-

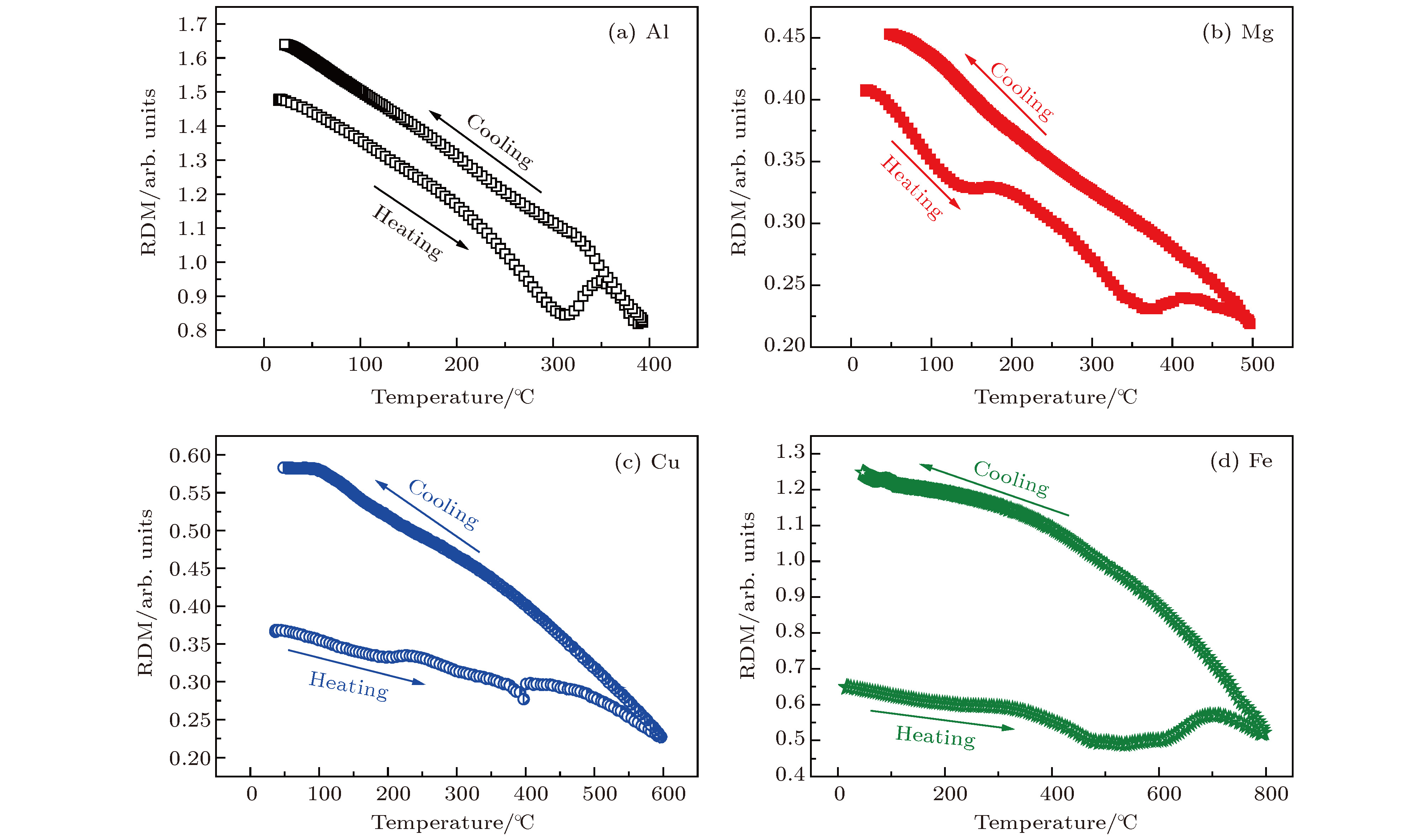

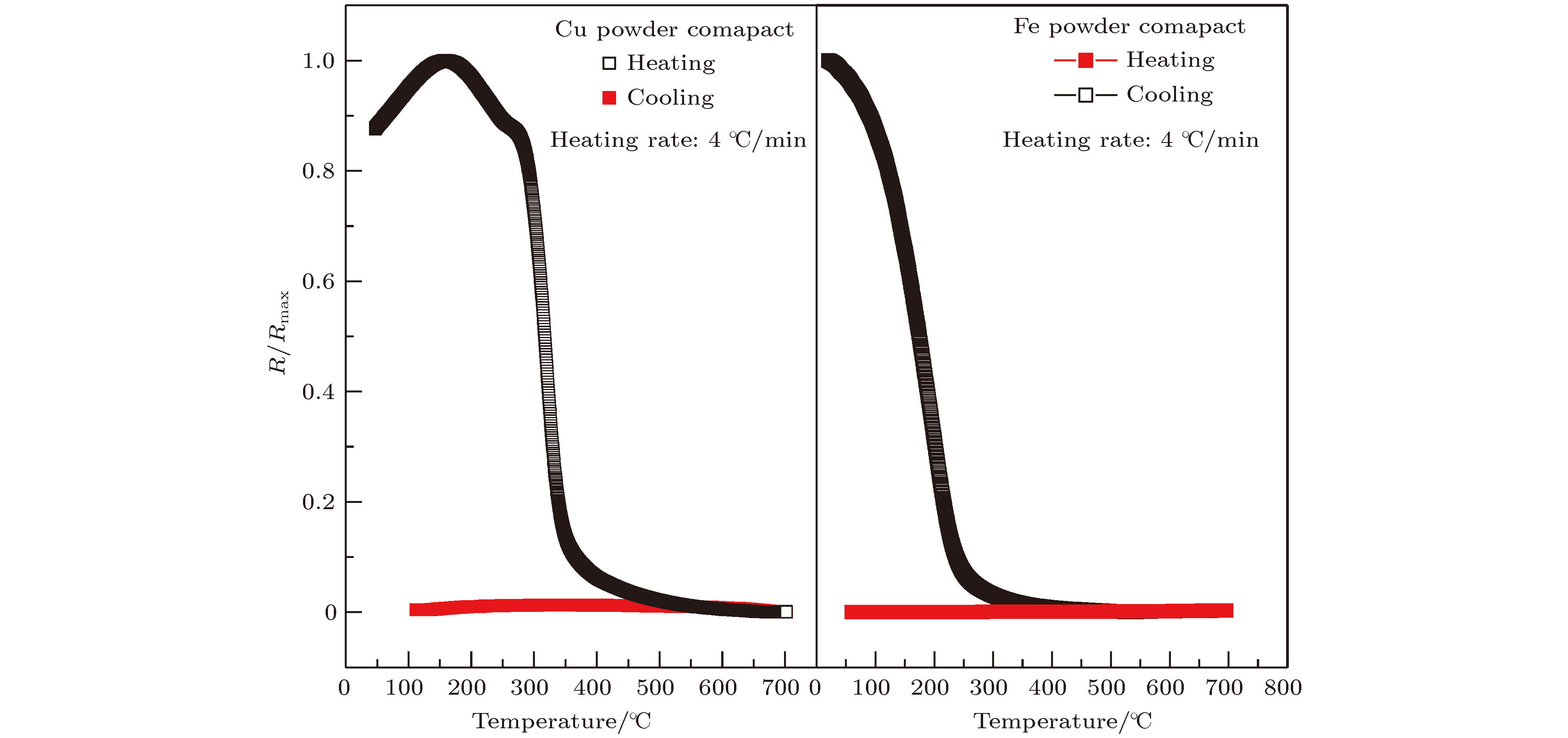

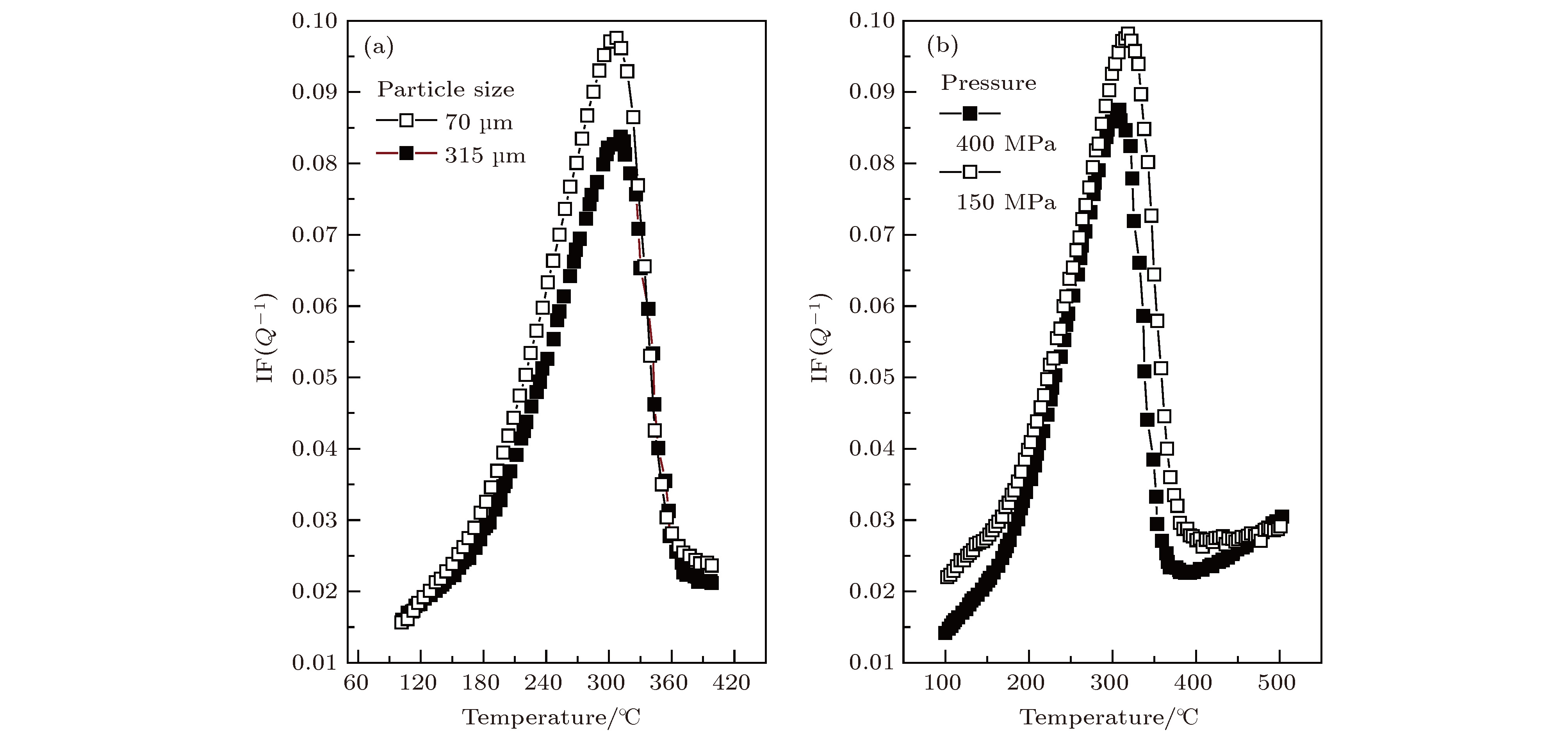

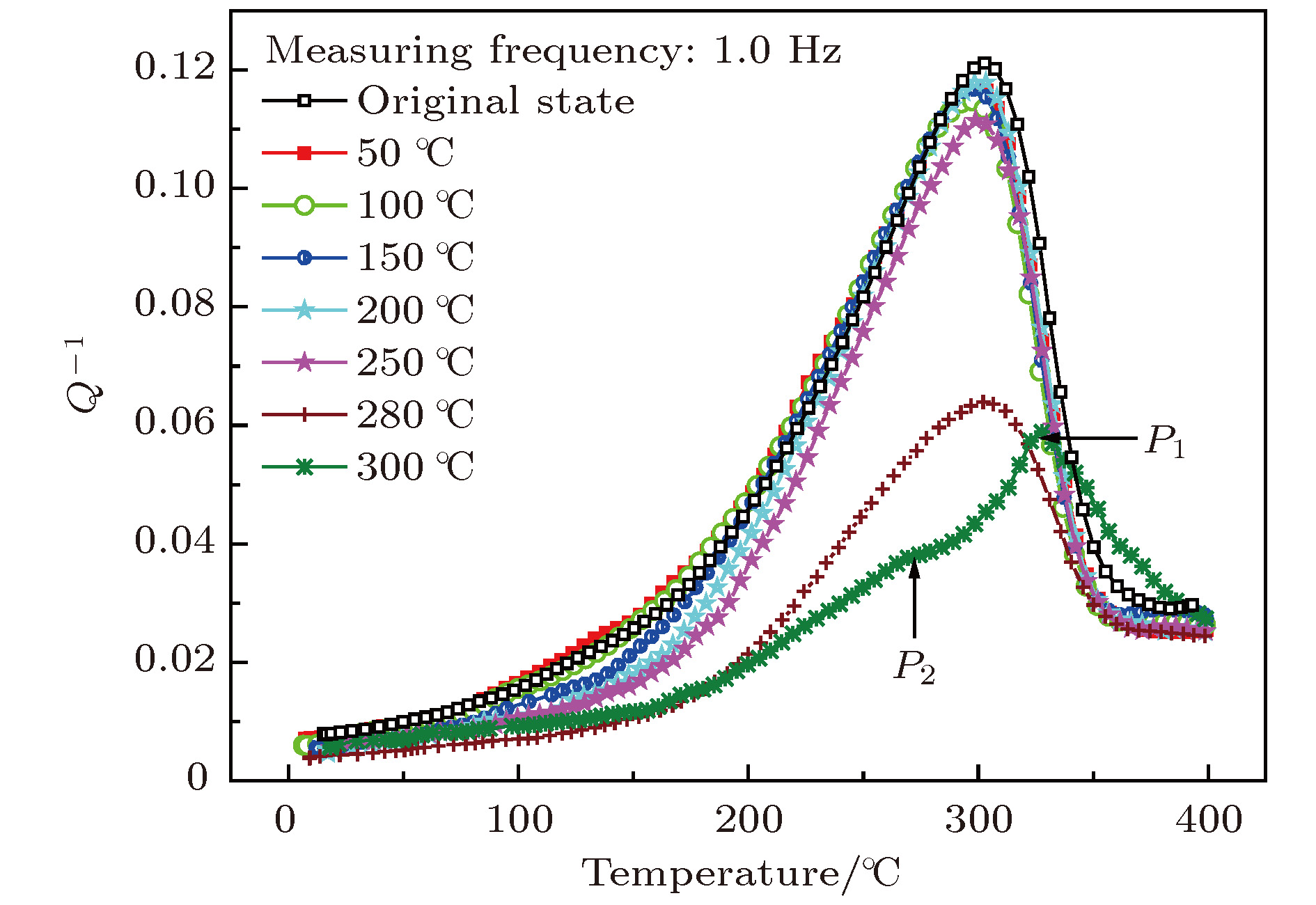

Sintering plays a decisive role to determine final product quality in the powder metallurgy process. Understanding the law of structure and defects as well as determining the initial sintering temperature and crystallization temperature will prove clear information to determine favorable sintering technology for the powder compacted billet. In this paper, the internal friction characteristics in the sintering process for powder compact billet, pure Al, Mg, Cu, Fe are systematically studied in terms of internal friction technology. Two internal friction peaks, named heating peak and cooling peak are respectively found in the first run. The cooling peak is a stable relaxational internal friction peak. It is concluded that the peak is associated with the viscous sliding of grain boundary based on the activation energy and peak temperature location. The heating peak is an unstable internal friction peak corresponding to the decline of resistance and relative dynamic modulus, the peak temperature being considered as an initial sintering temperature due to the great change of material performance. Furthermore, the heating peak is dependent on powder particle size and compressing pressure, which increases with the decrease of particle size or compressing pressure. The dependence can be understood according to the increase of weak bonding interface and activated slipping distance between powder particles. The internal friction of the powder compacted billet in the heating process gradually increases with the temperature increasing, which is mainly due to the micro sliding of the weak bonding interface, but the enhancing trend stops and internal friction rapidly declines when the temperature approaches to the peak location due to the transition of weak bonding interface to grain boundary, as a result, leading to the formation of the heating peak. The occurrence of therising temperature peak indicates the formation of grain boundary between powder particles in the sintering process of powder compacted billet. Correspondingly, the peak temperature can be used as a crystallization temperature.

-

Keywords:

- internal friction /

- metal powder compact /

- sintering /

- grain boundary

[1] Goetzel C G 1949 Treatise on Powder Metallurgy (New York: Interscience Publishing) p156

[2] Kingston W E 1951 The Physics of Powder Metallurgy (New York: McGraw-Hill Book Co., Inc.) p21

[3] 黄培云 2011 粉末冶金原理 (北京: 冶金工业出版社) 第288页

Huang P Y 2011 Powder Metallurgy Principle (Beijing: Metallurgical Industry Press) p288 (in Chinese)

[4] Krause R, Schatt W, Vetter B, Polity A 1990 Cryst. Res. Technol. 25 819

Google Scholar

Google Scholar

[5] Hübner C G, Staab T, Leipner H S 1995 Status Solidi A 150 653

Google Scholar

Google Scholar

[6] Wakai F, Nikolic Z S 2011 Acta Mater. 59 774

Google Scholar

Google Scholar

[7] 方前锋, 金学军 2014 内耗与力学谱基本原理及其应用 (上海: 上海交通大学出版社) 第1页

Fang Q F, Jin X J 2014 Basic Principle and Application of Internal Friction and Mechanical Spectrum (Shanghai: Shanghai Jiaotong University Press) p1 (in Chinese)

[8] 王清周, 陆冬梅, 崔春翔, 韩福生 2008 57 7083

Google Scholar

Google Scholar

Wang Q Z, Lu D M, Cui C X, Han F S 2008 Acta Phys. Sin. 57 7083

Google Scholar

Google Scholar

[9] 吴筱毅, 熊小敏, 张进修 2012 61 014601

Google Scholar

Google Scholar

Wu X Y, Xiong X M, Zhang J X 2012 Acta Phys. Sin. 61 014601

Google Scholar

Google Scholar

[10] 何庆, 杨春利, 吴修胜, 陈志军, 陈初升, 刘卫 2010 59 7979

Google Scholar

Google Scholar

He Q, Yang C L, Wu X S, Chen Z J, Chen C S, Liu W 2010 Acta Phys. Sin. 59 7979

Google Scholar

Google Scholar

[11] Xia Y, Wang X P, Gao Y X, Hu J, Zhuang Z, Guo L J, Fang Q F, Liu C S 2014 Chin. Phys. Lett. 31 016201

[12] Hao T, Tang H Y, Jiang W B, Wang X P, Fang Q F 2015 Arch. Metall. Mater. 60 2101

Google Scholar

Google Scholar

[13] Golovin I S, Mikhailovskaya A V, Ryazantseva M A, Geptin A, Solonin A N 2011 Phys. Met. Metallog. 112 622

Google Scholar

Google Scholar

[14] Golovin I S 2010 Phys. Met. Metallog. 110 405

Google Scholar

Google Scholar

[15] Fan G D, Zheng M Y, Hu X S, Xu C, Wu K, Golovin I S 2012 Mat. Sci. Eng. A 556 588

Google Scholar

Google Scholar

[16] Hao G L, Wang X F, Li X Y 2015 Chin. Phys. Lett. 32 026103

Google Scholar

Google Scholar

[17] 冯端 1999 金属物理学 (第三卷) (北京: 科学出版社) 第94页

Feng D 1999 Metal Physics (Vol. 3) (Beijing: Science Press) (in Chinese)

[18] 葛庭燧 2000 固体内耗理论基础 (北京: 科学出版社) 第103, 104页

Kê T S 2000 Theoretical Basis of Solid Internal Friction pp103, 104 (Beijing: Science Press) (in Chinese)

[19] 郝汀, 唐海银, 蒋卫斌, 方前锋 2015 第十一届全国内耗与力学谱及其应用学术会议, 延安, 中国 2015年8月 第16−19页

Hao T, Tang H Y, Jiang W B, Fang Q F 2015 Collection in 11th National Symposium on Solid Internal Friction and Mechanical Spectrum and Its Application Yan’an, China, August 2015 pp16−19 (in Chinese)

[20] Nowick A S, Berry B S 1972 Anelastic Relaxation in Crystalline Solids (New York and London: Academic Press) p58

[21] Fan G D, Zheng M Y, Hu X S, Xu C, Wu K, Golovin I S 2013 J. Alloy. Compd. 549 38

Google Scholar

Google Scholar

[22] Gunderov D V, Polyakov A V, Sitdikov V D, Churakova A A, Golovin I S 2013 Phys. Met. Metallog. 114 1078

-

-

[1] Goetzel C G 1949 Treatise on Powder Metallurgy (New York: Interscience Publishing) p156

[2] Kingston W E 1951 The Physics of Powder Metallurgy (New York: McGraw-Hill Book Co., Inc.) p21

[3] 黄培云 2011 粉末冶金原理 (北京: 冶金工业出版社) 第288页

Huang P Y 2011 Powder Metallurgy Principle (Beijing: Metallurgical Industry Press) p288 (in Chinese)

[4] Krause R, Schatt W, Vetter B, Polity A 1990 Cryst. Res. Technol. 25 819

Google Scholar

Google Scholar

[5] Hübner C G, Staab T, Leipner H S 1995 Status Solidi A 150 653

Google Scholar

Google Scholar

[6] Wakai F, Nikolic Z S 2011 Acta Mater. 59 774

Google Scholar

Google Scholar

[7] 方前锋, 金学军 2014 内耗与力学谱基本原理及其应用 (上海: 上海交通大学出版社) 第1页

Fang Q F, Jin X J 2014 Basic Principle and Application of Internal Friction and Mechanical Spectrum (Shanghai: Shanghai Jiaotong University Press) p1 (in Chinese)

[8] 王清周, 陆冬梅, 崔春翔, 韩福生 2008 57 7083

Google Scholar

Google Scholar

Wang Q Z, Lu D M, Cui C X, Han F S 2008 Acta Phys. Sin. 57 7083

Google Scholar

Google Scholar

[9] 吴筱毅, 熊小敏, 张进修 2012 61 014601

Google Scholar

Google Scholar

Wu X Y, Xiong X M, Zhang J X 2012 Acta Phys. Sin. 61 014601

Google Scholar

Google Scholar

[10] 何庆, 杨春利, 吴修胜, 陈志军, 陈初升, 刘卫 2010 59 7979

Google Scholar

Google Scholar

He Q, Yang C L, Wu X S, Chen Z J, Chen C S, Liu W 2010 Acta Phys. Sin. 59 7979

Google Scholar

Google Scholar

[11] Xia Y, Wang X P, Gao Y X, Hu J, Zhuang Z, Guo L J, Fang Q F, Liu C S 2014 Chin. Phys. Lett. 31 016201

[12] Hao T, Tang H Y, Jiang W B, Wang X P, Fang Q F 2015 Arch. Metall. Mater. 60 2101

Google Scholar

Google Scholar

[13] Golovin I S, Mikhailovskaya A V, Ryazantseva M A, Geptin A, Solonin A N 2011 Phys. Met. Metallog. 112 622

Google Scholar

Google Scholar

[14] Golovin I S 2010 Phys. Met. Metallog. 110 405

Google Scholar

Google Scholar

[15] Fan G D, Zheng M Y, Hu X S, Xu C, Wu K, Golovin I S 2012 Mat. Sci. Eng. A 556 588

Google Scholar

Google Scholar

[16] Hao G L, Wang X F, Li X Y 2015 Chin. Phys. Lett. 32 026103

Google Scholar

Google Scholar

[17] 冯端 1999 金属物理学 (第三卷) (北京: 科学出版社) 第94页

Feng D 1999 Metal Physics (Vol. 3) (Beijing: Science Press) (in Chinese)

[18] 葛庭燧 2000 固体内耗理论基础 (北京: 科学出版社) 第103, 104页

Kê T S 2000 Theoretical Basis of Solid Internal Friction pp103, 104 (Beijing: Science Press) (in Chinese)

[19] 郝汀, 唐海银, 蒋卫斌, 方前锋 2015 第十一届全国内耗与力学谱及其应用学术会议, 延安, 中国 2015年8月 第16−19页

Hao T, Tang H Y, Jiang W B, Fang Q F 2015 Collection in 11th National Symposium on Solid Internal Friction and Mechanical Spectrum and Its Application Yan’an, China, August 2015 pp16−19 (in Chinese)

[20] Nowick A S, Berry B S 1972 Anelastic Relaxation in Crystalline Solids (New York and London: Academic Press) p58

[21] Fan G D, Zheng M Y, Hu X S, Xu C, Wu K, Golovin I S 2013 J. Alloy. Compd. 549 38

Google Scholar

Google Scholar

[22] Gunderov D V, Polyakov A V, Sitdikov V D, Churakova A A, Golovin I S 2013 Phys. Met. Metallog. 114 1078

Catalog

Metrics

- Abstract views: 13344

- PDF Downloads: 74

- Cited By: 0

DownLoad:

DownLoad: