国建, 郝奇, 陶凯 2022 力学进展 52 117

Google Scholar

Google Scholar

Qiao J C, Zhang L T, Tong Y, Lü G J, Hao Q, Tao K 2022 Adv. Mech. 52 117

Google Scholar

Google Scholar

[6] Liu Y H, Wang D, Nakajima K, Zhang W, Hirata A, Nishi T, Inoue A, Chen M W 2011 Phys. Rev. Lett. 106 125504

Google Scholar

Google Scholar

[7] Wagner H, Bedorf D, Kuechemann S, Schwabe M, Zhang B, Arnold W, Samwer K 2011 Nat. Mater. 10 439

Google Scholar

Google Scholar

[8] 王峥, 汪卫华 2017 66 176103

Google Scholar

Google Scholar

Wang Z, Wang W H 2017 Acta Phys. Sin. 66 176103

Google Scholar

Google Scholar

[9] Johari G P 2002 J. Non-Cryst. Solids 307 317

[10] Lu Z, Jiao W, Wang W H, Bai H Y 2014 Phys. Rev. Lett. 113 045501

Google Scholar

Google Scholar

[11] Zhu F, Nguyen H K, Song S X, Aji D P B, Hirata A, Wang H, Nakajima K, Chen M W 2016 Nat. Commun. 7 11516

Google Scholar

Google Scholar

[12] Yu H B, Shen X, Wang Z, Gu L, Wang W H, Bai H Y 2012 Phys. Rev. Lett. 108 015504

Google Scholar

Google Scholar

[13] Wang Z, Wen P, Huo L S, Bai H Y, Wang W H 2012 Appl. Phys. Lett. 101 121906

Google Scholar

Google Scholar

[14] Wang Q, Liu J J, Ye Y F, Liu T T, Wang S, Liu C T, Lu J, Yang Y 2017 Mater. Today 20 293

Google Scholar

Google Scholar

[15] Liang S Y, Zhang L T, Wang B, Wang Y J, Pineda E, Qiao J C 2024 Intermetallics 164 108115

Google Scholar

Google Scholar

[16] Liu S N, Wang L F, Ge J C, Wu Z D, Ke Y B, Li Q, Sun B A, Feng T, Wu Y, Wang J T 2020 Acta Mater. 200 42

Google Scholar

Google Scholar

[17] Fan Y, Iwashita T, Egami T 2014 Nat. Commun. 5 5083

Google Scholar

Google Scholar

[18] Wang N, Ding J, Yan F, Asta M, Ritchie R O, Li L 2018 npj Comput. Mater. 4 19

Google Scholar

Google Scholar

[19] Cohen M H, Turnbull D 1959 J. Chem. Phys. 31 1164

Google Scholar

Google Scholar

[20] Wang W H 2019 Prog. Mater. Sci. 106 100561

Google Scholar

Google Scholar

[21] 汪卫华 2013 物理学进展 33 177

Wang W H 2013 Prog. Phys. 33 177

[22] Argon A S, Kuo H Y 1979 Mat. Sci. Eng. 39 101

Google Scholar

Google Scholar

[23] Cavaille J, Perez J, Johari G 1989 Phys. Rev. B 39 2411

Google Scholar

Google Scholar

[24] Guo J, Joo S H, Pi D, Kim W, Song Y, Kim H S, Zhang X, Kong D 2019 Adv. Eng. Mater. 21 1800918

Google Scholar

Google Scholar

[25] Chang C, Zhang H P, Zhao R, Li F C, Luo P, Li M Z, Bai H Y 2022 Nat. Mater. 21 1240

Google Scholar

Google Scholar

[26] Yang Q, Peng S X, Wang Z, Yu H B 2020 Natl. Sci. Rev. 7 1896

Google Scholar

Google Scholar

[27] Yu H B, Samwer K, Wang W H, Bai H Y 2013 Nat. Commun. 4 2204

Google Scholar

Google Scholar

[28] Qiao J C, Chen Y H, Casalini R, Pelletier J M, Yao Y 2019 J. Mater. Sci. Tech 35 982

Google Scholar

Google Scholar

[29] Yu H B, Wang W H, Bai H Y, Wu Y, Chen M W 2010 Phys. Rev. B 81 220201

Google Scholar

Google Scholar

[30] Demetriou M D, Launey M E, Garrett G, Schramm J P, Hofmann D C, Johnson W L, Ritchie R O 2011 Nat. Mater. 10 123

Google Scholar

Google Scholar

[31] Yu H B, Wang W H, Bai H Y, Samwer K 2014 Natl. Sci. Rev. 1 429

Google Scholar

Google Scholar

[32] Qiao J C, Pelletier J M 2012 J. Appl. Phys. 112 083528

Google Scholar

Google Scholar

[33] Hu L, Yue Y 2009 J. Phys. Chem. C 113 15001

Google Scholar

Google Scholar

[34] Zhang L T, Duan Y J, Crespo D, Pineda E, Wang Y J, Pelletier J M, Qiao J C 2021 Sci. China: Phys. , Mech. Astron. 64 1

[35] Egami T, Poon S J, Zhang Z, Keppens V 2007 Phys. Rev. B 76 024203

Google Scholar

Google Scholar

[36] Debenedetti P G, Stillinger F H 2001 Nature 410 259

Google Scholar

Google Scholar

[37] Wang Z, Wang W H 2019 Natl. Sci. Rev. 6 304

Google Scholar

Google Scholar

[38] Spaepen F 1977 Acta Metall. 25 407

Google Scholar

Google Scholar

[39] Argon A S 1979 Acta Metall. 27 47

Google Scholar

Google Scholar

[40] Falk M L, Langer J S 1998 Phys. Rev. E 57 7192

Google Scholar

Google Scholar

[41] Langer J S 2015 Phys. Rev. E 92 012318

Google Scholar

Google Scholar

[42] Huo L S, Zeng J F, Wang W H, Liu C T, Yang Y 2013 Acta Mater. 61 4329

Google Scholar

Google Scholar

[43] Ye J C, Lu J, Liu C T, Wang Q, Yang Y 2010 Nat. Mater. 9 619

Google Scholar

Google Scholar

[44] Palmer R G, Stein D L, Abrahams E, Anderson P W 1984 Phys. Rev. Lett. 53 958

Google Scholar

Google Scholar

[45] Gauthier C, Pelletier J M, David L, Vigier G, Perez J 2000 J. Non-Cryst. Solids 274 181

Google Scholar

Google Scholar

[46] Hao Q, Lü G J, Pineda E, Pelletier J M, Wang Y J, Yang Y, Qiao J C 2022 Int. J. Plast. 154 103288

Google Scholar

Google Scholar

[47] Makarov A S, Mitrofanov Y P, Konchakov R A, Kobelev N P, Csach K, Qiao J C, Khonik V A 2019 J. Non-Cryst. Solids 521 119474

Google Scholar

Google Scholar

[48] Hao Q, Qiao J C, Goncharova E V, Afonin G V, Liu M N, Cheng Y T, Khonik V 2020 Chin. Phys. B 29 086402

Google Scholar

Google Scholar

[49] Tao K, Khonik V A, Qiao J C 2023 Int. J. Mech. Sci. 240 107941

Google Scholar

Google Scholar

[50] Qiao J C, Pelletier J M 2012 Intermetallics 28 40

Google Scholar

Google Scholar

[51] Qiao J C, Casalini R, Pelletier J M 2014 J. Chem. Phys. 141 104510

[52] Perez J, Cavaille J Y, Etienne S, Jourdan C 1988 Rev. Phys. Appl. 23 125

Google Scholar

Google Scholar

[53] Rinaldi R, Gaertner R, Chazeau L, Gauthier C 2011 Int. J. Nonlin. Mech 46 496

Google Scholar

Google Scholar

[54] Bruns M, Hassani M, Varnik F, Hassanpour A, Divinski S, Wilde G 2021 Phys. Rev. Res. 3 013234

Google Scholar

Google Scholar

[55] Zhang C, Qiao J C, Pelletier J M, Yao Y 2017 Intermetallics 86 88

Google Scholar

Google Scholar

[56] Kawamura Y, Inoue A 2000 Appl. Phys. Lett. 77 1114

Google Scholar

Google Scholar

[57] 郝奇, 乔吉超, Pelletier J M 2020 力学学报 52 360

Google Scholar

Google Scholar

Hao Q, Qiao J C, Pelletier J M 2020 Acta Mech. Sin. 52 360

Google Scholar

Google Scholar

[58] Perez J 1998 Physics and Mechanics of Amorphous Polymers (Routledge, London) pp55–65

[59] Pelletier J M, Van de Moortèle B, Lu I 2002 Mat. Sci. Eng. A 336 190

Google Scholar

Google Scholar

-

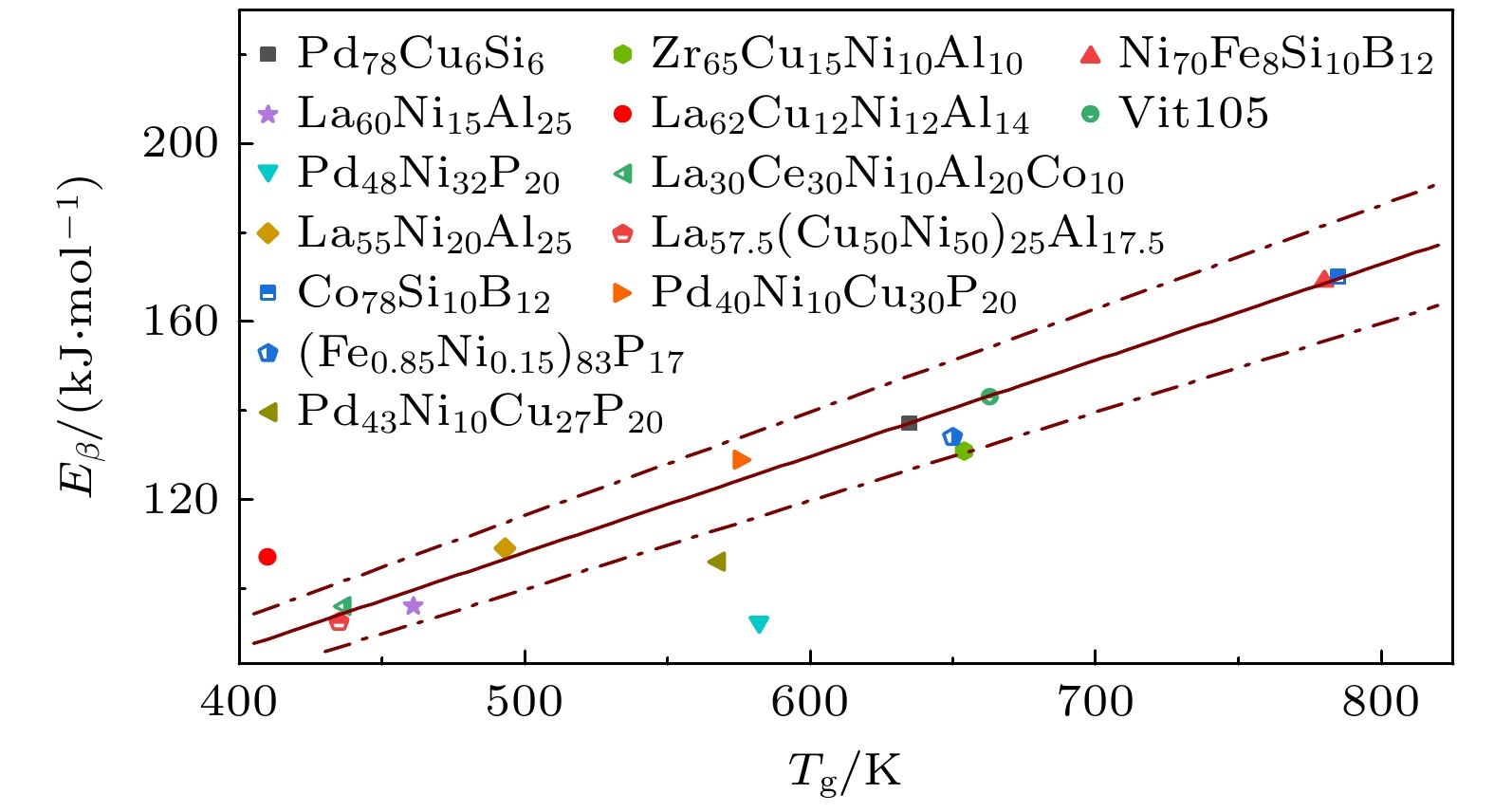

图 4 不同体系非晶合金的β弛豫名义激活能分布[31–34], 图中点划线区域为经验公式$ {{E}}_{{\beta } } =(24\pm 2){RT}\text{g} $包围区域

Fig. 4. Evolution of the β relaxation at different amorphous alloys with the glass transition temperature[31–34], dotted area in the figure is the area surrounded by empirical formula $ {{E}}_{{\beta } } =(24\pm 2) {R}{{T}}_{{\text{g} } }$.

图 7 (a) 铸态和退火态La62Cu12Ni12Al14非晶合金XRD衍射图; (b) 铸态和退火态La62Cu12Ni12Al14非晶合金蠕变曲线. 测试温度为390 K, 施加应力为60 MPa, 图中实线为KWW方程拟合曲线

Fig. 7. (a) XRD patterns of La62Cu12Ni12Al14 amorphous alloy with different states, as-cast state and annealed state; (b) creep deformation process of La62Cu12Ni12Al14 amorphous alloy with different states, as-cast state and annealed state. The measurement temperature is 373 K and the applied stress is 50 MPa, the solid lines denote KWW fitted curves.

图 9 (a)单轴拉伸回复实验过程中La62Cu12Ni12Al14非晶合金的时间-真实应变曲线; (b)实验过程中La62Cu12Ni12Al14非晶合金的真实应力-真实应变曲线, 符号为实验数据, 曲线为(5a)式计算得到

Fig. 9. (a) True strain-tine curve of La62Cu12Ni12Al14 amorphous alloy in uniaxial tensile and recovery experiment; (b) true stress-true strain curve of La62Cu12Ni12Al14 amorphous alloy, symbols represent the experimental data, solid line represents the calculated data of Eq. (5a).

-

[1] Sun B A, Wang W H 2015 Prog. Mater. Sci. 74 211

Google Scholar

Google Scholar

[2] Greer A L 1995 Science 267 1947

Google Scholar

Google Scholar

[3] Wang W H 2012 Prog. Mater. Sci. 57 487

Google Scholar

Google Scholar

[4] Qiao J C, Wang Q, Pelletier J M, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y 2019 Prog. Mater. Sci. 104 250

Google Scholar

Google Scholar

[5] 乔吉超, 张浪渟, 童钰, 吕国建, 郝奇, 陶凯 2022 力学进展 52 117

Google Scholar

Google Scholar

Qiao J C, Zhang L T, Tong Y, Lü G J, Hao Q, Tao K 2022 Adv. Mech. 52 117

Google Scholar

Google Scholar

[6] Liu Y H, Wang D, Nakajima K, Zhang W, Hirata A, Nishi T, Inoue A, Chen M W 2011 Phys. Rev. Lett. 106 125504

Google Scholar

Google Scholar

[7] Wagner H, Bedorf D, Kuechemann S, Schwabe M, Zhang B, Arnold W, Samwer K 2011 Nat. Mater. 10 439

Google Scholar

Google Scholar

[8] 王峥, 汪卫华 2017 66 176103

Google Scholar

Google Scholar

Wang Z, Wang W H 2017 Acta Phys. Sin. 66 176103

Google Scholar

Google Scholar

[9] Johari G P 2002 J. Non-Cryst. Solids 307 317

[10] Lu Z, Jiao W, Wang W H, Bai H Y 2014 Phys. Rev. Lett. 113 045501

Google Scholar

Google Scholar

[11] Zhu F, Nguyen H K, Song S X, Aji D P B, Hirata A, Wang H, Nakajima K, Chen M W 2016 Nat. Commun. 7 11516

Google Scholar

Google Scholar

[12] Yu H B, Shen X, Wang Z, Gu L, Wang W H, Bai H Y 2012 Phys. Rev. Lett. 108 015504

Google Scholar

Google Scholar

[13] Wang Z, Wen P, Huo L S, Bai H Y, Wang W H 2012 Appl. Phys. Lett. 101 121906

Google Scholar

Google Scholar

[14] Wang Q, Liu J J, Ye Y F, Liu T T, Wang S, Liu C T, Lu J, Yang Y 2017 Mater. Today 20 293

Google Scholar

Google Scholar

[15] Liang S Y, Zhang L T, Wang B, Wang Y J, Pineda E, Qiao J C 2024 Intermetallics 164 108115

Google Scholar

Google Scholar

[16] Liu S N, Wang L F, Ge J C, Wu Z D, Ke Y B, Li Q, Sun B A, Feng T, Wu Y, Wang J T 2020 Acta Mater. 200 42

Google Scholar

Google Scholar

[17] Fan Y, Iwashita T, Egami T 2014 Nat. Commun. 5 5083

Google Scholar

Google Scholar

[18] Wang N, Ding J, Yan F, Asta M, Ritchie R O, Li L 2018 npj Comput. Mater. 4 19

Google Scholar

Google Scholar

[19] Cohen M H, Turnbull D 1959 J. Chem. Phys. 31 1164

Google Scholar

Google Scholar

[20] Wang W H 2019 Prog. Mater. Sci. 106 100561

Google Scholar

Google Scholar

[21] 汪卫华 2013 物理学进展 33 177

Wang W H 2013 Prog. Phys. 33 177

[22] Argon A S, Kuo H Y 1979 Mat. Sci. Eng. 39 101

Google Scholar

Google Scholar

[23] Cavaille J, Perez J, Johari G 1989 Phys. Rev. B 39 2411

Google Scholar

Google Scholar

[24] Guo J, Joo S H, Pi D, Kim W, Song Y, Kim H S, Zhang X, Kong D 2019 Adv. Eng. Mater. 21 1800918

Google Scholar

Google Scholar

[25] Chang C, Zhang H P, Zhao R, Li F C, Luo P, Li M Z, Bai H Y 2022 Nat. Mater. 21 1240

Google Scholar

Google Scholar

[26] Yang Q, Peng S X, Wang Z, Yu H B 2020 Natl. Sci. Rev. 7 1896

Google Scholar

Google Scholar

[27] Yu H B, Samwer K, Wang W H, Bai H Y 2013 Nat. Commun. 4 2204

Google Scholar

Google Scholar

[28] Qiao J C, Chen Y H, Casalini R, Pelletier J M, Yao Y 2019 J. Mater. Sci. Tech 35 982

Google Scholar

Google Scholar

[29] Yu H B, Wang W H, Bai H Y, Wu Y, Chen M W 2010 Phys. Rev. B 81 220201

Google Scholar

Google Scholar

[30] Demetriou M D, Launey M E, Garrett G, Schramm J P, Hofmann D C, Johnson W L, Ritchie R O 2011 Nat. Mater. 10 123

Google Scholar

Google Scholar

[31] Yu H B, Wang W H, Bai H Y, Samwer K 2014 Natl. Sci. Rev. 1 429

Google Scholar

Google Scholar

[32] Qiao J C, Pelletier J M 2012 J. Appl. Phys. 112 083528

Google Scholar

Google Scholar

[33] Hu L, Yue Y 2009 J. Phys. Chem. C 113 15001

Google Scholar

Google Scholar

[34] Zhang L T, Duan Y J, Crespo D, Pineda E, Wang Y J, Pelletier J M, Qiao J C 2021 Sci. China: Phys. , Mech. Astron. 64 1

[35] Egami T, Poon S J, Zhang Z, Keppens V 2007 Phys. Rev. B 76 024203

Google Scholar

Google Scholar

[36] Debenedetti P G, Stillinger F H 2001 Nature 410 259

Google Scholar

Google Scholar

[37] Wang Z, Wang W H 2019 Natl. Sci. Rev. 6 304

Google Scholar

Google Scholar

[38] Spaepen F 1977 Acta Metall. 25 407

Google Scholar

Google Scholar

[39] Argon A S 1979 Acta Metall. 27 47

Google Scholar

Google Scholar

[40] Falk M L, Langer J S 1998 Phys. Rev. E 57 7192

Google Scholar

Google Scholar

[41] Langer J S 2015 Phys. Rev. E 92 012318

Google Scholar

Google Scholar

[42] Huo L S, Zeng J F, Wang W H, Liu C T, Yang Y 2013 Acta Mater. 61 4329

Google Scholar

Google Scholar

[43] Ye J C, Lu J, Liu C T, Wang Q, Yang Y 2010 Nat. Mater. 9 619

Google Scholar

Google Scholar

[44] Palmer R G, Stein D L, Abrahams E, Anderson P W 1984 Phys. Rev. Lett. 53 958

Google Scholar

Google Scholar

[45] Gauthier C, Pelletier J M, David L, Vigier G, Perez J 2000 J. Non-Cryst. Solids 274 181

Google Scholar

Google Scholar

[46] Hao Q, Lü G J, Pineda E, Pelletier J M, Wang Y J, Yang Y, Qiao J C 2022 Int. J. Plast. 154 103288

Google Scholar

Google Scholar

[47] Makarov A S, Mitrofanov Y P, Konchakov R A, Kobelev N P, Csach K, Qiao J C, Khonik V A 2019 J. Non-Cryst. Solids 521 119474

Google Scholar

Google Scholar

[48] Hao Q, Qiao J C, Goncharova E V, Afonin G V, Liu M N, Cheng Y T, Khonik V 2020 Chin. Phys. B 29 086402

Google Scholar

Google Scholar

[49] Tao K, Khonik V A, Qiao J C 2023 Int. J. Mech. Sci. 240 107941

Google Scholar

Google Scholar

[50] Qiao J C, Pelletier J M 2012 Intermetallics 28 40

Google Scholar

Google Scholar

[51] Qiao J C, Casalini R, Pelletier J M 2014 J. Chem. Phys. 141 104510

[52] Perez J, Cavaille J Y, Etienne S, Jourdan C 1988 Rev. Phys. Appl. 23 125

Google Scholar

Google Scholar

[53] Rinaldi R, Gaertner R, Chazeau L, Gauthier C 2011 Int. J. Nonlin. Mech 46 496

Google Scholar

Google Scholar

[54] Bruns M, Hassani M, Varnik F, Hassanpour A, Divinski S, Wilde G 2021 Phys. Rev. Res. 3 013234

Google Scholar

Google Scholar

[55] Zhang C, Qiao J C, Pelletier J M, Yao Y 2017 Intermetallics 86 88

Google Scholar

Google Scholar

[56] Kawamura Y, Inoue A 2000 Appl. Phys. Lett. 77 1114

Google Scholar

Google Scholar

[57] 郝奇, 乔吉超, Pelletier J M 2020 力学学报 52 360

Google Scholar

Google Scholar

Hao Q, Qiao J C, Pelletier J M 2020 Acta Mech. Sin. 52 360

Google Scholar

Google Scholar

[58] Perez J 1998 Physics and Mechanics of Amorphous Polymers (Routledge, London) pp55–65

[59] Pelletier J M, Van de Moortèle B, Lu I 2002 Mat. Sci. Eng. A 336 190

Google Scholar

Google Scholar

计量

- 文章访问数: 3684

- PDF下载量: 100

- 被引次数: 0

下载:

下载: