-

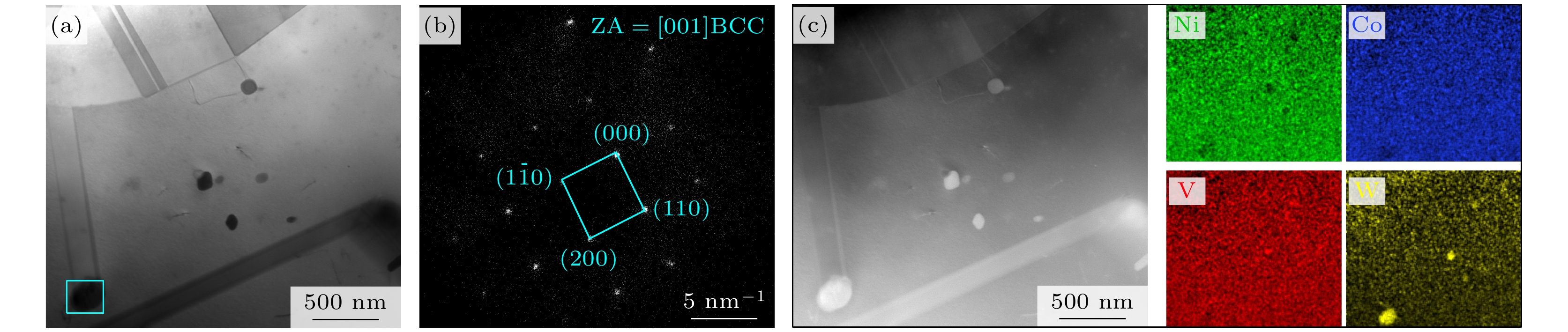

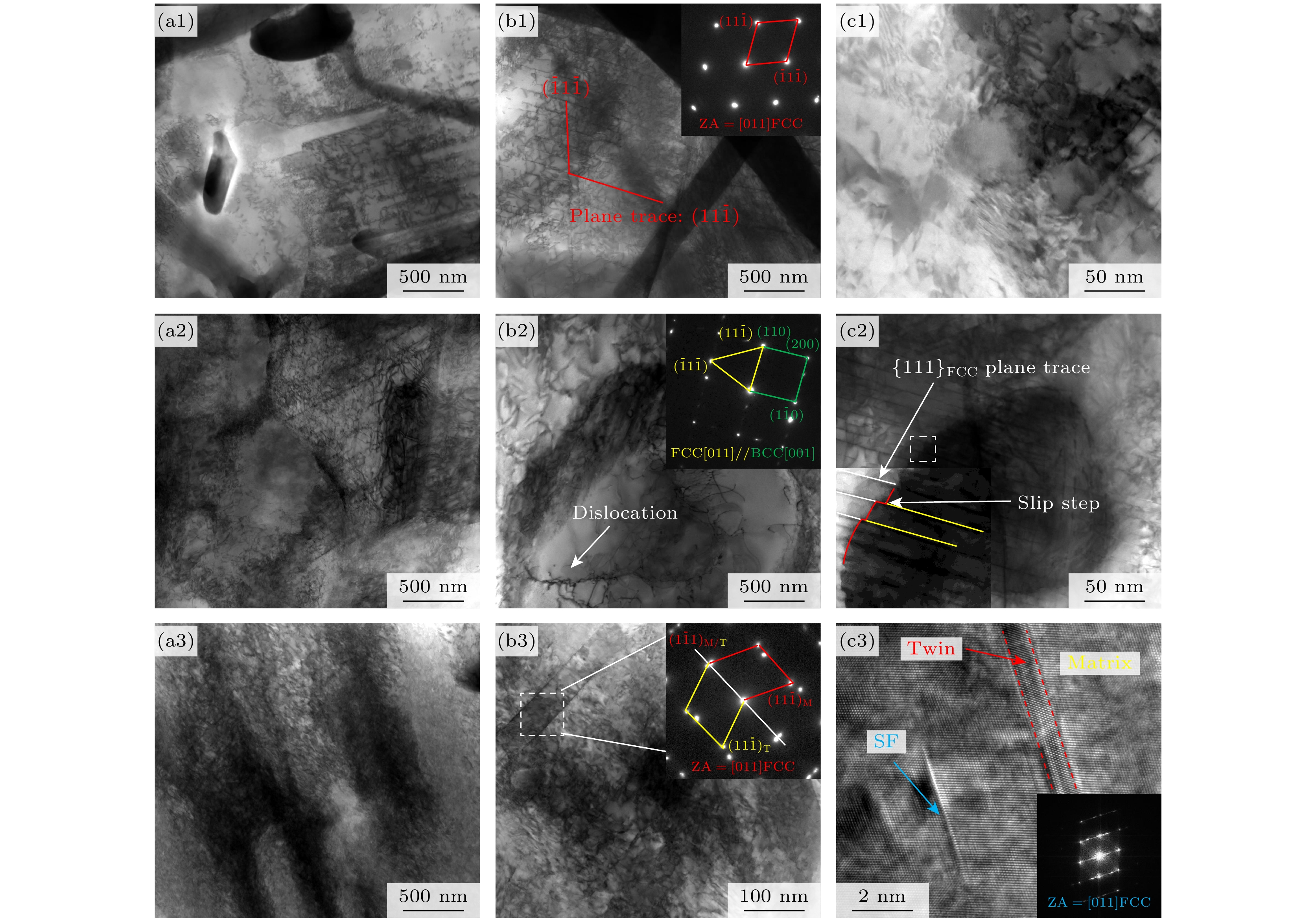

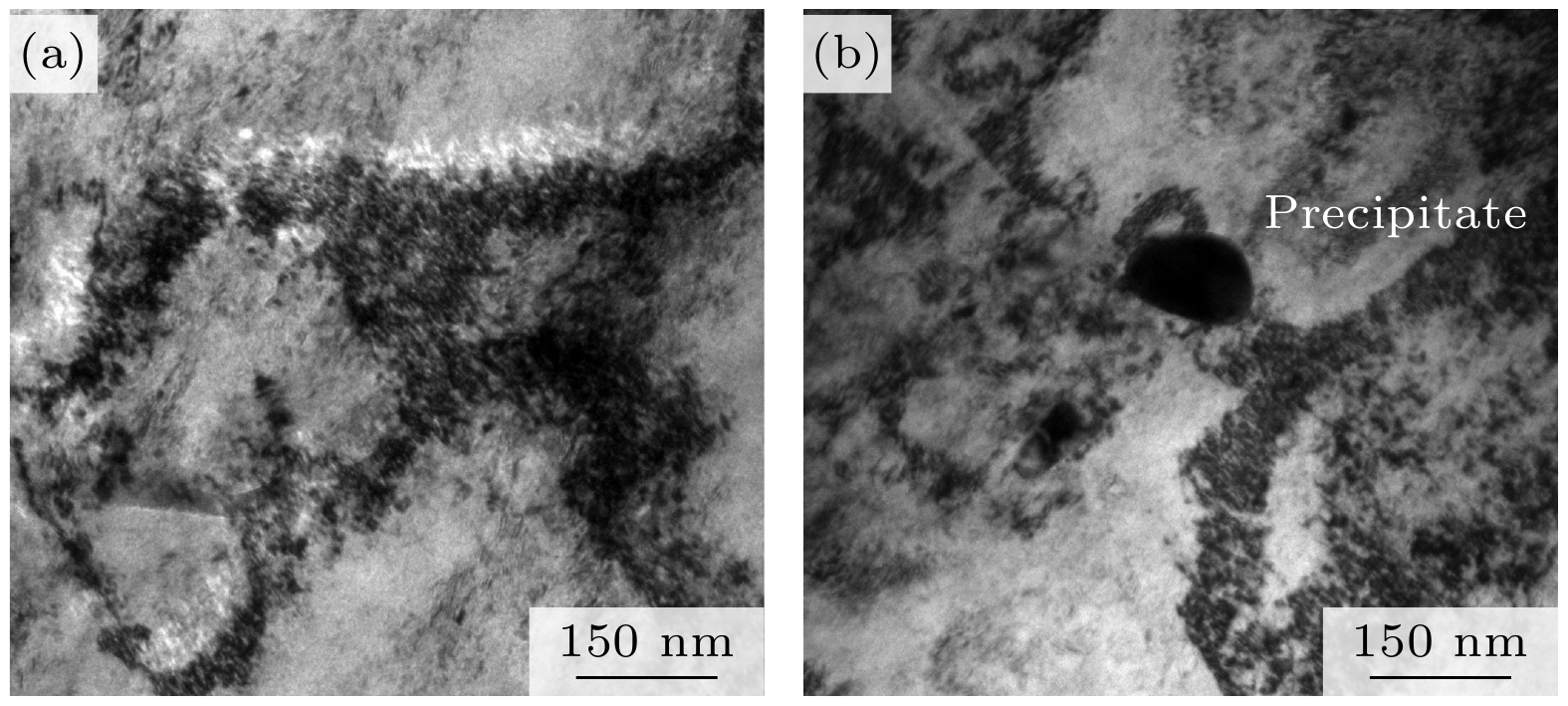

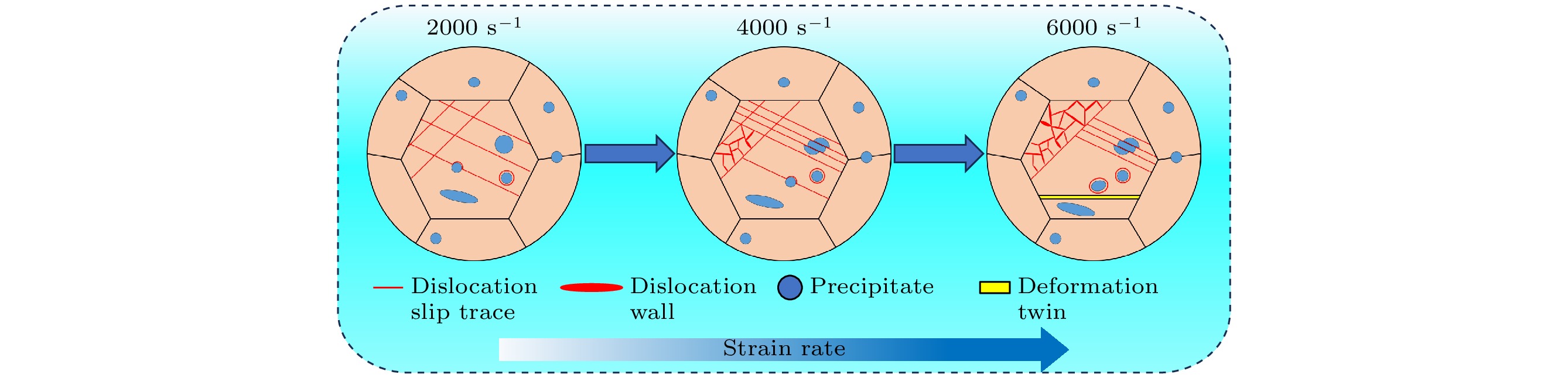

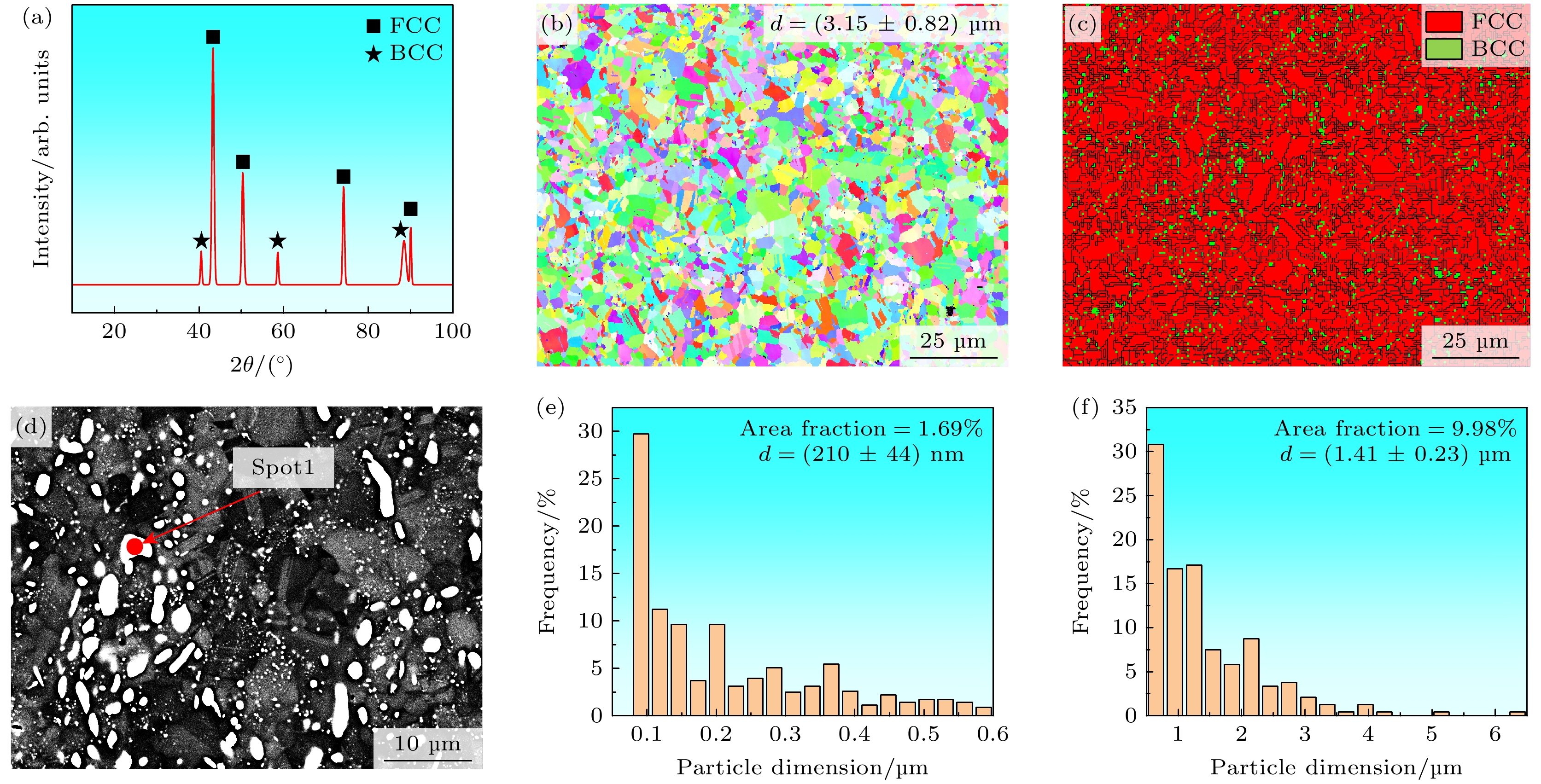

中熵合金因其独特的强塑性协同效应, 在高应变速率服役的结构材料领域展现出广阔应用前景. 本研究聚焦于NiCoV中熵合金体系, 通过引入高熔点钨元素(原子含量为5%)进行合金化设计, 采用真空电弧熔炼结合热机械处理工艺制备了(NiCoV)95W5合金. 基于分离式霍普金森压杆实验平台, 系统揭示了该合金在2000—6000 s–1高应变速率下的动态响应机制与变形机理. 研究发现: 合金展现出优异的应变速率敏感性(m = 0.42), 当应变速率从准静态(10–3 s–1)提升至动态(6000 s–1)时, 屈服强度显著提升162% (720→1887 MPa), 这一强化效应源于高应变速率下晶格畸变诱导的声子拖曳作用显著增强. 通过显微分析, 揭示了该合金体系在高应变速率下的多尺度协同变形机理: 2000 s–1时以位错平面滑移为主导, 当速率增至4000 s–1时形成高密度位错缠结网络并激发部分析出相协同变形, 而在6000 s–1条件下则通过诱发变形孪晶实现加工硬化的存续. 本研究阐明了W元素掺杂的NiCoV中熵合金动态力学行为与变形机制, 为设计具有优异动态力学响应的新型结构材料提供了参考.Medium-entropy alloys (MEAs), renowned for their outstanding strength and ductility, possess great potential for high strain-rate applications. This study focuses on a NiCoV-based MEA system, and proposes a novel alloy design strategy to fabricate the (NiCoV)95W5 alloy by introducing 5% (atomic percent) high-melting-point tungsten through vacuum arc melting coupled with thermomechanical processing. Split Hopkinson pressure bar (SHPB) experiments are conducted to elucidate the dynamic response mechanism and deformation behavior under high strain rates (2000-6000 s–1). The results show that due to severe lattice distortion, the enhanced phonon drag effect at elevated strain rates results in a substantial increase in yield strength from 720 MPa (10–3 s–1) to 1887 MPa (6000 s–1), an increase of 162%, accompanied by a relatively high strain-rate sensitivity (m = 0.42). Microscopic analysis reveals the multi-scale cooperative deformation mechanism of the alloy system under high strain rate. When the strain rate is 2000 s–1, the alloy exhibits a low dislocation density dominated by dislocation planar slip. As the strain rate increases to 4000 s–1, the increased flow stress and deformation promote the proliferation and entanglement of a large number of dislocations into high-density dislocation cells. The accumulation of dislocation stress leads to the coordinated deformation of precipitates and releases stress concentration at the phase interface. When the strain rate further increases to 6000–1, severe plastic deformation will lead to the formation of nanotwins within the matrix, which is the main strain hardening. This study elucidates the dynamic response mechanism of NiCoV MEA mediated by tungsten doping, providing a guidance for designing novel structural materials with excellent dynamic mechanical responses.

-

Keywords:

- medium-entropy alloy /

- dynamic compression deformation /

- work hardening /

- precipitation strengthening

[1] Cao T Q, Zhang Q, Wang L, Wang L, Xiao Y, Yao J H, Liu H Y, Ren Y, Liang J, Xue Y F, Li X Y 2023 Acta Mater. 260 119343

Google Scholar

Google Scholar

[2] 陈海华, 张先锋, 刘闯, 林琨富, 熊玮, 谈梦婷 2021 爆炸与冲击 41 30

Google Scholar

Google Scholar

Chen H H, Zhang X F, Liu C, Lin K F, Xiong W, Tan M T 2021 Explos. Shock Waves 41 30

Google Scholar

Google Scholar

[3] Yoshida S, Ikeuchi T, Bhattacharjee T, Bai Y, Shibata A, Tsuji N 2019 Acta Mater. 171 201

Google Scholar

Google Scholar

[4] Li W D, Xie D, Li D Y, Zhang Y, Gao Y F, Liaw P K 2021 Prog. Mater Sci. 118 100777

Google Scholar

Google Scholar

[5] Cai W J, Long Q, Lu S H, Wang K, He J Y, Zhao S T, Xiong Z P, Hu J, Xia W Z, Baker I, Gan K F, Song M, Wang Z W 2025 Int. J. Plast. 184 104204

Google Scholar

Google Scholar

[6] 朱满, 张成, 许军锋, 坚增运, 惠增哲 2025 金属学报 61 88

Zhu M, Zhang C, Xu J F, Jian Z Y, Hui Z Z 2025 Acta Metall. Sin. 61 88

[7] Li N, He J Y, Zhou Y H, Gu J, Ni S, Song M 2022 Mater. Sci. Eng. A 856 143944

Google Scholar

Google Scholar

[8] Jiang K, Li J G, Suo T 2024 Int. J. Plast. 176 103968

Google Scholar

Google Scholar

[9] Park J M, Moon J, Bae J W, Jang M J, Park J, Lee S, Kim H S 2018 Mater. Sci. Eng. A 719 155

Google Scholar

Google Scholar

[10] Yin B, Maresca F, Curtin W A 2020 Acta Mater. 188 486

Google Scholar

Google Scholar

[11] Cai W J, He J Y, Wang L, Yang W C, Xu X Q, Yaqoob K, Wang Z W, Song M 2023 Scr. Mater. 231 115463

Google Scholar

Google Scholar

[12] Sohn S S, Kwiatkowski da Silva A, Ikeda Y, Kormann F, Lu W, Choi W S, Gault B, Ponge D, Neugebauer J, Raabe D 2019 Adv. Mater. 31 1807142

Google Scholar

Google Scholar

[13] Sohn S S, Kim D G, Jo Y H, da Silva A K, Lu W, Breen A J, Gault B, Ponge D 2020 Acta Mater. 194 106

Google Scholar

Google Scholar

[14] He J Y, Cai W J, Li N, Wang L, Wang Z W, Dai S, Lei Z, Wu Z, Song M, Lu Z 2024 Int. J. Plast. 183 104180

Google Scholar

Google Scholar

[15] An F C, Hou J H, Liu J K, Qian B N, Lu W J 2023 Int. J. Plast. 160 103509

Google Scholar

Google Scholar

[16] Yang D C, Jo Y H, Ikeda Y, Körmann F, Sohn S S 2021 J. Mater. Sci. Technol. 90 159

Google Scholar

Google Scholar

[17] 刘俊鹏, 陈浩, 张弛, 杨志刚, 张勇, 戴兰宏 2023 金属学报 59 727

Google Scholar

Google Scholar

Liu J P, Chen H, Zhang C, Yang Z G, Zhang Y, Dai L H 2023 Acta Metall. Sin. 59 727

Google Scholar

Google Scholar

[18] Wang M Y, Li T P, Wang J P, Li G, Cheng C, Zheng Y X, Fu Y Q, Ni Y W 2023 Mater. Today Commun. 36 106822

Google Scholar

Google Scholar

[19] Hu M L, Song W D, Duan D B, Wu Y 2020 Int. J. Mech. Sci. 182 105738

Google Scholar

Google Scholar

[20] Yeh J W 2015 JOM 67 2254

Google Scholar

Google Scholar

[21] Li N, Chen W T, He J Y, Gu J, Wang Z W, Li Y, Song M 2021 Mater. Sci. Eng. A 827 142048

Google Scholar

Google Scholar

[22] Chen Y, Li Y, Cheng X, Wu C, Cheng B, Xu Z 2018 Materials (Basel) 11 208

Google Scholar

Google Scholar

[23] Jiao Z M, Ma S G, Chu M Y, Yang H J, Wang Z H, Zhang Y, Qiao J W 2015 J. Mater. Eng. Perform. 25 451

[24] Wang X T, Zhao Y K, Zhou J L, Xue Y F, Yuan F Q, Ma L L, Cao T Q, Wang L 2019 Mater. Trans. 60 929

Google Scholar

Google Scholar

[25] Zhang S, Wang Z, Yang H J, Qiao J W, Wang Z H, Wu Y C 2020 Intermetallics 121 106699

Google Scholar

Google Scholar

[26] Zhong X Z, Zhang Q M, Xie J, Wu M Z, Jiang F Q, Yan Y M, Wang Z W 2021 Mater. Sci. Eng. A 812 141147

Google Scholar

Google Scholar

[27] Moon J, Hong S I, Bae J W, Jang M J, Yim D, Kim H S 2017 Mater. Res. Lett. 5 472

Google Scholar

Google Scholar

[28] Pan X, Wang L, Xue L, Sabbaghian M, Lu P, Wu W, Huang G, Xing B, Wang H 2022 J. Mater. Res. Technol. 19 1627

Google Scholar

Google Scholar

[29] Tian J, Tang K, Wu Y K, Cao T H, Pang J B, Jiang F 2021 Mater. Sci. Eng. A 811 141054

Google Scholar

Google Scholar

[30] Li J, Fang Q H, Liu B, Liu Y 2018 Acta Mater. 147 35

Google Scholar

Google Scholar

[31] Li Z, Pradeep K G, Deng Y, Raabe D, Tasan C C 2016 Nature 534 227

Google Scholar

Google Scholar

[32] Liu S F, Wu Y, Wang H T, Lin W T, Shang Y Y, Liu J B, An K, Liu X J, Wang H, Lu Z P 2019 J. Alloys Compd. 792 444

Google Scholar

Google Scholar

[33] Tu J, Yang W H, Xu K, Zhou Z M, Dou Y C, Wang Y L 2021 Mater. Lett. 305 130770

Google Scholar

Google Scholar

[34] Laplanche G, Kostka A, Reinhart C, Hunfeld J, Eggeler G, George E P 2017 Acta Mater. 128 292

Google Scholar

Google Scholar

[35] Cheng G S, Shi Y Z, Wang Y H, Zhang F, Li R, Zhou Y H, Wu Z G, Ma C, Lei Z F, Lu Z P 2024 Acta Mater. 271 119903

Google Scholar

Google Scholar

[36] Wang Z, Lu W, Zhao H, Liebscher C H, He J, Ponge D, Raabe D, Li Z 2020 Sci. Adv. 6 eaba9543

Google Scholar

Google Scholar

[37] Tang Y, Wang R X, Xiao B, Zhang Z R, Li S, Qiao J W, Bai S X, Zhang Y, Liaw P K 2023 Prog. Mater Sci. 135 101090

Google Scholar

Google Scholar

[38] Huang A, Fensin S J, Meyers M A 2023 J. Mater. Res. Technol. 22 307

Google Scholar

Google Scholar

[39] Moon J, Hong S I, Seol J B, Bae J W, Park J M, Kim H S 2019 Mater. Res. Lett. 7 503

Google Scholar

Google Scholar

[40] Malka-Markovitz A, Devincre B, Mordehai D 2021 Scr. Mater. 190 7

Google Scholar

Google Scholar

[41] Gutierrez-Urrutia I, Raabe D 2012 Acta Mater. 60 5791

Google Scholar

Google Scholar

[42] Srivastava K, Weygand D, Caillard D, Gumbsch P 2020 Nat. Commun. 11 5098

Google Scholar

Google Scholar

[43] Sun J X, Zhang L, Huang Y F, Chen B S, Zhou J T, Liu W S, Ma Y Z 2023 Int. J. Refract. Met. Hard Mater 116 106363

Google Scholar

Google Scholar

[44] Wang F, Song M, Elkot M N, Yao N, Sun B, Song M, Wang Z, Raabe D 2024 Science 384 1017

Google Scholar

Google Scholar

[45] Sonkusare R, Jain R, Biswas K, Parameswaran V, Gurao N P 2020 J. Alloys Compd. 823 153763

Google Scholar

Google Scholar

[46] Shen S C, Wu C L, Xie P, Liu Y R 2022 Acta Metal. Sin. (English Letters) 35 1825

Google Scholar

Google Scholar

[47] Wang Z W, Lu W J, An F C, Song M, Ponge D, Raabe D, Li Z M 2022 Nat. Commun. 13 3598

Google Scholar

Google Scholar

-

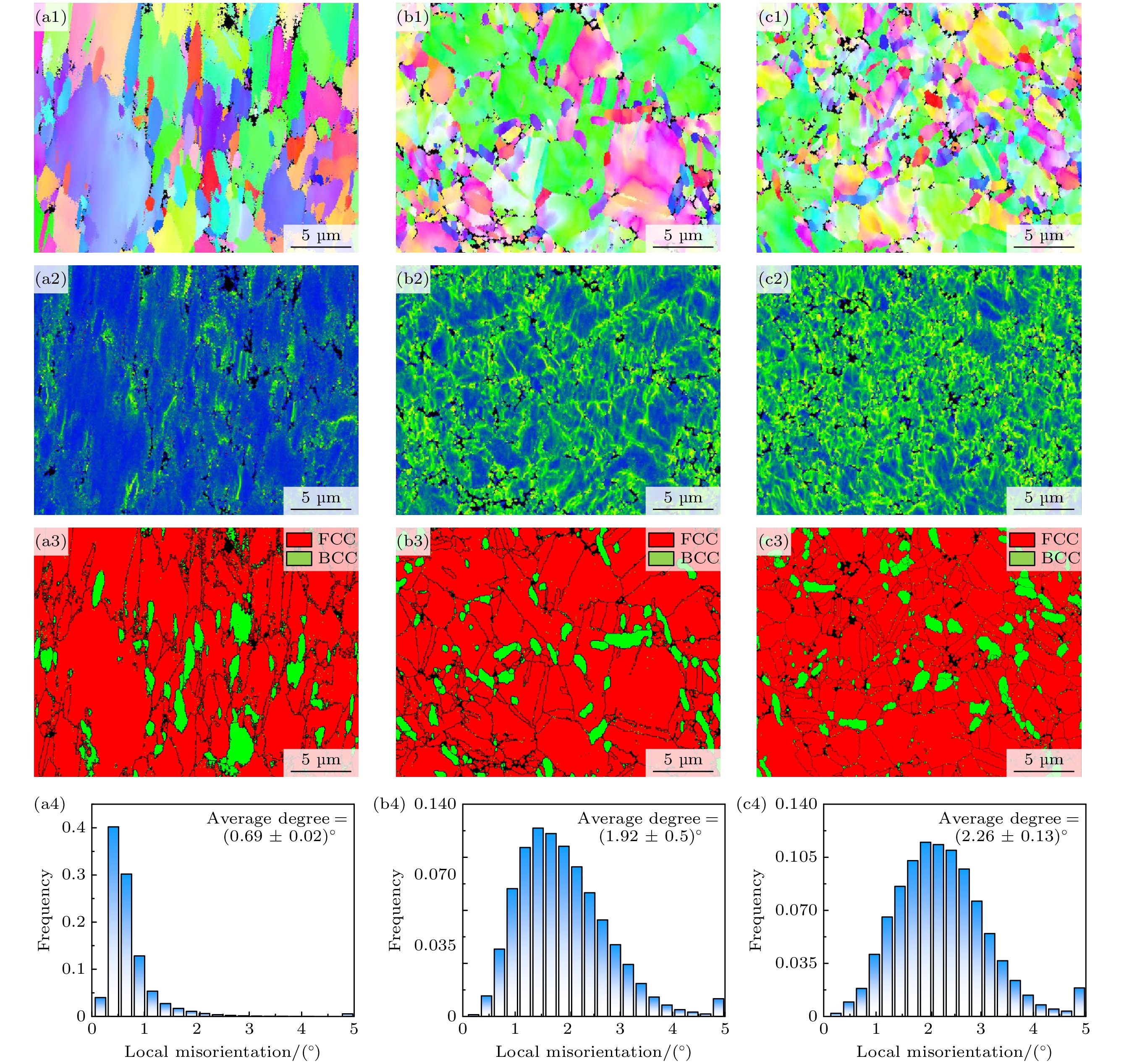

图 4 应变速率为2000, 4000与6000 s–1时对应的EBSD扫描图 (a1)—(c1) 不同应变速率对应的IPF图; (a2)—(c2) 对应的KAM分布图; (a3)—(c3) 对应的相图; (a4)—(c4) 对应的取向差频率分布统计

Fig. 4. EBSD scan results of 2000, 4000 and 6000 s–1 samples: (a1)–(c1) IPF map of corresponding strain rates; (a2)–(c2) KAM map: (a3)–(c3) phase map; (a4)–(c4) the corresponding frequency distribution.

图 5 不同应变速率的样品TEM表征 (a1)—(c1) 2000 s–1样品明场像与对应位置衍射花样; (a2)—(c2) 4000 s–1样品明场像与对应位置衍射花样; (a3)—(c3) 6000 s–1样品明场像、衍射花样与HRTEM 图像

Fig. 5. TEM images of samples at different strain rates: (a1)–(c1) BF images and SAED pattern of 2000 s–1 sample; (a2)–(c2) BF images and SAED pattern of 4000 s–1 sample; (a3)–(c3) BF images, SAED pattern and HRTEM images of 6000 s–1 sample.

-

[1] Cao T Q, Zhang Q, Wang L, Wang L, Xiao Y, Yao J H, Liu H Y, Ren Y, Liang J, Xue Y F, Li X Y 2023 Acta Mater. 260 119343

Google Scholar

Google Scholar

[2] 陈海华, 张先锋, 刘闯, 林琨富, 熊玮, 谈梦婷 2021 爆炸与冲击 41 30

Google Scholar

Google Scholar

Chen H H, Zhang X F, Liu C, Lin K F, Xiong W, Tan M T 2021 Explos. Shock Waves 41 30

Google Scholar

Google Scholar

[3] Yoshida S, Ikeuchi T, Bhattacharjee T, Bai Y, Shibata A, Tsuji N 2019 Acta Mater. 171 201

Google Scholar

Google Scholar

[4] Li W D, Xie D, Li D Y, Zhang Y, Gao Y F, Liaw P K 2021 Prog. Mater Sci. 118 100777

Google Scholar

Google Scholar

[5] Cai W J, Long Q, Lu S H, Wang K, He J Y, Zhao S T, Xiong Z P, Hu J, Xia W Z, Baker I, Gan K F, Song M, Wang Z W 2025 Int. J. Plast. 184 104204

Google Scholar

Google Scholar

[6] 朱满, 张成, 许军锋, 坚增运, 惠增哲 2025 金属学报 61 88

Zhu M, Zhang C, Xu J F, Jian Z Y, Hui Z Z 2025 Acta Metall. Sin. 61 88

[7] Li N, He J Y, Zhou Y H, Gu J, Ni S, Song M 2022 Mater. Sci. Eng. A 856 143944

Google Scholar

Google Scholar

[8] Jiang K, Li J G, Suo T 2024 Int. J. Plast. 176 103968

Google Scholar

Google Scholar

[9] Park J M, Moon J, Bae J W, Jang M J, Park J, Lee S, Kim H S 2018 Mater. Sci. Eng. A 719 155

Google Scholar

Google Scholar

[10] Yin B, Maresca F, Curtin W A 2020 Acta Mater. 188 486

Google Scholar

Google Scholar

[11] Cai W J, He J Y, Wang L, Yang W C, Xu X Q, Yaqoob K, Wang Z W, Song M 2023 Scr. Mater. 231 115463

Google Scholar

Google Scholar

[12] Sohn S S, Kwiatkowski da Silva A, Ikeda Y, Kormann F, Lu W, Choi W S, Gault B, Ponge D, Neugebauer J, Raabe D 2019 Adv. Mater. 31 1807142

Google Scholar

Google Scholar

[13] Sohn S S, Kim D G, Jo Y H, da Silva A K, Lu W, Breen A J, Gault B, Ponge D 2020 Acta Mater. 194 106

Google Scholar

Google Scholar

[14] He J Y, Cai W J, Li N, Wang L, Wang Z W, Dai S, Lei Z, Wu Z, Song M, Lu Z 2024 Int. J. Plast. 183 104180

Google Scholar

Google Scholar

[15] An F C, Hou J H, Liu J K, Qian B N, Lu W J 2023 Int. J. Plast. 160 103509

Google Scholar

Google Scholar

[16] Yang D C, Jo Y H, Ikeda Y, Körmann F, Sohn S S 2021 J. Mater. Sci. Technol. 90 159

Google Scholar

Google Scholar

[17] 刘俊鹏, 陈浩, 张弛, 杨志刚, 张勇, 戴兰宏 2023 金属学报 59 727

Google Scholar

Google Scholar

Liu J P, Chen H, Zhang C, Yang Z G, Zhang Y, Dai L H 2023 Acta Metall. Sin. 59 727

Google Scholar

Google Scholar

[18] Wang M Y, Li T P, Wang J P, Li G, Cheng C, Zheng Y X, Fu Y Q, Ni Y W 2023 Mater. Today Commun. 36 106822

Google Scholar

Google Scholar

[19] Hu M L, Song W D, Duan D B, Wu Y 2020 Int. J. Mech. Sci. 182 105738

Google Scholar

Google Scholar

[20] Yeh J W 2015 JOM 67 2254

Google Scholar

Google Scholar

[21] Li N, Chen W T, He J Y, Gu J, Wang Z W, Li Y, Song M 2021 Mater. Sci. Eng. A 827 142048

Google Scholar

Google Scholar

[22] Chen Y, Li Y, Cheng X, Wu C, Cheng B, Xu Z 2018 Materials (Basel) 11 208

Google Scholar

Google Scholar

[23] Jiao Z M, Ma S G, Chu M Y, Yang H J, Wang Z H, Zhang Y, Qiao J W 2015 J. Mater. Eng. Perform. 25 451

[24] Wang X T, Zhao Y K, Zhou J L, Xue Y F, Yuan F Q, Ma L L, Cao T Q, Wang L 2019 Mater. Trans. 60 929

Google Scholar

Google Scholar

[25] Zhang S, Wang Z, Yang H J, Qiao J W, Wang Z H, Wu Y C 2020 Intermetallics 121 106699

Google Scholar

Google Scholar

[26] Zhong X Z, Zhang Q M, Xie J, Wu M Z, Jiang F Q, Yan Y M, Wang Z W 2021 Mater. Sci. Eng. A 812 141147

Google Scholar

Google Scholar

[27] Moon J, Hong S I, Bae J W, Jang M J, Yim D, Kim H S 2017 Mater. Res. Lett. 5 472

Google Scholar

Google Scholar

[28] Pan X, Wang L, Xue L, Sabbaghian M, Lu P, Wu W, Huang G, Xing B, Wang H 2022 J. Mater. Res. Technol. 19 1627

Google Scholar

Google Scholar

[29] Tian J, Tang K, Wu Y K, Cao T H, Pang J B, Jiang F 2021 Mater. Sci. Eng. A 811 141054

Google Scholar

Google Scholar

[30] Li J, Fang Q H, Liu B, Liu Y 2018 Acta Mater. 147 35

Google Scholar

Google Scholar

[31] Li Z, Pradeep K G, Deng Y, Raabe D, Tasan C C 2016 Nature 534 227

Google Scholar

Google Scholar

[32] Liu S F, Wu Y, Wang H T, Lin W T, Shang Y Y, Liu J B, An K, Liu X J, Wang H, Lu Z P 2019 J. Alloys Compd. 792 444

Google Scholar

Google Scholar

[33] Tu J, Yang W H, Xu K, Zhou Z M, Dou Y C, Wang Y L 2021 Mater. Lett. 305 130770

Google Scholar

Google Scholar

[34] Laplanche G, Kostka A, Reinhart C, Hunfeld J, Eggeler G, George E P 2017 Acta Mater. 128 292

Google Scholar

Google Scholar

[35] Cheng G S, Shi Y Z, Wang Y H, Zhang F, Li R, Zhou Y H, Wu Z G, Ma C, Lei Z F, Lu Z P 2024 Acta Mater. 271 119903

Google Scholar

Google Scholar

[36] Wang Z, Lu W, Zhao H, Liebscher C H, He J, Ponge D, Raabe D, Li Z 2020 Sci. Adv. 6 eaba9543

Google Scholar

Google Scholar

[37] Tang Y, Wang R X, Xiao B, Zhang Z R, Li S, Qiao J W, Bai S X, Zhang Y, Liaw P K 2023 Prog. Mater Sci. 135 101090

Google Scholar

Google Scholar

[38] Huang A, Fensin S J, Meyers M A 2023 J. Mater. Res. Technol. 22 307

Google Scholar

Google Scholar

[39] Moon J, Hong S I, Seol J B, Bae J W, Park J M, Kim H S 2019 Mater. Res. Lett. 7 503

Google Scholar

Google Scholar

[40] Malka-Markovitz A, Devincre B, Mordehai D 2021 Scr. Mater. 190 7

Google Scholar

Google Scholar

[41] Gutierrez-Urrutia I, Raabe D 2012 Acta Mater. 60 5791

Google Scholar

Google Scholar

[42] Srivastava K, Weygand D, Caillard D, Gumbsch P 2020 Nat. Commun. 11 5098

Google Scholar

Google Scholar

[43] Sun J X, Zhang L, Huang Y F, Chen B S, Zhou J T, Liu W S, Ma Y Z 2023 Int. J. Refract. Met. Hard Mater 116 106363

Google Scholar

Google Scholar

[44] Wang F, Song M, Elkot M N, Yao N, Sun B, Song M, Wang Z, Raabe D 2024 Science 384 1017

Google Scholar

Google Scholar

[45] Sonkusare R, Jain R, Biswas K, Parameswaran V, Gurao N P 2020 J. Alloys Compd. 823 153763

Google Scholar

Google Scholar

[46] Shen S C, Wu C L, Xie P, Liu Y R 2022 Acta Metal. Sin. (English Letters) 35 1825

Google Scholar

Google Scholar

[47] Wang Z W, Lu W J, An F C, Song M, Ponge D, Raabe D, Li Z M 2022 Nat. Commun. 13 3598

Google Scholar

Google Scholar

计量

- 文章访问数: 1166

- PDF下载量: 70

- 被引次数: 0

下载:

下载: