-

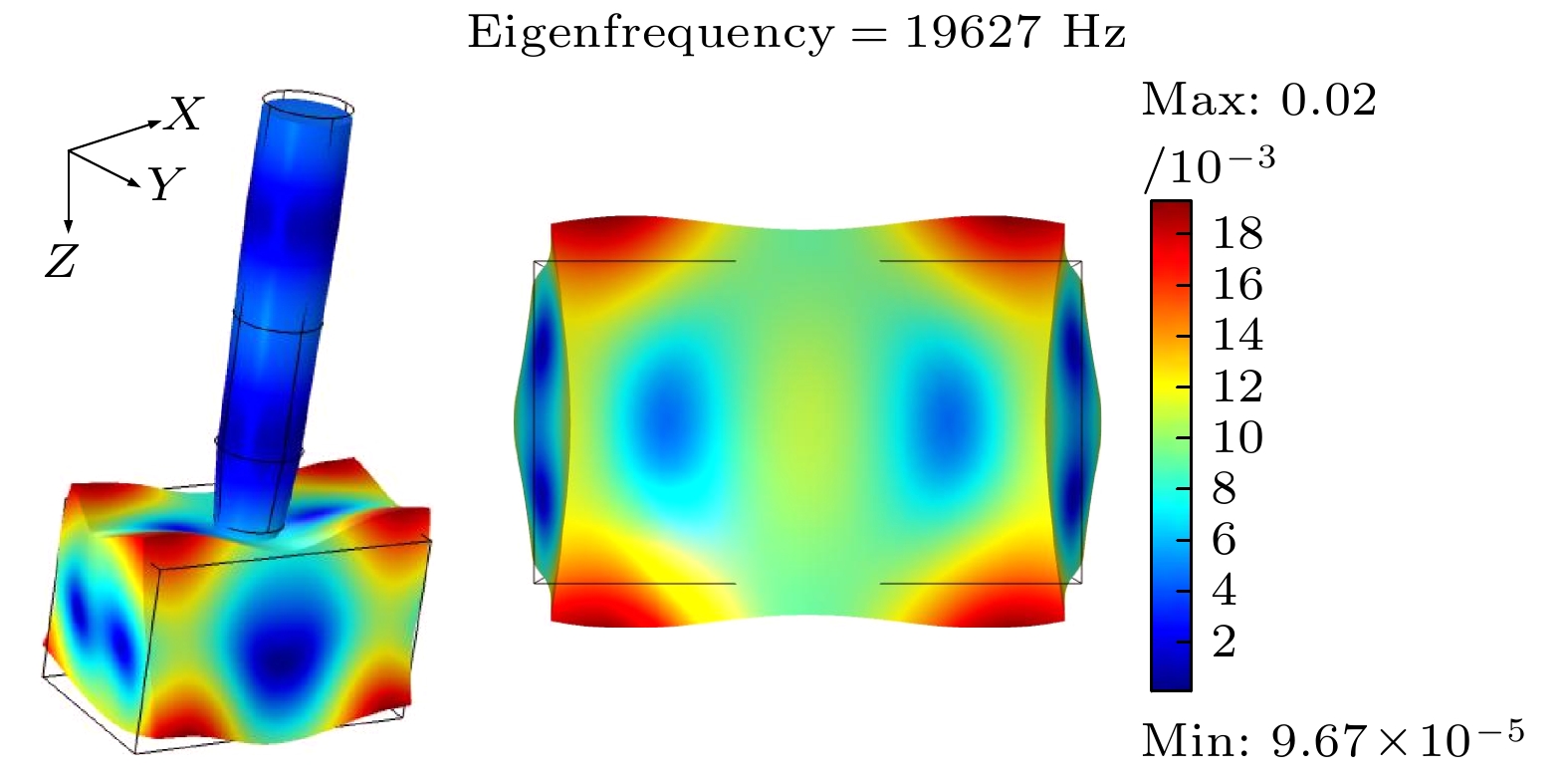

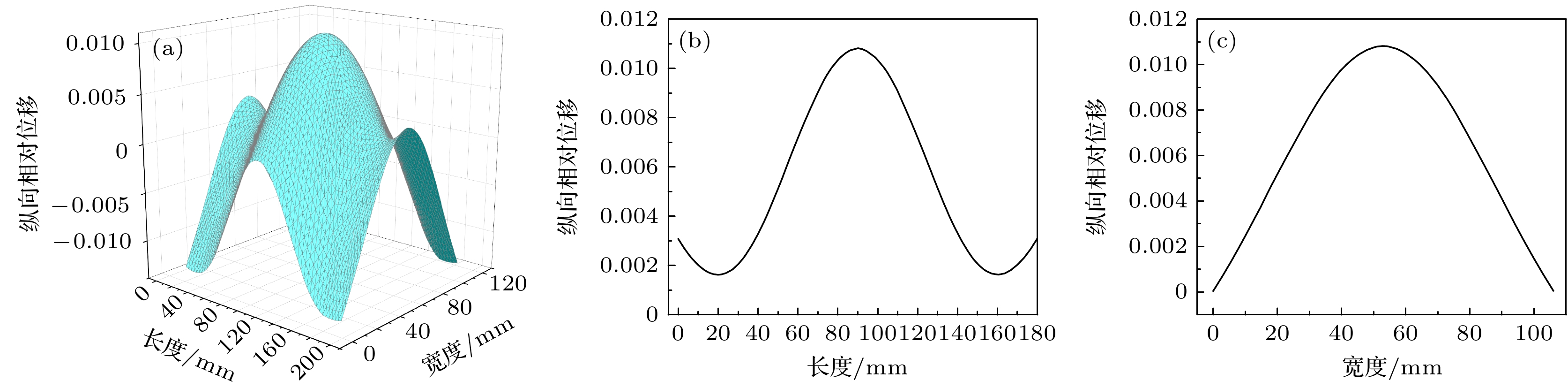

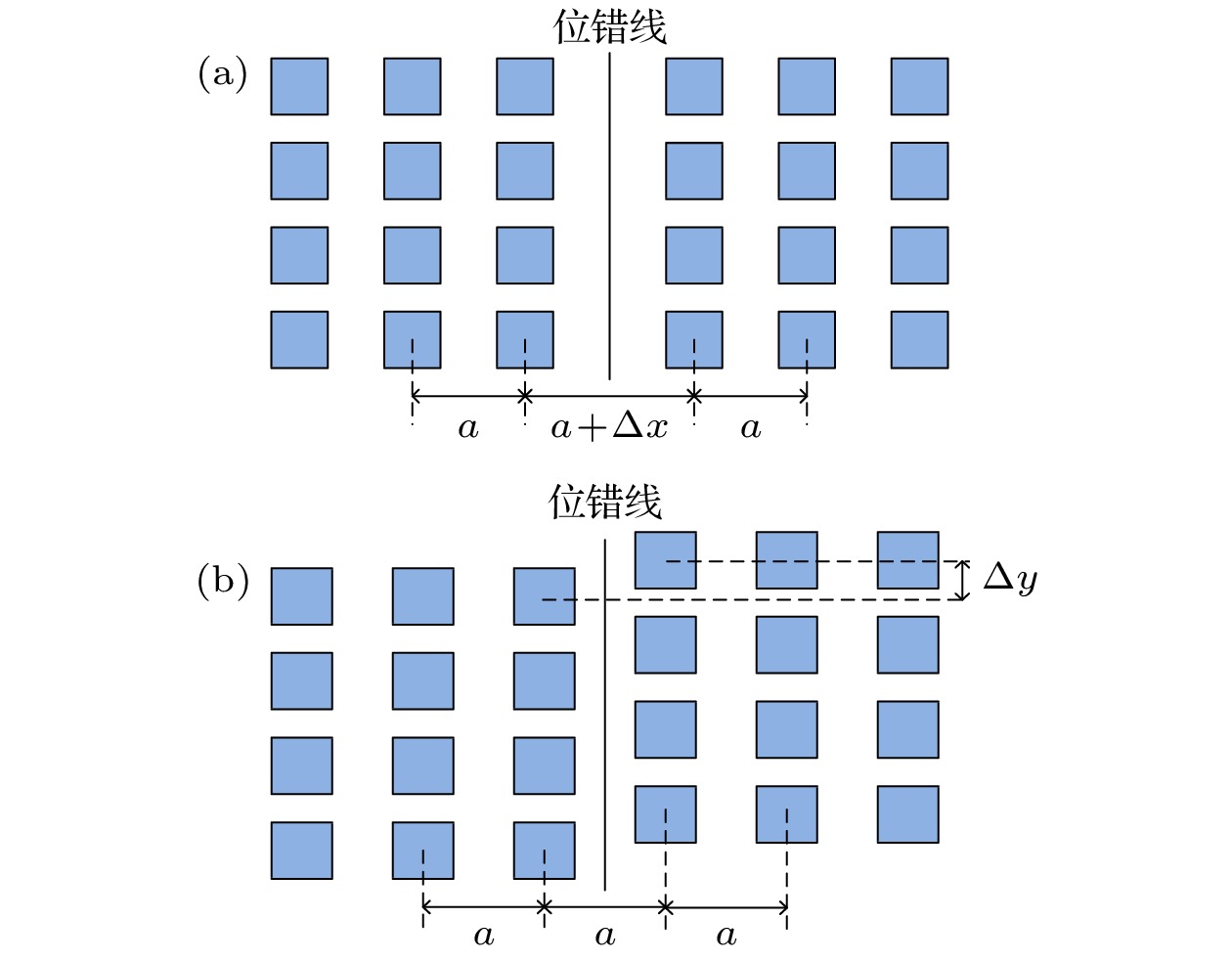

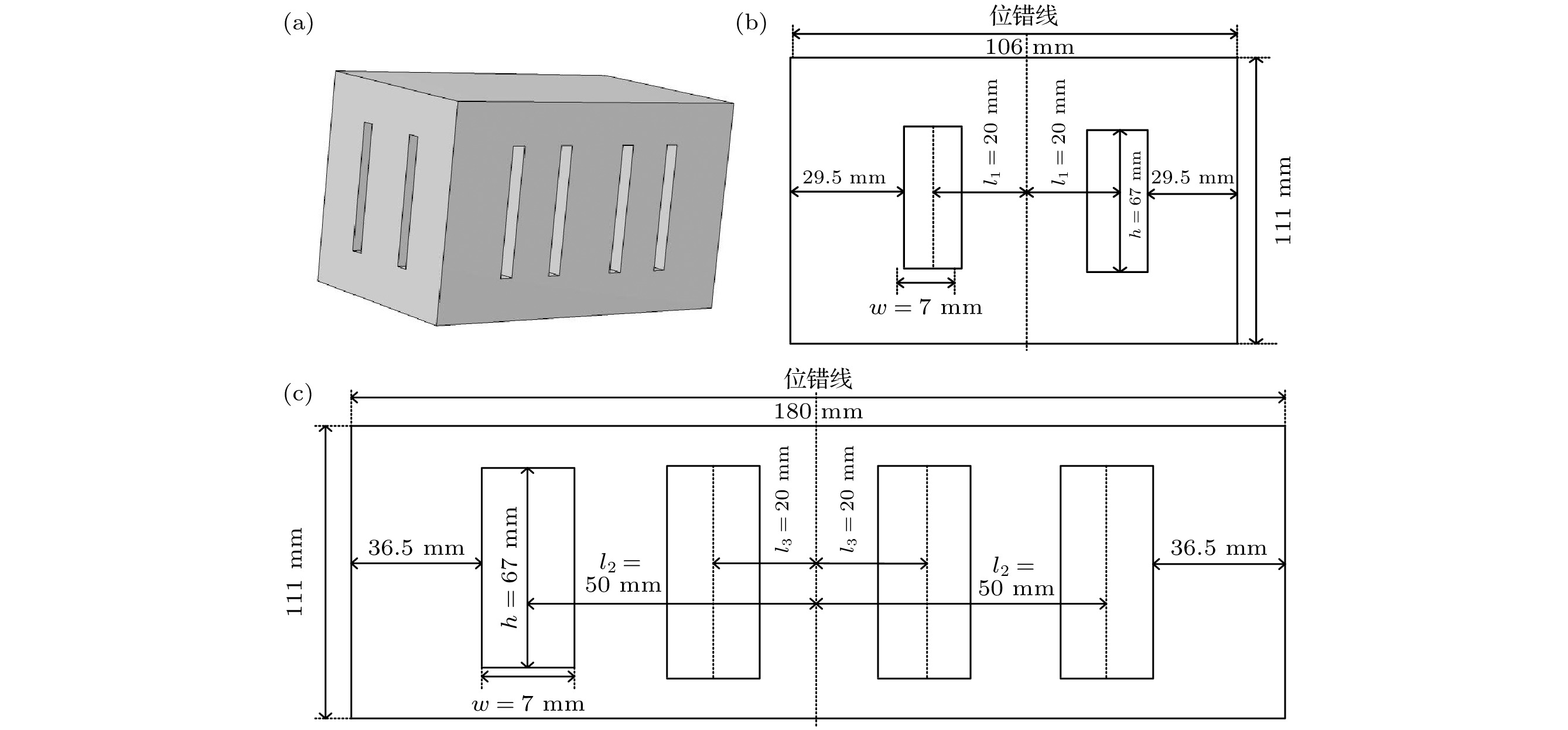

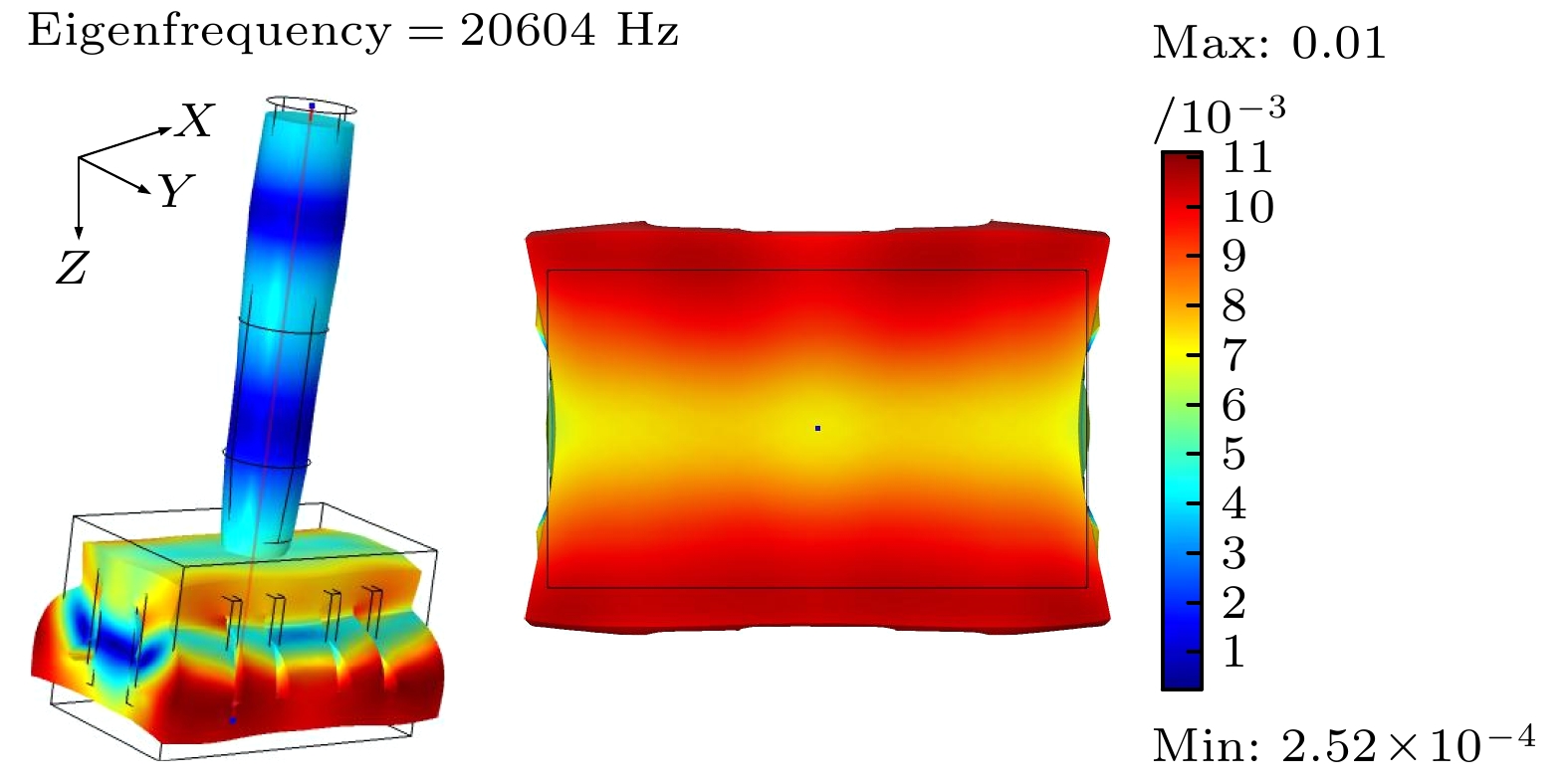

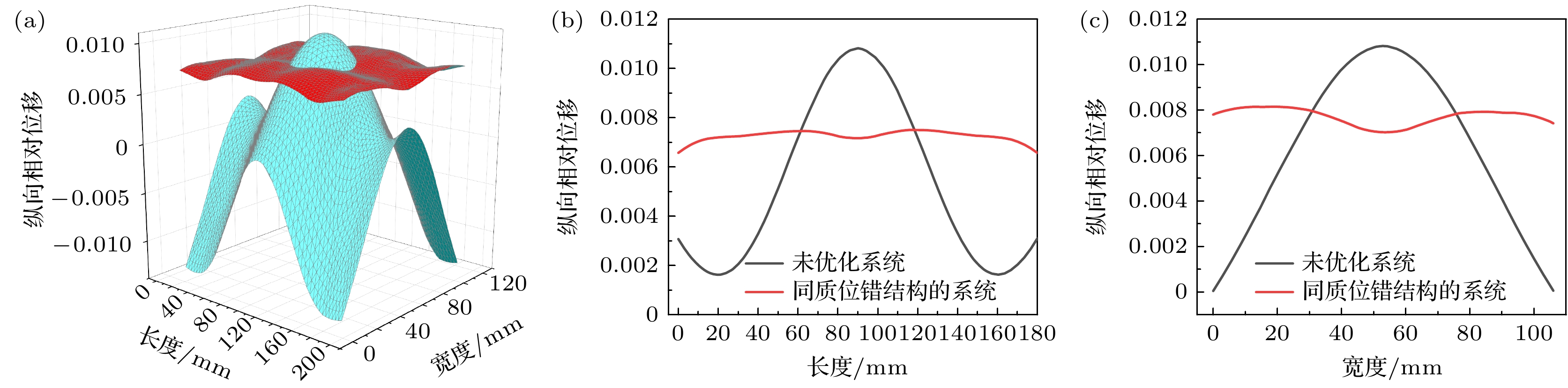

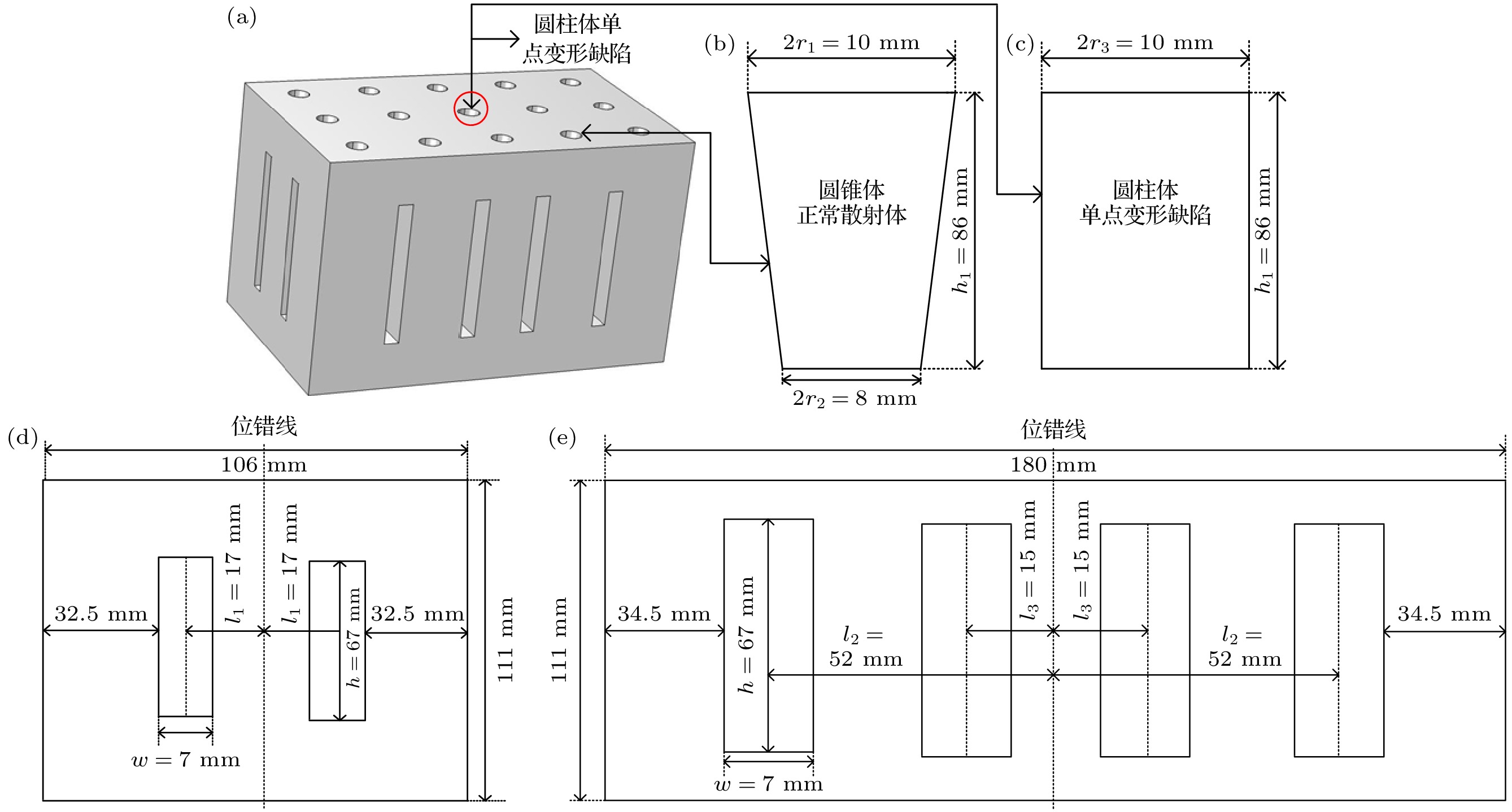

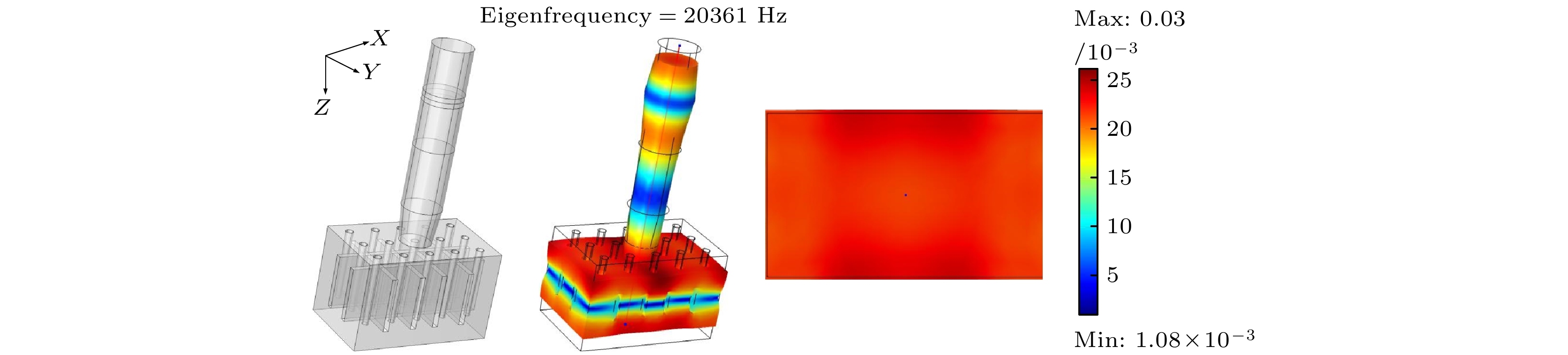

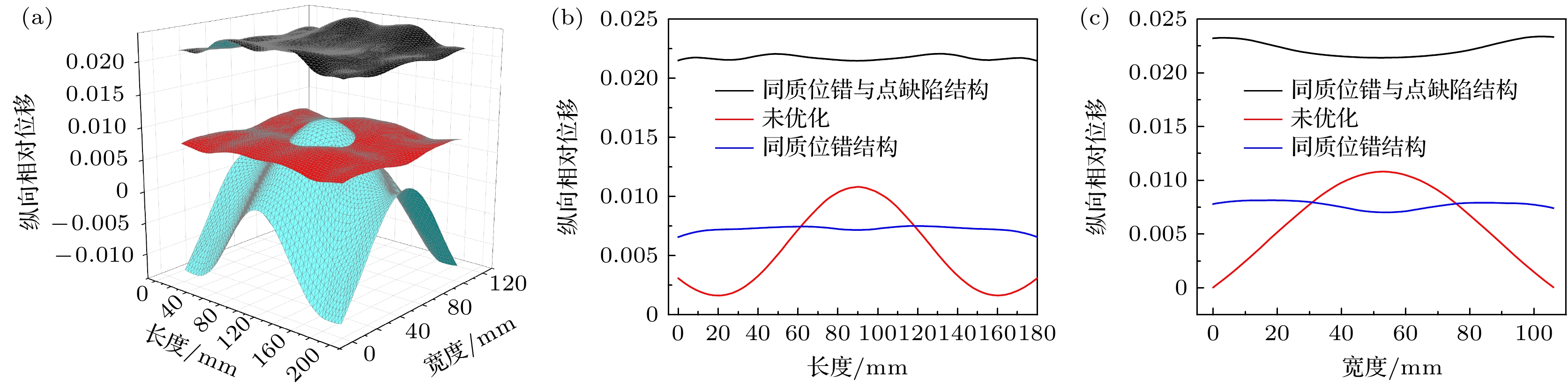

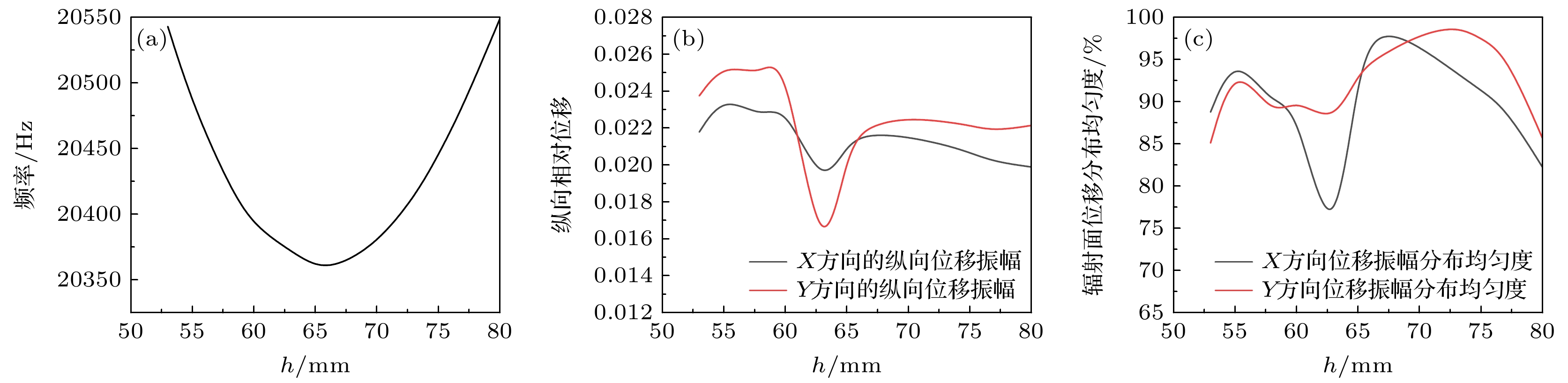

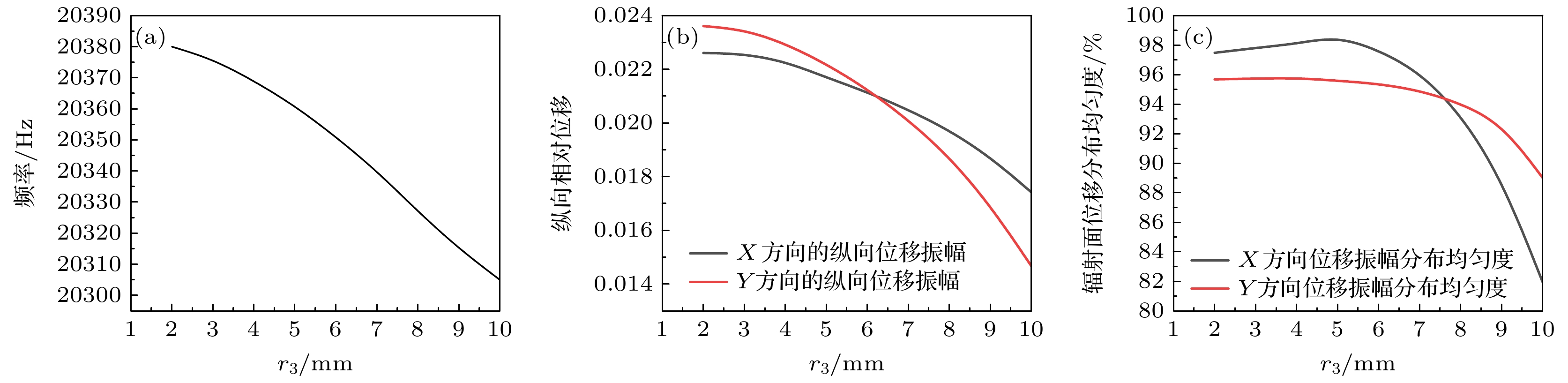

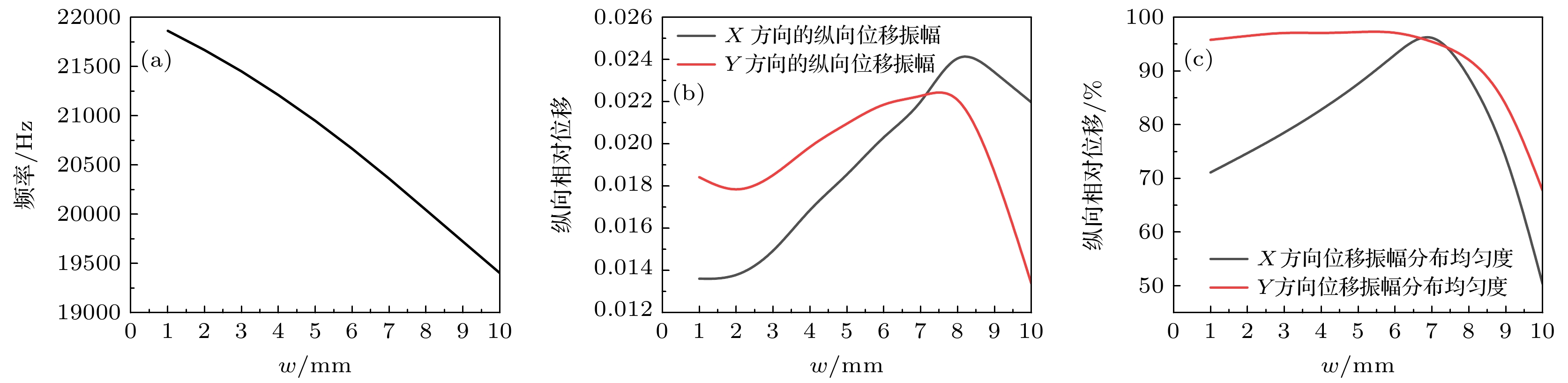

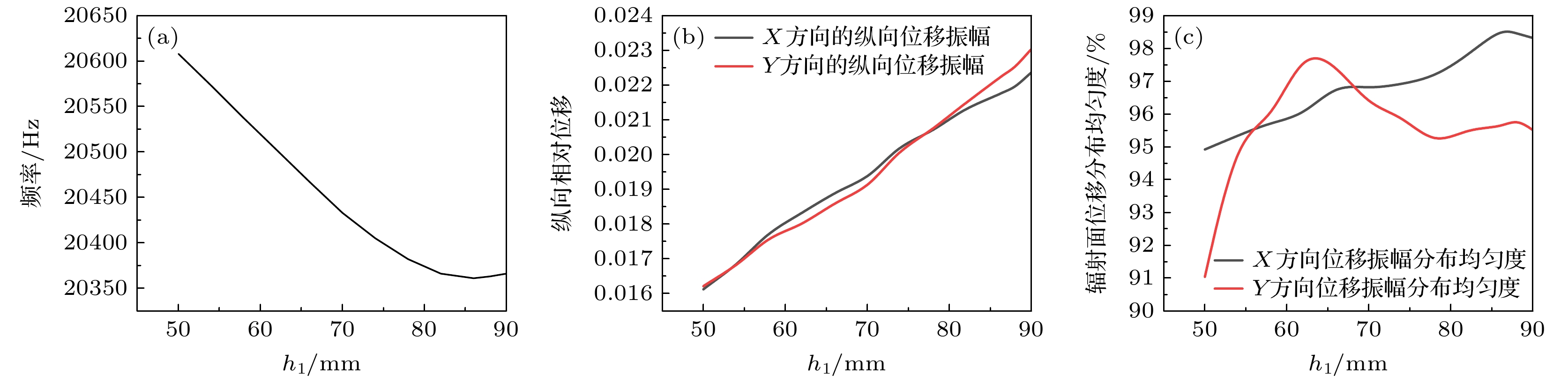

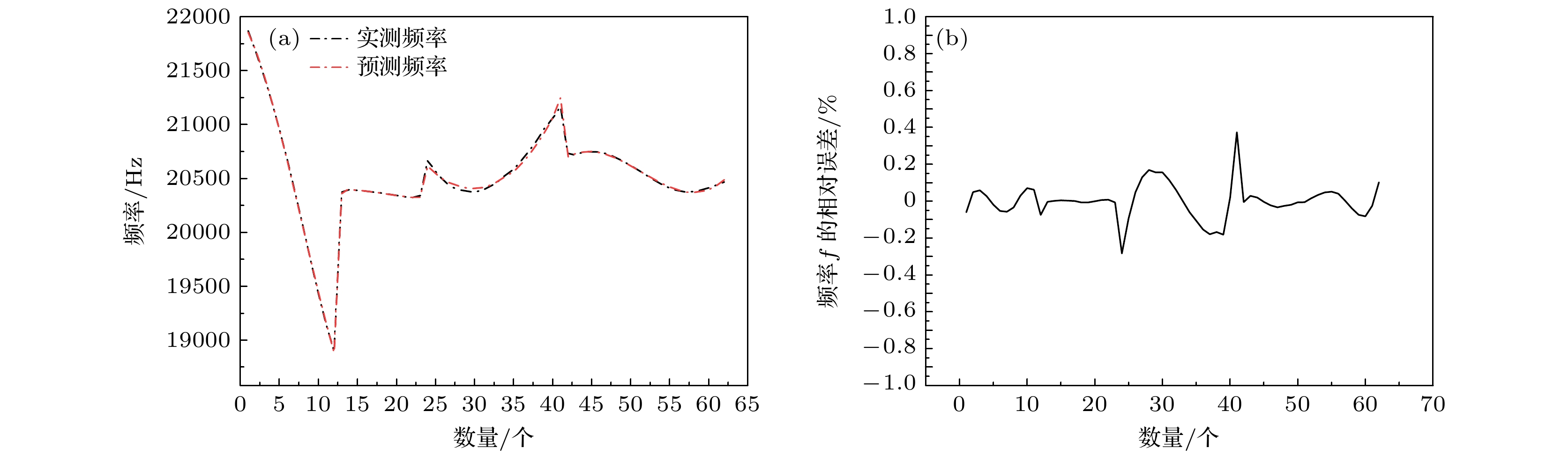

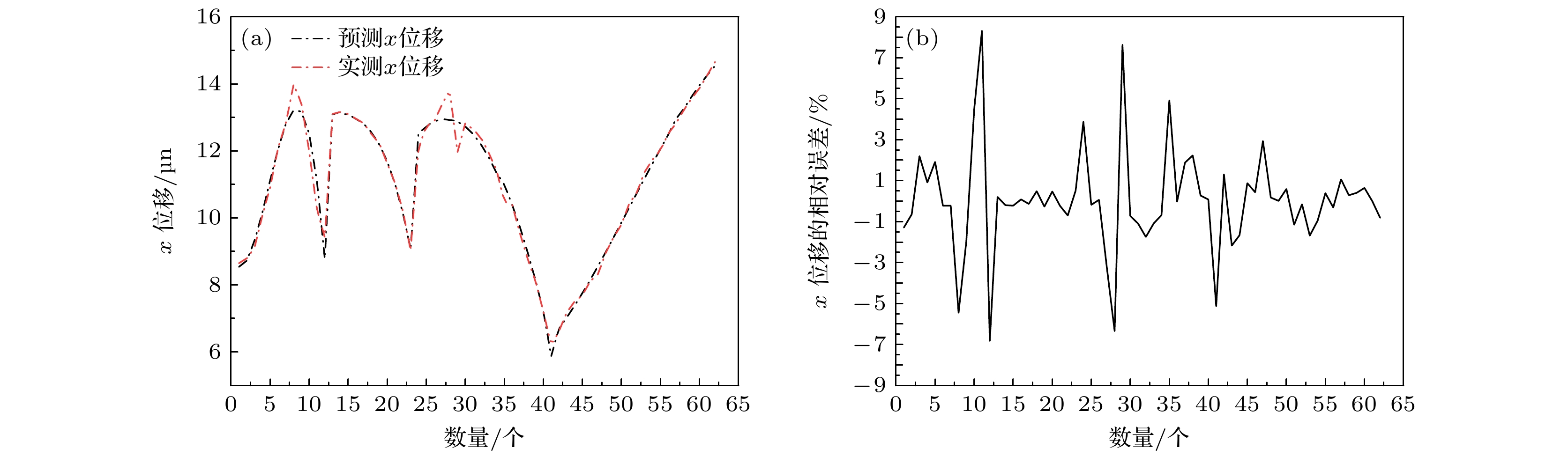

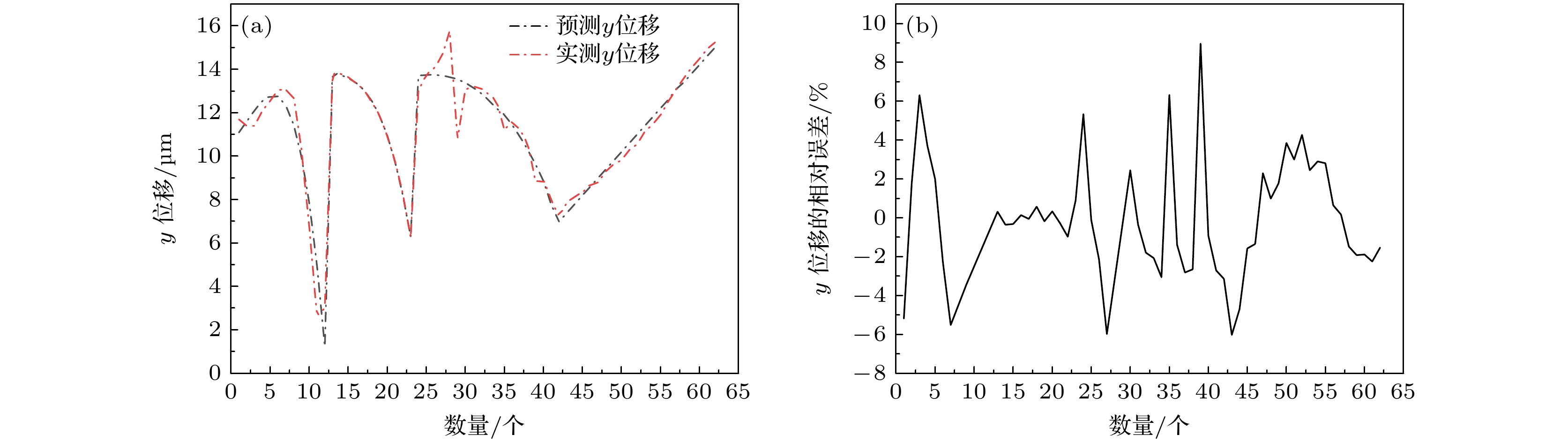

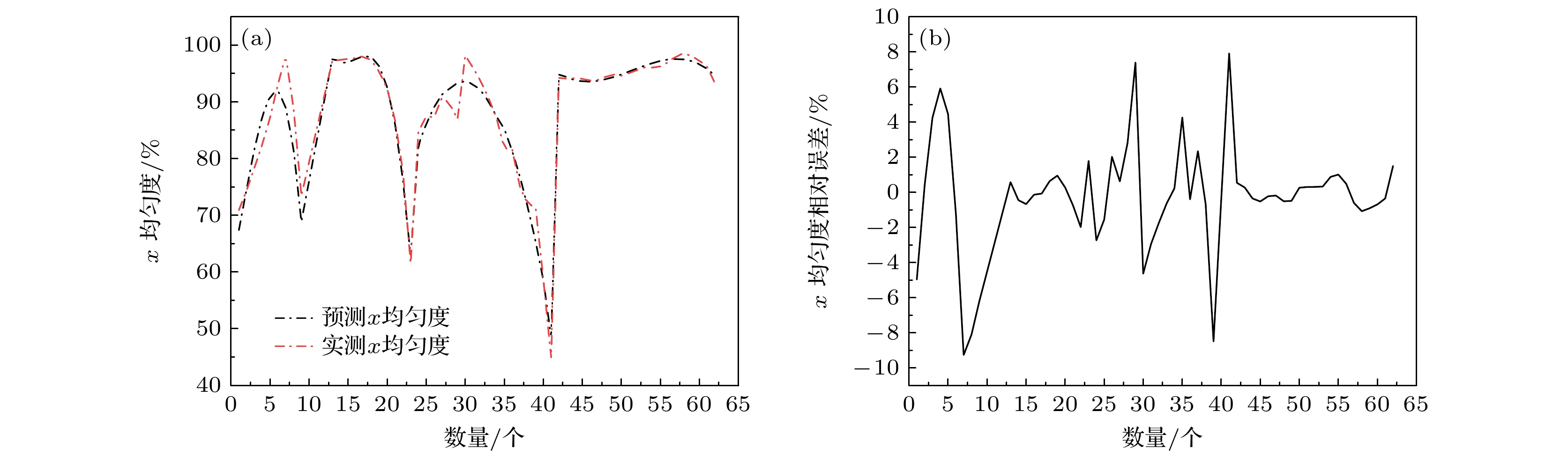

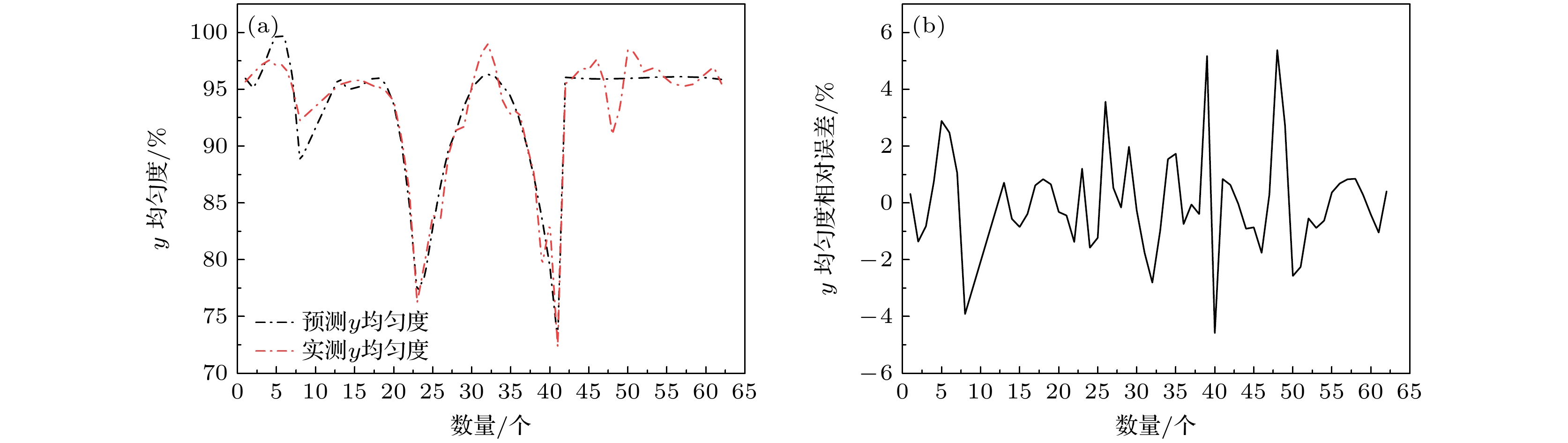

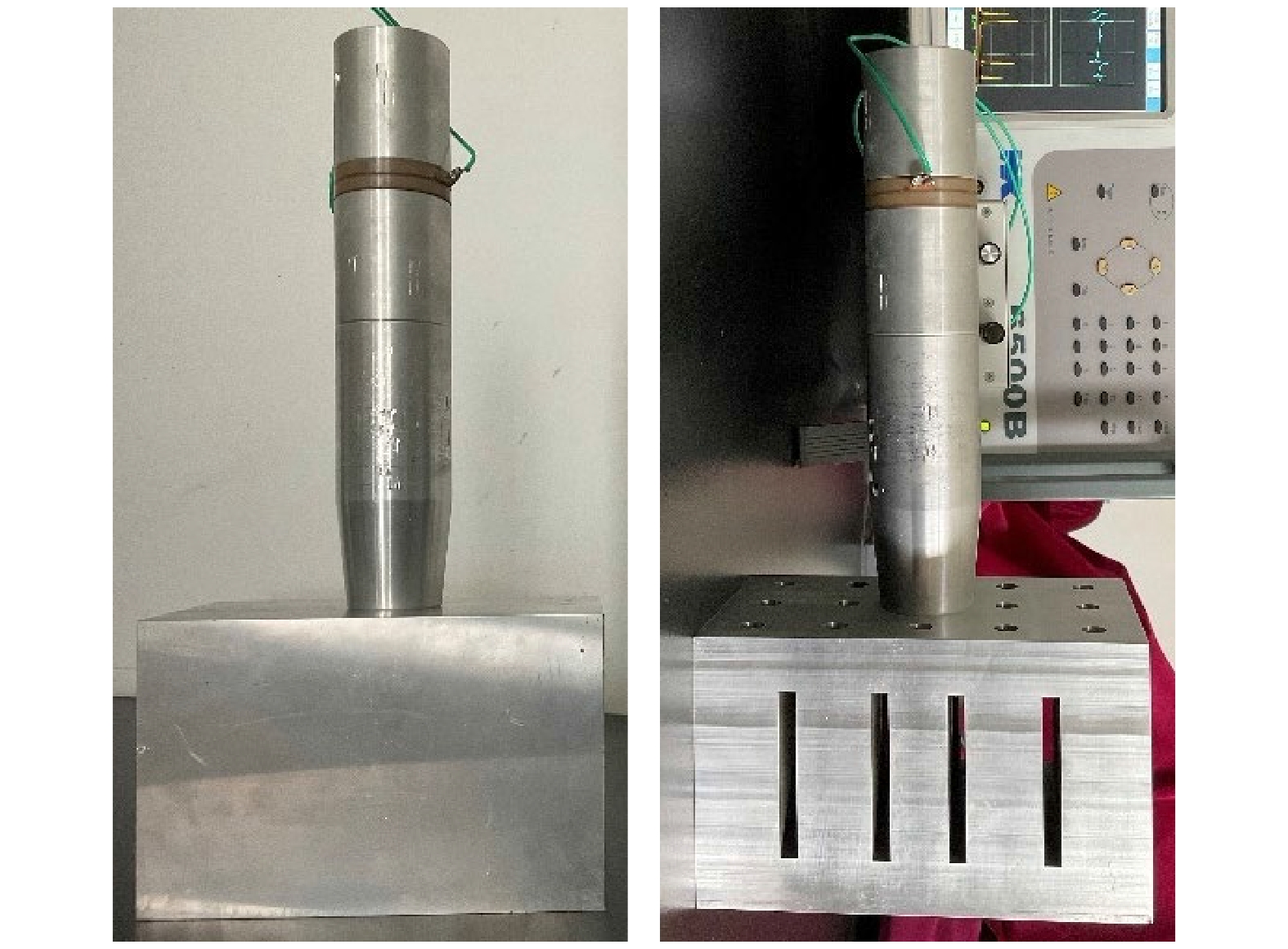

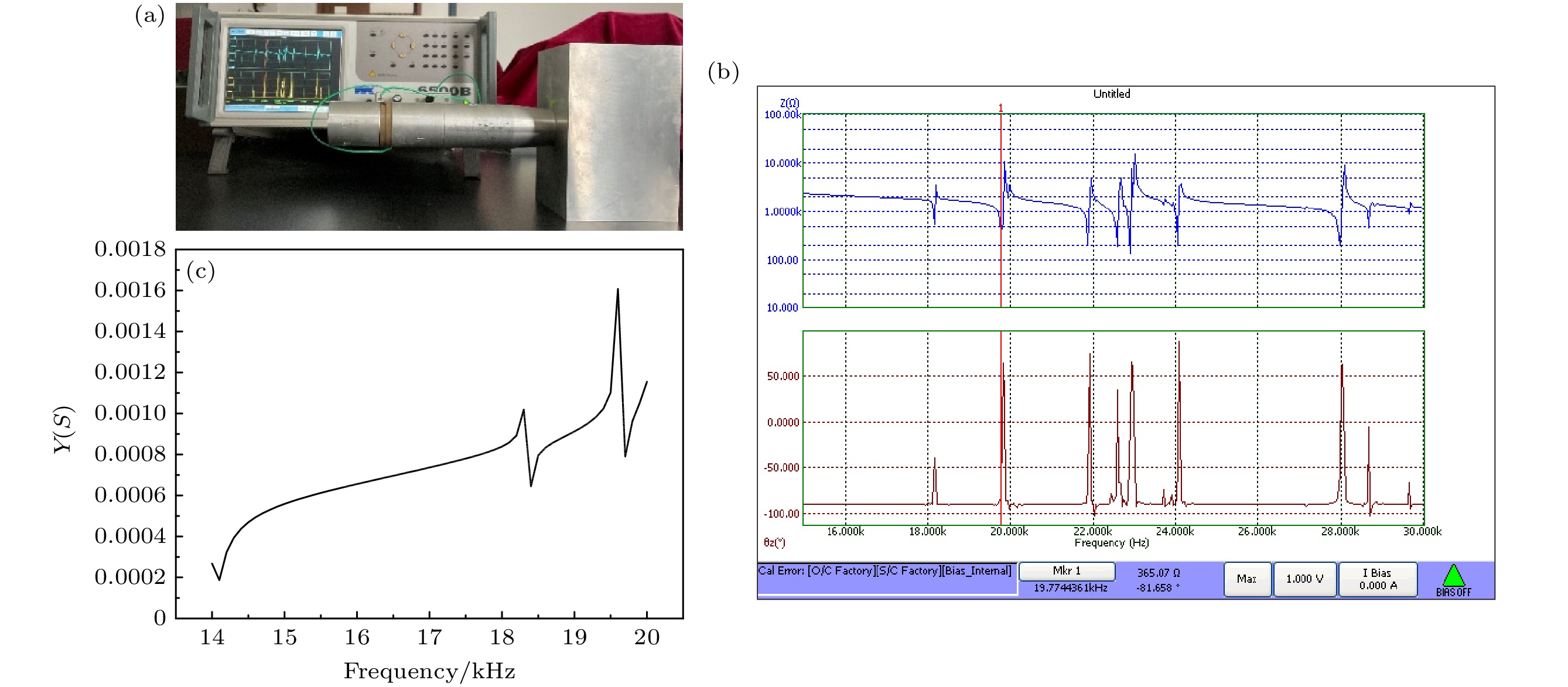

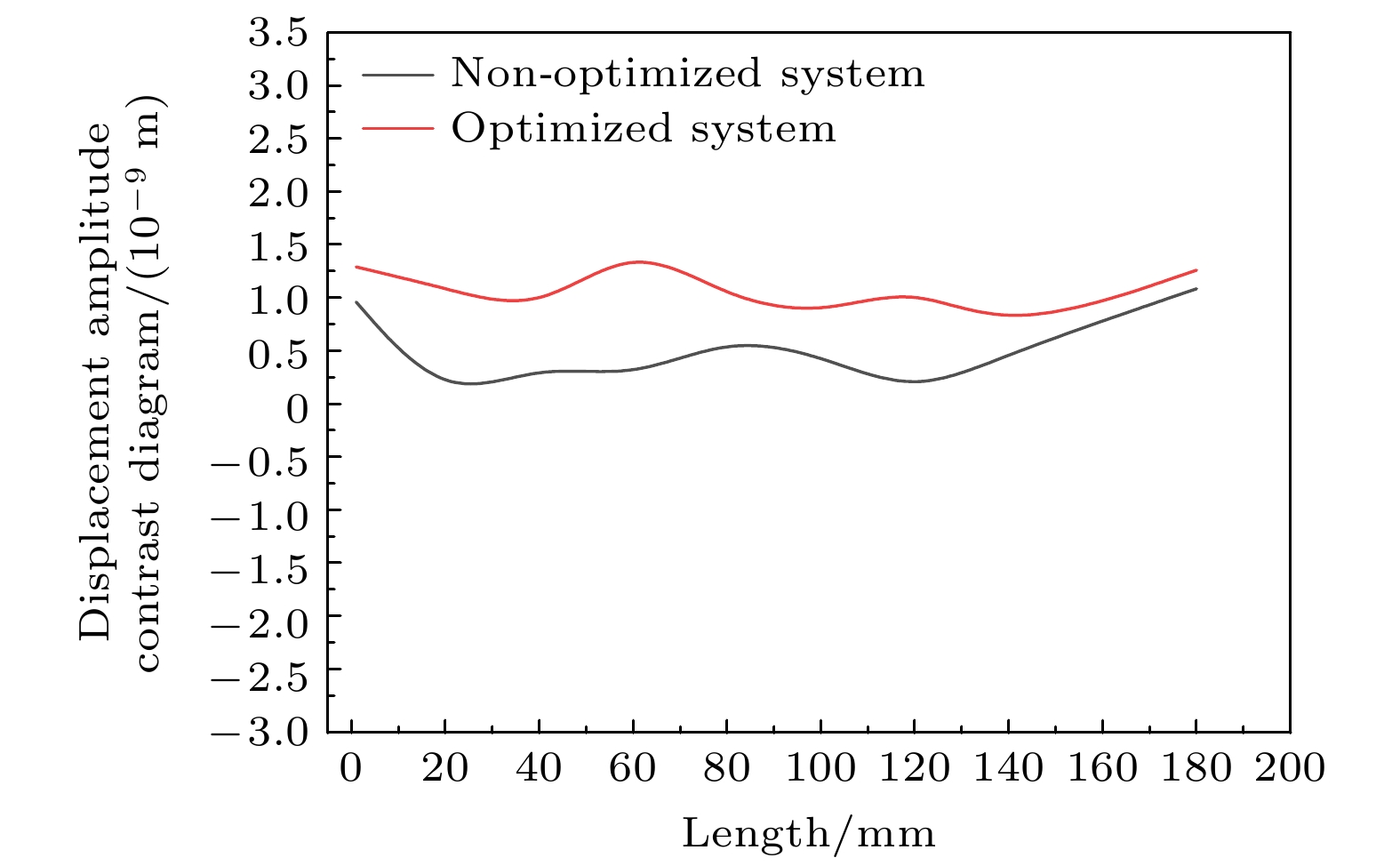

Large-scale three-dimensional ultrasonic vibration systems are susceptible to the influence of coupled vibration, resulting in a series of problems such as increased energy loss, small longitudinal displacement amplitude of the radiation surface, and uneven distribution of longitudinal displacement amplitude, which can seriously affect the working efficiency of ultrasonic processing system. How to effectively control the coupled vibration of large-scale three-dimensional ultrasonic transducer systems and optimize their performance has become an urgent problem in the field of power ultrasound. The research has found that some phononic crystal slots and point defect structures can suppress the lateral vibration of large-scale transducer systems, improve the uniformity of system amplitude distribution, and artificially regulate the performance of large-scale three-dimensional ultrasonic vibration systems by changing the configuration parameters of phononic crystal structures. However, excessive design parameters will inevitably increase the complexity of system design, and, currently, the optimization design of large-scale three-dimensional ultrasonic transducer systems relies on empirical trial and error methods which has low design efficiency and low success rate, and cannot guarantee the system performance. Therefore, in the study, homogeneous dislocations and point defect structures are introduced to optimize the design of large-scale three-dimensional ultrasonic vibration systems. Data analysis techniques are used to evaluate the influences of the configuration of homogeneous dislocations and point defect structures on the longitudinal displacement amplitude, amplitude distribution uniformity, radiated sound power, working bandwidth of the system’s radiation surface. And a predictive model for the performance of large-scale ultrasonic transducer system with homogeneous dislocation structure and near periodic defect structure is established, which can achieve intelligent design of large-scale power ultrasonic transducer system, improve design efficiency and success rate, and reduce the design cost.

-

Keywords:

- coupled vibration /

- large-scale three-dimensional ultrasonic vibration system /

- homogeneous dislocations /

- point defects /

- intelligent design

[1] 周光平, 梁明军, 王家宣 2004 声学技术 2004 183

Google Scholar

Google Scholar

Zhou G P, Liang M J, Wang J X 2004 Tech. Acous. 2004 183

Google Scholar

Google Scholar

[2] Mori E, Itoh K, Imamura A 1995 J. Acous. Soc. Jpn. 51 455

Google Scholar

Google Scholar

[3] Lin S 1995 Appl. Acous. 44 249

Google Scholar

Google Scholar

[4] Ren S C 1983 Acta Acus. 1 152

Google Scholar

Google Scholar

[5] Lin S 2009 IEEE Trans. Ultra. Ferr. Freq Cont. 56 1990.

Google Scholar

Google Scholar

[6] 俞宏沛 1994 声学与电子工程 1994 9

Yu H P 1994 Acous. Elec. Engi. 1994 9

[7] 周利生 1993 声学与电子工程 1993 28

Zhou L S 1993 Acous. Elec. Engi. 1993 28

[8] 周利生 1993 声学与电子工程 1993 16

Zhou L S 1993 Acous. Elec. Engi. 1993 16

[9] 林书玉, 张福成 1992 声学学报 1992 451

Lin S Y, Zhang F C 1991 J. Acous. 1992 451

[10] 林书玉, 张福成 1991 应用声学 1991 10

Google Scholar

Google Scholar

Lin S Y, Zhang F C 1991 Appl. Acous. 1991 10

Google Scholar

Google Scholar

[11] 林书玉, 张福成, 郭孝武 1991 声学学报 1991 91

Google Scholar

Google Scholar

Lin S Y, Zhang F C Guo X W 1991 J. Acous. 1991 91

Google Scholar

Google Scholar

[12] Lucas M, Smith A C 1997 J. Vibr. Acous. 119 410

Google Scholar

Google Scholar

[13] Cardoni A, Lucas M 2002 Ultrasonics 40 365

Google Scholar

Google Scholar

[14] Kumar R D, Rani M R, Elangovan S 2014 Appl. Mech. Mater. 592-594 859

Google Scholar

Google Scholar

[15] Yeon J L, Muhammad B S, Dong S P 2019 MATEC Web Conf. 257 1

Google Scholar

Google Scholar

[16] Adachi K, Ueha S 1990 J. Acous. Soc. Am. 87 208

Google Scholar

Google Scholar

[17] Thanh H N, Quang T Q, Cong L T 2017 IOP Conference Series:Materials Science and Engineering 241 1

Google Scholar

Google Scholar

[18] Rani M R, Prakasan K, Rudramoorthy R 2014 Int. J. Des. 5 344

Google Scholar

Google Scholar

[19] 程存弟 1991 应用声学 10 44

Google Scholar

Google Scholar

Chen C D 1991 Appl. Acous. 10 44

Google Scholar

Google Scholar

[20] 林书玉, 张福成 1992 声学技术 11 24

Google Scholar

Google Scholar

Lin S Y, Zhang F C 1992 Tech. Acous. 11 24

Google Scholar

Google Scholar

[21] 梁召峰, 周光平, 莫喜平, 张亦慧, 李正中 2008 机械科学与技术 27 334

Google Scholar

Google Scholar

Liang Z F, Zhou G P, Mo X P, Zhang Y H, Li Z Z 2008 Mech. Sci. Tech. 27 334

Google Scholar

Google Scholar

[22] 梁召峰, 周光平, 莫喜平, 李正中 2009 工程设计学报 16 200

Google Scholar

Google Scholar

Liang Z F, Zhou G P, Mo X P, Zhang Y H, Li Z Z 2009 Journal of Engineering Design 16 200

Google Scholar

Google Scholar

[23] 成桢, 郭建中 2010 声学技术 29 103

Chen Z, Guo J Z 2010 Tech. Acous. 29 103

[24] 赵甜甜, 林书玉, 段祎林 2018 67 024303

Google Scholar

Google Scholar

Zhao T T, Lin S Y, Duan Y L 2018 Acta Phys. Sin. 67 024303

Google Scholar

Google Scholar

[25] 王莎, 林书玉 2019 68 173

Google Scholar

Google Scholar

Wang S, Lin S Y 2019 Acta Phys. Sin. 68 173

Google Scholar

Google Scholar

[26] Wang S, Lin S Y 2019 Ultrasonics 99 105954.

Google Scholar

Google Scholar

[27] Lin J Y, Lin S Y 2020 Crystals 10 1

Google Scholar

Google Scholar

[28] Zhao Y C, Zhao F, Yuan L B 2006 J. Harbin Eng. Univ. 2006 617 [赵言诚, 赵芳, 苑立波 2006 哈尔滨工程大学学报 2006 617]

Google Scholar

Google Scholar

Zhao Y C, Zhao F, Yuan L B 2006 J. Harbin Eng. Univ. 2006 617

Google Scholar

Google Scholar

[29] Zhao F, Wan L B 2006 Acta Phys. Sin. 2 517 [赵芳, 苑立波 2006 2 517]

Google Scholar

Google Scholar

Zhao F, Wan L B 2006 Acta Phys. Sin. 2 517

Google Scholar

Google Scholar

[30] 何姣 2013 博士学位论文 (昆明: 云南师范大学)

He J 2013 Ph. D. Dissertation (Kunming: Yunnan Normal University

[31] 魏琦, 程营, 刘晓峻 2011 60 124301

Google Scholar

Google Scholar

Wei Q, Cheng Y, Liu X J 2011 Acta Phys. Sin. 60 124301

Google Scholar

Google Scholar

-

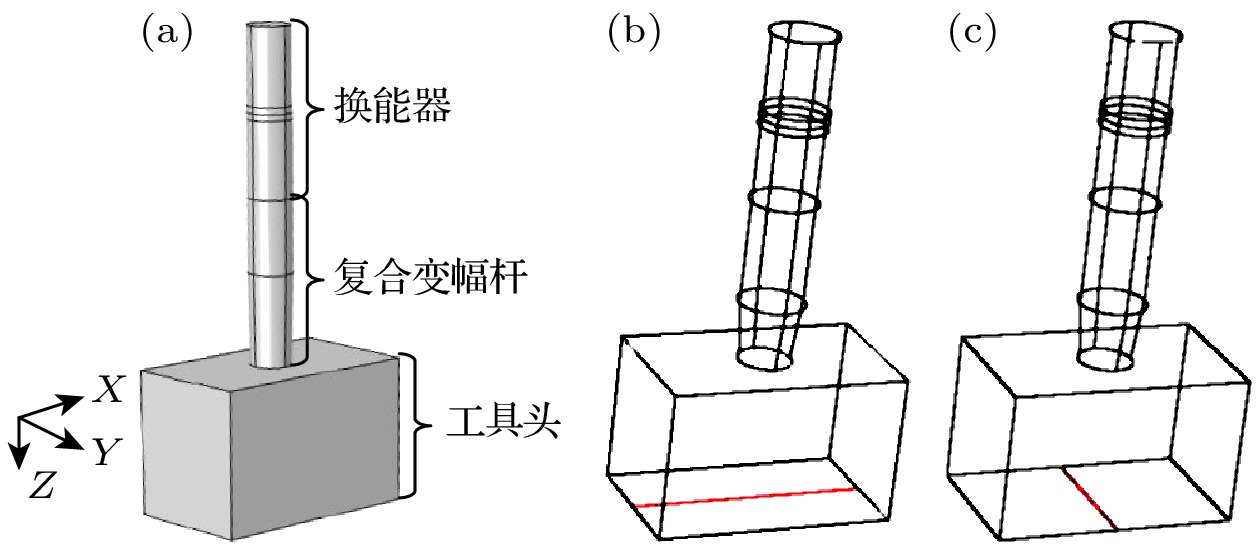

表 1 系统的材料和结构参数表

Table 1. Material and structural parameter table of the system.

部件 材料属性 形状 大端半径(长)/mm 小端半径(宽)/mm 高度/mm 换能器前盖板 Aluminum 6063-T83 等截面圆柱 25 25 56 换能器压电陶瓷片(两片) PZT-4 等截面圆环 25 25 6 换能器后盖板 Aluminum 6063-T83 等截面圆柱 25 25 56 复合变幅杆圆柱部分 Aluminum 6063-T83 等截面圆柱 25 25 77 复合变幅杆圆锥部分 Aluminum 6063-T83 圆锥 25 20 45 工具头 Aluminum 6063-T83 长方体 180 106 111 -

[1] 周光平, 梁明军, 王家宣 2004 声学技术 2004 183

Google Scholar

Google Scholar

Zhou G P, Liang M J, Wang J X 2004 Tech. Acous. 2004 183

Google Scholar

Google Scholar

[2] Mori E, Itoh K, Imamura A 1995 J. Acous. Soc. Jpn. 51 455

Google Scholar

Google Scholar

[3] Lin S 1995 Appl. Acous. 44 249

Google Scholar

Google Scholar

[4] Ren S C 1983 Acta Acus. 1 152

Google Scholar

Google Scholar

[5] Lin S 2009 IEEE Trans. Ultra. Ferr. Freq Cont. 56 1990.

Google Scholar

Google Scholar

[6] 俞宏沛 1994 声学与电子工程 1994 9

Yu H P 1994 Acous. Elec. Engi. 1994 9

[7] 周利生 1993 声学与电子工程 1993 28

Zhou L S 1993 Acous. Elec. Engi. 1993 28

[8] 周利生 1993 声学与电子工程 1993 16

Zhou L S 1993 Acous. Elec. Engi. 1993 16

[9] 林书玉, 张福成 1992 声学学报 1992 451

Lin S Y, Zhang F C 1991 J. Acous. 1992 451

[10] 林书玉, 张福成 1991 应用声学 1991 10

Google Scholar

Google Scholar

Lin S Y, Zhang F C 1991 Appl. Acous. 1991 10

Google Scholar

Google Scholar

[11] 林书玉, 张福成, 郭孝武 1991 声学学报 1991 91

Google Scholar

Google Scholar

Lin S Y, Zhang F C Guo X W 1991 J. Acous. 1991 91

Google Scholar

Google Scholar

[12] Lucas M, Smith A C 1997 J. Vibr. Acous. 119 410

Google Scholar

Google Scholar

[13] Cardoni A, Lucas M 2002 Ultrasonics 40 365

Google Scholar

Google Scholar

[14] Kumar R D, Rani M R, Elangovan S 2014 Appl. Mech. Mater. 592-594 859

Google Scholar

Google Scholar

[15] Yeon J L, Muhammad B S, Dong S P 2019 MATEC Web Conf. 257 1

Google Scholar

Google Scholar

[16] Adachi K, Ueha S 1990 J. Acous. Soc. Am. 87 208

Google Scholar

Google Scholar

[17] Thanh H N, Quang T Q, Cong L T 2017 IOP Conference Series:Materials Science and Engineering 241 1

Google Scholar

Google Scholar

[18] Rani M R, Prakasan K, Rudramoorthy R 2014 Int. J. Des. 5 344

Google Scholar

Google Scholar

[19] 程存弟 1991 应用声学 10 44

Google Scholar

Google Scholar

Chen C D 1991 Appl. Acous. 10 44

Google Scholar

Google Scholar

[20] 林书玉, 张福成 1992 声学技术 11 24

Google Scholar

Google Scholar

Lin S Y, Zhang F C 1992 Tech. Acous. 11 24

Google Scholar

Google Scholar

[21] 梁召峰, 周光平, 莫喜平, 张亦慧, 李正中 2008 机械科学与技术 27 334

Google Scholar

Google Scholar

Liang Z F, Zhou G P, Mo X P, Zhang Y H, Li Z Z 2008 Mech. Sci. Tech. 27 334

Google Scholar

Google Scholar

[22] 梁召峰, 周光平, 莫喜平, 李正中 2009 工程设计学报 16 200

Google Scholar

Google Scholar

Liang Z F, Zhou G P, Mo X P, Zhang Y H, Li Z Z 2009 Journal of Engineering Design 16 200

Google Scholar

Google Scholar

[23] 成桢, 郭建中 2010 声学技术 29 103

Chen Z, Guo J Z 2010 Tech. Acous. 29 103

[24] 赵甜甜, 林书玉, 段祎林 2018 67 024303

Google Scholar

Google Scholar

Zhao T T, Lin S Y, Duan Y L 2018 Acta Phys. Sin. 67 024303

Google Scholar

Google Scholar

[25] 王莎, 林书玉 2019 68 173

Google Scholar

Google Scholar

Wang S, Lin S Y 2019 Acta Phys. Sin. 68 173

Google Scholar

Google Scholar

[26] Wang S, Lin S Y 2019 Ultrasonics 99 105954.

Google Scholar

Google Scholar

[27] Lin J Y, Lin S Y 2020 Crystals 10 1

Google Scholar

Google Scholar

[28] Zhao Y C, Zhao F, Yuan L B 2006 J. Harbin Eng. Univ. 2006 617 [赵言诚, 赵芳, 苑立波 2006 哈尔滨工程大学学报 2006 617]

Google Scholar

Google Scholar

Zhao Y C, Zhao F, Yuan L B 2006 J. Harbin Eng. Univ. 2006 617

Google Scholar

Google Scholar

[29] Zhao F, Wan L B 2006 Acta Phys. Sin. 2 517 [赵芳, 苑立波 2006 2 517]

Google Scholar

Google Scholar

Zhao F, Wan L B 2006 Acta Phys. Sin. 2 517

Google Scholar

Google Scholar

[30] 何姣 2013 博士学位论文 (昆明: 云南师范大学)

He J 2013 Ph. D. Dissertation (Kunming: Yunnan Normal University

[31] 魏琦, 程营, 刘晓峻 2011 60 124301

Google Scholar

Google Scholar

Wei Q, Cheng Y, Liu X J 2011 Acta Phys. Sin. 60 124301

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 3597

- PDF Downloads: 96

- Cited By: 0

DownLoad:

DownLoad: