-

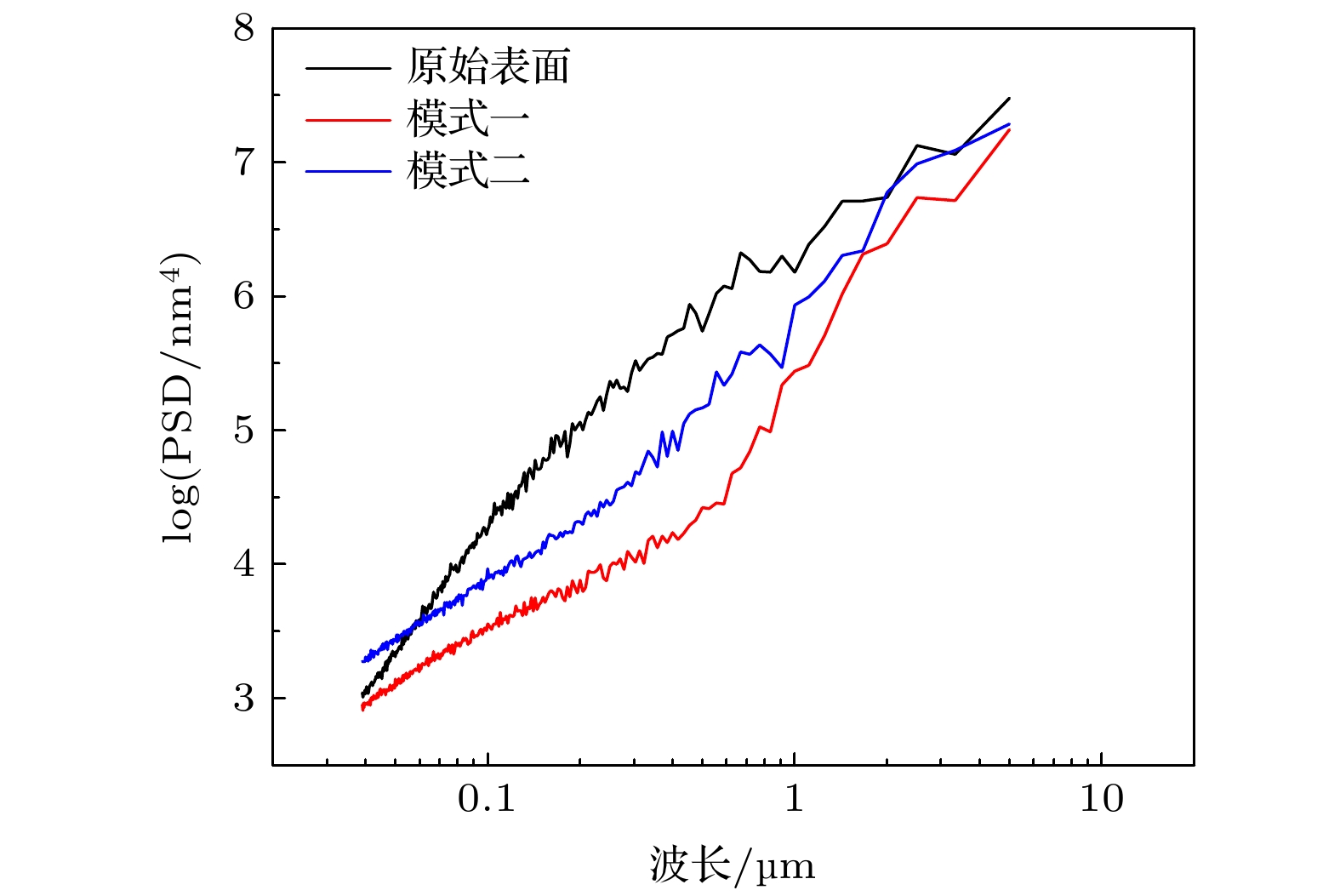

In this study, two kinds of gas cluster ion beam energy modes with different ion dose ratios are proposed to improve the traumatic surface of n-Si (100) single crystal. In mode1, low-dose high-energy clusters and high-dose low-energy clusters are used, while in mode2, high-dose high-energy clusters and low-dose low-energy clusters are used. The results show that the flattening effect of mode 1 is better than that of mode 2, and the root mean square roughness of mode 1 and mode 2 are 0.62 nm and 1.02 nm, respectively. This is because in multi-level energy mode 2, high-dose high-energy clusters are used to bombard the target surface in the early stage, so that more ion damages will be left after high-energy cluster bombardment. In the later stage, low-dose low-energy clusters can only remove part of the ion damages, and the repair strength is not strong enough. In multi-level energy mode1, we first use low-dose high-energy clusters to bombard the surface of the target, so that the high-energy clusters can quickly remove the shape objects with high protrusion on the sample surface, and in the low-dose mode, it will not leave too many ion damages, which is conducive to the later repair. In the first stage of multi-level energy mode, high-dose low-energy clusters are used to bombard the target surface, which can not only reduce the ion loss, but also increase the time for low-energy clusters to repair ion damages, thereby yielding the optimal flattening effect. In order to verify the relationship among the damage removal, ion damage degree and cluster energy, a single energy cluster bombardment experiment with mechanical damage is carried out before the multi-level energy mode modification is studied. The results show that when the cluster ions are accelerated at 15 kV high voltage, the scratch removal efficiency is highest, and the surface scratch is very shallow, but the decease of roughness is not obvious; when the cluster ions are accelerated at 8 kV and 5 kV, the sample surface becomes fine and the remaining ion damages are least. At the same time, a comparison of the target bombarded by the multi-level energy mode 1 clusters with that by the single energy clusters shows that the multi-level energy mode can obtain a smoother target surface than the single 15 keV high-energy cluster treatment; the multi-level energy mode can better remove scratches and other wounds than the single 5 keV low-energy cluster treatment. Multistage energy mode 1 integrates the advantages of high and low energy clusters, thereby achieving the best flattening effect.

-

Keywords:

- gas cluster ion beam /

- surface smoothing /

- ion dose ratio /

- multistage energy model /

- surface roughness

[1] Matsuo J, Katsumata H, Minami E, Yamada I 2000 Nucl. Instrum. Methods B 161-163 952

Google Scholar

Google Scholar

[2] Goto K, Matsuo J, Tada Y, Momiyama Y, Sugii T, Yamada I 1997 IEDM Tech. Digst. 471

Google Scholar

Google Scholar

[3] Toyoda N, Hagiwara N, Matsuo J, Yamada I 1999 Nucl. Instrum. MethodsB 148 639

Google Scholar

Google Scholar

[4] Yamada I, Takaoka G H 1993 Jpn. J. Appl. Phys. 32 2121

Google Scholar

Google Scholar

[5] Qin W, Howson R P, Akizuki M, Matsuo J, Takaoka G, Yamada I 1998 Mater. Chem. Phys. 54 258

Google Scholar

Google Scholar

[6] Seki T, Matsuo J, Yamada I 2000 Nucl. Instrum. Methods B 161–163 1007

[7] Tembrello. T A 1995 Nucl. Instrum. Methods B 99 225

Google Scholar

Google Scholar

[8] Sang J L, Chang M C, Boo K M, Ji Y B, Jae Y E, Myoung C C 2019 Bull. Korean Chem. Soc. 40 877

Google Scholar

Google Scholar

[9] Ieshkin A, Nazarev A, Tatarintsev A, Kireev D 2020 Mater. Lett. 272 127829

Google Scholar

Google Scholar

[10] Sumie K, Toyoda N, Yamada I 2013 Nucl. Instrum. MethodsB 307 290

Google Scholar

Google Scholar

[11] Zeng X M, Pelenovich V, Ieshkin A 2019 Rapid Commun. Mass. Spectrom. 33 1449

Google Scholar

Google Scholar

[12] Pelenovich V, Zeng X M, Rakhimov R, Zuo W B 2020 Mater. Lett. 264 127356

Google Scholar

Google Scholar

[13] Zeng X M, Pelenovich V, Zuo W B, Xing B, Tolstogouzov A 2020 Beilstein J. Nanotechnol. 11 383

Google Scholar

Google Scholar

[14] Yamada I, Matsuo J, Insepov Z, Akizuki M 1995 Nucl. Instrum. Methods B 106 165

Google Scholar

Google Scholar

[15] Yamada I, Matsuo J, Toyoda N, Kirkpatrick A 2001 Mater. Sci. Eng. R 34 231

Google Scholar

Google Scholar

[16] Prasalovich S, Popok V, Persson P, Campbell E E B 2005 J. Eur. Phys. D 36 79

Google Scholar

Google Scholar

[17] 曾晓梅, Vasiliy Pelenovich, Rakhim Rakhimov, 左文彬, 邢斌, 罗进宝, 张翔宇, 付德君 2020 69 093601

Google Scholar

Google Scholar

Zeng X M, Pelenovich V, Rakhimov R, Zuo W B, Xing B, Luo J B, Zhang X Y, Fu D J 2020 Acta Phys. Sin. 69 093601

Google Scholar

Google Scholar

[18] Tolstoguzov A B, Drozdov M N, Ieshkin A E, Tatarintsev A A, Myakon’kikh A V, Belykh S F, Korobeishchiko, N G, Pelenovich V 2020 JETP Letters. 111 467

Google Scholar

Google Scholar

[19] Merkle K J, Jager W 1981 Philos. Mag. A 44 741

Google Scholar

Google Scholar

[20] Gapann J 1995 Sensor Actuator. A 51 37

Google Scholar

Google Scholar

[21] Takeuchi D, Seki T, Aoki T, Matsuo J, Yamada I 1998 Mater. Chem. Phys. 54 76

Google Scholar

Google Scholar

[22] Matsuo J, Seki T, Yamada I 2003 Nucl. Instrum. Methods B 206 838

Google Scholar

Google Scholar

[23] Allen L P, Insepov Z, Fenner D B, Santeufemio, Brooks C W, Jones K S, Yamada I 2002 J. Appl. Phys. 92 3671

Google Scholar

Google Scholar

[24] Momota S, NojiIi Y 2006 Nucl. Instrum. Methods B 242 247

Google Scholar

Google Scholar

[25] Seki T, Kaneko T, Takeuchi D, Aoki T, Matsuo J, Insepov Z, Yamada I 1997 Nucl. Instrum. Methods B 121 498

Google Scholar

Google Scholar

[26] Pelenovich V, Zeng X M, Ieshkin A, Chernysh V S, Tolstogouzov A B 2019 J. Surf. Invest. 13 344

Google Scholar

Google Scholar

[27] VasiliyPelenovich, 曾晓梅, 罗进宝, RakhimRakhimov, 左文彬, 张翔宇, 田灿鑫, 邹长伟, 付德君, 杨兵 2021 70 053601

Google Scholar

Google Scholar

Pelenovich V, Zeng X M, Luo J B, Rakhimov R, Zuo W B, Zhang X Y, Tian C X, Zhou C W, Fu D J, Yang B 2021 Acta Phys. Sin. 70 053601

Google Scholar

Google Scholar

[28] Zeng X M, Pelenovich V, Liu C S, FuD J 2017 Chin. Phys. C 41 087003

Google Scholar

Google Scholar

[29] Zeng X M, Pelenovich V, Zuo W B 2019 Beilstein J. Nanotechnol. 10 135

Google Scholar

Google Scholar

-

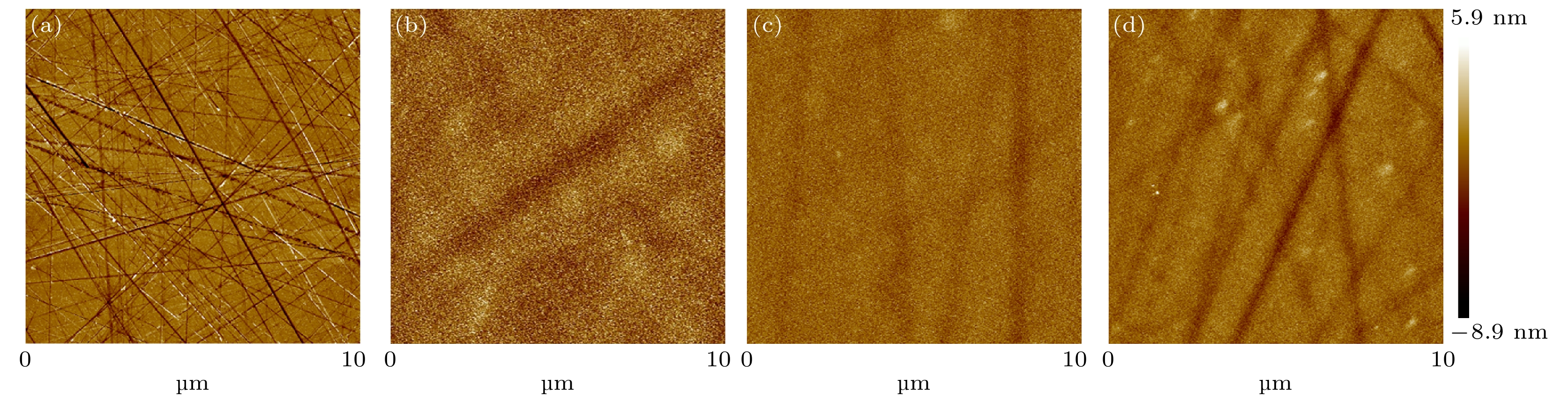

图 2 Si片经两种不同模式的Ar团簇垂直辐照后的AFM表面形貌图 (a) 0 keV (初始); (b) 15 keV + 8 keV + 5 keV多级能量(其离子剂量均为2 × 1016 cm–2); (c) 15 keV + 8 keV + 5 keV多级能量(其离子剂量分别为3 × 1016, 2 × 1016, 1 × 1016 cm–2)

Figure 2. AFM images of mechanically polished Si surface irradiated by two different modes of Ar cluster bombardment: (a) Initial surface; (b) 15 keV + 8 keV + 5 keV, consequently (all ion doses are 2 × 1016 cm–2); (c) 15 keV + 8 keV + 5 keV, consequently (ion doses respectively are 3 × 1016, 2 × 1016, 1 × 1016 cm–2)

图 4 Si片经不同能量的Ar团簇垂直辐照后的AFM表面形貌图 (a) 15 keV; (b) 5 keV; (c) 15 keV + 8 keV + 5 keV (离子剂量均为 2 × 1016 cm–2); (d) 15 keV + 8 keV + 5 keV (离子剂量分别为 3 × 1016, 2 × 1016、1 × 1016 cm–2); (e) 图(a)中孔洞的截面轮廓图; (f) 图(b)中孔洞的截面轮廓图; (g) 图(c)中孔洞的截面轮廓图; (h) 图(d)中孔洞的截面轮廓图

Figure 4. AFM images of mechanically polished Si surface after Ar cluster bombardment with different energy: (a) 15 keV; (b) 5 keV; (c) 15 keV + 8 keV + 5 keV, consequently (all ion doses are 2 × 1016 cm–2); (d) 15 keV + 8 keV + 5 keV, consequently (ion doses respectively are 3 × 1016, 2 × 1016, 1 × 1016 cm–2); (e) cross section of a crater from (a); (f) cross section of a crater from (b); (g) cross section of a crater from (c); (h) cross section of a crater from (d).

表 1 Si片样品的平坦化参数(团簇能量、离子剂量、抛光时间)和平坦化结果(均方根表面粗糙度Rq)

Table 1. The smoothing parameters (cluster energy, ion dose, smoothing time) and root mean square roughness Rq.

团簇能量

/keV离子剂量

/(ions·cm-2)抛光时间

/min均方根粗

糙度/nm0 0 0 1.69 15 6 × 1016 10 1.64 8 6 × 1016 20 1.07 5 6 × 1016 25 1.10 表 2 Si片样品的平坦化参数(团簇能量、离子剂量、抛光时间)和平坦化结果(均方根表面粗糙度Rq)

Table 2. The smoothing parameters (cluster energy, ion dose, smoothing time) and root mean square roughness Rq.

团簇能量/keV 离子剂量/(ions·cm–2) 抛光时间/min 均方根粗糙度/nm 0 0 0 1.69 15 + 8 + 5 2 × 1016 + 2 × 1016 + 2 × 1016 3 + 6 + 8 0.62 15 + 8 + 5 3 × 1016 + 2 × 1016+1 × 1016 5 + 6 + 4 1.02 -

[1] Matsuo J, Katsumata H, Minami E, Yamada I 2000 Nucl. Instrum. Methods B 161-163 952

Google Scholar

Google Scholar

[2] Goto K, Matsuo J, Tada Y, Momiyama Y, Sugii T, Yamada I 1997 IEDM Tech. Digst. 471

Google Scholar

Google Scholar

[3] Toyoda N, Hagiwara N, Matsuo J, Yamada I 1999 Nucl. Instrum. MethodsB 148 639

Google Scholar

Google Scholar

[4] Yamada I, Takaoka G H 1993 Jpn. J. Appl. Phys. 32 2121

Google Scholar

Google Scholar

[5] Qin W, Howson R P, Akizuki M, Matsuo J, Takaoka G, Yamada I 1998 Mater. Chem. Phys. 54 258

Google Scholar

Google Scholar

[6] Seki T, Matsuo J, Yamada I 2000 Nucl. Instrum. Methods B 161–163 1007

[7] Tembrello. T A 1995 Nucl. Instrum. Methods B 99 225

Google Scholar

Google Scholar

[8] Sang J L, Chang M C, Boo K M, Ji Y B, Jae Y E, Myoung C C 2019 Bull. Korean Chem. Soc. 40 877

Google Scholar

Google Scholar

[9] Ieshkin A, Nazarev A, Tatarintsev A, Kireev D 2020 Mater. Lett. 272 127829

Google Scholar

Google Scholar

[10] Sumie K, Toyoda N, Yamada I 2013 Nucl. Instrum. MethodsB 307 290

Google Scholar

Google Scholar

[11] Zeng X M, Pelenovich V, Ieshkin A 2019 Rapid Commun. Mass. Spectrom. 33 1449

Google Scholar

Google Scholar

[12] Pelenovich V, Zeng X M, Rakhimov R, Zuo W B 2020 Mater. Lett. 264 127356

Google Scholar

Google Scholar

[13] Zeng X M, Pelenovich V, Zuo W B, Xing B, Tolstogouzov A 2020 Beilstein J. Nanotechnol. 11 383

Google Scholar

Google Scholar

[14] Yamada I, Matsuo J, Insepov Z, Akizuki M 1995 Nucl. Instrum. Methods B 106 165

Google Scholar

Google Scholar

[15] Yamada I, Matsuo J, Toyoda N, Kirkpatrick A 2001 Mater. Sci. Eng. R 34 231

Google Scholar

Google Scholar

[16] Prasalovich S, Popok V, Persson P, Campbell E E B 2005 J. Eur. Phys. D 36 79

Google Scholar

Google Scholar

[17] 曾晓梅, Vasiliy Pelenovich, Rakhim Rakhimov, 左文彬, 邢斌, 罗进宝, 张翔宇, 付德君 2020 69 093601

Google Scholar

Google Scholar

Zeng X M, Pelenovich V, Rakhimov R, Zuo W B, Xing B, Luo J B, Zhang X Y, Fu D J 2020 Acta Phys. Sin. 69 093601

Google Scholar

Google Scholar

[18] Tolstoguzov A B, Drozdov M N, Ieshkin A E, Tatarintsev A A, Myakon’kikh A V, Belykh S F, Korobeishchiko, N G, Pelenovich V 2020 JETP Letters. 111 467

Google Scholar

Google Scholar

[19] Merkle K J, Jager W 1981 Philos. Mag. A 44 741

Google Scholar

Google Scholar

[20] Gapann J 1995 Sensor Actuator. A 51 37

Google Scholar

Google Scholar

[21] Takeuchi D, Seki T, Aoki T, Matsuo J, Yamada I 1998 Mater. Chem. Phys. 54 76

Google Scholar

Google Scholar

[22] Matsuo J, Seki T, Yamada I 2003 Nucl. Instrum. Methods B 206 838

Google Scholar

Google Scholar

[23] Allen L P, Insepov Z, Fenner D B, Santeufemio, Brooks C W, Jones K S, Yamada I 2002 J. Appl. Phys. 92 3671

Google Scholar

Google Scholar

[24] Momota S, NojiIi Y 2006 Nucl. Instrum. Methods B 242 247

Google Scholar

Google Scholar

[25] Seki T, Kaneko T, Takeuchi D, Aoki T, Matsuo J, Insepov Z, Yamada I 1997 Nucl. Instrum. Methods B 121 498

Google Scholar

Google Scholar

[26] Pelenovich V, Zeng X M, Ieshkin A, Chernysh V S, Tolstogouzov A B 2019 J. Surf. Invest. 13 344

Google Scholar

Google Scholar

[27] VasiliyPelenovich, 曾晓梅, 罗进宝, RakhimRakhimov, 左文彬, 张翔宇, 田灿鑫, 邹长伟, 付德君, 杨兵 2021 70 053601

Google Scholar

Google Scholar

Pelenovich V, Zeng X M, Luo J B, Rakhimov R, Zuo W B, Zhang X Y, Tian C X, Zhou C W, Fu D J, Yang B 2021 Acta Phys. Sin. 70 053601

Google Scholar

Google Scholar

[28] Zeng X M, Pelenovich V, Liu C S, FuD J 2017 Chin. Phys. C 41 087003

Google Scholar

Google Scholar

[29] Zeng X M, Pelenovich V, Zuo W B 2019 Beilstein J. Nanotechnol. 10 135

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6456

- PDF Downloads: 77

- Cited By: 0

DownLoad:

DownLoad: