-

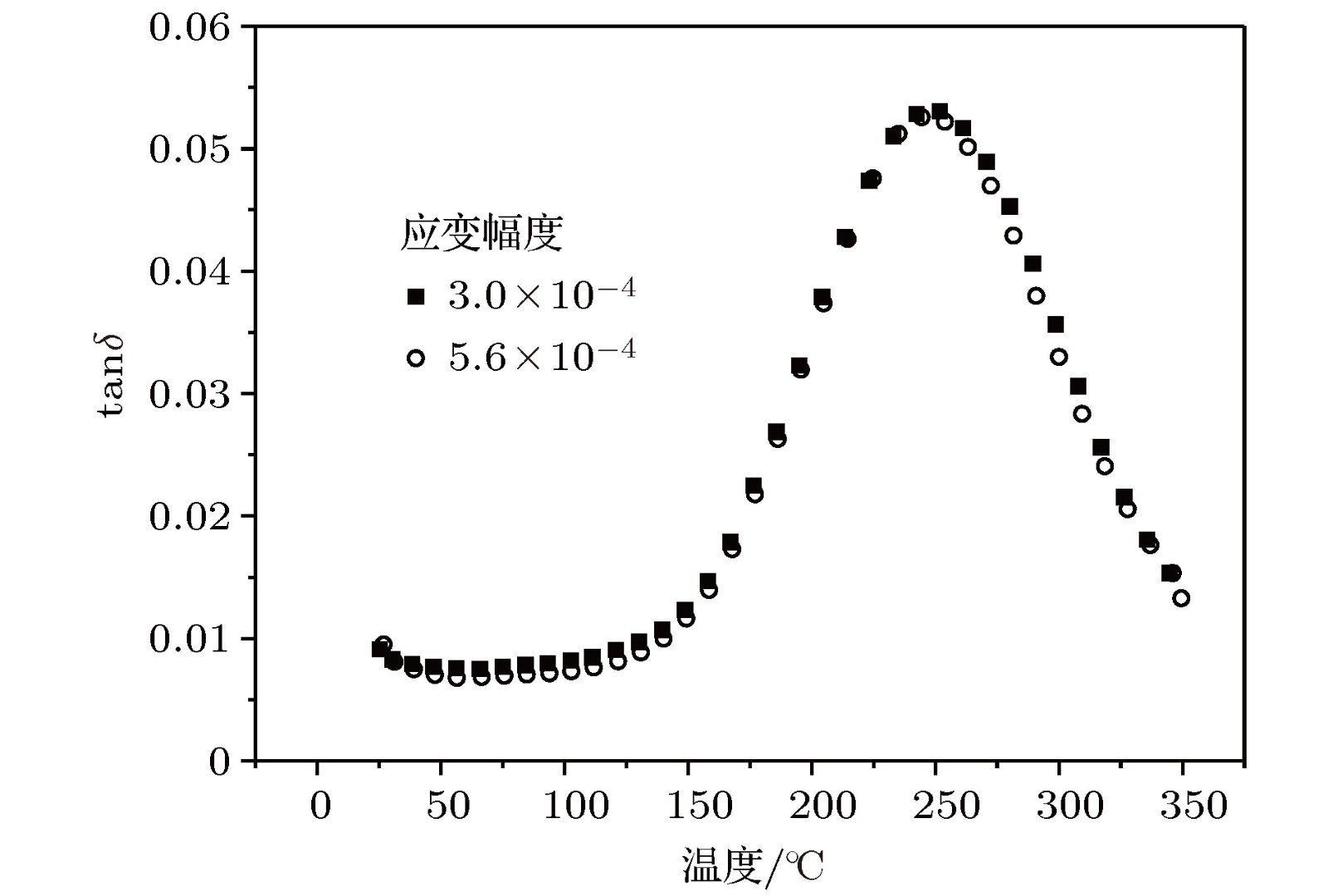

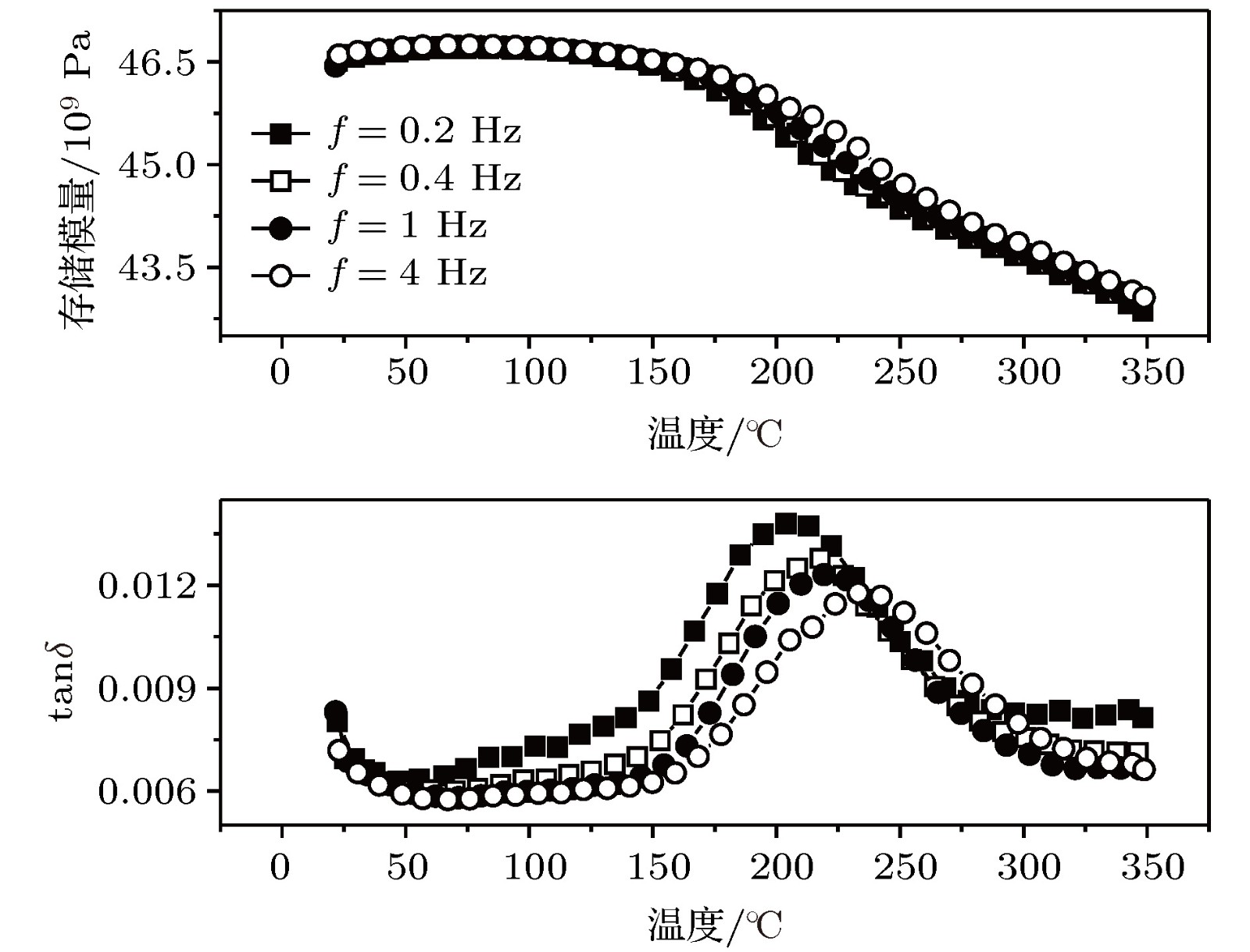

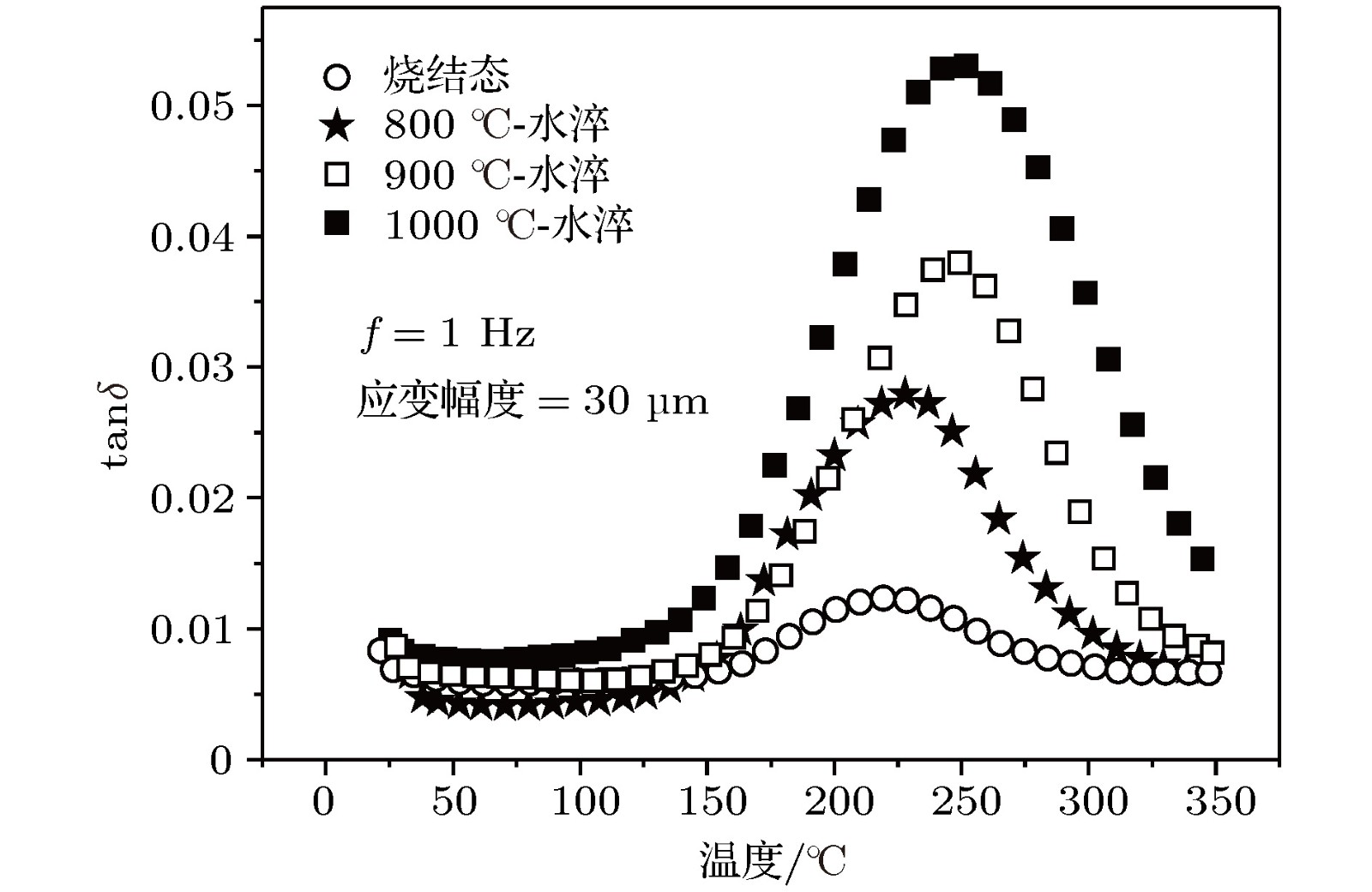

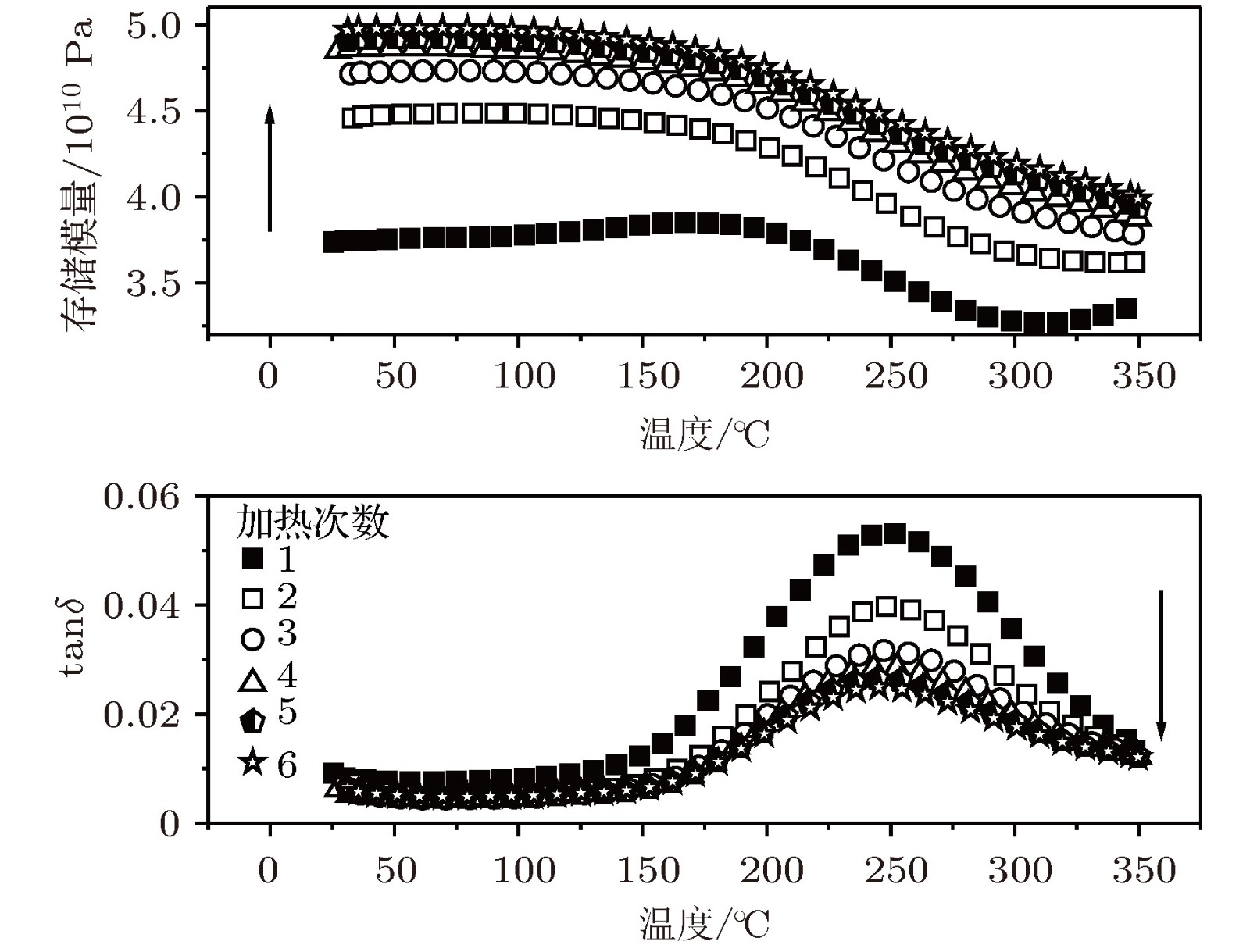

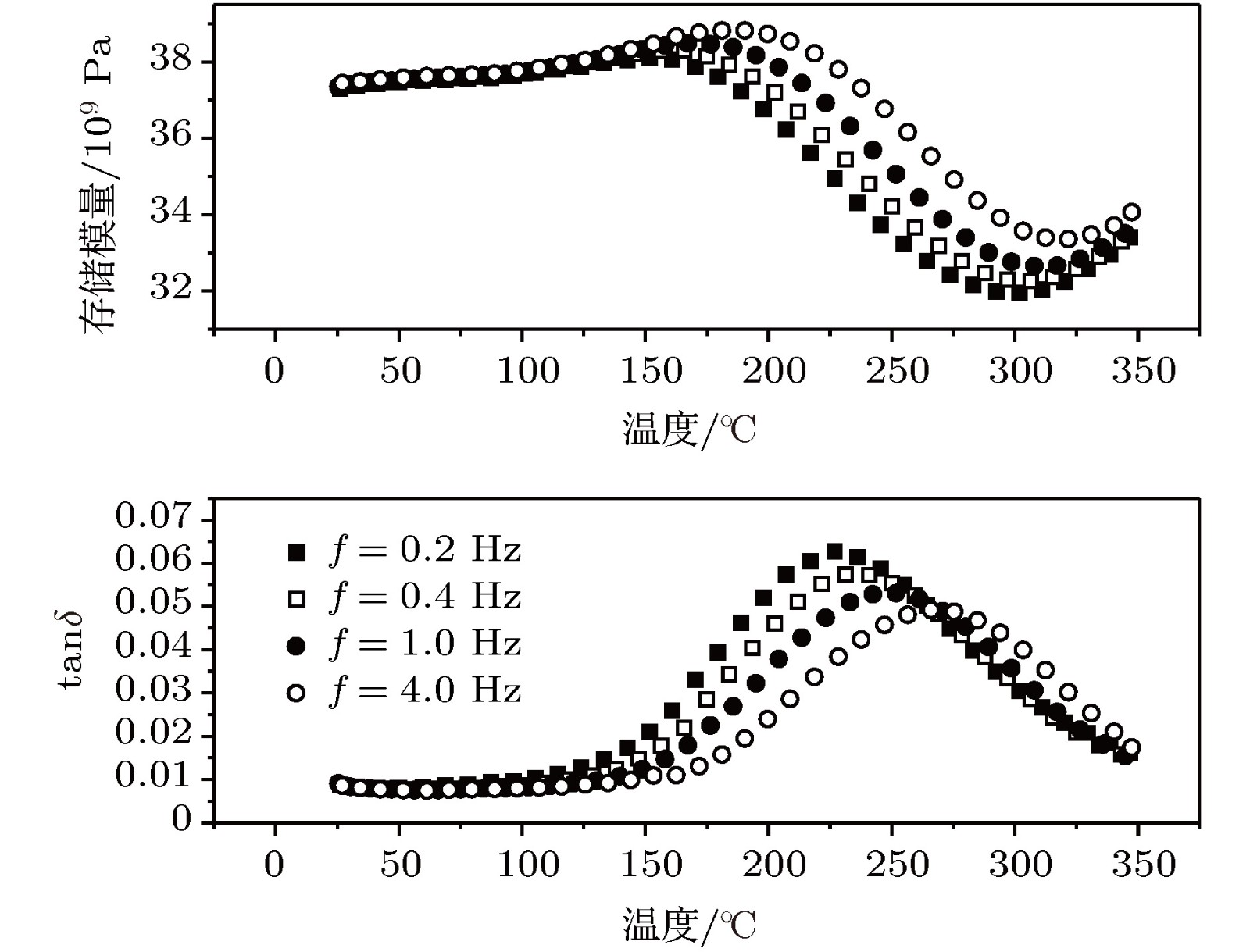

用粉末冶金方法制备了不同Nb含量的Ti-Nb合金. 用美国TA仪器公司的动力学分析仪Q800以单臂振动模式研究了不同Nb含量和不同热处理以及不同测量参数下的Ti-Nb合金的内耗行为, 用X-射线衍射检测了不同样品的微观结构. 实验表明, 在水淬的和烧结态的Ti-Nb合金的内耗-温度曲线上均发现了弛豫型的内耗峰, 这个内耗峰的高度与Nb含量有关, 在低Nb含量的Ti-Nb合金样品中不出现, 水淬样品内耗峰的最大值出现在Ti-35.4 wt.%Nb (以下称Ti-35.4Nb)的合金中, 烧结态样品的内耗峰高度在实验成分范围内单调地随Nb含量而增加. 水淬的Ti-35.4Nb合金的弛豫参数分别是激活能Hwq = (1.67 ± 0.1) eV和指数前因子τ0wq = 1.1 × 10-17 ± 1 s. 另外, 内耗峰的高度也与热处理有关, 水淬的Ti-35.4Nb合金比具有相同成分的烧结态的合金的内耗峰高得多, 淬火温度对内耗峰高度也有影响. 研究发现, 这个内耗峰与Ti-Nb合金中的β相有关, 峰高取决于β相的稳定性及其含量, 当β相的稳定性降低以及β相的量增加时, 峰高增加. 水淬Ti-35.4Nb合金中的β相是亚稳状态的β相(βM), 时效时βM能转变成稳定的α相和稳定β相(βS), 烧结态合金中的β相是βS. 不同热处理状态下Ti-35.4Nb合金样品的微观结构的不同导致了内耗峰高度的差别. 从微观结构分析, 在淬火的合金中, 峰高最大值出现在35 wt.% Nb含量附近的现象是由β相的稳定性和βM相的量随Nb含量变化引起的. 在烧结态的Ti-Nb合金中, 峰高单调地随Nb含量的增加而增加的情况是由βS的量决定的. 在循环应力作用下, βM或βS相晶格点阵中氧原子的跳动和氧原子与替代原子的相互作用是产生内耗峰的根源.

The β-type Ti-Nb alloys are potential shape memory and superelasticity materials. The interstitial atoms in the alloys have important effect on their physical and mechanical properties. For the interstitial atoms, the internal friction technique can be used to detect their distributions and status in the alloys. The influences of chemical compositions and heat treatments on the microstructures of the containing-oxygen Ti-Nb alloys are given, and a clear understanding and the relaxational mechanism of the internal friction peak correlated with oxygen are also clearly discussed by investigating the internal friction behavior of the alloys and the detecting their microstructures. The Ti-Nb alloys with different Nb content values are prepared by powder metallurgy. The internal friction behaviors of Ti-Nb alloys with different Nb content values and heat treatments are investigated by using dynamic mechanical analysis (dynamic mechanical analyzer, DMA) Q800 from TA Instruments in single cantilever mode under different testing parameters and conditions from room temperature to 350 ℃. The X-ray diffraction experiments are also carried out in order to detect the differences among the microstructures of the specimens with different heat treatments for the Ti-35.4Nb alloy. It is shown that relaxational internal friction peaks are found on the internal friction temperature dependent curves of the sintered and water-quenched alloys. The internal friction peak is correlated with Nb content. The peak does not appear in the sintered Ti-Nb alloys with low Nb content. The maximum of the internal friction peak appears in the quenched alloy with about 35% Nb. The internal friction peak height increases monotonically with Nb content increasing in the present testing composition range for the sintered alloys. The relaxation parameters are the activation energy Hwq = (1.67 ± 0.1) eV and the preexponential factor τowq = 1.1 × 10-17 ± 1 s for the quenched Ti-35.4Nb alloy . In addition, the peak height also depends on heat treatment. The water-quenched Ti-35.4Nb alloy has much higher internal friction peak than the as-sintered alloy with identical compositions. The internal friction peak height is also correlated with the quenching temperature. It is found that the peak is linked to the β phase of Ti-Nb alloys and that the peak height is determined by the stability and amount of the β phase from their microstructures. When the stability of the β phase decreases, the peak height increases, and the increase in the amount of β phase results in the increase of the peak height. The β phase in the quenched Ti-35.4Nb specimen is metastable β phase (βM), which can be transformed into the stable α and βS by ageing. The β phase in as-sintered specimen is the stable β phase (βS). The modifications of microstructures of the specimens with different heat treatments result in the difference in peak height between the water-quenched and as-sintered Ti-35.4Nb specimens. That the peak height presents a maximum in the vicinity of 35 wt.% Nb for the quenched alloys results from the variation of the stability and amount of βM with Nb content. That the height of the peak increases monotonically with Nb content increasing in as-sintered alloys is attributed to the increase of the amount of βS. It is suggested that the internal friction peak is related to oxygen jump in lattice or the interaction between the oxygen-substitute atoms in βM phase for the water-quenched alloys and those in βS phase for the as-sintered alloys. -

Keywords:

- internal friction /

- Ti-Nb alloy /

- interstitial atoms /

- Nb concentration

[1] Murray J L 1987 Phase Diagram of Binary Titanium Alloys, Materials Park (Ohio: American Society for Metals) p188

[2] Chen W M 2018 Calphad 60 98

Google Scholar

Google Scholar

[3] Grandini C R, Florêncio O, Filho W J B 2012 Defect Diffus. Forum 326-328 708

[4] Isaenkova M, Perlovich Y, Efimova E, Dmitry Z, Krymskaya O 2017 Mater. Sci. Forum 879 2561

[5] Blanter M S, Golovin I S, Neuhäuser H, Sinning H R 2007 Internal Friction in Metallic Materials: A Handbook (Springer Series in Materials Science) (Vol. 90) (Berlin: Springer Berlin Heidelberg) pp1−320

[6] Nowick A S, Berry B S 1972 Anelastic Relaxation in Crystalline Solids (Now York and London: Academic Press) p55, pp225−247

[7] Saitoh H, Yoshinaga N, Ushioda K 2004 Acta Mater. 52 1255

Google Scholar

Google Scholar

[8] Cantelli R 2006 Mater. Sci. Eng. A 442 5

Google Scholar

Google Scholar

[9] Weller M 2006 Mater. Sci. Eng. A 442 21

Google Scholar

Google Scholar

[10] Yin F X, Iwasaki S, Ping D H, Nagai K 2006 Adv. Mater. 18 1541

Google Scholar

Google Scholar

[11] Yin F X, Yu L, Ping D H, Iwasaki S 2009 Mater. Sci. Forum 614 175

Google Scholar

Google Scholar

[12] Florêncio O, Botta F W J, Grandini C R, Tejima H, Jodāo J A R 1994 J. Alloys Comp. 211−212 37

Google Scholar

Google Scholar

[13] Almeida L H , Grandini C R, Caram R 2009 Mater. Sci. Eng. A 521−522 59

Google Scholar

Google Scholar

[14] Yin F X, Yu L, Ping D H 2009 Mater. Sci. Eng. A 521−522 372

Google Scholar

Google Scholar

[15] Lu H, Li C X, Yin F X, Fang Q F, Umezawa O 2012 Mater. Sci. Eng. A 541 28

Google Scholar

Google Scholar

[16] Lu H, Li C X, Yin F X, Fang Q F,Umezawa O 2012 Solid State Phenom. 184 75

Google Scholar

Google Scholar

[17] Niemeyer T C, Gimenez J M A, Almeida L H, Grandini C R, Florêncio O 2002 Met. Res. 15 143

[18] Yu L, Yin F, Ping D 2007 Phys. Rev. B 75 174105

Google Scholar

Google Scholar

[19] Hartley C S, Steedly J E, Parsons L D 1965 in: Wheeler J A, Winslow F R (Editors) Diffusion in Body-centered Cubic Metals (Ohio: American Society for Metals)

[20] Miyazaki S, Kim H Y, Hosoda H 2006 Mater. Sci. Eng. A 438–440 18

[21] Matlakhova L A, Matlakhov A N, Monteiro S N 2008 Mater. Charact. 59 1234

Google Scholar

Google Scholar

[22] Zhou Z C, Du J, Zhang Y K, Gu S Y, Yan Y J, Yang H 2014 International Heat Treatment and Surface Engineering 8 144

Google Scholar

Google Scholar

[23] Abdel-Hady M, Hinoshita K, Morinaga M 2006 Scripta Mater. 55 477

Google Scholar

Google Scholar

[24] Rack H J, Kalish D, Fike K D 1970 Mater. Sci. Eng. 6 181

Google Scholar

Google Scholar

[25] Mantani Y, Tajima M 2006 Mater. Sci. Eng. A 442 409

Google Scholar

Google Scholar

[26] Fan Z 1993 Scripta Metall. Mater. 29 1427

Google Scholar

Google Scholar

[27] Ren X, Hagiwara M 2001 Acta Met. 49 3971

Google Scholar

Google Scholar

[28] Ping D H, Mitarai Y, Yin F X 2005 Scripta Mater. 52 1287

Google Scholar

Google Scholar

[29] Kim H Y, Kim J I, Inamura T, Hosoda H, Miyazaki S 2006 Mater. Sci. Eng. A 438−440 839

[30] Chang L L, Wang Y D, Ren Y 2016 Mater. Sci. Eng. A 651 442

Google Scholar

Google Scholar

[31] Dai S J, Wang Y, Chen F 2015 Mater. Charact. 104 16

Google Scholar

Google Scholar

[32] Martins Jr J R S, Araujo R O, Nogueira R A, Grandini C R 2016 Arch. Metall. Mater. 61 25

Google Scholar

Google Scholar

-

-

[1] Murray J L 1987 Phase Diagram of Binary Titanium Alloys, Materials Park (Ohio: American Society for Metals) p188

[2] Chen W M 2018 Calphad 60 98

Google Scholar

Google Scholar

[3] Grandini C R, Florêncio O, Filho W J B 2012 Defect Diffus. Forum 326-328 708

[4] Isaenkova M, Perlovich Y, Efimova E, Dmitry Z, Krymskaya O 2017 Mater. Sci. Forum 879 2561

[5] Blanter M S, Golovin I S, Neuhäuser H, Sinning H R 2007 Internal Friction in Metallic Materials: A Handbook (Springer Series in Materials Science) (Vol. 90) (Berlin: Springer Berlin Heidelberg) pp1−320

[6] Nowick A S, Berry B S 1972 Anelastic Relaxation in Crystalline Solids (Now York and London: Academic Press) p55, pp225−247

[7] Saitoh H, Yoshinaga N, Ushioda K 2004 Acta Mater. 52 1255

Google Scholar

Google Scholar

[8] Cantelli R 2006 Mater. Sci. Eng. A 442 5

Google Scholar

Google Scholar

[9] Weller M 2006 Mater. Sci. Eng. A 442 21

Google Scholar

Google Scholar

[10] Yin F X, Iwasaki S, Ping D H, Nagai K 2006 Adv. Mater. 18 1541

Google Scholar

Google Scholar

[11] Yin F X, Yu L, Ping D H, Iwasaki S 2009 Mater. Sci. Forum 614 175

Google Scholar

Google Scholar

[12] Florêncio O, Botta F W J, Grandini C R, Tejima H, Jodāo J A R 1994 J. Alloys Comp. 211−212 37

Google Scholar

Google Scholar

[13] Almeida L H , Grandini C R, Caram R 2009 Mater. Sci. Eng. A 521−522 59

Google Scholar

Google Scholar

[14] Yin F X, Yu L, Ping D H 2009 Mater. Sci. Eng. A 521−522 372

Google Scholar

Google Scholar

[15] Lu H, Li C X, Yin F X, Fang Q F, Umezawa O 2012 Mater. Sci. Eng. A 541 28

Google Scholar

Google Scholar

[16] Lu H, Li C X, Yin F X, Fang Q F,Umezawa O 2012 Solid State Phenom. 184 75

Google Scholar

Google Scholar

[17] Niemeyer T C, Gimenez J M A, Almeida L H, Grandini C R, Florêncio O 2002 Met. Res. 15 143

[18] Yu L, Yin F, Ping D 2007 Phys. Rev. B 75 174105

Google Scholar

Google Scholar

[19] Hartley C S, Steedly J E, Parsons L D 1965 in: Wheeler J A, Winslow F R (Editors) Diffusion in Body-centered Cubic Metals (Ohio: American Society for Metals)

[20] Miyazaki S, Kim H Y, Hosoda H 2006 Mater. Sci. Eng. A 438–440 18

[21] Matlakhova L A, Matlakhov A N, Monteiro S N 2008 Mater. Charact. 59 1234

Google Scholar

Google Scholar

[22] Zhou Z C, Du J, Zhang Y K, Gu S Y, Yan Y J, Yang H 2014 International Heat Treatment and Surface Engineering 8 144

Google Scholar

Google Scholar

[23] Abdel-Hady M, Hinoshita K, Morinaga M 2006 Scripta Mater. 55 477

Google Scholar

Google Scholar

[24] Rack H J, Kalish D, Fike K D 1970 Mater. Sci. Eng. 6 181

Google Scholar

Google Scholar

[25] Mantani Y, Tajima M 2006 Mater. Sci. Eng. A 442 409

Google Scholar

Google Scholar

[26] Fan Z 1993 Scripta Metall. Mater. 29 1427

Google Scholar

Google Scholar

[27] Ren X, Hagiwara M 2001 Acta Met. 49 3971

Google Scholar

Google Scholar

[28] Ping D H, Mitarai Y, Yin F X 2005 Scripta Mater. 52 1287

Google Scholar

Google Scholar

[29] Kim H Y, Kim J I, Inamura T, Hosoda H, Miyazaki S 2006 Mater. Sci. Eng. A 438−440 839

[30] Chang L L, Wang Y D, Ren Y 2016 Mater. Sci. Eng. A 651 442

Google Scholar

Google Scholar

[31] Dai S J, Wang Y, Chen F 2015 Mater. Charact. 104 16

Google Scholar

Google Scholar

[32] Martins Jr J R S, Araujo R O, Nogueira R A, Grandini C R 2016 Arch. Metall. Mater. 61 25

Google Scholar

Google Scholar

计量

- 文章访问数: 10122

- PDF下载量: 66

- 被引次数: 0

下载:

下载: