-

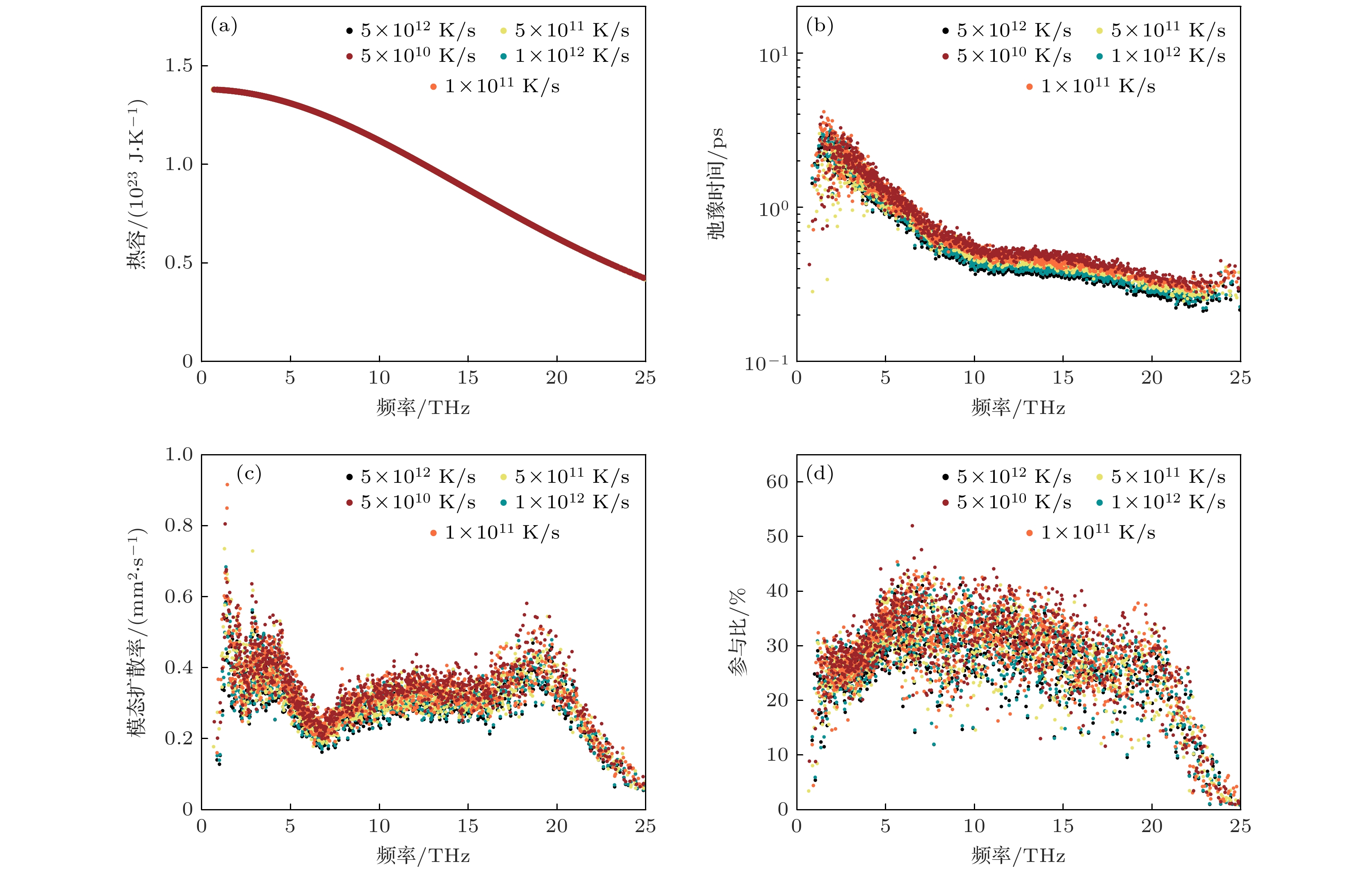

非晶态材料二氧化铪在微电子器件中具有广泛应用, 理解其微观导热机制对于提升电子器件的性能和可靠性至关重要. 以往的研究大多基于分子动力学和单一准简谐格林-久保方法, 难以准确考虑低频振动模式的导热贡献. 本文基于准简谐格林-久保理论, 结合流体动力学外推法, 对不同有序度的非晶二氧化铪结构的热输运机制进行全面研究. 该方法可有效克服单一准简谐格林-久保方法中的有限尺寸问题. 理论预测表明, 非晶二氧化铪的热导率与微观结构有序度呈现弱相关性. 基于模态分析表明, 中低频振动模式对热导率具有显著贡献, 是单一准简谐格林-久保方法低估非晶二氧化铪热导率的主要原因. 同时, 本文基于非谐动态结构因子分离了传播子和扩散子对非晶二氧化铪导热的贡献, 计算表明扩散子在所有非晶二氧化铪结构导热中均占据主导作用. 然而, 传播子的导热贡献仍不可忽略, 其占比可高达20%以上, 且随着有序度的增大而增大.

-

关键词:

- 热导率 /

- 非晶二氧化铪 /

- 准简谐格林-久保理论 /

- 流体力学外推方法

Amorphous hafnia (a-HfO2) has attracted considerable attention due to its excellent dielectric properties and broad applicability in the electronic industry. Considering that the self-heating is becoming the bottleneck for the performance and reliability of microelectronic devices, it is necessary to clarify the thermal transport mechanism in a-HfO2. The microstructures of a-HfO2 can be significantly changed during the fabrication process, whose effects on thermal transport remain to be revealed. Here, we conduct a comprehensive investigation of thermal transport in a-HfO2 based on the quasi-harmonic Green-Kubo (QHGK) theory combined with hydrodynamic extrapolation. The calculation scheme fully considers the contributions from low-frequency vibrational modes, overcoming the drawbacks of finite size in the single QHGK method and molecular dynamics simulation. It is found that the thermal conductivity (κ) of a-HfO2 is weakly related to its degree of order. The amorphous structures with slower quenching speed and higher degree of order have higher thermal conductivities due to their slightly larger relaxation times. Modal analyses show that the mid- and low-frequency vibrational modes have significant contributions to thermal transport in a-HfO2, which is the main reason for the underestimation of the κ in other methods. Based on the anharmonic dynamic structure factor, we further separate the contributions of two fundamental heat carriers in amorphous materials: propagons and diffusons. It is found that diffusons dominate the κ in all a-HfO2 structures. Nevertheless, the contribution of the propagons is non-negligible, accounting for more than 20% and increasing with the degree of structural ordering. This study provides new insights into the microscopic mechanisms and guidance for manipulating thermal transport in a-HfO2.-

Keywords:

- thermal conductivity /

- amorphous hafnia /

- quasi-harmonic Green-Kubo theory /

- hydrodynamic extrapolation method

[1] Wilk G D, Wallace R M, Anthony J 2001 J. Appl. Phys. 89 5243

Google Scholar

Google Scholar

[2] Chen J H, Liang M F, Song Y, Yuan J J, Zhang M Y, Luo Y M, Wang N N 2024 Chin. Phys. B 33 047503

Google Scholar

Google Scholar

[3] Wang Y, Zahid F, Wang J, Guo H 2012 Phys. Rev. B 85 224110

Google Scholar

Google Scholar

[4] 董典萌, 汪成, 张清怡, 张涛, 杨永涛, 夏翰驰, 王月晖, 吴真平 2023 72 097302

Google Scholar

Google Scholar

Dong D M, Wang C, Zhang Q Y, Zhang T, Yang Y T, Xia H C, Wang Y H, Wu Z P 2023 Acta. Phys. Sin. 72 097302

Google Scholar

Google Scholar

[5] Gao R, Liu C, Shi B, Li Y, Luo B, Chen R, Ouyang W, Gao H, Hu S, Wang Y 2024 Chin. Phys. Lett. 41 087701

Google Scholar

Google Scholar

[6] Chen S, Chen M, Liu Y, Cao D, Chen G 2024 Chin. Phys. B 33 098701

Google Scholar

Google Scholar

[7] McKenna K, Shluger A, Iglesias V, Porti M, Nafría M, Lanza M, Bersuker G 2011 Microelectron. Eng. 88 1272

Google Scholar

Google Scholar

[8] 袁国亮, 王琛皓, 唐文彬, 张睿, 陆旭兵 2023 72 097703

Google Scholar

Google Scholar

Yuan G L, Wang C H, Tang W B, Zhang R, Lu X B 2023 Acta. Phys. Sin. 72 097703

Google Scholar

Google Scholar

[9] Liu K, Liu K, Zhang X, Fang J, Jin F, Wu W, Ma C, Wang L 2024 Chin. Phys. Lett. 41 117701

Google Scholar

Google Scholar

[10] Scott E A, Gaskins J T, King S W, Hopkins P E 2018 APL Mater. 6 058302

Google Scholar

Google Scholar

[11] Lu S X, Cebe P 1996 Polymer 37 4857

Google Scholar

Google Scholar

[12] 何宇亮, 周衡南, 刘湘娜, 程光煦 1990 39 1796

Google Scholar

Google Scholar

He Y L, Zhou H N, Liu X N, Cheng G X, Yu S D 1990 Acta Phys. Sin. 39 1796

Google Scholar

Google Scholar

[13] Wang S, Wang C, Li M, Huang L, Ott R, Kramer M, Sordelet D, Ho K 2008 Phys. Rev. B 78 184204

Google Scholar

Google Scholar

[14] Wang Y, Fan Z, Qian P, Caro M A, Ala-Nissila T 2023 Phys. Rev. B 107 054303

Google Scholar

Google Scholar

[15] 林揆训, 林璇英, 梁厚蕴, 池凌飞, 余楚迎, 黄创君 2002 51 863

Google Scholar

Google Scholar

Lin K X, Lin X Y, Liang H Y, Chi L F, Yu C Y, Huang C J 2002 Acta. Phys. Sin. 51 863

Google Scholar

Google Scholar

[16] Kittel C 1949 Phys. Rev. 75 972

Google Scholar

Google Scholar

[17] Allen P B, Feldman J L 1989 Phys. Rev. Lett. 62 645

Google Scholar

Google Scholar

[18] Zhu X, Shao C 2022 Phys. Rev. B 106 014305

Google Scholar

Google Scholar

[19] Qiu R, Zeng Q Y, Han J S, Chen K, Kang D D, Yu X X, Dai J Y 2025 Phys. Rev. B 111 064103

Google Scholar

Google Scholar

[20] Luo T, Lloyd J R 2012 Adv. Funct. Mater. 22 2495

Google Scholar

Google Scholar

[21] Li S H, Yu X X, Bao H, Yang N 2018 J. Phys. Chem. C 122 13140

Google Scholar

Google Scholar

[22] Xi Q, Zhong J, He J, Xu X, Nakayama T, Wang Y, Liu J, Zhou J, Li B 2020 Chin. Phys. Lett. 37 104401

Google Scholar

Google Scholar

[23] Prasai K, Biswas P, Drabold D 2016 Semicond. Sci. Techn. 31 073002

Google Scholar

Google Scholar

[24] 朱美芳 1996 45 499

Google Scholar

Google Scholar

Zhu M F 1996 Acta Phys. Sin. 45 499

Google Scholar

Google Scholar

[25] Mu X, Wu X, Zhang T, Go D B, Luo T 2014 Sci. Rep. 4 3909

Google Scholar

Google Scholar

[26] 王学智, 汤雨婷, 车军伟, 令狐佳珺, 侯兆阳 2023 72 056101

Google Scholar

Google Scholar

Wang X Z, Tang Y T, Che J W, Linghu J J, Hou Z Y 2023 Acta Physica Sinica 72 056101

Google Scholar

Google Scholar

[27] Yang F H, Zeng Q Y, Chen B, Kang D D, Zhang S, Wu J H, Yu X X, Dai J Y 2022 Chin. Phys. Lett. 39 116301

Google Scholar

Google Scholar

[28] 鲍华 2013 62 1

Google Scholar

Google Scholar

Bao H 2013 Acta Phys. Sin. 62 1

Google Scholar

Google Scholar

[29] Qiu R, Zeng Q Y, Wang H, Kang D D, Yu X X, Dai J Y 2023 Chin. Phys. Lett. 40 116301

Google Scholar

Google Scholar

[30] Isaeva L, Barbalinardo G, Donadio D, Baroni S 2019 Nat. Commun. 10 3853

Google Scholar

Google Scholar

[31] Simoncelli M, Marzari N, Mauri F 2019 Nat. Phys. 15 809

Google Scholar

Google Scholar

[32] Harper A F, Iwanowski K, Witt W C, Payne M C, Simoncelli M 2024 Phys. Rev. Mater. 8 043601

Google Scholar

Google Scholar

[33] Fiorentino A, Pegolo P, Baroni S 2023 npj Comput. Mater. 9 157

Google Scholar

Google Scholar

[34] Barbalinardo G, Chen Z, Lundgren N W, Donadio D 2020 J. Appl. Phys. 128 135104

Google Scholar

Google Scholar

[35] Fan Z Y, Wang Y Z, Ying P H, Song K K, Wang J J, Wang Y, Zeng Z Z, Xu K, Lindgren E, Rahm J M, Gabourie A J, Liu J H, Dong H K, Wu J Y, Chen Y, Zhong Z, Sun J, Erhart P, Su Y J, Ala-Nissila T 2022 J. Chem. Phys. 157 114801

Google Scholar

Google Scholar

[36] Fan Z Y, Zeng Z Z, Zhang C Z, Wang Y Z, Song K K, Dong H K, Chen Y, Ala-Nissila T 2021 Phys. Rev. B 104 104309

Google Scholar

Google Scholar

[37] Zhang H, Gu X, Fan Z, Bao H 2023 Phys. Rev. B 108 045422

Google Scholar

Google Scholar

[38] Sivaraman G, Krishnamoorthy A N, Baur M, Holm C, Stan M, Csányi G, Benmore C, Vázquez-Mayagoitia Á 2020 npj Comput. Mater. 6 104

Google Scholar

Google Scholar

[39] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[40] Zeng Q Y, Yu X X, Yao Y P, Gao T Y, Chen B, Zhang S, Kang D D, Wang H, Dai J Y 2021 Phys. Rev. Res. 3 033116

Google Scholar

Google Scholar

[41] Franzblau D 1991 Phys. Rev. B 44 4925

Google Scholar

Google Scholar

[42] Le Roux S, Petkov V 2010 J. Appl. Crystallogr. 43 181

Google Scholar

Google Scholar

[43] Xiang X, Fan H, Zhou Y G 2024 J. Appl. Phys. 135 125102

Google Scholar

Google Scholar

[44] Zhang S L, Yi S L, Yang J Y, Liu J, Liu L H 2023 Int. J. Heat Mass Tran. 207 123971

Google Scholar

Google Scholar

[45] Panzer M A, Shandalov M, Rowlette J A, Oshima Y, Chen Y W, McIntyre P C, Goodson K E 2009 IEEE Electron Dev. Lett. 30 1269

Google Scholar

Google Scholar

[46] Lee S M, Cahill D G, Allen T H 1995 Phys. Rev. B 52 253

Google Scholar

Google Scholar

[47] Chaubey G S, Yao Y, Makongo J P, Sahoo P, Misra D, Poudeu P F, Wiley J B 2012 RSC Adv. 2 9207

Google Scholar

Google Scholar

[48] Tritt T M 2005 Thermal Conductivity: Theory, Properties, and Applications (Springer Science & Business Media

[49] Shenogin S, Bodapati A, Keblinski P, McGaughey A J 2009 J. Appl. Phys. 105 034906

Google Scholar

Google Scholar

[50] Seyf H R, Henry A 2016 J. Appl. Phys. 120 025101

Google Scholar

Google Scholar

-

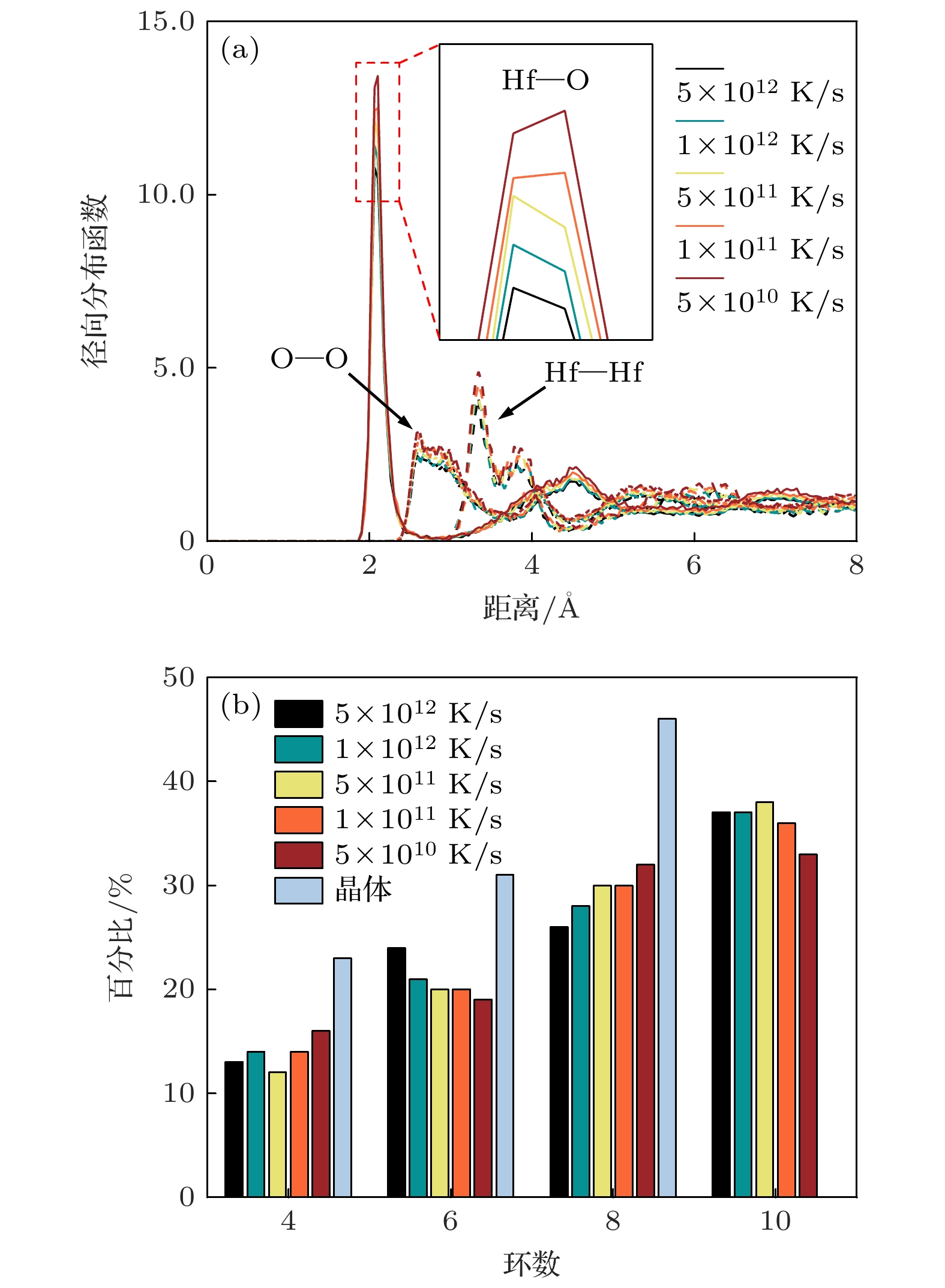

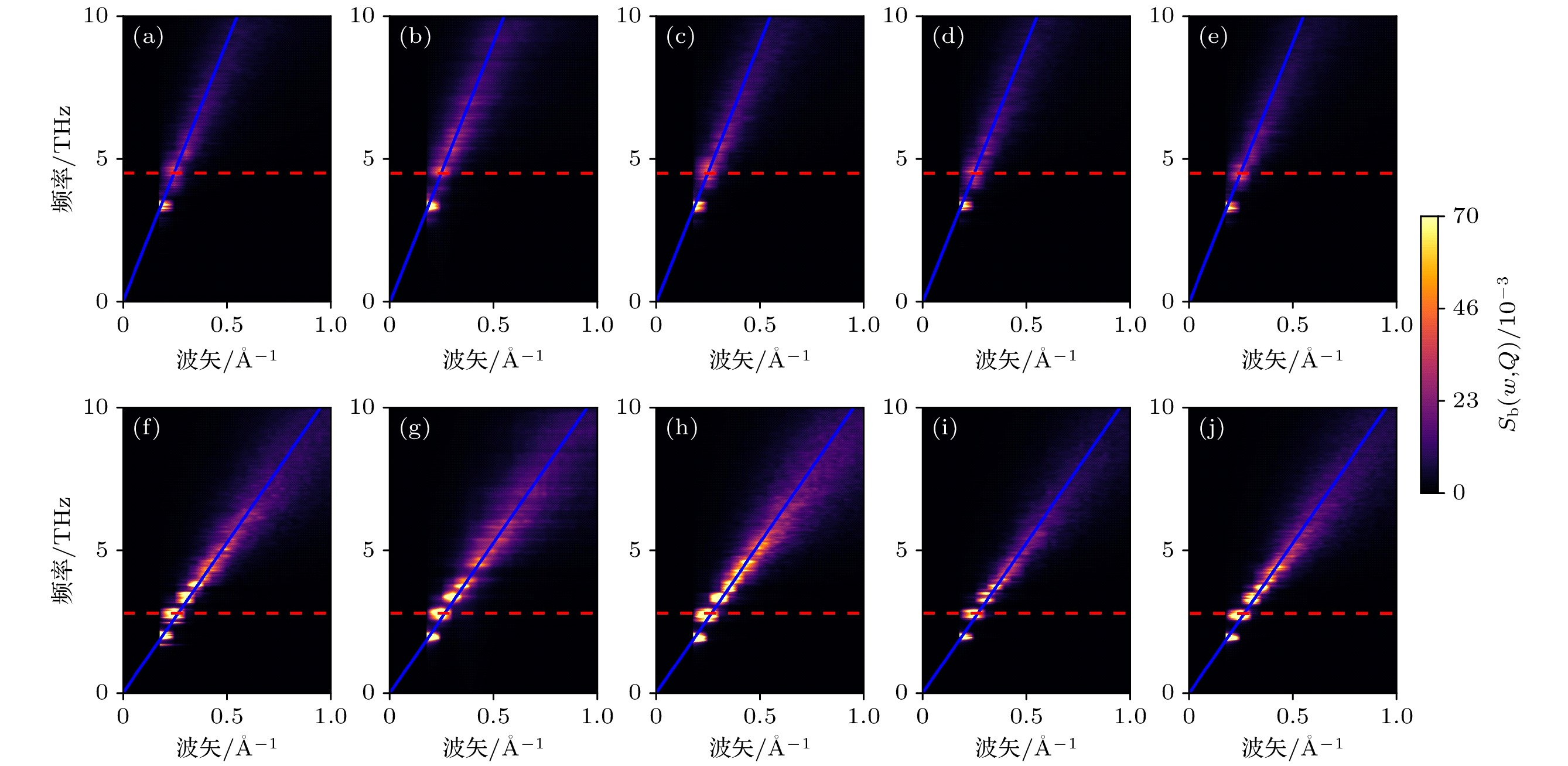

图 1 生成非晶结构过程中势能和均方位移累计值随模拟时间的变化, 图中灰色虚线之前为熔融过程, 灰色虚线与黑色实线之间为在温度4000 K下的弛豫过程, 红色点划线之后为退火过程

Fig. 1. Variation of potential energy and accumulated mean square displacement with simulation time during the generation of amorphous structures, the melting process is before the gray dashed line, the relaxation process at 4000 K is between the gray dashed line and the black solid line, and the annealing process is after the red dotted line.

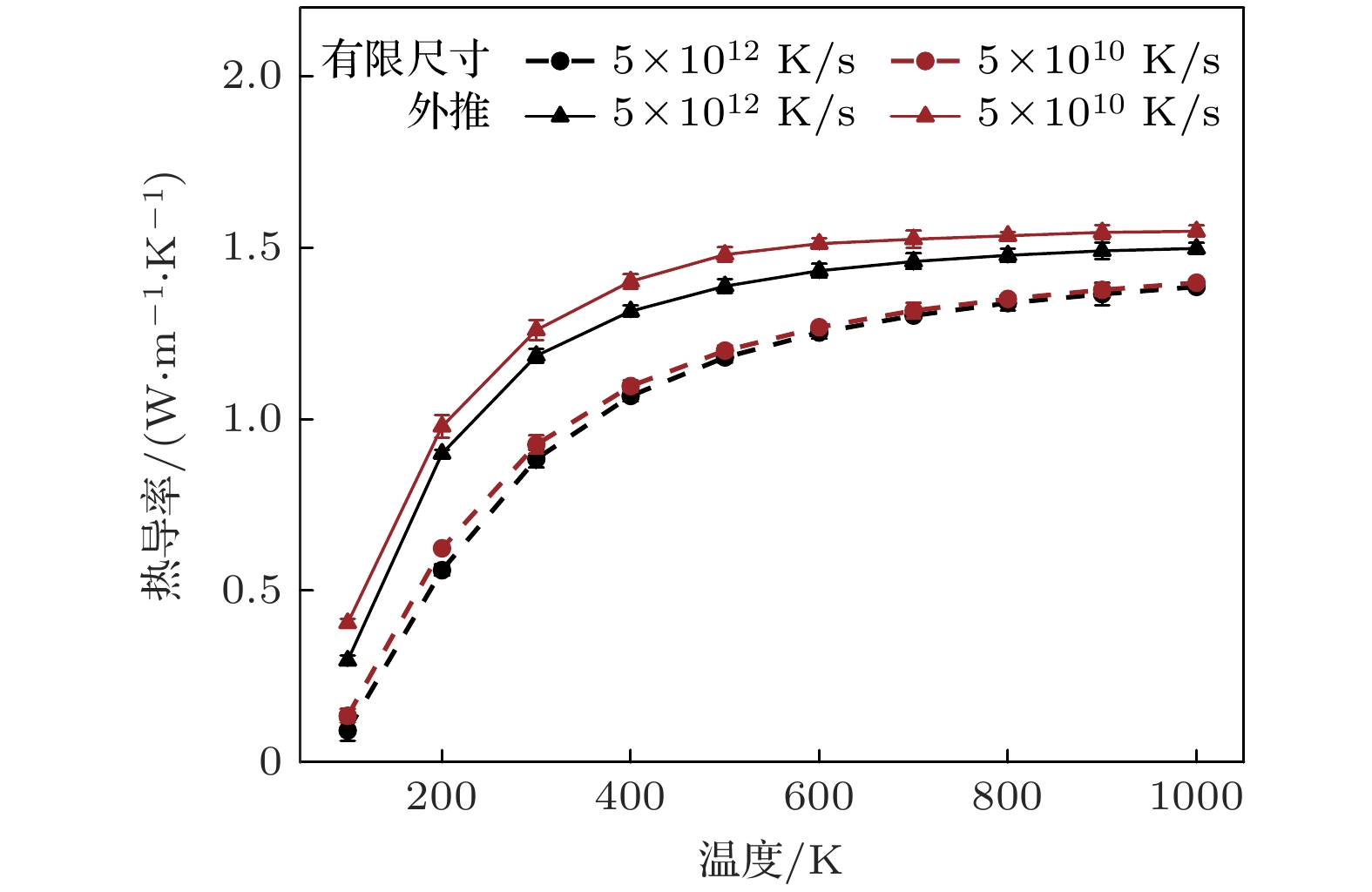

图 3 有限尺寸(2592个原子)和流体动力学外推法的非晶HfO2随温度变化的热导率, 图中图例的数值表示淬火速度, 误差棒为热导率标准差

Fig. 3. Thermal conductivity of amorphous HfO2 with temperature for finite size (2592 atoms) and the hydrodynamic extrapolation. The values of the legend denote the quenching rate, error bar is standard deviations of thermal conductivity.

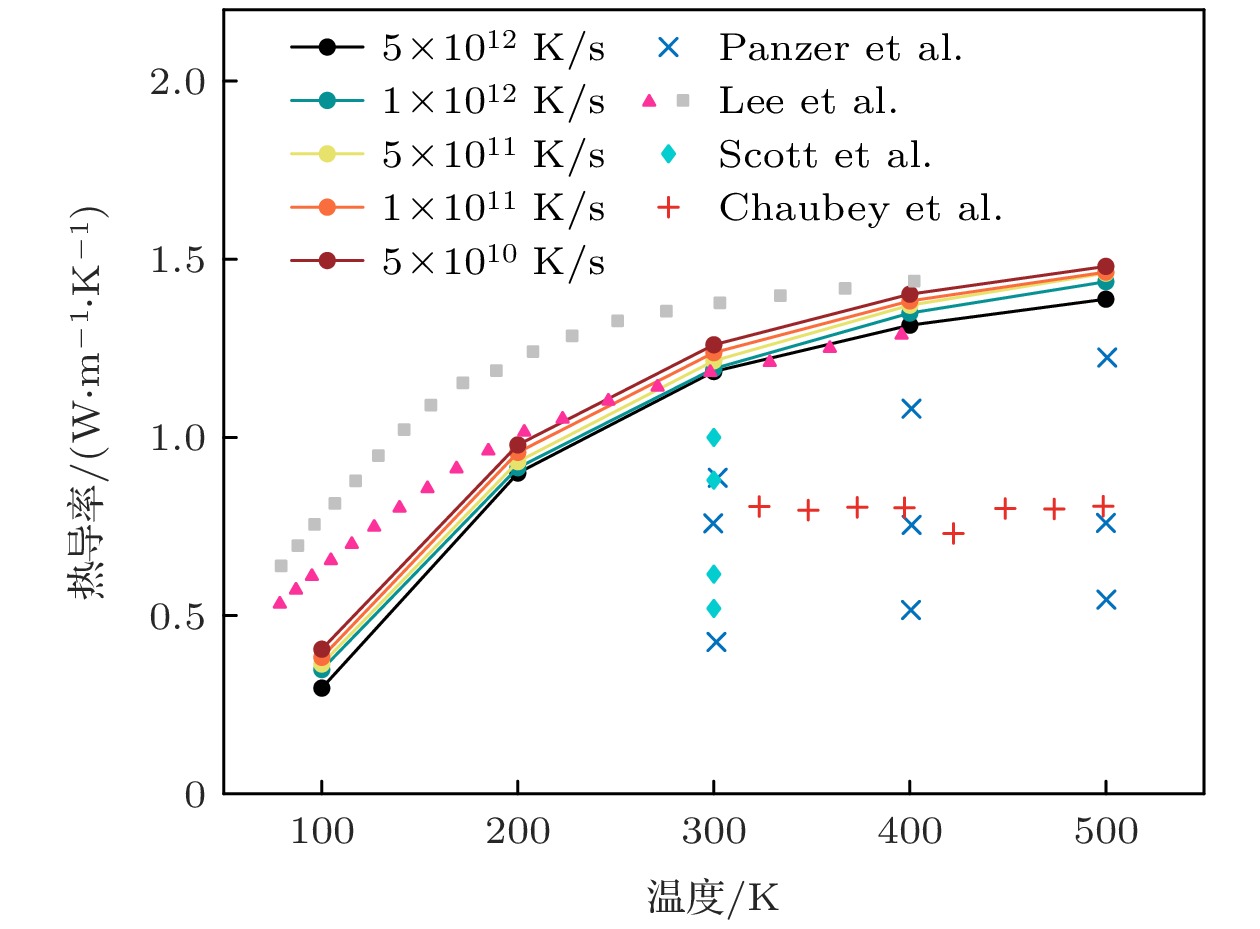

图 4 非晶HfO2热导率随温度变化关系, 图中散点是Panzer等[45]、Lee等[46]、Scott等[10]和Chaubey等[47]报道的非晶HfO2实验数据

Fig. 4. Temperature-dependent thermal conductivity of amorphous HfO2, scattered points in the figure are experimental data for amorphous HfO2 reported by Panzer et al.[45], Lee et al.[46], Scott et al.[10] and Chaubey et al.[47].

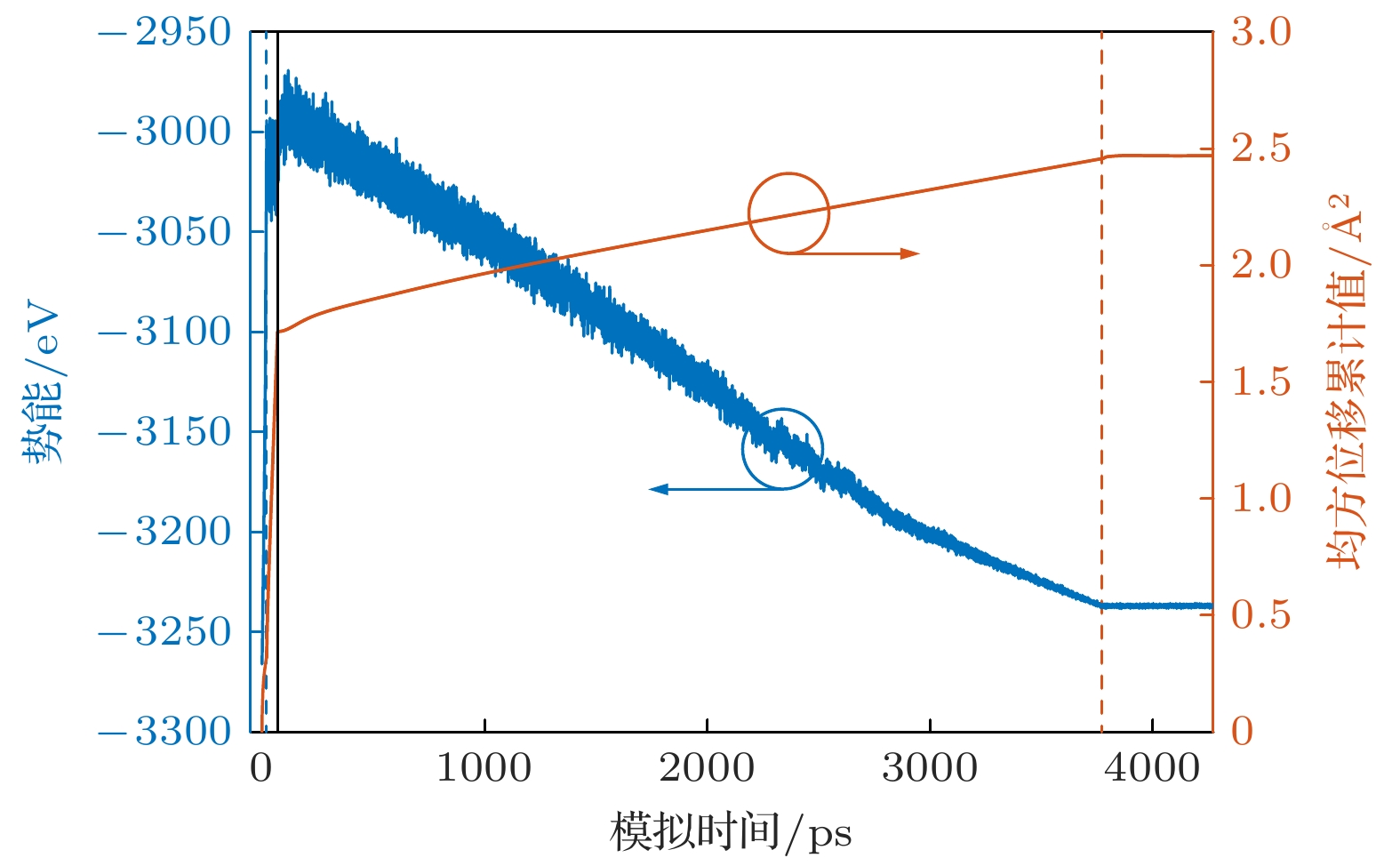

图 6 (a)—(e) 淬火速度分别为5×1012, 1×1012, 5×1011, 1×1011, 5×1010 K/s的非晶HfO2的纵向非谐动态结构因子; (f)—(j) 为对应淬火速度下的横向非谐动态结构因子; 图中颜色条是根据(8)式计算的非谐动态结构因子强度, 蓝色直线是非谐动态结构因子在低频部分的线性拟合, 红色虚线是选取的截止频率

Fig. 6. (a)–(e) Longitudinal anharmonic dynamic structure factors of amorphous HfO2 with different quenching rates of 5×1012, 1×1012, 5×1011, 1×1011, and 5×1010 K/s; (f)–(j) transverse anharmonic dynamic structure factors at corresponding quenching rates. The colorbar indicates the strength of the anharmonic dynamic structure factor calculated by Eq. (8), the blue straight line is a linear fit of the anharmonic dynamic structure factor in the low frequency part, and the red dashed line is the selected cut-off frequency.

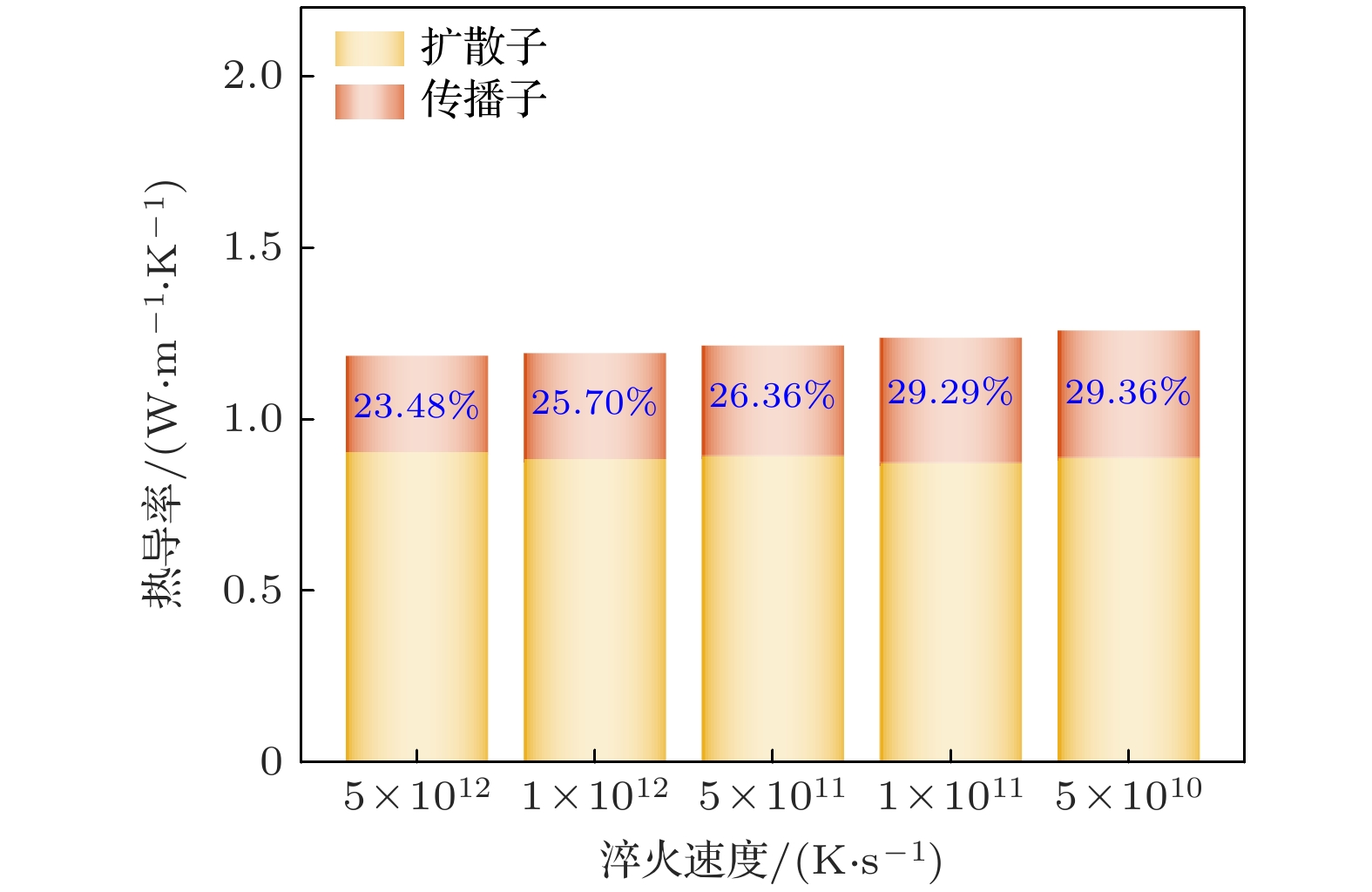

图 7 300 K温度下不同淬火速度非晶HfO2的传播子和扩散子对热导率的贡献, 图中的蓝色文字代表传播子对总热导率的贡献百分比

Fig. 7. Contributions of propagon and diffuson to thermal conductivity of amorphous HfO2 with different quenching rates at 300 K, the blue text in the figure represents the percentage contribution of propagon to the total thermal conductivity.

-

[1] Wilk G D, Wallace R M, Anthony J 2001 J. Appl. Phys. 89 5243

Google Scholar

Google Scholar

[2] Chen J H, Liang M F, Song Y, Yuan J J, Zhang M Y, Luo Y M, Wang N N 2024 Chin. Phys. B 33 047503

Google Scholar

Google Scholar

[3] Wang Y, Zahid F, Wang J, Guo H 2012 Phys. Rev. B 85 224110

Google Scholar

Google Scholar

[4] 董典萌, 汪成, 张清怡, 张涛, 杨永涛, 夏翰驰, 王月晖, 吴真平 2023 72 097302

Google Scholar

Google Scholar

Dong D M, Wang C, Zhang Q Y, Zhang T, Yang Y T, Xia H C, Wang Y H, Wu Z P 2023 Acta. Phys. Sin. 72 097302

Google Scholar

Google Scholar

[5] Gao R, Liu C, Shi B, Li Y, Luo B, Chen R, Ouyang W, Gao H, Hu S, Wang Y 2024 Chin. Phys. Lett. 41 087701

Google Scholar

Google Scholar

[6] Chen S, Chen M, Liu Y, Cao D, Chen G 2024 Chin. Phys. B 33 098701

Google Scholar

Google Scholar

[7] McKenna K, Shluger A, Iglesias V, Porti M, Nafría M, Lanza M, Bersuker G 2011 Microelectron. Eng. 88 1272

Google Scholar

Google Scholar

[8] 袁国亮, 王琛皓, 唐文彬, 张睿, 陆旭兵 2023 72 097703

Google Scholar

Google Scholar

Yuan G L, Wang C H, Tang W B, Zhang R, Lu X B 2023 Acta. Phys. Sin. 72 097703

Google Scholar

Google Scholar

[9] Liu K, Liu K, Zhang X, Fang J, Jin F, Wu W, Ma C, Wang L 2024 Chin. Phys. Lett. 41 117701

Google Scholar

Google Scholar

[10] Scott E A, Gaskins J T, King S W, Hopkins P E 2018 APL Mater. 6 058302

Google Scholar

Google Scholar

[11] Lu S X, Cebe P 1996 Polymer 37 4857

Google Scholar

Google Scholar

[12] 何宇亮, 周衡南, 刘湘娜, 程光煦 1990 39 1796

Google Scholar

Google Scholar

He Y L, Zhou H N, Liu X N, Cheng G X, Yu S D 1990 Acta Phys. Sin. 39 1796

Google Scholar

Google Scholar

[13] Wang S, Wang C, Li M, Huang L, Ott R, Kramer M, Sordelet D, Ho K 2008 Phys. Rev. B 78 184204

Google Scholar

Google Scholar

[14] Wang Y, Fan Z, Qian P, Caro M A, Ala-Nissila T 2023 Phys. Rev. B 107 054303

Google Scholar

Google Scholar

[15] 林揆训, 林璇英, 梁厚蕴, 池凌飞, 余楚迎, 黄创君 2002 51 863

Google Scholar

Google Scholar

Lin K X, Lin X Y, Liang H Y, Chi L F, Yu C Y, Huang C J 2002 Acta. Phys. Sin. 51 863

Google Scholar

Google Scholar

[16] Kittel C 1949 Phys. Rev. 75 972

Google Scholar

Google Scholar

[17] Allen P B, Feldman J L 1989 Phys. Rev. Lett. 62 645

Google Scholar

Google Scholar

[18] Zhu X, Shao C 2022 Phys. Rev. B 106 014305

Google Scholar

Google Scholar

[19] Qiu R, Zeng Q Y, Han J S, Chen K, Kang D D, Yu X X, Dai J Y 2025 Phys. Rev. B 111 064103

Google Scholar

Google Scholar

[20] Luo T, Lloyd J R 2012 Adv. Funct. Mater. 22 2495

Google Scholar

Google Scholar

[21] Li S H, Yu X X, Bao H, Yang N 2018 J. Phys. Chem. C 122 13140

Google Scholar

Google Scholar

[22] Xi Q, Zhong J, He J, Xu X, Nakayama T, Wang Y, Liu J, Zhou J, Li B 2020 Chin. Phys. Lett. 37 104401

Google Scholar

Google Scholar

[23] Prasai K, Biswas P, Drabold D 2016 Semicond. Sci. Techn. 31 073002

Google Scholar

Google Scholar

[24] 朱美芳 1996 45 499

Google Scholar

Google Scholar

Zhu M F 1996 Acta Phys. Sin. 45 499

Google Scholar

Google Scholar

[25] Mu X, Wu X, Zhang T, Go D B, Luo T 2014 Sci. Rep. 4 3909

Google Scholar

Google Scholar

[26] 王学智, 汤雨婷, 车军伟, 令狐佳珺, 侯兆阳 2023 72 056101

Google Scholar

Google Scholar

Wang X Z, Tang Y T, Che J W, Linghu J J, Hou Z Y 2023 Acta Physica Sinica 72 056101

Google Scholar

Google Scholar

[27] Yang F H, Zeng Q Y, Chen B, Kang D D, Zhang S, Wu J H, Yu X X, Dai J Y 2022 Chin. Phys. Lett. 39 116301

Google Scholar

Google Scholar

[28] 鲍华 2013 62 1

Google Scholar

Google Scholar

Bao H 2013 Acta Phys. Sin. 62 1

Google Scholar

Google Scholar

[29] Qiu R, Zeng Q Y, Wang H, Kang D D, Yu X X, Dai J Y 2023 Chin. Phys. Lett. 40 116301

Google Scholar

Google Scholar

[30] Isaeva L, Barbalinardo G, Donadio D, Baroni S 2019 Nat. Commun. 10 3853

Google Scholar

Google Scholar

[31] Simoncelli M, Marzari N, Mauri F 2019 Nat. Phys. 15 809

Google Scholar

Google Scholar

[32] Harper A F, Iwanowski K, Witt W C, Payne M C, Simoncelli M 2024 Phys. Rev. Mater. 8 043601

Google Scholar

Google Scholar

[33] Fiorentino A, Pegolo P, Baroni S 2023 npj Comput. Mater. 9 157

Google Scholar

Google Scholar

[34] Barbalinardo G, Chen Z, Lundgren N W, Donadio D 2020 J. Appl. Phys. 128 135104

Google Scholar

Google Scholar

[35] Fan Z Y, Wang Y Z, Ying P H, Song K K, Wang J J, Wang Y, Zeng Z Z, Xu K, Lindgren E, Rahm J M, Gabourie A J, Liu J H, Dong H K, Wu J Y, Chen Y, Zhong Z, Sun J, Erhart P, Su Y J, Ala-Nissila T 2022 J. Chem. Phys. 157 114801

Google Scholar

Google Scholar

[36] Fan Z Y, Zeng Z Z, Zhang C Z, Wang Y Z, Song K K, Dong H K, Chen Y, Ala-Nissila T 2021 Phys. Rev. B 104 104309

Google Scholar

Google Scholar

[37] Zhang H, Gu X, Fan Z, Bao H 2023 Phys. Rev. B 108 045422

Google Scholar

Google Scholar

[38] Sivaraman G, Krishnamoorthy A N, Baur M, Holm C, Stan M, Csányi G, Benmore C, Vázquez-Mayagoitia Á 2020 npj Comput. Mater. 6 104

Google Scholar

Google Scholar

[39] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[40] Zeng Q Y, Yu X X, Yao Y P, Gao T Y, Chen B, Zhang S, Kang D D, Wang H, Dai J Y 2021 Phys. Rev. Res. 3 033116

Google Scholar

Google Scholar

[41] Franzblau D 1991 Phys. Rev. B 44 4925

Google Scholar

Google Scholar

[42] Le Roux S, Petkov V 2010 J. Appl. Crystallogr. 43 181

Google Scholar

Google Scholar

[43] Xiang X, Fan H, Zhou Y G 2024 J. Appl. Phys. 135 125102

Google Scholar

Google Scholar

[44] Zhang S L, Yi S L, Yang J Y, Liu J, Liu L H 2023 Int. J. Heat Mass Tran. 207 123971

Google Scholar

Google Scholar

[45] Panzer M A, Shandalov M, Rowlette J A, Oshima Y, Chen Y W, McIntyre P C, Goodson K E 2009 IEEE Electron Dev. Lett. 30 1269

Google Scholar

Google Scholar

[46] Lee S M, Cahill D G, Allen T H 1995 Phys. Rev. B 52 253

Google Scholar

Google Scholar

[47] Chaubey G S, Yao Y, Makongo J P, Sahoo P, Misra D, Poudeu P F, Wiley J B 2012 RSC Adv. 2 9207

Google Scholar

Google Scholar

[48] Tritt T M 2005 Thermal Conductivity: Theory, Properties, and Applications (Springer Science & Business Media

[49] Shenogin S, Bodapati A, Keblinski P, McGaughey A J 2009 J. Appl. Phys. 105 034906

Google Scholar

Google Scholar

[50] Seyf H R, Henry A 2016 J. Appl. Phys. 120 025101

Google Scholar

Google Scholar

计量

- 文章访问数: 755

- PDF下载量: 30

- 被引次数: 0

下载:

下载: