-

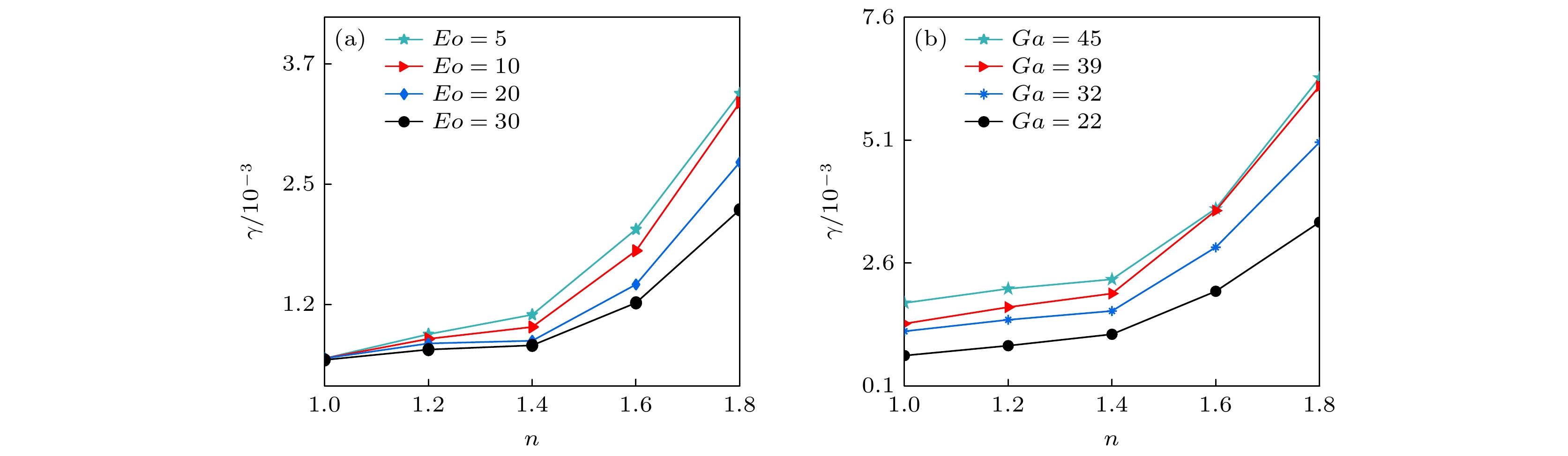

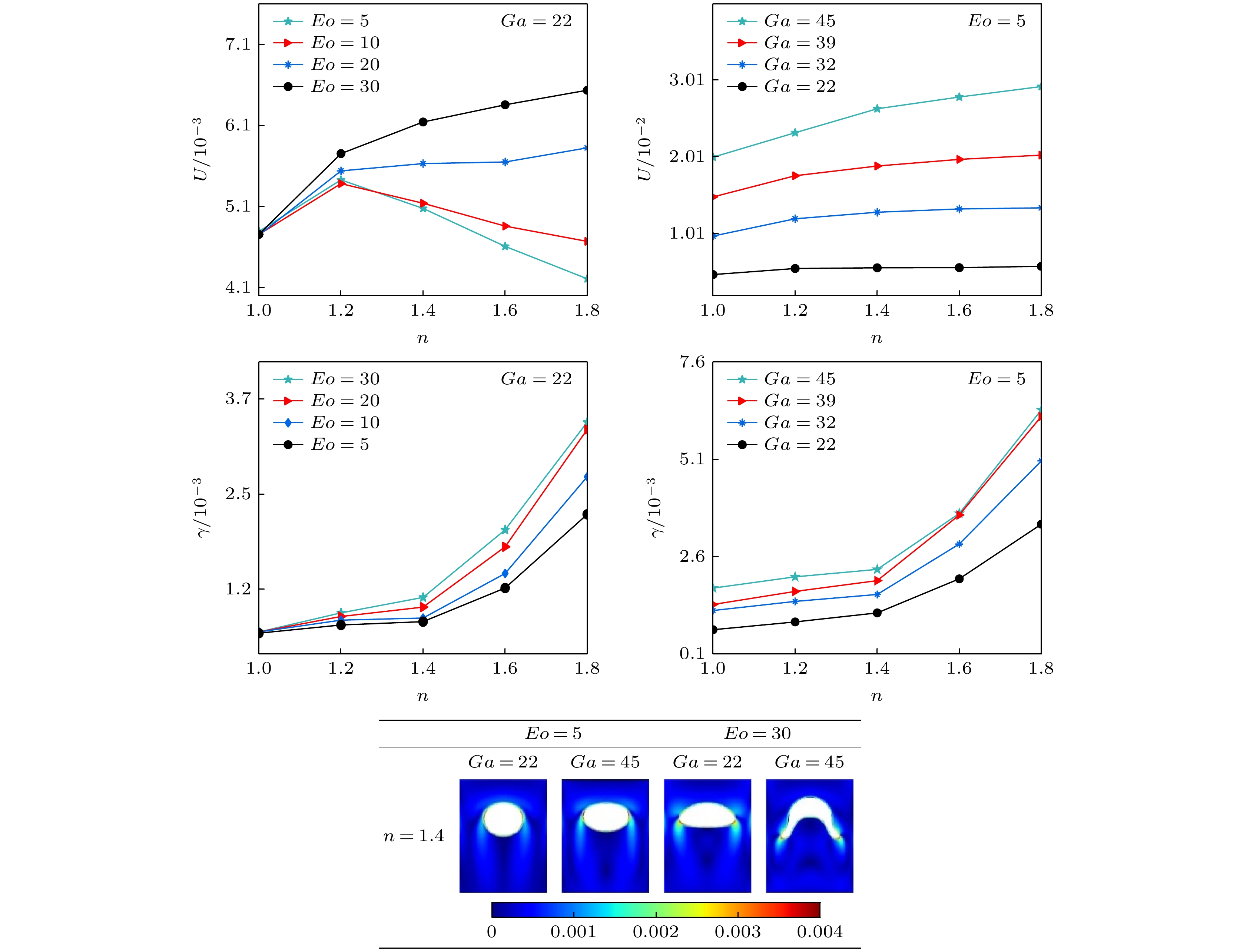

Bubble motion in non-Newtonian fluids is widely present in various industrial processes such as crude oil extraction, enhancement of boiling heat transfer, CO2 sequestration and wastewater treatment. System containing non-Newtonian liquid, as opposed to Newtonian liquid, has shear-dependent viscosity, which can change the hydrodynamic characteristics of the bubbles, such as their size, deformation, instability, terminal velocity, and shear rate, and ultimately affect the bubble rising behaviors. In this work, the dynamic behavior of bubble rising in a shear-thickened fluid is studied by using an incompressible lattice Boltzmann non-Newtonian gas-liquid two-phase flow model. The effects of the rheological exponent n, the Eötvös number (Eo), and the Galilei number (Ga) on the bubble deformation, terminal velocity, and the shear rate are investigated. The numerical results show that the degree of bubble deformation increases as Eo grows, and the effect of n on bubble deformation degree relates to Ga. On the other hand, the terminal velocity of the bubbles increases monotonically and nonlinearly with Ga for given Eo and n, and the effect of n on the terminal velocity of the bubbles turns stronger as Ga increases. When Ga is fixed and small, the terminal velocity of the bubble increases and then decreases with the increase of n at small Eo, and increases with the increase of n when Eo is large; but when Ga is fixed and large, the terminal velocity of the bubbles increases with the increase of n in a more uniform manner. In addition, regions with high shear rates can be found near the left end and right end of the bubble. The size of these regions grows with Eo and Ga, exhibiting an initial increase followed by a decrease as n increases. Finally, the orthogonal experimental method is used to obtain the influences of the aforementioned three factors on the shear rate and terminal velocity. The order of influence on shear rate is n, Ga and Eo which are arranged in descending order. For the terminal velocity, Ga has the greatest influence, followed by n, and Eo has the least influence.

-

Keywords:

- lattice Boltzmann method /

- bubble dynamics /

- shear-thickening fluid

[1] Wang C, Lu, Y L, Ye T X, Chen L, He L M 2023 Process Saf. Environ. 180 554

Google Scholar

Google Scholar

[2] Li E, Zeng X 2021 Water Sci. Technol. 84 404

Google Scholar

Google Scholar

[3] Xia Y C, Zhang R, Xing Y W, Gui X H 2019 Fuel. 235 687

Google Scholar

Google Scholar

[4] Hu X D, Wang J F, Xie J, Wang B J, Wang F 2023 Processes 11 2357

Google Scholar

Google Scholar

[5] Fei L L, Yang J P, Chen Y R, Mo H R, Luo K H 2020 Phys. Rev. Fluids 32 103312

Google Scholar

Google Scholar

[6] Gollakota A R K, Reddy M, Subramanyam M D, Kishore N 2016 Renew. Sust. Energ. Rev. 58 1543

Google Scholar

Google Scholar

[7] Chen X L, Wang M Q, Wang B, Hao H D, Shi H L, Wu Z A, Chen J X, Gai L M, Tao H C, Zhu B K, Wang B H 2023 Energies 16 1775

Google Scholar

Google Scholar

[8] Amirnia S, Debruyn J R, Bergougnou M A, Margaritis A 2013 Chem. Eng. Sci. 94 60

Google Scholar

Google Scholar

[9] Li S B, Ma Y G, Jiang S K, Fu T T, Zhu C Y, Li H Z 2012 J. Fluid. Eng. 134 084501

Google Scholar

Google Scholar

[10] Zhang L, Yang C, Mao Z S 2010 J. Non-Newtonian Fluid Mech. 165 555

Google Scholar

Google Scholar

[11] Premlata A R, Tripathi M K, Karri B, Sahu K C 2017 J. Non-Newtonian Fluid Mech. 239 53

Google Scholar

Google Scholar

[12] Pang M J, Lu M J 2018 Vacuum 153 101

Google Scholar

Google Scholar

[13] Pan K L, Chen Z J 2014 J. Comput. Appl. Math. 67 290

Google Scholar

Google Scholar

[14] Tripathi M K, Sahu K C, Karapetsas G, Matar O K 2015 J. Non-Newtonian Fluid Mech. 222 217

Google Scholar

Google Scholar

[15] Pillapakkam S B, Singh P, Blackmore D, Aubry N 2007 J. Fluid Mech. 589 215

Google Scholar

Google Scholar

[16] Xu X F, Zhang J, Liu F X, Wang X J, Wei W, Liu Z J 2017 Int. J. Multiph. Flow 95 84

Google Scholar

Google Scholar

[17] Battistella A, van Schijndel S J G, Roghair I 2020 J. Non-Newtonian Fluid Mech. 278 104249

Google Scholar

Google Scholar

[18] Morris J F 2020 Annu. Rev. Fluid Mech 52 121

Google Scholar

Google Scholar

[19] Wei M H, Lin K, Sun L 2022 Mater. Des. 216 110570

Google Scholar

Google Scholar

[20] Ohta M, Kimura S, Furukawa T, Yoshida Y, Sussman M 2012 J. Chem. Eng. Jpn. 45 713

Google Scholar

Google Scholar

[21] Ezzatneshan E, Khosroabadi A A 2022 J. Appl. Fluid Mech. 15 1771

Google Scholar

Google Scholar

[22] Zhang R Y, He X Y, Chen S Y 2000 Comput. Phys. Commun. 129 121

Google Scholar

Google Scholar

[23] He X Y, Chen S Y, Zhang R Y 1999 J. Comput. Phys. 152 642

Google Scholar

Google Scholar

[24] Du Rui, Wang Y B 2021 Appl. Math. Lett. 114 106911

Google Scholar

Google Scholar

[25] Chai Z H, Shi B C, Zhan C J 2022 Phys. Rev. E 106 055305

Google Scholar

Google Scholar

[26] Wanga L, Hea K, Wang H L 2023 Phys. Rev. E 108 055306

Google Scholar

Google Scholar

[27] Yu Y, Li Q, Qiu Y, Huang R Z 2021 Phys. Fluids 33 083306

Google Scholar

Google Scholar

[28] Liang H, Li Y, Chen J X, Xu J R 2019 Int. J. Heat Mass Tran. 130 1189

Google Scholar

Google Scholar

[29] Luo J W, Chen L, Ke H B, Zhang C D, Xia Y, Tao W Q 2023 Appl. Therm. Eng. 236 121732

Google Scholar

Google Scholar

[30] 娄钦, 黄一帆, 李凌 2019 68 214702

Google Scholar

Google Scholar

Lou Q, Huang Y F, Li L 2019 Acta Phys. Sin. 68 214702

Google Scholar

Google Scholar

[31] Peng Y, Laura S 2006 Phys. Fluids 18 042101

Google Scholar

Google Scholar

[32] Chai Z H, Zhao T S 2012 Phys. Rev. E 86 016705

Google Scholar

Google Scholar

-

表 1 不同参数下得到的气泡终端形状 (a) Eo = 200; (b) Ga = 3.0

Table 1. Bubble terminal deformation at different values of Eo and Ga: (a) Eo = 200; (b) Ga = 3.0.

表 2 气泡形状图

Table 2. Bubble shape map.

Ga = 22 Ga = 32 n = 1.0 n = 1.2 n = 1.4 n = 1.6 n = 1.8 n = 1.0 n = 1.2 n = 1.4 n = 1.6 n = 1.8 Eo = 5

Eo = 10

Eo = 20

Eo = 30

Ga = 39 Ga = 45 n = 1.0 n = 1.2 n = 1.4 n = 1.6 n = 1.8 n = 1.0 n = 1.2 n = 1.4 n = 1.6 n = 1.8 Eo = 5

Eo = 10

Eo = 20

Eo = 30

表 3 气泡周围剪切速率分布

Table 3. Shear rate distribution around the bubble.

Eo = 5 Eo = 30 Ga = 22 Ga = 45 Ga = 22 Ga = 45 n = 1

n = 1.2

n = 1.4

n = 1.6

n = 1.8

表 4 因素水平表

Table 4. Table of factor levels.

水平 因素 n Ga Eo ① 1.0 22 5 ② 1.2 32 10 ③ 1.4 39 20 ④ 1.6 45 30 ⑤ 1.8 — — 表 5 针对剪切速率的试验正交表

Table 5. Orthogonal table of tests for shear rate.

试验次数 因 素 剪切速率

(×10–6)n Ga Eo 1 1.0 22 5 718 2 1.0 32 20 1152 3 1.0 39 30 1443 4 1.0 45 10 1743 5 1.0 45 30 1673 6 1.2 22 30 798 7 1.2 32 10 1325 8 1.2 39 30 1659 9 1.2 45 5 2078 10 1.2 45 20 2035 11 1.4 22 30 837 12 1.4 32 5 1625 13 1.4 39 20 1904 14 1.4 45 30 2033 15 1.4 45 10 1872 16 1.6 22 20 1464 17 1.6 32 30 1747 18 1.6 39 10 2532 19 1.6 45 30 2732 20 1.6 45 5 3707 21 1.8 22 10 3329 22 1.8 32 30 2903 23 1.8 39 5 6200 24 1.8 45 20 4016 25 1.8 45 30 3519 表 8 针对终端速度的数据分析

Table 8. Data analysis for terminal speed.

试验均值/极差 因 素 n Ga Eo k1 1390.0 540.0 1707.0 k2 1608.8 1193.6 1623.6 k3 1783.8 1792.8 1735.2 k4 1851.4 2507.6 1737.9 k5 1907.6 — — R 517.6 1967.6 114.3 表 7 针对终端速度的试验正交表

Table 7. Orthogonal table of tests for terminal speed.

试验次数 因 素 终端速度

(×10–6)n Ga Eo 1 1.0 22 5 479 2 1.0 32 20 976 3 1.0 39 30 1487 4 1.0 45 10 2001 5 1.0 45 30 2007 6 1.2 22 30 575 7 1.2 32 10 1163 8 1.2 39 30 1734 9 1.2 45 5 2250 10 1.2 45 20 2322 11 1.4 22 30 614 12 1.4 32 5 1181 13 1.4 39 20 1889 14 1.4 45 30 2654 15 1.4 45 10 2581 16 1.6 22 20 565 17 1.6 32 30 1322 18 1.6 39 10 1906 19 1.6 45 30 2787 20 1.6 45 5 2677 21 1.8 22 10 467 22 1.8 32 30 1326 23 1.8 39 5 1948 24 1.8 45 20 2924 25 1.8 45 30 2873 表 6 针对剪切速率的数据分析

Table 6. Data analysis for shear rate.

试验均值/极差 因 素 n Ga Eo k1 1345.8 1429.2 2865.6 k2 1579.0 1750.4 2160.2 k3 1654.2 2747.6 2114.2 k4 2436.4 2540.8 1934.4 k5 3993.4 — — R 2647.6 1318.4 931.2 -

[1] Wang C, Lu, Y L, Ye T X, Chen L, He L M 2023 Process Saf. Environ. 180 554

Google Scholar

Google Scholar

[2] Li E, Zeng X 2021 Water Sci. Technol. 84 404

Google Scholar

Google Scholar

[3] Xia Y C, Zhang R, Xing Y W, Gui X H 2019 Fuel. 235 687

Google Scholar

Google Scholar

[4] Hu X D, Wang J F, Xie J, Wang B J, Wang F 2023 Processes 11 2357

Google Scholar

Google Scholar

[5] Fei L L, Yang J P, Chen Y R, Mo H R, Luo K H 2020 Phys. Rev. Fluids 32 103312

Google Scholar

Google Scholar

[6] Gollakota A R K, Reddy M, Subramanyam M D, Kishore N 2016 Renew. Sust. Energ. Rev. 58 1543

Google Scholar

Google Scholar

[7] Chen X L, Wang M Q, Wang B, Hao H D, Shi H L, Wu Z A, Chen J X, Gai L M, Tao H C, Zhu B K, Wang B H 2023 Energies 16 1775

Google Scholar

Google Scholar

[8] Amirnia S, Debruyn J R, Bergougnou M A, Margaritis A 2013 Chem. Eng. Sci. 94 60

Google Scholar

Google Scholar

[9] Li S B, Ma Y G, Jiang S K, Fu T T, Zhu C Y, Li H Z 2012 J. Fluid. Eng. 134 084501

Google Scholar

Google Scholar

[10] Zhang L, Yang C, Mao Z S 2010 J. Non-Newtonian Fluid Mech. 165 555

Google Scholar

Google Scholar

[11] Premlata A R, Tripathi M K, Karri B, Sahu K C 2017 J. Non-Newtonian Fluid Mech. 239 53

Google Scholar

Google Scholar

[12] Pang M J, Lu M J 2018 Vacuum 153 101

Google Scholar

Google Scholar

[13] Pan K L, Chen Z J 2014 J. Comput. Appl. Math. 67 290

Google Scholar

Google Scholar

[14] Tripathi M K, Sahu K C, Karapetsas G, Matar O K 2015 J. Non-Newtonian Fluid Mech. 222 217

Google Scholar

Google Scholar

[15] Pillapakkam S B, Singh P, Blackmore D, Aubry N 2007 J. Fluid Mech. 589 215

Google Scholar

Google Scholar

[16] Xu X F, Zhang J, Liu F X, Wang X J, Wei W, Liu Z J 2017 Int. J. Multiph. Flow 95 84

Google Scholar

Google Scholar

[17] Battistella A, van Schijndel S J G, Roghair I 2020 J. Non-Newtonian Fluid Mech. 278 104249

Google Scholar

Google Scholar

[18] Morris J F 2020 Annu. Rev. Fluid Mech 52 121

Google Scholar

Google Scholar

[19] Wei M H, Lin K, Sun L 2022 Mater. Des. 216 110570

Google Scholar

Google Scholar

[20] Ohta M, Kimura S, Furukawa T, Yoshida Y, Sussman M 2012 J. Chem. Eng. Jpn. 45 713

Google Scholar

Google Scholar

[21] Ezzatneshan E, Khosroabadi A A 2022 J. Appl. Fluid Mech. 15 1771

Google Scholar

Google Scholar

[22] Zhang R Y, He X Y, Chen S Y 2000 Comput. Phys. Commun. 129 121

Google Scholar

Google Scholar

[23] He X Y, Chen S Y, Zhang R Y 1999 J. Comput. Phys. 152 642

Google Scholar

Google Scholar

[24] Du Rui, Wang Y B 2021 Appl. Math. Lett. 114 106911

Google Scholar

Google Scholar

[25] Chai Z H, Shi B C, Zhan C J 2022 Phys. Rev. E 106 055305

Google Scholar

Google Scholar

[26] Wanga L, Hea K, Wang H L 2023 Phys. Rev. E 108 055306

Google Scholar

Google Scholar

[27] Yu Y, Li Q, Qiu Y, Huang R Z 2021 Phys. Fluids 33 083306

Google Scholar

Google Scholar

[28] Liang H, Li Y, Chen J X, Xu J R 2019 Int. J. Heat Mass Tran. 130 1189

Google Scholar

Google Scholar

[29] Luo J W, Chen L, Ke H B, Zhang C D, Xia Y, Tao W Q 2023 Appl. Therm. Eng. 236 121732

Google Scholar

Google Scholar

[30] 娄钦, 黄一帆, 李凌 2019 68 214702

Google Scholar

Google Scholar

Lou Q, Huang Y F, Li L 2019 Acta Phys. Sin. 68 214702

Google Scholar

Google Scholar

[31] Peng Y, Laura S 2006 Phys. Fluids 18 042101

Google Scholar

Google Scholar

[32] Chai Z H, Zhao T S 2012 Phys. Rev. E 86 016705

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4450

- PDF Downloads: 150

- Cited By: 0

DownLoad:

DownLoad: