-

By using large-scale atomic/molecular massively parallel simulator (LAMMPS) code, a molecular dynamics simulation is performed in the NPT ensemble at zero pressure to investigate the influence of melting rates γ on the evolutional characteristics of vanadium atomic structure such as body-centered cubic (BCC), hexagonal close-packed structure (HCP), face centered cubic (FCC), simple cubic (SC) and icosahedra (ICO) during the rapid melting of solid vanadium crystal at five different melting rates (γ1 = 1 × 1011 K/s, γ2 = 1 × 1012 K/s, γ3 = 1 × 1013 K/s, γ4 = 1 × 1014 K/s , γ5 = 1 × 1015 K/s), in which 16000 atoms in a cubic box under the periodic boundary condition are considered, and their motion equations are solved by Verlet’s algorithm in the velocity form in time steps of 1 fs. Constant pressure P and temperature T are imposed by a modified Nose-Hoover method for both P and T variables, and an embedded-atom model (EAM) potential is utilized. For identifying the local atomic structures of liquid and solid vanadium at different temperatures, a polyhedral template matching method (PTMM) is used by measuring the root-mean square deviation (RMSD), in which clusters are classified as the topology of the local atomic environment without any ambiguity in the classification. Subsequently, the variation of the potential energy, entropy and Gibbs free energy of FCC, HCP, BCC and ICO vanadium clusters are calculated through ab initio MD simulation in the canonical ensemble (NVT) at selected temperatures, and the lowest-energy dynamic structure and its corresponding static heating structure are also shown in this paper. Based on the above calculated results, it is found that the melting point of refractory metal vanadium increases obviously with the increase of heating rate, but the heating rate only presents a limited effect on the population of atomic structure for each of BCC, HCP, FCC, SC and ICO. Namely, the temperature still plays a dominant role in the rapid melting process of V rather than heating rate. Moreover, the ab initio MD simulation and thermodynamics analysis further reveal that lots of ICO clusters of vanadium can exist stably in the liquid region rather than in solid crystal, which is not only due to its higher stability and longer lifetime than those of crystalline atomic clusters, but also because ICO possesses higher entropy and lower Gibbs free energy in high temperature liquid region.

-

Keywords:

- molecular dynamics /

- vanadium /

- melting /

- cluster

[1] Cheng Y Q, Ma E 2011 Prog. Mater. Sci. 56 379

Google Scholar

Google Scholar

[2] Baletto F 2005 Rev. Mod. Phys. 77 371

Google Scholar

Google Scholar

[3] Turci F, Tarjus G, Royall C P 2017 Phys. Rev. Lett. 118 215501

Google Scholar

Google Scholar

[4] Shen Y T, Kim T H, Gangopadhyay A K, Kelton K F 2009 Phys. Rev. Lett. 102 057801

Google Scholar

Google Scholar

[5] Sprakel J, Zaccone A, Spaepen F, Schall P, Weitz D 2017 Phys. Rev. Lett. 118 088003

Google Scholar

Google Scholar

[6] Şopu D, Stukowski A, Stoica M, Scudino S 2017 Phys. Rev. Lett. 119 195503

Google Scholar

Google Scholar

[7] Jiang Y Q, Wen D D, Peng P 2017 J. Mole. Liquids 230 271

Google Scholar

Google Scholar

[8] Jiang Y Q, Wen D D, Peng P, Han S C, Hou Z Y 2015 Comput. Mater. Sci. 99 156

Google Scholar

Google Scholar

[9] Zhong L, Wang J, Sheng H, Zhang Z, Mao S X 2014 Nature 512 177

Google Scholar

Google Scholar

[10] 蒋元祺, 彭平 2018 67 132101

Google Scholar

Google Scholar

Jiang Y Q, Peng P 2018 Acta Phys. Sin. 67 132101

Google Scholar

Google Scholar

[11] Jiang Y Q, Peng P 2020 Chin. Phys. B. 29 046105

Google Scholar

Google Scholar

[12] Jiang Y Q, Wen D D, He W X, Peng P 2018 Mol. Simulat. 44 1183

Google Scholar

Google Scholar

[13] 武振伟, 李茂枝, 徐莉梅, 汪卫华 2017 66 176405

Google Scholar

Google Scholar

Wu Z W, Li M Z, Xu L M, Wang W H 2017 Acta Phys. Sin. 66 176405

Google Scholar

Google Scholar

[14] 邓永和, 文大东, 彭超, 韦彦丁, 赵瑞, 彭平 2016 65 066401

Google Scholar

Google Scholar

Deng Y H, Wen D D, Peng C, Wei Y D, Zhao R, Peng P 2016 Acta Phys. Sin. 65 066401

Google Scholar

Google Scholar

[15] 孙保安, 王利峰, 邵建华 2017 66 178103

Google Scholar

Google Scholar

Sun B A, Wang L F, Shao J H 2017 Acta Phys. Sin. 66 178103

Google Scholar

Google Scholar

[16] Yang M H, Cai B, Sun Y, Zhang F, Wang Y F, Wang C Z, Ho K M 2019 Phys. Rev. Mater. 3 125602

Google Scholar

Google Scholar

[17] 孙奕韬, 王超, 吕玉苗, 胡远超, 罗鹏, 刘明, 咸海杰, 赵德乾, 丁大伟, 孙保安, 潘明祥, 闻平, 白海洋, 柳延辉, 汪卫华 2018 67 126101

Google Scholar

Google Scholar

Sun Y T, Wang C, Lü Y M, Hu Y C, Luo P, Liu M, Xian H J, Zhao D Q, Ding D W, Sun B A, Pan M X, Wen P, Bai H Y, Liu Y H, Wang W H 2018 Acta Phys. Sin. 67 126101

Google Scholar

Google Scholar

[18] Li M X, Zhao S F, Lu Z, Hirata A, Wen P, Bai H Y, Chen M W, Schroers J, Liu Y H, Wang W H 2019 Nature 569 99

Google Scholar

Google Scholar

[19] Sheng H W, Luo W K, Alamgir F M, Bai J M, Ma E 2006 Nature 439 419

Google Scholar

Google Scholar

[20] Hirata A, Kang L J, Fujita T, Klumov B, Matsue K, Kotani M, Yavari A R, Chen M W 2013 Science 341 376

Google Scholar

Google Scholar

[21] Wang H Q, Li H F 2015 RSC Adv. 5 94685

Google Scholar

Google Scholar

[22] Sosso C C, Chen J, Stephen J, Fitzner M, Pedevilla P, Zen A, Michaelides A 2016 Chem. Rev. 116 7078

Google Scholar

Google Scholar

[23] Taherkhani F, Akbarzadeh H, Rezania H 2014 J. Alloys. Compd. 617 746

Google Scholar

Google Scholar

[24] Chen L, Wang Q, Xiong L 2017 J. Nanopart. Res. 19 300

Google Scholar

Google Scholar

[25] Zhang Z, Hu W, Xiao S 2006 Phys. Rev. B 73 125443

Google Scholar

Google Scholar

[26] Nunez S, Lopez J M, Aguado A 2012 Nanoscale 4 6481

Google Scholar

Google Scholar

[27] Steenbergen K G, Gaston N 2013 Phys. Chem. Chem. Phys. 15 15325

Google Scholar

Google Scholar

[28] Taran S, Garip A K, Arslan H 2020 J. Clus. Sci. 10876

Google Scholar

Google Scholar

[29] Taran S, Garip A K, Arslan H 2020 Chin. Phys. B 29 077801

Google Scholar

Google Scholar

[30] Elatresh S F, Bonev S A, Gregoryanz E, Ashcroft N W 2016 Phys. Rev. B 94 104107

Google Scholar

Google Scholar

[31] Zhao C Y, Tao Y, Yu Y S 2020 Int. J. Mass. Tran. 150 119382

Google Scholar

Google Scholar

[32] Feng D, Feng Y, Yuan S, Zhang X, Wang G 2017 Appl. Therm. Eng. 111 1457

Google Scholar

Google Scholar

[33] Fang X W, Wang C Z, Yao Y X, Ding Z J, Ho K M 2011 Phys. Rev. B 83 224203

Google Scholar

Google Scholar

[34] Aguado A, Jarrold M F 2011 Annu. Rev. Phys. Chem. 62 151

Google Scholar

Google Scholar

[35] Lekka C E, Papaconstantopoulos D A 2007 Surf. Sci. 601 3937

Google Scholar

Google Scholar

[36] Pyfer K L, Kafader J O, Yalamanchali A, Jarrold M F 2014 J. Phys. Chem. A 118 4900

Google Scholar

Google Scholar

[37] Haberland H, Hippler T, Donges J, Kostko O, Schmidt M, Issendorff B 2005 Phys. Rev. Lett. 94 035701

Google Scholar

Google Scholar

[38] Zhang L, Sun H 2010 Phys. Status Solidi 207 1178

Google Scholar

Google Scholar

[39] Jena P, Sun Q 2018 Chem. Rev. 118 5755

Google Scholar

Google Scholar

[40] Chacko S, Joshi K, Kanhere D G 2004 Phys. Rev. Lett. 92 135506

Google Scholar

Google Scholar

[41] Rapacioli M, Tarrat N, Spiegelman F 2018 J. Phys. Chem. A 122 4092

Google Scholar

Google Scholar

[42] Breaux G.A, Benirschke R C, Sugai T, Kinnear B S, Jarrold M F 2003 Phys. Rev. Lett. 91 215508

Google Scholar

Google Scholar

[43] Nelli D, Ferrando R 2019 Nanoscale 11 13040

Google Scholar

Google Scholar

[44] Settem M, Kanjarla A K 2020 Sci. Rep. 10 3296

Google Scholar

Google Scholar

[45] Wu J, Qi L, You H, Gross A, Li J, Yang H 2012 J. Am. Chem. Soc. 134 11880

Google Scholar

Google Scholar

[46] Zhang J, Chen J, Hu P, Wang H 2020 Chin. Chem. Lett. 31 890

Google Scholar

Google Scholar

[47] Mao H K, Chen X J, Ding Y, Li B, Wang B 2018 Rev. Mod. Phys. 90 015007

Google Scholar

Google Scholar

[48] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[49] Cai J, Ye Y 1996 Phys. Rev. B 54 8398

Google Scholar

Google Scholar

[50] Stukowski A 2010 Model. Simul. Mater. Sc. 18 015012

Google Scholar

Google Scholar

[51] Larsen P M, Schmidt S, Schiøtz J 2016 Model. Simul. Mater. Sc. 24 055007

Google Scholar

Google Scholar

[52] 蒋元祺 2015 博士学位论文(长沙: 湖南大学)

Jiang Y Q 2015 Ph. D. Dissertation (Changsha: Hunan University) (in Chinese)

-

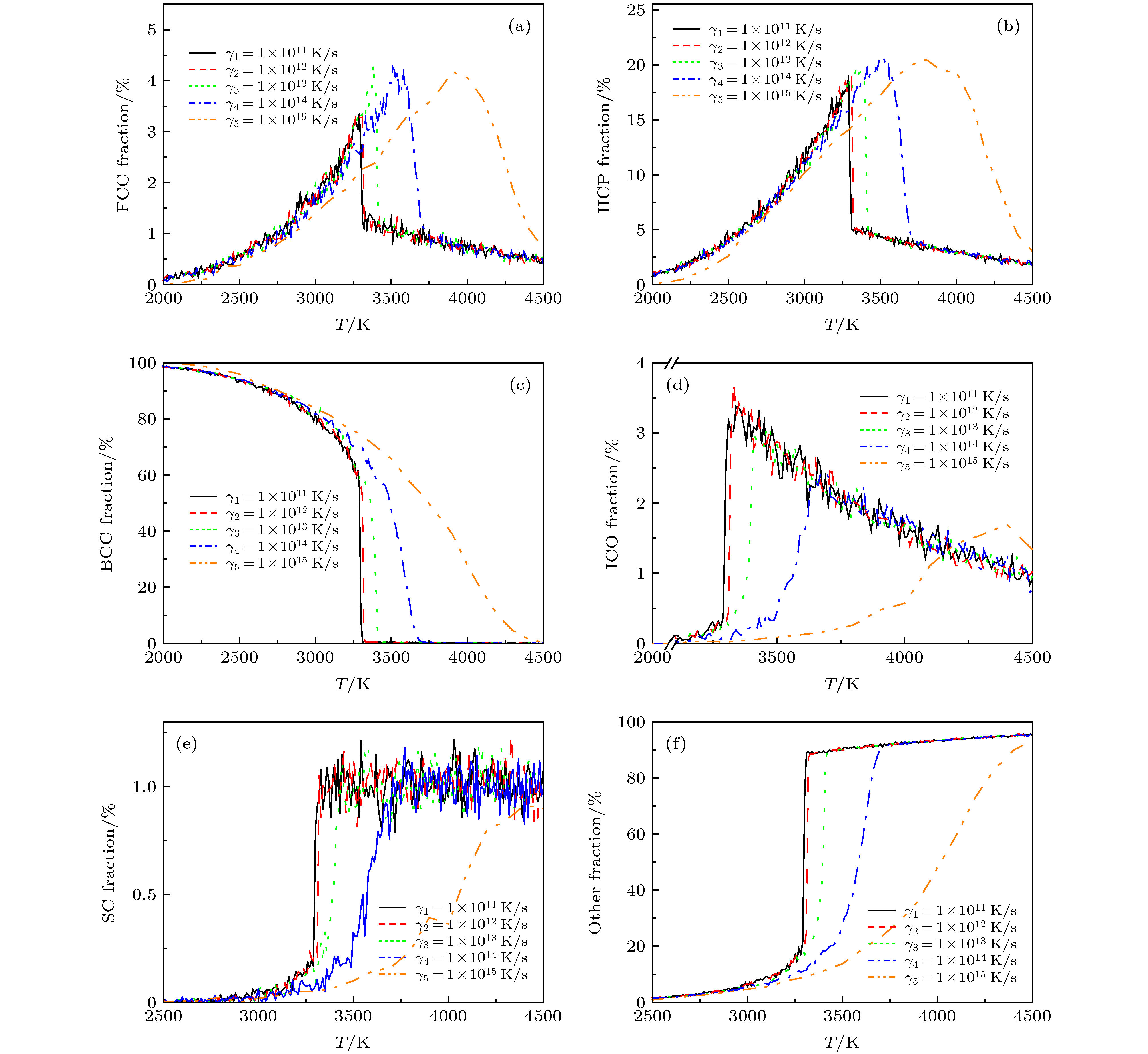

图 7 利用多面体模板匹配法分析得到的5种不同熔化速率下各种类型团簇原子分布随温度的演变关系 (a) FCC; (b) HCP; (c) BCC; (d) ICO; (e) SC; (f)其他类型团簇

Figure 7. The fraction of the various types atoms in V system as a function of temperature obtained from the polyhedral template matching at five various rates: (a) FCC; (b) HCP; (c) BCC; (d) ICO; (e) SC; (f) other types atoms counts.

-

[1] Cheng Y Q, Ma E 2011 Prog. Mater. Sci. 56 379

Google Scholar

Google Scholar

[2] Baletto F 2005 Rev. Mod. Phys. 77 371

Google Scholar

Google Scholar

[3] Turci F, Tarjus G, Royall C P 2017 Phys. Rev. Lett. 118 215501

Google Scholar

Google Scholar

[4] Shen Y T, Kim T H, Gangopadhyay A K, Kelton K F 2009 Phys. Rev. Lett. 102 057801

Google Scholar

Google Scholar

[5] Sprakel J, Zaccone A, Spaepen F, Schall P, Weitz D 2017 Phys. Rev. Lett. 118 088003

Google Scholar

Google Scholar

[6] Şopu D, Stukowski A, Stoica M, Scudino S 2017 Phys. Rev. Lett. 119 195503

Google Scholar

Google Scholar

[7] Jiang Y Q, Wen D D, Peng P 2017 J. Mole. Liquids 230 271

Google Scholar

Google Scholar

[8] Jiang Y Q, Wen D D, Peng P, Han S C, Hou Z Y 2015 Comput. Mater. Sci. 99 156

Google Scholar

Google Scholar

[9] Zhong L, Wang J, Sheng H, Zhang Z, Mao S X 2014 Nature 512 177

Google Scholar

Google Scholar

[10] 蒋元祺, 彭平 2018 67 132101

Google Scholar

Google Scholar

Jiang Y Q, Peng P 2018 Acta Phys. Sin. 67 132101

Google Scholar

Google Scholar

[11] Jiang Y Q, Peng P 2020 Chin. Phys. B. 29 046105

Google Scholar

Google Scholar

[12] Jiang Y Q, Wen D D, He W X, Peng P 2018 Mol. Simulat. 44 1183

Google Scholar

Google Scholar

[13] 武振伟, 李茂枝, 徐莉梅, 汪卫华 2017 66 176405

Google Scholar

Google Scholar

Wu Z W, Li M Z, Xu L M, Wang W H 2017 Acta Phys. Sin. 66 176405

Google Scholar

Google Scholar

[14] 邓永和, 文大东, 彭超, 韦彦丁, 赵瑞, 彭平 2016 65 066401

Google Scholar

Google Scholar

Deng Y H, Wen D D, Peng C, Wei Y D, Zhao R, Peng P 2016 Acta Phys. Sin. 65 066401

Google Scholar

Google Scholar

[15] 孙保安, 王利峰, 邵建华 2017 66 178103

Google Scholar

Google Scholar

Sun B A, Wang L F, Shao J H 2017 Acta Phys. Sin. 66 178103

Google Scholar

Google Scholar

[16] Yang M H, Cai B, Sun Y, Zhang F, Wang Y F, Wang C Z, Ho K M 2019 Phys. Rev. Mater. 3 125602

Google Scholar

Google Scholar

[17] 孙奕韬, 王超, 吕玉苗, 胡远超, 罗鹏, 刘明, 咸海杰, 赵德乾, 丁大伟, 孙保安, 潘明祥, 闻平, 白海洋, 柳延辉, 汪卫华 2018 67 126101

Google Scholar

Google Scholar

Sun Y T, Wang C, Lü Y M, Hu Y C, Luo P, Liu M, Xian H J, Zhao D Q, Ding D W, Sun B A, Pan M X, Wen P, Bai H Y, Liu Y H, Wang W H 2018 Acta Phys. Sin. 67 126101

Google Scholar

Google Scholar

[18] Li M X, Zhao S F, Lu Z, Hirata A, Wen P, Bai H Y, Chen M W, Schroers J, Liu Y H, Wang W H 2019 Nature 569 99

Google Scholar

Google Scholar

[19] Sheng H W, Luo W K, Alamgir F M, Bai J M, Ma E 2006 Nature 439 419

Google Scholar

Google Scholar

[20] Hirata A, Kang L J, Fujita T, Klumov B, Matsue K, Kotani M, Yavari A R, Chen M W 2013 Science 341 376

Google Scholar

Google Scholar

[21] Wang H Q, Li H F 2015 RSC Adv. 5 94685

Google Scholar

Google Scholar

[22] Sosso C C, Chen J, Stephen J, Fitzner M, Pedevilla P, Zen A, Michaelides A 2016 Chem. Rev. 116 7078

Google Scholar

Google Scholar

[23] Taherkhani F, Akbarzadeh H, Rezania H 2014 J. Alloys. Compd. 617 746

Google Scholar

Google Scholar

[24] Chen L, Wang Q, Xiong L 2017 J. Nanopart. Res. 19 300

Google Scholar

Google Scholar

[25] Zhang Z, Hu W, Xiao S 2006 Phys. Rev. B 73 125443

Google Scholar

Google Scholar

[26] Nunez S, Lopez J M, Aguado A 2012 Nanoscale 4 6481

Google Scholar

Google Scholar

[27] Steenbergen K G, Gaston N 2013 Phys. Chem. Chem. Phys. 15 15325

Google Scholar

Google Scholar

[28] Taran S, Garip A K, Arslan H 2020 J. Clus. Sci. 10876

Google Scholar

Google Scholar

[29] Taran S, Garip A K, Arslan H 2020 Chin. Phys. B 29 077801

Google Scholar

Google Scholar

[30] Elatresh S F, Bonev S A, Gregoryanz E, Ashcroft N W 2016 Phys. Rev. B 94 104107

Google Scholar

Google Scholar

[31] Zhao C Y, Tao Y, Yu Y S 2020 Int. J. Mass. Tran. 150 119382

Google Scholar

Google Scholar

[32] Feng D, Feng Y, Yuan S, Zhang X, Wang G 2017 Appl. Therm. Eng. 111 1457

Google Scholar

Google Scholar

[33] Fang X W, Wang C Z, Yao Y X, Ding Z J, Ho K M 2011 Phys. Rev. B 83 224203

Google Scholar

Google Scholar

[34] Aguado A, Jarrold M F 2011 Annu. Rev. Phys. Chem. 62 151

Google Scholar

Google Scholar

[35] Lekka C E, Papaconstantopoulos D A 2007 Surf. Sci. 601 3937

Google Scholar

Google Scholar

[36] Pyfer K L, Kafader J O, Yalamanchali A, Jarrold M F 2014 J. Phys. Chem. A 118 4900

Google Scholar

Google Scholar

[37] Haberland H, Hippler T, Donges J, Kostko O, Schmidt M, Issendorff B 2005 Phys. Rev. Lett. 94 035701

Google Scholar

Google Scholar

[38] Zhang L, Sun H 2010 Phys. Status Solidi 207 1178

Google Scholar

Google Scholar

[39] Jena P, Sun Q 2018 Chem. Rev. 118 5755

Google Scholar

Google Scholar

[40] Chacko S, Joshi K, Kanhere D G 2004 Phys. Rev. Lett. 92 135506

Google Scholar

Google Scholar

[41] Rapacioli M, Tarrat N, Spiegelman F 2018 J. Phys. Chem. A 122 4092

Google Scholar

Google Scholar

[42] Breaux G.A, Benirschke R C, Sugai T, Kinnear B S, Jarrold M F 2003 Phys. Rev. Lett. 91 215508

Google Scholar

Google Scholar

[43] Nelli D, Ferrando R 2019 Nanoscale 11 13040

Google Scholar

Google Scholar

[44] Settem M, Kanjarla A K 2020 Sci. Rep. 10 3296

Google Scholar

Google Scholar

[45] Wu J, Qi L, You H, Gross A, Li J, Yang H 2012 J. Am. Chem. Soc. 134 11880

Google Scholar

Google Scholar

[46] Zhang J, Chen J, Hu P, Wang H 2020 Chin. Chem. Lett. 31 890

Google Scholar

Google Scholar

[47] Mao H K, Chen X J, Ding Y, Li B, Wang B 2018 Rev. Mod. Phys. 90 015007

Google Scholar

Google Scholar

[48] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[49] Cai J, Ye Y 1996 Phys. Rev. B 54 8398

Google Scholar

Google Scholar

[50] Stukowski A 2010 Model. Simul. Mater. Sc. 18 015012

Google Scholar

Google Scholar

[51] Larsen P M, Schmidt S, Schiøtz J 2016 Model. Simul. Mater. Sc. 24 055007

Google Scholar

Google Scholar

[52] 蒋元祺 2015 博士学位论文(长沙: 湖南大学)

Jiang Y Q 2015 Ph. D. Dissertation (Changsha: Hunan University) (in Chinese)

Catalog

Metrics

- Abstract views: 9743

- PDF Downloads: 150

- Cited By: 0

DownLoad:

DownLoad: