-

Thermoelectric materials, which can convert heat energy into electric energy and also from electric energy into heat energy, have aroused widespread interest of both theoretical and technological researches recently. Graphene is a typical two-dimensional carbon nanomaterial and regarded as a competitive candidate for the next-generation micro/nano-devices. Unfortunately, graphene is an inefficient thermoelectric material due to the extremely high thermal conductivity. To overcome this drawback, exploring an effective way to improve the thermoelectric performance is of critical importance. In this paper, using the nonequilibrium Green’s function approach, we systematically investigate the effects of grain boundary on the thermoelectric properties of graphene nanoribbons. The results show that owing to the existence of grain boundary, the phonons and electrons encounter great scatterings when they transmit through the polycrystalline graphene nanoribbons. These scatterings cause the phononic and electronic transmission coefficient to decrease dramatically, and thus leading the thermal conductance (including both electron and phonon parts) of graphene nanoribbons to be evidently suppressed. Meanwhile, such scatterings induce more intense transmission peaks and pits in the electronic transmission spectrum of polycrystalline graphene nanoribbons. Generally, the Seebeck coefficient depends on the derivative of electronic transmission coefficient. The larger the logarithmic derivative of transmission, the higher the Seebeck coefficient can be obtained. Therefore Seebeck coefficient is improved obviously in the polycrystalline graphene nanoribbons. Based on such two positive effects, the thermoelectric performance of polycrystalline graphene nanoribbons is significantly enhanced. At room temperature, the thermoelectric figure of merit of polycrystalline graphene nanoribbons can approach to 0.3, which is about 6 times larger than that of pristine graphene nanoribbon (figure of merit is about 0.05). It is also found that the quantity of grain boundaries and length of system can further improve the thermoelectric properties of the polycrystalline graphene nanoribbons, while the width of system has a limited influence on it. This is because the quantity of grain boundaries and length of polycrystalline graphene nanoribbons can give rise to more intense phonon and electron scatterings and further decreasing of thermal conductance and enhancement of Seebeck coefficient. The results presented in this paper demonstrate that polycrystalline structure is indeed an effective way to improve the thermoelectric conversion efficiency of graphene nanoribbons, and provide a theoretical guideline for designing and preparing thermoelectric devices based on graphene nanoribbons.

[1] Tritt T M 2011 Annu. Rev. Mater. Res. 41 433

Google Scholar

Google Scholar

[2] Dresselhaus M S, Chen G, Tang M Y, Yang R G, Lee H, Wang D Z, Ren Z F, Fleurial J P, Gogna P 2007 Adv. Mater. 19 1043

Google Scholar

Google Scholar

[3] Snyder G J, Toberer E S 2008 Nat. Mater. 7 105

Google Scholar

Google Scholar

[4] Zhu L, Li R, Yao K 2017 Phys. Chem. Chem. Phys. 19 4085

Google Scholar

Google Scholar

[5] Zhu L, Li B, Yao K 2018 Nanotechnology 29 325206

Google Scholar

Google Scholar

[6] Zhu L, Zou F, Gao G Y, Yao K 2017 Sci. Rep. 7 497

Google Scholar

Google Scholar

[7] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[8] Geim A K 2009 Science 324 1530

Google Scholar

Google Scholar

[9] Barone V, Hod O, Scuseria G E 2006 Nano Lett. 6 2748

Google Scholar

Google Scholar

[10] Lee C, Wei X, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[11] Nan H Y, Ni Z H, Wang J, Zafar Z, Shi Z X, Wang Y Y 2013 J. Raman Spectrosc. 44 1018

Google Scholar

Google Scholar

[12] Zhang H J, Zheng G G, Chen Y Y, Zou X J, Xu L H 2018 Chin. Phys. Lett. 35 038102

Google Scholar

Google Scholar

[13] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer H L 2008 Solid State Commun. 146 351

Google Scholar

Google Scholar

[14] Dragoman D, Dragoman M 2007 Appl. Phys. Lett. 91 203116

Google Scholar

Google Scholar

[15] Zhang H S, Guo Z X, Gong X G, Cao J X 2012 J. Appl. Phys. 112 123508

Google Scholar

Google Scholar

[16] Nika D L, Pokatilov E P, Askerov A S, Balandin A A 2009 Phys. Rev. B 79 155413

Google Scholar

Google Scholar

[17] Karamitaheri H, Pourfath M, Faez R, Kosina H 2011 J. Appl. Phys. 110 054506

Google Scholar

Google Scholar

[18] Haskins J, Kınacı A, Sevik C, Sevinçli H, Cuniberti G, Çagǧın T 2011 ACS Nano 5 3779

Google Scholar

Google Scholar

[19] 张嵛, 刘连庆, 焦念东, 席宁, 王越超, 董再励 2012 61 137101

Google Scholar

Google Scholar

Zhang Y, Liu L Q, Jiao N D, Xi N, Wang Y C, Dong Z L 2012 Acta Phys. Sin. 61 137101

Google Scholar

Google Scholar

[20] Tran V T, Saint Martin J, Dollfus P, Volz S 2017 Sci. Rep. 7 2313

Google Scholar

Google Scholar

[21] 林琦, 陈余行, 吴建宝, 孔宗敏 2011 60 097103

Lin Q, Chen Y H, Wu J B, Kong Z M 2011 Acta Phys. Sin. 60 097103

[22] Huang P Y, Ruiz Vargas C S, van der Zande Arend M, Whitney W S, Levendorf M P, Kevek J W, Shivank G, Alden J S, Hustedt C J, Zhu Y, Park J W, McEuen P L, Muller D A 2011 Nature 469 389

Google Scholar

Google Scholar

[23] Li X S, Cai W W, An J, Kim S, Nah J, Yang D X, Piner R, Velamakanni A, Jung I, Tutuc E, Banerjee S K, Colombo L, Ruoff R S 2009 Science 324 1312

Google Scholar

Google Scholar

[24] Yazyev O V, Louie S G 2010 Nat. Mater. 9 806

Google Scholar

Google Scholar

[25] Lee G H, Cooper R C, An S J, Lee S, Zande A, Petrone N, Hammerberg A G, Lee C, Crawford B, Oliver W, Kysar J W, Hone J 2013 Science 340 1073

Google Scholar

Google Scholar

[26] Rassin G, Shenoy V B, Ruoff R S 2010 Science 330 946

Google Scholar

Google Scholar

[27] Bagri A, Kim S P, Ruoff R S, Shenoy V B 2011 Nano Lett. 11 3917

Google Scholar

Google Scholar

[28] Wang J S, Wang J, Lu J T 2008 Eur. Phys. J. B 62 381

Google Scholar

Google Scholar

[29] Yamamoto T, Watanabe K 2006 Phys. Rev. Lett. 96 255503

Google Scholar

Google Scholar

[30] Xiao H P, Cao W, Ouyang T, Xu X Y, Ding Y C, Zhong J X 2018 Appl. Phys. Lett. 112 233107

Google Scholar

Google Scholar

[31] Ghosh S, Calizo I, Teweldebrhan D, Pokatilov E P, Nika D L, Balandin A A, Bao W, Miao F, Lau C N 2008 Appl. Phys. Lett. 92 151911

Google Scholar

Google Scholar

[32] Li T C, Lu S P 2008 Phys. Rev. B 77 085408

Google Scholar

Google Scholar

[33] Pereira V M, Neto A H C, Peres N M R 2009 Phys. Rev. B 80 045401

[34] Ouyang T, Hu M 2014 Nanotechnology 25 245401

Google Scholar

Google Scholar

-

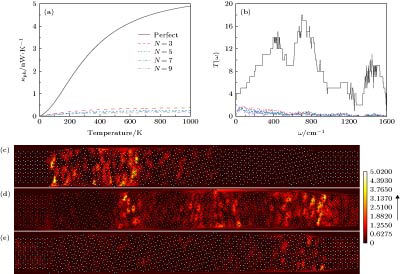

图 2 完美石墨烯纳米带和多晶石墨烯纳米带的(a)声子热导和(b)声子透射系数(其中L = 196.48 Å, W = 17.04Å); (c)−(e)多晶石墨烯纳米带(N = 5)在3个典型频率下(频率分别是160.68, 585.04, 951.72 Hz)的声子局域态密度

Figure 2. Comparison of (a) the phonon conductance, (b) the phonon transmission for perfect graphene nanoribbons and polycrystalline graphene nanoribbons (where L = 196.48 Å, W = 17.04 Å); (c)−(e) the local density of states in polycrystalline graphene (N = 5) at three typical frequency (160.68, 585.04 and 951.72 Hz).

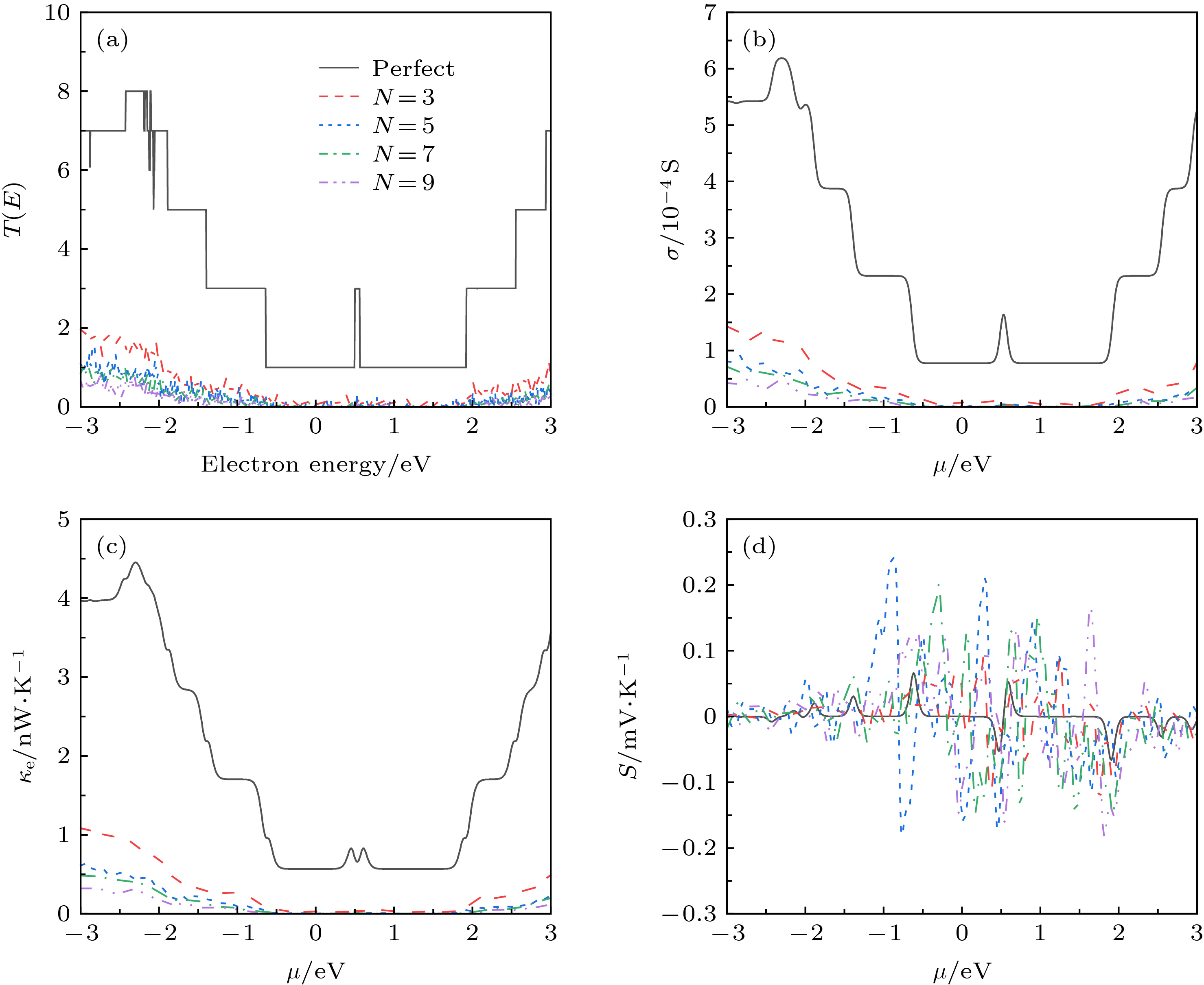

图 3 完美石墨烯纳米带和多晶石墨烯纳米带的电子性质 (a)电子透射系数; (b)电子电导; (c)电子热导; (d)塞贝克系数

Figure 3. Electronic properties of perfect graphene and polycrystalline graphene: (a) The electronic transmission coefficient; (b) the electronic conductance; (c) the electronic contributed thermal conductance; (d) the Seebeck coefficient.

-

[1] Tritt T M 2011 Annu. Rev. Mater. Res. 41 433

Google Scholar

Google Scholar

[2] Dresselhaus M S, Chen G, Tang M Y, Yang R G, Lee H, Wang D Z, Ren Z F, Fleurial J P, Gogna P 2007 Adv. Mater. 19 1043

Google Scholar

Google Scholar

[3] Snyder G J, Toberer E S 2008 Nat. Mater. 7 105

Google Scholar

Google Scholar

[4] Zhu L, Li R, Yao K 2017 Phys. Chem. Chem. Phys. 19 4085

Google Scholar

Google Scholar

[5] Zhu L, Li B, Yao K 2018 Nanotechnology 29 325206

Google Scholar

Google Scholar

[6] Zhu L, Zou F, Gao G Y, Yao K 2017 Sci. Rep. 7 497

Google Scholar

Google Scholar

[7] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[8] Geim A K 2009 Science 324 1530

Google Scholar

Google Scholar

[9] Barone V, Hod O, Scuseria G E 2006 Nano Lett. 6 2748

Google Scholar

Google Scholar

[10] Lee C, Wei X, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[11] Nan H Y, Ni Z H, Wang J, Zafar Z, Shi Z X, Wang Y Y 2013 J. Raman Spectrosc. 44 1018

Google Scholar

Google Scholar

[12] Zhang H J, Zheng G G, Chen Y Y, Zou X J, Xu L H 2018 Chin. Phys. Lett. 35 038102

Google Scholar

Google Scholar

[13] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer H L 2008 Solid State Commun. 146 351

Google Scholar

Google Scholar

[14] Dragoman D, Dragoman M 2007 Appl. Phys. Lett. 91 203116

Google Scholar

Google Scholar

[15] Zhang H S, Guo Z X, Gong X G, Cao J X 2012 J. Appl. Phys. 112 123508

Google Scholar

Google Scholar

[16] Nika D L, Pokatilov E P, Askerov A S, Balandin A A 2009 Phys. Rev. B 79 155413

Google Scholar

Google Scholar

[17] Karamitaheri H, Pourfath M, Faez R, Kosina H 2011 J. Appl. Phys. 110 054506

Google Scholar

Google Scholar

[18] Haskins J, Kınacı A, Sevik C, Sevinçli H, Cuniberti G, Çagǧın T 2011 ACS Nano 5 3779

Google Scholar

Google Scholar

[19] 张嵛, 刘连庆, 焦念东, 席宁, 王越超, 董再励 2012 61 137101

Google Scholar

Google Scholar

Zhang Y, Liu L Q, Jiao N D, Xi N, Wang Y C, Dong Z L 2012 Acta Phys. Sin. 61 137101

Google Scholar

Google Scholar

[20] Tran V T, Saint Martin J, Dollfus P, Volz S 2017 Sci. Rep. 7 2313

Google Scholar

Google Scholar

[21] 林琦, 陈余行, 吴建宝, 孔宗敏 2011 60 097103

Lin Q, Chen Y H, Wu J B, Kong Z M 2011 Acta Phys. Sin. 60 097103

[22] Huang P Y, Ruiz Vargas C S, van der Zande Arend M, Whitney W S, Levendorf M P, Kevek J W, Shivank G, Alden J S, Hustedt C J, Zhu Y, Park J W, McEuen P L, Muller D A 2011 Nature 469 389

Google Scholar

Google Scholar

[23] Li X S, Cai W W, An J, Kim S, Nah J, Yang D X, Piner R, Velamakanni A, Jung I, Tutuc E, Banerjee S K, Colombo L, Ruoff R S 2009 Science 324 1312

Google Scholar

Google Scholar

[24] Yazyev O V, Louie S G 2010 Nat. Mater. 9 806

Google Scholar

Google Scholar

[25] Lee G H, Cooper R C, An S J, Lee S, Zande A, Petrone N, Hammerberg A G, Lee C, Crawford B, Oliver W, Kysar J W, Hone J 2013 Science 340 1073

Google Scholar

Google Scholar

[26] Rassin G, Shenoy V B, Ruoff R S 2010 Science 330 946

Google Scholar

Google Scholar

[27] Bagri A, Kim S P, Ruoff R S, Shenoy V B 2011 Nano Lett. 11 3917

Google Scholar

Google Scholar

[28] Wang J S, Wang J, Lu J T 2008 Eur. Phys. J. B 62 381

Google Scholar

Google Scholar

[29] Yamamoto T, Watanabe K 2006 Phys. Rev. Lett. 96 255503

Google Scholar

Google Scholar

[30] Xiao H P, Cao W, Ouyang T, Xu X Y, Ding Y C, Zhong J X 2018 Appl. Phys. Lett. 112 233107

Google Scholar

Google Scholar

[31] Ghosh S, Calizo I, Teweldebrhan D, Pokatilov E P, Nika D L, Balandin A A, Bao W, Miao F, Lau C N 2008 Appl. Phys. Lett. 92 151911

Google Scholar

Google Scholar

[32] Li T C, Lu S P 2008 Phys. Rev. B 77 085408

Google Scholar

Google Scholar

[33] Pereira V M, Neto A H C, Peres N M R 2009 Phys. Rev. B 80 045401

[34] Ouyang T, Hu M 2014 Nanotechnology 25 245401

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9594

- PDF Downloads: 171

- Cited By: 0

DownLoad:

DownLoad: