-

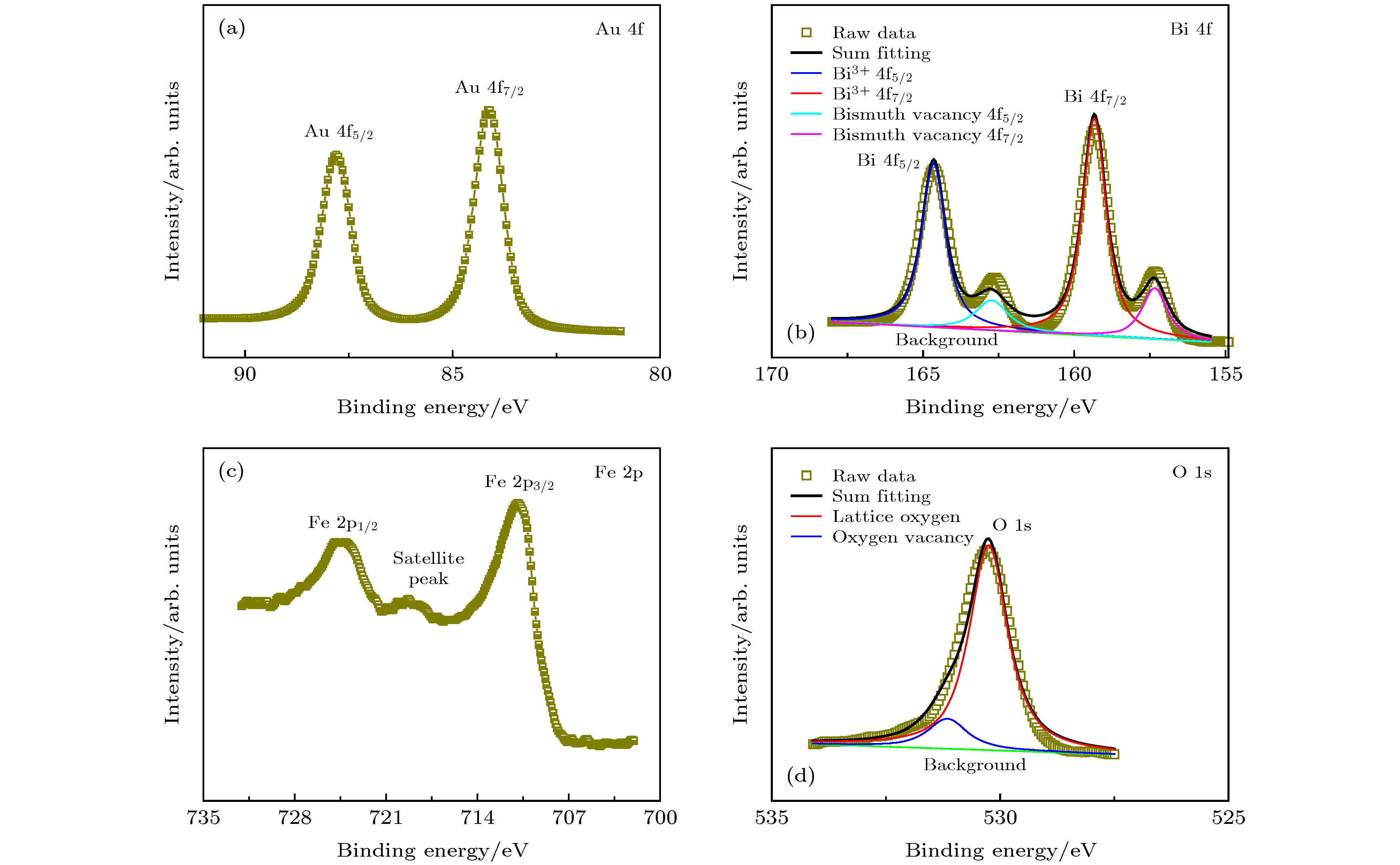

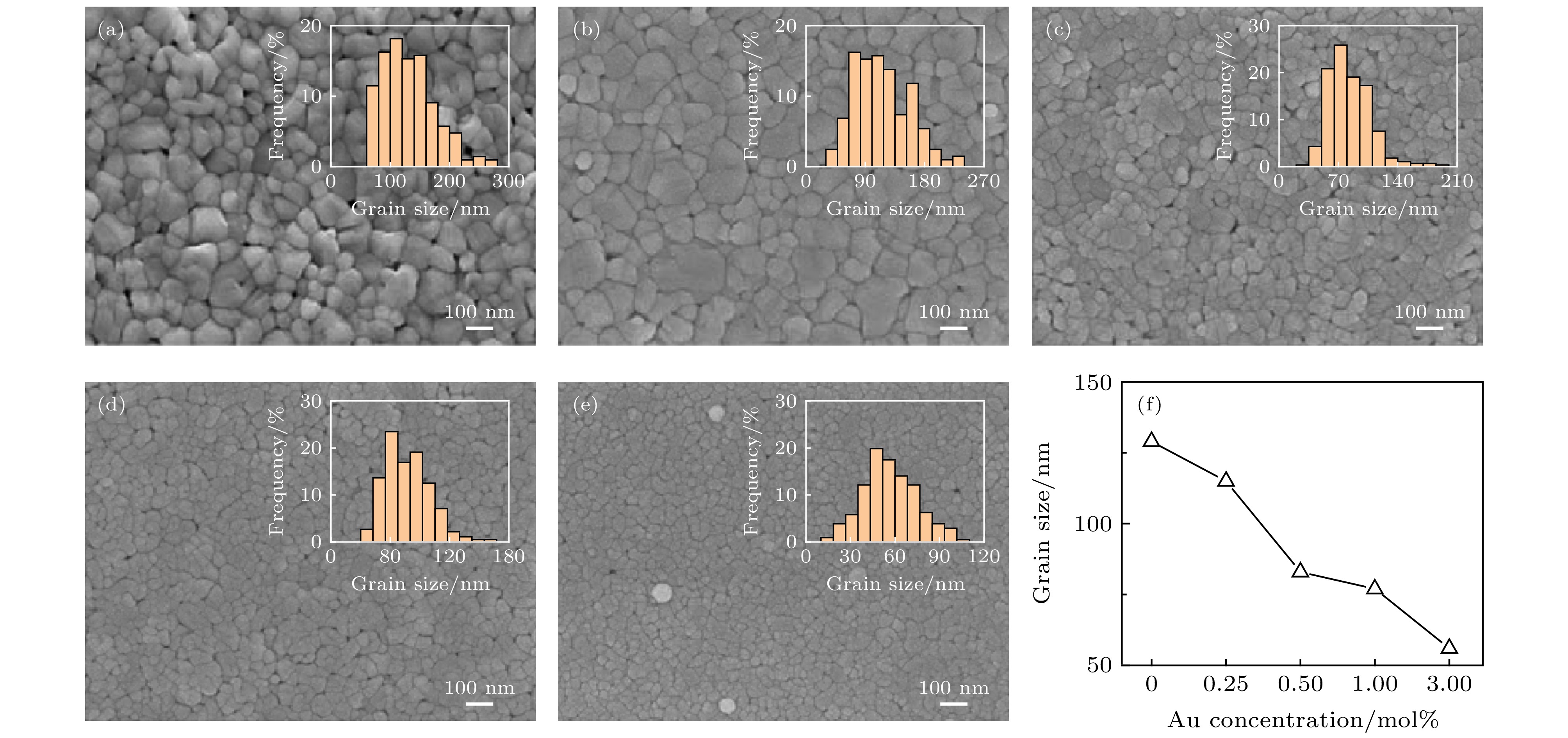

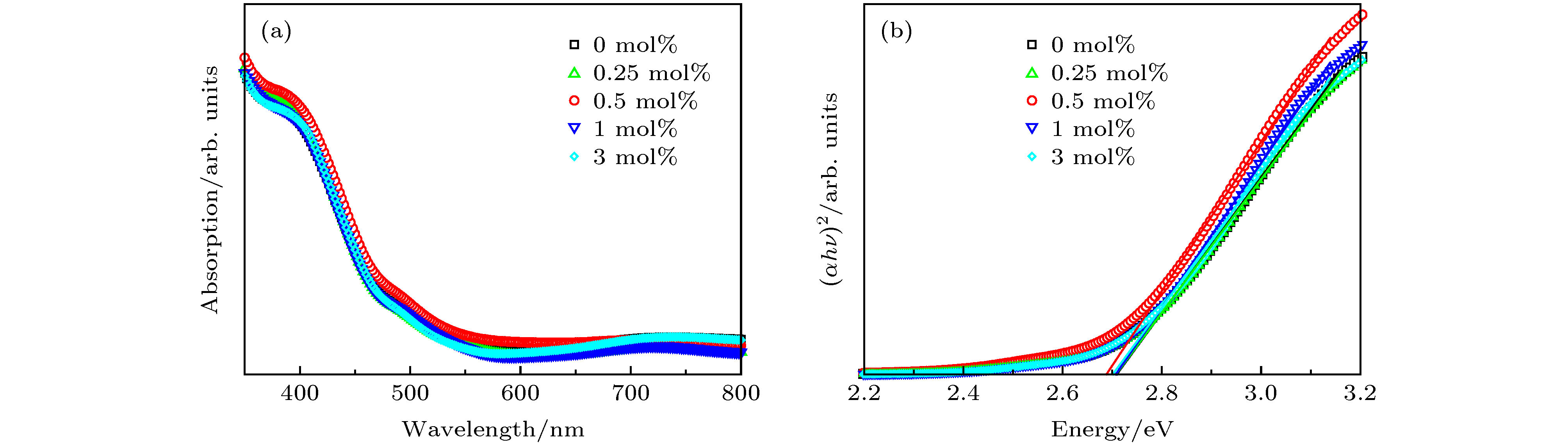

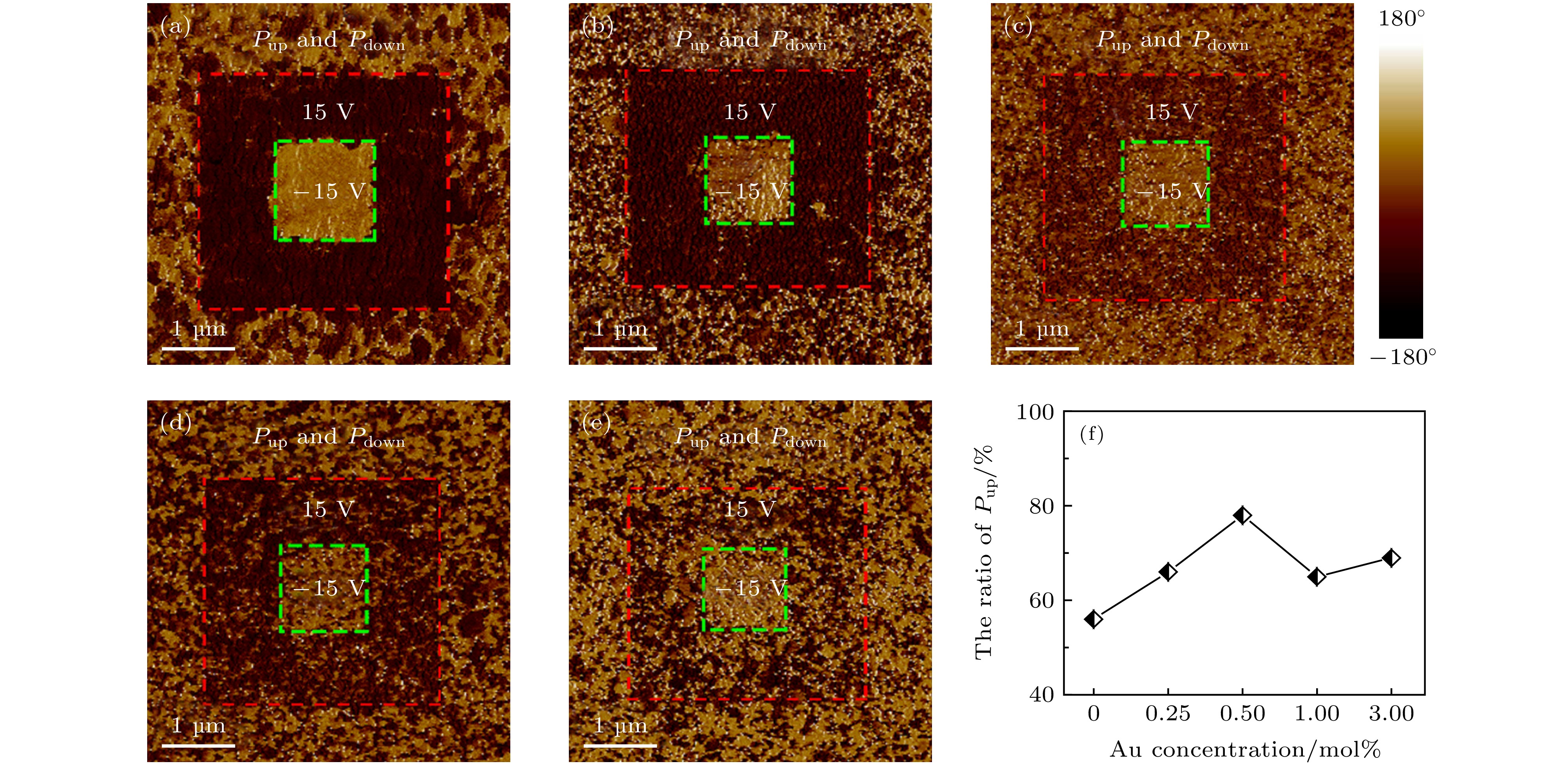

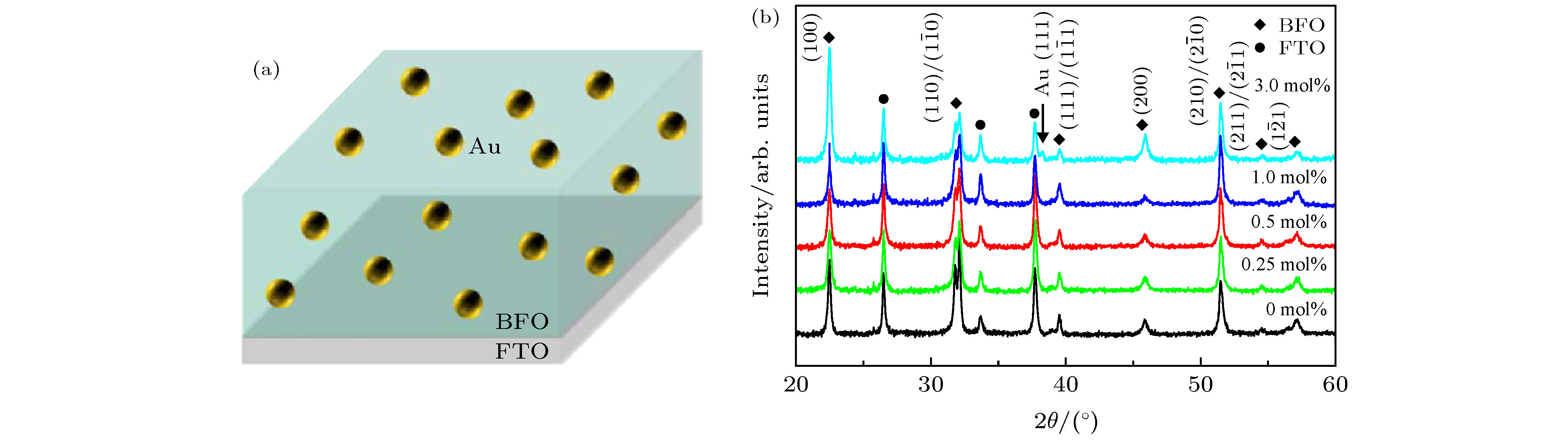

存在对称性破缺引起的自极化及通过外界刺激可以改变其极化状态的铁电薄膜, 是一类重要的光电功能材料. 铁电薄膜的光伏效应在光探测、能量转换和非易失性存储等领域表现出了潜在应用前景. 针对铁电薄膜光电流密度较小, 且存在退极化现象导致的光伏性能退化问题, 有必要寻求提高薄膜自极化的新途径, 并对其导电性进行调控, 进一步优化铁电薄膜的光伏性能. 本文采用溶胶-凝胶法在FTO导电玻璃上沉积了Au纳米粒子弥散分布在铁酸铋(BiFeO3, BFO)薄膜中的Au-BFO纳米复合薄膜, 研究了Au含量(0, 0.25 mol%, 0.5 mol%, 1 mol%和3 mol%)与此复合薄膜微观组织、电学和光伏性能的关系, 以确定Au的最佳添加量. 压电力显微镜的测量结果表明, Au含量为0.5 mol%时, Au-BFO纳米复合薄膜具有较强的自极化现象. 随着Au含量的增大, Au-BFO纳米复合薄膜的导电机制由肖特基发射模型转变为空间电荷限制电流. 对复合薄膜的光伏性能进行测试, 结果表明Au含量为0.5 mol%时, Au-BFO纳米复合薄膜的开路电压和短路电流分别是BFO薄膜的近3和5倍. Au-BFO纳米复合薄膜光伏效应的改善主要来源于复合薄膜的自极化现象增强和导电机制转变. 本文提拱了一种简单有效的改善铁电薄膜光伏效应的方法, 为进一步理解铁电薄膜的光伏效应提供了新的视角.Ferroelectric films, are an important class of photoelectric functional material, which possess the following characteristics: the breaking of their symmetry can lead to self-polarization and this polarization state can be regulated by external stimuli. The photovoltaic properties of ferroelectric films have been extensively investigated due to their potential applications in the field of photodetection, energy conversion harvesting and nonvolatile storage. In view of the small photocurrent density and the degradation of photovoltaic property caused by the depolarization effect in ferroelectric films, it is necessary to explore an approach to improving the self-polarization phenomenon and regulating the conduction mechanism to further optimize their photovoltaic properties. Here in this work, BiFeO3 (BFO) films dispersed with Au nanoparticles are deposited on FTO glass substrates by the sol-gel method to obtain the Au-BFO nanocomposite films. Moreover, the relationships between Au content (0 mol%, 0.25 mol%, 0.5 mol%, 1 mol% and 3 mol%) and microstructure, electrical and photovoltaic properties of Au-BFO nanocomposite films are investigated to determine the optimal Au content. Piezoresponse force microscopy studies show that the Au-BFO nanocomposite film with 0.5 mol% Au has the strong self-polarization phenomenon. With the increase of Au content, the conduction mechanism of the Au-BFO nanocomposite films is described by the space-charge limited current theory but not the Schottky emission model any more. The photovoltaic properties of the Au-BFO nanocomposite films first increase and then decrease. When Au content is 0.5 mol%, the Au-BFO nanocomposite film has the best photovoltaic property. The open-circuit voltage and short-circuit photocurrent density of the Au-BFO nanocomposite film with 0.5 mol% Au increase nearly 3 and 5 times counterparts of the BFO film, respectively. The photovoltaic effects of Au-BFO nanocomposite films are improved mainly by regulating the self-polarization phenomenon and conduction mechanism. This study demonstrates the merits of BFO films dispersed with Au nanoparticles, specifically, the photovoltaic properties of Au-BFO nanocomposite films are further optimized. In this work, we propose a simple and effective method to regulate the electrical and photovoltaic properties of ferroelectric films, which provides a new perspective for further understanding the photovoltaic effects of ferroelectric films.

-

Keywords:

- BiFeO3 /

- electrical property /

- photovoltaic property

[1] 蔡田怡, 雎胜 2018 67 157801

Google Scholar

Google Scholar

Cai T Y, Ju S 2018 Acta Phys. Sin. 67 157801

Google Scholar

Google Scholar

[2] Li D, Zheng D X, Jin C, Li P, Liu X J, Zheng W C, Bai H L 2018 Adv. Electron. Mater. 4 1800171

Google Scholar

Google Scholar

[3] Guo R, You L, Zhou Y, Lim Z S, Zou X, Chen L, Ramesh R, Wang J 2013 Nat. Commun. 4 1990

Google Scholar

Google Scholar

[4] Wu J, Fan Z, Xiao D, Zhu J, Wang J 2016 Prog. Mater. Sci. 84 335

Google Scholar

Google Scholar

[5] 朱立峰, 潘文远, 谢燕, 张波萍, 尹阳, 赵高磊 2019 68 217701

Google Scholar

Google Scholar

Zhu L F, Pan W Y, Xie Y, Zhang B P, Yin Y, Zhao G L 2019 Acta Phys. Sin. 68 217701

Google Scholar

Google Scholar

[6] Wu J 2018 Advances in Lead-Free Piezoelectric Materials (New York: Springer) pp301–378

[7] Wang L, Jin K J, Ge C, Wang C, Guo H Z, Lu H B, Yang G Z 2013 Appl. Phys. Lett. 102 252907

Google Scholar

Google Scholar

[8] Kamala Bharathi K, Lee W M, Ho Sung J, Soo Lim J, Jin Kim S, Chu K, Won Park J, Hyun Song J, Jo M H, Yang C H 2013 Appl. Phys. Lett. 102 012908

Google Scholar

Google Scholar

[9] Bai Y, Wang Z J, He B, Cui J Z, Zhang Z D 2017 ACS Omega 2 9067

Google Scholar

Google Scholar

[10] Zhang W, Yang M M, Liang X, Zheng H W, Wang Y, Gao W X, Yuan G L, Zhang W F, Li X G, Luo H S, Zheng R K 2015 Nano Energy 18 315

Google Scholar

Google Scholar

[11] Zhang Y, Zheng H, Wang X, Li H, Wu Y, Zhang Y, Su H, Yuan G 2020 Ceram. Int. 46 10083

Google Scholar

Google Scholar

[12] Swain A B, Rath M, Pal S, Ramachandra Rao M S, Subramanian V, Murugavel P 2018 Appl. Phys. Lett. 113 233902

Google Scholar

Google Scholar

[13] Xie Z, Yang Y, Fang L, Wang Y, Ding X, Yuan G, Liu J M 2019 App. Phys. Lett. 115 112902

Google Scholar

Google Scholar

[14] Wang Y, Nan C W 2006 Appl. Phys. Lett. 89 052903

Google Scholar

Google Scholar

[15] Wang H L, Ning X K, Wang Z J 2015 RSC Adv. 5 76783

Google Scholar

Google Scholar

[16] Wang Z, Hu T, Tang L, Ma N, Song C, Han G, Weng W, Du P 2008 Appl. Phys. Lett. 93 222901

Google Scholar

Google Scholar

[17] Li Y Z, Wang Z J, Bai Y, Liu W, Zhang Z D 2019 J. Am. Ceram. Soc. 102 5253

Google Scholar

Google Scholar

[18] Zhang P, Wang T, Gong J 2015 Adv. Mater. 27 5328

Google Scholar

Google Scholar

[19] Maruyama R, Sakamoto W, Yuitoo I, Takeuchi T, Hayashi K, Yogo T 2016 Jpn. J. Appl. Phys. 55 10TA14

Google Scholar

Google Scholar

[20] Almusallam A, Luo Z, Komolafe A, Yang K, Robinson A, Torah R, Beeby S 2017 Nano Energy 33 146

Google Scholar

Google Scholar

[21] Yang X, Su X, Shen M, Zheng F, Xin Y, Zhang L, Hua M, Chen Y, Harris V G 2012 Adv. Mater. 24 1202

Google Scholar

Google Scholar

[22] Li F Z, Zheng H W, Zhu M S, Zhang X A, Yuan G L, Xie Z S, Li X H, Yue G T, Zhang W F 2017 J. Mater. Chem. C 5 10615

Google Scholar

Google Scholar

[23] Eerenstein W, Morrison F D, Dho J, Blamire M G, Scott J F, Mathur N D 2005 Science 307 1203a

Google Scholar

Google Scholar

[24] Fang L, Liu J, Ju S, Zheng F, Dong W, Shen M 2010 Appl. Phys. Lett. 97 242501

Google Scholar

Google Scholar

[25] Zhao Z, Buscaglia V, Viviani M, Buscaglia M T, Mitoseriu L, Testino A, Nygren M, Johnsson M, Nanni P 2004 Phys. Rev. B 70 024107

Google Scholar

Google Scholar

[26] Tsutsumi N, Kosugi R, Kinashi K, Sakai W 2016 ACS Appl. Mater. Interfaces 8 16816

Google Scholar

Google Scholar

[27] Paik H, Choi Y Y, Hong S, No K 2015 Sci. Rep. 5 13209

Google Scholar

Google Scholar

[28] Cheng C W, Tseng Y C, Wu T B, Chou L J 2004 J. Mater. Res. 19 1043

Google Scholar

Google Scholar

[29] Kim Y, Cho Y, Hong S, Bühlmann S, Park H, Min D K, Kim S H, No K 2006 Appl. Phys. Lett. 89 172909

Google Scholar

Google Scholar

[30] Sun W, Zhou Z, Luo J, Wang K, Li J F 2017 J. Appl. Phys. 121 064101

Google Scholar

Google Scholar

[31] He B, Wang Z 2016 ACS Appl. Mater. Interfaces 8 6736

Google Scholar

Google Scholar

[32] Yang T, Wei J, Guo Y, Lv Z, Xu Z, Cheng Z 2019 ACS Appl. Mater. Interfaces 11 23372

Google Scholar

Google Scholar

-

图 5 Au-BFO纳米复合薄膜的面外PFM相位图像, 其中Au含量为 (a) 0 mol%, (b) 0.25 mol%, (c) 0.5 mol%, (d) 1 mol%, (e) 3 mol%; (f) 向上的自极化Pup所占比例随Au含量的变化

Fig. 5. Out-of-plane PFM phase images of the Au-BFO nanocomposite films with (a) 0 mol%, (b) 0.25 mol%, (c) 0.5 mol%, (d) 1 mol%, (e) 3 mol%; (f) the variation of the ratio of Pup with Au content.

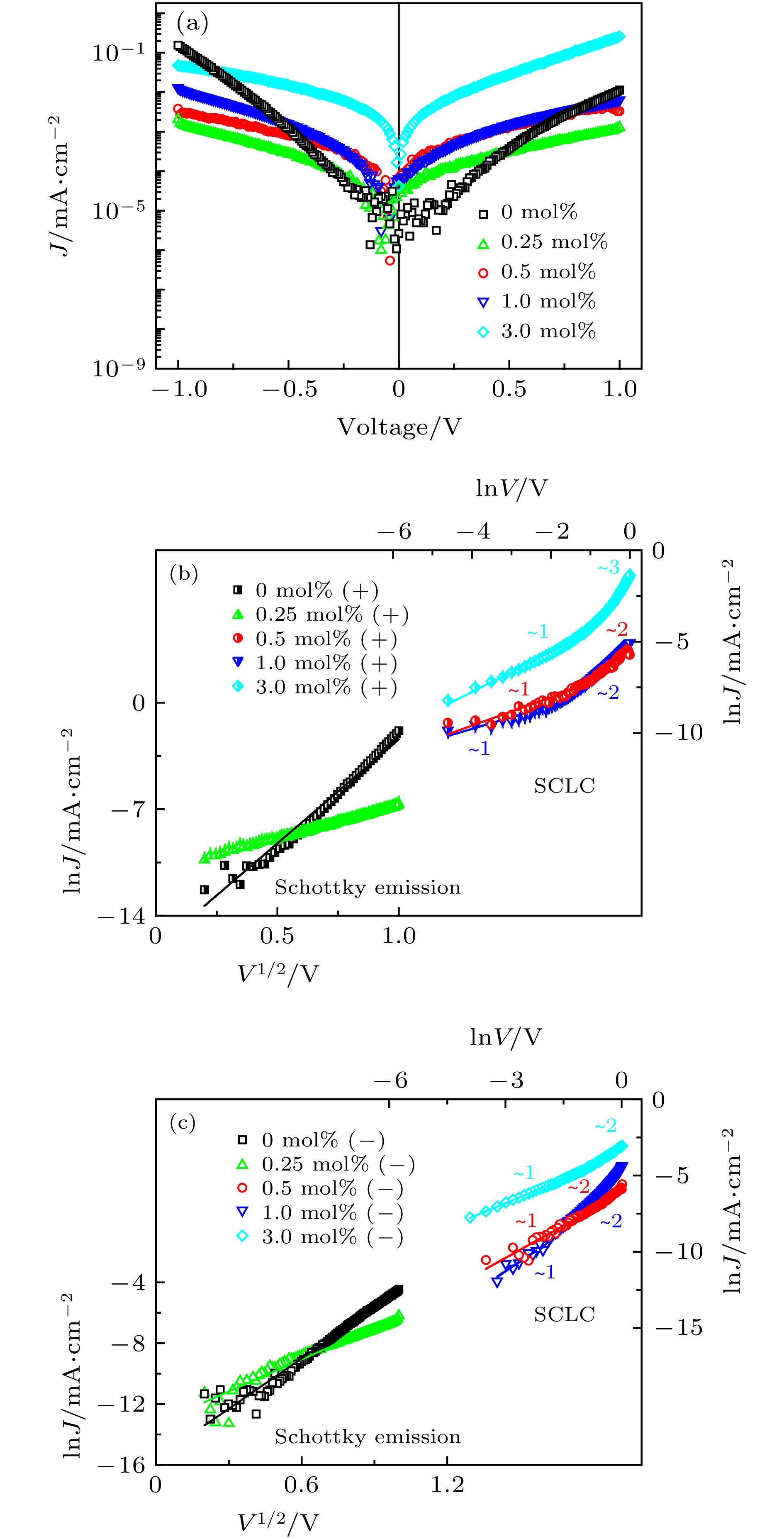

图 6 Au-BFO纳米复合薄膜在 (a) 暗态下的电流密度-电压(J-V)曲线; (b) 正电压段和(c) 负向电压段的lnJ-V1/2和lnJ-lnV曲线分别符合肖特基发射和空间电荷限制电流机制

Fig. 6. Current density vs. voltage (J-V) characteristics of the Au-BFO nanocomposite films (a) in dark; lnJ vs. V1/2 curves fitted using the Schottky emission and lnJ vs. lnV curves fitted using space-charge limited current for the (b) positive and (c) negative branches.

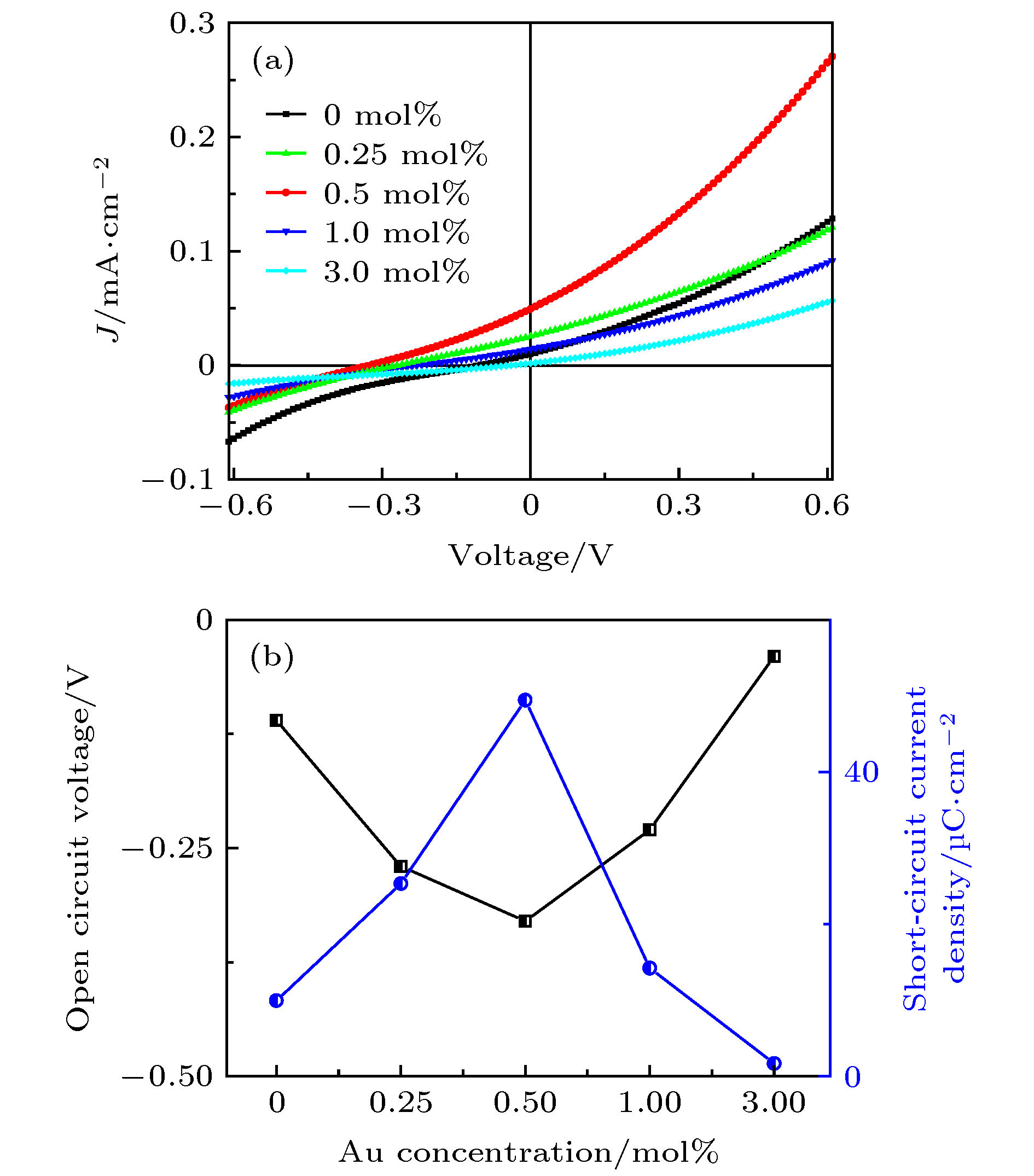

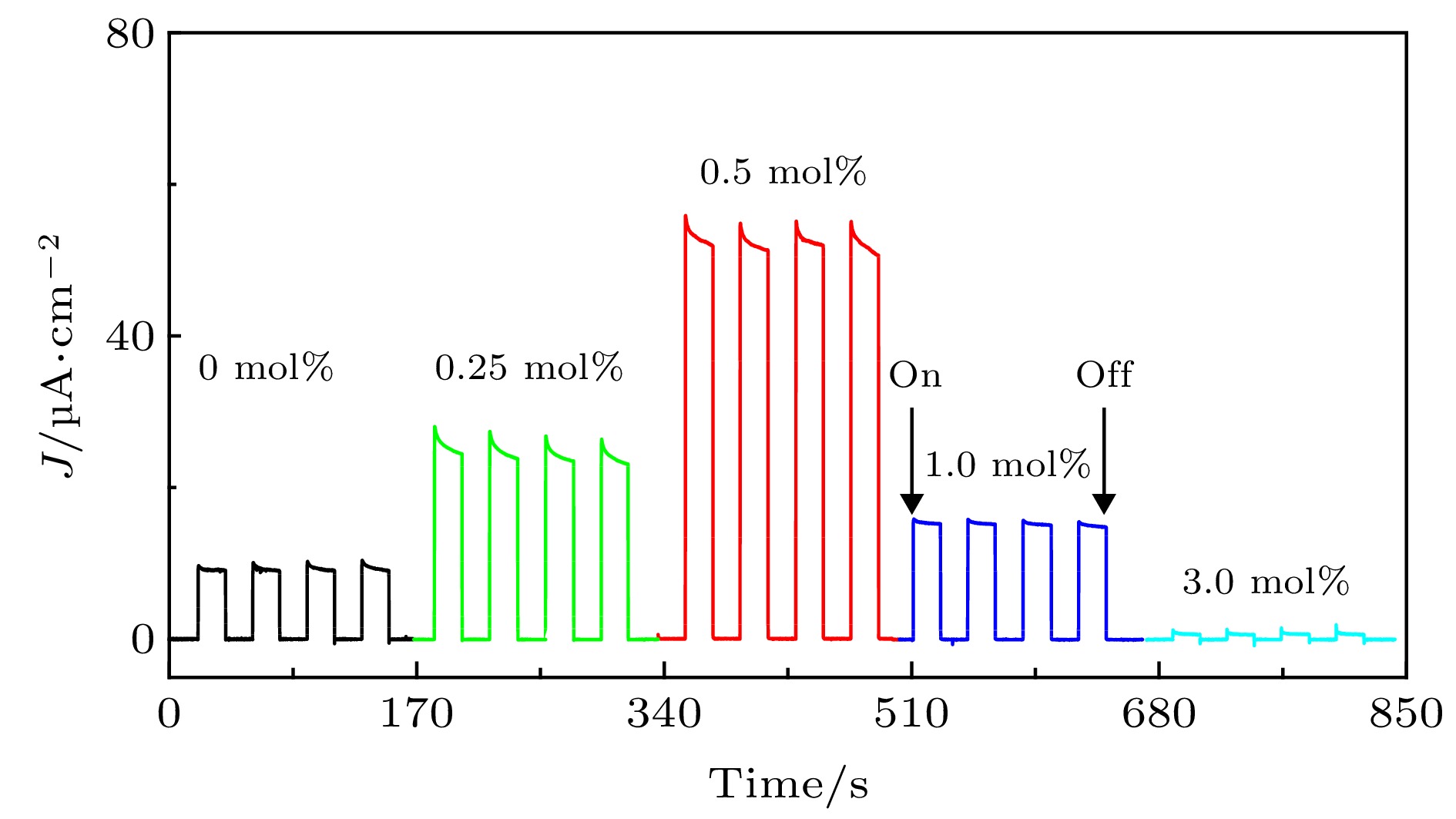

图 7 Au-BFO纳米复合薄膜的 (a) 光电流密度-电压(J-V)曲线(Au含量为0, 0.25 mol%, 0.5 mol%, 1 mol%和3 mol%)和(b) 开路电压和短路电流密度随Au含量的变化

Fig. 7. (a) Photovoltaic (J-V) curves of the Au-BFO nanocomposite films with 0, 0.25 mol%, 0.5 mol%, 1 mol%, and 3 mol% Au, and (b) variation of open-circuit voltages and short-circuit photocurrent densities with Au content.

-

[1] 蔡田怡, 雎胜 2018 67 157801

Google Scholar

Google Scholar

Cai T Y, Ju S 2018 Acta Phys. Sin. 67 157801

Google Scholar

Google Scholar

[2] Li D, Zheng D X, Jin C, Li P, Liu X J, Zheng W C, Bai H L 2018 Adv. Electron. Mater. 4 1800171

Google Scholar

Google Scholar

[3] Guo R, You L, Zhou Y, Lim Z S, Zou X, Chen L, Ramesh R, Wang J 2013 Nat. Commun. 4 1990

Google Scholar

Google Scholar

[4] Wu J, Fan Z, Xiao D, Zhu J, Wang J 2016 Prog. Mater. Sci. 84 335

Google Scholar

Google Scholar

[5] 朱立峰, 潘文远, 谢燕, 张波萍, 尹阳, 赵高磊 2019 68 217701

Google Scholar

Google Scholar

Zhu L F, Pan W Y, Xie Y, Zhang B P, Yin Y, Zhao G L 2019 Acta Phys. Sin. 68 217701

Google Scholar

Google Scholar

[6] Wu J 2018 Advances in Lead-Free Piezoelectric Materials (New York: Springer) pp301–378

[7] Wang L, Jin K J, Ge C, Wang C, Guo H Z, Lu H B, Yang G Z 2013 Appl. Phys. Lett. 102 252907

Google Scholar

Google Scholar

[8] Kamala Bharathi K, Lee W M, Ho Sung J, Soo Lim J, Jin Kim S, Chu K, Won Park J, Hyun Song J, Jo M H, Yang C H 2013 Appl. Phys. Lett. 102 012908

Google Scholar

Google Scholar

[9] Bai Y, Wang Z J, He B, Cui J Z, Zhang Z D 2017 ACS Omega 2 9067

Google Scholar

Google Scholar

[10] Zhang W, Yang M M, Liang X, Zheng H W, Wang Y, Gao W X, Yuan G L, Zhang W F, Li X G, Luo H S, Zheng R K 2015 Nano Energy 18 315

Google Scholar

Google Scholar

[11] Zhang Y, Zheng H, Wang X, Li H, Wu Y, Zhang Y, Su H, Yuan G 2020 Ceram. Int. 46 10083

Google Scholar

Google Scholar

[12] Swain A B, Rath M, Pal S, Ramachandra Rao M S, Subramanian V, Murugavel P 2018 Appl. Phys. Lett. 113 233902

Google Scholar

Google Scholar

[13] Xie Z, Yang Y, Fang L, Wang Y, Ding X, Yuan G, Liu J M 2019 App. Phys. Lett. 115 112902

Google Scholar

Google Scholar

[14] Wang Y, Nan C W 2006 Appl. Phys. Lett. 89 052903

Google Scholar

Google Scholar

[15] Wang H L, Ning X K, Wang Z J 2015 RSC Adv. 5 76783

Google Scholar

Google Scholar

[16] Wang Z, Hu T, Tang L, Ma N, Song C, Han G, Weng W, Du P 2008 Appl. Phys. Lett. 93 222901

Google Scholar

Google Scholar

[17] Li Y Z, Wang Z J, Bai Y, Liu W, Zhang Z D 2019 J. Am. Ceram. Soc. 102 5253

Google Scholar

Google Scholar

[18] Zhang P, Wang T, Gong J 2015 Adv. Mater. 27 5328

Google Scholar

Google Scholar

[19] Maruyama R, Sakamoto W, Yuitoo I, Takeuchi T, Hayashi K, Yogo T 2016 Jpn. J. Appl. Phys. 55 10TA14

Google Scholar

Google Scholar

[20] Almusallam A, Luo Z, Komolafe A, Yang K, Robinson A, Torah R, Beeby S 2017 Nano Energy 33 146

Google Scholar

Google Scholar

[21] Yang X, Su X, Shen M, Zheng F, Xin Y, Zhang L, Hua M, Chen Y, Harris V G 2012 Adv. Mater. 24 1202

Google Scholar

Google Scholar

[22] Li F Z, Zheng H W, Zhu M S, Zhang X A, Yuan G L, Xie Z S, Li X H, Yue G T, Zhang W F 2017 J. Mater. Chem. C 5 10615

Google Scholar

Google Scholar

[23] Eerenstein W, Morrison F D, Dho J, Blamire M G, Scott J F, Mathur N D 2005 Science 307 1203a

Google Scholar

Google Scholar

[24] Fang L, Liu J, Ju S, Zheng F, Dong W, Shen M 2010 Appl. Phys. Lett. 97 242501

Google Scholar

Google Scholar

[25] Zhao Z, Buscaglia V, Viviani M, Buscaglia M T, Mitoseriu L, Testino A, Nygren M, Johnsson M, Nanni P 2004 Phys. Rev. B 70 024107

Google Scholar

Google Scholar

[26] Tsutsumi N, Kosugi R, Kinashi K, Sakai W 2016 ACS Appl. Mater. Interfaces 8 16816

Google Scholar

Google Scholar

[27] Paik H, Choi Y Y, Hong S, No K 2015 Sci. Rep. 5 13209

Google Scholar

Google Scholar

[28] Cheng C W, Tseng Y C, Wu T B, Chou L J 2004 J. Mater. Res. 19 1043

Google Scholar

Google Scholar

[29] Kim Y, Cho Y, Hong S, Bühlmann S, Park H, Min D K, Kim S H, No K 2006 Appl. Phys. Lett. 89 172909

Google Scholar

Google Scholar

[30] Sun W, Zhou Z, Luo J, Wang K, Li J F 2017 J. Appl. Phys. 121 064101

Google Scholar

Google Scholar

[31] He B, Wang Z 2016 ACS Appl. Mater. Interfaces 8 6736

Google Scholar

Google Scholar

[32] Yang T, Wei J, Guo Y, Lv Z, Xu Z, Cheng Z 2019 ACS Appl. Mater. Interfaces 11 23372

Google Scholar

Google Scholar

计量

- 文章访问数: 11636

- PDF下载量: 262

- 被引次数: 0

下载:

下载: