-

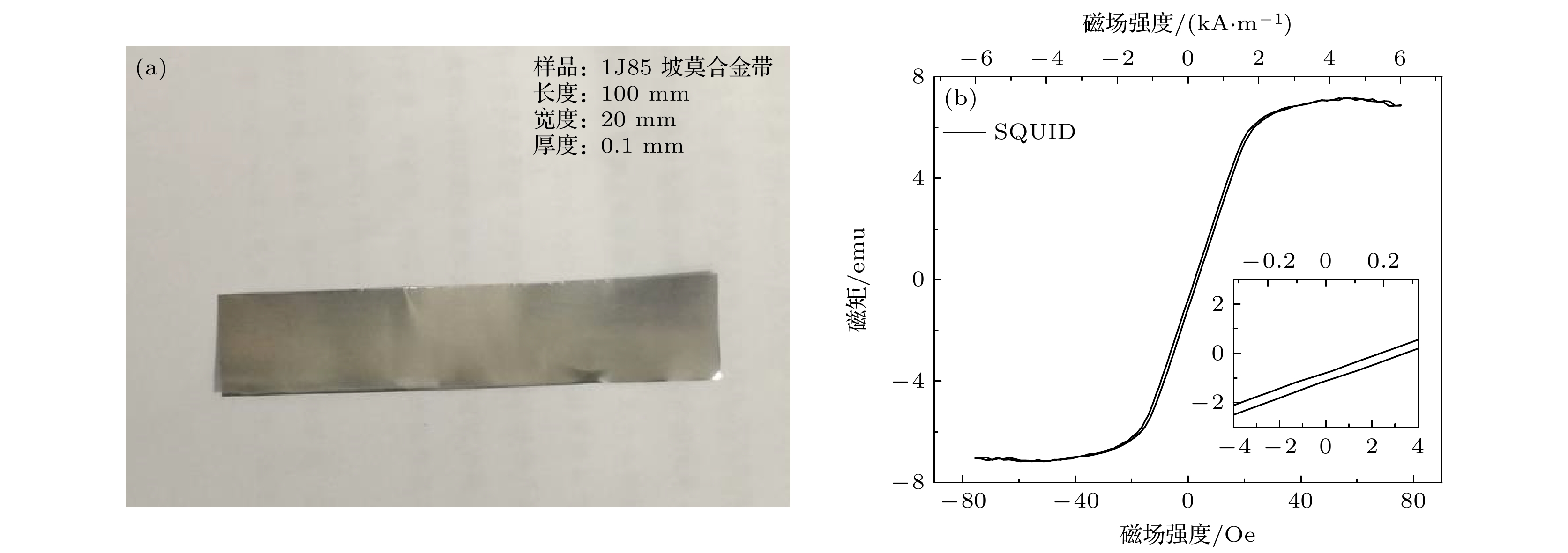

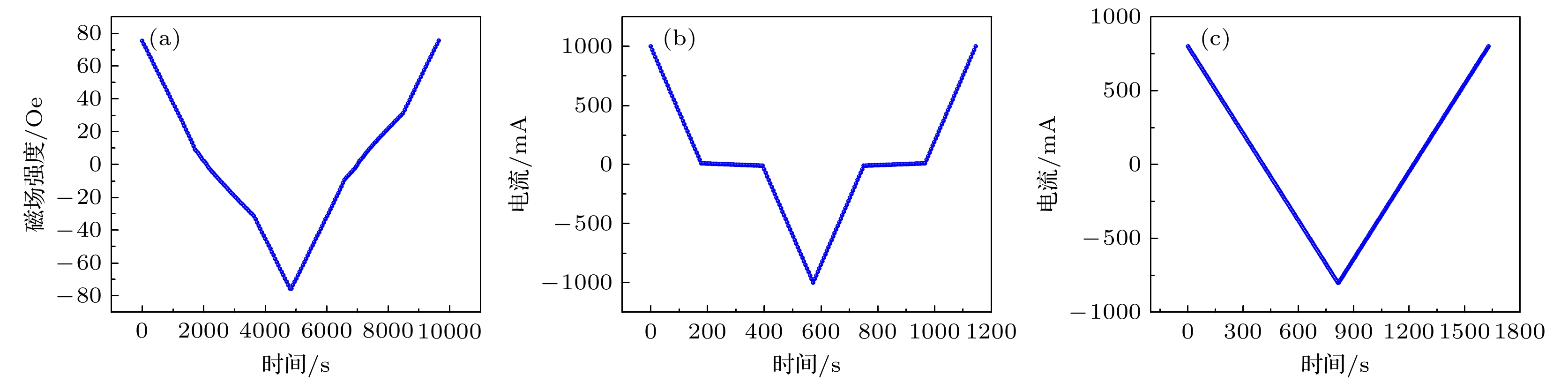

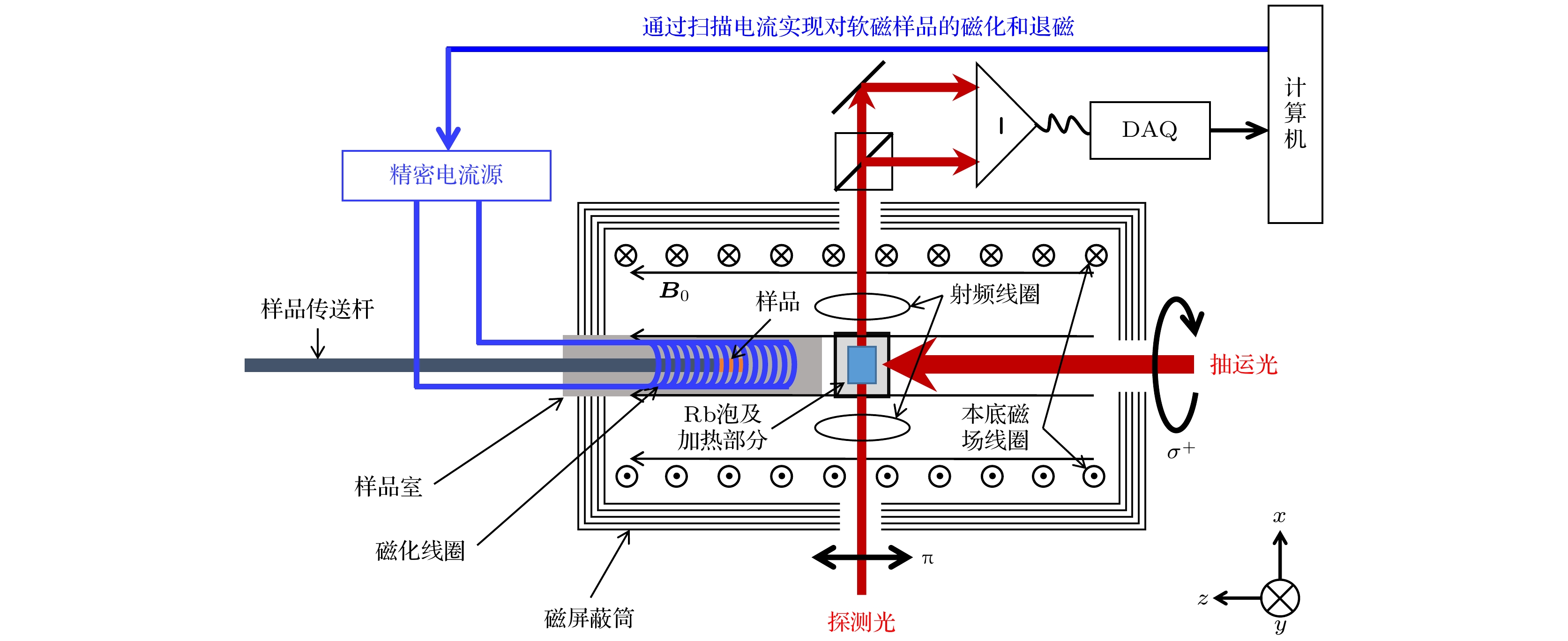

报道了在开磁路中利用抽运-检测型铷原子磁力仪测量软磁材料矫顽力的实验装置和方法. 磁屏蔽筒中的本底磁场、磁化线圈和软磁样品在铷泡空间位置产生的磁场均平行于磁屏蔽筒的轴线方向; 扫描磁化线圈中的电流实现软磁样品的磁化和退磁, 用抽运-检测型铷原子磁力仪分别在磁化线圈中有样品和无样品的条件下测量铷泡空间位置处的磁场; 在相等电流值条件下, 用有样品测得的磁场值减去无样品测得的磁场值, 获得软磁样品在铷泡空间位置产生的磁场, 用软磁样品在铷泡位置处产生磁场为零来判定其磁化强度由饱和值减小到零的条件, 用磁滞回线计算出样品的平均矫顽力. 采用本文提出的测量装置和方法测量带状坡莫合金软磁样品的矫顽力, 10次测量的平均值为40.63 A/m, 矫顽力测量再现性以相对标准偏差表示为0.16%, 该方法具有无零点漂移、复现性好、测量速度快、原位测量等优点.

We report an experimental device and method of measuring the coercivity of soft magnetic material in an open magnetic circuit by using a pump-probe rubidium atomic magnetometer. The experimental device consists of a background magnetic field generation module, a pump-probe atomic magnetometer, a soft magnetic material magnetization and demagnetization module, and a software in a computer. The uniform background magnetic field ranging from 200 nT to 20000 nT along the z-axis at the rubidium bubble’s position is generated by a current carrying coil which is placed in a five-layer magnetic shielding cylinder. The saturation magnetization and demagnetization of soft magnetic material are realized by the soft magnetic sample magnetization and demagnetization module, respectively, which consists of a sample chamber, a soft magnetic sample, a magnetizing coil, a precision current source and a sample transfer rod. The sample chamber is placed in the magnetic field uniform area of the magnetizing coil which is placed in the magnetic shielding cylinder, and the sample transfer rod is used to transfer the soft magnetic sample into the center of the magnetizing coil. Both the rubidium bubble and the soft magnetic sample are placed on the z-axis of the magnetic shielding cylinder, and their distance is greater than or equal to 10 cm. The axis of the magnetizing coil coincides with the axis of the magnetic shielding cylinder, which ensures that the background magnetic field, the magnetic field generated by the magnetizing coil, and the magnetic field generated by the soft magnetic sample at the rubidium bubble’s position are all parallel to the axis direction of the magnetic shielding cylinder. The software in the computer realizes the magnetization and demagnetization of the soft magnetic sample by controlling the current output by the precision current source to the magnetizing coil, and also controls the pump-probe atomic magnetometer to measure the magnetic field at the rubidium bubble’s position. When the soft magnetic sample is magnetized or demagnetized in cycles, the magnetic field generated by the soft magnetic sample at the rubidium bubble’s position is obtained by subtracting the magnetic field value measured in advance when the sample is not placed in the sample chamber from the magnetic field value measured at same current value when the sample is placed in the sample chamber. Note that the sample does not move during the hysteresis loop measurement. When the magnetization of the soft magnetic sample decreases from the saturation value to zero, the magnetic field generated by the soft magnetic sample at the rubidium bubble’s position is zero, and the average coercivity of the sample can be calculated from the hysteresis loop. We use a superconducting quantum interference device (SQUID), a pump-detection rubidium atomic magnetometer and a Hall probe to measure the coercivity of the same permalloy strip sample, the average coercivities are 42.15 A/m, 40.632 A/m and 38.64 A/m, the biases of the hysteresis loops are 229.74 A/m, –0.95 A/m and –52.88 A/m, and the times of each measurement cycle are 9639 s, 1144 s, and 1630 s, respectively. The reproducibility of ten repeated measurements by using the pump-probe atomic magnetometer, expressed as relative standard deviation, is 0.16%, which is an order of magnitude higher than the counterparts from the methods described in China’s national standards GB/T 3656-2008 and GB/T 13888-2009. The accumulated drift of the biases of ten hysteresis loops measured by the pump-probe atomic magnetometer is 0.3 A/m. Based on the above experimental results, the coercivity measurement method by using the pump-probe atomic magnetometer has the advantages of no zero-point drift, good repeatability, fast measurement speed, and in-situ measurement, and has the potential applications in the basic research field and industrial field of magnetism. -

Keywords:

- atomic magnetometer /

- pump-probe /

- soft magnetic material /

- coercivity

[1] 何峻, 赵栋梁 2015 金属功能材料 22 1

Google Scholar

Google Scholar

He J, Zhao D L 2015 Metal. Funct. Mater. 22 1

Google Scholar

Google Scholar

[2] 陈海英 2000 现代仪器 6 5

Google Scholar

Google Scholar

Chen H Y 2000 Modern Instruments 6 5

Google Scholar

Google Scholar

[3] 张焱, 高政祥, 高进 曹立志 2003 现代仪器 9 36

Google Scholar

Google Scholar

Zhang Y, Gao Z X, Gao J, Cao L Z 2003 Modern Instruments 9 36

Google Scholar

Google Scholar

[4] 于红云 2014 63 047502

Google Scholar

Google Scholar

Yu H Y 2014 Acta Phys. Sin. 63 047502

Google Scholar

Google Scholar

[5] GB/T 3656—2008 软磁材料矫顽力的抛移测量方法 第3页

GB/T 3656—2008 Method of Coercivity Measurement for Magnetically Soft Materials by Pull out Procedure p3 (in Chinese)

[6] GB/T 13888—2009/IEC 60404-7—1982 在开磁路中测量磁性材料矫顽力的方法 第2—4页

GB/T 13888—2009/IEC 60404-7—1982 Method of Measurehment of the Coercivity of Magnetic Materials in an Open Magnetic Circuit pp2–4 (in Chinese)

[7] GB/T 13012—2008/IEC 60404-4—2000 软磁材料直流磁性能的测量方法 第1—18页

GB/T 13012—2008/IEC 60404-4—2000 Methods of Measurement of d. c. Magnetic Properties of Magnetically Soft Materials pp1–18 (in Chinese)

[8] YB/T 5251—2013 软磁合金带卷绕环形铁芯 第7页

YB/T 5251—2013 Magnetic Cores Wound with Soft Magnetic Alloy Strips p7 (in Chinese)

[9] 王春梅, 赵振杰, 阮建中, 李赫, 沈国土 2016 物理实验 36 13

Google Scholar

Google Scholar

Wang C M, Zhao Z J, Ruan J Z, Li H, Shen G T 2016 Phys. Experiment. 36 13

Google Scholar

Google Scholar

[10] Allred J C, Lyman R N, Kornack T W, Romalis M V 2002 Phys. Rev. Lett. 89 130801

Google Scholar

Google Scholar

[11] Kominis I K, Kornack T W, Allred J C, Romailis M V 2003 Nature 422 596

Google Scholar

Google Scholar

[12] Dang H B, Maloof A C, Romalis M V 2010 Appl. Phys. Lett. 97 151110

Google Scholar

Google Scholar

[13] Master D, Pandey S, Ring H, Ledbetter M P, Knappe S, Kitching J, Budker D 2011 Rev. Sci. Instrum. 82 086112

Google Scholar

Google Scholar

[14] Xu S, Donaldson M H, Pines A, Rochester S M, Budker D, Yashchuk V V 2006 Appl. Phys. Lett. 89 224105

Google Scholar

Google Scholar

[15] Xu S, Yashchuk V V, Donaldson M H, Rochester S M, Budker D, Pines A 2006 Proc. Natl. Acad. Sci. USA 103 12668

Google Scholar

Google Scholar

[16] Johnson C, Adolphi N L, Butler K L, Lovato D M, Larson R, Schwindt P D D, Flynn E R 2012 J. Magn. Magn. Mater. 324 2613

Google Scholar

Google Scholar

[17] Kim Y J, Savukov I, Huang J H, Nath P 2017 Appl. Phys. Lett. 110 043702

Google Scholar

Google Scholar

[18] Colombo S, Lebedev V, Grujic Z D, Dolgovskiy V, Weis A 2016 Int. J. Mag. Part. Imag. 2 1604001

Google Scholar

Google Scholar

[19] Miao P X, Zheng W Q, Yang S Y, Wu B, Cheng B, Tu J H, Ke H L, Yang W, Wang J, Cui J Z, Lin Q 2019 J. Opt. Soc. Am. B 36 819

Google Scholar

Google Scholar

[20] 缪培贤, 杨世宇, 王剑祥, 廉吉庆, 涂建辉, 杨炜, 崔敬忠 2017 66 160701

Google Scholar

Google Scholar

Miao P X, Yang S Y, Wang J X, Lian J Q, Tu J H, Yang W, Cui J Z 2017 Acta Phys. Sin. 66 160701

Google Scholar

Google Scholar

[21] 缪培贤, 杨世宇, 崔敬忠, 刘志栋 2020 真空与低温 26 494

Google Scholar

Google Scholar

Miao P X, Yang S Y, Cui J Z, Liu Z D 2020 Vac. Cryogen. 26 494

Google Scholar

Google Scholar

[22] 陈大勇, 缪培贤, 史彦超, 崔敬忠, 刘志栋, 陈江, 王宽 2022 71 024202

Google Scholar

Google Scholar

Chen D Y, Miao P X, Shi Y C, Cui J Z, Liu Z D, Chen J, Wang K 2022 Acta Phys. Sin. 71 024202

Google Scholar

Google Scholar

[23] 杨宝, 缪培贤, 史彦超, 冯浩, 张金海, 崔敬忠, 刘志栋 2020 中国激光 47 1012001

Google Scholar

Google Scholar

Yang B, Miao P X, Shi Y C, Feng H, Zhang J H, Cui J Z, Liu Z D 2020 Chin. J. Lasers 47 1012001

Google Scholar

Google Scholar

[24] 缪培贤 2022 真空与低温 28 592

Google Scholar

Google Scholar

Miao P X 2022 Vac. Cryogen. 28 592

Google Scholar

Google Scholar

[25] 李东辉 2020 硕士学位论文 (南京: 东南大学)

Li D H 2020 M. S. Thesis (Nanjing: Southeast University) (in Chinese)

-

图 3 在开磁路中利用抽运-检测型原子磁力仪测量软磁样品的矫顽力的实验结果 (a)用抽运-检测型原子磁力仪测量的数据曲线; (b)软磁样品的磁滞回线; (c)软磁样品的矫顽力; (d)磁滞回线的偏置

Fig. 3. Experimental results of measuring the coercivity of a soft magnetic sample in an open magnetic circuit by a pump-probe atomic magnetometer: (a) Curves measured by the pump-probe atomic magnetometer; (b) hysteresis loops of the soft magnetic sample; (c) coercivity of the soft magnetic sample; (d) bias of the hysteresis loop.

图 4 在开磁路中利用霍尔探头测量软磁样品矫顽力的实验结果 (a)测量装置示意图; (b)用霍尔探头测量的磁滞回线; (c)软磁样品的矫顽力; (d)磁滞回线的偏置

Fig. 4. Experimental results of measuring the coercivity of a soft magnetic sample in an open magnetic circuit by a Hall probe: (a) Schematic diagram of experimental device; (b) hysteresis loops measured by the Hall probe; (c) coercivity of the soft magnetic sample; (d) bias of the hysteresis loop.

-

[1] 何峻, 赵栋梁 2015 金属功能材料 22 1

Google Scholar

Google Scholar

He J, Zhao D L 2015 Metal. Funct. Mater. 22 1

Google Scholar

Google Scholar

[2] 陈海英 2000 现代仪器 6 5

Google Scholar

Google Scholar

Chen H Y 2000 Modern Instruments 6 5

Google Scholar

Google Scholar

[3] 张焱, 高政祥, 高进 曹立志 2003 现代仪器 9 36

Google Scholar

Google Scholar

Zhang Y, Gao Z X, Gao J, Cao L Z 2003 Modern Instruments 9 36

Google Scholar

Google Scholar

[4] 于红云 2014 63 047502

Google Scholar

Google Scholar

Yu H Y 2014 Acta Phys. Sin. 63 047502

Google Scholar

Google Scholar

[5] GB/T 3656—2008 软磁材料矫顽力的抛移测量方法 第3页

GB/T 3656—2008 Method of Coercivity Measurement for Magnetically Soft Materials by Pull out Procedure p3 (in Chinese)

[6] GB/T 13888—2009/IEC 60404-7—1982 在开磁路中测量磁性材料矫顽力的方法 第2—4页

GB/T 13888—2009/IEC 60404-7—1982 Method of Measurehment of the Coercivity of Magnetic Materials in an Open Magnetic Circuit pp2–4 (in Chinese)

[7] GB/T 13012—2008/IEC 60404-4—2000 软磁材料直流磁性能的测量方法 第1—18页

GB/T 13012—2008/IEC 60404-4—2000 Methods of Measurement of d. c. Magnetic Properties of Magnetically Soft Materials pp1–18 (in Chinese)

[8] YB/T 5251—2013 软磁合金带卷绕环形铁芯 第7页

YB/T 5251—2013 Magnetic Cores Wound with Soft Magnetic Alloy Strips p7 (in Chinese)

[9] 王春梅, 赵振杰, 阮建中, 李赫, 沈国土 2016 物理实验 36 13

Google Scholar

Google Scholar

Wang C M, Zhao Z J, Ruan J Z, Li H, Shen G T 2016 Phys. Experiment. 36 13

Google Scholar

Google Scholar

[10] Allred J C, Lyman R N, Kornack T W, Romalis M V 2002 Phys. Rev. Lett. 89 130801

Google Scholar

Google Scholar

[11] Kominis I K, Kornack T W, Allred J C, Romailis M V 2003 Nature 422 596

Google Scholar

Google Scholar

[12] Dang H B, Maloof A C, Romalis M V 2010 Appl. Phys. Lett. 97 151110

Google Scholar

Google Scholar

[13] Master D, Pandey S, Ring H, Ledbetter M P, Knappe S, Kitching J, Budker D 2011 Rev. Sci. Instrum. 82 086112

Google Scholar

Google Scholar

[14] Xu S, Donaldson M H, Pines A, Rochester S M, Budker D, Yashchuk V V 2006 Appl. Phys. Lett. 89 224105

Google Scholar

Google Scholar

[15] Xu S, Yashchuk V V, Donaldson M H, Rochester S M, Budker D, Pines A 2006 Proc. Natl. Acad. Sci. USA 103 12668

Google Scholar

Google Scholar

[16] Johnson C, Adolphi N L, Butler K L, Lovato D M, Larson R, Schwindt P D D, Flynn E R 2012 J. Magn. Magn. Mater. 324 2613

Google Scholar

Google Scholar

[17] Kim Y J, Savukov I, Huang J H, Nath P 2017 Appl. Phys. Lett. 110 043702

Google Scholar

Google Scholar

[18] Colombo S, Lebedev V, Grujic Z D, Dolgovskiy V, Weis A 2016 Int. J. Mag. Part. Imag. 2 1604001

Google Scholar

Google Scholar

[19] Miao P X, Zheng W Q, Yang S Y, Wu B, Cheng B, Tu J H, Ke H L, Yang W, Wang J, Cui J Z, Lin Q 2019 J. Opt. Soc. Am. B 36 819

Google Scholar

Google Scholar

[20] 缪培贤, 杨世宇, 王剑祥, 廉吉庆, 涂建辉, 杨炜, 崔敬忠 2017 66 160701

Google Scholar

Google Scholar

Miao P X, Yang S Y, Wang J X, Lian J Q, Tu J H, Yang W, Cui J Z 2017 Acta Phys. Sin. 66 160701

Google Scholar

Google Scholar

[21] 缪培贤, 杨世宇, 崔敬忠, 刘志栋 2020 真空与低温 26 494

Google Scholar

Google Scholar

Miao P X, Yang S Y, Cui J Z, Liu Z D 2020 Vac. Cryogen. 26 494

Google Scholar

Google Scholar

[22] 陈大勇, 缪培贤, 史彦超, 崔敬忠, 刘志栋, 陈江, 王宽 2022 71 024202

Google Scholar

Google Scholar

Chen D Y, Miao P X, Shi Y C, Cui J Z, Liu Z D, Chen J, Wang K 2022 Acta Phys. Sin. 71 024202

Google Scholar

Google Scholar

[23] 杨宝, 缪培贤, 史彦超, 冯浩, 张金海, 崔敬忠, 刘志栋 2020 中国激光 47 1012001

Google Scholar

Google Scholar

Yang B, Miao P X, Shi Y C, Feng H, Zhang J H, Cui J Z, Liu Z D 2020 Chin. J. Lasers 47 1012001

Google Scholar

Google Scholar

[24] 缪培贤 2022 真空与低温 28 592

Google Scholar

Google Scholar

Miao P X 2022 Vac. Cryogen. 28 592

Google Scholar

Google Scholar

[25] 李东辉 2020 硕士学位论文 (南京: 东南大学)

Li D H 2020 M. S. Thesis (Nanjing: Southeast University) (in Chinese)

计量

- 文章访问数: 6003

- PDF下载量: 88

- 被引次数: 0

下载:

下载: