-

Al-Si alloys have been widely used in electronic information, communication, and other fields because of their high specific strength, excellent castability and good thermal conductivity. In recent years, with the rapid development of 5G communication technology, electronic communication equipment is gradually developing towards high integration and lightweight. The power of related equipment is higher and higher, which puts forward higher requirements for thermal conductivity and mechanical properties of materials. Si can improve the fluidity and strength of the Al-Si alloy, but a large amount of Si will aggravate the lattice distortion and increases amount of eutectic Si. This will reduce the plasticity of the alloy, increase the electron scattering and reduce the thermal conductivity. In order to improve the mechanical properties and thermal conductivity of Al-Si alloys, chemical inoculation is generally used. Sr is usually used as modifier and Al-B serves as grain refiner. However, the simultaneous addition of Sr and B into Al-Si alloy results in “poisoning” phenomenon, it becomes impossible to refine α-Al grains and modify eutectic Si simultaneously. In recent years, rare earth La has attracted more and more attention in improving the properties of aluminum alloys. However, previous studies mainly focused on the effects of La addition, consequently, the research on the effects of combined addition of La, Sr, B on the microstructure and properties of Al-7%Si-0.6%Fe alloy is lacking. In this work, solidification experiments are performed to investigate the effects of combined addition of La, Sr, B on the microstructure and properties of Al-7%Si-0.6%Fe alloy. The results show that the addition of trace rare earth La can effectively eliminate the poisoning effect of Sr and B, and enhance the modification effect of eutectic Si. Besides, the addition of La can promote the formation of α-Al heterogeneous nucleation substrate LaB6 and La can be used as a surfactant to reduce the undercooling of α-Al nucleation, thus it refines α-Al grains. The thermal conductivity of the alloy is significantly improved when the addition of La ranges from 0.02% to 0.06%; with the further increase of La addition, LaAlSi intermetallic compounds are formed in the alloy, leading the thermal conductivity of the alloy to decrease. -

Keywords:

- Al-Si alloys /

- micro-alloying element La /

- solidification microstructure /

- thermal conductivity

[1] 高学鹏, 李新涛, 郄喜望, 吴亚萍, 李喜孟, 李廷举 2007 56 1188

Google Scholar

Google Scholar

Gao X P, Li X T, Qie X W, Wu Y P, Li X M, Li T J 2007 Acta Phys. Sin. 56 1188

Google Scholar

Google Scholar

[2] Dursun T, Soutis C 2014 Mater. Des. 55 862

Google Scholar

Google Scholar

[3] Kim Y M, Choi S W, KimY C 2023 J. Therm. Anal. Calorim. 140 10749

Google Scholar

Google Scholar

[4] Chen Z N, Kang H J, Fan G H, Li J H, Jie J C 2016 Acta Mater. 120 168

Google Scholar

Google Scholar

[5] 宋岩, 江鸿翔, 赵九洲, 何杰, 张丽丽, 李世欣 2021 70 086402

Google Scholar

Google Scholar

Song Y, Jiang H X, Zhao J Z, He J, Zhang L L, Li S X 2021 Acta Phys. Sin. 70 086402

Google Scholar

Google Scholar

[6] Bolzoni L, Xia M X, Babu N H 2016 Sci. Rep. 6 39554

Google Scholar

Google Scholar

[7] Ferrarini C F, Bolfarini C, Kiminami C S, Botta W J 2004 Mater. Sci. Eng. A 375 577

Google Scholar

Google Scholar

[8] Dang B, Zhang X, Chen Y Z, Chen C X, Wang H T, Liu F 2016 Sci. Rep. 6 30874

Google Scholar

Google Scholar

[9] Wang J Y, Wang B J, Huang L F 2017 Mater. Sci. Technol. 33 1235

Google Scholar

Google Scholar

[10] 王宝剑, 王建元, 吴文华, 翟薇, 王旭, 靳占奎, 魏炳波 2023 中国科学:技术科学 53 353

Wang B J, Wang J Y, Wu W H, Zhai W, Wang X, Jin Z K, Wei B B 2023 Sci. China Technol. Sci. 53 353

[11] Banerjee K, Chatterjee U K 2000 Mater. J. Mater. Sci. Technol. 16 517

Google Scholar

Google Scholar

[12] Timelli G, Caliari D, Rakhmonov J 2016 J. Mater. Sci. Technol. 32 515

Google Scholar

Google Scholar

[13] Birol Y 2012 Mater. Sci. Technol. 28 363

Google Scholar

Google Scholar

[14] Barrirero J, Engstler M, Ghafoor N 2014 J. Alloys Compd. 611 410

Google Scholar

Google Scholar

[15] Chen J K, Hung H Y, Wang C F, Tang N K 2017 Int. J. Heat Mass Transf. 105 189

Google Scholar

Google Scholar

[16] Li J H, Wang X D, Ludwig T H, Tsunekawa Y, Arnberg L, Jiang J Z 2015 Acta Mater. 84 153

Google Scholar

Google Scholar

[17] Jiang H X, Li S X, Zheng Q J, Zhang L L, He J, Song Y, Deng C K, Zhao J Z 2020 Mater. Des. 195 108991

Google Scholar

Google Scholar

[18] Zheng Q J, Jiang H X, He J, Zhang L L, Zhao J Z 2021 Sci. China Technol. Sci. 64 2012

Google Scholar

Google Scholar

[19] Jiang H X, Zheng Q J, Song Y, Li Y Q, Li S X, He J, Zhang L L, Zhao J Z 2022 Mater Charact. 185 111750

Google Scholar

Google Scholar

[20] Chen Y, Pan Y, Lu T, Tao S W, Wu J L 2014 Mater. Des. 64 432

Google Scholar

Google Scholar

[21] 郑秋菊, 叶中飞, 江鸿翔, 张丽丽, 赵九洲 2021 金属学报 57 103

Zheng Q J, Ye Z F, Jiang H X, Lu M, Zhang L L, Zhao J Z 2021 Acta Mater. Sin. 57 103

[22] Heo U, Han D W, Kim S, Mo C B 2022 Mater. Today Commun. 32 104005

Google Scholar

Google Scholar

[23] Bakhtiyarov S I, Overfelt R A, Teodorescu S G 2001 J. Mater. Sci. 36 4643

Google Scholar

Google Scholar

[24] Huang L, Gunther E, Doetsch C, Mehling H 2010 Thermochim. Acta 509 93

Google Scholar

Google Scholar

[25] Birol Y 2012 Mater. Sci. Technol. 28 70

Google Scholar

Google Scholar

[26] Cui X L, Wu Y Y, Gao T, Liu X F 2014 J. Alloys Compd. 615 906

Google Scholar

Google Scholar

[27] Lu T, Pan Y, Wu J L, Tao S W, Chen Y 2015 Int. J. Min. Met. Mater. 22 405

Google Scholar

Google Scholar

[28] Takeuchi A, Inoue A 2005 Mater. Trans. 46 2817

Google Scholar

Google Scholar

[29] Lu S Z, Hellawell A 1987 Metall. Trans. 18A 1721

[30] Li C L, Pan Y, Lu T, Jing L J, Pi J H 2018 Met. Mater. Int. 24 1133

Google Scholar

Google Scholar

[31] Luo Q, Li X L, Li Q 2023 J. Mater. Sci. Technol. 135 97

Google Scholar

Google Scholar

[32] Zhang M X, Kelly P M 2005 Scr. Mater. 52 963

Google Scholar

Google Scholar

[33] Jing L J, Pan Y, Lu T, Pi J H, Gu T F 2018 T. Nonferr. Metal. Soc. 28 1687

Google Scholar

Google Scholar

[34] Easton M A, StJohn D H 2001 130th TMS Annual Meeting New Orleans, La, February 11–15, 2000 p927

[35] Zhou S H, Napolitano R E 2006 Acta Mater. 54 831

Google Scholar

Google Scholar

[36] Zhang L L, Jiang H X, He J, Zhao J Z 2020 Scr. Mater. 179 99

Google Scholar

Google Scholar

[37] Li S B, Du W B, Wang X D 2018 Acta Metall. Sin. 54 911

Google Scholar

Google Scholar

[38] Hou J P, Wang Q, Zhang Z J, Tian Y Z, Wu X M, Yang H J, Li X W, Zhang Z F 2017 Mater. Des. 132 148

Google Scholar

Google Scholar

[39] Mayadas A F, Shatzkes M 1970 Phys.Rev.B. 1 1382

Google Scholar

Google Scholar

[40] Weng W P, Nagaumi H, Sheng X D, Fan W Z, Chen X C, Wang X N 2019 Light Metals Symposium at the 148th TMS Annual Meeting San Antonio, TX, March 10–12, 2019 p193

[41] Sauvage X, Bobruk E V, Murashkin M Y 2015 Acta Mater. 98 355

Google Scholar

Google Scholar

[42] Ma S M, Wang X M 2019 Mater. Sci. Eng. A 754 46

Google Scholar

Google Scholar

-

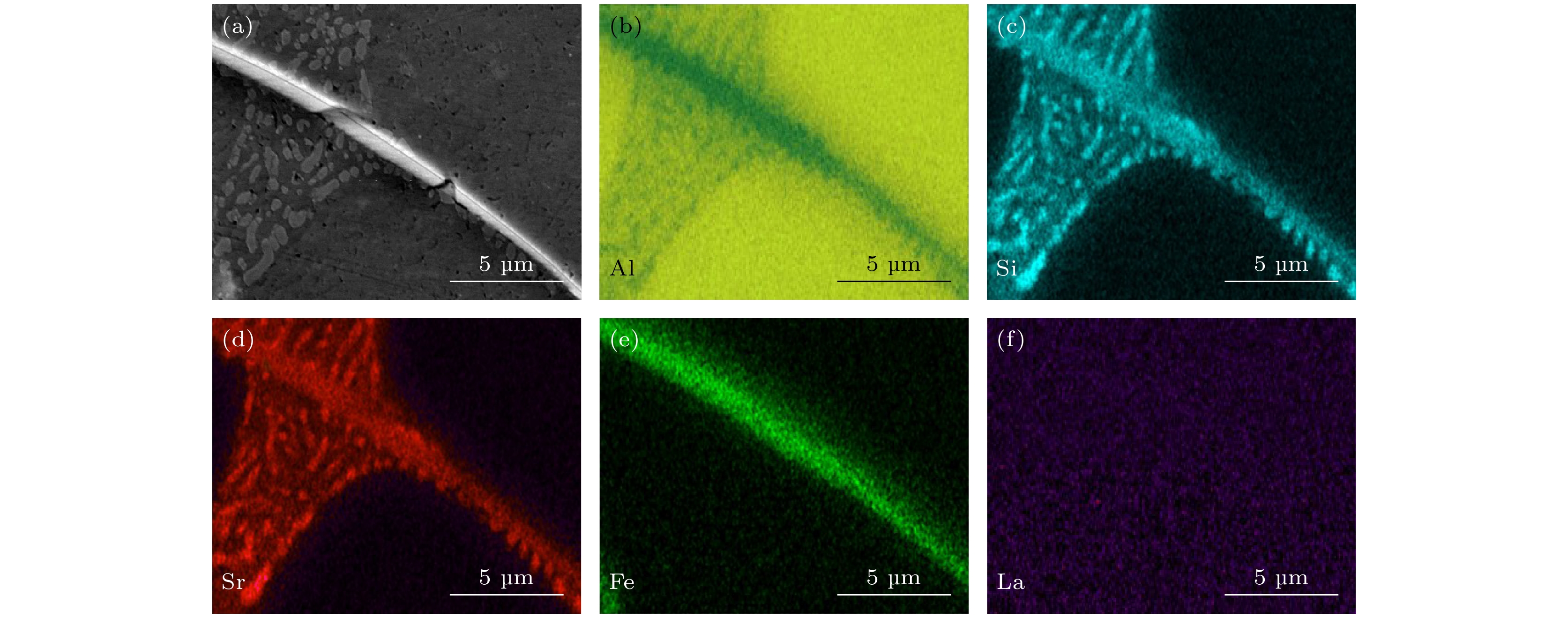

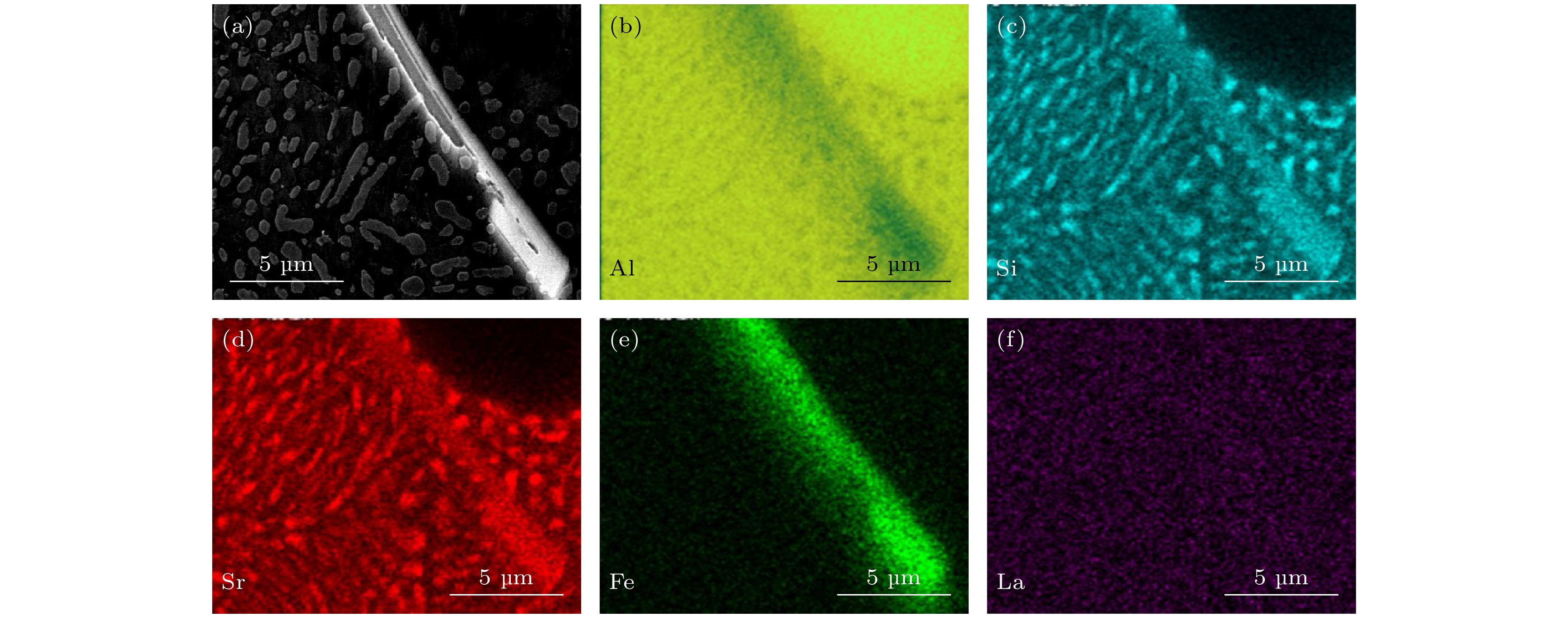

图 1 不同Sr, B, La添加量的Al-7%Si-0.6%Fe合金中共晶硅的SEM图像 (a) 0; (b) 0.024% B; (c) 0.02% Sr; (d) 0.02% Sr和0.024% B; (e) 0.02% Sr, 0.024% B和0.02% La; (f) 0.02% Sr, 0.024% B和0.1% La

Figure 1. SEM images of eutectic Si in the Al-7%Si-0.6%Fe alloys with different Sr, B and La addition: (a) 0; (b) 0.024% B; (c) 0.02% Sr; (d) 0.02% Sr and 0.024% B; (e) 0.02% Sr, 0.024% B and 0.02% La; (f) 0.02% Sr, 0.024% B and 0.1% La.

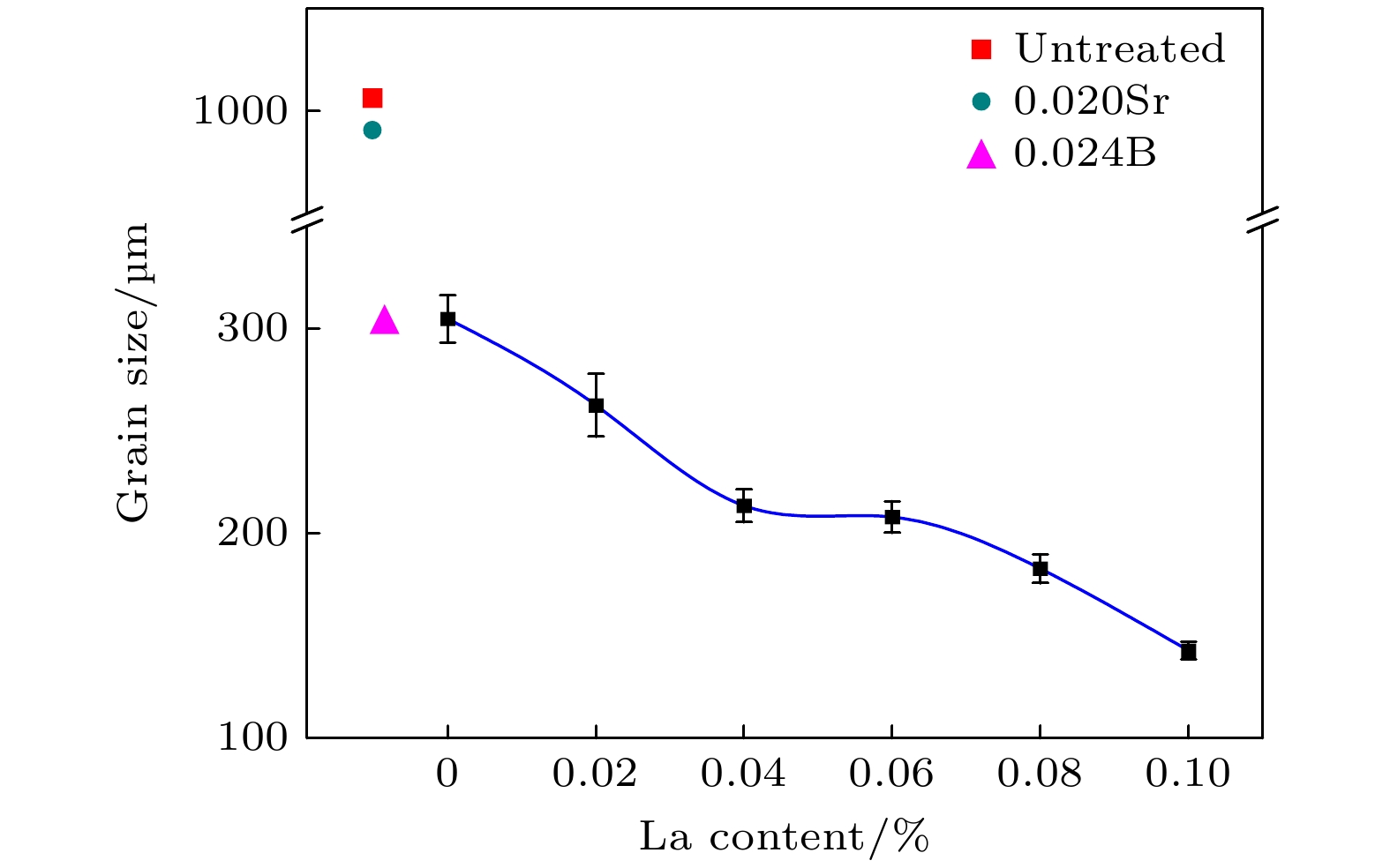

图 6 不同Sr, B, La添加量的Al-7%Si-0.6%Fe合金的OM图像 (a) 0; (b) 0.02% Sr; (c) 0.024% B; (d) 0.02% Sr和0.024% B; (e) 0.02% Sr, 0.024% B和0.02% La; (f) 0.02% Sr, 0.024% B和0.04% La; (g) 0.02% Sr, 0.024% B和0.06% La; (h) 0.02% Sr, 0.024% B和0.08% La; (i) 0.02% Sr, 0.024% B和0.10% La

Figure 6. OM images of Al-7%Si-0.6%Fe alloys with different Sr, B, La addition: (a) 0; (b) 0.02% Sr; (c) 0.024% B; (d) 0.02% Sr and 0.024% B; (e) 0.02% Sr, 0.024% B and 0.02% La; (f) 0.02% Sr, 0.024% B and 0.04% La; (g) 0.02% Sr, 0.024% B and 0.06% La; (h) 0.02% Sr, 0.024% B and 0.08% La; (i) 0.02% Sr, 0.024% B and 0.10% La.

表 1 实验合金的化学成分(%)

Table 1. Chemical compositions of alloys (%).

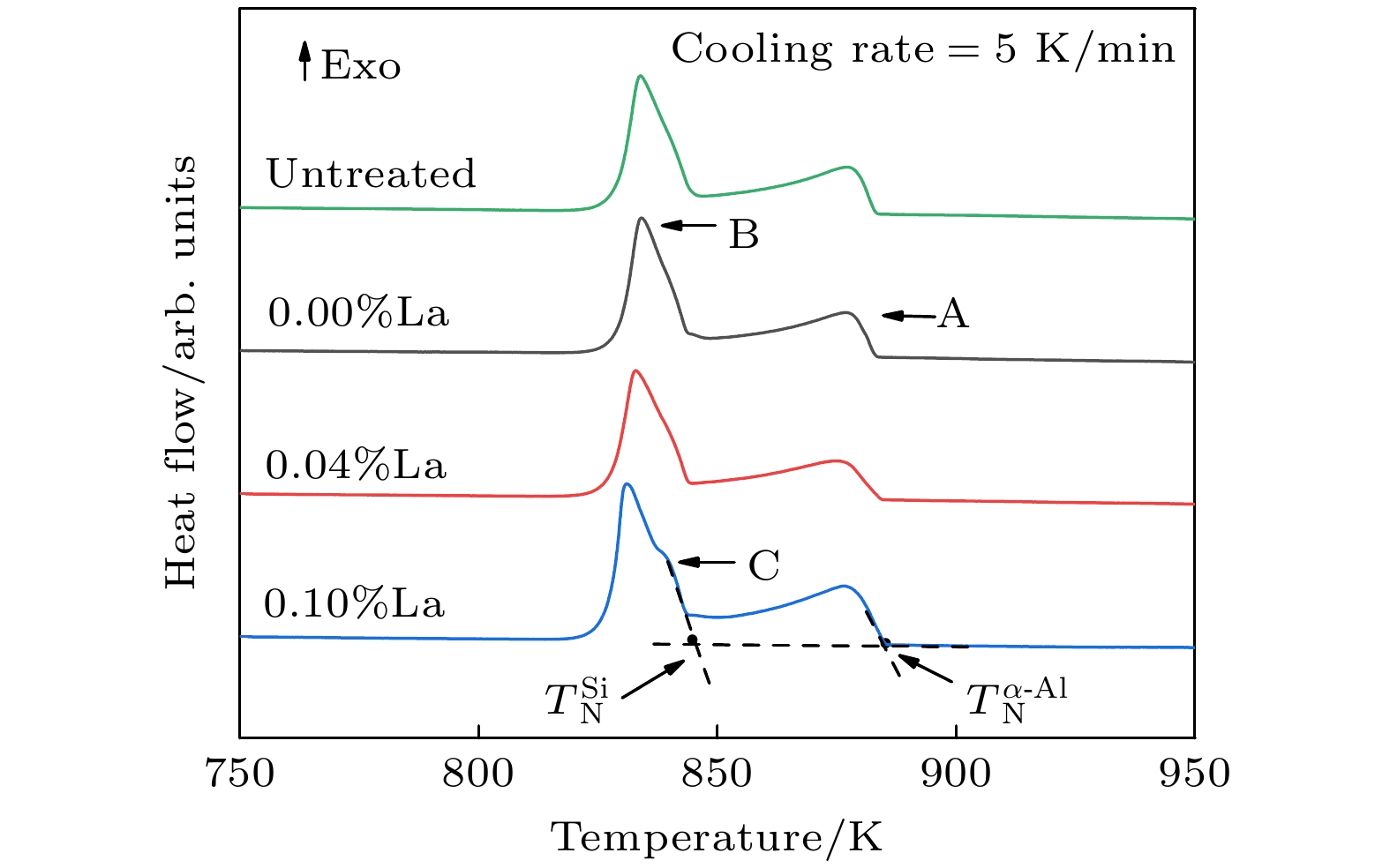

Alloy B Sr La Si Fe Al Untreated 0 0 0 7 0.6 余量 0.024%B 0.024 0 0 7 0.6 余量 0.02%Sr 0 0.02 0 7 0.6 余量 0.02%Sr+0.024%B 0.024 0.02 0 7 0.6 余量 0.02%La 0.024 0.02 0.02 7 0.6 余量 0.04%La 0.024 0.02 0.04 7 0.6 余量 0.06%La 0.024 0.02 0.06 7 0.6 余量 0.08%La 0.024 0.02 0.08 7 0.6 余量 0.10%La 0.024 0.02 0.10 7 0.6 余量 表 2 Al-7%Si-0.6%Fe合金中α-Al、共晶Si的形核温度TN和过冷度ΔT

Table 2. Change of the nucleation temperature and the nucleation undercooling for the α-Al and the eutectic Si with different La addition.

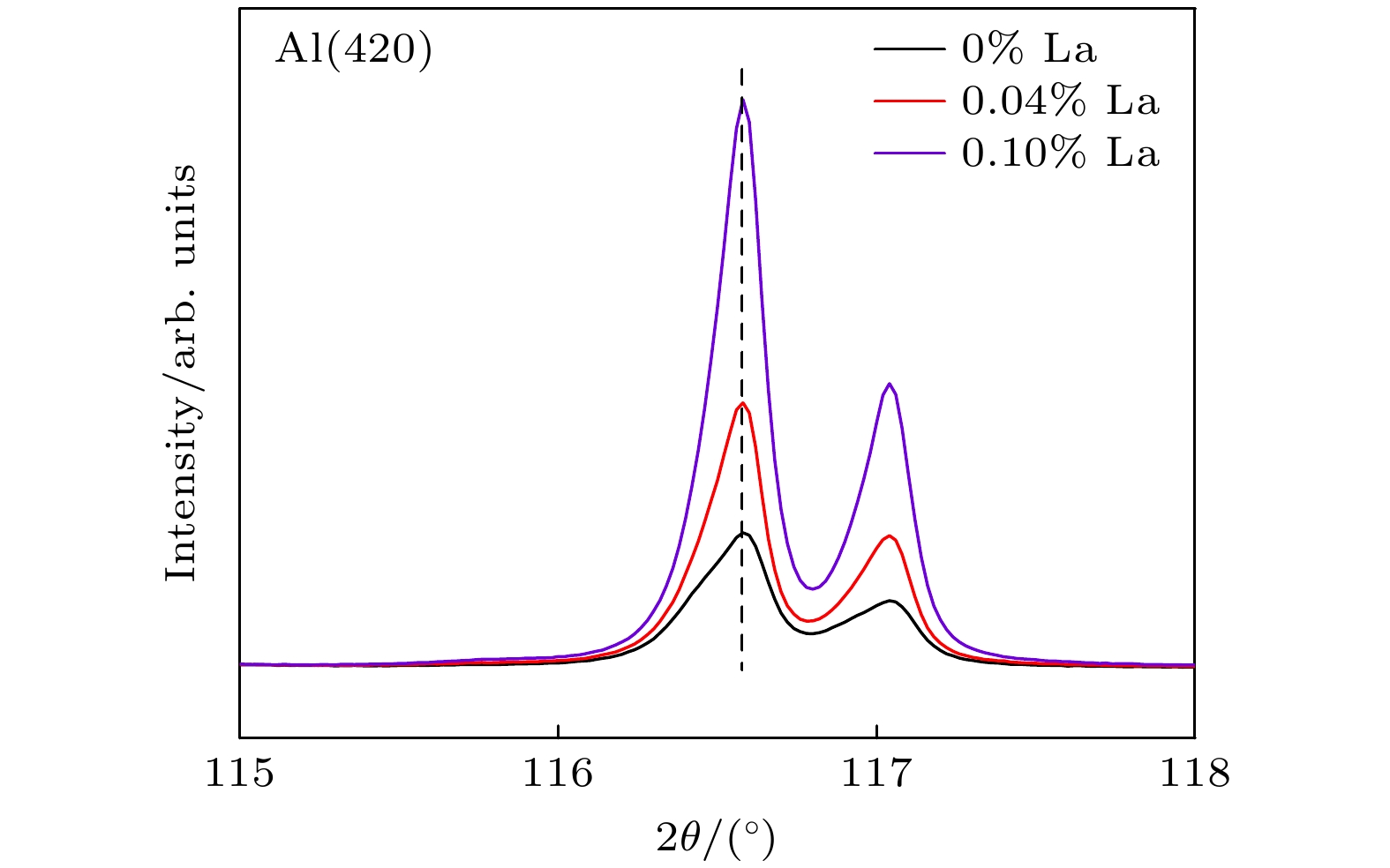

Alloy TN(α-Al)/K ΔT(α-Al)/K TN(Si)/K ΔT(Si)/K Untreated 883.1 6 846.0 1.1 0.00%La 883.1 3 844.0 3.1 0.04%La 884.2 1.9 843.8 3.3 0.10%La 885.2 0.9 843.8 3.3 Element B-Sr B-La B-Ti B-V B-Cr Enthalpy/

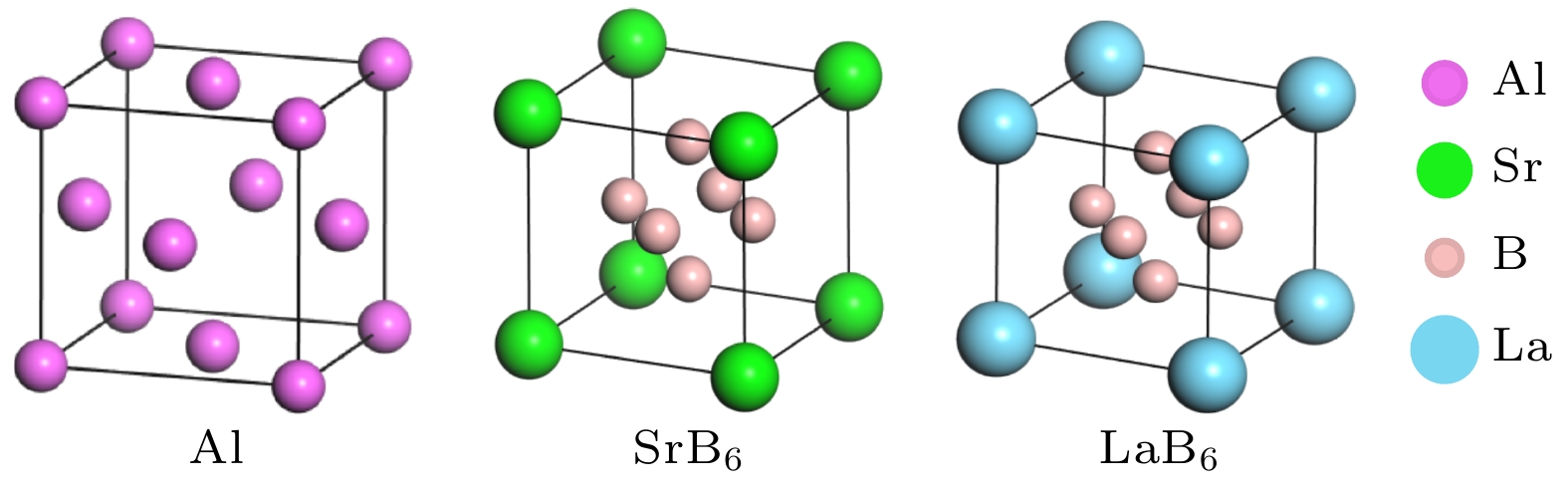

(kJ·mol–1)–18 –47 –58 –42 –31 表 4 Al与SrB6, Al与LaB6之间可能的密排和近似密排方向及其错配度

Table 4. Interatomic spacing misfit along possible matching directions between LaB6 and Al matrix, SrB6 and Al matrix.

[100]Al/ [100]SrB6 [100]Al/ [110]SrB6 [100]Al/ [111]SrB6 [110]Al/ [100]SrB6 [110]Al/ [110]SrB6 [110]Al/ [111]SrB6 [112]Al/ [100]SrB6 [112]Al/ [110]SrB6 [112]Al/ [111]SrB6 3.68% 46.63% 79.57% 26.69% 3.68% 26.98% 15.35% 19.72% 46.62% [100]Al/ [100]LaB6 [100]Al/ [110]LaB6 [100]Al/ [111]LaB6 [110]Al/ [100]LaB6 [110]Al/ [110]LaB6 [110]Al/ [111]LaB6 [112]Al/ [100]LaB6 [112]Al/ [110]LaB6 [100]Al/ [111]LaB6 2.67% 45.20% 77.82% 27.40% 2.67% 25.74% 16.17% 18.55% 45.19% 表 5 SrB6与Al, LaB6与Al之间可能的密排和近似密排面对及其错配度

Table 5. Interplanar spacing mismatch between close or nearly close packed planes in LaB6 and Al matrix, SrB6 and Al matrix.

(200)Al/ (100)SrB6 (200)Al/ (110)SrB6 (200)Al/ (111)SrB6 (220)Al/ (100)SrB6 (220)Al/ (110)SrB6 (220)Al/ (111)SrB6 (111)Al/ (100)SrB6 (111)Al/ (110)SrB6 (111)Al/ (111)SrB6 3.68% 26.70% 40.23% 46.63% 3.67% 15.47% 79.40% 26.84% 3.42% (200)Al/ (100)LaB6 (200)Al/ (110)LaB6 (200)Al/ (111)LaB6 (220)Al/ (100)LaB6 (220)Al/ (110)LaB6 (220)Al/ (111)LaB6 (111)Al/ (100)LaB6 (111)Al/ (110)LaB6 (111)Al/ (111)LaB6 2.67% 27.41% 40.73% 45.20% 2.65% 16.17% 77.65% 26.60% 2.56% -

[1] 高学鹏, 李新涛, 郄喜望, 吴亚萍, 李喜孟, 李廷举 2007 56 1188

Google Scholar

Google Scholar

Gao X P, Li X T, Qie X W, Wu Y P, Li X M, Li T J 2007 Acta Phys. Sin. 56 1188

Google Scholar

Google Scholar

[2] Dursun T, Soutis C 2014 Mater. Des. 55 862

Google Scholar

Google Scholar

[3] Kim Y M, Choi S W, KimY C 2023 J. Therm. Anal. Calorim. 140 10749

Google Scholar

Google Scholar

[4] Chen Z N, Kang H J, Fan G H, Li J H, Jie J C 2016 Acta Mater. 120 168

Google Scholar

Google Scholar

[5] 宋岩, 江鸿翔, 赵九洲, 何杰, 张丽丽, 李世欣 2021 70 086402

Google Scholar

Google Scholar

Song Y, Jiang H X, Zhao J Z, He J, Zhang L L, Li S X 2021 Acta Phys. Sin. 70 086402

Google Scholar

Google Scholar

[6] Bolzoni L, Xia M X, Babu N H 2016 Sci. Rep. 6 39554

Google Scholar

Google Scholar

[7] Ferrarini C F, Bolfarini C, Kiminami C S, Botta W J 2004 Mater. Sci. Eng. A 375 577

Google Scholar

Google Scholar

[8] Dang B, Zhang X, Chen Y Z, Chen C X, Wang H T, Liu F 2016 Sci. Rep. 6 30874

Google Scholar

Google Scholar

[9] Wang J Y, Wang B J, Huang L F 2017 Mater. Sci. Technol. 33 1235

Google Scholar

Google Scholar

[10] 王宝剑, 王建元, 吴文华, 翟薇, 王旭, 靳占奎, 魏炳波 2023 中国科学:技术科学 53 353

Wang B J, Wang J Y, Wu W H, Zhai W, Wang X, Jin Z K, Wei B B 2023 Sci. China Technol. Sci. 53 353

[11] Banerjee K, Chatterjee U K 2000 Mater. J. Mater. Sci. Technol. 16 517

Google Scholar

Google Scholar

[12] Timelli G, Caliari D, Rakhmonov J 2016 J. Mater. Sci. Technol. 32 515

Google Scholar

Google Scholar

[13] Birol Y 2012 Mater. Sci. Technol. 28 363

Google Scholar

Google Scholar

[14] Barrirero J, Engstler M, Ghafoor N 2014 J. Alloys Compd. 611 410

Google Scholar

Google Scholar

[15] Chen J K, Hung H Y, Wang C F, Tang N K 2017 Int. J. Heat Mass Transf. 105 189

Google Scholar

Google Scholar

[16] Li J H, Wang X D, Ludwig T H, Tsunekawa Y, Arnberg L, Jiang J Z 2015 Acta Mater. 84 153

Google Scholar

Google Scholar

[17] Jiang H X, Li S X, Zheng Q J, Zhang L L, He J, Song Y, Deng C K, Zhao J Z 2020 Mater. Des. 195 108991

Google Scholar

Google Scholar

[18] Zheng Q J, Jiang H X, He J, Zhang L L, Zhao J Z 2021 Sci. China Technol. Sci. 64 2012

Google Scholar

Google Scholar

[19] Jiang H X, Zheng Q J, Song Y, Li Y Q, Li S X, He J, Zhang L L, Zhao J Z 2022 Mater Charact. 185 111750

Google Scholar

Google Scholar

[20] Chen Y, Pan Y, Lu T, Tao S W, Wu J L 2014 Mater. Des. 64 432

Google Scholar

Google Scholar

[21] 郑秋菊, 叶中飞, 江鸿翔, 张丽丽, 赵九洲 2021 金属学报 57 103

Zheng Q J, Ye Z F, Jiang H X, Lu M, Zhang L L, Zhao J Z 2021 Acta Mater. Sin. 57 103

[22] Heo U, Han D W, Kim S, Mo C B 2022 Mater. Today Commun. 32 104005

Google Scholar

Google Scholar

[23] Bakhtiyarov S I, Overfelt R A, Teodorescu S G 2001 J. Mater. Sci. 36 4643

Google Scholar

Google Scholar

[24] Huang L, Gunther E, Doetsch C, Mehling H 2010 Thermochim. Acta 509 93

Google Scholar

Google Scholar

[25] Birol Y 2012 Mater. Sci. Technol. 28 70

Google Scholar

Google Scholar

[26] Cui X L, Wu Y Y, Gao T, Liu X F 2014 J. Alloys Compd. 615 906

Google Scholar

Google Scholar

[27] Lu T, Pan Y, Wu J L, Tao S W, Chen Y 2015 Int. J. Min. Met. Mater. 22 405

Google Scholar

Google Scholar

[28] Takeuchi A, Inoue A 2005 Mater. Trans. 46 2817

Google Scholar

Google Scholar

[29] Lu S Z, Hellawell A 1987 Metall. Trans. 18A 1721

[30] Li C L, Pan Y, Lu T, Jing L J, Pi J H 2018 Met. Mater. Int. 24 1133

Google Scholar

Google Scholar

[31] Luo Q, Li X L, Li Q 2023 J. Mater. Sci. Technol. 135 97

Google Scholar

Google Scholar

[32] Zhang M X, Kelly P M 2005 Scr. Mater. 52 963

Google Scholar

Google Scholar

[33] Jing L J, Pan Y, Lu T, Pi J H, Gu T F 2018 T. Nonferr. Metal. Soc. 28 1687

Google Scholar

Google Scholar

[34] Easton M A, StJohn D H 2001 130th TMS Annual Meeting New Orleans, La, February 11–15, 2000 p927

[35] Zhou S H, Napolitano R E 2006 Acta Mater. 54 831

Google Scholar

Google Scholar

[36] Zhang L L, Jiang H X, He J, Zhao J Z 2020 Scr. Mater. 179 99

Google Scholar

Google Scholar

[37] Li S B, Du W B, Wang X D 2018 Acta Metall. Sin. 54 911

Google Scholar

Google Scholar

[38] Hou J P, Wang Q, Zhang Z J, Tian Y Z, Wu X M, Yang H J, Li X W, Zhang Z F 2017 Mater. Des. 132 148

Google Scholar

Google Scholar

[39] Mayadas A F, Shatzkes M 1970 Phys.Rev.B. 1 1382

Google Scholar

Google Scholar

[40] Weng W P, Nagaumi H, Sheng X D, Fan W Z, Chen X C, Wang X N 2019 Light Metals Symposium at the 148th TMS Annual Meeting San Antonio, TX, March 10–12, 2019 p193

[41] Sauvage X, Bobruk E V, Murashkin M Y 2015 Acta Mater. 98 355

Google Scholar

Google Scholar

[42] Ma S M, Wang X M 2019 Mater. Sci. Eng. A 754 46

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4743

- PDF Downloads: 95

- Cited By: 0

DownLoad:

DownLoad: