-

Amorphous rare earth (RE)-transition metal (TM) ferrimagnetic alloy films have been intensively studied recently in spintronics and ultrafast information storage due to the large perpendicular magnetic anisotropy (PMA), ultrafast magnetization switching, and the presence of magnetization compensation and angular momentum compensation. In this work, we fabricate X/Tbx(Fe0.75Co0.25)1–x/X (0.13 ≤ x ≤ 0.32, X = SiO2, Pt and W) trilayers by magnetron sputtering, and systematically investigate the magnetic properties and thermal stabilities of the ultrathin TbFeCo films encapsulated by heavy metals Pt and W at room temperature. The 5–50-nm-thick TbFeCo films sandwiched by SiO2 exhibit PMA with magnetic compensation occurring in Tb concentration x between 0.21 with 0.24. For 3-nm- and 5- nm-thick TbFeCo ultrathin films encapsulated by Pt, however, there is no magnetic compensation observed throughout the composition range 0.13 ≤ x ≤ 0.32 with the film magnetization dominated by the FeCo moment. Nevertheless, the weakened PMA for the Pt/ultrathin TbFeCo/Pt trilayers is completely destroyed after annealing at 250 ℃. When the buffer layer and capping layer of Pt are replaced by W, the ultrathin TbFeCo films show magnetic compensation at 0.21 < x < 0.24, so do the thick TbFeCo films. The effective PMA field (HK) exceeds 11.5 T for the W/ultrathin TbFeCo/W films near the compensation composition, and remarkably, the HK decreases slowly on annealing, with PMA maintained even after annealing at 350–400℃. We further prepare [Pt/TbFeCo]5/Pt and [W/TbFeCo]5/W multilayers to clarify the origin of the huge difference between Pt/ultrathin TbFeCo/Pt and the W counterpart. It is found that there are partial recrystallization and phase separation for TbFeCo layer around the Pt/TbFeCo interface, leading to the disappearance of magnetic compensation and the deterioration of the PMA in the Pt/ultrathin TbFeCo/Pt films. With large PMA, W/ultrathin TbFeCo/W films show the presence of magnetic compensation, and excellent thermal robustness. The present study provides a promising heavy metal/RE-TM heterostructure for spintronic applications.

-

Keywords:

- ferrimagnetic alloy/heavy metal heterostructure /

- magnetic compensation /

- perpendicular magnetic anisotropy /

- thermal stability

[1] Ishibashi M, Yakushiji K, Kawaguchi M, Tsukamoto A, Nakatsuji S, Hayashi M 2022 Appl. Phys. Lett. 120 022405

Google Scholar

Google Scholar

[2] Seung Ham W, Kim S, Kim D H, Kim K J, Okuno T, Yoshikawa H, Tsukamoto A, Moriyama T, Ono T 2017 Appl. Phys. Lett. 110 242405

Google Scholar

Google Scholar

[3] Li W, Yan J, Tang M, Lou S, Zhang Z, Zhang X L, Jin Q Y 2018 Phys. Rev. B 97 184432

Google Scholar

Google Scholar

[4] Radu I, Vahaplar K, Stamm C, Kachel T, Kimel A V 2011 Nature 472 205

Google Scholar

Google Scholar

[5] Kim D H, Okuno T, Kim S K, Oh S H, Nishimura T, Hirata Y, Futakawa Y, Yoshikawa H, Tsukamoto A, Tserkovnyak Y, Shiota Y, Moriyama T, Kim K J, Lee K J, Ono T 2019 Phys. Rev. Lett. 122 127203

Google Scholar

Google Scholar

[6] Chaudhari P, Cuomo J J, Gambino R J 1973 Appl. Phys. Lett. 22 337

Google Scholar

Google Scholar

[7] Ota S, Van Thach P, Awano H, Ando A, Toyoki K, Kotani Y, Nakamura T, Koyama T, Chiba D 2021 Sci. Rep. 11 6237

Google Scholar

Google Scholar

[8] Ceballos A, Charilaou M, Molina-Ruiz M, Hellman F 2022 J. Appl. Phys. 131 033901

Google Scholar

Google Scholar

[9] Hebler B, Hassdenteufel A, Reinhardt P, Karl H, Albrecht M 2016 Front. Mater. 3 8

[10] Mizoguchi T, III G S C 1979 J. Appl. Phys. 50 3570

Google Scholar

Google Scholar

[11] Suzuki Y, Takayama S, Kirino F, Ohta N 1987 IEEE Trans. Magn. 23 2275

Google Scholar

Google Scholar

[12] III G S C, Mizoguchi T 1978 J. Appl. Phys. 49 1753

Google Scholar

Google Scholar

[13] Harris V G, Aylesworth K D, Das B N, Elam W T, Koon N C 1992 IEEE Trans. Magn. 28 2958

Google Scholar

Google Scholar

[14] Harris V G, Aylesworth K D, Das B N, Elam W T, Koon N C 1992 Phys. Rev. Lett. 69 1939

Google Scholar

Google Scholar

[15] Takagi H, Tsunashima S, Uchiyama S, Fujii T 1979 J. Appl. Phys. 50 1642

Google Scholar

Google Scholar

[16] Leamy H J, Dirks A G 1979 J. Appl. Phys. 50 2871

Google Scholar

Google Scholar

[17] Suzuki, Takao 1985 J. Magn. Magn. Mater. 50 265

Google Scholar

Google Scholar

[18] Egami T, Graham C, Dmowski W, Zhou P, Flanders P, Marinero E, Notarys H, Robinson C 2003 IEEE Trans. Magn. 23 2269

[19] Meiklejohn W H 1986 Proc. IEEE 74 1570

Google Scholar

Google Scholar

[20] Wang Y J, Leng Q W 1990 Phys. Rev. B 41 651

Google Scholar

Google Scholar

[21] Mergel D, Heitmann H, Hansen P 1993 Phys. Rev. B 47 882

Google Scholar

Google Scholar

[22] Shan Z S, Sellmyer D J 1990 Phys. Rev. B 42 10433

Google Scholar

Google Scholar

[23] Cheng S C N, Kryder M H 1991 J. Appl. Phys. 69 7202

Google Scholar

Google Scholar

[24] Manchon A, Železný J, Miron I M, Jungwirth T, Sinova J, Thiaville A, Garello K, Gambardella P 2019 Rev. Mod. Phys. 91 035004

Google Scholar

Google Scholar

[25] Dyakonov M I, Perel V I 1971 Phys. Lett. A 35 459

Google Scholar

Google Scholar

[26] Miron I M, Gaudin G, Auffret S, Rodmacq B, Schuhl A, Pizzini S, Vogel J, Gambardella P 2010 Nat. Mater. 9 230

Google Scholar

Google Scholar

[27] Ueda K, Mann M, de Brouwer P W P, Bono D, Beach G S D 2017 Phys. Rev. B 96 064410

Google Scholar

Google Scholar

[28] Je S G, Rojas-Sánchez J C, Pham T H, Vallobra P, Malinowski G, Lacour D, Fache T, Cyrille M C, Kim D Y, Choe S B, Belmeguenai M, Hehn M, Mangin S, Gaudin G, Boulle O 2018 Appl. Phys. Lett. 112 062401

Google Scholar

Google Scholar

[29] Lee J W, Park J Y, Yuk J M, Park B G 2020 Phys. Rev. Appl. 13 044030

Google Scholar

Google Scholar

[30] Kim S K, Beach G S D, Lee K J, Ono T, Rasing T, Yang H 2022 Nat. Mater. 21 24

Google Scholar

Google Scholar

-

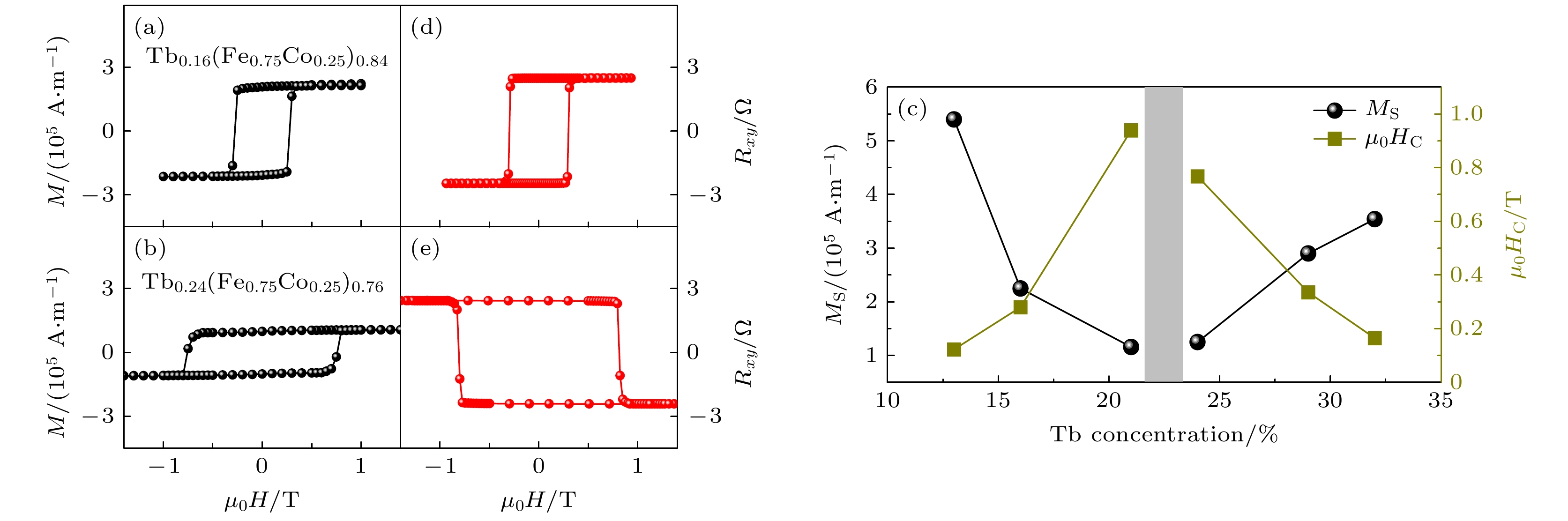

图 1 (a) SiO2(3 nm)/Tb0.16(Fe0.75Co0.25)0.84(50 nm)/SiO2(3 nm)的面外方向磁滞回线; (b) SiO2(3 nm)/Tb0.24(Fe0.75Co0.25)0.76(50 nm)/SiO2(3 nm)的面外方向磁滞回线; (c) SiO2(3 nm)/Tbx(Fe0.75Co0.25)1–x(50 nm)/SiO2(3 nm) 的饱和磁化强度和垂直矫顽力随Tb含量的变化; (d) SiO2(3 nm)/Tb0.16(Fe0.75Co0.25)0.84(50 nm)/SiO2(3 nm)的霍尔电阻回线; (e) SiO2(3 nm)/ Tb0.24(Fe0.75Co0.25)0.76(50 nm)/SiO2(3 nm)的霍尔电阻回线

Figure 1. The out plane of M-H loops of the samples of (a) SiO2(3 nm)/Tb0.16(Fe0.75Co0.25)0.84(50 nm)/SiO2(3 nm) and (b) SiO2(3 nm)/Tb0.24(Fe0.75Co0.25)0.76(50 nm)/SiO2(3 nm); (c) the saturation magnetization and perpendicular coercivity as a function of Tb concentration for SiO2(3 nm)/ Tbx(Fe0.75Co0.25)1–x(50 nm)/SiO2(3 nm). The Hall resistance loops of the samples (e) SiO2(3 nm)/Tb0.16(Fe0.75Co0.25)0.84(50 nm)/SiO2(3 nm) and (f) SiO2(3 nm)/Tb0.24(Fe0.75Co0.25)0.76(50 nm)/SiO2(3 nm).

图 2 (a) Pt(3 nm)/Tb0.13(Fe0.75Co0.25)0.87(3, 5 nm)/Pt(3 nm)的霍尔电阻回线; (b) Pt(3 nm)/Tb0.24(Fe0.75Co0.25)0.76(3, 5 nm)/Pt(3 nm)的霍尔电阻回线; (c) Pt(3 nm)/Tbx (Fe0.75Co0.25)1–x(5 nm)/Pt(3 nm)的矫顽力随Tb含量的变化; (d) Pt(3 nm)/Tbx(Fe0.75Co0.25)1–x(3, 5 nm)/Pt(3 nm)的饱和反常霍尔电阻随Tb含量的变化. 图(c)的插图为Pt(3 nm)/Tb0.21 (Fe0.75Co0.25)0.79 (5 nm)/Pt(3 nm)样品在制备态和250 ℃ 退火后的归一化霍尔电阻回线

Figure 2. The Hall loops of the samples of (a) Pt(3 nm)/Tb0.13(Fe0.75Co0.25)0.87(3, 5 nm)/Pt(3 nm), and (b) Pt(3 nm)/Tb0.24(Fe0.75Co0.25)0.76(3, 5 nm)/Pt(3 nm); (c) the coercivity as a function of Tb concentration for Pt(3 nm)/Tbx(Fe0.75Co0.25)1–x(5 nm)/Pt(3 nm); (d) the saturated anomalous Hall resistance as a function of Tb concentration in Pt(3 nm)/Tbx(Fe0.75Co0.25)1–x(3, 5 nm)/Pt(3 nm). The inset in Figure (c) shows the normalized Hall resistance loops of the sample Pt(3 nm)/Tb0.21(Fe0.75Co0.25)0.79(5 nm)/Pt(3 nm) in the as-deposited state and after annealed 250 ℃.

图 3 (a) W(5 nm)/Tb0.21(Fe0.75Co0.25)0.79(3, 5 nm)/W(5 nm)的霍尔电阻回线; (b) W(5 nm)/Tb0.24(Fe0.75Co0.25)0.76(3, 5 nm)/W(5 nm)的霍尔电阻回线; (c) W(5 nm)/Tbx(Fe0.75Co0.25)1–x(3, 5 nm)/W(5 nm)的反常霍尔电阻随Tb含量的变化; (d) W(5 nm)/Tb0.24(Fe0.75Co0.25)0.76(5 nm)/W(5 nm)经过300和350 °C退火后的霍尔电阻回线; (e) W(5 nm)/ Tb0.16(Fe0.75Co0.25)0.84(5 nm)/W(5 nm)的横向霍尔电阻随面内纵向外磁场的变化; (f) W(5 nm)/ Tbx(Fe0.75Co0.25)1–x(5 nm)/W(5 nm)在制备态和300 ℃ 退火后的垂直矫顽力和有效垂直磁各向异性场随Tb含量的变化, 蓝线和深黄线分别代表制备态下的矫顽力和有效垂直各向异性场, 橙线和黑线分别代表退火后矫顽力和有效各向异性场

Figure 3. The Hall loops of the samples of (a) W(5 nm)/Tb0.21(Fe0.75Co0.25)0.79(3, 5 nm)/W(5 nm) and (b) W(5 nm)/Tb0.24(Fe0.75Co0.25)0.76(3, 5 nm)/W(5 nm); (c) the anomalous Hall resistance as a function of the Tb concentration in samples W(5 nm)/Tbx(Fe0.75Co0.25)1–x(3, 5 nm)/W(5 nm); (d) the Hall loops of the sample W(5 nm)/Tb0.24(Fe0.75Co0.25)0.76(5 nm)/W(5 nm) after annealed at 300 and 350 ℃; (e) the transverse Hall resistance as a function of longitudinal in-plane field for the sample W(5 nm)/ Tb0.16(Fe0.75Co0.25)0.84(5 nm)/W(5 nm); (f) the coercivity and effective perpendicular anisotropic field as a function of Tb concentration in W(5 nm)/Tbx(Fe0.75Co0.25)1–x(5 nm)/W(5 nm), where blue circle and dark yellow circle represent the coercivity and effective perpendicular anisotropic fields in the as-deposited samples, respectively, and orange circle and black circle represent the corresponding parameters for the 300 ℃ annealed samples.

图 4 (a) [Pt(3 nm)/Tb0.16(Fe0.75Co0.25)0.84(5 nm)]5/Pt(3 nm)多层膜和Pt(3 nm)/ Tb0.16(Fe0.75Co0.25)0.84(25 nm)/Pt(3 nm)三层膜的面外方向磁滞回线; (b) [W(5 nm)/ Tb0.16(Fe0.75Co0.25)0.84(5 nm)]5/W(5 nm)多层膜和W(5 nm)/Tb0.16(Fe0.75Co0.25)0.84(25 nm)/W(5 nm)三层膜的面外方向磁滞回线; (c) 上述Pt, W多层膜和三层膜样品的X射线衍射图, 插图为对应衍射峰的放大图

Figure 4. The out plane of M-H loops of samples of (a) [Pt(3 nm)/Tb0.16(Fe0.75Co0.25)0.84(5 nm)]5/Pt(3 nm), Pt(3 nm)/Tb0.16(Fe0.75Co0.25)0.84(25 nm)/Pt(3 nm), and (b) [W(5 nm)/Tb0.16(Fe0.75Co0.25)0.84(5 nm)]5/W(5 nm), W(5 nm)/ Tb0.16(Fe0.75Co0.25)0.84(25 nm/ W(5 nm). (c) The X-ray diffraction patterns of above four samples. The inset shows the zoom of the diffraction peaks.

-

[1] Ishibashi M, Yakushiji K, Kawaguchi M, Tsukamoto A, Nakatsuji S, Hayashi M 2022 Appl. Phys. Lett. 120 022405

Google Scholar

Google Scholar

[2] Seung Ham W, Kim S, Kim D H, Kim K J, Okuno T, Yoshikawa H, Tsukamoto A, Moriyama T, Ono T 2017 Appl. Phys. Lett. 110 242405

Google Scholar

Google Scholar

[3] Li W, Yan J, Tang M, Lou S, Zhang Z, Zhang X L, Jin Q Y 2018 Phys. Rev. B 97 184432

Google Scholar

Google Scholar

[4] Radu I, Vahaplar K, Stamm C, Kachel T, Kimel A V 2011 Nature 472 205

Google Scholar

Google Scholar

[5] Kim D H, Okuno T, Kim S K, Oh S H, Nishimura T, Hirata Y, Futakawa Y, Yoshikawa H, Tsukamoto A, Tserkovnyak Y, Shiota Y, Moriyama T, Kim K J, Lee K J, Ono T 2019 Phys. Rev. Lett. 122 127203

Google Scholar

Google Scholar

[6] Chaudhari P, Cuomo J J, Gambino R J 1973 Appl. Phys. Lett. 22 337

Google Scholar

Google Scholar

[7] Ota S, Van Thach P, Awano H, Ando A, Toyoki K, Kotani Y, Nakamura T, Koyama T, Chiba D 2021 Sci. Rep. 11 6237

Google Scholar

Google Scholar

[8] Ceballos A, Charilaou M, Molina-Ruiz M, Hellman F 2022 J. Appl. Phys. 131 033901

Google Scholar

Google Scholar

[9] Hebler B, Hassdenteufel A, Reinhardt P, Karl H, Albrecht M 2016 Front. Mater. 3 8

[10] Mizoguchi T, III G S C 1979 J. Appl. Phys. 50 3570

Google Scholar

Google Scholar

[11] Suzuki Y, Takayama S, Kirino F, Ohta N 1987 IEEE Trans. Magn. 23 2275

Google Scholar

Google Scholar

[12] III G S C, Mizoguchi T 1978 J. Appl. Phys. 49 1753

Google Scholar

Google Scholar

[13] Harris V G, Aylesworth K D, Das B N, Elam W T, Koon N C 1992 IEEE Trans. Magn. 28 2958

Google Scholar

Google Scholar

[14] Harris V G, Aylesworth K D, Das B N, Elam W T, Koon N C 1992 Phys. Rev. Lett. 69 1939

Google Scholar

Google Scholar

[15] Takagi H, Tsunashima S, Uchiyama S, Fujii T 1979 J. Appl. Phys. 50 1642

Google Scholar

Google Scholar

[16] Leamy H J, Dirks A G 1979 J. Appl. Phys. 50 2871

Google Scholar

Google Scholar

[17] Suzuki, Takao 1985 J. Magn. Magn. Mater. 50 265

Google Scholar

Google Scholar

[18] Egami T, Graham C, Dmowski W, Zhou P, Flanders P, Marinero E, Notarys H, Robinson C 2003 IEEE Trans. Magn. 23 2269

[19] Meiklejohn W H 1986 Proc. IEEE 74 1570

Google Scholar

Google Scholar

[20] Wang Y J, Leng Q W 1990 Phys. Rev. B 41 651

Google Scholar

Google Scholar

[21] Mergel D, Heitmann H, Hansen P 1993 Phys. Rev. B 47 882

Google Scholar

Google Scholar

[22] Shan Z S, Sellmyer D J 1990 Phys. Rev. B 42 10433

Google Scholar

Google Scholar

[23] Cheng S C N, Kryder M H 1991 J. Appl. Phys. 69 7202

Google Scholar

Google Scholar

[24] Manchon A, Železný J, Miron I M, Jungwirth T, Sinova J, Thiaville A, Garello K, Gambardella P 2019 Rev. Mod. Phys. 91 035004

Google Scholar

Google Scholar

[25] Dyakonov M I, Perel V I 1971 Phys. Lett. A 35 459

Google Scholar

Google Scholar

[26] Miron I M, Gaudin G, Auffret S, Rodmacq B, Schuhl A, Pizzini S, Vogel J, Gambardella P 2010 Nat. Mater. 9 230

Google Scholar

Google Scholar

[27] Ueda K, Mann M, de Brouwer P W P, Bono D, Beach G S D 2017 Phys. Rev. B 96 064410

Google Scholar

Google Scholar

[28] Je S G, Rojas-Sánchez J C, Pham T H, Vallobra P, Malinowski G, Lacour D, Fache T, Cyrille M C, Kim D Y, Choe S B, Belmeguenai M, Hehn M, Mangin S, Gaudin G, Boulle O 2018 Appl. Phys. Lett. 112 062401

Google Scholar

Google Scholar

[29] Lee J W, Park J Y, Yuk J M, Park B G 2020 Phys. Rev. Appl. 13 044030

Google Scholar

Google Scholar

[30] Kim S K, Beach G S D, Lee K J, Ono T, Rasing T, Yang H 2022 Nat. Mater. 21 24

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5019

- PDF Downloads: 96

- Cited By: 0

DownLoad:

DownLoad: