-

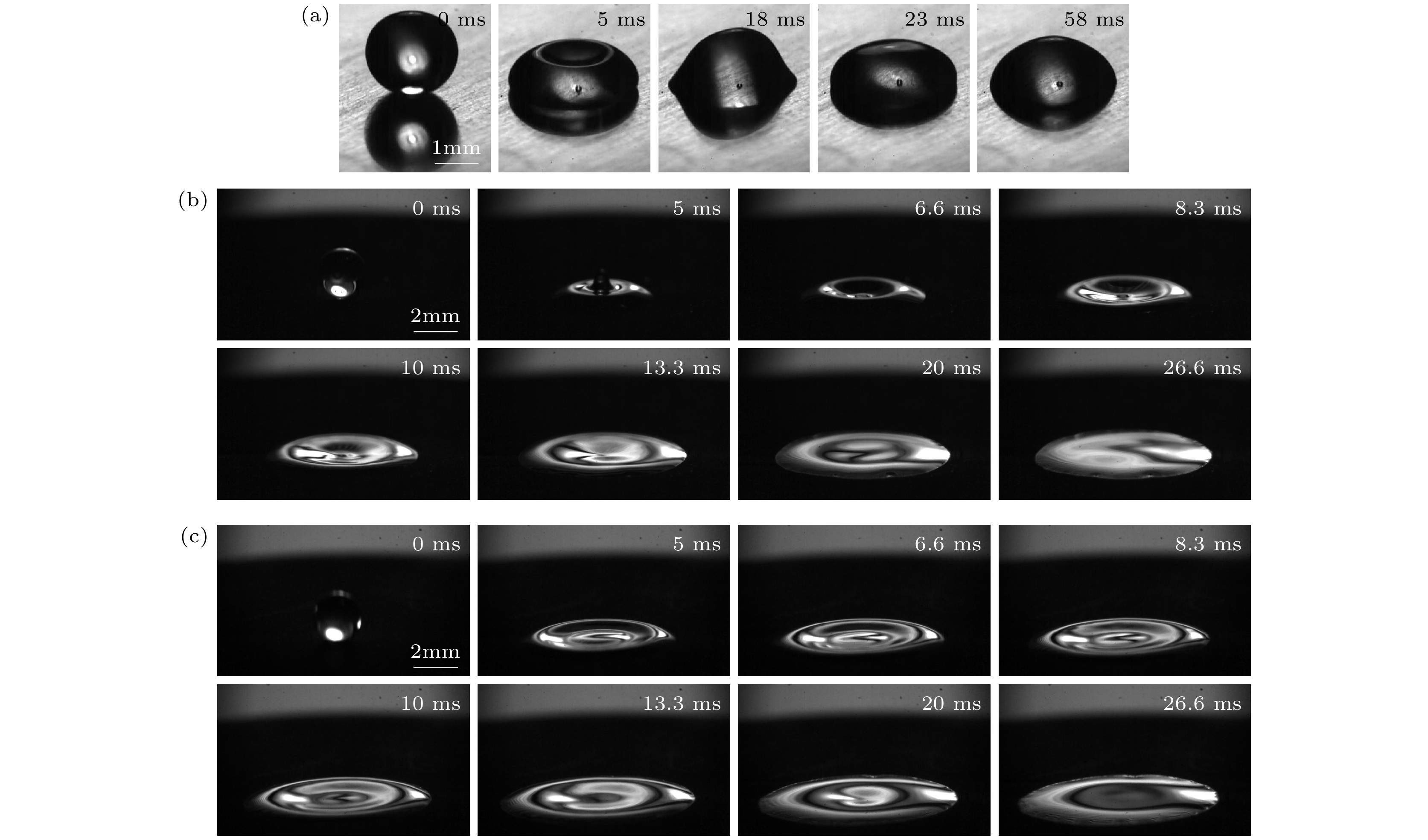

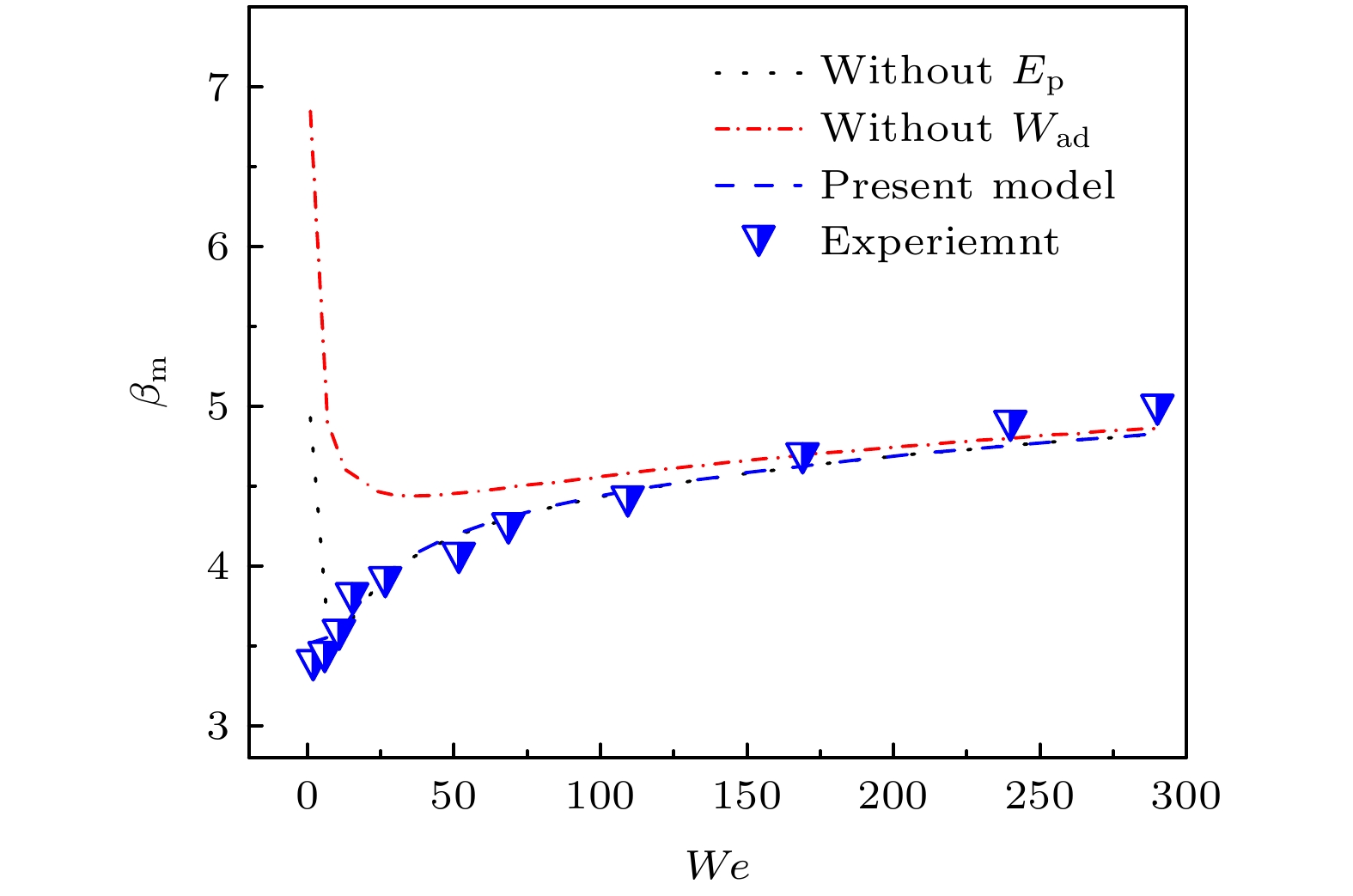

Liquid droplets impacting on the solid surface is an ubiquitous phenomenon in natural, agricultural, and industrial processes. The maximum spreading diameter of a liquid droplet impacting on a solid surface is a significant parameter in the industrial applications such as inkjet printing, spray coating, and spray cooling. However, former models cannot accurately predict the maximum spreading diameter on a superhydrophilic surface, especially under low Weber number (We). In this work, the spreading characteristics of a water droplet impacting on a superhydrophilic surface are explored by high-speed technique. The spherical cap of the spreading droplet, gravitational potential energy, and auxiliary dissipation are introduced into the modified theoretical model based on the energy balance. The model includes two viscous dissipation terms: the viscous dissipation of the initial kinetic energy and the auxiliary dissipation in spontaneous spreading. The energy component analysis in the spreading process shows that the kinetic energy, surface energy, and gravitational potential energy are all transformed into the viscous dissipation on the superhydrophilic surface. The transformation of surface energy into viscous dissipation is dominant at lower We while the transformation of kinetic energy into viscous dissipation is dominant at higher We. It is found that the gravitational potential energy and auxiliary dissipation play a significant role in spreading performance at low We according to the energy component analysis. Moreover, the energy components predicted by the modified model accord well with the experimental data. As a result, the proposed model can predict the maximum spreading diameter of a droplet impacting on the superhydrophilic surface accurately. Furthermore, the model proposed in this work can predict the maximum spreading diameter of the droplet impacting on the hydrophilic surface and hydrophobic surface. The results of this work are of great significance for controlling droplet spreading diameter in spray cooling and falling film evaporation.

-

Keywords:

- superhydrophilic surfaces /

- maximum spreading diameter /

- gravitational potential energy /

- auxiliary dissipation

[1] Liang G, Mudawar I 2016 Int. J. Heat Mass Transfer 101 577

Google Scholar

Google Scholar

[2] 马学虎, 兰忠, 王凯, 陈彦松, 程雅琦, 杜宾港, 叶轩 2018 化工学报 69 9

Google Scholar

Google Scholar

Ma X H, Lan Z, Wang K, Chen Y S, Cheng Y Q, Du B G, Ye X 2018 J. Chem. Ind. Eng. 69 9

Google Scholar

Google Scholar

[3] Snoeijer J H, Andreotti B 2013 Annu. Rev. Fluid Mech. 45 269

Google Scholar

Google Scholar

[4] 朱君悦, 段远源, 王晓东, 闵琪 2014 化工学报 65 765

Google Scholar

Google Scholar

Zhu J Y, Duan Y Y, Wang X D, Min Q 2014 J. Chem. Ind. Eng. 65 765

Google Scholar

Google Scholar

[5] 刘海龙, 沈学峰, 王睿, 曹宇, 王军锋 2018 力学学报 50 1024

Google Scholar

Google Scholar

Liu H L, Shen X F, Wang R, Cao Y, Wang J F 2018 Acta Mech. Sin. 50 1024

Google Scholar

Google Scholar

[6] 闵琪, 段远源, 王晓东, 吴莘馨 2013 热科学与技术 12 335

Google Scholar

Google Scholar

Min Q, Duan Y Y, Wang X D, Wu X X 2013 J. Therm. Sci. Technol. 12 335

Google Scholar

Google Scholar

[7] Hu H B, Chen L B, Bao L Y, Huang S H 2014 Chin. Phys. B 23 074702

Google Scholar

Google Scholar

[8] Sun Z H, Han R J 2008 Chin. Phys. B 17 3185

Google Scholar

Google Scholar

[9] Wang Y B, Wang Y F, Gao S R, Yang Y R, Wang X D, Chen M 2020 Langmuir 36 9306

Google Scholar

Google Scholar

[10] Hu H B, Huang S H, Chen L B 2013 Chin. Phys. B 22 084702

Google Scholar

Google Scholar

[11] Song M, Liu Z, Ma Y, Dong Z, Wang Y, Jiang L 2017 NPG Asia Mater. 9 1

Google Scholar

Google Scholar

[12] 王高远, 胥蕊娜, 陈剑楠, 陈学, 姜培学 2018 工程热 39 1797

Google Scholar

Google Scholar

Wang G Y, Xu R N, Chen J N, Chen X, Jiang P X 2018 J. Eng. Thermphys. 39 1797

Google Scholar

Google Scholar

[13] Lin S, Zhao B, Zou S, Guo J, Wei Z, Chen L 2018 J. Colloid Interface Sci. 516 86

Google Scholar

Google Scholar

[14] Lee J B, Derome D, Guyer R, Carmeliet J 2016 Langmuir 32 1299

Google Scholar

Google Scholar

[15] Tang C, Qin M, Weng X, Zhang X, Zhang P, Li J, Huang Z 2017 Int. J. Multiphase Flow 96 56

Google Scholar

Google Scholar

[16] 荣松, 沈世全, 王天友, 车志钊 2019 68 154701

Google Scholar

Google Scholar

Rong S, Shen S Q, Wang T Y, Che Z Z 2019 Acta Phys. Sin. 68 154701

Google Scholar

Google Scholar

[17] Ding B, Wang H, Zhu X, Chen R, Liao Q 2018 Int. J. Heat Mass Transfer 124 1025

Google Scholar

Google Scholar

[18] 范瑶, 王宏, 朱恂, 黄格永, 丁玉栋, 廖强 2016 化工学报 67 2709

Google Scholar

Google Scholar

Fan Y, Wang H, Zhu X, Huang G Y, Ding Y D, Liao Q 2016 J. Chem. Ind. Eng. 67 2709

Google Scholar

Google Scholar

[19] Ding B, Wang H, Zhu X, Chen R, Liao Q 2019 Int. J. Heat Mass Transfer 138 844

Google Scholar

Google Scholar

[20] Chen M, Wu D, Chen D, Deng J, Liu H, Jiang J 2020 Chem. Eng. Sci. 226 115864

Google Scholar

Google Scholar

[21] 焦云龙, 刘小君, 逄明华, 刘焜 2016 65 016801

Google Scholar

Google Scholar

Jiao Y L, Liu X J, Pang M H, Liu K 2016 Acta Phys. Sin. 65 016801

Google Scholar

Google Scholar

[22] 叶学民, 李永康, 李春曦 2016 65 234701

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. Sin. 65 234701

Google Scholar

Google Scholar

[23] Roisman I V 2009 Phys. Fluids 21 052104

Google Scholar

Google Scholar

[24] Liang G, Chen Y, Chen L, Shen S 2019 Ind. Eng. Chem. Res. 58 10053

Google Scholar

Google Scholar

[25] Laan N, de Bruin K G, Bartolo D, Josserand C, Bonn D 2014 Phys. Rev. Appl. 2 044018

Google Scholar

Google Scholar

[26] Lee J B, Laan N, de Bruin K G, Skantzaris G, Shahidzadeh N, Derome D, Carmeliet J, Bonn D 2016 J. Fluid Mech. 786 R4

Google Scholar

Google Scholar

[27] Chandra S, Avedisian C T 1991 Proc. R. Soc. A 432 13

Google Scholar

Google Scholar

[28] Pasandideh‐Fard M, Qiao Y M, Chandra S, Mostaghimi J 1996 Phys. Fluids 8 650

Google Scholar

Google Scholar

[29] Mao T, Kuhn D C S, Tran H 1997 AlChE J. 43 2169

Google Scholar

Google Scholar

[30] Ukiwe C, Kwok D Y 2005 Langmuir 21 666

Google Scholar

Google Scholar

[31] Huang H M, Chen X P 2018 Phys. Fluids 30 022106

Google Scholar

Google Scholar

[32] Park H, Carr W W, Zhu J, Morris J F 2003 AlChE J. 49 2461

Google Scholar

Google Scholar

[33] Li Ri, Ashgriz Nasser, Sanjeev C 2010 J. Fluids Eng. 132 061302

Google Scholar

Google Scholar

[34] Gao X, Li R 2014 AlChE J. 60 2683

Google Scholar

Google Scholar

[35] Wang F, Yang L, Wang L, Zhu Y, Fang T 2019 Langmuir 35 3204

Google Scholar

Google Scholar

[36] Panda A, Pati A R, Saha B, Kumar A, Mohapatra S S 2019 Chem. Eng. Sci. 207 527

Google Scholar

Google Scholar

[37] Zhang Z, Jiang P X, Christopher D M, Liang X-G 2015 Int. J. Heat Mass Transfer 80 26

Google Scholar

Google Scholar

[38] Zheng Y, Ma X, Li Y, Jiang R, Wang K, Lan Z, Liang Q 2017 Appl. Therm. Eng. 111 1548

Google Scholar

Google Scholar

[39] Nam Y, Ju Y S 2013 J. Adhes. Sci. Technol. 27 2163

Google Scholar

Google Scholar

[40] Vadillo D C, Soucemarianadin A, Delattre C, Roux D C D 2009 Phys. Fluids 21 122002

Google Scholar

Google Scholar

-

图 1 液滴铺展实验系统(A: 高速摄像机(Photron APX RS); B: 高速摄像机(Photron Mini UX100); C: 微量注射泵(LSP01-1 BH); D: 液滴生成装置; E: 恒温台; F: 高亮光源; G: 数据采集设备; G: 精确自动控制位移的直线位移滑台)

Figure 1. The droplet spreading experiment platform. (A: high speed camera (Photron APX RS); B: high speed camera (Photron Mini UX100); C: micro syringe pump (LSP01-1 BH); D: droplet generating device; E: heating platform; F: diffuse light source; G: data acquisition computer; H: linear displacement slide.

表 1 基于能量守恒的最大铺展因子的预测模型

Table 1. Theoretical models for predicting the maximum spreading factor.

文献 最大铺展模型预测表达式 表面润湿

性/(°)We 液滴形态 Lee等[14] $\begin{aligned} \rho {V_0}{D_0} + 12\sigma\qquad\qquad\qquad\qquad\quad\qquad\qquad\qquad\qquad \\= 3\sigma (1 - \cos \theta )\beta _{\rm{m} }^2 + 8\sigma \dfrac{1}{ { {\beta _{\rm{m} } } } } + 3\sqrt { {b / c} } \rho V_{\rm{0} }^2{D_0}\beta _{\rm{m} }^{ {5 / 2} }\dfrac{1}{ {\sqrt {Re} } }\end{aligned}$ 60—115 1—290 圆饼 Chandra等[27] $\dfrac{3}{2}\dfrac{ {We} }{ {Re} }\beta _{\rm{m} }^4 + \left( {1 - \cos \theta } \right)\beta _{\rm{m} }^2 - \left( {\dfrac{1}{3}We + 4} \right) = 0$ ~32 ~43 圆饼 Pasandideh-

Fard等[28]${\beta _{\rm{m} } } = \sqrt {\dfrac{ {We + 12} }{ {3\left( {1 - \cos {\theta _{\rm{a} } } } \right) + 4\left( { { {We} / {\sqrt {Re} } } } \right)} } }$ 27—140 27—447 圆饼 Mao等[29] $\left( {\dfrac{ {1 - \cos \theta } }{4} + 0.35\dfrac{ {We} }{ {\sqrt {Re} } } } \right)\beta _{\rm{m} }^4 - \left( {\dfrac{ {We} }{ {12} } + 1} \right)\beta + \dfrac{2}{3} = 0$ 30—120 5—1000 圆饼 Ukiwe等[30] $\left( {We + 12} \right){\beta _{\rm{m} } } = 8 + \beta _{\rm{m} }^3\left[ {3\left( {1 - \cos \theta } \right) + 4\dfrac{ {We} }{ {\sqrt {Re} } } } \right]$ 57—90 18—370 圆饼 Huang等[31] $\begin{aligned}\frac{3}{4}\left( {\frac{ {We} }{ {\sqrt {Re} } } + \frac{ {We^*} }{ {\sqrt {Re^*} } } } \right)\beta _{\rm{m} }^4 + 3\left( {1 - \cos {\theta _{\rm{a} } } } \right)\beta _{\rm{m} }^3 \qquad\\ - \left( {We + 12} \right){\beta _{\rm{m} } } + 8 = 0, ~~{V_0} < V^* \qquad\qquad\qquad\end{aligned}$

$\begin{aligned} \frac{3}{4}\left( {\frac{ {We} }{ {\sqrt {Re} } } + \frac{ {We^*} }{ {\sqrt {Re^*} } }\frac{ {Re^*} }{ {Re} } } \right)\beta _{\rm{m} }^4 + 3\left( {1 - \cos {\theta _{\rm{a} } } } \right)\beta _{\rm{m} }^3 \\ - \left( {We + 12} \right){\beta _{\rm{m} } } + 8 = 0,~~ {V_0} > V^*\qquad\qquad\qquad \end{aligned}$64—110 2—500 圆饼 Park等[32] $\begin{aligned} \left( {0.33\frac{ {We} }{ {\sqrt {Re} } } - \frac{1}{4}\cos \theta + \frac{1}{2}\left( {\frac{ {1 - \cos {\theta _{\rm{a} } } } }{ { { {\sin }^2}{\theta _{\rm{a} } } } } } \right)} \right)\beta _{\rm{m} }^2 \\ - 1 - \frac{ {We} }{ {12} } + \frac{ {\Delta {E_{\rm{s} } } } }{ { {\text{π} }D_0^2\sigma } } = 0 \qquad\qquad\qquad\qquad\quad\end{aligned}$ 31—113 0.2—180 球冠 Li等[33] $\dfrac{ {We} }{ {12} }\left( {1 - {C_{\rm{k} } } - \dfrac{3}{ {2\sqrt {Re} } }\displaystyle\int_{ {H_{\rm{m} } } }^{ {H_{\rm{s} } } } { {d^2}{\rm{d} }h} } \right) = {C_{\rm{S} } }P\left( { {D_{\rm{e} } } } \right) - P\left( { {D_{ {\rm{max} } } } } \right)$ 30—150 0—10 球冠 Gao等[34] $\begin{aligned} 1 + \frac{ {We} }{ {12} } = \frac{1}{6}\left[ {\frac{1}{ { { {\hat r}_{\rm{c} } } } } + \frac{1}{ { { {\hat R}_{\rm{c} } } } } } \right] + 4{\theta _{\rm{a} } }{ {\hat r}_{\rm{c} } }{ {\hat R}_{\rm{c} } } + {\left( { { {\hat R}_{\rm{c} } } - { {\hat r}_{\rm{c} } }\sin {\theta _{\rm{a} } } } \right)^2} \\ + {\left( { { {\hat R}_{\rm{c} } } + { {\hat r}_{\rm{c} } }\sin {\theta _{\rm{a} } } } \right)^2}\left( {\frac{4}{3}\frac{ {We} }{ {\sqrt {Re} } } - \cos {\theta _{\rm{a} } } } \right) \qquad\quad\end{aligned}$ 74—155 135—210 圆环 Wang等[35] $\begin{aligned} We + 12 =\qquad \qquad\qquad \qquad\qquad \qquad\qquad\qquad\qquad\qquad\qquad \qquad\\ \frac{3}{4}\left( {\frac{ {We} }{ {\sqrt {Re} } } + \alpha \frac{ {W{e_{\rm{c} } } } }{ {\sqrt {R{e_{\rm{c} } } } } } } \right)\beta _{\rm{m} }^3 + 3\left( {1 - \cos {\theta _{\rm{a} } } } \right)\beta _{\rm{m} }^2 + 12\bigg\{ \frac{ {\xi _{\rm{r} }^2} }{ { { {\left( {1 - \cos {\theta _{\rm{m} } } } \right)}^2} } } \\ \times \bigg[ {\sin ^2}{\theta _{\rm{m} } } - \frac{ { {\beta _{\rm{m} } } } }{ { {\xi _{\rm{r} } } } }\sin {\theta _{\rm{m} } }(1 - \cos {\theta _{\rm{m} } }) + 2(1 - \cos {\theta _{\rm{m} } }) \bigg] \qquad \qquad \qquad \\ \left. + 2{\xi _{\rm{r} } }\left( {\frac{ { {\beta _{\rm{m} } } } }{2} - {\xi _{\rm{r} } }\frac{ {\sin {\theta _{\rm{m} } } } }{ {1 - \cos {\theta _{\rm{m} } } } } } \right)\left( {\left| {1 - \kappa } \right| + \frac{ { {\theta _{\rm{m} } } } }{ {1 - \cos {\theta _{\rm{m} } } } } } \right) \right\}\qquad\qquad \quad \end{aligned}$ 34—100 0.1—427 环状-薄片 表 2 超亲水表面最大铺展因子βm实验结果与以往典型模型预测值[27-32]之间的比较

Table 2. Comparison of previous model[27-32] prediction value of βm with experimental data

V0/(m·s–1) We βm-exp Chandra 等[27] Pasandideh-Fard 等[28] Mao等[29] Park等[32] Ukiwe 等[30] Huang等[31] 0.25 1.91 3.41 2.4 6.37 3.05 11.31 5.84 0.58 0.44 5.90 3.46 2.1 4.82 2.55 7.93 4.42 0.44 0.60 10.77 3.60 1.97 4.37 2.41 6.67 4.02 0.35 0.71 15.26 3.82 1.93 4.20 2.37 6.09 3.90 0.29 0.93 25.59 3.93 1.89 4.07 2.35 5.41 3.82 0.20 130 51.17 4.08 1.90 4.08 2.38 4.9 3.93 0.12 1.50 68.59 4.26 1.91 4.13 2.41 4.78 3.93 0.10 1.89 109.3 4.43 1.93 4.26 2.47 4.67 4.07 0.06 2.35 168.98 4.70 1.97 4.42 2.54 4.66 4.24 0.04 2.8 239.89 4.90 2.00 4.57 2.60 4.72 4.39 0.03 3.08 290.08 5.00 2.02 4.67 2.64 4.76 4.48 0.02 表 3 本文模型预测值与文献[28,29]中不同润湿性表面的最大铺展因子的实验值对比

Table 3. Comparison of current theoretical model of βm with experimental data in literature[28,29].

固体/液体 D0, mm V0/(m·s–1) We θ/(°) βm-exp βm-model (βm-exp–βm-model)/ βm-model 玻璃/水 2.7 0.55 11.21 37 1.77 2.41 0.26 玻璃/水 2.7 0.82 24.91 37 2.20 2.74 0.19 玻璃/水 2.7 1.00 37.05 37 2.53 2.94 0.14 玻璃/水 2.7 1.58 92.48 37 3.11 3.51 0.11 玻璃/水 2.7 1.86 128.17 37 3.70 3.81 0.03 玻璃/水 2.7 2.77 284.26 37 4.50 4.48 0.00 玻璃/水 2.7 3.72 512.67 37 4.94 4.89 0.01 不锈钢/水 2.7 0.55 11.21 67 1.67 1.95 0.14 不锈钢/水 2.7 0.82 24.91 67 2.16 2.28 0.05 不锈钢/水 2.7 1.00 37.05 67 2.34 2.51 0.06 不锈钢/水 2.7 1.58 92.48 67 3.09 3.13 0.01 不锈钢/水 2.7 1.86 128.17 67 3.67 3.38 0.08 不锈钢/水 2.7 2.77 284.26 67 4.42 4.15 0.06 不锈钢/水 2.7 3.72 512.67 67 4.88 4.65 0.05 石蜡/水 2.7 0.55 11.21 97 1.65 1.58 0.04 石蜡/水 2.7 0.82 24.91 97 2.10 1.91 0.10 石蜡/水 2.7 1.00 37.05 97 2.26 2.13 0.06 石蜡/水 2.7 1.58 92.48 97 3.01 2.79 0.07 石蜡/水 2.7 1.86 128.17 97 3.60 3.09 0.16 石蜡/水 2.7 2.77 284.26 97 4.32 3.89 0.11 石蜡/水 2.7 3.72 512.67 97 4.78 4.44 0.08 蜂蜡/水 0.62 2.61 59 111 2.65 2.19 0.21 蜂蜡/水 0.78 3.29 118 111 3.18 2.76 0.15 蜂蜡/水 0.89 3.71 171 111 3.45 3.09 0.11 蜂蜡/水 0.98 4.00 219 111 3.79 3.33 0.14 蜂蜡/水 1.05 4.28 271 111 3.91 3.53 0.10 -

[1] Liang G, Mudawar I 2016 Int. J. Heat Mass Transfer 101 577

Google Scholar

Google Scholar

[2] 马学虎, 兰忠, 王凯, 陈彦松, 程雅琦, 杜宾港, 叶轩 2018 化工学报 69 9

Google Scholar

Google Scholar

Ma X H, Lan Z, Wang K, Chen Y S, Cheng Y Q, Du B G, Ye X 2018 J. Chem. Ind. Eng. 69 9

Google Scholar

Google Scholar

[3] Snoeijer J H, Andreotti B 2013 Annu. Rev. Fluid Mech. 45 269

Google Scholar

Google Scholar

[4] 朱君悦, 段远源, 王晓东, 闵琪 2014 化工学报 65 765

Google Scholar

Google Scholar

Zhu J Y, Duan Y Y, Wang X D, Min Q 2014 J. Chem. Ind. Eng. 65 765

Google Scholar

Google Scholar

[5] 刘海龙, 沈学峰, 王睿, 曹宇, 王军锋 2018 力学学报 50 1024

Google Scholar

Google Scholar

Liu H L, Shen X F, Wang R, Cao Y, Wang J F 2018 Acta Mech. Sin. 50 1024

Google Scholar

Google Scholar

[6] 闵琪, 段远源, 王晓东, 吴莘馨 2013 热科学与技术 12 335

Google Scholar

Google Scholar

Min Q, Duan Y Y, Wang X D, Wu X X 2013 J. Therm. Sci. Technol. 12 335

Google Scholar

Google Scholar

[7] Hu H B, Chen L B, Bao L Y, Huang S H 2014 Chin. Phys. B 23 074702

Google Scholar

Google Scholar

[8] Sun Z H, Han R J 2008 Chin. Phys. B 17 3185

Google Scholar

Google Scholar

[9] Wang Y B, Wang Y F, Gao S R, Yang Y R, Wang X D, Chen M 2020 Langmuir 36 9306

Google Scholar

Google Scholar

[10] Hu H B, Huang S H, Chen L B 2013 Chin. Phys. B 22 084702

Google Scholar

Google Scholar

[11] Song M, Liu Z, Ma Y, Dong Z, Wang Y, Jiang L 2017 NPG Asia Mater. 9 1

Google Scholar

Google Scholar

[12] 王高远, 胥蕊娜, 陈剑楠, 陈学, 姜培学 2018 工程热 39 1797

Google Scholar

Google Scholar

Wang G Y, Xu R N, Chen J N, Chen X, Jiang P X 2018 J. Eng. Thermphys. 39 1797

Google Scholar

Google Scholar

[13] Lin S, Zhao B, Zou S, Guo J, Wei Z, Chen L 2018 J. Colloid Interface Sci. 516 86

Google Scholar

Google Scholar

[14] Lee J B, Derome D, Guyer R, Carmeliet J 2016 Langmuir 32 1299

Google Scholar

Google Scholar

[15] Tang C, Qin M, Weng X, Zhang X, Zhang P, Li J, Huang Z 2017 Int. J. Multiphase Flow 96 56

Google Scholar

Google Scholar

[16] 荣松, 沈世全, 王天友, 车志钊 2019 68 154701

Google Scholar

Google Scholar

Rong S, Shen S Q, Wang T Y, Che Z Z 2019 Acta Phys. Sin. 68 154701

Google Scholar

Google Scholar

[17] Ding B, Wang H, Zhu X, Chen R, Liao Q 2018 Int. J. Heat Mass Transfer 124 1025

Google Scholar

Google Scholar

[18] 范瑶, 王宏, 朱恂, 黄格永, 丁玉栋, 廖强 2016 化工学报 67 2709

Google Scholar

Google Scholar

Fan Y, Wang H, Zhu X, Huang G Y, Ding Y D, Liao Q 2016 J. Chem. Ind. Eng. 67 2709

Google Scholar

Google Scholar

[19] Ding B, Wang H, Zhu X, Chen R, Liao Q 2019 Int. J. Heat Mass Transfer 138 844

Google Scholar

Google Scholar

[20] Chen M, Wu D, Chen D, Deng J, Liu H, Jiang J 2020 Chem. Eng. Sci. 226 115864

Google Scholar

Google Scholar

[21] 焦云龙, 刘小君, 逄明华, 刘焜 2016 65 016801

Google Scholar

Google Scholar

Jiao Y L, Liu X J, Pang M H, Liu K 2016 Acta Phys. Sin. 65 016801

Google Scholar

Google Scholar

[22] 叶学民, 李永康, 李春曦 2016 65 234701

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. Sin. 65 234701

Google Scholar

Google Scholar

[23] Roisman I V 2009 Phys. Fluids 21 052104

Google Scholar

Google Scholar

[24] Liang G, Chen Y, Chen L, Shen S 2019 Ind. Eng. Chem. Res. 58 10053

Google Scholar

Google Scholar

[25] Laan N, de Bruin K G, Bartolo D, Josserand C, Bonn D 2014 Phys. Rev. Appl. 2 044018

Google Scholar

Google Scholar

[26] Lee J B, Laan N, de Bruin K G, Skantzaris G, Shahidzadeh N, Derome D, Carmeliet J, Bonn D 2016 J. Fluid Mech. 786 R4

Google Scholar

Google Scholar

[27] Chandra S, Avedisian C T 1991 Proc. R. Soc. A 432 13

Google Scholar

Google Scholar

[28] Pasandideh‐Fard M, Qiao Y M, Chandra S, Mostaghimi J 1996 Phys. Fluids 8 650

Google Scholar

Google Scholar

[29] Mao T, Kuhn D C S, Tran H 1997 AlChE J. 43 2169

Google Scholar

Google Scholar

[30] Ukiwe C, Kwok D Y 2005 Langmuir 21 666

Google Scholar

Google Scholar

[31] Huang H M, Chen X P 2018 Phys. Fluids 30 022106

Google Scholar

Google Scholar

[32] Park H, Carr W W, Zhu J, Morris J F 2003 AlChE J. 49 2461

Google Scholar

Google Scholar

[33] Li Ri, Ashgriz Nasser, Sanjeev C 2010 J. Fluids Eng. 132 061302

Google Scholar

Google Scholar

[34] Gao X, Li R 2014 AlChE J. 60 2683

Google Scholar

Google Scholar

[35] Wang F, Yang L, Wang L, Zhu Y, Fang T 2019 Langmuir 35 3204

Google Scholar

Google Scholar

[36] Panda A, Pati A R, Saha B, Kumar A, Mohapatra S S 2019 Chem. Eng. Sci. 207 527

Google Scholar

Google Scholar

[37] Zhang Z, Jiang P X, Christopher D M, Liang X-G 2015 Int. J. Heat Mass Transfer 80 26

Google Scholar

Google Scholar

[38] Zheng Y, Ma X, Li Y, Jiang R, Wang K, Lan Z, Liang Q 2017 Appl. Therm. Eng. 111 1548

Google Scholar

Google Scholar

[39] Nam Y, Ju Y S 2013 J. Adhes. Sci. Technol. 27 2163

Google Scholar

Google Scholar

[40] Vadillo D C, Soucemarianadin A, Delattre C, Roux D C D 2009 Phys. Fluids 21 122002

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 13629

- PDF Downloads: 330

- Cited By: 0

DownLoad:

DownLoad: