-

Spintronic devices utilize the spin property of electrons for the storage, transmission, and processing of information, and they possess inherent advantages such as low power consumption and non-volatility, thus attracting widespread attention from both academia and industry. Spin-orbit torque (SOT) is an efficient method of manipulating magnetic moments through using electric current for writing, controlling the spin-orbit coupling (SOC) effect within materials to achieve the mutual conversion between charge current and spin current. Enhancing the efficiency of charge-spin conversion is a critical issue in the field of spintronics. Strontium ruthenate (SRO) in transition metal oxides (TMO) has attracted significant attention as a spin source material in SOT devices due to its large and tunable charge-to-spin conversion efficiency. However, current research on SOT control in SRO primarily focuses on utilizing substrate strain, with limited exploration of other control methods. Crystal orientation can produce various novel physical properties by affecting material symmetry and electronic structure, which is one of the important means to control the properties of TMO materials. Considering the close correlation between the SOT effect and electronic structure as well as surface states, crystal orientation is expected to affect SOT properties by adjusting the electronic band structure of TMO. This work investigates the effect of crystal orientation on the SOT performance of SrRuO3 film and develops a novel approach for SOT control. The (111)-oriented SRO/CoPt heterostructures and SOT devices are prepared by using pulse laser deposition, magnetron sputtering, and micro-nano processing techniques. Through harmonic Hall voltage(HHV) measurements, we find that the SOT efficiency reaches 0.39, and the spin Hall conductivity attains 2.19×105

$\hbar $ /2e Ω–1·m–1, which are 86% and 369% higher than those of the (001) orientation, respectively. Furthermore, current-driven perpendicular magnetization switching is achieved in SrRuO3(111) device at a low critical current density of 2.4×1010 A/m2, which is 37% lower than that of the (001) orientation. These results demonstrate that the crystal orientation can serve as an effective approach to significantly enhancing the comprehensive performance of SrRuO3-based SOT devices, thus providing a new idea for developing high-efficiency spintronic devices.-

Keywords:

- transition metal oxide /

- charge-spin interconversion /

- spin-orbit torque /

- crystal orientation control

[1] Sasikanth M, Dmitri E N, Ian A Y 2018 Nat. Phys. 14 338

Google Scholar

Google Scholar

[2] Dieny B, Prejbeanu I L, Garello K, Gambardella P, Freitas P, Lehndorff R, Raberg W, Ebels U, Demokritov S O, Akerman J, Deac A, Pirro P, Adelmann C, Anane A, Chumak A V, Hirohata A, Mangin S, Valenzuela S O, Cengiz Onbaşlı M, d’Aquino M, Prenat G, Finocchio G, Lopez-Diaz L, Chantrell R, Chubykalo-Fesenko O, Bortolotti P 2020 Nat. Electron. 3 446

Google Scholar

Google Scholar

[3] Manchon A, Železný J, M. Miron I, Jungwirth T, Sinova J, Thiaville A, Garello K, Gambardella P 2019 Rev. Mod. Phys. 91 035004

Google Scholar

Google Scholar

[4] Miron I M, Garello K, Gaudin G, Zermatten P-J, Costache M V, Auffret S, Bandiera S, Rodmacq B, Schuhl A, Gambardella P 2011 Nature 476 189

Google Scholar

Google Scholar

[5] Shao Q, Li P, Liu L, Yang H, Fukami S, Razavi A, Wu H, Wang K, Freimuth F, Mokrousov Y, Stiles M D, Emori S, Hoffmann A, Åkerman J, Roy K, Wang J, Yang S, Garello K, Zhang W 2021 IEEE T. Magn. 57 800439

[6] Chen H, Yi D 2021 APL Mater. 9 060908

Google Scholar

Google Scholar

[7] 劳斌, 郑轩, 李晟, 汪志明 2023 72 097702

Google Scholar

Google Scholar

Lao B, Zheng X, Li S, Wang Z M 2023 Acta Phys. Sin. 72 097702

Google Scholar

Google Scholar

[8] Nan T, Anderson T J, Gibbons J, Hwang K, Campbell N, Zhou H, Dong Y Q, Kim G Y, Shao D F, Paudel T R, Reynolds N, Wang X J, Sun N X, Tsymbal E Y, Choi S Y, Rzchowski, Kim Y B, Ralph D C, Eom C B 2018 Proc. Natl. Acad. Sci. 33 16186

[9] Everhardt A S, DC M , Huang X, Sayed S, Gosavi T A, Tang Y, Lin C, Manipatruni S, Young I A, Datta S, Wang J, and Ramesh R 2019 Phys. Rev. Mater. 3 051201

[10] Wang H L, Meng K Y, Zhang P X, Hou J T, Finley J, Han J H, Yang F Y, Liu L Q 2019 Appl. Phys. Lett. 114 232406

Google Scholar

Google Scholar

[11] Liu L, Qin Q, Lin W N, Li C J, Xie Q D, He S K, Shu X Y, Zhou C H, Lim Z, Yu J H, Lu W L, Li M S, Yan X B, Pennycook S J, Chen J S 2019 Nat. Nanotechnol. 14 939

Google Scholar

Google Scholar

[12] Wahler M, Homonnay N, Richter T, Müller A, Eisenschmidt C, Fuhrmann B, Schmidt G 2016 Sci. Rep. 6 28727

Google Scholar

Google Scholar

[13] Ou Y X, Wang Z, Chang C S, Nair H P, Paik H J, Reynolds N, Ralph D C, Muller D A, Schlom D G, Buhrman R A 2019 Nano Lett. 19 3663

Google Scholar

Google Scholar

[14] Emori S, Alaan U S, Gray M T, Sluka V, Chen Y, Kent A, Suzuki Y 2016 Phys. Rev. B 94 224423

Google Scholar

Google Scholar

[15] Eom C B, Cava R J, Fleming R M, Phillips J M, Vandover R B, Marshall J H, Hsu J W P, Krajewski J J, Peck W F 1992 Science 258 1766

Google Scholar

Google Scholar

[16] Koster G, Klein L, Siemons W, Rijnders G, Dodge J S, Eom C-B, Blank D H A, Beasley M R, 2012 Rev. Mod. Phys. 84 253

Google Scholar

Google Scholar

[17] Wei J W, Zhong H, Liu J Z, Wang X, Meng F Q, Xu H J, Liu Y Z, Luo X, Zhang Q H, Guang Y, Feng J F, Zhang J, Yang L H, Ge C, Gu L, Jin K J, Yu G Q, Han X F 2021 Adv. Funct. Mater. 31 2100380

Google Scholar

Google Scholar

[18] Zhou J, Shu X Y, Lin W N, Shao D F, Chen S H, Liu L, Yang P, Tsymbal E Y, Chen J S 2021 Adv. Mater. 33 2007114

Google Scholar

Google Scholar

[19] Li S, Lao B, Lu Z X, Zheng X, Zhao K N, Gong L G, Tang T, Wu K Y, Li R W, Wang Z M 2023 Phys. Rev. Mater. 7 024418

Google Scholar

Google Scholar

[20] Dagotto E 2005 Science 309 257

Google Scholar

Google Scholar

[21] Ahn C, Cavalleri A, Georges A, Ismail-Beigi S, Millis A J, Triscone J-M 2021 Nat. Mater. 20 1462

Google Scholar

Google Scholar

[22] Lu Z X, Yang Y J, Wen L J, Feng J T, Lao B, Zheng X, Li S, Zhao K N, Cao B S, Ren Z L, Song D S, Du H F, Guo Y Y, Zhong Z C, Hao X F, Wang Z M, Li R W 2022 NPJ Flex. Electron. 6 9

Google Scholar

Google Scholar

[23] Wang Z M, Zhong Z C, MckeownWalker S, Ristic Z, Ma J Z, Bruno F Y, Ricco S, Sangiovanni G, Eres G, Plumb N C, Patthey L, Shi M, Mesot J, Baumberger F, Radovic M 2017 Nano Lett. 17 2561

Google Scholar

Google Scholar

[24] Peng W, Park S Y, Roh C J, Mun J, Ju H, Kim J, Ko E K, Liang Z G, Hahn S, Zhang J F, Sanchez A M, Walker D, Hindmarsh S, Si L, Jo Y J, Jo Y, Kim T H, Kim C, Wang L F, Kim M Y, Lee J S, Noh T W, Lee D 2024 Nat. Phys. 20 450

Google Scholar

Google Scholar

[25] Hayashi M, Kim J, Yamanouchi M, Ohno H 2014 Phys. Rev. B 89 144425

Google Scholar

Google Scholar

[26] Kim J, Sinha J, Hayashi M, Yamanouchi M, Fukami S, Suzuki T, Mitani S, Ohno H 2013 Nat. Mater. 12 240

Google Scholar

Google Scholar

[27] Yang M Y, Cai K M, Ju H L, Edmonds K W, Yang G, Liu S, Li B H, Zhang B, Sheng Y, Wang S G, Ji Y, Wang K Y 2016 Sci. Rep. 6 20778

Google Scholar

Google Scholar

[28] Liu L, Pai C F, Li Y, Tseng H W, Ralph D C, Buhrman R A 2012 Science 336 555

Google Scholar

Google Scholar

[29] Zhu L, Ralph D C, Buhrman R A 2021 Appl. Phys. Rev. 8 031308

Google Scholar

Google Scholar

[30] Garello K, Miron I M, Avci C O, Freimuth F, Mokrousov Y, Blugel S, Auffret S, Boulle O, Gaudin G, Gambardella P 2013 Nat. Nanotechnol. 8 587

Google Scholar

Google Scholar

[31] Jin F, Gu M Q, Ma C, Guo E J, Zhu J, Qu L L, Zhang Z X, Zhang K X, Xu L Q, Chen B B, Chen F, Gao G Y, Rondinelli J M, Wu W B 2020 Nano Lett. 20 1131

Google Scholar

Google Scholar

[32] Wang Z Z, Qi W H, Bi J C, Li X Y, Chen Y, Yang F, Cao Y W, Gu L, Zhang Q H, Wang H H, Zhang J D, Guo J D, Liu X R 2022 Chin. Phys. B 31 126801

Google Scholar

Google Scholar

-

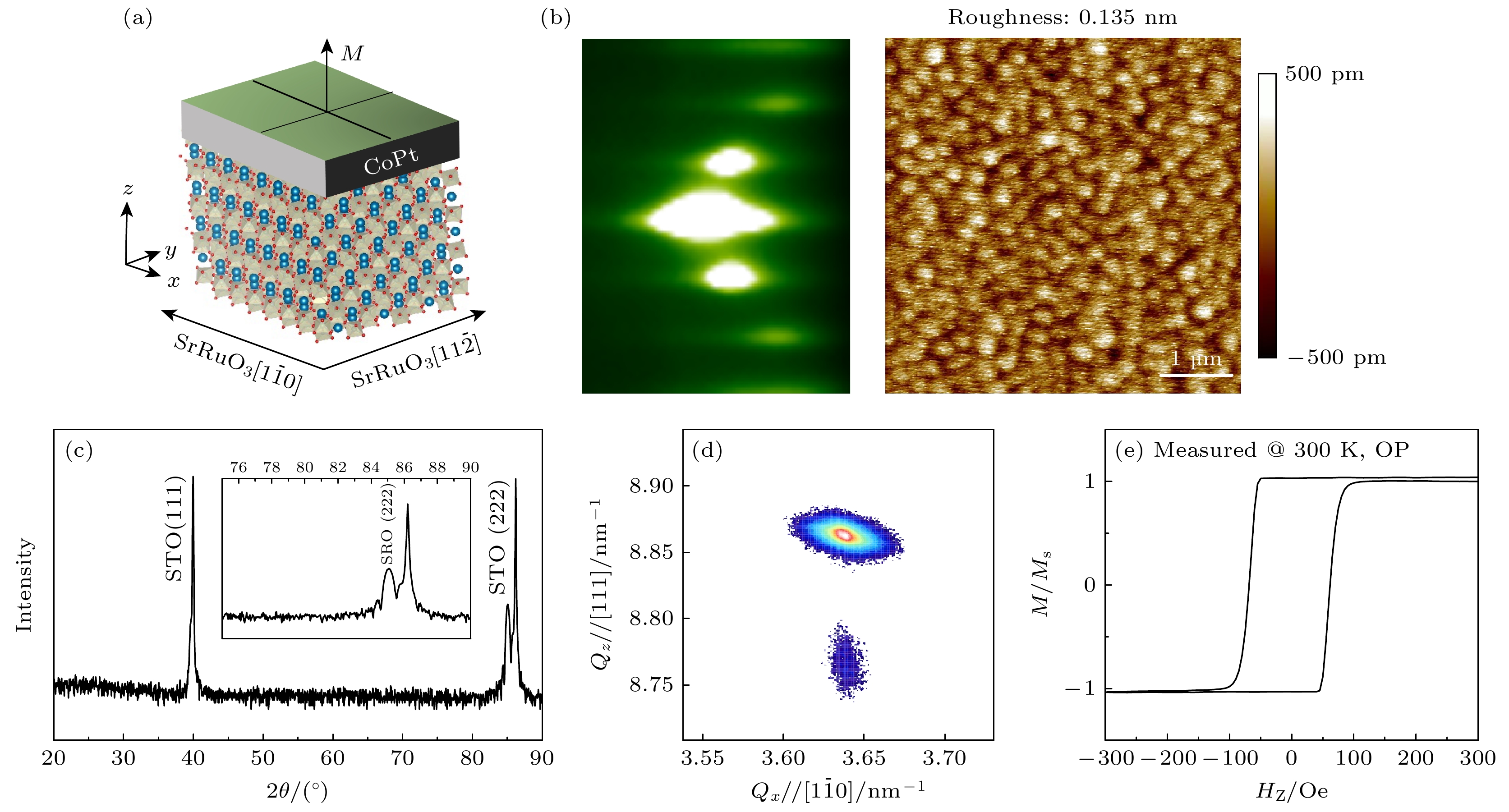

图 1 (111)-SRO/CoPt异质结构的表征结果 (a) SRO/CoPt薄膜异质结构示意图; (b) SRO薄膜表面的原位反射高能电子衍射(RHEED)图像及原子力显微镜(AFM)图像, 均方根粗糙度约为0.135 nm; (c) 在STO (111)衬底上生长的SRO薄膜的XRD $ \theta $-2$ \theta $ 扫描结果, 插图为SRO和STO的(222)峰附近范围的放大图; (d) SRO薄膜(132)峰附近的倒易空间映射结果; (e) CoPt的面外MOKE表征

Figure 1. SRO/CoPt heterostructure: (a) Schematic diagram of the SRO/CoPt thin film heterostructure; (b) in-situ reflection high-energy electron diffraction (RHEED) image and atomic force microscopy (AFM) image of the SRO surface, the root-mean-square roughness is about 0.135 nm; (c) XRD $ \theta $-2$ \theta $ scan results of the SRO film grown on the STO (111) substrate, the inset is an enlarged view of the region near the (222) peaks of SRO and STO; (d) X-ray reciprocal space mapping (RSM) results of the SRO film; (e) out-of-plane MOKE characterization of CoPt.

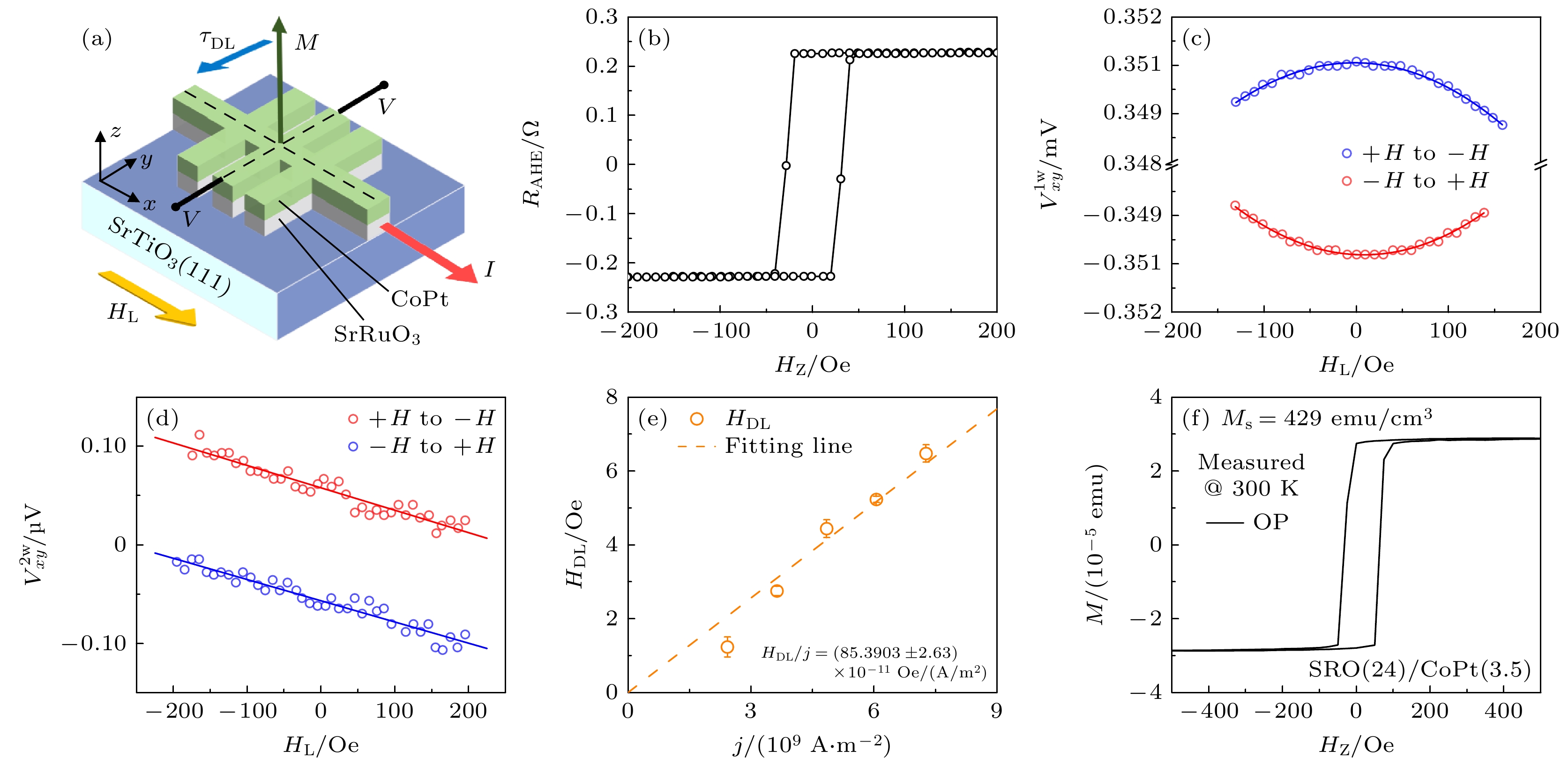

图 2 SRO/CoPt样品在纵向场HL下的谐波霍尔电压测量 (a) 样品测量的示意图, 交流电流I沿x方向施加, 外加磁场HL沿x (纵向)方向施加; (b) 施加垂直于平面的变化磁场HZ测得的反常霍尔电阻RAHE; (c) I = 1.5 mA下, 一次和(d)二次谐波霍尔电压信号随纵向场HL变化的情况; (e) SOT有效场HDL随电流密度JSRO (分流至SRO的电流密度)的变化; (f) 室温下SRO/CoPt的面外SQUID测量, 由此得出饱和磁化强度Ms

Figure 2. Harmonic Hall voltage measurements of the SRO/CoPt sample under a longitudinal field HL. (a) Schematic diagram of the sample measurement. The AC current I is applied along the x-direction. The external magnetic field HL is applied along the x (longitudinal) direction. (b) Anomalous Hall resistance RAHE measured by applying a magnetic field HZ perpendicular to the plane. (c) First and (d) second harmonic Hall voltage signals as a function of the longitudinal field HL at I = 1.5 mA. (e) Variation of the SOT effective field HDL with the current density JSRO (current density shunted to SRO). (f) Out-of-plane SQUID measurement of SRO/CoPt at room temperature, from which the saturation magnetization Ms is obtained.

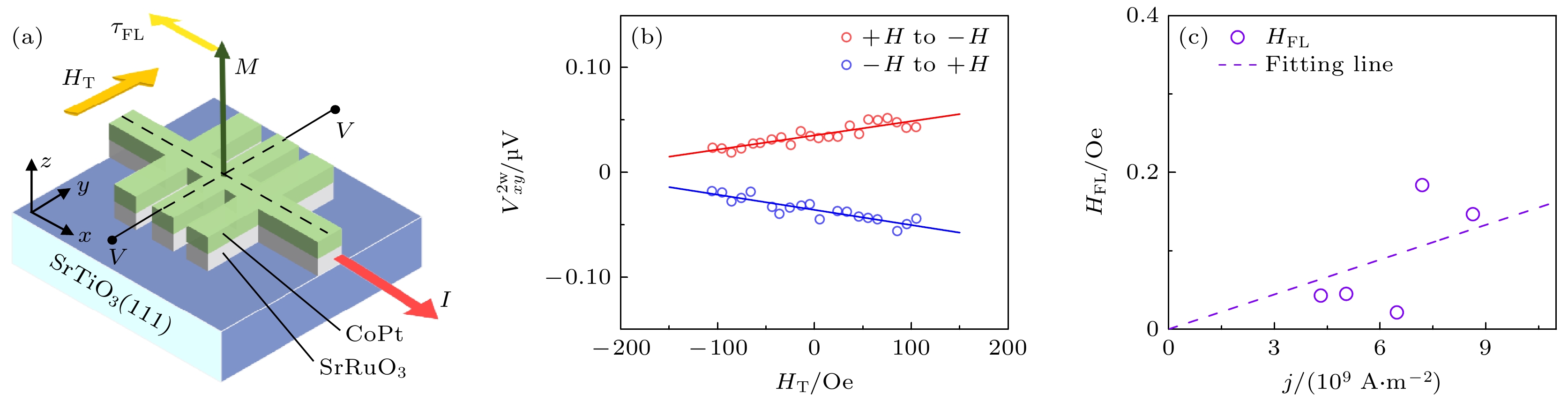

图 3 SRO/CoPt样品在横向场HT下的谐波霍尔电压测量 (a) 样品测量的示意图, 交流电流I沿x方向施加, 外加磁场H沿y (横向)方向施加; (b) I = 2.5 mA下, 在横向磁场HT下测得的二次谐波霍尔电压信号; (c) SOT有效场HFL随电流密度JSRO (分流至SRO的电流密度)的变化

Figure 3. Harmonic Hall voltage measurements of the SRO/CoPt sample under a transverse field HT: (a) Schematic diagram of the sample measurement, the AC current I is applied along the x-direction, the external magnetic field H is applied along the y (transverse) direction; (b) second harmonic Hall voltage signal measured under the transverse magnetic field HT at I = 2.5 mA; (c) variation of the SOT effective field HFL with the current density JSRO (current density shunted to SRO).

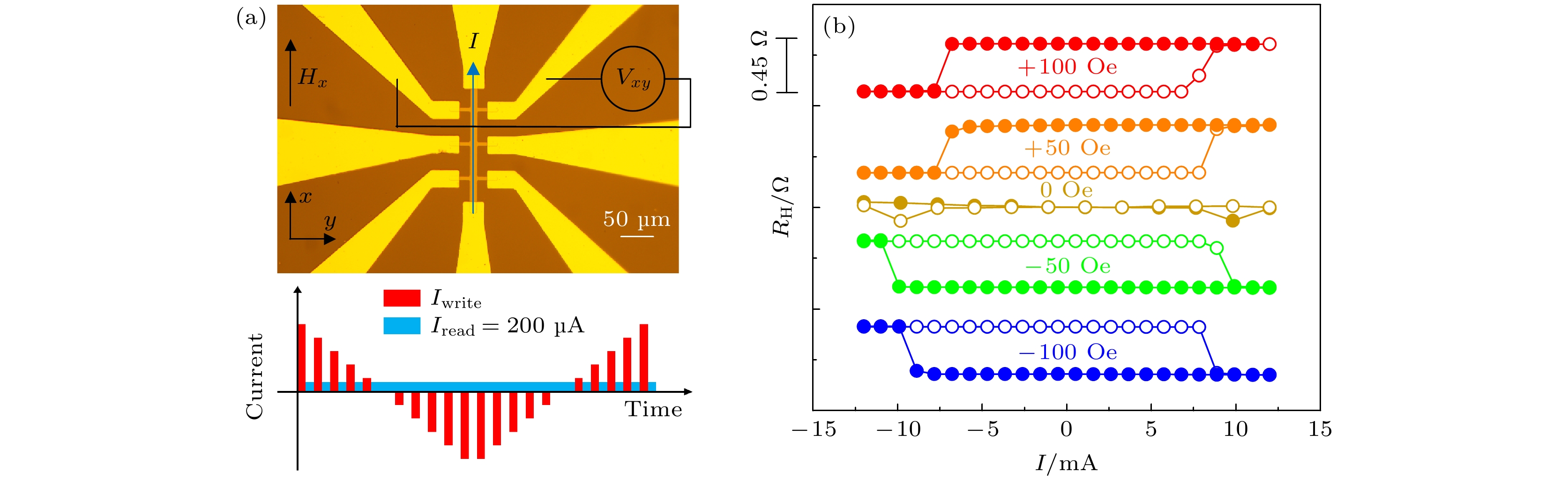

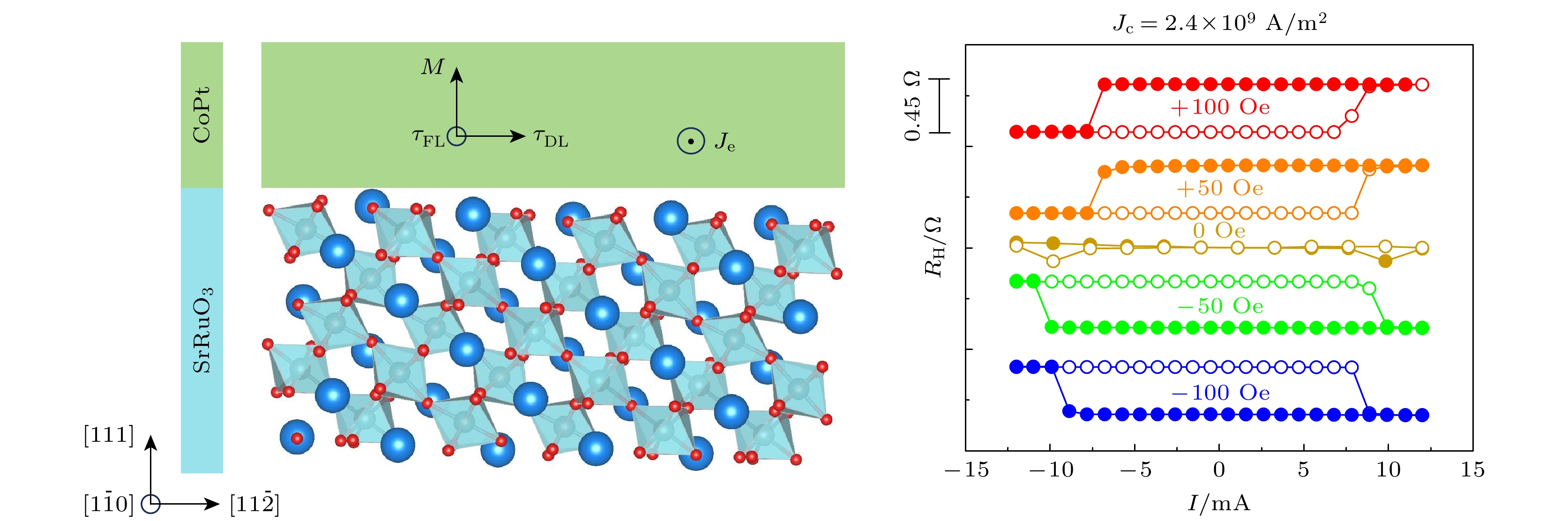

图 4 (111)-SRO/CoPt异质结构由自旋轨道力矩(SOT)驱动的垂直磁化翻转 (a)生长了电极的Hall bar的显微镜图像及磁矩翻转测量的几何图示, 脉冲电流Iwrite用于翻转磁化状态, 而直流恒定电流IDC用于读取(上图), Iwrite(±12 mA)和 Iread(200 μA)的序列图(下); (b) 样品在不同外加磁场Hx下, Iwrite驱动的磁化翻转, RH表示霍尔电阻的变化

Figure 4. Perpendicular magnetization switching driven by spin-orbit torque (SOT) in the [111]-SRO/CoPt sample: (a) Microscope image of the Hall bar with electrodes and a schematic diagram of the magnetization switching measurement geometry. Pulsed current Iwrite is used to switch the magnetization state, while DC constant current IDC is used to read (Top), sequence diagram of Iwrite (±12 mA) and Iread (200 μA) (Below); (b) the magnetization of the sample driven by Iwrite switching under different applied magnetic fields Hx, RH indicates the change in Hall resistance.

-

[1] Sasikanth M, Dmitri E N, Ian A Y 2018 Nat. Phys. 14 338

Google Scholar

Google Scholar

[2] Dieny B, Prejbeanu I L, Garello K, Gambardella P, Freitas P, Lehndorff R, Raberg W, Ebels U, Demokritov S O, Akerman J, Deac A, Pirro P, Adelmann C, Anane A, Chumak A V, Hirohata A, Mangin S, Valenzuela S O, Cengiz Onbaşlı M, d’Aquino M, Prenat G, Finocchio G, Lopez-Diaz L, Chantrell R, Chubykalo-Fesenko O, Bortolotti P 2020 Nat. Electron. 3 446

Google Scholar

Google Scholar

[3] Manchon A, Železný J, M. Miron I, Jungwirth T, Sinova J, Thiaville A, Garello K, Gambardella P 2019 Rev. Mod. Phys. 91 035004

Google Scholar

Google Scholar

[4] Miron I M, Garello K, Gaudin G, Zermatten P-J, Costache M V, Auffret S, Bandiera S, Rodmacq B, Schuhl A, Gambardella P 2011 Nature 476 189

Google Scholar

Google Scholar

[5] Shao Q, Li P, Liu L, Yang H, Fukami S, Razavi A, Wu H, Wang K, Freimuth F, Mokrousov Y, Stiles M D, Emori S, Hoffmann A, Åkerman J, Roy K, Wang J, Yang S, Garello K, Zhang W 2021 IEEE T. Magn. 57 800439

[6] Chen H, Yi D 2021 APL Mater. 9 060908

Google Scholar

Google Scholar

[7] 劳斌, 郑轩, 李晟, 汪志明 2023 72 097702

Google Scholar

Google Scholar

Lao B, Zheng X, Li S, Wang Z M 2023 Acta Phys. Sin. 72 097702

Google Scholar

Google Scholar

[8] Nan T, Anderson T J, Gibbons J, Hwang K, Campbell N, Zhou H, Dong Y Q, Kim G Y, Shao D F, Paudel T R, Reynolds N, Wang X J, Sun N X, Tsymbal E Y, Choi S Y, Rzchowski, Kim Y B, Ralph D C, Eom C B 2018 Proc. Natl. Acad. Sci. 33 16186

[9] Everhardt A S, DC M , Huang X, Sayed S, Gosavi T A, Tang Y, Lin C, Manipatruni S, Young I A, Datta S, Wang J, and Ramesh R 2019 Phys. Rev. Mater. 3 051201

[10] Wang H L, Meng K Y, Zhang P X, Hou J T, Finley J, Han J H, Yang F Y, Liu L Q 2019 Appl. Phys. Lett. 114 232406

Google Scholar

Google Scholar

[11] Liu L, Qin Q, Lin W N, Li C J, Xie Q D, He S K, Shu X Y, Zhou C H, Lim Z, Yu J H, Lu W L, Li M S, Yan X B, Pennycook S J, Chen J S 2019 Nat. Nanotechnol. 14 939

Google Scholar

Google Scholar

[12] Wahler M, Homonnay N, Richter T, Müller A, Eisenschmidt C, Fuhrmann B, Schmidt G 2016 Sci. Rep. 6 28727

Google Scholar

Google Scholar

[13] Ou Y X, Wang Z, Chang C S, Nair H P, Paik H J, Reynolds N, Ralph D C, Muller D A, Schlom D G, Buhrman R A 2019 Nano Lett. 19 3663

Google Scholar

Google Scholar

[14] Emori S, Alaan U S, Gray M T, Sluka V, Chen Y, Kent A, Suzuki Y 2016 Phys. Rev. B 94 224423

Google Scholar

Google Scholar

[15] Eom C B, Cava R J, Fleming R M, Phillips J M, Vandover R B, Marshall J H, Hsu J W P, Krajewski J J, Peck W F 1992 Science 258 1766

Google Scholar

Google Scholar

[16] Koster G, Klein L, Siemons W, Rijnders G, Dodge J S, Eom C-B, Blank D H A, Beasley M R, 2012 Rev. Mod. Phys. 84 253

Google Scholar

Google Scholar

[17] Wei J W, Zhong H, Liu J Z, Wang X, Meng F Q, Xu H J, Liu Y Z, Luo X, Zhang Q H, Guang Y, Feng J F, Zhang J, Yang L H, Ge C, Gu L, Jin K J, Yu G Q, Han X F 2021 Adv. Funct. Mater. 31 2100380

Google Scholar

Google Scholar

[18] Zhou J, Shu X Y, Lin W N, Shao D F, Chen S H, Liu L, Yang P, Tsymbal E Y, Chen J S 2021 Adv. Mater. 33 2007114

Google Scholar

Google Scholar

[19] Li S, Lao B, Lu Z X, Zheng X, Zhao K N, Gong L G, Tang T, Wu K Y, Li R W, Wang Z M 2023 Phys. Rev. Mater. 7 024418

Google Scholar

Google Scholar

[20] Dagotto E 2005 Science 309 257

Google Scholar

Google Scholar

[21] Ahn C, Cavalleri A, Georges A, Ismail-Beigi S, Millis A J, Triscone J-M 2021 Nat. Mater. 20 1462

Google Scholar

Google Scholar

[22] Lu Z X, Yang Y J, Wen L J, Feng J T, Lao B, Zheng X, Li S, Zhao K N, Cao B S, Ren Z L, Song D S, Du H F, Guo Y Y, Zhong Z C, Hao X F, Wang Z M, Li R W 2022 NPJ Flex. Electron. 6 9

Google Scholar

Google Scholar

[23] Wang Z M, Zhong Z C, MckeownWalker S, Ristic Z, Ma J Z, Bruno F Y, Ricco S, Sangiovanni G, Eres G, Plumb N C, Patthey L, Shi M, Mesot J, Baumberger F, Radovic M 2017 Nano Lett. 17 2561

Google Scholar

Google Scholar

[24] Peng W, Park S Y, Roh C J, Mun J, Ju H, Kim J, Ko E K, Liang Z G, Hahn S, Zhang J F, Sanchez A M, Walker D, Hindmarsh S, Si L, Jo Y J, Jo Y, Kim T H, Kim C, Wang L F, Kim M Y, Lee J S, Noh T W, Lee D 2024 Nat. Phys. 20 450

Google Scholar

Google Scholar

[25] Hayashi M, Kim J, Yamanouchi M, Ohno H 2014 Phys. Rev. B 89 144425

Google Scholar

Google Scholar

[26] Kim J, Sinha J, Hayashi M, Yamanouchi M, Fukami S, Suzuki T, Mitani S, Ohno H 2013 Nat. Mater. 12 240

Google Scholar

Google Scholar

[27] Yang M Y, Cai K M, Ju H L, Edmonds K W, Yang G, Liu S, Li B H, Zhang B, Sheng Y, Wang S G, Ji Y, Wang K Y 2016 Sci. Rep. 6 20778

Google Scholar

Google Scholar

[28] Liu L, Pai C F, Li Y, Tseng H W, Ralph D C, Buhrman R A 2012 Science 336 555

Google Scholar

Google Scholar

[29] Zhu L, Ralph D C, Buhrman R A 2021 Appl. Phys. Rev. 8 031308

Google Scholar

Google Scholar

[30] Garello K, Miron I M, Avci C O, Freimuth F, Mokrousov Y, Blugel S, Auffret S, Boulle O, Gaudin G, Gambardella P 2013 Nat. Nanotechnol. 8 587

Google Scholar

Google Scholar

[31] Jin F, Gu M Q, Ma C, Guo E J, Zhu J, Qu L L, Zhang Z X, Zhang K X, Xu L Q, Chen B B, Chen F, Gao G Y, Rondinelli J M, Wu W B 2020 Nano Lett. 20 1131

Google Scholar

Google Scholar

[32] Wang Z Z, Qi W H, Bi J C, Li X Y, Chen Y, Yang F, Cao Y W, Gu L, Zhang Q H, Wang H H, Zhang J D, Guo J D, Liu X R 2022 Chin. Phys. B 31 126801

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5354

- PDF Downloads: 229

- Cited By: 0

DownLoad:

DownLoad: