-

Hydrogen, as one of the most well-developed green energy materials, has played an important role in industrial development, human production and life, and the treatment of diseases in recent years. Hydrogen sensor is an important safety monitoring equipment in chemical production. Developing long-term and efficient hydrogen gas sensor for real-time monitoring has become increasingly important and urgent. Hydrogen, as one of the main combustible gases present in the petrochemical production process, is of great research significance and challenging in meeting the need of cycling gas identification and highly sensitive detection. Therefore, it is of great practical value to develop the low-cost, low-power and highly sensitive miniature hydrogen gas sensors . In this work, a gold-doped tin dioxide nanostructured ultra-sensitive and highly specific micro-nanosensor is obtained based on the in-situ synthesis of micro-hot plates. It is shown that the sensitivity of this nanosensor is as high as 100 for hydrogen at 50 ppm, and the sensitivity of ethanol, an important interference gas, is only 1/22 of that of hydrogen at the same concentration, which has an obvious suppression effect. For the same concentration of carbon monoxide, methane and other interference gases do not show any response. XPS characterization shows that the defective oxygen ratio of the material is the main reason for the ultra-sensitivity of the sensor. Meanwhile, in this study, the precursor solution of gold-doped tin dioxide is prepared by using chloroauric acid and tin tetrachloride crystals as raw materials; the nanosized morphology structure is prepared by templating the generation of sensitive materials using polystyrene microspheres; the in-situ synthesis method is realized by applying a voltage to the calcination of a micro hot plate. Through this nanoscale templating in-situ heating method, a gold-loaded tin dioxide nanosensor is prepared. Note that the template assisted in-situ grown

$ {\mathrm{A}}{\mathrm{u}} $ loaded Tin Oxide nano sensor is abbreviated as$ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{Au}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ Sensor . In order to illustrate the sensing mechanism, we analyze the elemental compositions, and the results show that under the condition of the high defective oxygen content, the in-situ heating method of templated preparation of$ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ nano-sensor containing arrays of polystyrene spheres becomes an important reason for the ultra-sensitivity to hydrogen, high specificity, and the suppression of the important interfering gas, ethanol. Moreover, the in situ preparation method can be flexibly and scalably used to prepare high-performance miniaturized gas sensors with a variety of hollow-sphere nanostructured metal oxides, in order to obtain excellent sensitivity and adjustable selectivity.-

Keywords:

- in-situ growth /

- ultra sensitive /

- gas sensors

[1] Kim D, Kim S, Shin H, Koo W, Jang J, Kang J, Jeong Y J, Kim I 2019 ACS Nano 13 6071

Google Scholar

Google Scholar

[2] Hung P S, Chou Y S, Huang B H, Cheng I K, Wang G R, Chung W A, Pan F M, Wu P W 2020 Sens. Actuat. B Chem. 325 128779

Google Scholar

Google Scholar

[3] Han M, Kim J K, Lee J, An H K, Yun J P, Kang S W, Jung D 2020 J. Nanosci. Nanotechnol. 20 4470

Google Scholar

Google Scholar

[4] Yi J X, Zhang H, Zhang Z B, Chen D D 2018 Sens. Actuat. B Chem. 268 456

Google Scholar

Google Scholar

[5] Okazaki S, Kawada H, Koshiba Y, Kasai N, Maru Y, Mizutani T, Takesaki Y, Shimano S 2023 Int. J. Hydrogen Energy 48 9512

Google Scholar

Google Scholar

[6] Dinh T, Choi I, Son Y, Kim J 2016 Sens. Actuat. B Chem. 231 529

Google Scholar

Google Scholar

[7] Ahmed S, Sinha S K 2022 Environ. Sci. Pollut. Res. 30 24975

Google Scholar

Google Scholar

[8] Wang F, Hu K, Liu H, Zhao Q, Wang K, Zhang Y 2020 Int. J. Hydrogen Energy 45 7234

Google Scholar

Google Scholar

[9] Zhou Q, Sussman A, Chang J, Dong J, Zettl A, Mickelson W 2015 Sens. Actuat. A 223 67

Google Scholar

Google Scholar

[10] Wang J, Yang J, Chen D, Jin L, Li Y, Zhang Y, Xu L, Guo Y, Lin F, Wu F 2018 IEEE Sens. J. 18 6765

Google Scholar

Google Scholar

[11] Bai H N, Guo H, Wang J, Dong Y, Liu B, Guo F Q, Chen D J, Zhang R, Zheng Y D 2021 Sens. Actuat. B Chem. 331 129441

Google Scholar

Google Scholar

[12] Hu J, Zhang T, Chen Y, Xu P, Zheng D, Li X 2022 Nanomaterials 12 1001

Google Scholar

Google Scholar

[13] Zhu Z, Xing X, Feng D, Li Z, Tian Y, Yang D 2021 Nanoscale 13 12669

Google Scholar

Google Scholar

[14] Chen D L, Hou X X, Li T, Yin L, Fan B B, Wang H L, Li X J, Xu H L, Lu H X, Zhang R, Sun J 2011 Sens. Actuat. B Chem. 153 373

Google Scholar

Google Scholar

[15] Luo X, Lou Z, Wang L, Zheng X, Zhang T 2014 New J. Chem. 38 84

Google Scholar

Google Scholar

[16] Zhang Z L, Yin C B, Yang L, Jiang J, Guo Y 2019 J. Alloys Compd. 785 819

Google Scholar

Google Scholar

[17] Meng X N, Bi M, Xiao Q, Gao W 2022 Int. J. Hydrogen Energy 47 3157

Google Scholar

Google Scholar

[18] Wang Y, Zhao Z T, Sun Y J, Li P W, Ji J L, Chen Y, Zhang W D, Hu J 2017 Sens. Actuat. B Chem. 240 664

Google Scholar

Google Scholar

[19] Algamili A S, Khir M H M, Dennis J O, Ahmed A Y, Alabsi S S, Ba Hashwan S S, Junaid M M 2021 Nanoscale Res. Lett. 16 16

Google Scholar

Google Scholar

[20] Rao A, Long H, Harley-Trochimczyk A, Pham T, Zettl A, Carraro C, Maboudian R 2017 ACS Appl. Mater. Interfaces 9 2634

Google Scholar

Google Scholar

[21] Zhang S M, Zhang P P, Wang Y, Ma Y Y, Zhong J, Sun X H 2014 ACS Appl. Mater. Interfaces 6 14975

Google Scholar

Google Scholar

[22] Moulder J F, Chastain J, King R C 1992 Chem. Phys. Lett. 220 7

[23] Zhang P, Sham T K 2003 Phys. Rev. Lett. 90 243001

Google Scholar

Google Scholar

[24] Liu X Y, Liu M H, Luo Y C, Mou C Y, Lin S D, Cheng H K, Chen J M, Lee J F, Lin T S 2012 J. Am. Chem. Soc. 134 10251

Google Scholar

Google Scholar

-

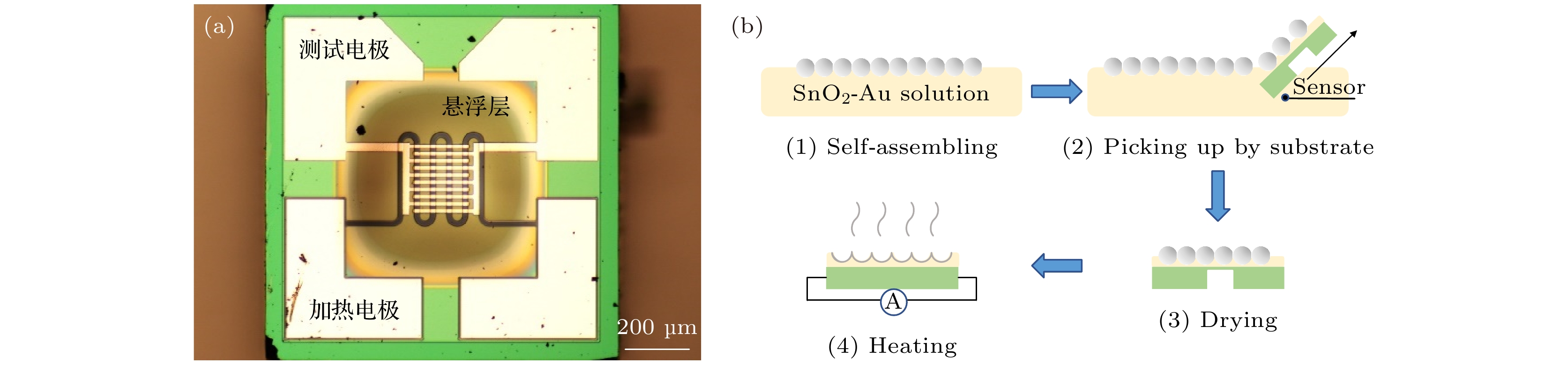

图 1 (a)微热板芯片的光学显微镜图; (b)模板化原位加热制备$ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $传感器, 其中, (1)小球自组装在前驱体溶液表面形成单层PS小球模板, (2)将微热板芯片以10°—20°的角度对含有PS小球阵列的前驱体溶液进行拾取, (3)将微热板芯片在室温下进行干燥, (4)原位加热微热板芯片至4.5 V(550 ℃)得到纳米碗状结构

Figure 1. (a) Optical microscope image of micro hot plate chip; (b) preparation of $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ sensor by templated in-situ synthesis: (1) The spheres self-assemble on the surface of the precursor solution to form a monolayer PS sphere template, (2) pick up the micro hot plate chip at an angle of 10°–20° to the precursor solution containing the PS sphere array, (3) dry the microplate chip at room temperature, (4) in-situ heating of microhotplate chips to 4.5 V (550 ℃) to obtain a nanobowl-like structures.

图 2 含有PS小球阵列模板法原位加热的$ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $前驱体材料的SEM图 (a)位于敏感材料表面的PS小球原位加热之前的排列图; (b)位于敏感材料表面的PS小球原位加热后得到纳米碗状的结构图

Figure 2. SEM images of $ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ precursor material containing PS sphere array template method synthesized in-situ: (a) The arrangement of PS spheres located on the surface of sensitive material before in-situ heating; (b) the nano-bowl-like structure obtained after in-situ heating of PS spheres located on the surface of sensitive material.

图 3 $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ 传感器及3种参考传感器在最佳工作温度下对浓度50 ppm氢气的响应结果图 (a) $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ 传感器, 含有PS小球阵列模板法原位加热的$ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $纳米传感器; (b)参考传感器1, 含有PS小球阵列模板法管式炉煅烧的$ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $纳米传感器; (c)参考传感器2, 含有PS小球阵列模板法原位加热的纯$ {{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $纳米传感器; (d)参考传感器3, 原位加热的$ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $纳米传感器

Figure 3. The response of the $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ sensor and three reference sensors to 50 ppm hydrogen at optimum operating temperature: (a) $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ sensor, in-situ synthesis of $ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ nanosensor containing PS sphere array template method; (b) reference sensor 1, $ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ nanosensor containing PS pellet array template method of tube furnace calcination; (c) reference sensor 2, pure $ {{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ nanosensor containing PS pellet array template method of in-situ synthesis; (d) reference sensor 3: $ {\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ nanosensor of in-situ synthesis.

图 4 TIS-Au-$ {{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ 传感器及3种参考传感器对50 ppm氢气及3种常见的石化背景下干扰气体的选择性对比图

Figure 4. Comparison of the selectivity of the TIS-Au-$ {{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ sensor and three reference sensors for 50 ppm hydrogen and three common interfering gases in a petrochemical background.

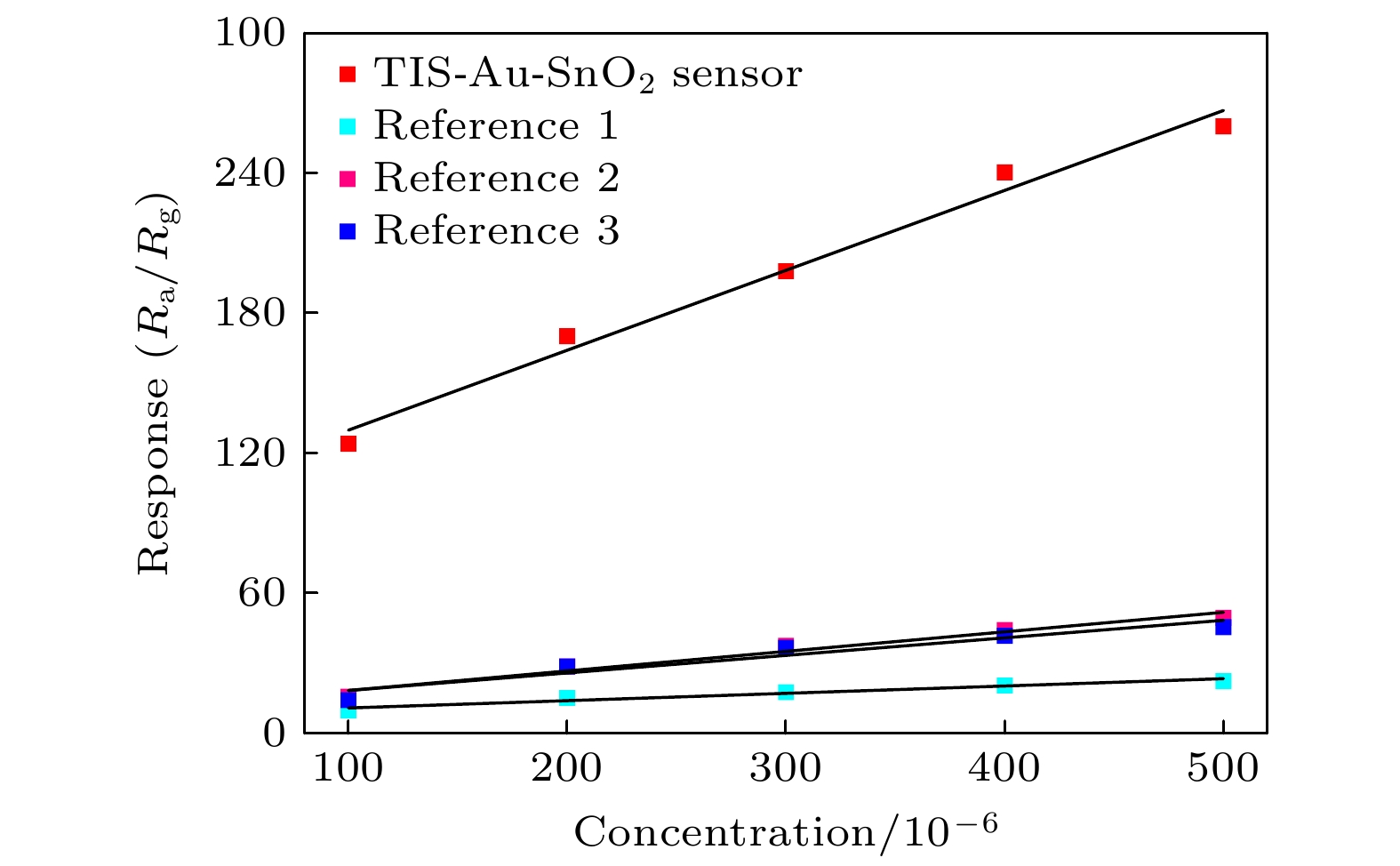

图 5 $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ 传感器及3种参考传感器在浓度范围为100—500 ppm氢气之间的线性响应范围

Figure 5. The linear response of the $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ sensor and three reference sensors in the concentration range of 100–500 ppm hydrogen.

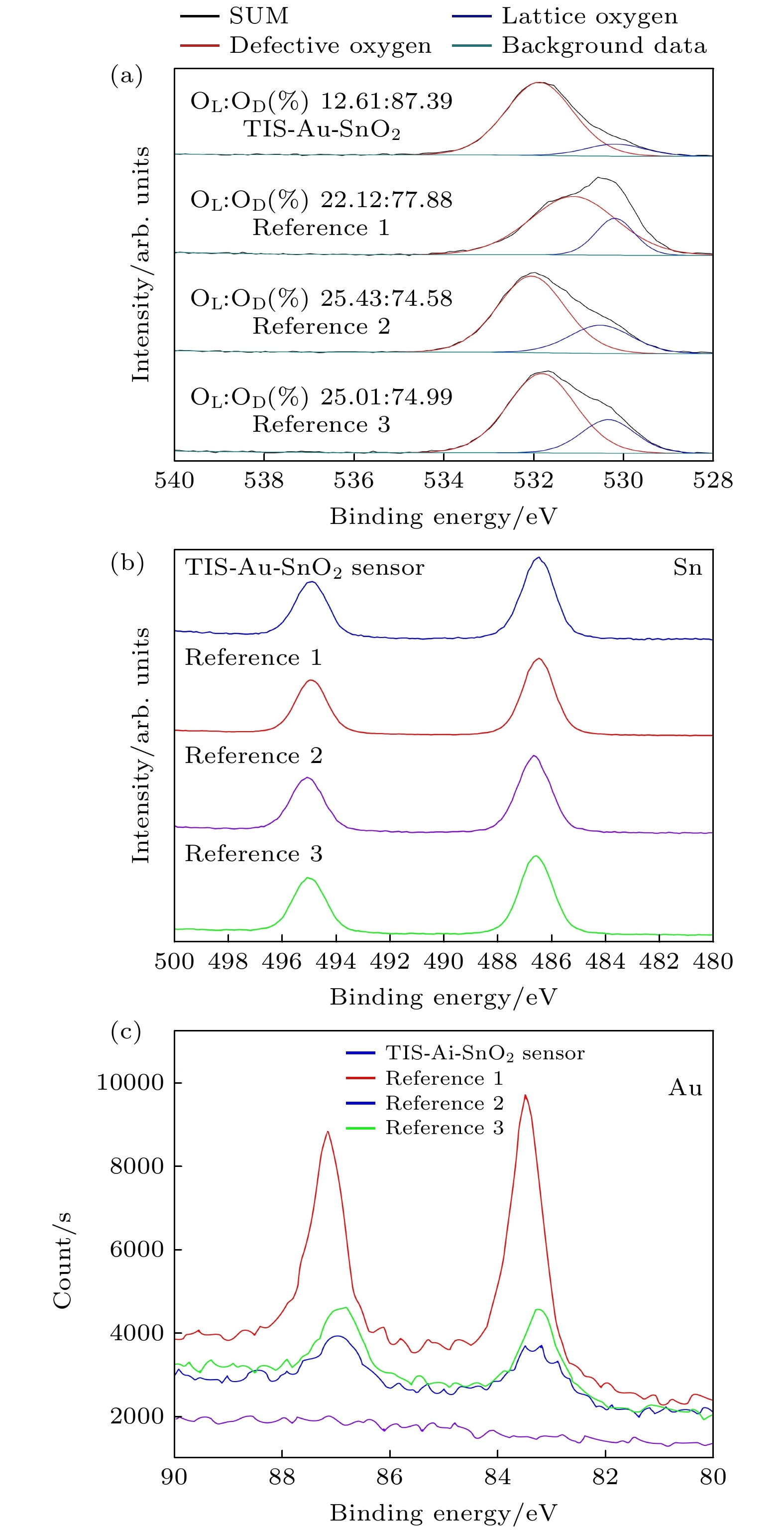

图 6 $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ 传感器及3种参考传感器在不同区域的XPS光谱 (a) O区域; (b) Sn区域; (c) Au区域

Figure 6. XPS spectra of $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $ Sensor and three reference sensor in different regions: (a) O region; (b) Sn region; (c) Au region.

表 1 不同传感器的性能结果比较

Table 1. Comparison of performance results for different sensors.

传感器 最佳工作温度/℃ 对50 ppm氢气的灵敏响应度 特异性(氢气: 乙醇) 100—500 ppm氢气的线性灵敏度/ppm $ {\mathrm{T}}{\mathrm{I}}{\mathrm{S}}\text{-}{\mathrm{A}}{\mathrm{u}}\text{-}{{\mathrm{S}}{\mathrm{n}}{\mathrm{O}}}_{2} $传感器 300 100 22 34/100 参考传感器1 300 8.9 4.2 3/100 参考传感器2 400 8.7 2.2 8/100 参考传感器3 350 10 2.5 7/100 -

[1] Kim D, Kim S, Shin H, Koo W, Jang J, Kang J, Jeong Y J, Kim I 2019 ACS Nano 13 6071

Google Scholar

Google Scholar

[2] Hung P S, Chou Y S, Huang B H, Cheng I K, Wang G R, Chung W A, Pan F M, Wu P W 2020 Sens. Actuat. B Chem. 325 128779

Google Scholar

Google Scholar

[3] Han M, Kim J K, Lee J, An H K, Yun J P, Kang S W, Jung D 2020 J. Nanosci. Nanotechnol. 20 4470

Google Scholar

Google Scholar

[4] Yi J X, Zhang H, Zhang Z B, Chen D D 2018 Sens. Actuat. B Chem. 268 456

Google Scholar

Google Scholar

[5] Okazaki S, Kawada H, Koshiba Y, Kasai N, Maru Y, Mizutani T, Takesaki Y, Shimano S 2023 Int. J. Hydrogen Energy 48 9512

Google Scholar

Google Scholar

[6] Dinh T, Choi I, Son Y, Kim J 2016 Sens. Actuat. B Chem. 231 529

Google Scholar

Google Scholar

[7] Ahmed S, Sinha S K 2022 Environ. Sci. Pollut. Res. 30 24975

Google Scholar

Google Scholar

[8] Wang F, Hu K, Liu H, Zhao Q, Wang K, Zhang Y 2020 Int. J. Hydrogen Energy 45 7234

Google Scholar

Google Scholar

[9] Zhou Q, Sussman A, Chang J, Dong J, Zettl A, Mickelson W 2015 Sens. Actuat. A 223 67

Google Scholar

Google Scholar

[10] Wang J, Yang J, Chen D, Jin L, Li Y, Zhang Y, Xu L, Guo Y, Lin F, Wu F 2018 IEEE Sens. J. 18 6765

Google Scholar

Google Scholar

[11] Bai H N, Guo H, Wang J, Dong Y, Liu B, Guo F Q, Chen D J, Zhang R, Zheng Y D 2021 Sens. Actuat. B Chem. 331 129441

Google Scholar

Google Scholar

[12] Hu J, Zhang T, Chen Y, Xu P, Zheng D, Li X 2022 Nanomaterials 12 1001

Google Scholar

Google Scholar

[13] Zhu Z, Xing X, Feng D, Li Z, Tian Y, Yang D 2021 Nanoscale 13 12669

Google Scholar

Google Scholar

[14] Chen D L, Hou X X, Li T, Yin L, Fan B B, Wang H L, Li X J, Xu H L, Lu H X, Zhang R, Sun J 2011 Sens. Actuat. B Chem. 153 373

Google Scholar

Google Scholar

[15] Luo X, Lou Z, Wang L, Zheng X, Zhang T 2014 New J. Chem. 38 84

Google Scholar

Google Scholar

[16] Zhang Z L, Yin C B, Yang L, Jiang J, Guo Y 2019 J. Alloys Compd. 785 819

Google Scholar

Google Scholar

[17] Meng X N, Bi M, Xiao Q, Gao W 2022 Int. J. Hydrogen Energy 47 3157

Google Scholar

Google Scholar

[18] Wang Y, Zhao Z T, Sun Y J, Li P W, Ji J L, Chen Y, Zhang W D, Hu J 2017 Sens. Actuat. B Chem. 240 664

Google Scholar

Google Scholar

[19] Algamili A S, Khir M H M, Dennis J O, Ahmed A Y, Alabsi S S, Ba Hashwan S S, Junaid M M 2021 Nanoscale Res. Lett. 16 16

Google Scholar

Google Scholar

[20] Rao A, Long H, Harley-Trochimczyk A, Pham T, Zettl A, Carraro C, Maboudian R 2017 ACS Appl. Mater. Interfaces 9 2634

Google Scholar

Google Scholar

[21] Zhang S M, Zhang P P, Wang Y, Ma Y Y, Zhong J, Sun X H 2014 ACS Appl. Mater. Interfaces 6 14975

Google Scholar

Google Scholar

[22] Moulder J F, Chastain J, King R C 1992 Chem. Phys. Lett. 220 7

[23] Zhang P, Sham T K 2003 Phys. Rev. Lett. 90 243001

Google Scholar

Google Scholar

[24] Liu X Y, Liu M H, Luo Y C, Mou C Y, Lin S D, Cheng H K, Chen J M, Lee J F, Lin T S 2012 J. Am. Chem. Soc. 134 10251

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 3200

- PDF Downloads: 61

- Cited By: 0

DownLoad:

DownLoad: