-

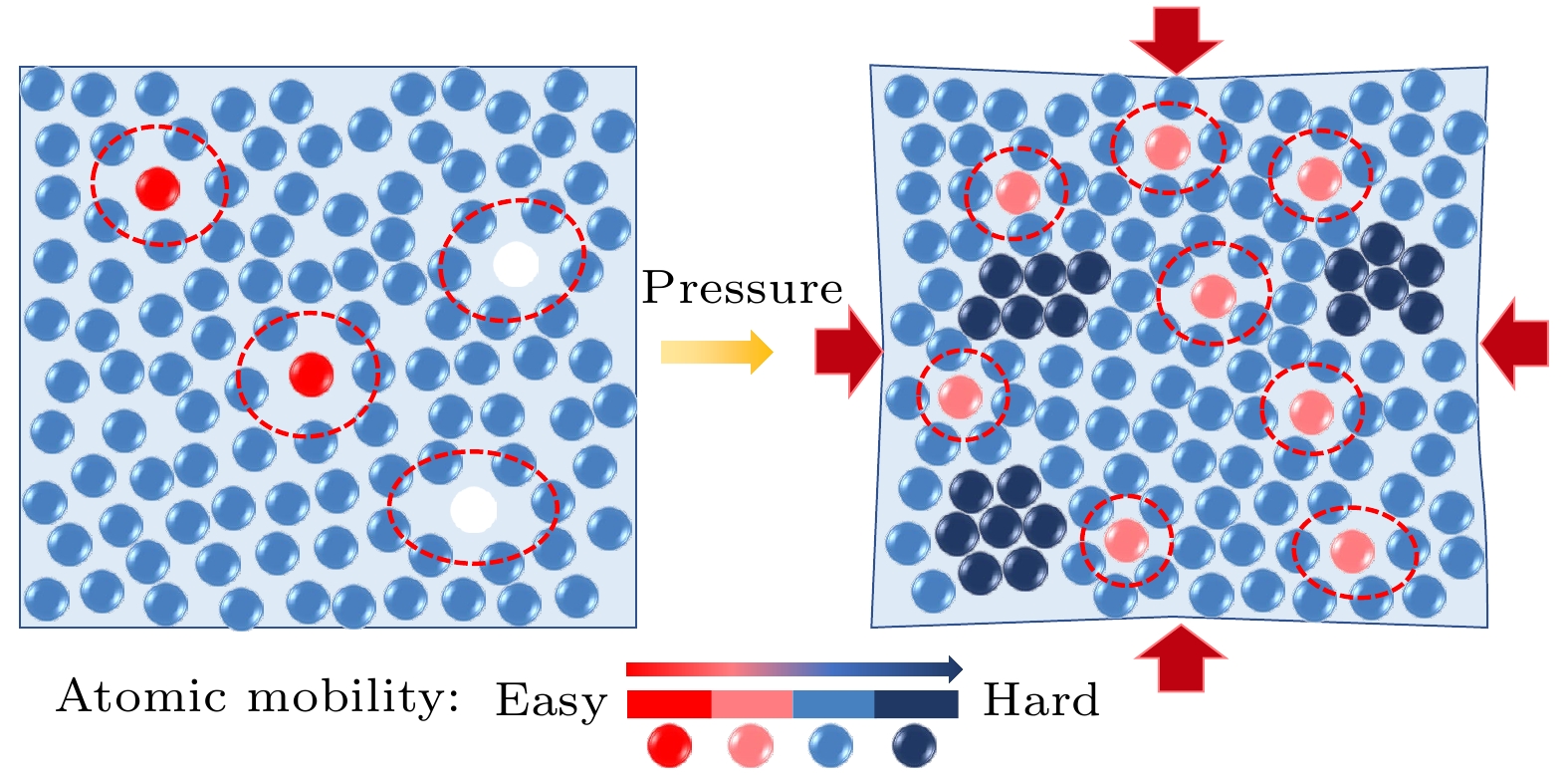

The atomic-scale structure and concomitant mechanical property evolution of a ribbon-shaped Fe78Si9B13 metallic glass after local plastic flow are investigated. By using abrasive papers as a medium to transport the pressure, the equivalent pressure on the ribbon surface is sufficiently magnified. Multiple shear bands pervading along their surface are generated simultaneously after deformation. The densification processes triggered by the cooperative atomic rearrangements in the short and medium-range are revealed by analyzing the synchrotron diffraction patterns in reciprocal space and real space. Meanwhile, the local plastic flow enhances the structural heterogeneity. In contrast to the strain-softening under uniaxial loading, these structural changes contribute to the improvement of resistance to subsequent deformation. As a result, the Vickers hardness of the deformed Fe78Si9B13 metallic glass increases compared with the undeformed sample, manifesting a local strain-hardening behavior.

[1] Greer A L, Cheng Y Q, Ma E 2013 Mat. Sci. Eng. R 74 71

Google Scholar

Google Scholar

[2] Pan J, Chen Q, Liu L, Li Y 2011 Acta Mater. 59 5146

Google Scholar

Google Scholar

[3] Jang D, Greer J R 2010 Nat. Mater. 9 215

Google Scholar

Google Scholar

[4] Pan J, Ivanov Y P, Zhou W H, Li Y, Greer A L 2020 Nature 578 559

Google Scholar

Google Scholar

[5] Wang T, Si J J, Wu Y D, Lv K, Liu Y H, Hui X D 2018 Scripta Mater. 150 106

Google Scholar

Google Scholar

[6] Spaepen F 1977 Acta Metall. 25 407

Google Scholar

Google Scholar

[7] Dmowski W, Yokoyama Y, Chuang A, Ren Y, Umemoto M, Tsuchiya K, Inoue A, Egami T 2010 Acta Mater. 58 429

Google Scholar

Google Scholar

[8] Rosner H, Peterlechner M, Kubel C, Schmidt V, Wilde G 2014 Ultramicroscopy 142 1

Google Scholar

Google Scholar

[9] Shen L Q, Luo P, Hu Y C, Bai H Y, Sun Y H, Sun B A, Liu Y H, Wang W H 2018 Nat. Commun. 9 4414

Google Scholar

Google Scholar

[10] Shahabi H S, Scudino S, Kaban I, Stoica M, Escher B, Menzel S, Vaughan G B M, Kühn U, Eckert J 2016 Acta Mater. 111 187

Google Scholar

Google Scholar

[11] Ma E, Ding J 2016 Mater. Today 19 568

Google Scholar

Google Scholar

[12] Qiao J C, Wang Q, Pelletier J M, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y 2019 Prog. Mater. Sci. 104 250

Google Scholar

Google Scholar

[13] Cubuk E D, Ivancic R J S, Schoenholz S S, et al. 2017 Science 358 1033

Google Scholar

Google Scholar

[14] Wei D, Yang J, Jiang M Q, Wei B C, Wang Y J, Dai L H 2019 Phys. Rev. B 99 014115

Google Scholar

Google Scholar

[15] Zhu F, Song S X, Reddy K M, Hirata A, Chen M W 2018 Nat. Commun. 9 3965

Google Scholar

Google Scholar

[16] Li B S, Xie S H, Kruzic J J 2019 Acta Mater. 176 278

Google Scholar

Google Scholar

[17] Wakeda M, Saida J 2019 Sci. Technol. Adv. Mater. 20 632

Google Scholar

Google Scholar

[18] Kim H K, Ahn J P, Lee B J, Park K W, Lee J C 2018 Acta Mater. 157 209

Google Scholar

Google Scholar

[19] Luo L S, Wang B B, Dong F Y, Su Y Q, Guo E Y, Xu Y J, Wang M Y, Wang L, Yu J X, Ritchie R O, Guo J J, Fu H Z 2019 Acta Mater. 171 216

Google Scholar

Google Scholar

[20] Ebner C, Escher B, Gammer C, Eckert J, Pauly S, Rentenberger C 2018 Acta Mater. 160 147

Google Scholar

Google Scholar

[21] Bian X L, Zhao D, Kim J T, Sopu D, Wang G, Pippan R, Eckert J 2019 Mater. Sci. Eng. A 752 36

Google Scholar

Google Scholar

[22] Kovács Z, Schafler E, Kis V K, Szommer P J, Révész Á 2018 J. Non-Cryst. Solids 498 25

Google Scholar

Google Scholar

[23] Dai J, Wang Y G, Yang L, Xia G T, Zeng Q S, Lou H B 2017 Scripta Mater. 127 88

Google Scholar

Google Scholar

[24] Wang J G, Hu Y C, Guan P F, Song K K, Wang L, Wang G, Pan Y, Sarac B, Eckert J 2017 Sci. Rep. 7 7076

Google Scholar

Google Scholar

[25] Taghvaei A H, Shirazifard N G, Ramasamy P, Bednarčik J, Eckert J 2018 J. Alloy. Compd. 748 553

Google Scholar

Google Scholar

[26] Yüce E, Sarac B, Ketov S, Reissner M, Eckert J 2021 J. Alloy. Compd. 872 159620

Google Scholar

Google Scholar

[27] Huang B, Ge T P, Liu G L, Luan J H, He Q F, Yuan Q X, Huang W X, Zhang K, Bai H Y, Shek C H, Liu C T, Yang Y, Wang W H 2018 Acta Mater. 155 69

Google Scholar

Google Scholar

[28] Ma D, Stoica A D, Wang X L 2009 Nat. Mater. 8 30

Google Scholar

Google Scholar

[29] Zeng Q S, Kono Y, Lin Y, Zeng Z D, Wang J Y, Sinogeikin S V, Park C, Meng Y, Yang W G, Mao H K, Mao W L 2014 Phys. Rev. Lett. 112 185502

Google Scholar

Google Scholar

[30] Micoulaut M, Bauchy M 2013 Phys. Status Solidi B 250 976

Google Scholar

Google Scholar

[31] Wu Z W, Li M Z, Wang W H, Liu K X 2015 Nat. Commun. 6 6035

Google Scholar

Google Scholar

[32] Dmowski W, Iwashita T, Chuang C P, Almer J, Egami T 2010 Phys. Rev. Lett. 105 205502

Google Scholar

Google Scholar

[33] Liu S N, Wang L F, Ge J C, Wu Z D, Ke Y B, Li Q, Sun B A, Feng T, Wu Y, Wang J T, Hahn H, Ren Y, Almer J D, Wang X L, Lan S 2020 Acta Mater. 200 42

Google Scholar

Google Scholar

[34] Taghvaei A H, Shahabi H S, Bednarčik J, Eckert J 2015 J. Appl. Phys. 117 044902

Google Scholar

Google Scholar

[35] Scudino S, Stoica M, Kaban I, Prashanth K G, Vaughan G B M, Eckert J 2015 J. Alloy. Compd. 639 465

Google Scholar

Google Scholar

[36] Chen Z Q, Huang L, Wang F, Huang P, Lu T J, Xu K W 2016 Mater. Design 109 179

Google Scholar

Google Scholar

[37] Zhu F, Hirata A, Liu P, Song S X, Tian Y, Han J H, Fujita T, Chen M W 2017 Phys. Rev. Lett. 119 215501

Google Scholar

Google Scholar

[38] Jaafari Z, Seifoddini A, Hasani S 2019 Metall. Mater. Trans. A 50 2875

Google Scholar

Google Scholar

[39] Sarac B, Ivanov Y P, Chuvilin A, Schoberl T, Stoica M, Zhang Z L, Eckert J 2018 Nat. Commun. 9 1333

Google Scholar

Google Scholar

[40] Wang Z T, Pan J, Li Y, Schuh C A 2013 Phys. Rev. Lett. 111 135504

Google Scholar

Google Scholar

[41] Stolpe M, Kruzic J J, Busch R 2014 Acta Mater. 64 231

Google Scholar

Google Scholar

[42] Das J, Tang M B, Kim K B, Theissmann R, Baier F, Wang W H, Eckert J 2005 Phys. Rev. Lett. 94 205501

Google Scholar

Google Scholar

[43] Bhowmick R, Raghavan R, Chattopadhyay K, Ramamurty U 2006 Acta Mater. 54 4221

Google Scholar

Google Scholar

[44] Tong Y, Iwashita T, Dmowski W, Bei H, Yokoyama Y, Egami T 2015 Acta Mater. 86 240

Google Scholar

Google Scholar

[45] Küchemann S, Liu C Y, Dufresne E M, Shin J, Maaß R 2018 Phys. Rev. B 97 014204

Google Scholar

Google Scholar

-

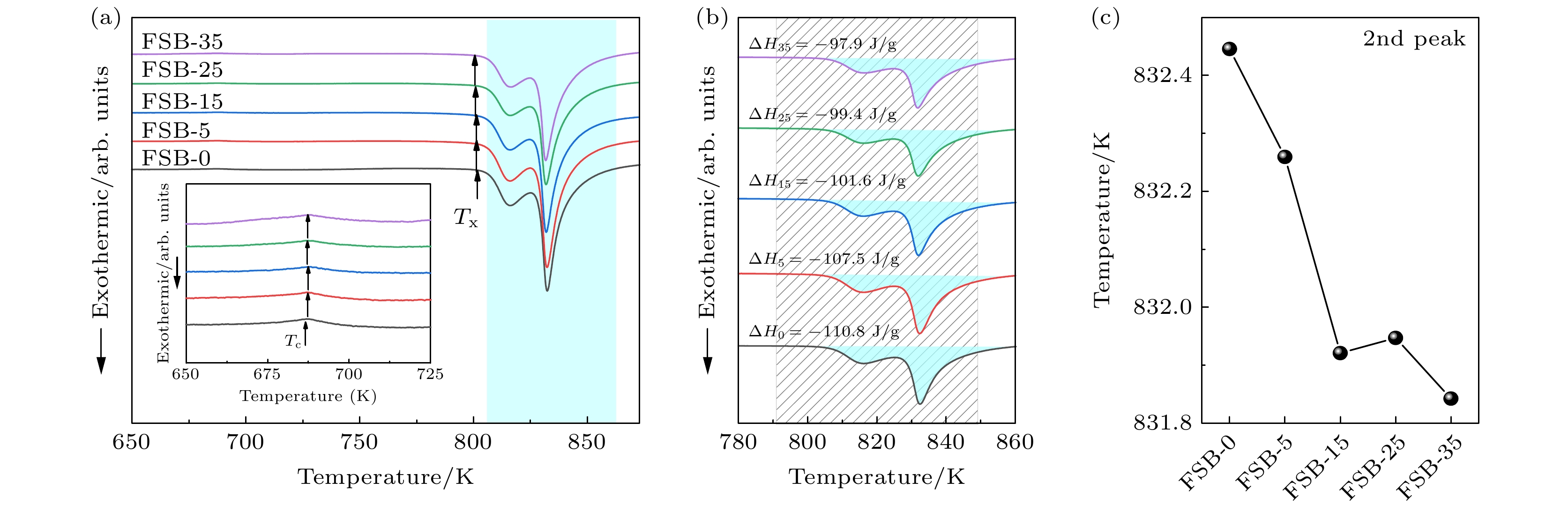

图 3 (a) 样品变形前后的DSC曲线, 插图是样品Tc附近的放大图; (b) 不同样品总的释放焓的比较; (c) 各样品上所对应第二峰的位置

Figure 3. (a) DSC curves of the samples before and after deformation, the inset is the enlargement near the Tc of samples; (b) comparison of the total enthalpy release on various samples; (c) the position of the corresponding second peak on various samples.

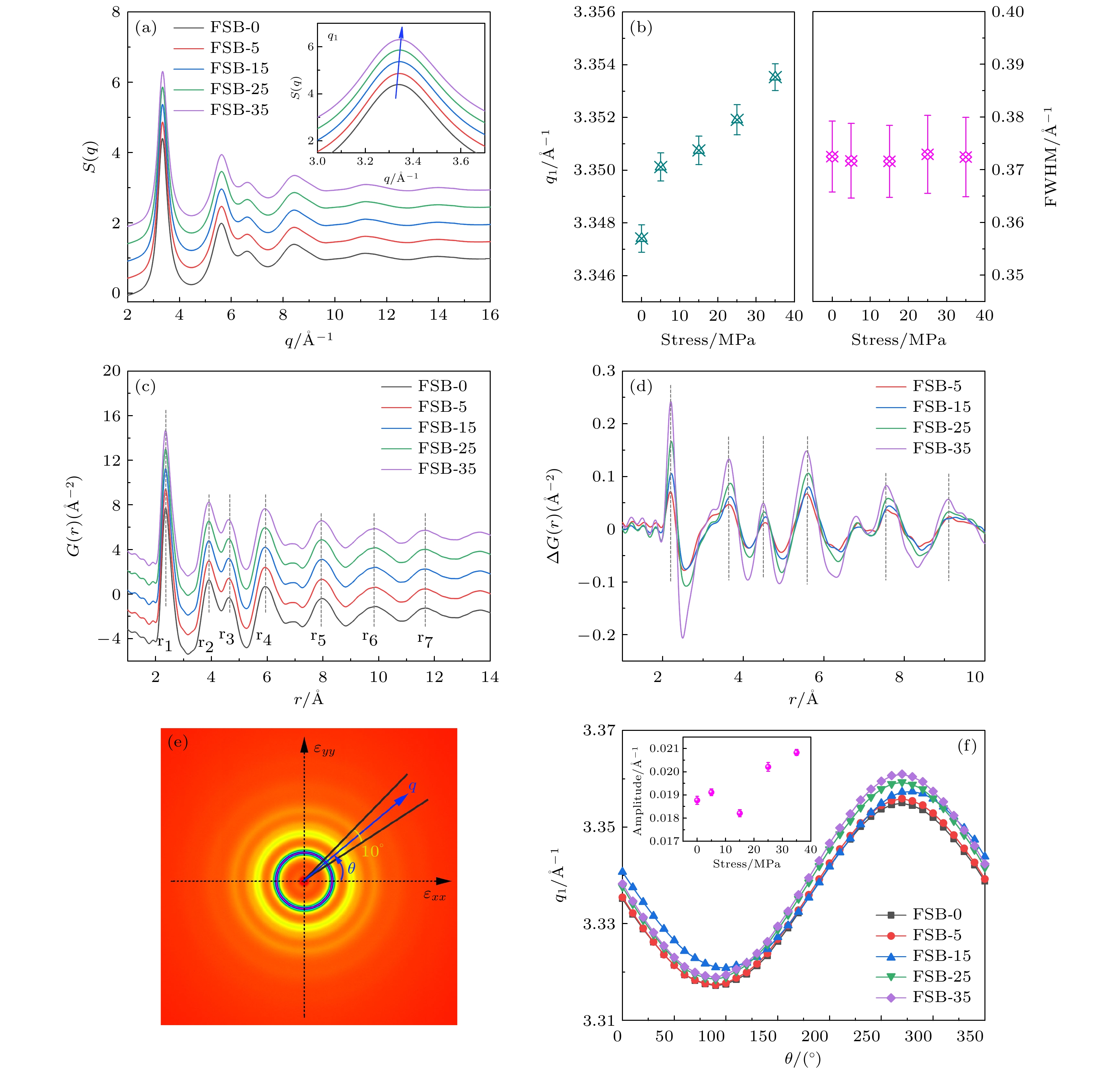

图 4 (a) Fe78Si9B13金属玻璃的结构因子S(q), 插图是第一峰附近的局部放大曲线(数据沿S(q)轴进行了移动); (b) S(q)中第一个峰的峰位和FWHM; (c) Fe78Si9B13金属玻璃的约化对分布函数G(r), 其中虚线标记了特征峰的位置; (d) 通过减去未变形样品的数据得到的G(r)的差异; (e)获取随方位角变化的衍射图谱的示意图; (f) 由pseudo-Voigt函数拟合S(q)中第一个峰的峰位与方位角的函数, 插图是由正弦函数拟合得出的振幅

Figure 4. (a) Structure factor S(q) of the Fe78Si9B13 metallic glasses, and the inset is the enlarged curves around the first peak (The data is shifted along S(q) axis for clarification); (b) peak position and FWHM of the first peak in S(q); (c) reduced pair distribution function G(r) of the Fe78Si9B13 metallic glasses, in which the dashed lines label the positions of characteristic peaks; (d) the difference in G(r) obtained by subtracting the data of the undeformed sample as a reference; (e) schematic diagram illustrating the acquisition of angular-dependent diffraction patterns; (f) position of the first peak in S(q) obtained from pseudo-Voigt function fitting as a function of angle, and the inset is the amplitude of oscillation derived from the sinusoidal function fitting.

图 6 Fe78Si9B13金属玻璃未变形(a)和变形(b)的HRTEM图像, 插图是相对应的FFT模式, 黄色的圆圈标出了低亮度的区域; Fe78Si9B13金属玻璃未变形(c)和变形(d)的环形暗场扫描TEM (ADF-STEM)图像

Figure 6. HRTEM images of the undeformed (a) and deformed (b) Fe78Si9B13 metallic glasses. The insets are the corresponding FFT patterns, and the yellow circles mark the regions with low brightness. Annular dark-field scanning TEM (ADF-STEM) images of the undeformed (c) and deformed (d) Fe78Si9B13 metallic glasses.

图 7 未变形(a)和变形(c) Fe78Si9B13金属玻璃压痕的金相显微镜图像; 未变形FSB-0试样(b)和FSB-35试样(d)的维氏硬度等值线图

Figure 7. Metallographic microscope images of the indentations for the undeformed (a) and deformed (c) Fe78Si9B13 metallic glasses; Vickers hardness contour plots of the undeformed FSB-0 sample (b) and the FSB-35 sample (d).

-

[1] Greer A L, Cheng Y Q, Ma E 2013 Mat. Sci. Eng. R 74 71

Google Scholar

Google Scholar

[2] Pan J, Chen Q, Liu L, Li Y 2011 Acta Mater. 59 5146

Google Scholar

Google Scholar

[3] Jang D, Greer J R 2010 Nat. Mater. 9 215

Google Scholar

Google Scholar

[4] Pan J, Ivanov Y P, Zhou W H, Li Y, Greer A L 2020 Nature 578 559

Google Scholar

Google Scholar

[5] Wang T, Si J J, Wu Y D, Lv K, Liu Y H, Hui X D 2018 Scripta Mater. 150 106

Google Scholar

Google Scholar

[6] Spaepen F 1977 Acta Metall. 25 407

Google Scholar

Google Scholar

[7] Dmowski W, Yokoyama Y, Chuang A, Ren Y, Umemoto M, Tsuchiya K, Inoue A, Egami T 2010 Acta Mater. 58 429

Google Scholar

Google Scholar

[8] Rosner H, Peterlechner M, Kubel C, Schmidt V, Wilde G 2014 Ultramicroscopy 142 1

Google Scholar

Google Scholar

[9] Shen L Q, Luo P, Hu Y C, Bai H Y, Sun Y H, Sun B A, Liu Y H, Wang W H 2018 Nat. Commun. 9 4414

Google Scholar

Google Scholar

[10] Shahabi H S, Scudino S, Kaban I, Stoica M, Escher B, Menzel S, Vaughan G B M, Kühn U, Eckert J 2016 Acta Mater. 111 187

Google Scholar

Google Scholar

[11] Ma E, Ding J 2016 Mater. Today 19 568

Google Scholar

Google Scholar

[12] Qiao J C, Wang Q, Pelletier J M, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y 2019 Prog. Mater. Sci. 104 250

Google Scholar

Google Scholar

[13] Cubuk E D, Ivancic R J S, Schoenholz S S, et al. 2017 Science 358 1033

Google Scholar

Google Scholar

[14] Wei D, Yang J, Jiang M Q, Wei B C, Wang Y J, Dai L H 2019 Phys. Rev. B 99 014115

Google Scholar

Google Scholar

[15] Zhu F, Song S X, Reddy K M, Hirata A, Chen M W 2018 Nat. Commun. 9 3965

Google Scholar

Google Scholar

[16] Li B S, Xie S H, Kruzic J J 2019 Acta Mater. 176 278

Google Scholar

Google Scholar

[17] Wakeda M, Saida J 2019 Sci. Technol. Adv. Mater. 20 632

Google Scholar

Google Scholar

[18] Kim H K, Ahn J P, Lee B J, Park K W, Lee J C 2018 Acta Mater. 157 209

Google Scholar

Google Scholar

[19] Luo L S, Wang B B, Dong F Y, Su Y Q, Guo E Y, Xu Y J, Wang M Y, Wang L, Yu J X, Ritchie R O, Guo J J, Fu H Z 2019 Acta Mater. 171 216

Google Scholar

Google Scholar

[20] Ebner C, Escher B, Gammer C, Eckert J, Pauly S, Rentenberger C 2018 Acta Mater. 160 147

Google Scholar

Google Scholar

[21] Bian X L, Zhao D, Kim J T, Sopu D, Wang G, Pippan R, Eckert J 2019 Mater. Sci. Eng. A 752 36

Google Scholar

Google Scholar

[22] Kovács Z, Schafler E, Kis V K, Szommer P J, Révész Á 2018 J. Non-Cryst. Solids 498 25

Google Scholar

Google Scholar

[23] Dai J, Wang Y G, Yang L, Xia G T, Zeng Q S, Lou H B 2017 Scripta Mater. 127 88

Google Scholar

Google Scholar

[24] Wang J G, Hu Y C, Guan P F, Song K K, Wang L, Wang G, Pan Y, Sarac B, Eckert J 2017 Sci. Rep. 7 7076

Google Scholar

Google Scholar

[25] Taghvaei A H, Shirazifard N G, Ramasamy P, Bednarčik J, Eckert J 2018 J. Alloy. Compd. 748 553

Google Scholar

Google Scholar

[26] Yüce E, Sarac B, Ketov S, Reissner M, Eckert J 2021 J. Alloy. Compd. 872 159620

Google Scholar

Google Scholar

[27] Huang B, Ge T P, Liu G L, Luan J H, He Q F, Yuan Q X, Huang W X, Zhang K, Bai H Y, Shek C H, Liu C T, Yang Y, Wang W H 2018 Acta Mater. 155 69

Google Scholar

Google Scholar

[28] Ma D, Stoica A D, Wang X L 2009 Nat. Mater. 8 30

Google Scholar

Google Scholar

[29] Zeng Q S, Kono Y, Lin Y, Zeng Z D, Wang J Y, Sinogeikin S V, Park C, Meng Y, Yang W G, Mao H K, Mao W L 2014 Phys. Rev. Lett. 112 185502

Google Scholar

Google Scholar

[30] Micoulaut M, Bauchy M 2013 Phys. Status Solidi B 250 976

Google Scholar

Google Scholar

[31] Wu Z W, Li M Z, Wang W H, Liu K X 2015 Nat. Commun. 6 6035

Google Scholar

Google Scholar

[32] Dmowski W, Iwashita T, Chuang C P, Almer J, Egami T 2010 Phys. Rev. Lett. 105 205502

Google Scholar

Google Scholar

[33] Liu S N, Wang L F, Ge J C, Wu Z D, Ke Y B, Li Q, Sun B A, Feng T, Wu Y, Wang J T, Hahn H, Ren Y, Almer J D, Wang X L, Lan S 2020 Acta Mater. 200 42

Google Scholar

Google Scholar

[34] Taghvaei A H, Shahabi H S, Bednarčik J, Eckert J 2015 J. Appl. Phys. 117 044902

Google Scholar

Google Scholar

[35] Scudino S, Stoica M, Kaban I, Prashanth K G, Vaughan G B M, Eckert J 2015 J. Alloy. Compd. 639 465

Google Scholar

Google Scholar

[36] Chen Z Q, Huang L, Wang F, Huang P, Lu T J, Xu K W 2016 Mater. Design 109 179

Google Scholar

Google Scholar

[37] Zhu F, Hirata A, Liu P, Song S X, Tian Y, Han J H, Fujita T, Chen M W 2017 Phys. Rev. Lett. 119 215501

Google Scholar

Google Scholar

[38] Jaafari Z, Seifoddini A, Hasani S 2019 Metall. Mater. Trans. A 50 2875

Google Scholar

Google Scholar

[39] Sarac B, Ivanov Y P, Chuvilin A, Schoberl T, Stoica M, Zhang Z L, Eckert J 2018 Nat. Commun. 9 1333

Google Scholar

Google Scholar

[40] Wang Z T, Pan J, Li Y, Schuh C A 2013 Phys. Rev. Lett. 111 135504

Google Scholar

Google Scholar

[41] Stolpe M, Kruzic J J, Busch R 2014 Acta Mater. 64 231

Google Scholar

Google Scholar

[42] Das J, Tang M B, Kim K B, Theissmann R, Baier F, Wang W H, Eckert J 2005 Phys. Rev. Lett. 94 205501

Google Scholar

Google Scholar

[43] Bhowmick R, Raghavan R, Chattopadhyay K, Ramamurty U 2006 Acta Mater. 54 4221

Google Scholar

Google Scholar

[44] Tong Y, Iwashita T, Dmowski W, Bei H, Yokoyama Y, Egami T 2015 Acta Mater. 86 240

Google Scholar

Google Scholar

[45] Küchemann S, Liu C Y, Dufresne E M, Shin J, Maaß R 2018 Phys. Rev. B 97 014204

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7533

- PDF Downloads: 126

- Cited By: 0

DownLoad:

DownLoad: