-

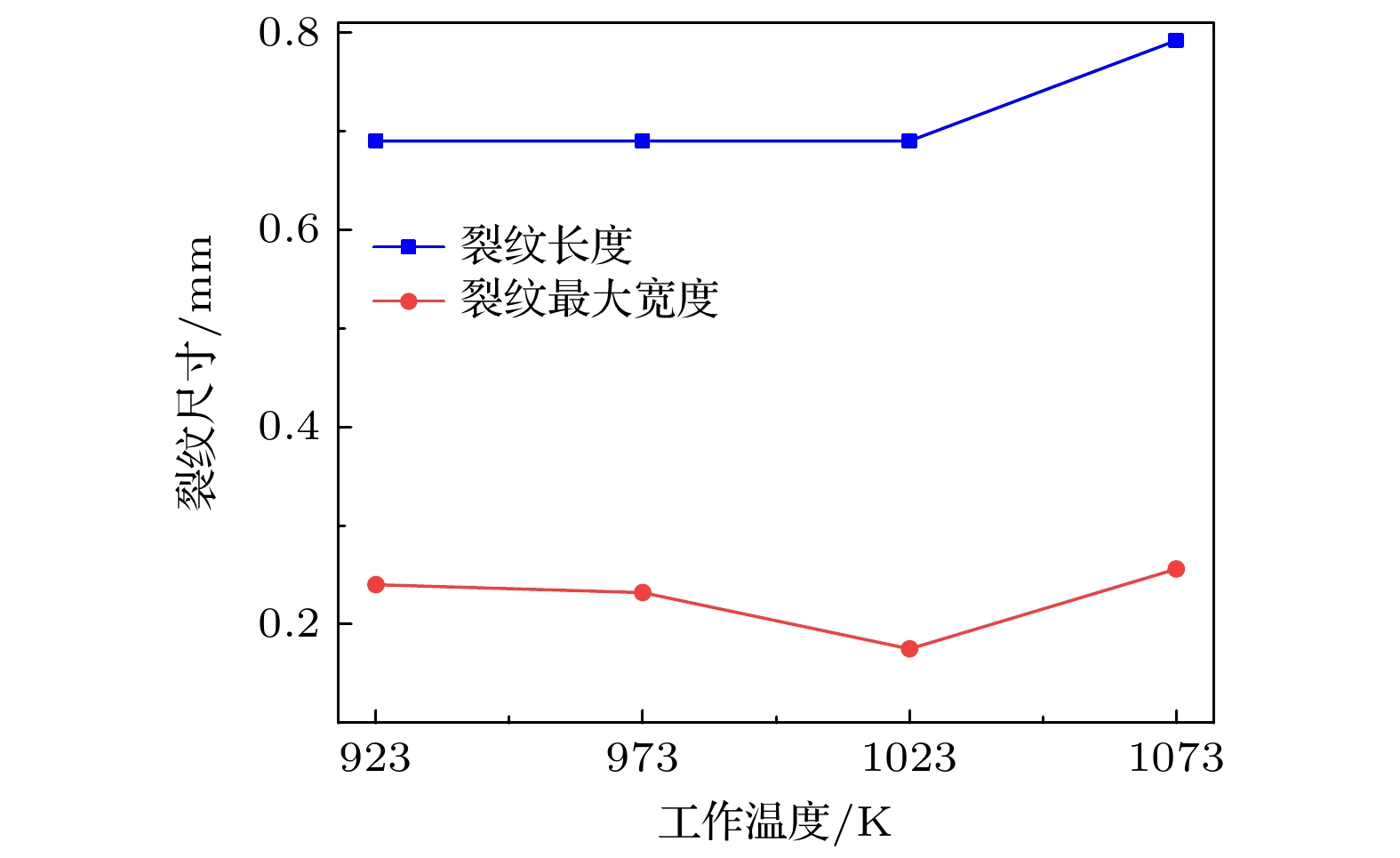

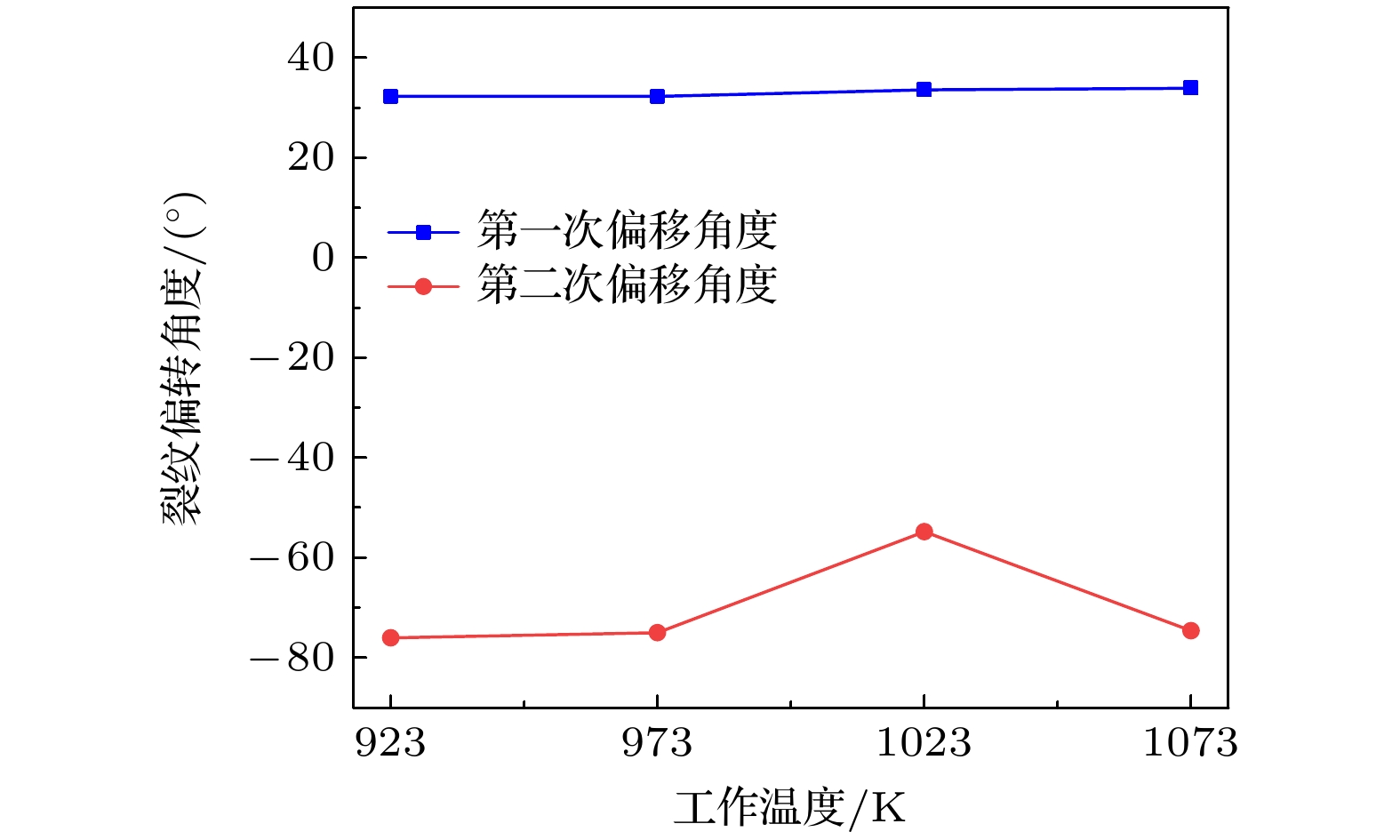

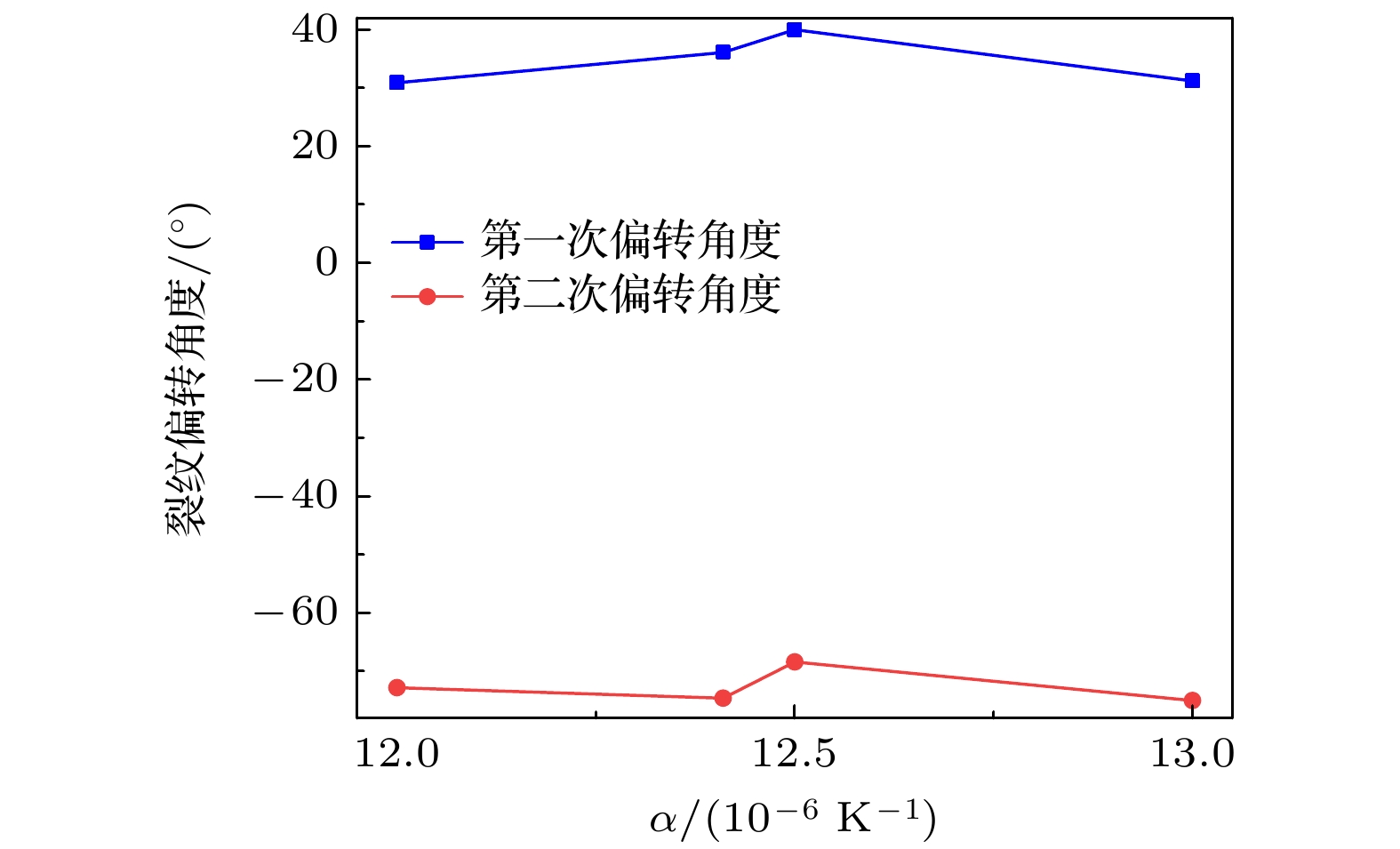

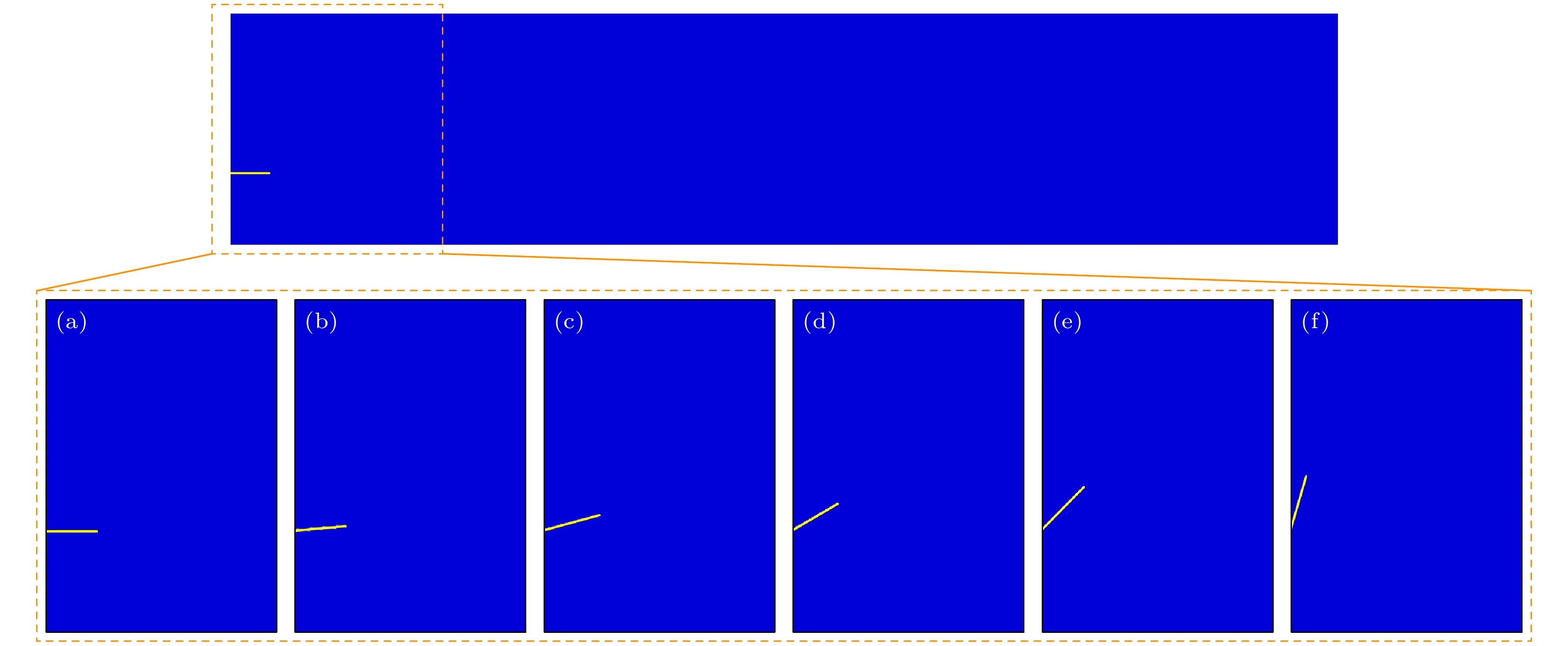

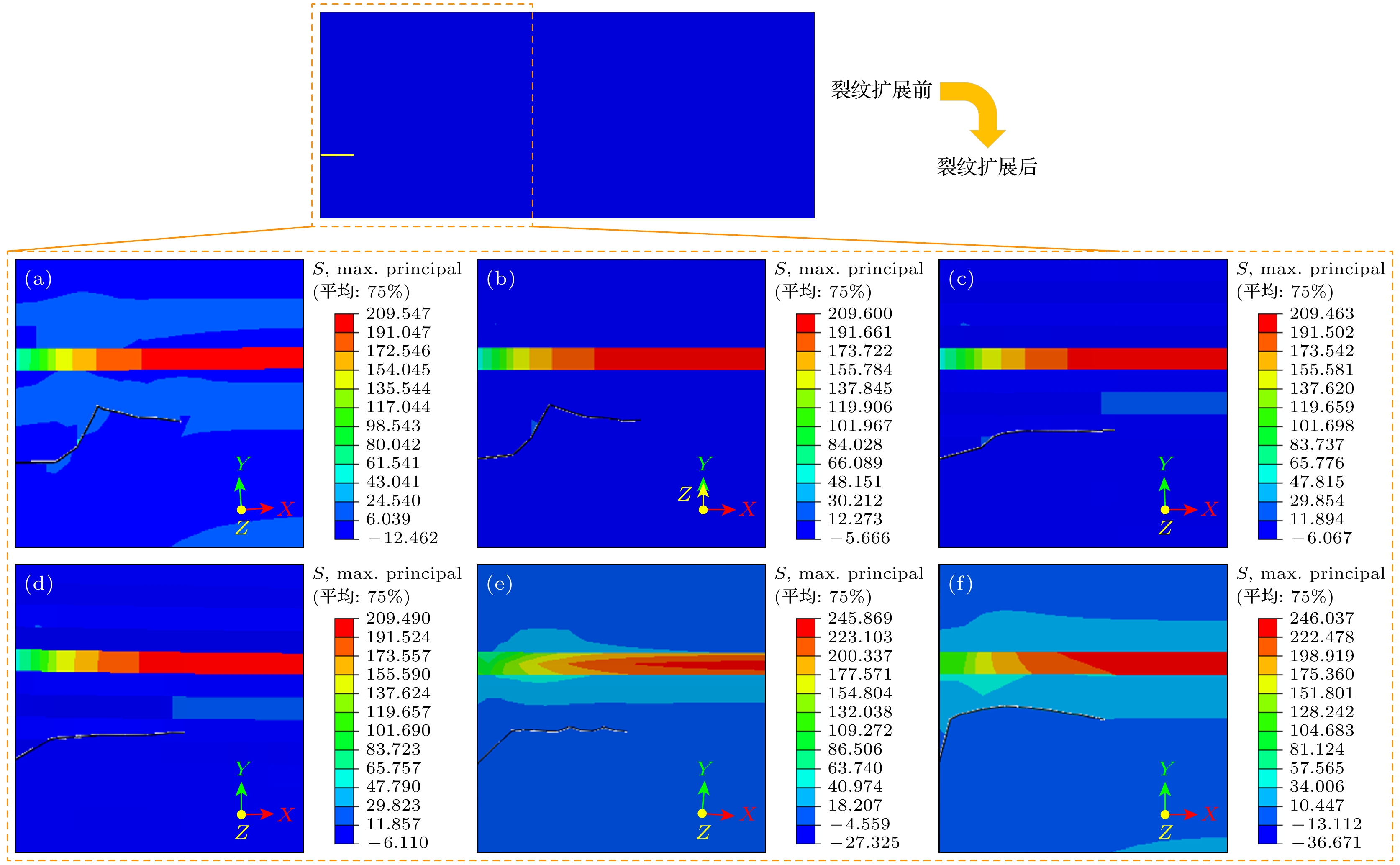

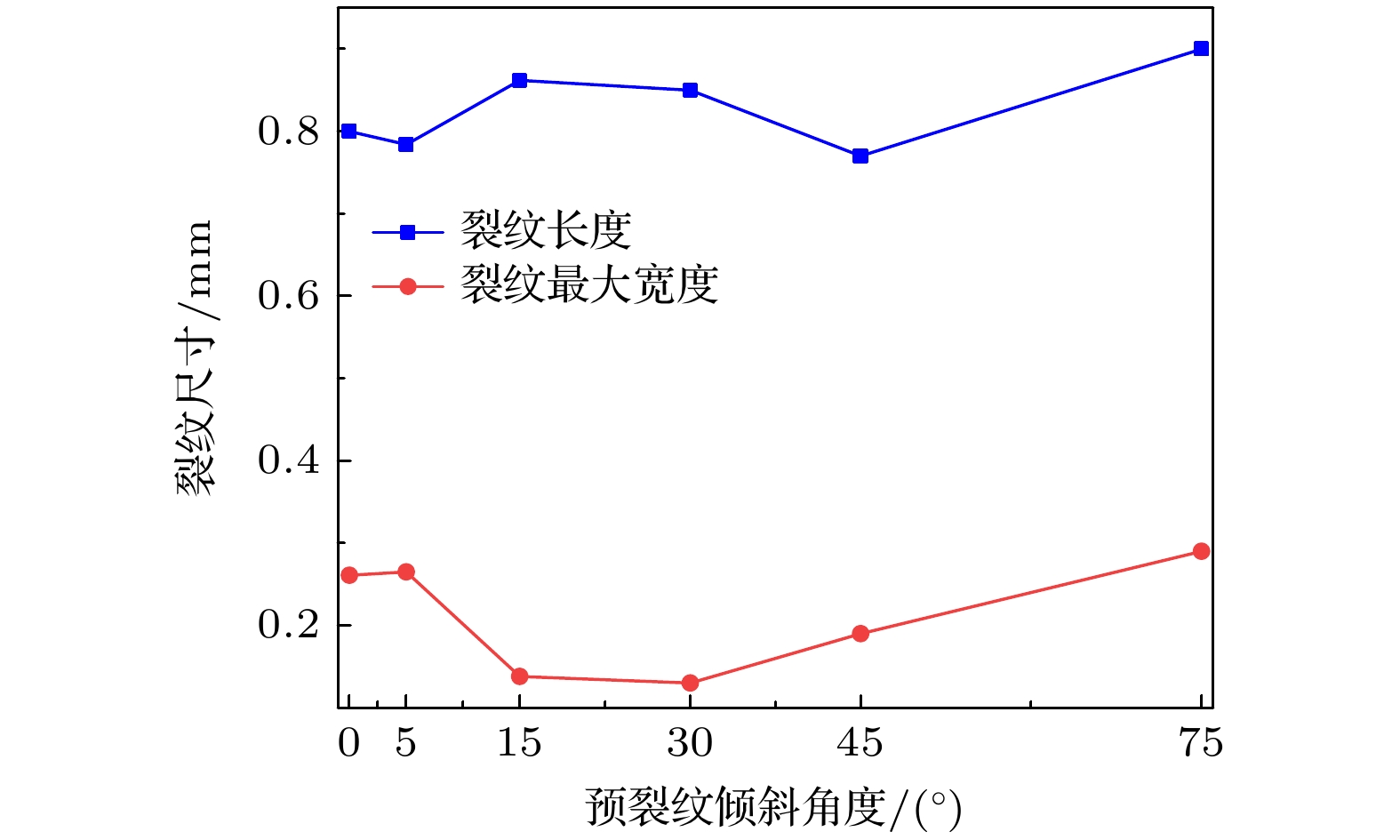

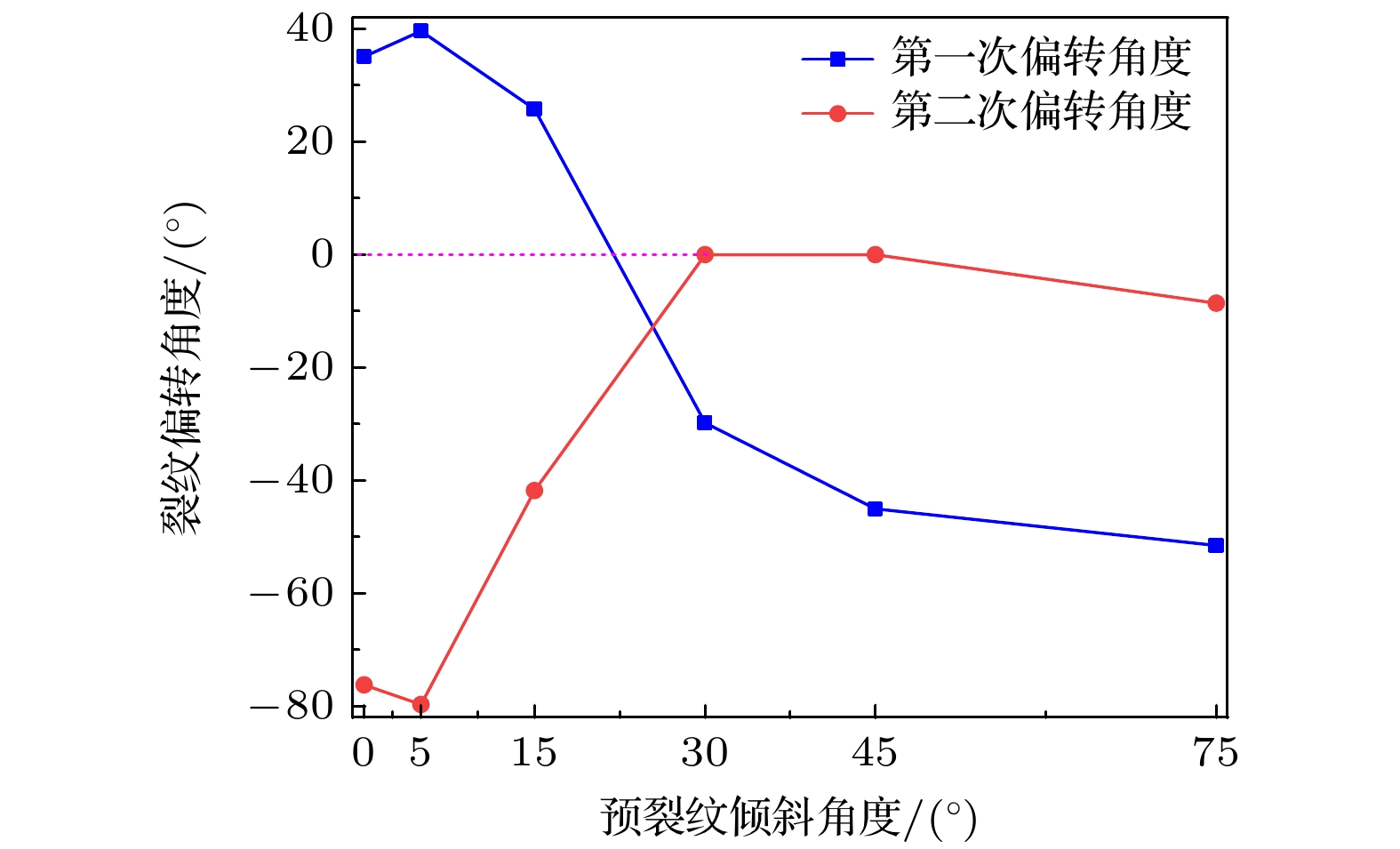

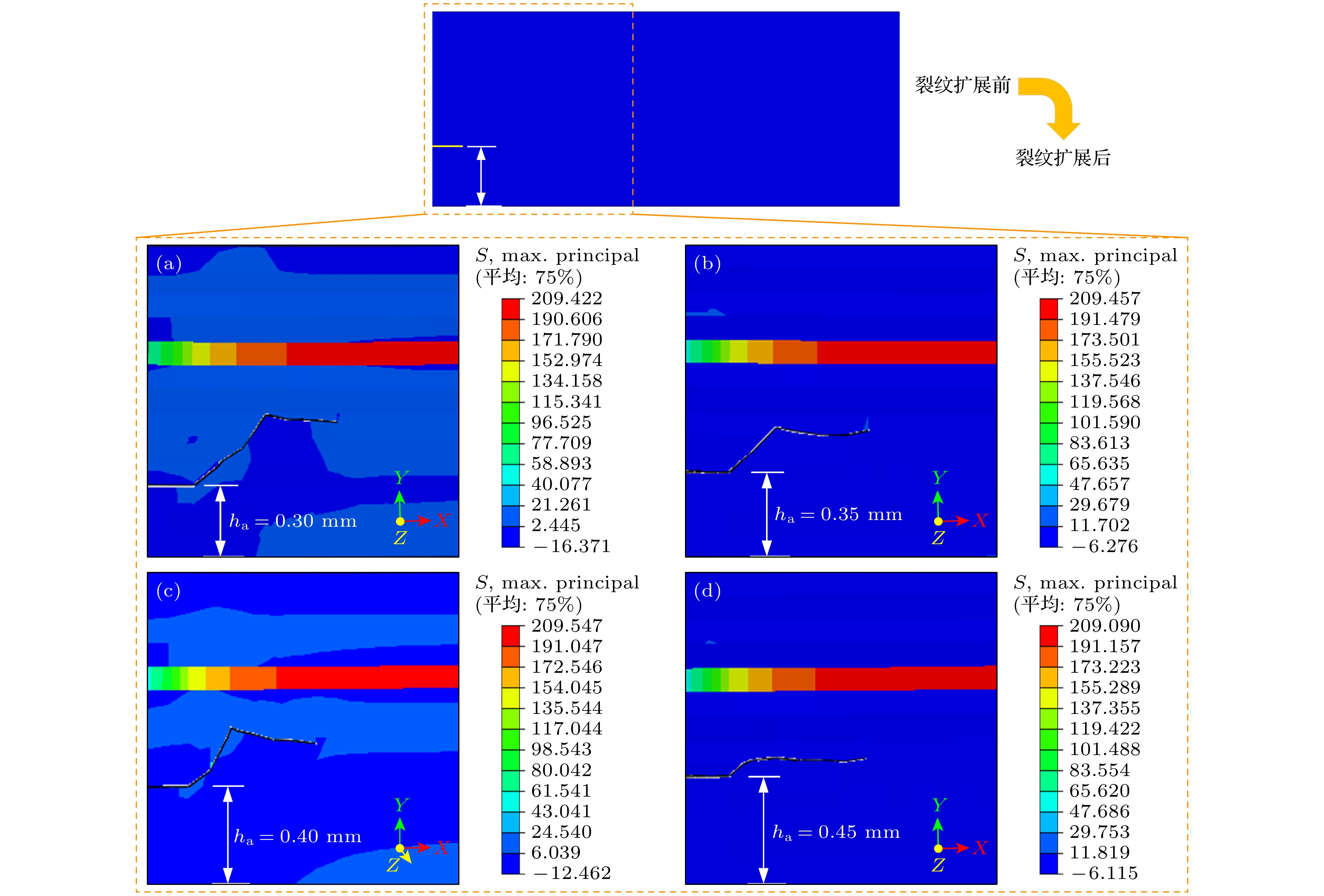

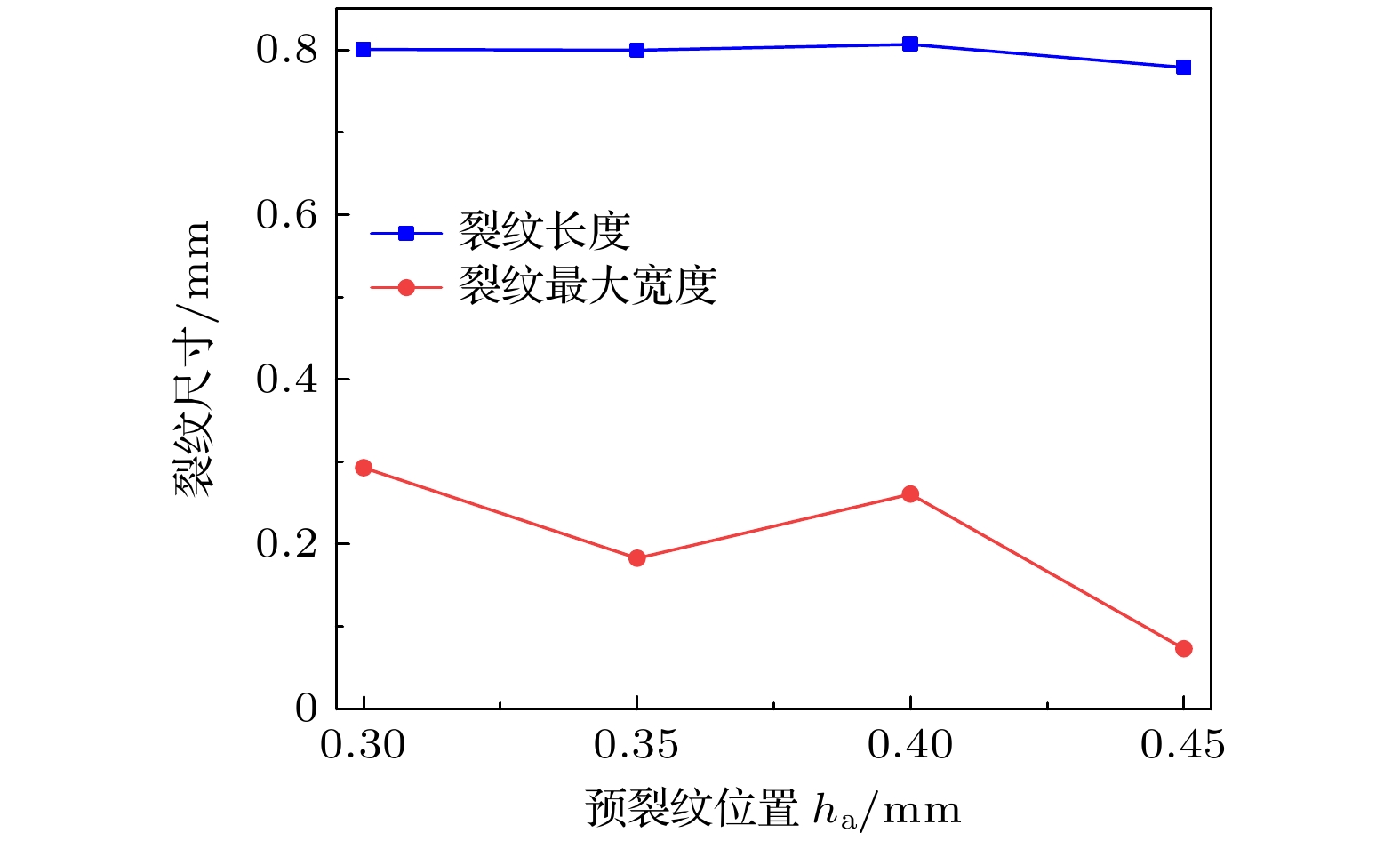

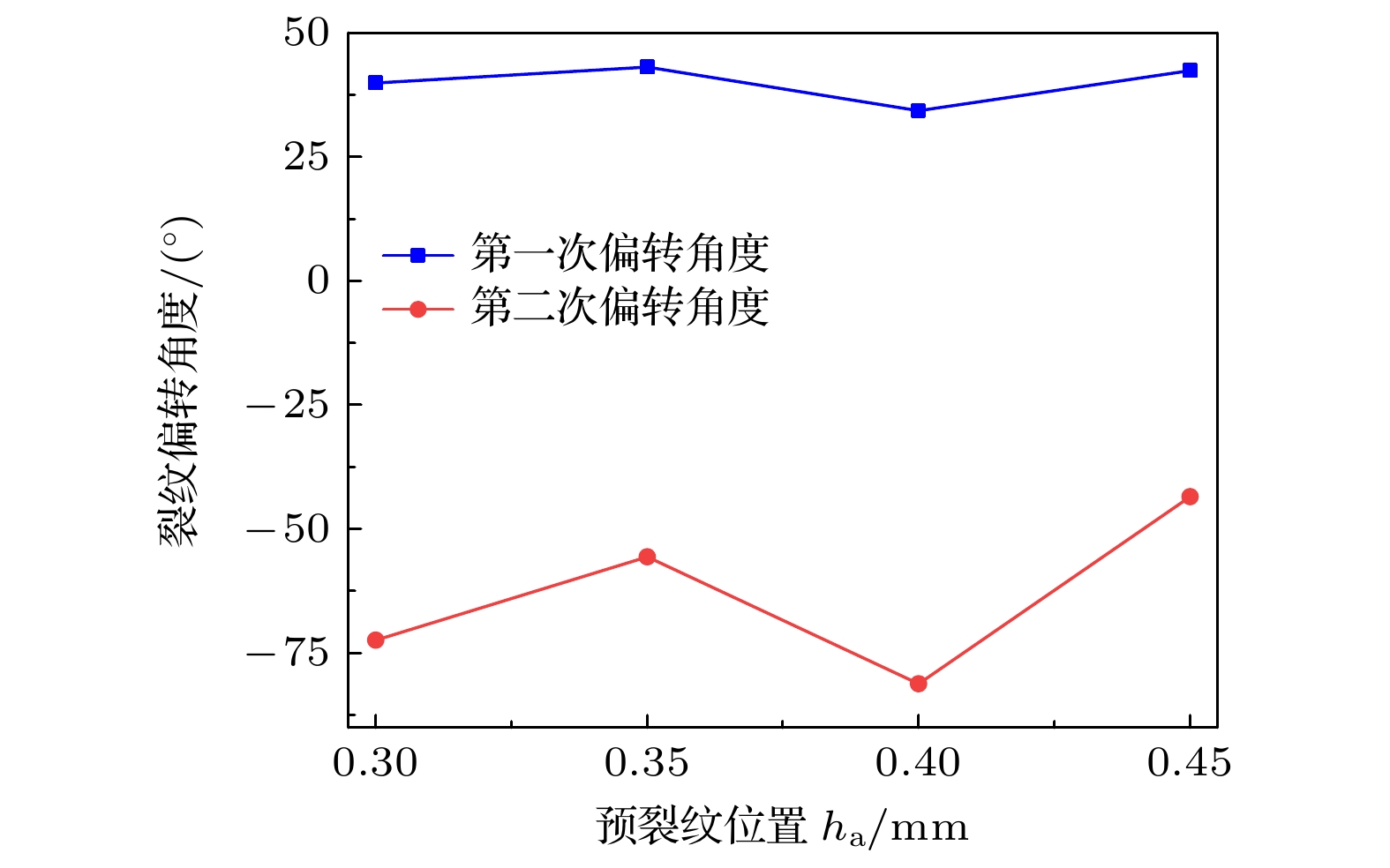

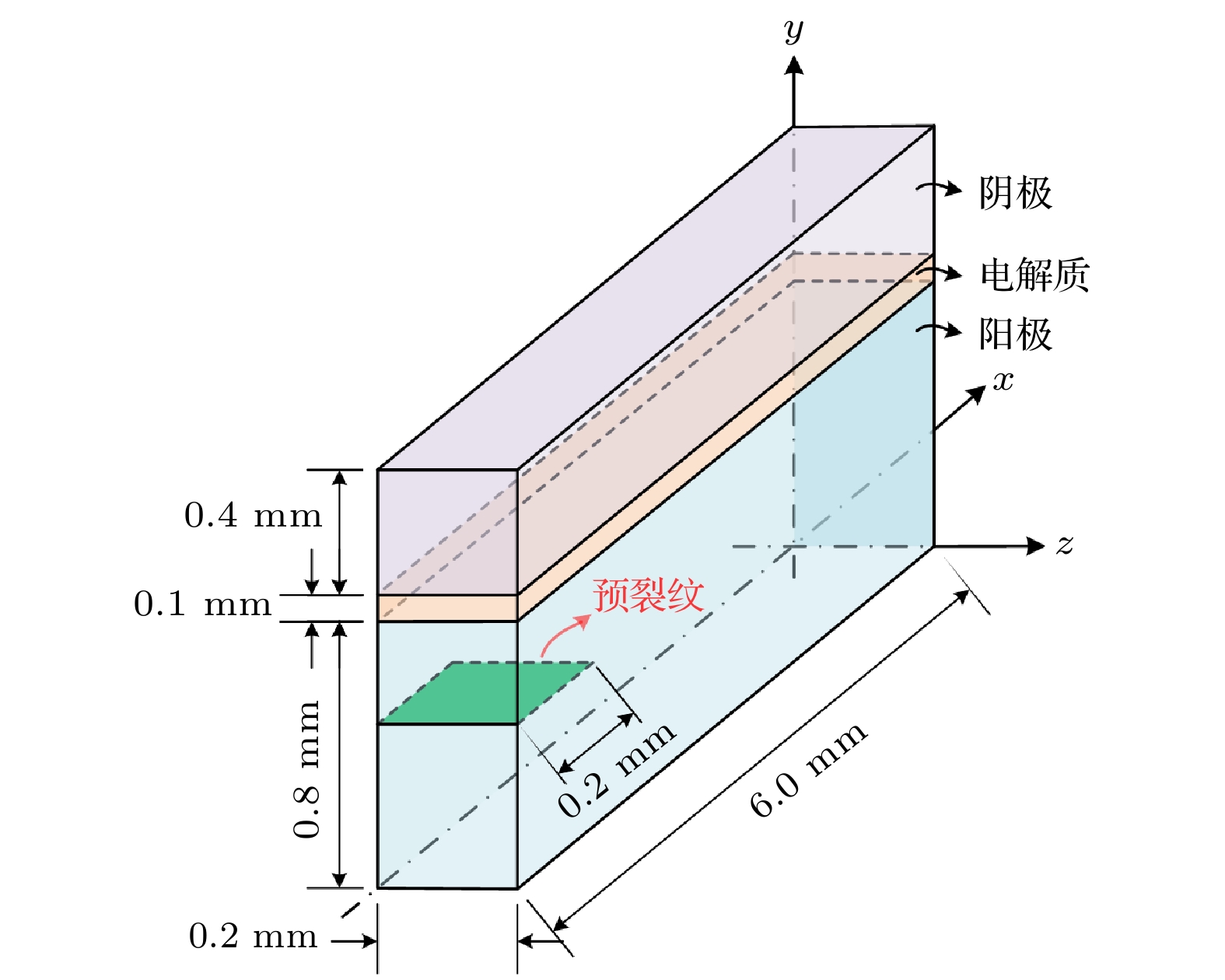

The mechanical performance of solid oxide fuel cell is one of the main factors limiting its commercialization process. In order to reduce the degree of crack propagation in the cooling process and improve the stability and durability of the cell, the finite element analysis is conducted on a three-dimensional model of solid oxide fuel cell containing pre-crack. Utilizing the extended finite element method (XFEM) and fracture theory, and considering the stress distribution, length and maximum width after crack propagation and deflection angle of crack as criteria, this paper investigates the influence of various parameters, including working temperature, material properties, pre-crack angle, and pre-crack location, on pre-crack propagation behavior and proposes a solution based on material optimization and structural optimization to improve the stability of the cell. A pre-crack is set at the left boundary of the anode to analyze the influence of different operating conditions on the propagation of anode cracks in the cell. The correctness of finite element simulation is verified by comparing the simulation results with theoretical results of crack stress intensity factors in the same model. From the comprehensive analysis of the thermal stress of the cell, the crack length and maximum width after pre-crack propagation, and the two deflection angles of crack propagation, it can be seen that within the selected parameters, in order to ensure the stability of the cell and inhibit the degree of crack propagation, the operating temperature of the cell should not be lower than 1023 K, and the thermal expansion coefficient of anode should be less than 12.50×10–6 K–1. In addition, when the pre-crack angle is 45° or 0.45 mm away from the bottom of anode, the maximum width after crack propagation is the smallest, and the propagation path is the most predictable. In this case, the cell is affected by the smallest crack range and the highest stability. This research provides a guidance for suppressing crack propagation in solid oxide fuel cell, improving the lifetime and promoting the commercialization process of fuel cell.

-

Keywords:

- solid oxide fuel cell /

- pre-crack /

- crack propagation /

- thermal stress

[1] Minh N Q, Takahashi T 1995 Science and Technology of Ceramic Fuel Cells. (Amsterdam: Elsevier Science) p147

[2] Singhal S C, Kendall K 2002 Mater. Today 5 55

Google Scholar

Google Scholar

[3] 申双林, 张小坤, 万兴文, 郑克晴, 凌意瀚, 王绍荣 2022 71 164401

Google Scholar

Google Scholar

Shen S L, Zhang X K, Wan X W, Zheng K Q, Ling Y H, Wang S R 2022 Acta Phys. Sin. 71 164401

Google Scholar

Google Scholar

[4] 徐晗, 张璐, 党政 2020 69 098801

Google Scholar

Google Scholar

Xu H, Zhang L, Dang Z 2020 Acta Phys. Sin. 69 098801

Google Scholar

Google Scholar

[5] 李凯, 李霄, 李箭, 谢佳苗 2019 无机材料学报 34 611

Google Scholar

Google Scholar

Li K, Li X, Li J, Xie J M 2019 J. Inorg. Mater. 34 611

Google Scholar

Google Scholar

[6] Su Y, Zhu D Y, Zhang T T, Zhang Y R, Han W P, Zhang J, Ramakrishna S, Long Y Z 2022 Chin. Phys. B 31 057305

Google Scholar

Google Scholar

[7] Shao Q, Fernández-González R, Ruiz-Morales J, et al. 2015 Int. J. Hydrogen Energy 40 16509

Google Scholar

Google Scholar

[8] Shao Q, Bouhala L, Fiorelli D, Fahs M, Younes A, Núñez P, Belouettar S, Makradi A 2016 Int. J. Solids Struct. 78–79 189

Google Scholar

Google Scholar

[9] Joulaee N, Makradi A, Ahzi S, Khaleel M A, Koeppel B K 2009 Int. J. Mech. Mater. Des. 5 217

Google Scholar

Google Scholar

[10] Nguyen B N, Koeppel B J, Ahzi S, Khaleel M A, Singh P 2006 J. Am. Ceram. Soc. 89 1358

Google Scholar

Google Scholar

[11] Li Q Q, Xue D X, Feng C Y, Zhang X W, Li G J 2022 J. Electrochem. Soc. 169 073507

Google Scholar

Google Scholar

[12] Bouhala L, Belouettar S, Makradi A, Rémond Y 2010 Mater. Des. 31 1033

Google Scholar

Google Scholar

[13] Pitakthapanaphong S, Busso E P 2005 Model Simul. Mater. Sci. Eng. 13 531

Google Scholar

Google Scholar

[14] Kim S J, Choi M B, Park M, Kim H, Son J W, Lee J H, Kim B K, Lee H, Kim S G, Yoon K 2017 J. Power Sources 360 284

Google Scholar

Google Scholar

[15] 李录贤, 王铁军 2005 力学进展 35 5

Google Scholar

Google Scholar

Li L X, Wang T J 2005 Adv. Mech. 35 5

Google Scholar

Google Scholar

[16] 王自强, 陈少华 2009 高等断裂力学(北京: 科学技术出版社) 第87页

Wang Z Q, Chen S H 2009 Advanced Fracture Mechanics (Beijing: Science and Technology Press) p87

[17] Ergodan F, Sih G C 1963 J. Basic Sci. Eng. 85 520

[18] Chang K J 1981 Eng. Fract. Mech. 14 107

Google Scholar

Google Scholar

[19] Hussain M A, Pu S L, Underwood J H 1974 Strain Energy Release Rate for a Crack under Combined Mode I and Mode II (West Conshohocken: ASTM International) p35

[20] Mori M, Yamamoto T, Itoh H, Inaba H, Tagawa H 1998 J. Electrochem. Soc. 145 1374

Google Scholar

Google Scholar

[21] Sameshima S, Ichikawa T, Kawaminami M, Hirata Y 1999 Mater. Chem. Phys. 61 31

Google Scholar

Google Scholar

[22] Nakajo A, Mueller F, Brouwer J, Favrat D 2012 Int. J. Hydrogen Energy 37 9249

Google Scholar

Google Scholar

[23] Nakajo A, Mueller F, Brouwer J, Favrat D 2012 Int. J. Hydrogen Energy 37 9269

Google Scholar

Google Scholar

[24] Petruzzi L, Cocchi S, Fineschi F 2003 J. Power Sources 118 96

Google Scholar

Google Scholar

[25] Nakajo A, Kuebler J, Faes A, et al. 2012 Ceram. Int. 38 3907

Google Scholar

Google Scholar

[26] Chatterjee A, Sharma G, Varshney J, Neogy S, Singh R N 2017 Mater. Sci. Eng. 684 626

Google Scholar

Google Scholar

[27] Nakajo A, Stiller C, Harkegard G, Bolland O 2006 J. Power Sources 158 287

Google Scholar

Google Scholar

[28] Tada H, Paris P C, Irwin G R 1973 The Stress Analysis of Cracks Handbook (New York: ASME Press) p30

[29] 朱传锐 2010 硕士学位论文 (郑州: 河南理工大学)

Zhu C Y 2010 M. S. Thesis (Zhengzhou: Henan Polytechnic University

[30] 陈浩 2022 博士学位论文 (兰州: 兰州大学)

Chen H 2022 Ph. D. Dissertation (Lanzhou: Lanzhou University

[31] Junya K, Hirohisa S, Katsuhiro K, Toshio N 2004 J. Alloys Compd. 365 253

Google Scholar

Google Scholar

[32] Pihlatie M, Kaiser A, Mogensen M 2009 J. Eur. Ceram. Soc. 29 1657

Google Scholar

Google Scholar

[33] Biswas S, Nithyanantham T, Saraswathi N, Bandopadhyay S 2009 J. Mater. Sci. 44 778

Google Scholar

Google Scholar

[34] Chen T, Yao C, Hu L, Huang C, Li X 2019 Thin Wall. Struct 143 143106196

[35] El-Emam M H, Salim A H, Sallam M E H 2016 J. Struct. Eng. 143 04016229

-

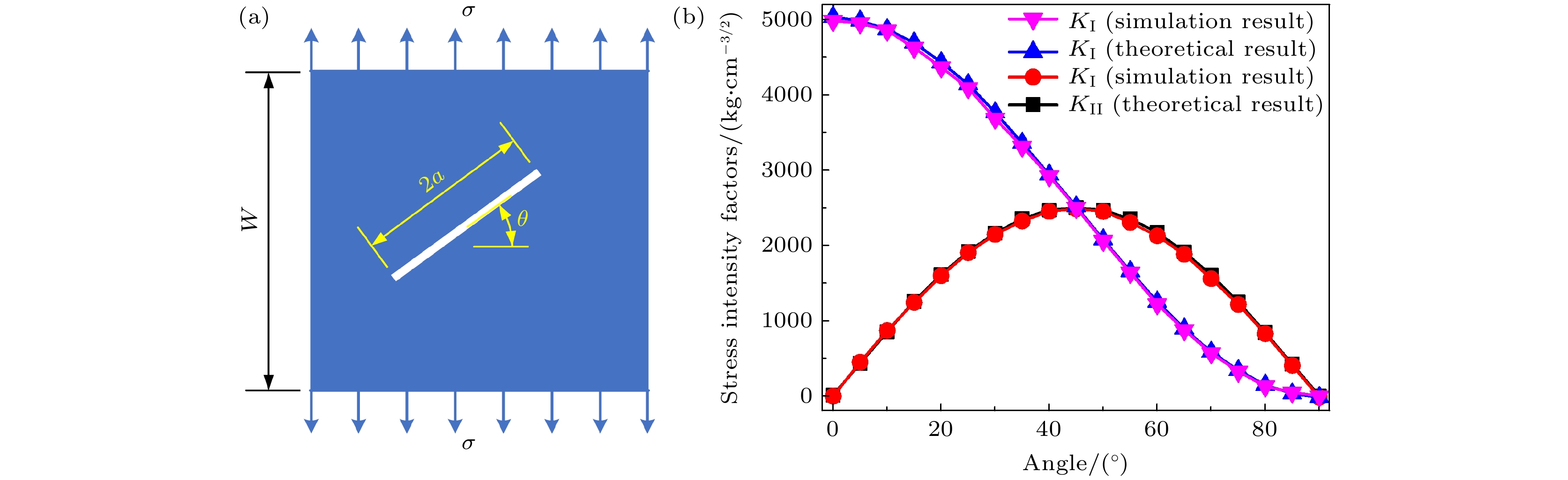

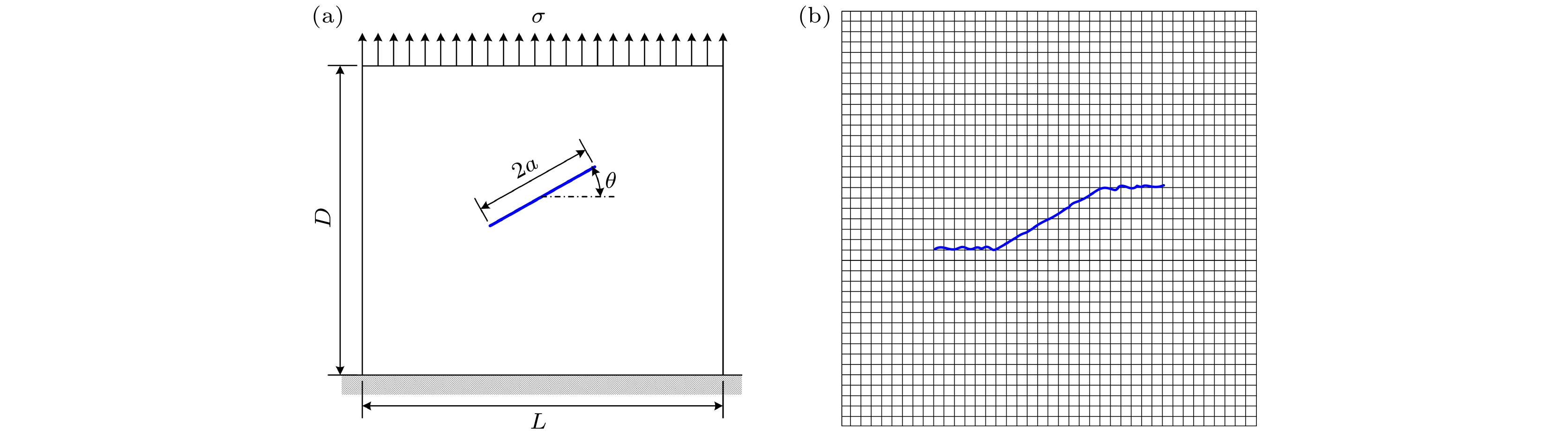

图 2 应力强度因子随倾斜角变化的数值计算结果与理论解析解的对比图 (a) 无限大平板几何模型和边界条件; (b) 应力强度因子对比曲线

Figure 2. The comparison between the numerical result and theoretical analytical solution of stress intensity factor with the inclination angle : (a) The infinite plate geometric model and boundary conditions; (b) stress-intensity factor contrast curve.

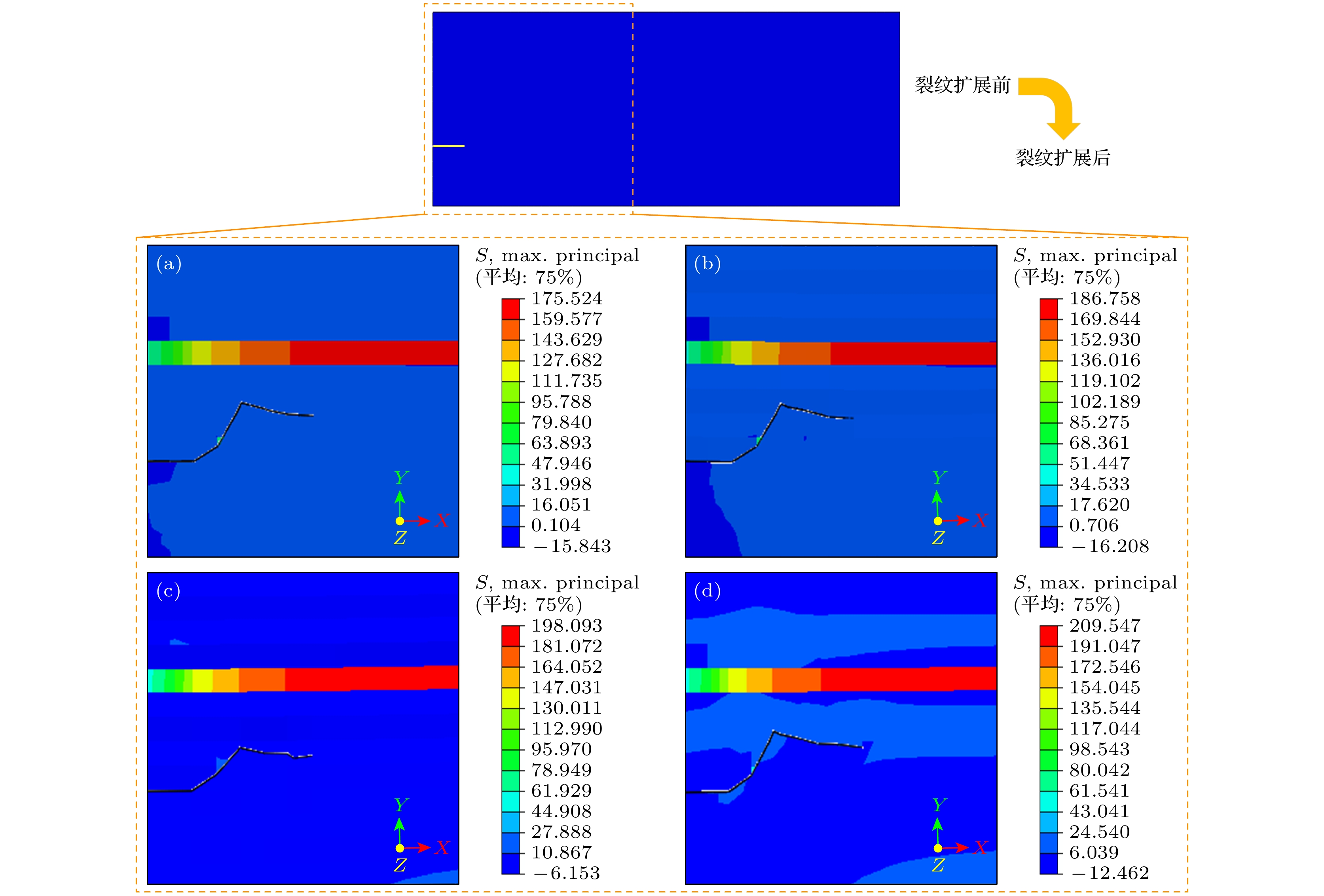

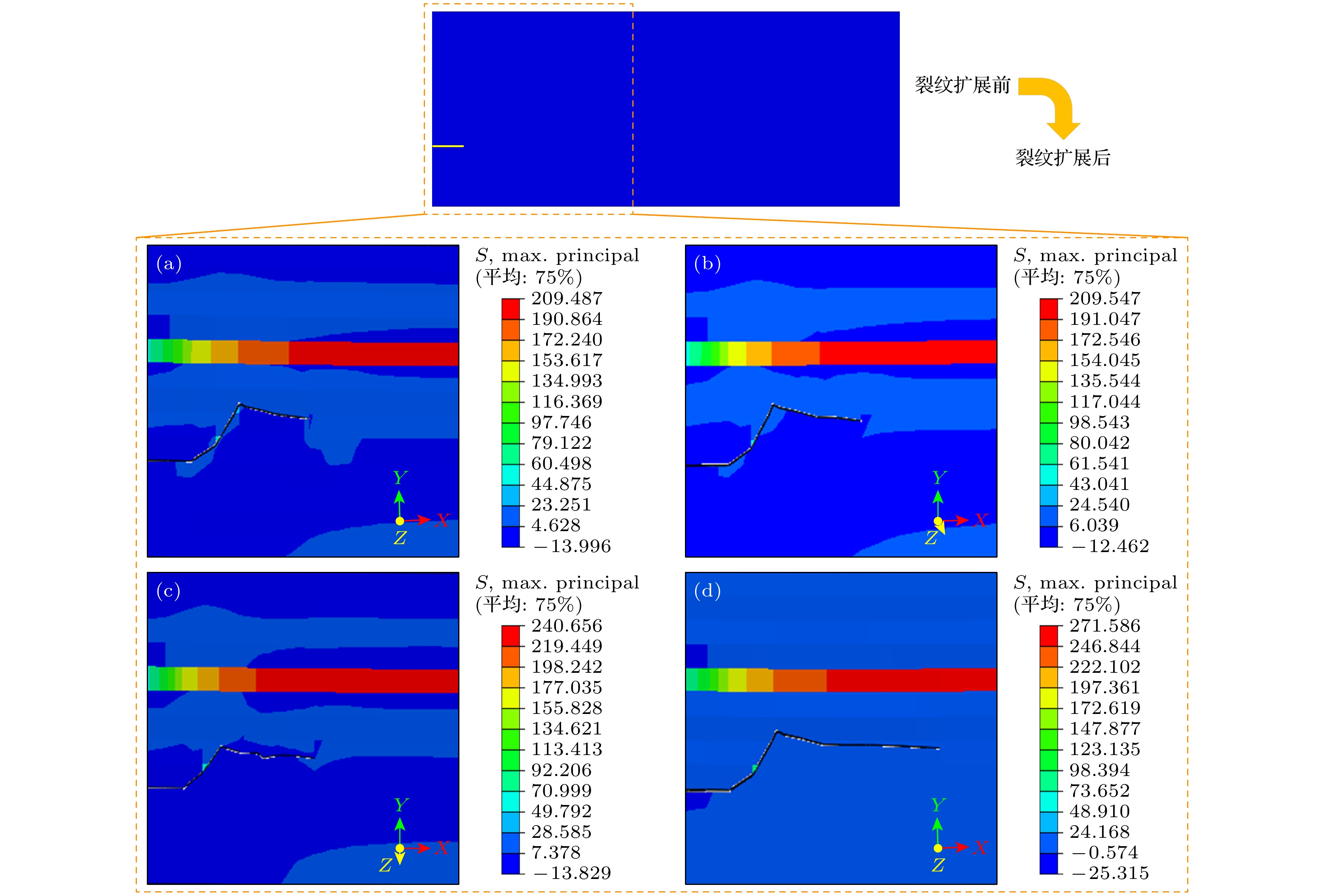

图 7 不同热膨胀系数下SOFC阳极预裂纹扩展后的应力云图(Z-方向视图) (a) 12.00×10–6 K–1; (b) 12.41×10–6 K–1; (c) 12.50×10–6 K–1; (d) 13.00×10–6 K–1

Figure 7. Stress nephogram of SOFC anode pre-crack propagation under different thermal expansion coefficients (Z-direction view): (a) 12.00×10–6 K–1; (b) 12.41×10–6 K–1; (c) 12.50×10–6 K–1; (d) 13.00×10–6 K–1

材料属性 阳极

Ni-YSZ电解质

YSZ阴极

LSM弹性模量

E/GPa298 K 72.5 196.3 41.3 1073 K 58.1 148.6 48.3 泊松比 μ 298 K 0.36 0.31 0.33 1073 K 0.36 0.31 0.33 热膨胀系数

α/(10–6 K–1)298 K 12.41 10.0 9.8 1073 K 12.60 10.5 11.8 表 2 裂纹开裂后左端裂尖的应力强度因子和开裂角

Table 2. Stress intensity factor and cracking angle at the left crack tip after crack propagation.

步数 KI/(MPa·$ \sqrt {\text{m}} $) KII/(MPa·$ \sqrt {\text{m}} $) θ/(º) 前人结果[29] 本文结果 误差/% 前人结果[29] 本文结果 误差/% 前人结果[29] 本文结果 误差/% 初始 1.7394 1.7380 0.08 1.000 1.002 0.20 –0.7528 –0.7530 0.03 1 2.1129 2.1131 0.02 –0.6982 –0.6985 0.04 0.5442 0.5445 0.05 2 4.2294 4.2294 0 0.7843 0.7845 0.03 –0.5365 –0.5365 0 3 4.2843 4.2845 0.07 –0.6983 –0.6988 0.07 0.4596 0.4601 0.10 4 4.2254 4.2254 0 0.7370 0.7374 0.05 –0.4498 –0.4498 0 5 4.2779 4.2784 0.01 –0.5585 –0.5590 0.09 0.3123 0.3123 0 6 4.2528 4.2533 0.01 0.4764 0.4768 0.08 –0.2526 –0.2527 0.04 表 3 裂纹开裂后右端裂尖的应力强度因子和开裂角

Table 3. Stress intensity factor and crack angle of right end crack tip after crack propagation.

步数 KI/(MPa·$ \sqrt {\text{m}} $) KII/(MPa·$ \sqrt {\text{m}} $) θ/(º) 前人结果[29] 本文结果 误差

/%前人结果[29] 本文结果 误差

/%前人结果[29] 本文结果 误差

/%初始 1.7803 1.7805 0.01 0.9857 0.9857 0 –0.7393 –0.7393 0 1 2.1168 2.1168 0 –0.7279 –0.7282 0.04 0.5593 0.5588 0.08 2 2.4731 2.4736 0.02 0.7963 0.7963 0 –0.5344 –0.5340 0.07 3 2.6760 2.6757 0.01 –0.8094 –0.8099 0.06 0.5110 0.5110 0 4 2.9802 2.9805 0.01 0.8856 0.8856 0 –0.5044 0.5048 0.08 5 3.3000 3.3000 0 –0.9070 0.9073 0.03 0.4759 0.4759 0 6 3.6713 3.6709 0.01 0.9229 0.9233 0.04 0.4441 0.4435 0.13 表 4 不同方案的阳极热膨胀系数

Table 4. The thermal expansion coefficient of anode in different schemes.

参 数 298 K 1073 K 阳极热膨胀系数/(10–6 K–1) 12.00 12.60 12.41 12.60 12.50 13.13 13.00 13.65 -

[1] Minh N Q, Takahashi T 1995 Science and Technology of Ceramic Fuel Cells. (Amsterdam: Elsevier Science) p147

[2] Singhal S C, Kendall K 2002 Mater. Today 5 55

Google Scholar

Google Scholar

[3] 申双林, 张小坤, 万兴文, 郑克晴, 凌意瀚, 王绍荣 2022 71 164401

Google Scholar

Google Scholar

Shen S L, Zhang X K, Wan X W, Zheng K Q, Ling Y H, Wang S R 2022 Acta Phys. Sin. 71 164401

Google Scholar

Google Scholar

[4] 徐晗, 张璐, 党政 2020 69 098801

Google Scholar

Google Scholar

Xu H, Zhang L, Dang Z 2020 Acta Phys. Sin. 69 098801

Google Scholar

Google Scholar

[5] 李凯, 李霄, 李箭, 谢佳苗 2019 无机材料学报 34 611

Google Scholar

Google Scholar

Li K, Li X, Li J, Xie J M 2019 J. Inorg. Mater. 34 611

Google Scholar

Google Scholar

[6] Su Y, Zhu D Y, Zhang T T, Zhang Y R, Han W P, Zhang J, Ramakrishna S, Long Y Z 2022 Chin. Phys. B 31 057305

Google Scholar

Google Scholar

[7] Shao Q, Fernández-González R, Ruiz-Morales J, et al. 2015 Int. J. Hydrogen Energy 40 16509

Google Scholar

Google Scholar

[8] Shao Q, Bouhala L, Fiorelli D, Fahs M, Younes A, Núñez P, Belouettar S, Makradi A 2016 Int. J. Solids Struct. 78–79 189

Google Scholar

Google Scholar

[9] Joulaee N, Makradi A, Ahzi S, Khaleel M A, Koeppel B K 2009 Int. J. Mech. Mater. Des. 5 217

Google Scholar

Google Scholar

[10] Nguyen B N, Koeppel B J, Ahzi S, Khaleel M A, Singh P 2006 J. Am. Ceram. Soc. 89 1358

Google Scholar

Google Scholar

[11] Li Q Q, Xue D X, Feng C Y, Zhang X W, Li G J 2022 J. Electrochem. Soc. 169 073507

Google Scholar

Google Scholar

[12] Bouhala L, Belouettar S, Makradi A, Rémond Y 2010 Mater. Des. 31 1033

Google Scholar

Google Scholar

[13] Pitakthapanaphong S, Busso E P 2005 Model Simul. Mater. Sci. Eng. 13 531

Google Scholar

Google Scholar

[14] Kim S J, Choi M B, Park M, Kim H, Son J W, Lee J H, Kim B K, Lee H, Kim S G, Yoon K 2017 J. Power Sources 360 284

Google Scholar

Google Scholar

[15] 李录贤, 王铁军 2005 力学进展 35 5

Google Scholar

Google Scholar

Li L X, Wang T J 2005 Adv. Mech. 35 5

Google Scholar

Google Scholar

[16] 王自强, 陈少华 2009 高等断裂力学(北京: 科学技术出版社) 第87页

Wang Z Q, Chen S H 2009 Advanced Fracture Mechanics (Beijing: Science and Technology Press) p87

[17] Ergodan F, Sih G C 1963 J. Basic Sci. Eng. 85 520

[18] Chang K J 1981 Eng. Fract. Mech. 14 107

Google Scholar

Google Scholar

[19] Hussain M A, Pu S L, Underwood J H 1974 Strain Energy Release Rate for a Crack under Combined Mode I and Mode II (West Conshohocken: ASTM International) p35

[20] Mori M, Yamamoto T, Itoh H, Inaba H, Tagawa H 1998 J. Electrochem. Soc. 145 1374

Google Scholar

Google Scholar

[21] Sameshima S, Ichikawa T, Kawaminami M, Hirata Y 1999 Mater. Chem. Phys. 61 31

Google Scholar

Google Scholar

[22] Nakajo A, Mueller F, Brouwer J, Favrat D 2012 Int. J. Hydrogen Energy 37 9249

Google Scholar

Google Scholar

[23] Nakajo A, Mueller F, Brouwer J, Favrat D 2012 Int. J. Hydrogen Energy 37 9269

Google Scholar

Google Scholar

[24] Petruzzi L, Cocchi S, Fineschi F 2003 J. Power Sources 118 96

Google Scholar

Google Scholar

[25] Nakajo A, Kuebler J, Faes A, et al. 2012 Ceram. Int. 38 3907

Google Scholar

Google Scholar

[26] Chatterjee A, Sharma G, Varshney J, Neogy S, Singh R N 2017 Mater. Sci. Eng. 684 626

Google Scholar

Google Scholar

[27] Nakajo A, Stiller C, Harkegard G, Bolland O 2006 J. Power Sources 158 287

Google Scholar

Google Scholar

[28] Tada H, Paris P C, Irwin G R 1973 The Stress Analysis of Cracks Handbook (New York: ASME Press) p30

[29] 朱传锐 2010 硕士学位论文 (郑州: 河南理工大学)

Zhu C Y 2010 M. S. Thesis (Zhengzhou: Henan Polytechnic University

[30] 陈浩 2022 博士学位论文 (兰州: 兰州大学)

Chen H 2022 Ph. D. Dissertation (Lanzhou: Lanzhou University

[31] Junya K, Hirohisa S, Katsuhiro K, Toshio N 2004 J. Alloys Compd. 365 253

Google Scholar

Google Scholar

[32] Pihlatie M, Kaiser A, Mogensen M 2009 J. Eur. Ceram. Soc. 29 1657

Google Scholar

Google Scholar

[33] Biswas S, Nithyanantham T, Saraswathi N, Bandopadhyay S 2009 J. Mater. Sci. 44 778

Google Scholar

Google Scholar

[34] Chen T, Yao C, Hu L, Huang C, Li X 2019 Thin Wall. Struct 143 143106196

[35] El-Emam M H, Salim A H, Sallam M E H 2016 J. Struct. Eng. 143 04016229

Catalog

Metrics

- Abstract views: 1652

- PDF Downloads: 60

- Cited By: 0

DownLoad:

DownLoad: