-

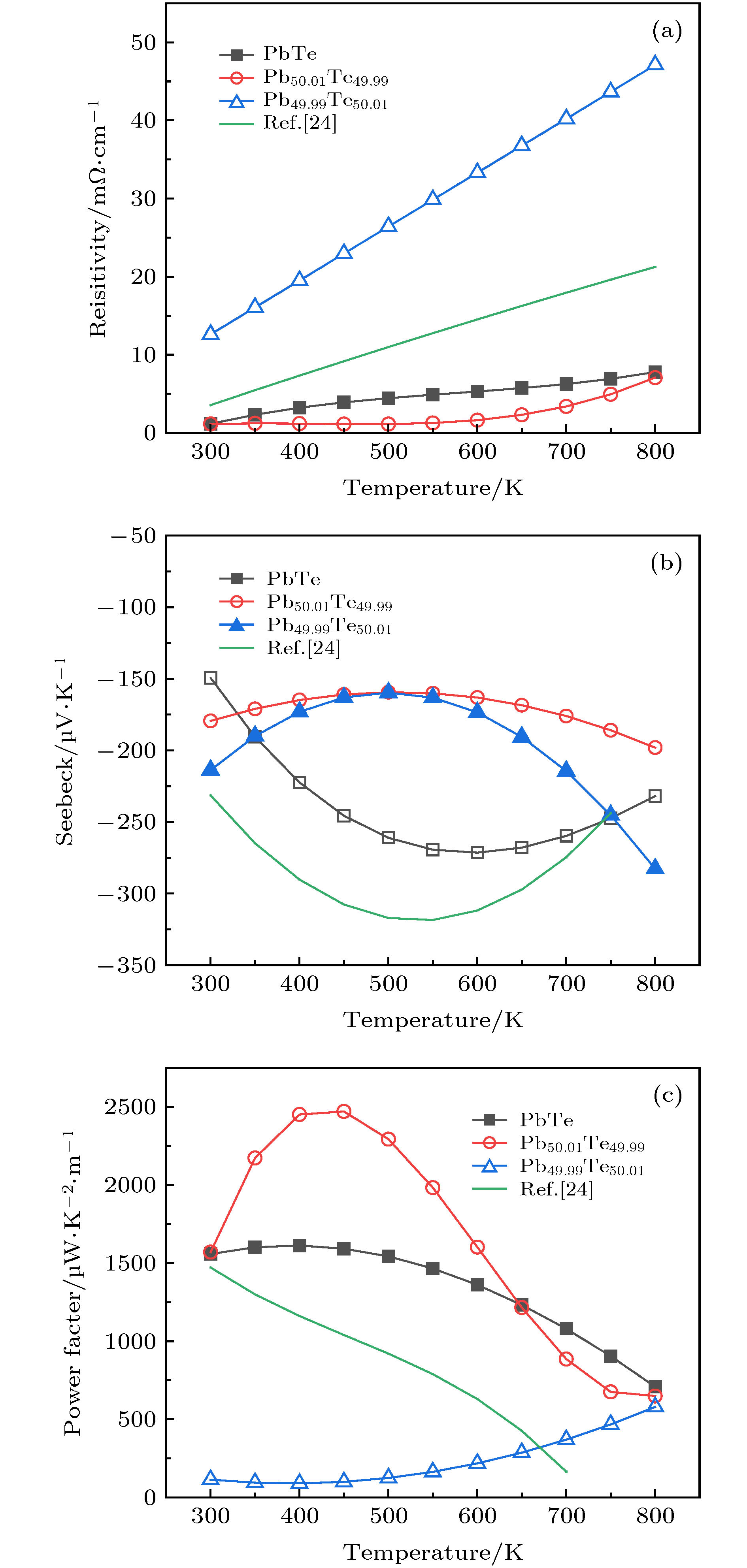

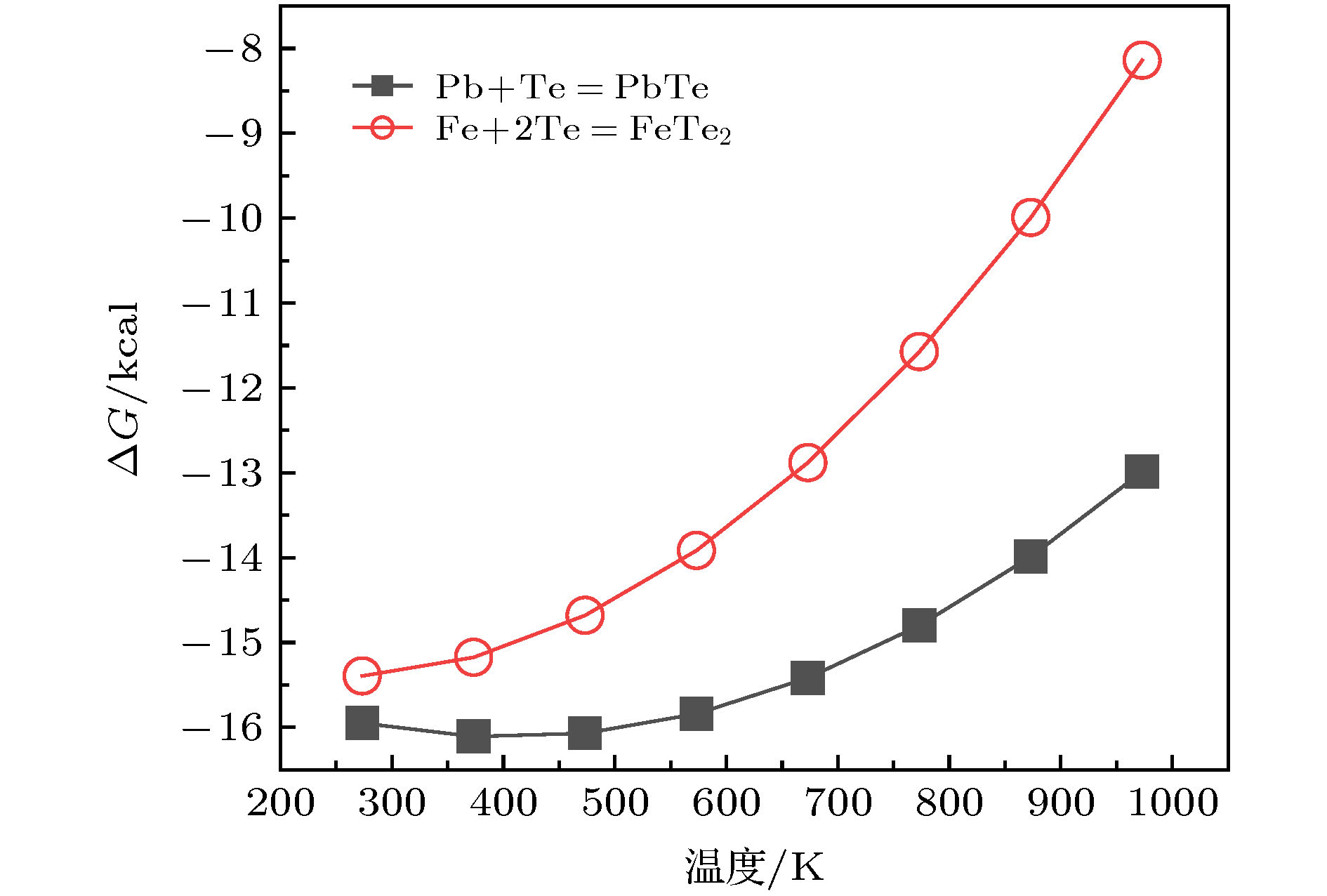

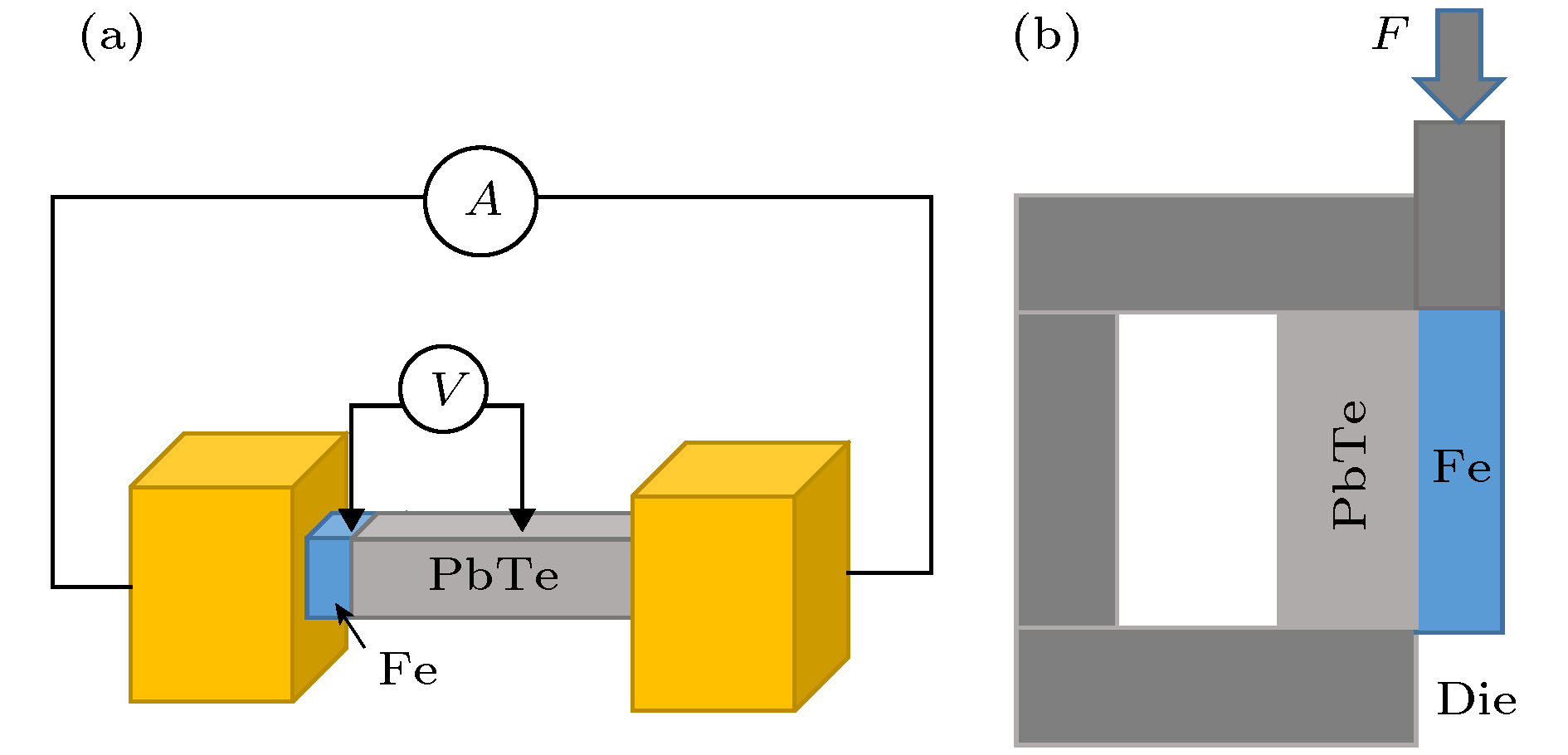

PbTe具有极高的热电转化效率, 本文以获得高质量、高转化效率的PbTe热电接头为目标. Pb的过量可以提高载流子浓度, 进而提高PbTe的热电性能, 复合电极能够改善界面势垒, 降低接触电阻. 传统方法通过抑制元素扩散降低接触电阻与提升剪切强度存在矛盾, 本文通过引入复合电极, 在电极材料与热电材料之间形成中间层, 抑制PbTe一侧Pb元素的扩散, 在降低接触电阻的同时提高了剪切强度. 通过调整PbTe的化学计量比, 得到样品Pb50.01Te49.99, 在Fe电极中混入Te和Pb, 将其与Pb50.01Te49.99一步热压烧结, 获得所需要的PbTe热电电极接头. 研究结果表明, 复合电极的接触电阻与纯Fe连接的相比, 接触电阻有近75%的降低, 为26.61 μΩ·cm2, 更加接近文献报道的最低值10 μΩ·cm2, 同时剪切强度相比于纯Fe电极也有较大幅度的提升, 这为获得性能优良的PbTe热电接头提供了新思路.The conversion efficiency of thermoelectric material PbTe is high. A high-quality and high-conversion-efficiency PbTe thermoelectric connector is investigated systematically. Excess Pb in composition can increase the carrier concentration and improve the thermoelectric performance of PbTe. The composite electrode can improve the interface barrier and reduce the contact resistance. Traditional processes of making contacts onto bulk crystalline PbTe-based materials do not work for reducing the contact resistance by inhibiting element diffusion and increasing the shear strength at the same time. In this study, we consider a composite electrode which can form an intermediate layer to suppress the diffusion of the Pb element on the PbTe side. This work not only reduces the contact resistance, but also increases the shear strength. The sample Pb50.01Te49.99 is obtained by adjusting the stoichiometric ratio of PbTe; Te and Pb are mixed in the Fe electrode. The composite electrode and Pb50.01Te49.99 are hot-pressed and sintered in one step to obtain the required PbTe thermoelectric electrode joint. We find that the contact resistance of the composite electrode is reduced by nearly 75% compared with that of metallization layer (Fe) connection. The smallest value is 26.610 μΩ·cm2 which is closer to the lowest 10 μΩ·cm2 reported in the literature than the counterpart of pure Fe electrode, and the shear strength is also greatly improved simultaneously. This work provides a new idea for obtaining PbTe thermoelectric connectors with excellent performance.

-

Keywords:

- thermoelectric material /

- thermoelectric joint /

- thermal stability /

- PbTe

[1] He J, Tritt T M 2017 Science 357 6358

Google Scholar

Google Scholar

[2] Crane D, LaGrandeur J, Jovovic V, Ranalli M, Adldinger M, Poliquin E, Dean J, Kossakovski D, Mazar B, Maranville C 2012 J. Electron. Mater. 42 1582

Google Scholar

Google Scholar

[3] Xie Y, Wu S, Yang C 2016 Appl. Energy 164 620

Google Scholar

Google Scholar

[4] Shen J, Wang Z, Chu J, Bai S, Zhao X, Chen L, Zhu T 2019 ACS Appl. Mater. Interfaces 11 14182

Google Scholar

Google Scholar

[5] LaLonde A D, Pei Y, Wang H, Jeffrey S G 2011 Mater. Today 14 526

Google Scholar

Google Scholar

[6] Biswas K, He J, Blum I D, Wu C I, Hogan T P, Seidman D N, Dravid V P, Kanatzidis M G 2012 Nature 489 414

Google Scholar

Google Scholar

[7] Wu H J, Zhao L D, Zheng F S, Wu D, Pei Y L, Tong X, Kanatzidis M G, He J Q 2014 Nat. Commun. 5 4515

Google Scholar

Google Scholar

[8] Wu D, Zhao L D, Tong X, Li W, Wu L, Tan Q, Pei Y, Huang L, Li J F, Zhu Y, Kanatzidis M G, He J 2015 Energy Environ. Sci. 8 2056

Google Scholar

Google Scholar

[9] Wu Y, Pei J, Zhang R 2020 J. Alloys Compd. 830 154451

Google Scholar

Google Scholar

[10] Fu L, Yin M, Wu D, Li W, Feng D, Huang L, He J 2017 Energy Environ. Sci. 10 2030

Google Scholar

Google Scholar

[11] LaLonde A D, Pei Y, Snyder G J 2011 Energy Environ. Sci. 4 6

Google Scholar

Google Scholar

[12] Heremans J P, Thrush C M, Morelli D T 2005 J. Appl. Phys. 98 2229

Google Scholar

Google Scholar

[13] Xiao Y, Wu H, Li W, Yin M, Pei Y, Zhang Y, Fu L, Chen Y, Pennycook S J, Huang L, He J, Zhao L D 2017 J. Am. Chem. Soc. 139 18732

Google Scholar

Google Scholar

[14] Weinstein M, Mlavsky A I 1962 Rev. Sci. Instrum. 33 1119

Google Scholar

Google Scholar

[15] Li C C, Drymiotis F, Liao L L, Dai M J, Liu C K, Chen C L, Chen Y Y, Kao C R, Snyder G J 2015 Energy Convers. Manage. 98 134

Google Scholar

Google Scholar

[16] Hu X, Jood P, Ohta M, Kunii M, Nagase K, Nishiate H, Kanatzidis M G, Yamamoto A 2016 Energy Environ. Sci. 9 517

Google Scholar

Google Scholar

[17] Zhang, Q H, Qiu P F, Chen L D 2017 Energy Environ. Sci. 10 4

Google Scholar

Google Scholar

[18] Singh A, Bhattacharya S, Thinaharan C, Aswal D K, Gupta S K, Yakhmi J V, Bhanumurthy K 2009 J. Phys. D: Appl. Phys. 42 015502

Google Scholar

Google Scholar

[19] Li C C, Drymiotis F, Liao L L, Hung H T, Ke J H, Liu C K, Kao C R, Snyder G J 2015 J. Mater. Chem. C 3 10590

Google Scholar

Google Scholar

[20] Ferreres X R, Aminorroaya Yamini S, Nancarrow M, Zhang C 2016 Mater. Des. 107 90

Google Scholar

Google Scholar

[21] Liu W, Jie Q, Kim H S, Ren Z 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[22] Oguni Y, Iida T, Matsumoto A, et al. 2007 Mrs Proceedings 09 1044

Google Scholar

Google Scholar

[23] Sakamoto T, Iida T, Honda Y, Tada M, Sekiguchi T, Nishio K, Kogo Y, Takanashi Y 2012 J. Electron. Mater. 41 1805

Google Scholar

Google Scholar

[24] 邢媛, 李洪涛 2018 科技视界 8 1

Google Scholar

Google Scholar

Xing Y, Li H T 2018 IDA Pap. 8 1

Google Scholar

Google Scholar

[25] Schneider C, Schichtel P, Mogwitz B, Rohnke M, Janek J 2017 Solid State Ionics 303 119

Google Scholar

Google Scholar

[26] 夏海洋 2015 博士学位论文 (北京: 清华大学)

Xia H Y 2015 Ph. D. Dissertation (Beijing: Tsinghua University) (in Chinese)

[27] Zou J, Wu F S, Wang B, Liu H 2010 Electronics Process Technology 31 1

[28] Wu H F, Zhang H J, Lu Y H, Yan Y H, Li H Y, Bao S N, He P M 2014 Chin. Phys. B 23 127901

Google Scholar

Google Scholar

[29] Qin H, Guo B, Wang L, Zhang M, Xu B, Shi K, Pan T, Zhou L, Chen J, Qiu Y, Xi B, Sou I K, Yu D, Chen W Q, He H, Ye F, Mei J W, Wang G 2020 Nano Lett. 20 3160

Google Scholar

Google Scholar

[30] Skipetrov E P, Kruleveckaya O V, Skipetrova L A, Slynko E I, Slynko V E 2014 Appl. Phys. Lett. 105 022101

Google Scholar

Google Scholar

-

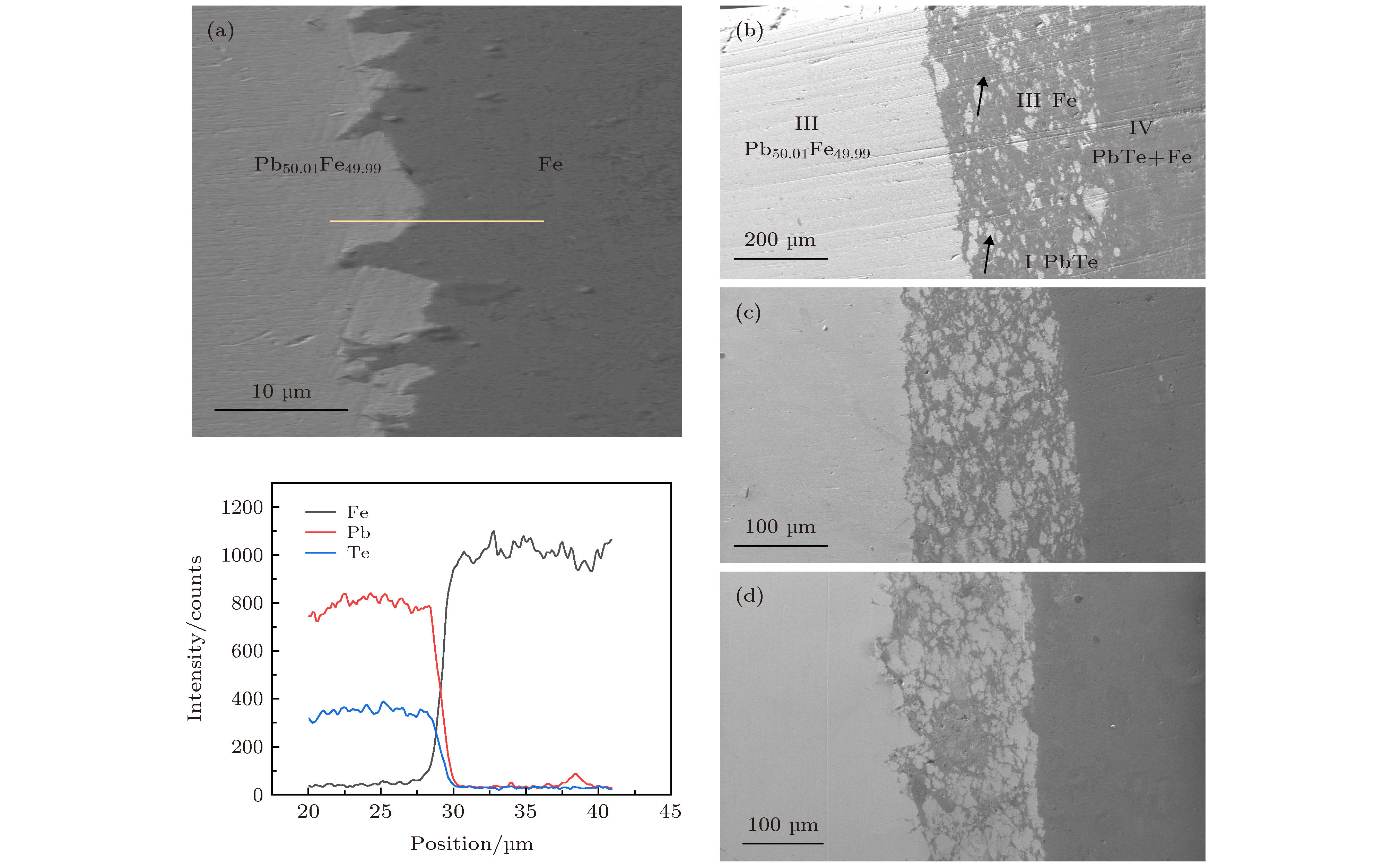

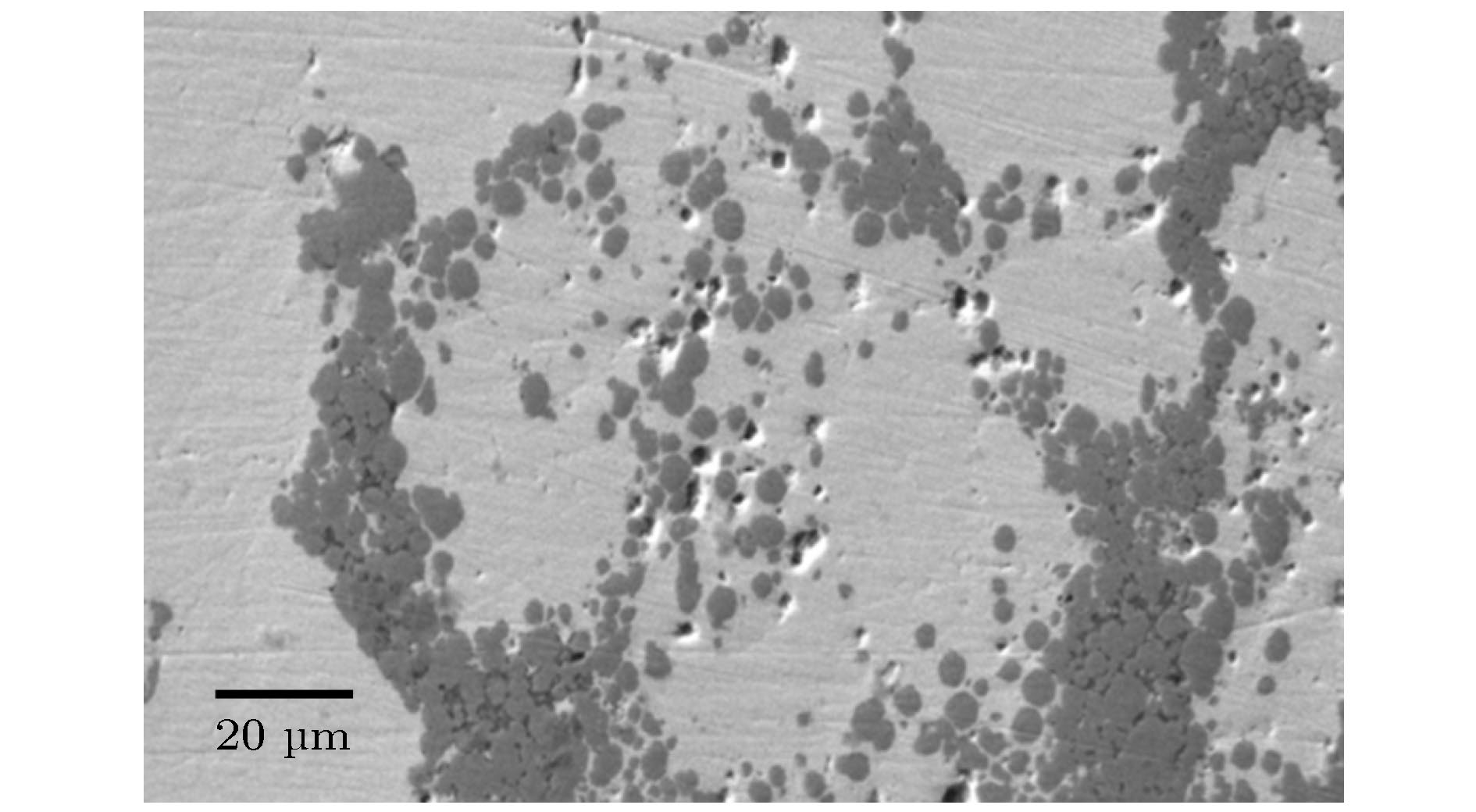

图 3 (a) 1号样品 (Pb50.01Te49.99/Fe)EDS能谱分析图; (b), (c), (d) 样品2 (Pb50.01Te49.99/Fe0.8Pb0.15Te0.05), 3 (Pb50.01Te49.99/Fe0.7Pb0.15Te0.15), 4 (Pb50.01Te49.99/ Fe0.6Pb0.15Te0.25)的扫描图片

Fig. 3. (a) EDS spectrum analysis of sample 1 (Pb50.01Te49.99/Fe); (b), (c), (d) scan pictures of sample 2 (Pb50.01Te49.99/Fe0.8Pb0.15Te0.05), 3 (Pb50.01Te49.99/Fe0.7Pb0.15Te0.15), 4 (Pb50.01Te49.99/Fe0.6Pb0.15Te0.25).

图 8 1 (Pb50.01Te49.99/Fe), 2 (Pb50.01Te49.99/Fe0.8Pb0.15Te0.05), 3 (Pb50.01Te49.99/ Fe0.7Pb0.15Te0.15), 4 (Pb50.01Te49.99/Fe0.6Pb0.15Te0.25)号样品500 ℃, 保温10 d时前后接触电阻对比

Fig. 8. Samples 1 (Pb50.01Te49.99/Fe), 2 (Pb50.01Te49.99/Fe0.8Pb0.15Te0.05), 3 (Pb50.01Te49.99/Fe0.7Pb0.15Te0.15), 4 (Pb50.01Te49.99/Fe0.6Pb0.15Te0.25) contact resistance before and after aging at 500 ℃, 10 d.

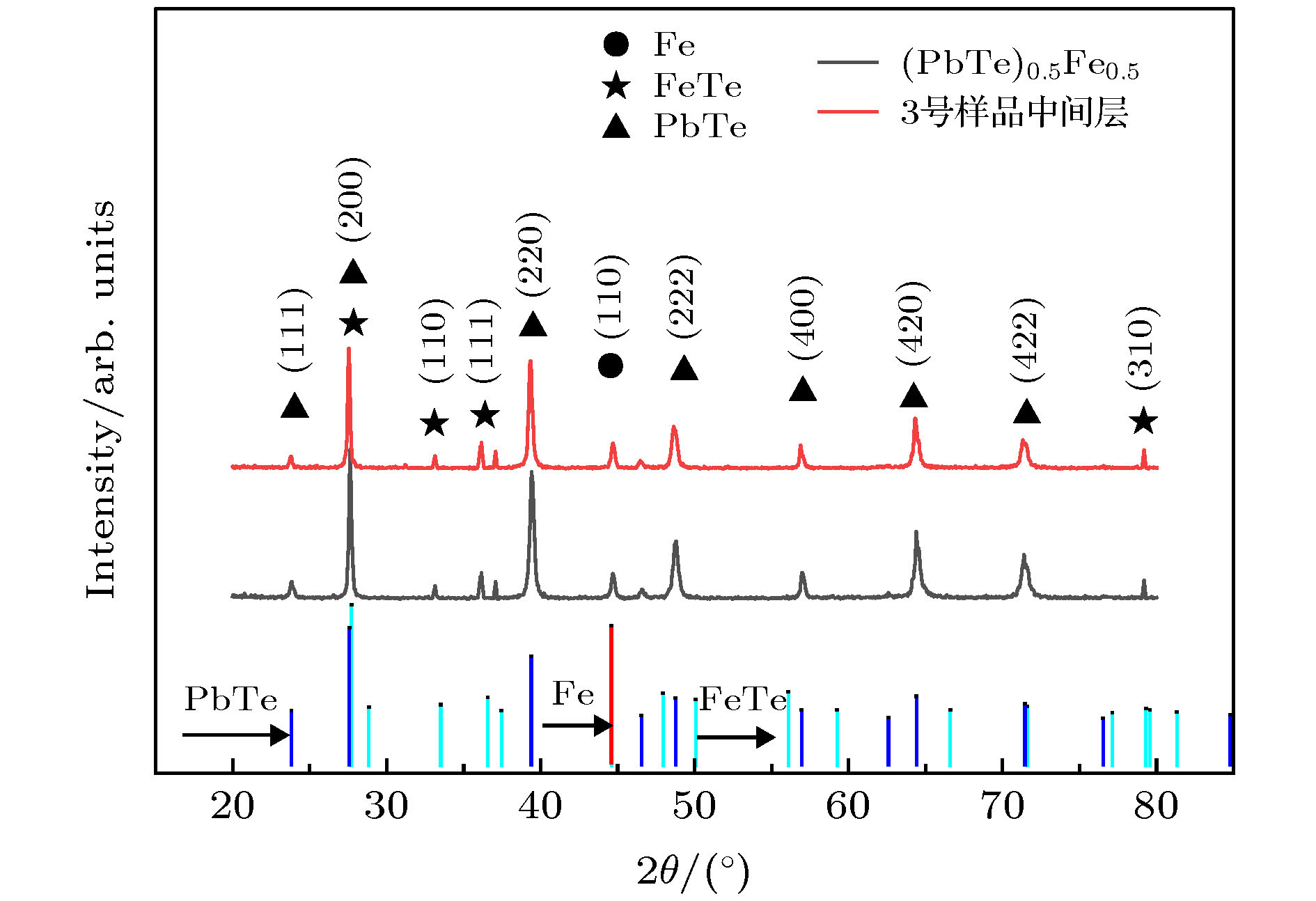

图 9 (a) 2 (Pb50.01Te49.99/Fe0.8Pb0.15Te0.05), 3 (Pb50.01Te49.99/Fe0.7Pb0.15Te0.15), 4 (Pb50.01Te49.99/ Fe0.6Pb0.15Te0.25)号热电接头的电极一侧XRD 图; (b) PbTe, Pb50.01Te49.99, Pb50.04 Te49.96, (PbTe)0.5Fe0.5的电阻率随温度的变化

Fig. 9. (a) XRD patterns of the electrode side of thermoelectric connectors 2 (Pb50.01Te49.99/Fe0.8Pb0.15Te0.05), 3 (Pb50.01Te49.99/Fe0.7Pb0.15Te0.15), 4 (Pb50.01Te49.99/ Fe0.6Pb0.15Te0.25); (b) variation of the resistivity of PbTe, Pb50.01Te49.99, (PbTe)0.5Fe0.5, Pb50.04Te49.96 with temperature.

图 11 1 (Pb50.01Te49.99/Fe), 2 (Pb50.01Te49.99/Fe0.8Pb0.15Te0.05), 3 (Pb50.01Te49.99/Fe0.7Pb0.15Te0.15), 4 (Pb50.01Te49.99/Fe0.6Pb0.15Te0.25)号样品10 d, 500 ℃时效前后剪切强度对比

Fig. 11. Shear strength comparison of samples 1 (Pb50.01Te49.99/Fe), 2 (Pb50.01Te49.99/Fe0.8Pb0.15Te0.05), 3 (Pb50.01Te49.99/Fe0.7Pb0.15Te0.15), 4 (Pb50.01Te49.99/ Fe0.6Pb0.15Te0.25) before and after aging at 500 ℃ 10 d.

区域 Pb/at% Te/at% Fe/at% I 48.97 51.03 0 II 0 3.25 96.75 -

[1] He J, Tritt T M 2017 Science 357 6358

Google Scholar

Google Scholar

[2] Crane D, LaGrandeur J, Jovovic V, Ranalli M, Adldinger M, Poliquin E, Dean J, Kossakovski D, Mazar B, Maranville C 2012 J. Electron. Mater. 42 1582

Google Scholar

Google Scholar

[3] Xie Y, Wu S, Yang C 2016 Appl. Energy 164 620

Google Scholar

Google Scholar

[4] Shen J, Wang Z, Chu J, Bai S, Zhao X, Chen L, Zhu T 2019 ACS Appl. Mater. Interfaces 11 14182

Google Scholar

Google Scholar

[5] LaLonde A D, Pei Y, Wang H, Jeffrey S G 2011 Mater. Today 14 526

Google Scholar

Google Scholar

[6] Biswas K, He J, Blum I D, Wu C I, Hogan T P, Seidman D N, Dravid V P, Kanatzidis M G 2012 Nature 489 414

Google Scholar

Google Scholar

[7] Wu H J, Zhao L D, Zheng F S, Wu D, Pei Y L, Tong X, Kanatzidis M G, He J Q 2014 Nat. Commun. 5 4515

Google Scholar

Google Scholar

[8] Wu D, Zhao L D, Tong X, Li W, Wu L, Tan Q, Pei Y, Huang L, Li J F, Zhu Y, Kanatzidis M G, He J 2015 Energy Environ. Sci. 8 2056

Google Scholar

Google Scholar

[9] Wu Y, Pei J, Zhang R 2020 J. Alloys Compd. 830 154451

Google Scholar

Google Scholar

[10] Fu L, Yin M, Wu D, Li W, Feng D, Huang L, He J 2017 Energy Environ. Sci. 10 2030

Google Scholar

Google Scholar

[11] LaLonde A D, Pei Y, Snyder G J 2011 Energy Environ. Sci. 4 6

Google Scholar

Google Scholar

[12] Heremans J P, Thrush C M, Morelli D T 2005 J. Appl. Phys. 98 2229

Google Scholar

Google Scholar

[13] Xiao Y, Wu H, Li W, Yin M, Pei Y, Zhang Y, Fu L, Chen Y, Pennycook S J, Huang L, He J, Zhao L D 2017 J. Am. Chem. Soc. 139 18732

Google Scholar

Google Scholar

[14] Weinstein M, Mlavsky A I 1962 Rev. Sci. Instrum. 33 1119

Google Scholar

Google Scholar

[15] Li C C, Drymiotis F, Liao L L, Dai M J, Liu C K, Chen C L, Chen Y Y, Kao C R, Snyder G J 2015 Energy Convers. Manage. 98 134

Google Scholar

Google Scholar

[16] Hu X, Jood P, Ohta M, Kunii M, Nagase K, Nishiate H, Kanatzidis M G, Yamamoto A 2016 Energy Environ. Sci. 9 517

Google Scholar

Google Scholar

[17] Zhang, Q H, Qiu P F, Chen L D 2017 Energy Environ. Sci. 10 4

Google Scholar

Google Scholar

[18] Singh A, Bhattacharya S, Thinaharan C, Aswal D K, Gupta S K, Yakhmi J V, Bhanumurthy K 2009 J. Phys. D: Appl. Phys. 42 015502

Google Scholar

Google Scholar

[19] Li C C, Drymiotis F, Liao L L, Hung H T, Ke J H, Liu C K, Kao C R, Snyder G J 2015 J. Mater. Chem. C 3 10590

Google Scholar

Google Scholar

[20] Ferreres X R, Aminorroaya Yamini S, Nancarrow M, Zhang C 2016 Mater. Des. 107 90

Google Scholar

Google Scholar

[21] Liu W, Jie Q, Kim H S, Ren Z 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[22] Oguni Y, Iida T, Matsumoto A, et al. 2007 Mrs Proceedings 09 1044

Google Scholar

Google Scholar

[23] Sakamoto T, Iida T, Honda Y, Tada M, Sekiguchi T, Nishio K, Kogo Y, Takanashi Y 2012 J. Electron. Mater. 41 1805

Google Scholar

Google Scholar

[24] 邢媛, 李洪涛 2018 科技视界 8 1

Google Scholar

Google Scholar

Xing Y, Li H T 2018 IDA Pap. 8 1

Google Scholar

Google Scholar

[25] Schneider C, Schichtel P, Mogwitz B, Rohnke M, Janek J 2017 Solid State Ionics 303 119

Google Scholar

Google Scholar

[26] 夏海洋 2015 博士学位论文 (北京: 清华大学)

Xia H Y 2015 Ph. D. Dissertation (Beijing: Tsinghua University) (in Chinese)

[27] Zou J, Wu F S, Wang B, Liu H 2010 Electronics Process Technology 31 1

[28] Wu H F, Zhang H J, Lu Y H, Yan Y H, Li H Y, Bao S N, He P M 2014 Chin. Phys. B 23 127901

Google Scholar

Google Scholar

[29] Qin H, Guo B, Wang L, Zhang M, Xu B, Shi K, Pan T, Zhou L, Chen J, Qiu Y, Xi B, Sou I K, Yu D, Chen W Q, He H, Ye F, Mei J W, Wang G 2020 Nano Lett. 20 3160

Google Scholar

Google Scholar

[30] Skipetrov E P, Kruleveckaya O V, Skipetrova L A, Slynko E I, Slynko V E 2014 Appl. Phys. Lett. 105 022101

Google Scholar

Google Scholar

计量

- 文章访问数: 8416

- PDF下载量: 137

- 被引次数: 0

下载:

下载: