-

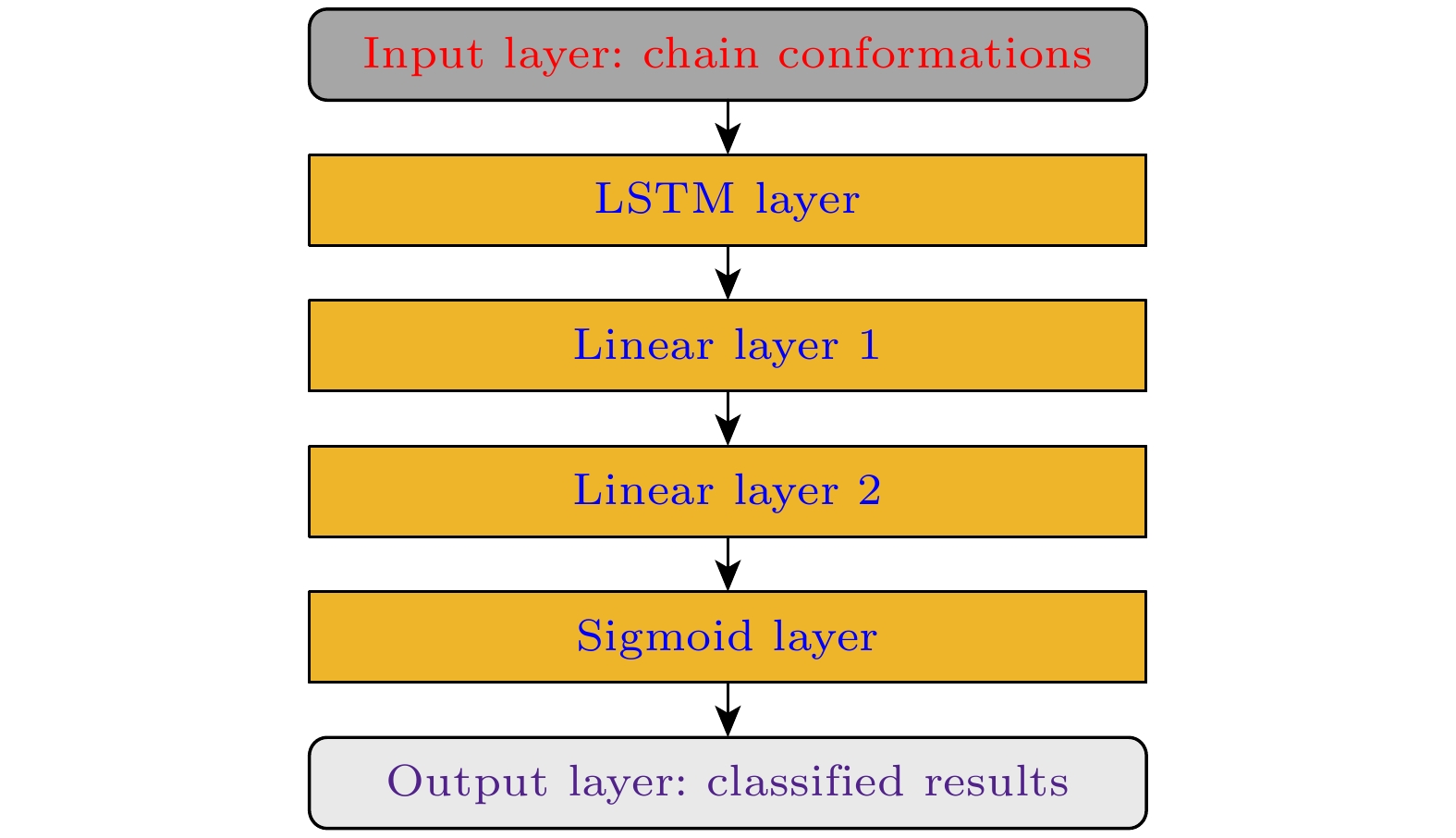

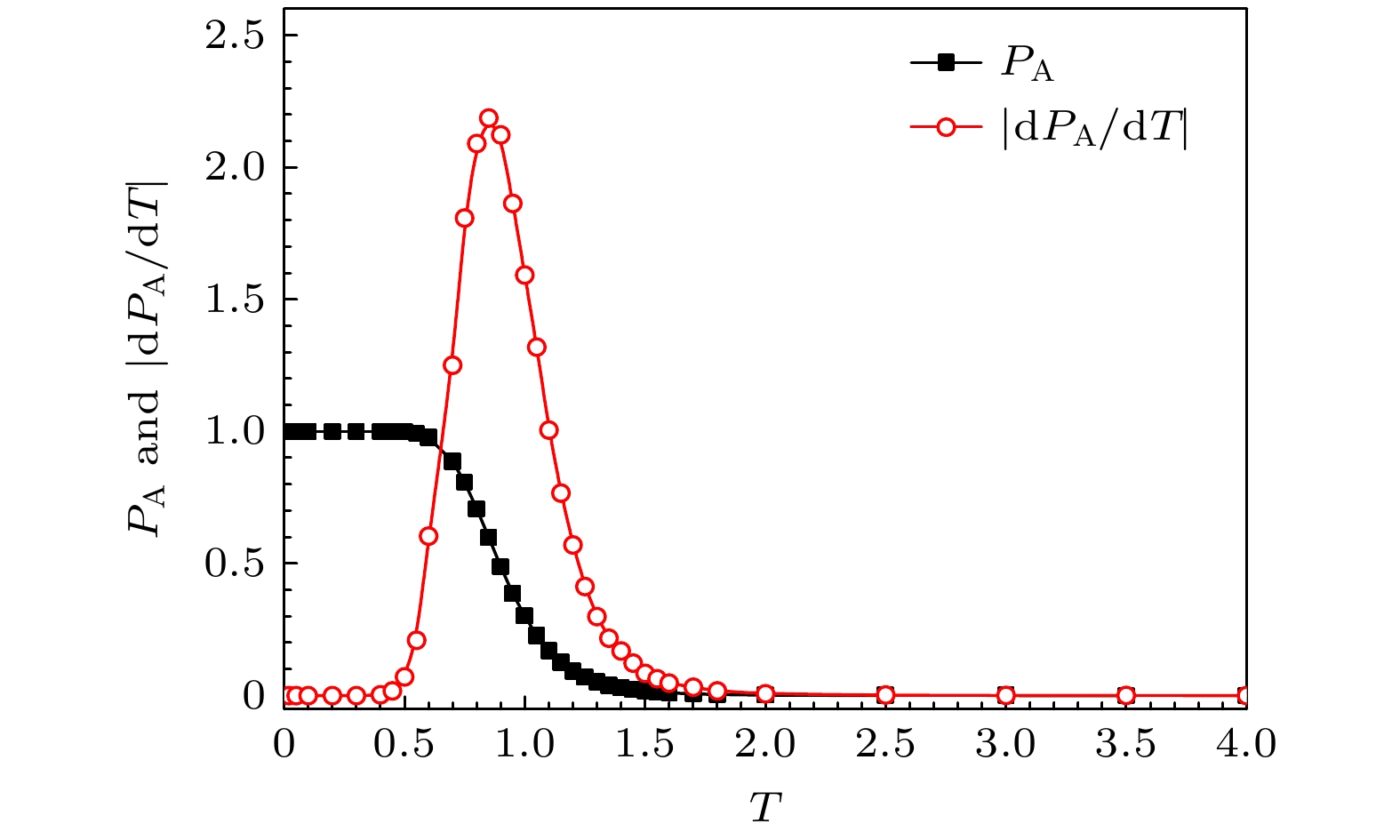

Collapse and critical adsorption of polymers are two crucial phase transitions in polymer science, both are accompanied by significant changes in polymer conformation. In this paper, Langevin dynamics and dynamic Monte Carlo methods are used to simulate the collapse and critical adsorption of polymer, respectively, and corresponding phase transition temperatures are estimated. Meanwhile, a large number of polymer conformations at different temperatures are obtained. In the machine learning method, a large number of extended random coil and collapsed spherical, desorption and adsorption conformations are used to train the neural network, so that the neural network can learn the characteristics of different states of the polymer, and it can quickly and accurately analyze the polymer conformations at different temperatures and obtain the corresponding collapse phase transition temperature and critical adsorption temperature. The results demonstrate that machine learning can correctly calculate the phase transition temperature of polymer system, which provides new ideas and methods for machine learning technology in the study of polymer phase transitions.

-

Keywords:

- polymer /

- collapse /

- critical adsorption /

- machine learning

[1] Hinton G, Deng L, Yu D, et al. 2012 IEEE Signal Process. Mag. 29 82

Google Scholar

Google Scholar

[2] Silver D, Huang A, Maddison C J, et al. 2016 Nature 529 484

Google Scholar

Google Scholar

[3] Umehara M, Stein H S, Guevarra D, et al. 2019 NPJ Comput. Mater. 5 34

Google Scholar

Google Scholar

[4] Iwasaki Y, Takeuchi I, Stanev V, et al. 2019 Sci. Rep. 9 2751

Google Scholar

Google Scholar

[5] 陈江芷, 杨晨温, 任捷 2021 70 144204

Google Scholar

Google Scholar

Chen J Z, Yang C W, Ren J 2021 Acta Phys. Sin. 70 144204

Google Scholar

Google Scholar

[6] Cencer M M, Moore J S, Assary R S 2022 Polym. Int. 71 537

Google Scholar

Google Scholar

[7] Zhang Y, Xu X 2021 J. Mol. Graphics Modell. 103 107796

Google Scholar

Google Scholar

[8] Liang Z, Li Z, Zhou S, et al. 2022 Cell Reports Physical Science 3 100931

Google Scholar

Google Scholar

[9] Zhang K, Li X, Jin Y, Jiang Y 2022 Soft Matter 18 6270

Google Scholar

Google Scholar

[10] Xu Y, Wang Z G 2021 Macromolecules 54 10984

Google Scholar

Google Scholar

[11] Milner S T 1991 Science 251 905

Google Scholar

Google Scholar

[12] Besteman K, Lee J O, Wiertz F G M, Heering H A, Dekker C 2003 Nano Lett. 3 727

Google Scholar

Google Scholar

[13] Duan X, Zhang R, Ding M, Huang Q, Xu W S, Shi T, An L 2017 Polymer 122 125

Google Scholar

Google Scholar

[14] Sumithra K, Brandau M, Straube E 2009 J. Chem. Phys. 130 234901

Google Scholar

Google Scholar

[15] Li Y W, Wüst T, Landau D P 2013 Phys. Rev. E 87 012706

Google Scholar

Google Scholar

[16] Yang Q H, Wu F, Wang Q, Luo M B 2016 J. Polym. Sci. Part B: Polym. Phys. 54 2359

Google Scholar

Google Scholar

[17] Ziebarth J D, Gardiner A A, Wang Y M, Jeong Y, Ahn J, Jin Y, Chang T 2016 Macromolecules 49 8780

Google Scholar

Google Scholar

[18] Bhattacharya D, Patra T K 2021 Macromolecules 54 3065

Google Scholar

Google Scholar

[19] Nguyen T, Bavarian M 2022 Ind. Eng. Chem. Res. 61 12690

Google Scholar

Google Scholar

[20] Weeks J D, Chandler D, Andersen H C 1971 J. Chem. Phys. 54 5237

Google Scholar

Google Scholar

[21] Chremos A, Glynos E, Koutsos V, Camp P J 2009 Soft Matter 5 637

Google Scholar

Google Scholar

[22] Hochreiter S, Schmidhuber J A 1997 Neural Comput. 9 1735

Google Scholar

Google Scholar

[23] Loshchilov I, Hutter F 2017 arXiv:1711.05101 [cs.LG

[24] Luo M B, Tsehay D A, Sun L Z 2017 J. Chem. Phys. 147 034901

Google Scholar

Google Scholar

[25] Yang X, Wu F, Hu D D, Zhang S, Luo M B 2019 Chin. Phys. Lett. 36 098202

Google Scholar

Google Scholar

[26] Qi H K, Yang X, Yang Q H, Luo M B 2022 Polymer 259 125330

Google Scholar

Google Scholar

-

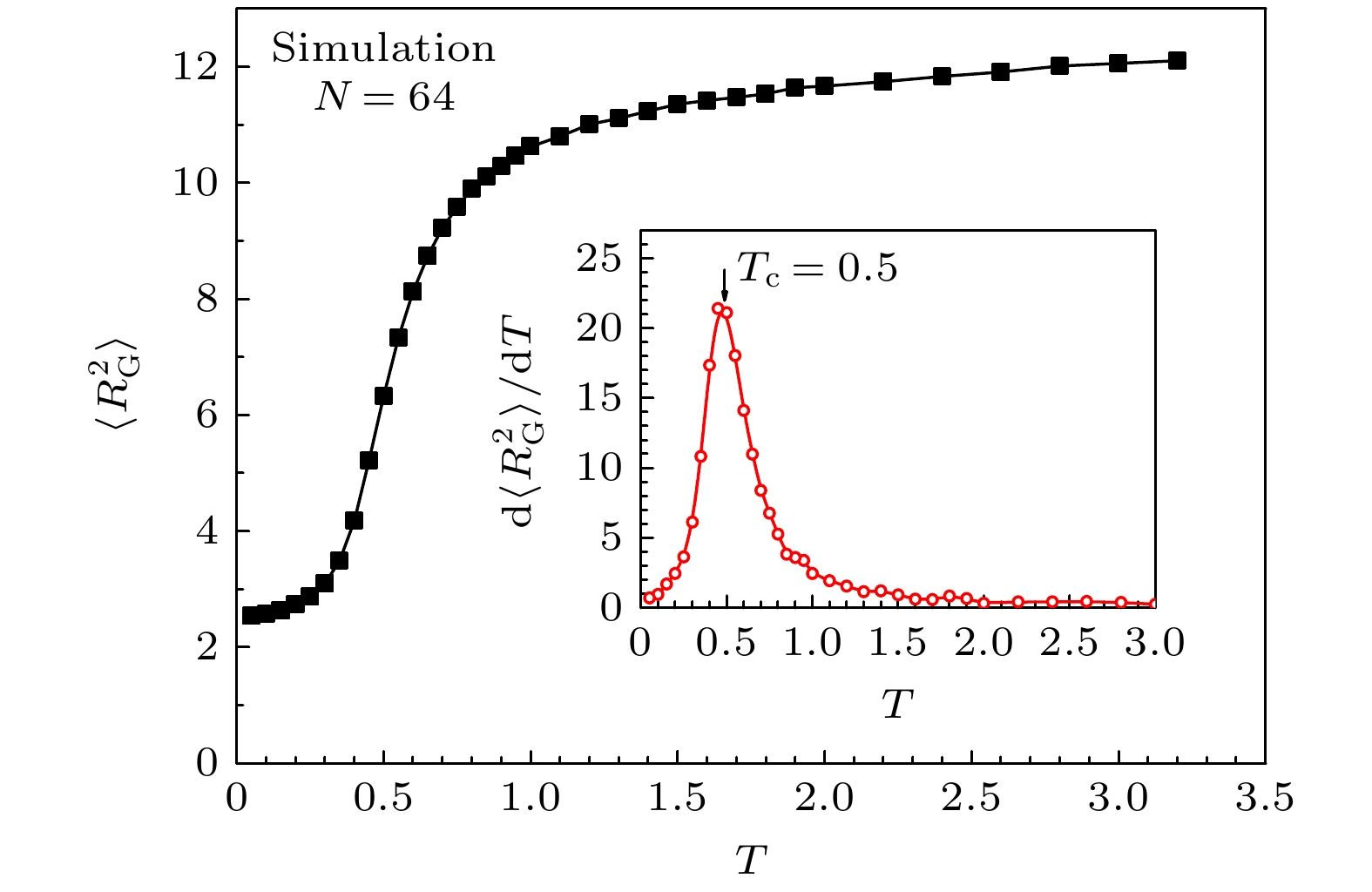

图 4 高分子均方回转半径$ \left\langle{{R}_{{\mathrm{G}}}^{2}}\right\rangle $与温度T的关系的朗之万动力学模拟结果. 插图给出了$ \left\langle{{R}_{{\mathrm{G}}}^{2}}\right\rangle $对T的导数与T的关系

Figure 4. Simulation results of the mean square radius of gyration $ \left\langle{{R}_{{\mathrm{G}}}^{2}}\right\rangle $ versus temperature T. The inset presents the $ \left\langle{{R}_{{\mathrm{G}}}^{2}}\right\rangle $ derivative of T in relation to T.

图 5 高分子平方回转半径$ {R}_{{\mathrm{G}}}^{2} $在温度T = 0.01 (a), 0.5 (b)和3.2 (c)的概率分布. 插图分别给出了T = 0.01 和 3.2 时高分子的典型构象

Figure 5. Plots of the probability distribution of square radius of gyration $ {R}_{{\mathrm{G}}}^{2} $ for polymer at temperatures T = 0.01 (a), 0.5 (b), and 3.2 (c). The insets show the typical polymer conformations at T = 0.01 and 3.2.

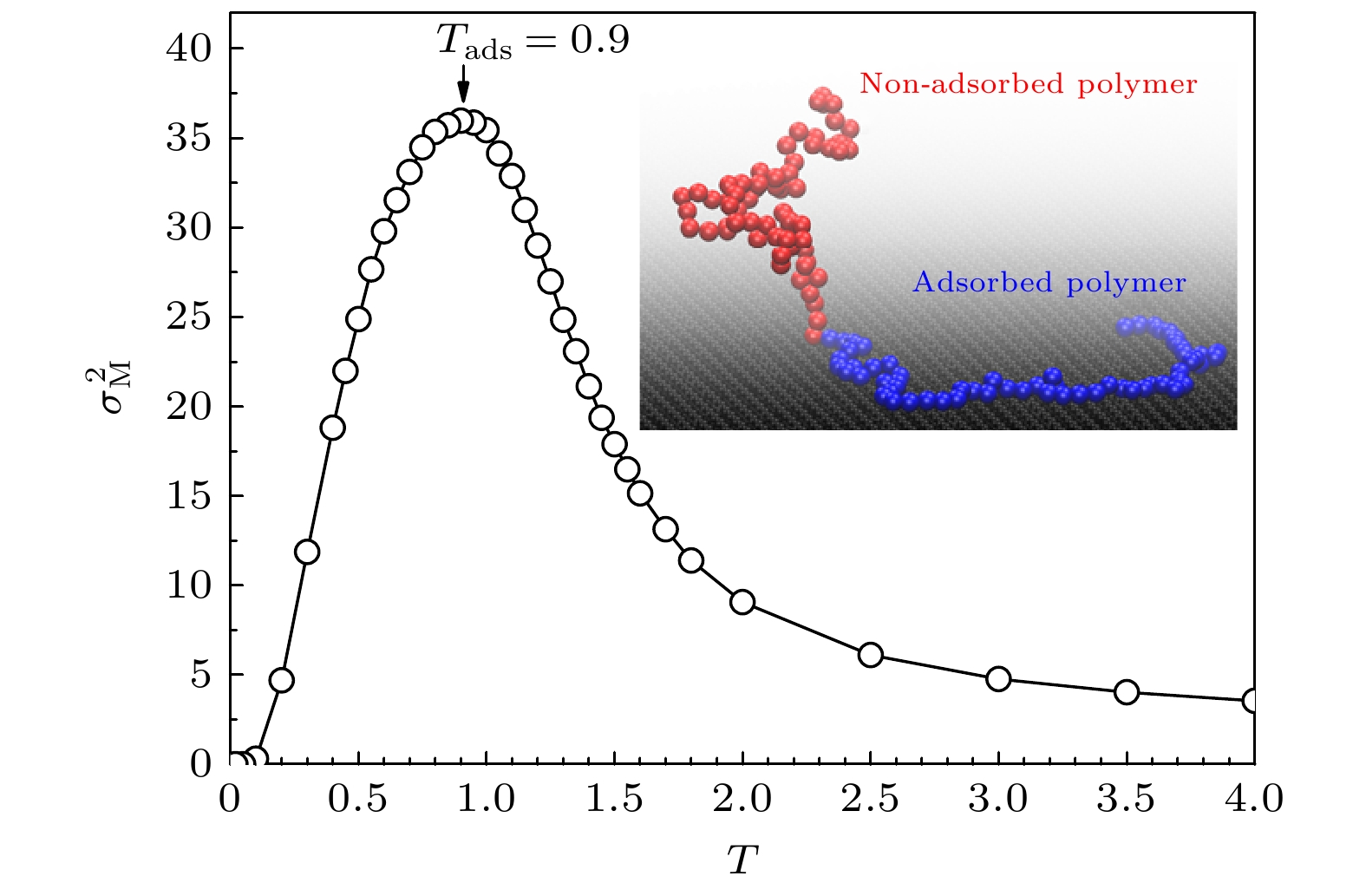

图 7 高分子吸附链节数涨落$ {\sigma }_{\rm M}^{2} $与温度T的关系的动力学Monte Carlo模拟结果. 插图给出了高温的非吸附态和低温的吸附态高分子构象

Figure 7. Plot of the fluctuation of adsorption monomer number $ {\sigma }_{\rm M}^{2} $ of polymer chain versus temperature T. The inset presents non-adsorbed polymer at high temperature and adsorbed polymer at low temperature.

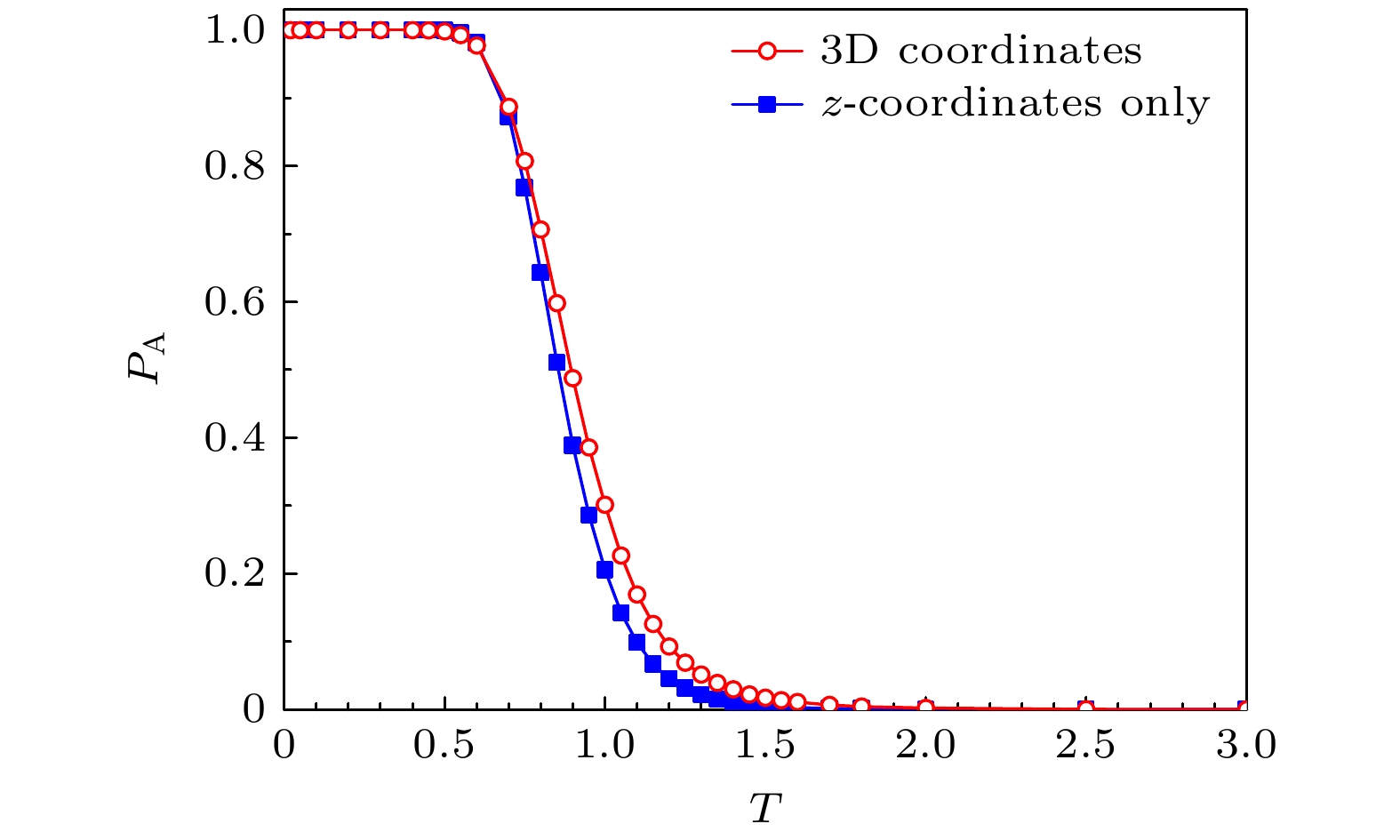

图 10 机器学习得到的吸附态概率PA在(0, 0.2), (0.2, 0.8)和(0.8, 1)三个范围内高分子构象相对于构象的吸附数M和链质心高度zc的分布

Figure 10. Distribution of polymer conformation relative to the adsorbed number M and the mean height zc for the adsorption probability PA obtained by machine learning in three ranges of (0, 0.2), (0.2, 0.8) and (0.8, 1).

-

[1] Hinton G, Deng L, Yu D, et al. 2012 IEEE Signal Process. Mag. 29 82

Google Scholar

Google Scholar

[2] Silver D, Huang A, Maddison C J, et al. 2016 Nature 529 484

Google Scholar

Google Scholar

[3] Umehara M, Stein H S, Guevarra D, et al. 2019 NPJ Comput. Mater. 5 34

Google Scholar

Google Scholar

[4] Iwasaki Y, Takeuchi I, Stanev V, et al. 2019 Sci. Rep. 9 2751

Google Scholar

Google Scholar

[5] 陈江芷, 杨晨温, 任捷 2021 70 144204

Google Scholar

Google Scholar

Chen J Z, Yang C W, Ren J 2021 Acta Phys. Sin. 70 144204

Google Scholar

Google Scholar

[6] Cencer M M, Moore J S, Assary R S 2022 Polym. Int. 71 537

Google Scholar

Google Scholar

[7] Zhang Y, Xu X 2021 J. Mol. Graphics Modell. 103 107796

Google Scholar

Google Scholar

[8] Liang Z, Li Z, Zhou S, et al. 2022 Cell Reports Physical Science 3 100931

Google Scholar

Google Scholar

[9] Zhang K, Li X, Jin Y, Jiang Y 2022 Soft Matter 18 6270

Google Scholar

Google Scholar

[10] Xu Y, Wang Z G 2021 Macromolecules 54 10984

Google Scholar

Google Scholar

[11] Milner S T 1991 Science 251 905

Google Scholar

Google Scholar

[12] Besteman K, Lee J O, Wiertz F G M, Heering H A, Dekker C 2003 Nano Lett. 3 727

Google Scholar

Google Scholar

[13] Duan X, Zhang R, Ding M, Huang Q, Xu W S, Shi T, An L 2017 Polymer 122 125

Google Scholar

Google Scholar

[14] Sumithra K, Brandau M, Straube E 2009 J. Chem. Phys. 130 234901

Google Scholar

Google Scholar

[15] Li Y W, Wüst T, Landau D P 2013 Phys. Rev. E 87 012706

Google Scholar

Google Scholar

[16] Yang Q H, Wu F, Wang Q, Luo M B 2016 J. Polym. Sci. Part B: Polym. Phys. 54 2359

Google Scholar

Google Scholar

[17] Ziebarth J D, Gardiner A A, Wang Y M, Jeong Y, Ahn J, Jin Y, Chang T 2016 Macromolecules 49 8780

Google Scholar

Google Scholar

[18] Bhattacharya D, Patra T K 2021 Macromolecules 54 3065

Google Scholar

Google Scholar

[19] Nguyen T, Bavarian M 2022 Ind. Eng. Chem. Res. 61 12690

Google Scholar

Google Scholar

[20] Weeks J D, Chandler D, Andersen H C 1971 J. Chem. Phys. 54 5237

Google Scholar

Google Scholar

[21] Chremos A, Glynos E, Koutsos V, Camp P J 2009 Soft Matter 5 637

Google Scholar

Google Scholar

[22] Hochreiter S, Schmidhuber J A 1997 Neural Comput. 9 1735

Google Scholar

Google Scholar

[23] Loshchilov I, Hutter F 2017 arXiv:1711.05101 [cs.LG

[24] Luo M B, Tsehay D A, Sun L Z 2017 J. Chem. Phys. 147 034901

Google Scholar

Google Scholar

[25] Yang X, Wu F, Hu D D, Zhang S, Luo M B 2019 Chin. Phys. Lett. 36 098202

Google Scholar

Google Scholar

[26] Qi H K, Yang X, Yang Q H, Luo M B 2022 Polymer 259 125330

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4268

- PDF Downloads: 127

- Cited By: 0

DownLoad:

DownLoad: