-

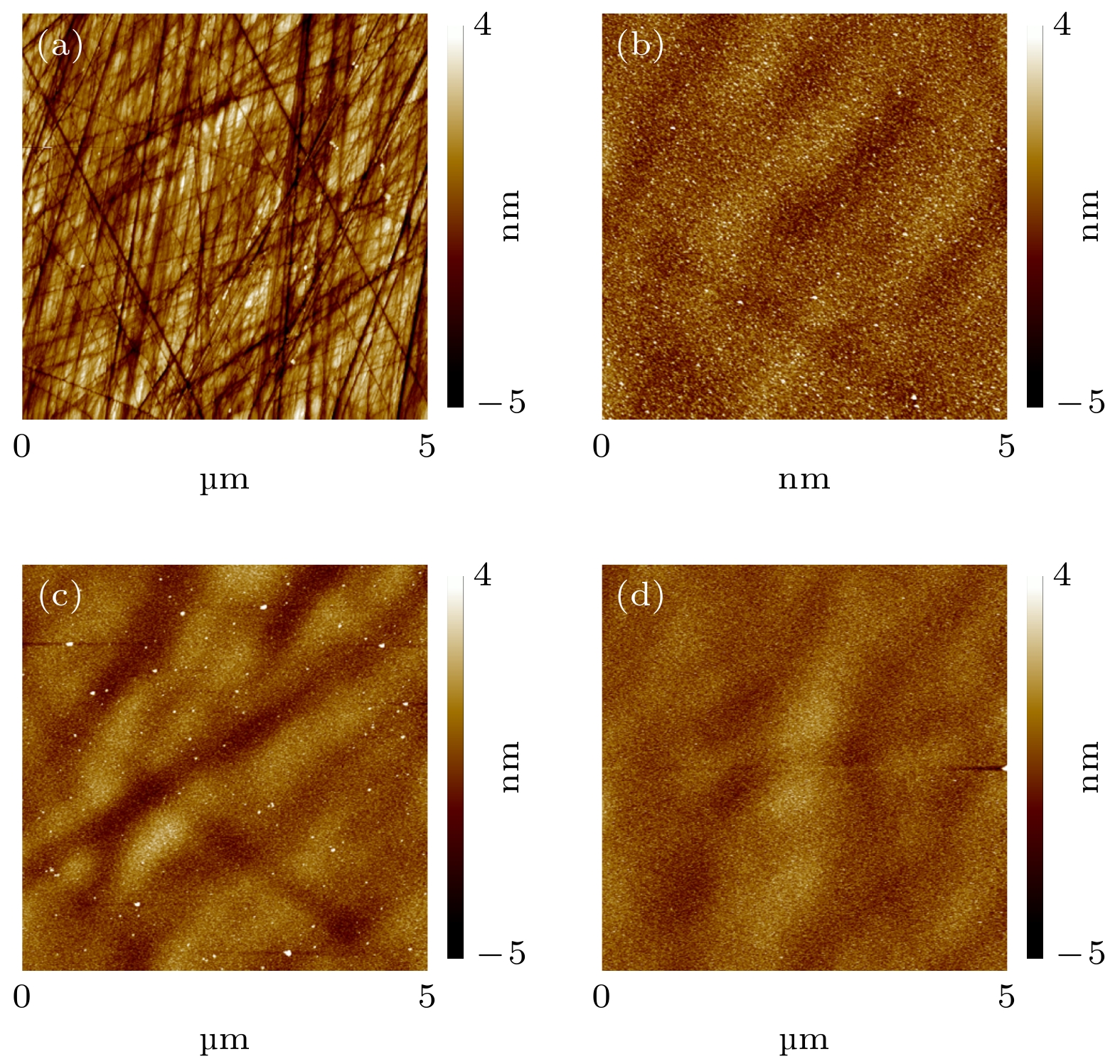

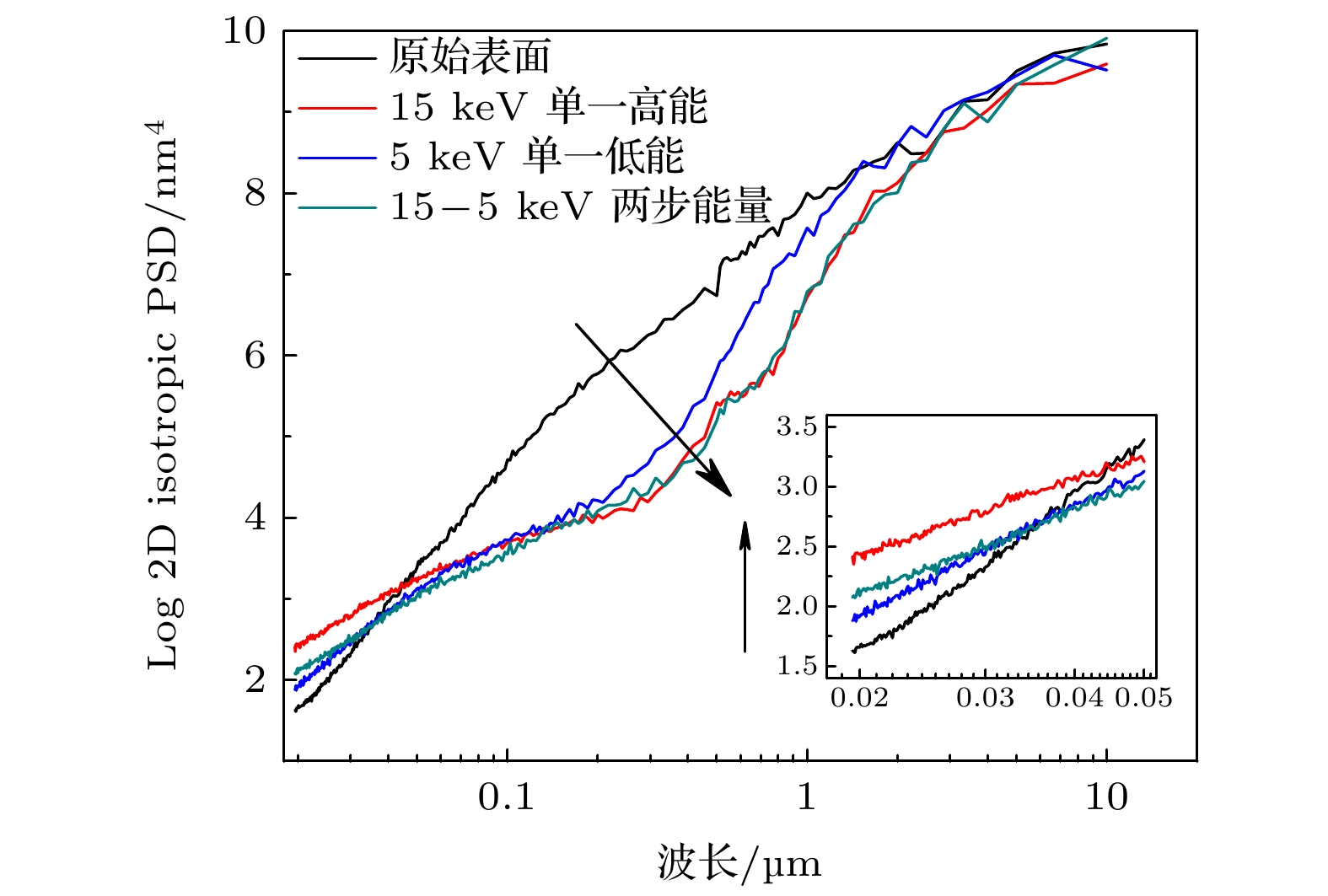

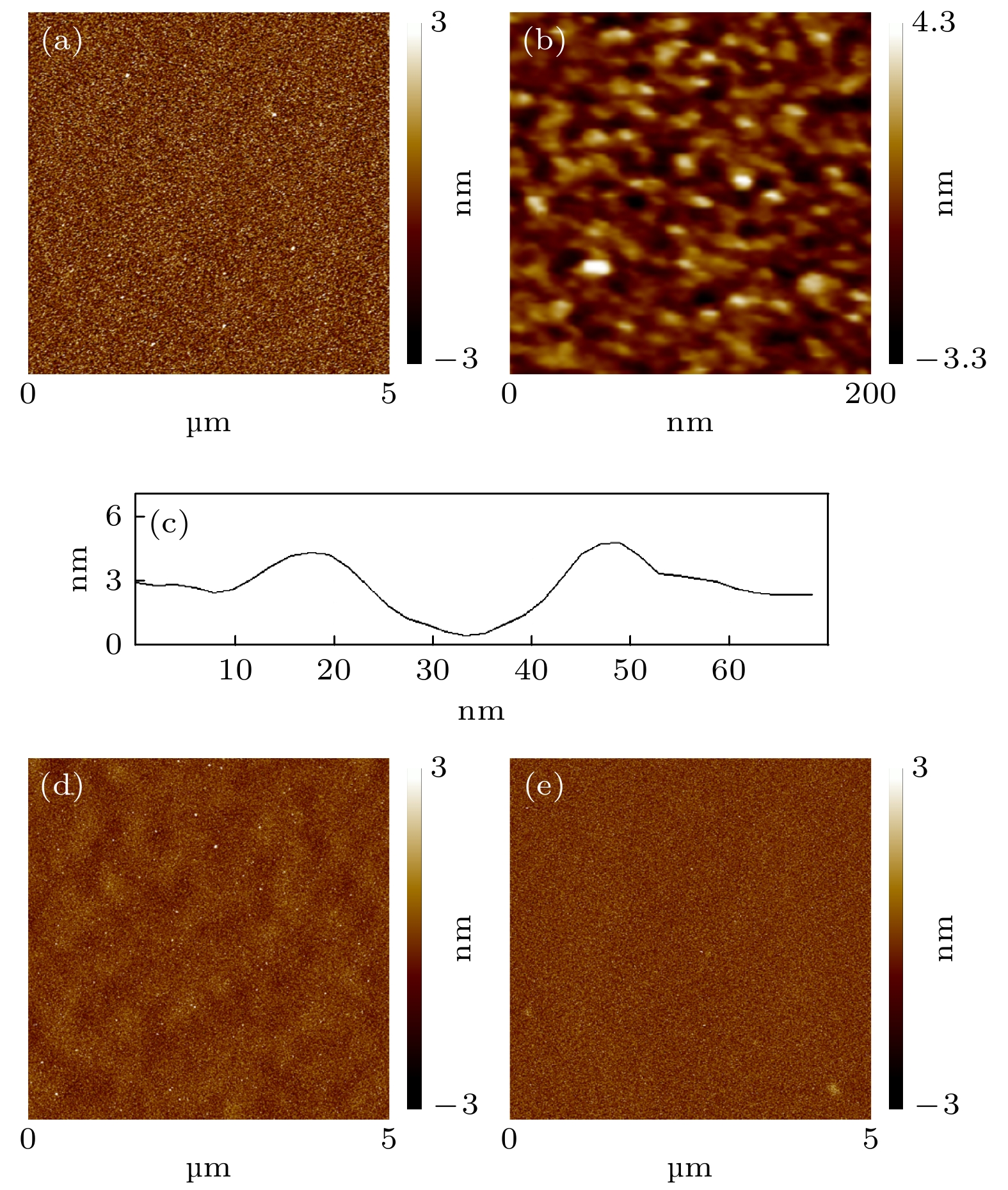

In this study we use the double step gas cluster ion beam treatment to improve smoothing process of mechanically polished 4H-SiC (1000) wafers and compare it with conventional single-step smoothing. The first step is a higher energy treatment with 15 keV Ar cluster ions, and the second step is a lower 5 keV treatment. Single-step treatments are performed at 15 and 5 keV. It is shown that single-step 15 keV smoothing as compared with lower 5 keV one is very effective for removing the initial surface morphological feature (scratches), however, cluster ions impacting on the surface can create larger craters, resulting in roughness Rq of 1.05 nm. Whereas, 5 keV treatment at a selected fluence cannot remove initial scratches, which requires using higher fluences, i.e. such smoothing becomes time consuming. On the other hand, crater morphology with such a treatment is less developed, hence, the roughness slightly decreases to 0.9 nm. Using the double-step treatment, one can obtain the surface with lower Rq roughness of 0.78 nm as compared with single-step treatment, at the same total cluster ion fluence. Therefore, the double-step treatment combines the advantages of the effective smoothing of scratches at high energy and smaller crater morphology at low energy. To evaluate the contribution of the cluster morphology introduced by the accelerated clusters into the total roughness, the cluster ion beam treatment of an atomically smooth 4H-SiC (1000) surface is also carried out. It is shown that the crater diameter increases in a range of 15–30 nm with the cluster energy increasing. More detailed analysis of the smoothing process is carried out by using two-dimensional isotropic PSD function. It is shown that the cluster treatment of mechanically polished 4H-SiC wafers effectively reduces the roughness in a wavelength range of 0.05–0.20 μm and the efficiency of smoothing is higher at higher cluster energy. In a range of 0.02–0.05 μm, a roughening effect is observed, which is due to the formation of craters. This roughening effect can be effectively reduced by the subsequent lower energy step treatment, which can be shown by the PSD function analysis of the smooth SiC surface treated initially by cluster ion beam.

-

Keywords:

- gas cluster ion beam /

- surface smoothing /

- steps energy model /

- surface roughness

[1] Yamada I, Matsuo J, Toyoda N, Kirkpatrick A 2001 Mater. Sci. Eng., R 34 231

Google Scholar

Google Scholar

[2] Toyoda N, Ogawa A 2017 J. Phys. D: Appl. Phys. 50 184003

Google Scholar

Google Scholar

[3] Korobeishchikov N G, Nikolaev I V, Roenko M A 2019 Nucl. Instrum. Methods B 438 1

Google Scholar

Google Scholar

[4] Suzuki K, Kusakari M, Fujii M, Seki T, Aoki T, Matsuo J 2016 Surf. Interface Anal. 48 1119

Google Scholar

Google Scholar

[5] Toyoda N, Tilakaratne B, Saleem I, Chu W K 2019 Appl. Phys. Rev. 6 020901

Google Scholar

Google Scholar

[6] Ieshkin A, Kireev D, Ozerova K, Senatulin B 2020 Mater. Lett. 272 127829

Google Scholar

Google Scholar

[7] Prasalovich S, Popok V, Persson P, Campbell E E B 2005 Eur. J. Phys. D 36 79

Google Scholar

Google Scholar

[8] Gspann J 1995 Sens. Actuators A 51 37

Google Scholar

Google Scholar

[9] Takeuchi D, Seki T, Aoki T, Matsuo J, Yamada I 1998 Mater. Chem. Phys. 54 76

Google Scholar

Google Scholar

[10] Matsuo J, Seki T, Yamada I 2003 Nucl. Instrum. Methods B 206 838

Google Scholar

Google Scholar

[11] Houzumi S, Takeshima K, Mochiji K, Toyoda N, Yamada I 2008 Electron. Commun. Jpn. 91 312

[12] Greer J A, Fenner D B, Hautala J, Allen L P, DiFilippo V, Toyoda N, Yamada I, Matsuo J, Minamid E, Katsumata H 2000 Surf. Coat. Technol. 133-134 273

Google Scholar

Google Scholar

[13] Isogai H, Toyoda E, Senda T, Izunome K, Kashima K, Toyoda N, Yamada I 2007 Nucl. Instrum. Methods B 257 683

Google Scholar

Google Scholar

[14] Seki T, Matsuo J 2007 Surf. Coat. Technol. 201 8646

Google Scholar

Google Scholar

[15] Toyoda N, Fujimoto A, Yamada I 2013 Jpn. J. Appl. Phys. 52 06GF01

Google Scholar

Google Scholar

[16] Matsuo J, Toyoda N, Akizuki M, Yamada I 1997 Nucl. Instrum. Methods B 121 459

Google Scholar

Google Scholar

[17] 曾晓梅, Vasiliy Pelenovich, Rakhim Rakhimov, 左文彬, 邢斌, 罗进宝, 张翔宇, 付德君 2020 69 093601

Google Scholar

Google Scholar

Zeng X M, Pelenovich V, Rakhimov R, Zuo W B, Xing B, Luo J B, Zhang X Y, Fu D J 2020 Acta Phys. Sin. 69 093601

Google Scholar

Google Scholar

[18] Zeng X M, Pelenovich V, Wang Z S, Zuo W B, Belykh S, Tolstogouzov A, Fu D J, Xiao X H 2019 Beilstein J. Nanotechnol. 10 135

Google Scholar

Google Scholar

[19] Pelenovich V O, Zeng X M, Ieshkin A E, Chernysh V S, Tolstogouzov A B, Yang B, Fu D J 2019 J. Surf. Invest. 13 344

Google Scholar

Google Scholar

[20] Zeng X M, Pelenovich V, Liu C S, Fu D J 2017 Chin. Phys. C 41 087003

Google Scholar

Google Scholar

-

图 1 4H-SiC(1000)经不同能量的Ar团簇垂直辐照后的AFM表面形貌图 (a) 15 keV; (b) 15 keV (更高倍率); (c) 图(b)中弧坑的截面轮廓图; (d) 5 keV; (e) 两步法, 15, 5 keV

Figure 1. AFM images of 4H-SiC(1000) surface after Ar cluster bombardment at different energies: (a) 15 keV; (b) 15 keV at higher magnification; (c) cross section of a crater from Fig. (b); (d) 5 keV; (e) 15 keV and subsequent 5 keV.

表 1 具有原子级平坦表面4H-SiC的团簇辐照参数(团簇能量、离子剂量、辐照时间)和辐照结果(均方根表面粗糙度Rq)

Table 1. The smoothing parameters (cluster energy, ion flux, and treatment time) and root mean square roughness Rq. The samples have atomically smooth initial surface.

团簇能

量/keV离子剂量/(1016 ions·cm–2) 辐照时

间/min均方根粗

糙度/nm0 0 0 0.15 15 3 20 0.99 5 3 40 0.61 15–5 1.5+1.5 10+20 0.62 表 2 4H-SiC(1000)样品(含有机械损伤)的平坦化参数(团簇能量、离子剂量、平坦化时间)和平坦化结果(均方根表面粗糙度Rq)

Table 2. The smoothing parameters (cluster energy, ion flux, and treatment time) and root mean square roughness Rq. The samples have mechanically polished (scratched) initial surface.

团簇能

量/keV离子剂量/(1016 ions·cm–2) 抛光时

间/min均方根粗

糙度/nm0 0 0 1.35 15 3 20 1.05 5 3 40 0.90 15–5 1.5+1.5 10+20 0.78 -

[1] Yamada I, Matsuo J, Toyoda N, Kirkpatrick A 2001 Mater. Sci. Eng., R 34 231

Google Scholar

Google Scholar

[2] Toyoda N, Ogawa A 2017 J. Phys. D: Appl. Phys. 50 184003

Google Scholar

Google Scholar

[3] Korobeishchikov N G, Nikolaev I V, Roenko M A 2019 Nucl. Instrum. Methods B 438 1

Google Scholar

Google Scholar

[4] Suzuki K, Kusakari M, Fujii M, Seki T, Aoki T, Matsuo J 2016 Surf. Interface Anal. 48 1119

Google Scholar

Google Scholar

[5] Toyoda N, Tilakaratne B, Saleem I, Chu W K 2019 Appl. Phys. Rev. 6 020901

Google Scholar

Google Scholar

[6] Ieshkin A, Kireev D, Ozerova K, Senatulin B 2020 Mater. Lett. 272 127829

Google Scholar

Google Scholar

[7] Prasalovich S, Popok V, Persson P, Campbell E E B 2005 Eur. J. Phys. D 36 79

Google Scholar

Google Scholar

[8] Gspann J 1995 Sens. Actuators A 51 37

Google Scholar

Google Scholar

[9] Takeuchi D, Seki T, Aoki T, Matsuo J, Yamada I 1998 Mater. Chem. Phys. 54 76

Google Scholar

Google Scholar

[10] Matsuo J, Seki T, Yamada I 2003 Nucl. Instrum. Methods B 206 838

Google Scholar

Google Scholar

[11] Houzumi S, Takeshima K, Mochiji K, Toyoda N, Yamada I 2008 Electron. Commun. Jpn. 91 312

[12] Greer J A, Fenner D B, Hautala J, Allen L P, DiFilippo V, Toyoda N, Yamada I, Matsuo J, Minamid E, Katsumata H 2000 Surf. Coat. Technol. 133-134 273

Google Scholar

Google Scholar

[13] Isogai H, Toyoda E, Senda T, Izunome K, Kashima K, Toyoda N, Yamada I 2007 Nucl. Instrum. Methods B 257 683

Google Scholar

Google Scholar

[14] Seki T, Matsuo J 2007 Surf. Coat. Technol. 201 8646

Google Scholar

Google Scholar

[15] Toyoda N, Fujimoto A, Yamada I 2013 Jpn. J. Appl. Phys. 52 06GF01

Google Scholar

Google Scholar

[16] Matsuo J, Toyoda N, Akizuki M, Yamada I 1997 Nucl. Instrum. Methods B 121 459

Google Scholar

Google Scholar

[17] 曾晓梅, Vasiliy Pelenovich, Rakhim Rakhimov, 左文彬, 邢斌, 罗进宝, 张翔宇, 付德君 2020 69 093601

Google Scholar

Google Scholar

Zeng X M, Pelenovich V, Rakhimov R, Zuo W B, Xing B, Luo J B, Zhang X Y, Fu D J 2020 Acta Phys. Sin. 69 093601

Google Scholar

Google Scholar

[18] Zeng X M, Pelenovich V, Wang Z S, Zuo W B, Belykh S, Tolstogouzov A, Fu D J, Xiao X H 2019 Beilstein J. Nanotechnol. 10 135

Google Scholar

Google Scholar

[19] Pelenovich V O, Zeng X M, Ieshkin A E, Chernysh V S, Tolstogouzov A B, Yang B, Fu D J 2019 J. Surf. Invest. 13 344

Google Scholar

Google Scholar

[20] Zeng X M, Pelenovich V, Liu C S, Fu D J 2017 Chin. Phys. C 41 087003

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8567

- PDF Downloads: 126

- Cited By: 0

DownLoad:

DownLoad: