-

The physicochemical properties of Au atoms adsorbed on the surface on an atomic scale play a very important role in preparing nanodevices and surface catalysis. In this paper, we use frequency modulated Kelvin probe force microscopy (FM-KPFM)to study the multi-bit adsorbed charge distribution of Au on the surface of Si(111)-(7×7) at room temperature. Firstly, the surface topography and local contact potential difference (LCPD) of Au at different adsorption sites in Si(111)-(7×7) are successfully obtained by using home-made ultra-high vacuum Kelvin probe force microscopy. Secondly, we analyze the atomic characteristics of specific atomic positions of Au/Si(111)-(7×7) by force spectroscopy and potential difference, and realize the atomic identification . The adsorption characteristics of Au/Si(111)-(7×7) surface charge transfer and Au are explained by combining differential charge density calculations. The results show that Au atom adsorption mainly is in the form of single atom and cluster . Specifically, the Au cluster is adsorbed at the three central positions of Si(111)-(7×7) in a hexagonal structure of six atoms. Individual Au atoms are adsorbed to the positions of central adatoms of Si(111)-(7×7). At the same time, through the measurement of potential difference, it is known that a single Au atom and Au cluster lose electrons, presenting a positive electrical characteristic. The results of surface differential charge density show that Au undergoes charge transfer during adsorption, losing part of the charge, which locally reduces the work function at the position of the adsorbed atom. In the range of distances where short-range forces, local contact potential energy differences and differential charge densities change, the theoretical results and experimental results are in reasonable agreement.

-

Keywords:

- Kelvin probe force microscopy /

- Si(111)-(7×7) /

- local contact potential difference /

- surface charge

[1] Bocquet F, Nony L, Loppacher C, Glatzel T 2008 Phys. Rev. B 78 035410

Google Scholar

Google Scholar

[2] Abraham D W, Williams C, Slinkman J, Wickramasinghe H K 1991 J. Vac. Sci. Technol. B 9 703

Google Scholar

Google Scholar

[3] 温焕飞, 菅原康弘, 李艳君 2020 69 210701

Google Scholar

Google Scholar

Wen H F, Sugawara Y, Li Y J 2020 Acta Phys. Sin. 69 210701

Google Scholar

Google Scholar

[4] Wen H F, Li Y J, Arima E, Naitoh Y, Sugawara Y, Xu R, Cheng Z H 2017 Nanotechnology 28 105704

Google Scholar

Google Scholar

[5] Wen H F, Miyazaki M, Zhang Q, Adachi Y, Li Y J, Sugawara Y 2018 Phys. Chem. Chem. Phys. 20 28331

Google Scholar

Google Scholar

[6] Ma Z M, Shi Y B, Mu J L, Qu Z, Zhang X M, Li Q, Liu J 2017 Appl. Surf. Sci. 394 472

Google Scholar

Google Scholar

[7] Jia J F, Wang J Z, Liu X, Xue Q K, Li Z Q, Kawazoe Y, Zhang S B 2002 Appl. Phys. Lett. 80 3186

Google Scholar

Google Scholar

[8] Wu K, Fujikawa Y, Nagao T, Hasegawa Y, Nakayama K S, Xue Q K, Wang E G, Briere T, Kumar V, Kawazoe Y, Zhang S B, Sakurai T 2003 Phys. Rev. Lett. 91 126101

Google Scholar

Google Scholar

[9] Hu L, Huang B, Liu F 2021 Phys. Rev. Lett. 126 176101

Google Scholar

Google Scholar

[10] Arai T, Inamura R, Kura D, Tomitori M 2018 Phys. Rev. B 97 115428

Google Scholar

Google Scholar

[11] Tanishiro Y, Takahashi M, Takahashi S 1985 J. Vac. Sci. Technol. A 3 1502

Google Scholar

Google Scholar

[12] Zhang L, Jeon Y J, Shim H, Lee G 2012 J. Vac. Sci. Technol. A 30 061406

Google Scholar

Google Scholar

[13] Qu B , Hu J H, Li H, Li W J, Huang M L, Wu Q H 2015 Surf. Interface Anal. 47 926

Google Scholar

Google Scholar

[14] Liu Q, Fu Q, Shao X J, Ma X H, Wu X F, Wang K D, Xiao X D 2017 Appl. Surf. Sci. 401 225

Google Scholar

Google Scholar

[15] Li W, Ding W, Gong Y, Ju D 2021 Surface. Coatings 11 281

Google Scholar

Google Scholar

[16] Baranov D S, Vlaic S, Baptista, J, Cofler E, Stolyarov V S, Roditchev D, Pons S 2022 Nano. Lett. 22 652

Google Scholar

Google Scholar

[17] 王慧云 冯婕 王旭东 温阳 魏久焱 温焕飞 石云波 马宗敏 李艳君 刘俊 2022 71 060702

Google Scholar

Google Scholar

Wang H Y, Feng J, Wang X D, Wen Y, Wei J Y, Wen H F, Shi Y B, Ma Z M, Li Y J, Liu Jun 2022 Acta Phys. Sin. 71 060702

Google Scholar

Google Scholar

[18] 周颖慧 2007 博士学位论文 (厦门: 厦门大学)

Zhou Y H 2007 Ph. D. Dissertation(Xiamen: Xiamen University) (in Chinese)

[19] 魏久焱 马宗敏 温焕飞 2020 电子显微学报 39 122

Google Scholar

Google Scholar

Wei J Y, Ma Z M, Wen H F 2020 J. Chin. Electron Microsc. Soc. 39 122

Google Scholar

Google Scholar

[20] Yurtsever A, Sugimoto Y, Tanaka H, Abe M, Morita S, Ondrác M, Pou P, Pérez R, Jelínek P 2013 Phys. Rev. B 87 155403

Google Scholar

Google Scholar

[21] Pou P, Ghasemi S A, Jelinek P, Lenosky T, Goedecker S, Perez R 2009 Nanotechnology 20 264015

Google Scholar

Google Scholar

[22] Chen G, Xiao X D, Kawazoe Y, Gong X G, Chan C T 2009 Phys. Rev. B 79 115301

Google Scholar

Google Scholar

[23] Wandelt K 1997 Appl. Surf. Sci. 111 1

Google Scholar

Google Scholar

[24] Gross L, Mohn F, Liljeroth P, Repp J, Giessibl F J, Meyer G 2009 Science 324 1428

Google Scholar

Google Scholar

[25] Huang Z, Lin Y, Han C, Han C, Sun Y Y, Wu K, Chen E 2021 J. Phys. Chem. C 125 7944

Google Scholar

Google Scholar

[26] Zhou Y H, Wu Q H, Li S P, Kang J Y 2007 Surf. Rev. Lett. 14 657

Google Scholar

Google Scholar

-

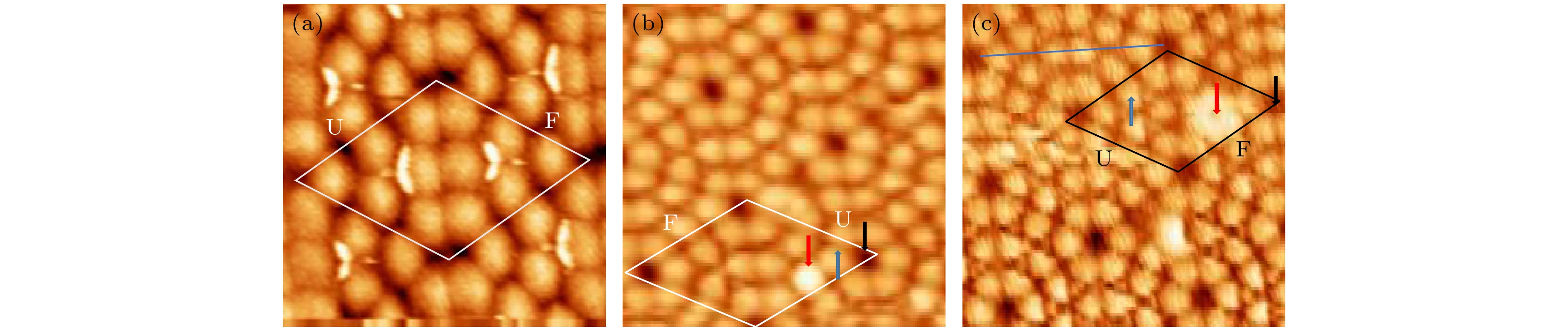

图 3 AFM 形貌图 (a) Si(111)-(7×7)表面, 图像尺寸为4.5 nm×2.5 nm (f0 = 162 kHz, Q = 1638, Δf = –45 Hz, A = 7 nm); (b) Au原子吸附在Si(111)-(7×7) 表面, 图像尺寸为5.3 nm×5.5 nm (f0 = 151 kHz, Q = 15011, Δf = –45 Hz, A = 7 nm); (c) Au 团簇吸附在Si(111)-(7×7) 表面, 图像尺寸为6.5 nm × 5.5 nm (f0 = 151 kHz, Q = 15011, Δf = –33.1 Hz, A = 7 nm)

Figure 3. AFM images: (a) Si(111)-(7×7) surface, image size of 4.5 nm×2.5 nm (f0 = 162 kHz, Q = 1638, Δf = –45 Hz, A = 7 nm); (b) Au atoms adsorbed on Si(111)-(7×7) surface, image size of 5.3 nm×5.5 nm (f0 = 151 kHz, Q = 15011, Δf = –45 Hz, A = 7 nm); (c) Au cluster adsorbed on Si(111)-(7×7) surface , image size of 6.5 nm×5.5 nm (f0 = 151 kHz, Q = 15011, Δf = –33.1 Hz, A = 7 nm)

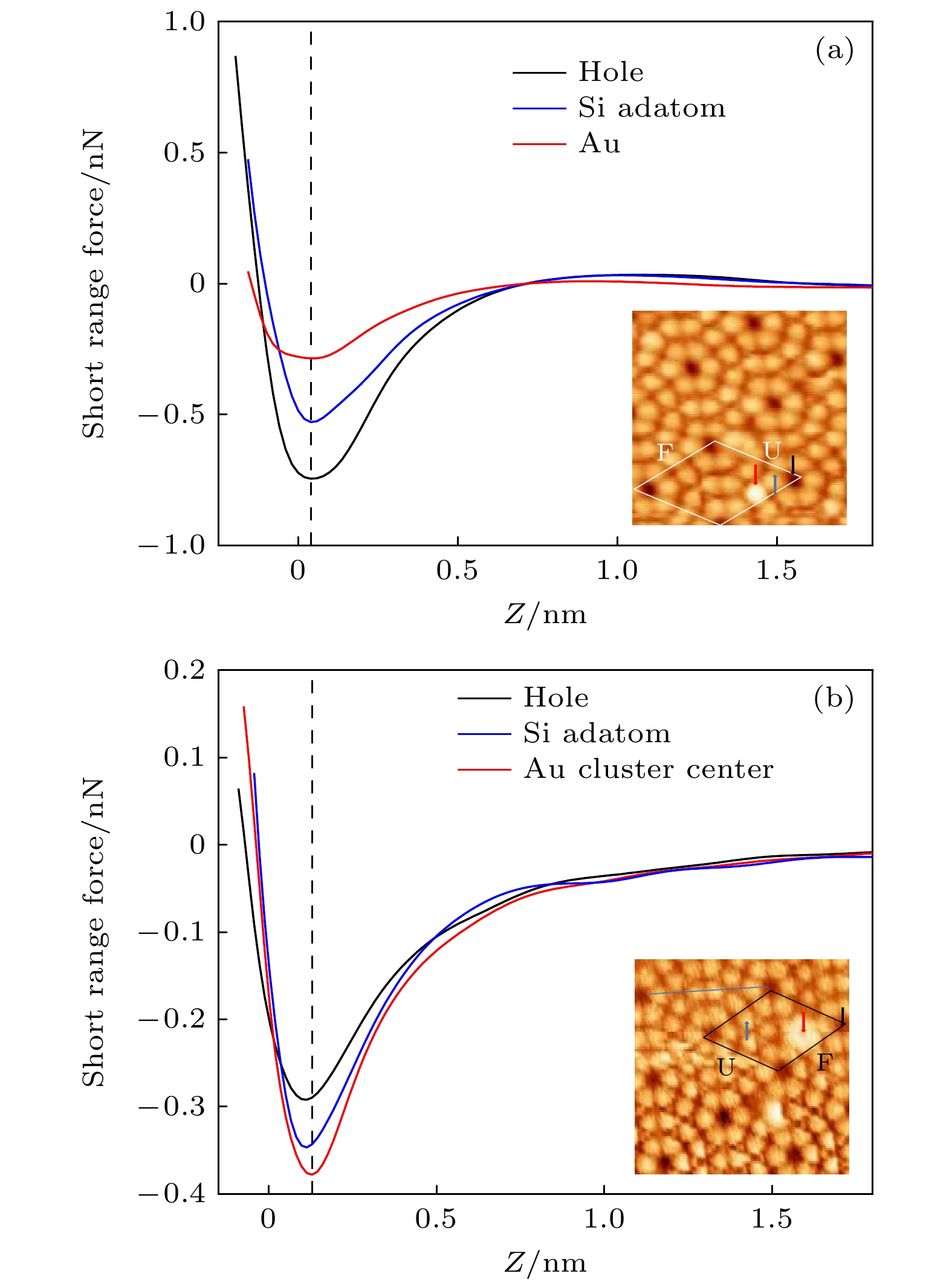

图 4 (a) Au/Si(111)-(7×7) 表面特定原子位置(图3(b))测量的短程力曲线, 箭头和绘图线的颜色代表相同; (b) Au团簇/Si(111)-(7×7) 表面特定原子位置(图3(c))测量的短程力曲线

Figure 4. (a) Short range force curves measured over the atomic positions (Fig.3(b)) of Au/Si(111)-(7×7) surfces. The color code for arrows and plot lines is the same; (b) short range force curves measured over the atomic positions (Fig.3(c)) of Au cluster/Si(111)-(7×7) surfaces.

图 5 在不同针尖-样品表面距离下测得的探针本征频率频移与样品所加偏压关系曲线. 偏压值为0 V该处原子为中性金原子Au0; 偏压值为–0.2 V该处原子为带正电金原子Au+(以Δf = –4 Hz测量为起始点, 标记为Z = 0)

Figure 5. Bias-spectroscopy curves measured at several tip surface separations to extract the bias voltage that minimizes the tip-surface electrostatic interaction. The bias value is 0 V, the atom is the neutral Au atom(Au0); bias value is –0.2 V, where the atom is a positively charged Au atom (Au+) (Starting point with Δf = –4 Hz measurement, marked as Z= 0)

图 6 单个Au原子吸附在Si(111)-(7×7) 表面的 (a) 形貌图和 (b) VLCPD 图, 图像尺寸为6.5 nm×5 nm (f0 =151 kHz, Q = 15011, Δf = –66.2 Hz, A = 7 nm,

$ {V}_{{\rm{a}}{\rm{c}}} $ = 500 mV,$ {f}_{{\rm{a}}{\rm{c}}} $ = 500 Hz); (c) 形貌和 (d) VLCPD图的剖线图Figure 6. (a) Topography and (b) VLCPD image of Au atoms absorbed on Si(111)-(7×7) surface, image size: 6.5 nm×5 nm (f0 = 151 kHz, Q = 15011, Δf = –66.2 Hz, A = 7 nm,

$ {V}_{{\rm{a}}{\rm{c}}} $ = 500 mV,$ {f}_{{\rm{a}}{\rm{c}}} $ = 500 Hz); (c) topography and (d) line profiles of VLCPD图 7 Au 团簇在Si (111)-(7×7) 表面的 (a) 形貌图和(b) VLCPD 图, 图像尺寸为 4.8 nm×2.5 nm (f0 = 151 kHz, Q = 15011, Δf = –33.1 Hz, A = 7 nm,

${V}_{\rm ac}$ = 500 mV,${f}_{{\rm{ac}}}$ = 500 Hz); (c) 形貌和 (d) VLCPD图的剖线图(图7选取自图3(a)中的部分图像, 图7中的蓝色线标注在图3(a)中, 紫色虚线圆圈为侧视图中的Au原子, 并不是截线位置上的Au原子)Figure 7. (a) Topography and (b) VLCPD image of Au cluster absorbed on Si (111)-(7×7) surface, image size of 4.8 nm×2.5 nm (f0 = 151 kHz, Q = 15011, Δf = –33.1 Hz, A = 7 nm,

$ {V}_{{\rm{a}}{\rm{c}}} $ = 500 mV,$ {f}_{{\rm{a}}{\rm{c}}} $ = 500 Hz); (c) topography and (d) line profiles of VLCPD. (Fig.7 is selected from some of the images in Fig. 3(a), and the blue line in Fig.7 is denoted in Fig. 3(a), the purple dotted circle is the Au atom in the side view, not the Au atom in the truncated position).图 8 (a) Si (111)-(7×7)表面的单个Au原子模型, (b) Si (111)-(7×7)表面的Au团簇模型(灰色和蓝色球是表面的亚表面Si原子和Si顶戴原子, 绿色球是剩余原子, 紫色球是Au原子); (c) Au原子和(d) Au团簇吸附位置在对应AFM图上的示意图

Figure 8. (a) Model of Au atoms absorbed on Si (111)-(7×7) surface, (b) model of Au cluster absorbed on Si (111)-(7×7) surface (the gray and blue balls are subsurface Si atoms and Si adatoms on the surface, the green balls are rest atoms, the pink balls are Au atoms); Schematic of adsorption position on the corresponding AFM images of (c) Au atoms and (d) Au cluster.

图 9 (a) 吸附在Si(111)-(7×7)表面高配位上的Au原子差分电荷密度分布; (b)吸附在Si (111)-(7×7)表面Au团簇的差分电荷密度分布

Figure 9. (a) Differential charge density distribution of Au atom adsorbed on the high coordination of Si (111)-(7×7) surface; (b) differential charge density distribution of Au cluster adsorbed on Si (111)-(7×7) surface.

-

[1] Bocquet F, Nony L, Loppacher C, Glatzel T 2008 Phys. Rev. B 78 035410

Google Scholar

Google Scholar

[2] Abraham D W, Williams C, Slinkman J, Wickramasinghe H K 1991 J. Vac. Sci. Technol. B 9 703

Google Scholar

Google Scholar

[3] 温焕飞, 菅原康弘, 李艳君 2020 69 210701

Google Scholar

Google Scholar

Wen H F, Sugawara Y, Li Y J 2020 Acta Phys. Sin. 69 210701

Google Scholar

Google Scholar

[4] Wen H F, Li Y J, Arima E, Naitoh Y, Sugawara Y, Xu R, Cheng Z H 2017 Nanotechnology 28 105704

Google Scholar

Google Scholar

[5] Wen H F, Miyazaki M, Zhang Q, Adachi Y, Li Y J, Sugawara Y 2018 Phys. Chem. Chem. Phys. 20 28331

Google Scholar

Google Scholar

[6] Ma Z M, Shi Y B, Mu J L, Qu Z, Zhang X M, Li Q, Liu J 2017 Appl. Surf. Sci. 394 472

Google Scholar

Google Scholar

[7] Jia J F, Wang J Z, Liu X, Xue Q K, Li Z Q, Kawazoe Y, Zhang S B 2002 Appl. Phys. Lett. 80 3186

Google Scholar

Google Scholar

[8] Wu K, Fujikawa Y, Nagao T, Hasegawa Y, Nakayama K S, Xue Q K, Wang E G, Briere T, Kumar V, Kawazoe Y, Zhang S B, Sakurai T 2003 Phys. Rev. Lett. 91 126101

Google Scholar

Google Scholar

[9] Hu L, Huang B, Liu F 2021 Phys. Rev. Lett. 126 176101

Google Scholar

Google Scholar

[10] Arai T, Inamura R, Kura D, Tomitori M 2018 Phys. Rev. B 97 115428

Google Scholar

Google Scholar

[11] Tanishiro Y, Takahashi M, Takahashi S 1985 J. Vac. Sci. Technol. A 3 1502

Google Scholar

Google Scholar

[12] Zhang L, Jeon Y J, Shim H, Lee G 2012 J. Vac. Sci. Technol. A 30 061406

Google Scholar

Google Scholar

[13] Qu B , Hu J H, Li H, Li W J, Huang M L, Wu Q H 2015 Surf. Interface Anal. 47 926

Google Scholar

Google Scholar

[14] Liu Q, Fu Q, Shao X J, Ma X H, Wu X F, Wang K D, Xiao X D 2017 Appl. Surf. Sci. 401 225

Google Scholar

Google Scholar

[15] Li W, Ding W, Gong Y, Ju D 2021 Surface. Coatings 11 281

Google Scholar

Google Scholar

[16] Baranov D S, Vlaic S, Baptista, J, Cofler E, Stolyarov V S, Roditchev D, Pons S 2022 Nano. Lett. 22 652

Google Scholar

Google Scholar

[17] 王慧云 冯婕 王旭东 温阳 魏久焱 温焕飞 石云波 马宗敏 李艳君 刘俊 2022 71 060702

Google Scholar

Google Scholar

Wang H Y, Feng J, Wang X D, Wen Y, Wei J Y, Wen H F, Shi Y B, Ma Z M, Li Y J, Liu Jun 2022 Acta Phys. Sin. 71 060702

Google Scholar

Google Scholar

[18] 周颖慧 2007 博士学位论文 (厦门: 厦门大学)

Zhou Y H 2007 Ph. D. Dissertation(Xiamen: Xiamen University) (in Chinese)

[19] 魏久焱 马宗敏 温焕飞 2020 电子显微学报 39 122

Google Scholar

Google Scholar

Wei J Y, Ma Z M, Wen H F 2020 J. Chin. Electron Microsc. Soc. 39 122

Google Scholar

Google Scholar

[20] Yurtsever A, Sugimoto Y, Tanaka H, Abe M, Morita S, Ondrác M, Pou P, Pérez R, Jelínek P 2013 Phys. Rev. B 87 155403

Google Scholar

Google Scholar

[21] Pou P, Ghasemi S A, Jelinek P, Lenosky T, Goedecker S, Perez R 2009 Nanotechnology 20 264015

Google Scholar

Google Scholar

[22] Chen G, Xiao X D, Kawazoe Y, Gong X G, Chan C T 2009 Phys. Rev. B 79 115301

Google Scholar

Google Scholar

[23] Wandelt K 1997 Appl. Surf. Sci. 111 1

Google Scholar

Google Scholar

[24] Gross L, Mohn F, Liljeroth P, Repp J, Giessibl F J, Meyer G 2009 Science 324 1428

Google Scholar

Google Scholar

[25] Huang Z, Lin Y, Han C, Han C, Sun Y Y, Wu K, Chen E 2021 J. Phys. Chem. C 125 7944

Google Scholar

Google Scholar

[26] Zhou Y H, Wu Q H, Li S P, Kang J Y 2007 Surf. Rev. Lett. 14 657

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7396

- PDF Downloads: 118

- Cited By: 0

DownLoad:

DownLoad: