-

BCC(体心立方)和FCC(面心立方)结构共存的高熵合金通常具有优异的综合力学性能, Al元素可以促进含Cu高熵合金由FCC向BCC结构转变. 本文基于Chan-Hilliard方程和Allen-Cahn方程, 建立AlxCuMnNiFe高熵合金三维相场模型, 模拟了AlxCuMnNiFe高熵合金(x = 0.4, 0.5, 0.6, 0.7)在823 K等温时效时纳米富Cu相的微观演化过程. 结果表明, AlxCuMnNiFe高熵合金时效时会产生两种复杂核壳结构: 富Cu核/B2s壳以及B2c核/FeMn壳, 通过讨论分析发现形成的B2c对纳米富Cu相的形成起到抑制作用, 这种抑制作用随着Al元素的增加而变大; 结合经验公式做出AlxCuMnNiFe高熵合金富Cu相的屈服强度随时效时间的变化曲线, 得到峰值屈服强度的时效时间和合金体系, 可以为时效工艺提供参考.High-entropy alloys with BCC and FCC coexisting structures usually have excellent comprehensive mechanical properties, and Al element can promote the transformation of Cu-containing high-entropy alloys from FCC structure to BCC structure to obtain the BCC and FCC coexisting structures. In order to illustrate the process of phase separation of high entropy alloys, a low-cost Al-TM transition group element high-entropy alloy is selected in this work. Based on the Chan-Hilliard equation and Allen-Cahn equation, a three-dimensional phase field model of AlxCuMnNiFe high-entropy alloy is established, and the microscopic evolution of the nano-Cu-rich phase of AlxCuMnNiFe high-entropy alloy (x = 0.4, 0.5, 0.6, 0.7) at 823 K isothermal aging is simulated. The results show that the AlxCuMnNiFe high-entropy alloy generates two complex core-shell structures upon aging: Cu-rich core/B2s shell and B2c core/FeMn shell, and it is found through discussion and analysis that the formed B2c plays an inhibitory role in the formation of the nano-Cu-rich phase, and that this inhibitory role becomes larger with the increase of Al element. Combining the empirical formula, the curve of yield strength of the Cu-rich phase varying with the aging time is obtained for the AlxCuMnNiFe high-entropy alloy, and the overall yield strength of the high-entropy alloy has a rising-and-then-falling trend with the change of time, and the aging time of the peak yield strength and the alloy system are obtained from the change of the curve, so that the best alloy system and aging time of the high-entropy alloy can provide a reference for aging process.

-

Keywords:

- phase field method /

- high entropy alloy /

- Cu-rich phase /

- elastic energy

[1] Cantor B, Chang I T H, Knight P, Vincent A 2004 Mater. Sci. Eng., A 375 213

[2] Zhang Y 2019 High-Entropy Materials (Singapore: Springer Nature Singapore Pte Ltd) p215

[3] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y. 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[4] Zhou Y J, Zhang Y, Wang Y L, Chen G L 2007 Appl. Phys. Lett. 90 253

[5] Niu S Z, Kou H C, Wang J, Li J S 2021 Rare Met. 40 2508

[6] Sha M H, Zhang L, Zhang J W, Li N, Li T Z, Wang N 2017 Rare Met. Mater. Eng. 46 1237

Google Scholar

Google Scholar

[7] Chen X, Hu J X, Liu Y, Xiang F 2021 Met. Mater. Int. 27 2230

Google Scholar

Google Scholar

[8] Pradeep K G, Wanderka N, Choi P, Banhart J, Murty B S, Raabe D 2013 Acta Mater. 61 4696

Google Scholar

Google Scholar

[9] Jones N G, Frezza A, Stone H J 2014 Mater. Sci. Eng., A 615 214

Google Scholar

Google Scholar

[10] Dąbrowa J, Cieślak G, Stygar M, Mroczka K, Berebt K, Kulik T, Danielewski M 2017 Intermetallics 84 52

Google Scholar

Google Scholar

[11] Wu P H, Liu N, Yang W, Zhu Z X, Liu Y P, Wang X J 2015 Mater. Sci. Eng. , A 642 142

Google Scholar

Google Scholar

[12] Xian X, Lin L, Zhong Z, Zhang C, Chen C, Song K J, Cheng J G, Wu Y C 2018 Mater. Sci. Eng., A 713 134

Google Scholar

Google Scholar

[13] Borkar T, Gwalani B, Choudhuri D, Alam T, Mantri A S, Gibson M A 2016 Intermetallics 71 31

Google Scholar

Google Scholar

[14] Gwalani B, Choudhuri D, Soni V, Ren Y, Styles M, Hwang J Y, Nam S J, Ryu H, Hong S H, Banerjee R 2017 Acta Mater. 129 170

Google Scholar

Google Scholar

[15] Shim S H, Pouraliakbar H, Hong S I 2022 Scr. Mater. 210 114473

Google Scholar

Google Scholar

[16] Lahiri A 2022 J. Indian Inst. Sci. 102 39

Google Scholar

Google Scholar

[17] Chen L Q 2002 Annu. Rev. Mater. Res. 32 113

Google Scholar

Google Scholar

[18] Chen L Q, Zhao Y H 2021 Prog. Mater. Sci. 124 100868

[19] Xin T Z, Zhao Y H, Mahjoub R, Jiang J X, Yadav A, Nomoto K, Niu R M, Tang S, Ji F, Quadir Z, Miskovic D, Daniels J, Xu W Q, Liao X Z, Chen L Q, Hagihara K, Li X Y, Ringer S, Ferry M 2021 Sci. Adv. 7 eabf3039

Google Scholar

Google Scholar

[20] Tian X L, Zhao Y H, Peng D W, Guo Q W, Hou H 2021 Trans. Nonferrous Met. Soc. China 31 1175

Google Scholar

Google Scholar

[21] Tian X L, Zhao Y H, Gu T, Guo Y L, Xu F Q, Hou H 2022 Mater. Sci. Eng., A 849 143485

Google Scholar

Google Scholar

[22] Zhao Y H, Zhang B, Hou H, Chen W P, Wang M 2019 J. Mater. Sci. Technol. 35 1044

Google Scholar

Google Scholar

[23] Zhang J B, Wang H F, Kuang W W, Zhang Y C, Li S, Zhao Y H, Herlach D M 2018 Acta Mater. 148 86

Google Scholar

Google Scholar

[24] Chen W P, Zhao Y H, Yang S, Zhang D, Hou H 2021 Adv. Compos. Hybrid Mater. 4 371

Google Scholar

Google Scholar

[25] Biner S B, Rao W, Zhang Y 2016 J. Nucl. Mater. 468 9

Google Scholar

Google Scholar

[26] Koyama T, Onodera H 2005 Mater. Trans. 46 1187

Google Scholar

Google Scholar

[27] Zhao Y H. 2022 Intermetallics 144 107528

Google Scholar

Google Scholar

[28] Zeng Y F, Cai X R, Koslowski M 2019 Acta Mater. 164 1

Google Scholar

Google Scholar

[29] Kadirvel K, Kloenne Z, Jensen J K, Fraser H, Wang Y 2021 Appl. Phys. Lett. 119 171905

Google Scholar

Google Scholar

[30] Zuo X J, Coutinho Y, Chatterjee S, Moelans N 2022 Mater. Theor. 6 12

Google Scholar

Google Scholar

[31] Li J L, Li Z, Wang Q, Dong C, Liaw P K 2020 Acta Mater. 197 10

Google Scholar

Google Scholar

[32] Coutinho Y A, Kunwar A, Moelans N 2022 J. Mater. Sci. 57 10600

Google Scholar

Google Scholar

[33] Zhao Y H, Liu K X, Hou H, Chen L Q 2022 Mater. Des. 216 110555

Google Scholar

Google Scholar

[34] Zhao Y H, Sun Y Y, Hou H. 2022 Prog. Nat. Sci.-Mater. Int. 32 358

Google Scholar

Google Scholar

[35] Sun Y Y, Zhao Y H, Zhao B J, Yang W K, Li X L 2019 J. Mater. Sci. 54 11263

Google Scholar

Google Scholar

[36] 蒋新安, 赵宇宏, 杨文奎, 田晓琳, 侯华 2022 71 080201

Google Scholar

Google Scholar

Jiang X A, Zhao Y H, Yang W K, Tian X L, Hou H 2022 Acta Phys. Sin. 71 080201

Google Scholar

Google Scholar

[37] 栾亨伟, 赵威, 姚可夫 2020 材料热处理学报 41 1

Luan H W, Zhao W, Yao K F 2020 Trans. Mater. Heat Treat. 41 1

[38] Pang C, Jiang B B, Shi Y, Wang Q, Dong C 2015 J. Alloys Compd. 652 63

Google Scholar

Google Scholar

[39] 郝家苗 2020 硕士学位论文 (大连: 大连理工大学)

Hao J M 2020 M. S. Thesis (Dalian: Dalian University of Technology) (in chinese)

[40] Chen L Q 2002 Annual Review of Materials Research 32 113

[41] Kuang W W, Wang H F, Li X, Zhang J B, Qing Z, Zhao Y H 2018 Acta Mater. 159 16

Google Scholar

Google Scholar

[42] Cahn J W 1961 Acta Metall. 9 795

Google Scholar

Google Scholar

[43] Cahn J W, Hilliard J E 1958 J. Chem. Phys. 28 258

Google Scholar

Google Scholar

[44] Kitashima T, Harada H. 2009 Acta Mater. 57 2020

Google Scholar

Google Scholar

[45] Tsukada Y, Koyama T, Murata Y, Miura N, Kondo Y 2014 Comput. Mater. Sci. 83 371

Google Scholar

Google Scholar

[46] Deng S, Chen W M, Zhong J, Zhang L J, Du Y, Chen L 2017 Calphad 56 230

Google Scholar

Google Scholar

[47] Allen S, Cahn J W 1992 Acta Metall. 20 423

[48] Chen H L, Mao H, Chen Q 2018 Mater. Chem. Phys. 210 279

Google Scholar

Google Scholar

[49] Luo Z, Du Y, Liu Y L, Tang S, Pan Y F, Mao H, Peng Y B, Liu W S, Liu Z K 2018 Calphad 63 190

Google Scholar

Google Scholar

[50] Li Y S, Zhu H, Zhang L, Cheng X L 2012 J. Nucl. Mater. 429 13

Google Scholar

Google Scholar

[51] Moelans N, Blanpain B, Wollants P 2008 Calphad 32 268

Google Scholar

Google Scholar

[52] Neumann G, Tuijn C 2011 Self-diffusion and Impurity Diffusion in Pure Metals: Handbook of Experimental Data Elsevier

[53] Khachaturian A G 1983 Acta Crystallogr.

[54] Shen C, Wang Y 2005 Handb. Mater. Model.

[55] Koyama T, Hashimoto K, Onodera H 2006 Mater. Trans. 47 2765

Google Scholar

Google Scholar

[56] Cale W F, Totemeier T C 2003 Smithells Metals Reference Book (Oxford: Butter worth-Heinemann)

[57] Sonkusare R, Swain A, Rahul M R, Samal S, Gurao N P, Biswas k, Singh S S, Nayan N 2019 Mater. Sci. Eng., A 759 415

Google Scholar

Google Scholar

[58] 龚子杰, 李春辉, 李晓宇, 李炜, 陈伟, 赵东国, 刘润芳 2022 精密成形工程 14 83

Google Scholar

Google Scholar

Gong Z J, Li C H, Li X N, Li W, Chen W, Zhao D G, Liu R F 2022 J. Netshape Form. Eng. 14 83

Google Scholar

Google Scholar

[59] Takeuchi A, Inoue A 2007 Mater. Trans., JIM 41 1372

[60] Li B, Zhang L, Li C L, Li Q L, Chen J, Shun G G, Weng Y Q, Xu B, Hu S Y, Liu W 2018 J. Nucl. Mater. 507 59

Google Scholar

Google Scholar

[61] 程一丹 2018 硕士学位论文 (西安: 西安工业大学)

Cheng Y D 2018 M. S. Thesis (Xi'an: Xi'an Technological University) (in Chinese)

[62] 王晓姣 2016 博士学位论文 (上海: 上海大学)

Wang X J 2016 Ph. D. Dissertation (Shanghai: Shanghai University) (in Chinese)

[63] Jiao Z B, Luan J H, Miller M K, Yu C Y, Liu C T 2015 Acta Mater. 84 283

Google Scholar

Google Scholar

[64] Isheim D, Kolli R P, Fine M E, Seidman D N 2006 Scr. Mater. 55 35

Google Scholar

Google Scholar

[65] Russell K C, Brown L M 1972 Acta Metall. 20 969

Google Scholar

Google Scholar

[66] Hahn S I, Hwang S J 2009 J. Alloys Compd. 483 207

Google Scholar

Google Scholar

[67] Dinsdale A T 1991 Calphad 15 317

Google Scholar

Google Scholar

[68] Liu X Y, Wang G, Hu Y, Ji Y Z, Rong Y M, Hu Y Z, Chen L Q 2021 Mater. Sci. Eng., A. 814 141223

Google Scholar

Google Scholar

-

图 1 时效温度为823 K时Al0.7Cu1.5Mn1Ni1Fe1.5高熵合金三维形貌演化图 (a)—(e) 分别表示元素Cu, Ni, Al, Mn, Fe元素以及序参量的形貌; (1)—(5)表示不同演化时间

Fig. 1. Evolution of three-dimensional morphology of Al0.7Cu1.5Mn1Ni1Fe1.5 high entropy alloys at aging temperature of 823 K: (a)–(e) The morphology of elements Cu, Ni, Al, Mn, Fe and order parameters, respectively; (1)–(5) indicates different evolution times.

图 3 t * = 20000时Al0.7Cu1.5Mn1Ni1Fe1.5高熵合金形貌图 (a) Ni的三维空间分布, 球状的B2相和环状的B2壳; (b) 球状富Cu相及周围元素分布; (c) 球状B2相及周围元素分布; (d) 短棒状的富Cu相及元素分布; (e) 球状富Cu相成分曲线; (f) 球状B2相成分曲线; (g) 短棒状富Cu相成分曲线

Fig. 3. Morphology of Al0.7Cu1.5Mn1Ni1Fe1.5 high-entropy alloy at t * = 20000: (a) Three-dimensional spatial distribution of Ni, spherical B2 phase and annular B2 shell; (b) spherical Cu-rich phase and surrounding elemental distribution; (c) spherical B2 phase and surrounding elemental distribution; (d) short rod-like Cu-rich phase and elemental distribution; (e) spherical Cu-rich phase composition curve; (f) spherical B2 phase composition curve; (g) short rod-shaped Cu-rich phase composition curve.

图 4 在时效温度为823 K时Al0.7Cu1.5Mn1Ni1Fe1.5高熵合金B2-NiAl演化图 (a)—(f) B2-NiAl相不同元素不随时间变化得三维演化图; (g)—(l)相对应时刻的成分曲线

Fig. 4. The evolution of Al0.6Cu1.5Mn1Ni1Fe1.5 high-entropy alloy B2-NiAl at an aging temperature of 823 K: (a)–(f) The three-dimensional evolution of different elements of B2-NiAl phase without changing with time; (g)–(l) the composition curves obtained at the corresponding time.

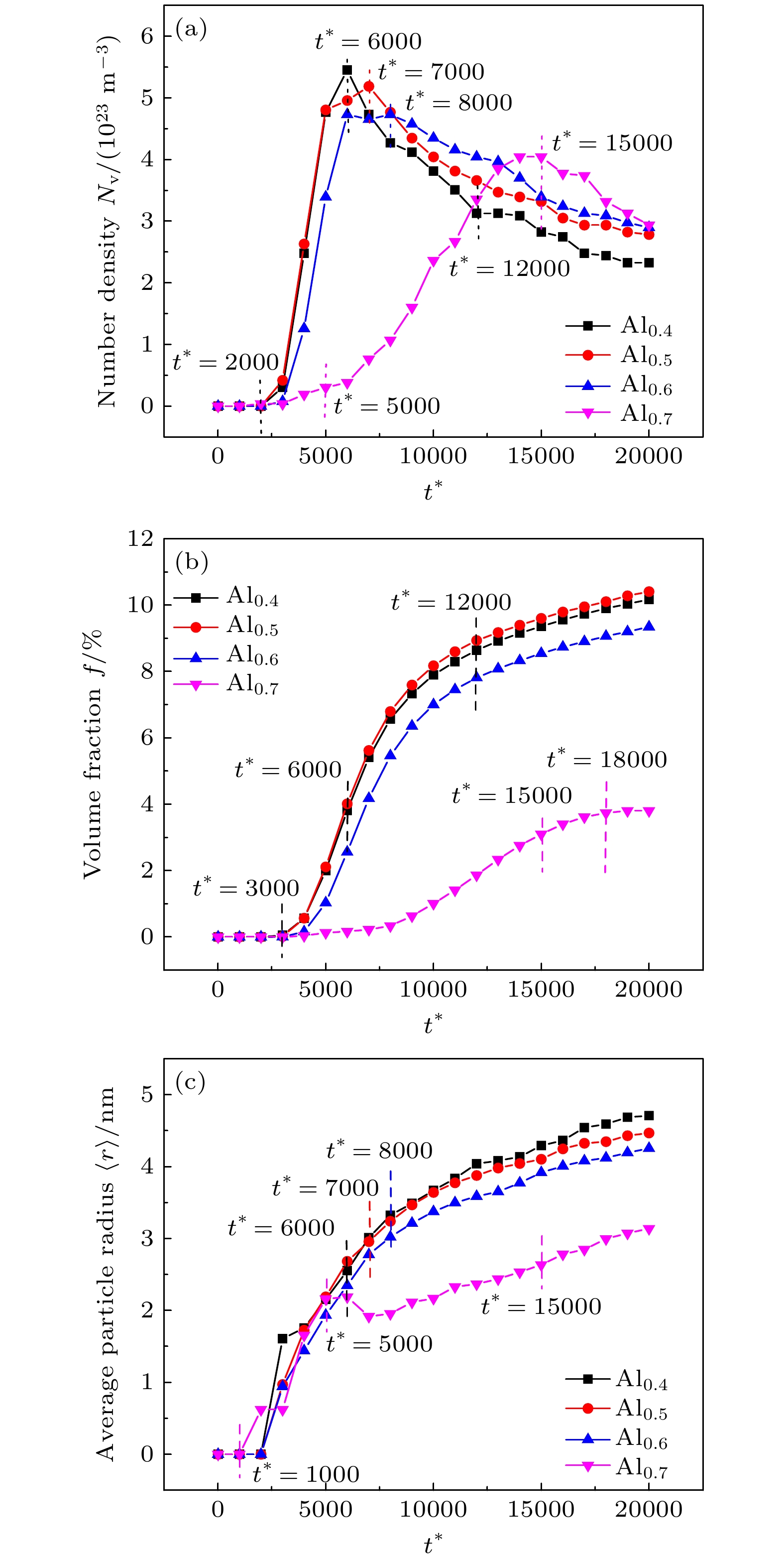

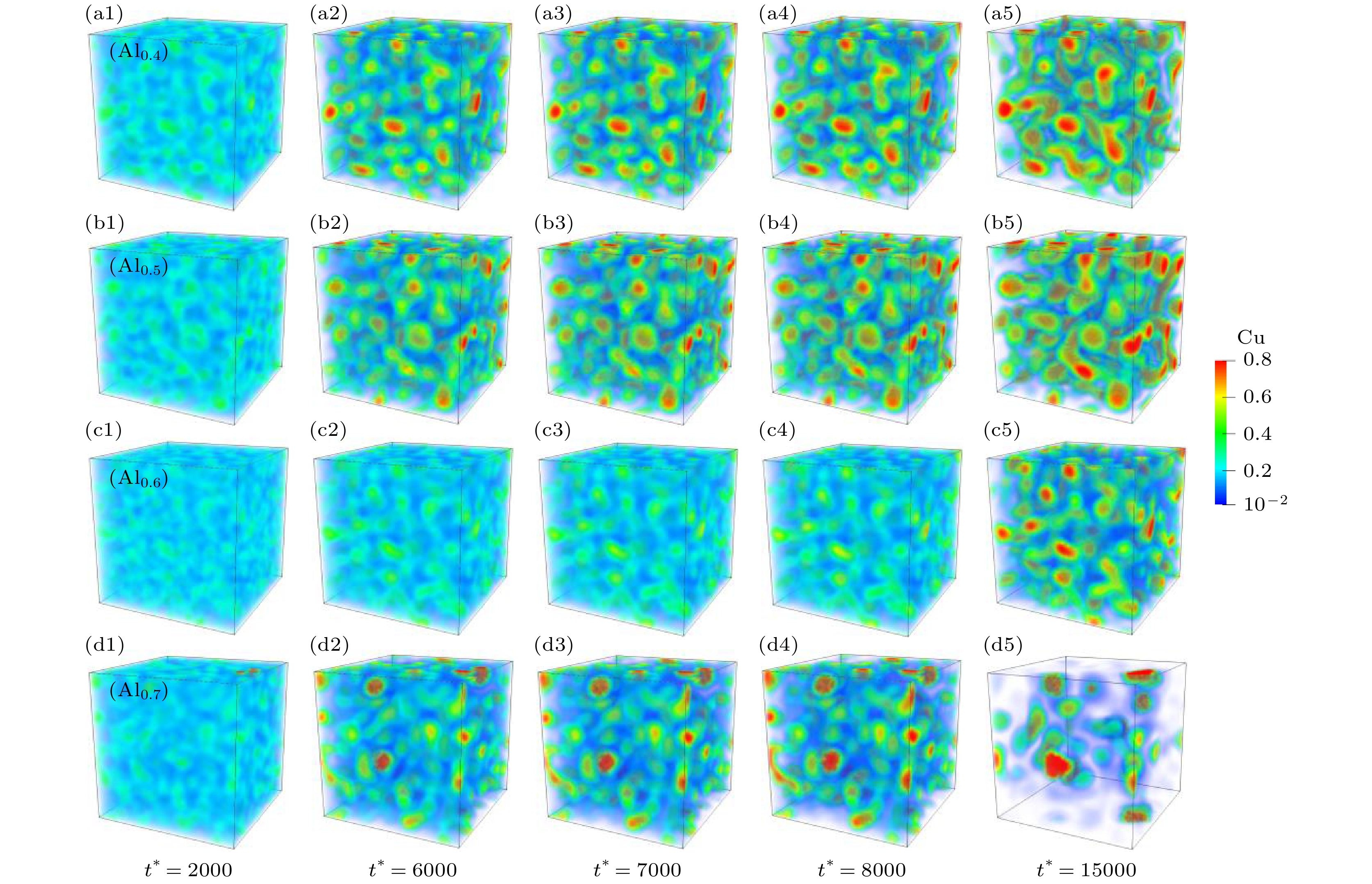

图 6 不同合金体系在随时间变化的三维模拟图 (a)—(d) 表示Al0.4, Al0.5, Al0.6, Al0.7四个体系. (1)—(5)分别表示开始形核时间以及四个体系到达峰值数量密度的时间

Fig. 6. Three-dimensional simulations of different alloy systems over time, (a)–(d) for Al0.4, Al0.5, Al0.6, and Al0.7, respectively; (1)–(5) for the start of nucleation and the time to peak number density for the four systems, respectively.

表 1 合金元素成分的原子百分含量(单位: %)

Table 1. Atomic percent of alloying element composition (unit: %).

Alloy system Al Cu Mn Ni Fe Al0.4Cu1.5Mn1Ni1Fe1.5 7.4 27.8 18.5 18.5 27.8 Al0.5Cu1.5Mn1Ni1Fe1.5 9.2 27.2 18.2 18.2 27.2 Al0.6Cu1.5Mn1Ni1Fe1.5 10.8 26.8 17.8 17.8 26.8 Al0.7Cu1.5Mn1Ni1Fe1.5 12.28 26.36 17.5 17.5 26.36 表 2 合金元素的频率因子和扩散激活能[52]

Table 2. Frequency factor and activation energy of alloying elements.

Alloy elements Cu Mn Ni Al ${D}_{i}^{0, \varphi }/{({10}^{-5}~{\rm{m} } }^{2}{\cdot}{ {\rm{s} } }^{-1}$) ${\rm{\alpha } }({\rm{B} }{\rm{C} }{\rm{C} })$ 4.70 14.90 14.00 53.50 ${\rm{\gamma } }({\rm{F} }{\rm{C} }{\rm{C} })$ 4.30 1.78 1.08 2.20 ${Q}_{i}^{0, \varphi }/{({10}^{5}~{\rm{J} }{\cdot}{\rm{m} }{\rm{o} }{\rm{l} } }^{-1}$) ${\rm{\alpha } }({\rm{B} }{\rm{C} }{\rm{C} })$ 2.44 2.63 2.64 2.71 ${\rm{\gamma } } ({\rm{F} }{\rm{C} }{\rm{C} } )$ 2.80 2.64 2.73 2.67 $ {D}_{i}^{0, \varphi } $-frequency factor; $ {Q}_{i}^{0, \varphi } $-diffusion activation energy 表 3 相场模型参数

Table 3. Phase field parameters.

Parameter type Parameter Value Unit Cahn-Hilliard model[55] $ {\kappa }_{c} $ $ 5.0\times {10}^{-15} $ ${\rm{J} \cdot}{ {\rm{m} } }^{2}{\cdot{\rm{m} }{\rm{o} }{\rm{l} } }^{-1}$ $ {\kappa }_{\eta } $ $ 1.0\times {10}^{-15} $ $ {\rm{J}}{\cdot{\rm{m}}}^{2}{\cdot{\rm{m}}{\rm{o}}{\rm{l}}}^{-1} $ $ Y $ $ 2.14\times {10}^{11} $ $ {\rm{P}}{\rm{a}} $ $ {V}_{{\rm{m}}} $ $ 7.09\times {10}^{-6} $ ${ {\rm{m} } }^{3}{\cdot {\rm{m} }{\rm{o} }{\rm{l} } }^{-1}$ $ W $ $ 5.0\times {10}^{3} $ ${\rm J} {\cdot} {\rm mol}^{-1}$ $ T $ 823 K Elasticity constant[56] $ {C}_{11}^{{\rm{m}}} $ 228 GPa $ {C}_{12}^{{\rm{m}}} $ 132 GPa $ {C}_{44}^{{\rm{m}}} $ 116.5 GPa $ {C}_{11}^{{\rm{p}}} $ 169 GPa $ {C}_{12}^{{\rm{p}}} $ 122 GPa $ {C}_{44}^{{\rm{p}}} $ 75.3 GPa Lattice misfit coefficient[55] $ {\varepsilon }_{{\rm{C}}{\rm{u}}}^{0} $ $ 3.29\times {10}^{-2} $ $ {\varepsilon }_{{\rm{M}}{\rm{n}}}^{0} $ $ 5.22\times {10}^{-4} $ $ {\varepsilon }_{{\rm{N}}{\rm{i}}}^{0} $ $ 4.75\times {10}^{-4} $ $ {\varepsilon }_{{\rm{A}}{\rm{l}}}^{0} $ $ 1.64\times {10}^{-4} $ Simulation parameters $ {\rm{d}}x $ 1 nm $ {\rm{d}}y $ 1 nm $ {\rm{d}}z $ 1 nm $ \Delta t $ 0.01 $ {\kappa }_{c}, {\kappa }_{\eta } $-gradient energy coefficient; $ Y $-average stiffness; $ {V}_{{\rm{m}}} $-molar volume; $ W $-structural transformation barriers; $ {C}_{11}^{{\rm{m}}}, {C}_{12}^{{\rm{m}}}, {C}_{44}^{{\rm{m}}} $-elastic constant of the matrix phase; $ {C}_{11}^{{\rm{p}}}, {C}_{12}^{{\rm{p}}}, {C}_{44}^{{\rm{p}}} $-elastic constant of the precipitated phase; $ {\varepsilon }_{i}^{0}(i={\rm{C}}{\rm{u}}, {\rm{M}}{\rm{n}}, {\rm{N}}{\rm{i}}, {\rm{A}}{\rm{l}}) $- lattice misfit coefficients of Cu, Mn, Ni, Al; $ {\rm{d}}x, {\rm{d}}y, {\rm{d}}z $ unit length of simulated meshes; $ \Delta t $-unit time step 表 4 AlxCuMnNiFe中各元素的

$ {\Delta H}_{{\rm{m}}{\rm{i}}{\rm{x}}} $ [59](单位: kJ/mol)Table 4.

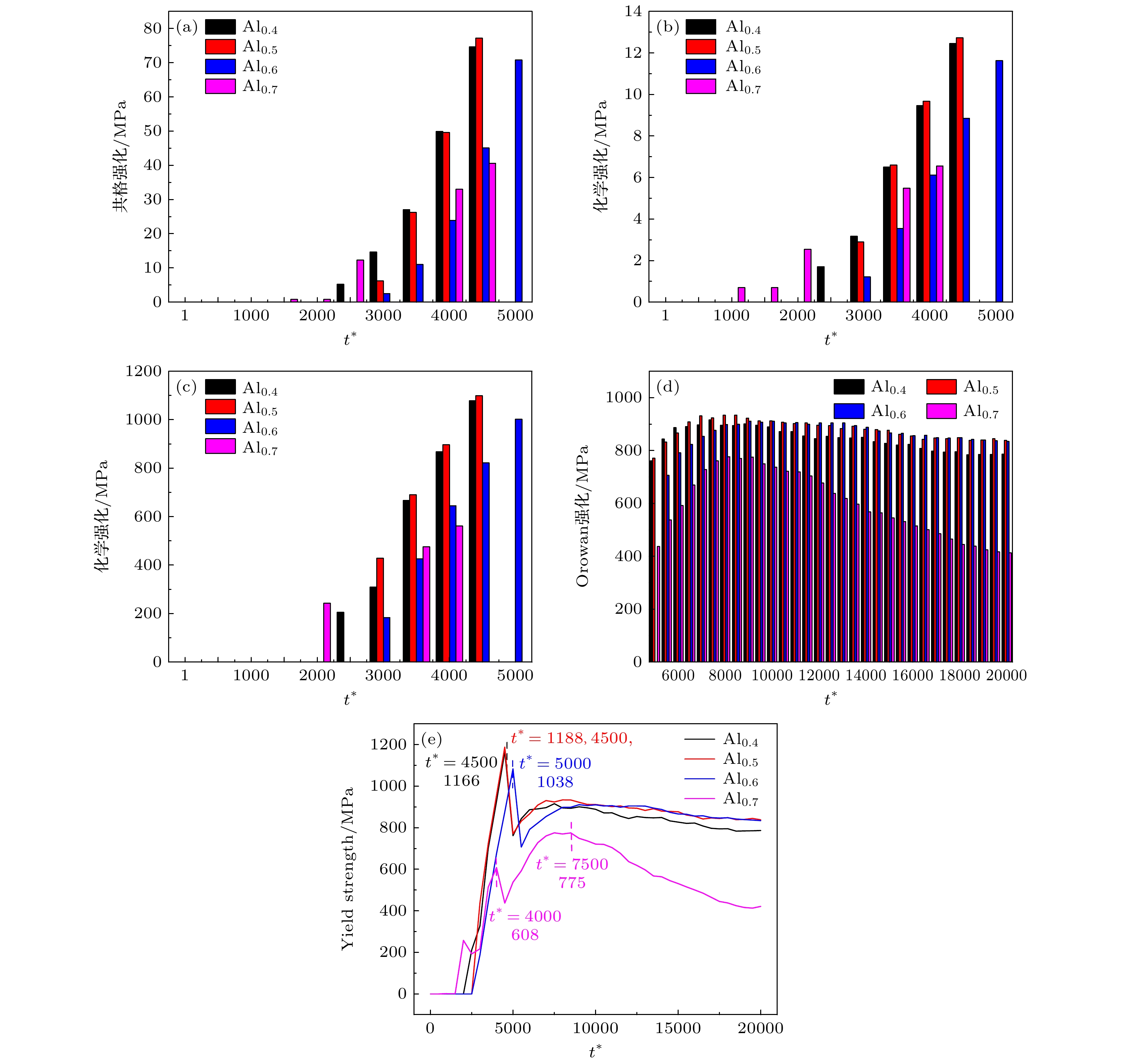

$ {\Delta H}_{{\rm{m}}{\rm{i}}{\rm{x}}} $ between elements in AlxCuMnNiFe alloy (unit: kJ/mol)Alloy elements Al Cu Mn Ni Fe Al — –1 –19 –22 –11 Cu –1 — 4 4 13 Mn –19 4 — –8 0 Ni –22 4 –8 — –2 Fe –11 13 0 –2 — 表 5 不同合金体系强化的基本数据

Table 5. Basic data on strengthening of different alloy systems.

Alloy system t * $ {N}_{v} $/($ \times {10}^{23}{{\rm{m}}}^{-3}) $ f/% r/nm Strengthening/MPa Al0.4Cu1.5Mn1Ni1Fe1.5 4500 3.9291 0.0116 1.9148 1166 Al0.5Cu1.5Mn1Ni1Fe1.5 4500 4.0817 0.0123 1.9286 1188 Al0.6Cu1.5Mn1Ni1Fe1.5 5000 3.3951 0.0103 1.9343 1038 Al0.7Cu1.5Mn1Ni1Fe1.5 7500 4.04 0.031 2.63 775 When r$\; \leqslant \;$2 nm, it is a dislocation slicing mechanism, and when r > 2 nm, it is a dislocation bypassing mechanism. -

[1] Cantor B, Chang I T H, Knight P, Vincent A 2004 Mater. Sci. Eng., A 375 213

[2] Zhang Y 2019 High-Entropy Materials (Singapore: Springer Nature Singapore Pte Ltd) p215

[3] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y. 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[4] Zhou Y J, Zhang Y, Wang Y L, Chen G L 2007 Appl. Phys. Lett. 90 253

[5] Niu S Z, Kou H C, Wang J, Li J S 2021 Rare Met. 40 2508

[6] Sha M H, Zhang L, Zhang J W, Li N, Li T Z, Wang N 2017 Rare Met. Mater. Eng. 46 1237

Google Scholar

Google Scholar

[7] Chen X, Hu J X, Liu Y, Xiang F 2021 Met. Mater. Int. 27 2230

Google Scholar

Google Scholar

[8] Pradeep K G, Wanderka N, Choi P, Banhart J, Murty B S, Raabe D 2013 Acta Mater. 61 4696

Google Scholar

Google Scholar

[9] Jones N G, Frezza A, Stone H J 2014 Mater. Sci. Eng., A 615 214

Google Scholar

Google Scholar

[10] Dąbrowa J, Cieślak G, Stygar M, Mroczka K, Berebt K, Kulik T, Danielewski M 2017 Intermetallics 84 52

Google Scholar

Google Scholar

[11] Wu P H, Liu N, Yang W, Zhu Z X, Liu Y P, Wang X J 2015 Mater. Sci. Eng. , A 642 142

Google Scholar

Google Scholar

[12] Xian X, Lin L, Zhong Z, Zhang C, Chen C, Song K J, Cheng J G, Wu Y C 2018 Mater. Sci. Eng., A 713 134

Google Scholar

Google Scholar

[13] Borkar T, Gwalani B, Choudhuri D, Alam T, Mantri A S, Gibson M A 2016 Intermetallics 71 31

Google Scholar

Google Scholar

[14] Gwalani B, Choudhuri D, Soni V, Ren Y, Styles M, Hwang J Y, Nam S J, Ryu H, Hong S H, Banerjee R 2017 Acta Mater. 129 170

Google Scholar

Google Scholar

[15] Shim S H, Pouraliakbar H, Hong S I 2022 Scr. Mater. 210 114473

Google Scholar

Google Scholar

[16] Lahiri A 2022 J. Indian Inst. Sci. 102 39

Google Scholar

Google Scholar

[17] Chen L Q 2002 Annu. Rev. Mater. Res. 32 113

Google Scholar

Google Scholar

[18] Chen L Q, Zhao Y H 2021 Prog. Mater. Sci. 124 100868

[19] Xin T Z, Zhao Y H, Mahjoub R, Jiang J X, Yadav A, Nomoto K, Niu R M, Tang S, Ji F, Quadir Z, Miskovic D, Daniels J, Xu W Q, Liao X Z, Chen L Q, Hagihara K, Li X Y, Ringer S, Ferry M 2021 Sci. Adv. 7 eabf3039

Google Scholar

Google Scholar

[20] Tian X L, Zhao Y H, Peng D W, Guo Q W, Hou H 2021 Trans. Nonferrous Met. Soc. China 31 1175

Google Scholar

Google Scholar

[21] Tian X L, Zhao Y H, Gu T, Guo Y L, Xu F Q, Hou H 2022 Mater. Sci. Eng., A 849 143485

Google Scholar

Google Scholar

[22] Zhao Y H, Zhang B, Hou H, Chen W P, Wang M 2019 J. Mater. Sci. Technol. 35 1044

Google Scholar

Google Scholar

[23] Zhang J B, Wang H F, Kuang W W, Zhang Y C, Li S, Zhao Y H, Herlach D M 2018 Acta Mater. 148 86

Google Scholar

Google Scholar

[24] Chen W P, Zhao Y H, Yang S, Zhang D, Hou H 2021 Adv. Compos. Hybrid Mater. 4 371

Google Scholar

Google Scholar

[25] Biner S B, Rao W, Zhang Y 2016 J. Nucl. Mater. 468 9

Google Scholar

Google Scholar

[26] Koyama T, Onodera H 2005 Mater. Trans. 46 1187

Google Scholar

Google Scholar

[27] Zhao Y H. 2022 Intermetallics 144 107528

Google Scholar

Google Scholar

[28] Zeng Y F, Cai X R, Koslowski M 2019 Acta Mater. 164 1

Google Scholar

Google Scholar

[29] Kadirvel K, Kloenne Z, Jensen J K, Fraser H, Wang Y 2021 Appl. Phys. Lett. 119 171905

Google Scholar

Google Scholar

[30] Zuo X J, Coutinho Y, Chatterjee S, Moelans N 2022 Mater. Theor. 6 12

Google Scholar

Google Scholar

[31] Li J L, Li Z, Wang Q, Dong C, Liaw P K 2020 Acta Mater. 197 10

Google Scholar

Google Scholar

[32] Coutinho Y A, Kunwar A, Moelans N 2022 J. Mater. Sci. 57 10600

Google Scholar

Google Scholar

[33] Zhao Y H, Liu K X, Hou H, Chen L Q 2022 Mater. Des. 216 110555

Google Scholar

Google Scholar

[34] Zhao Y H, Sun Y Y, Hou H. 2022 Prog. Nat. Sci.-Mater. Int. 32 358

Google Scholar

Google Scholar

[35] Sun Y Y, Zhao Y H, Zhao B J, Yang W K, Li X L 2019 J. Mater. Sci. 54 11263

Google Scholar

Google Scholar

[36] 蒋新安, 赵宇宏, 杨文奎, 田晓琳, 侯华 2022 71 080201

Google Scholar

Google Scholar

Jiang X A, Zhao Y H, Yang W K, Tian X L, Hou H 2022 Acta Phys. Sin. 71 080201

Google Scholar

Google Scholar

[37] 栾亨伟, 赵威, 姚可夫 2020 材料热处理学报 41 1

Luan H W, Zhao W, Yao K F 2020 Trans. Mater. Heat Treat. 41 1

[38] Pang C, Jiang B B, Shi Y, Wang Q, Dong C 2015 J. Alloys Compd. 652 63

Google Scholar

Google Scholar

[39] 郝家苗 2020 硕士学位论文 (大连: 大连理工大学)

Hao J M 2020 M. S. Thesis (Dalian: Dalian University of Technology) (in chinese)

[40] Chen L Q 2002 Annual Review of Materials Research 32 113

[41] Kuang W W, Wang H F, Li X, Zhang J B, Qing Z, Zhao Y H 2018 Acta Mater. 159 16

Google Scholar

Google Scholar

[42] Cahn J W 1961 Acta Metall. 9 795

Google Scholar

Google Scholar

[43] Cahn J W, Hilliard J E 1958 J. Chem. Phys. 28 258

Google Scholar

Google Scholar

[44] Kitashima T, Harada H. 2009 Acta Mater. 57 2020

Google Scholar

Google Scholar

[45] Tsukada Y, Koyama T, Murata Y, Miura N, Kondo Y 2014 Comput. Mater. Sci. 83 371

Google Scholar

Google Scholar

[46] Deng S, Chen W M, Zhong J, Zhang L J, Du Y, Chen L 2017 Calphad 56 230

Google Scholar

Google Scholar

[47] Allen S, Cahn J W 1992 Acta Metall. 20 423

[48] Chen H L, Mao H, Chen Q 2018 Mater. Chem. Phys. 210 279

Google Scholar

Google Scholar

[49] Luo Z, Du Y, Liu Y L, Tang S, Pan Y F, Mao H, Peng Y B, Liu W S, Liu Z K 2018 Calphad 63 190

Google Scholar

Google Scholar

[50] Li Y S, Zhu H, Zhang L, Cheng X L 2012 J. Nucl. Mater. 429 13

Google Scholar

Google Scholar

[51] Moelans N, Blanpain B, Wollants P 2008 Calphad 32 268

Google Scholar

Google Scholar

[52] Neumann G, Tuijn C 2011 Self-diffusion and Impurity Diffusion in Pure Metals: Handbook of Experimental Data Elsevier

[53] Khachaturian A G 1983 Acta Crystallogr.

[54] Shen C, Wang Y 2005 Handb. Mater. Model.

[55] Koyama T, Hashimoto K, Onodera H 2006 Mater. Trans. 47 2765

Google Scholar

Google Scholar

[56] Cale W F, Totemeier T C 2003 Smithells Metals Reference Book (Oxford: Butter worth-Heinemann)

[57] Sonkusare R, Swain A, Rahul M R, Samal S, Gurao N P, Biswas k, Singh S S, Nayan N 2019 Mater. Sci. Eng., A 759 415

Google Scholar

Google Scholar

[58] 龚子杰, 李春辉, 李晓宇, 李炜, 陈伟, 赵东国, 刘润芳 2022 精密成形工程 14 83

Google Scholar

Google Scholar

Gong Z J, Li C H, Li X N, Li W, Chen W, Zhao D G, Liu R F 2022 J. Netshape Form. Eng. 14 83

Google Scholar

Google Scholar

[59] Takeuchi A, Inoue A 2007 Mater. Trans., JIM 41 1372

[60] Li B, Zhang L, Li C L, Li Q L, Chen J, Shun G G, Weng Y Q, Xu B, Hu S Y, Liu W 2018 J. Nucl. Mater. 507 59

Google Scholar

Google Scholar

[61] 程一丹 2018 硕士学位论文 (西安: 西安工业大学)

Cheng Y D 2018 M. S. Thesis (Xi'an: Xi'an Technological University) (in Chinese)

[62] 王晓姣 2016 博士学位论文 (上海: 上海大学)

Wang X J 2016 Ph. D. Dissertation (Shanghai: Shanghai University) (in Chinese)

[63] Jiao Z B, Luan J H, Miller M K, Yu C Y, Liu C T 2015 Acta Mater. 84 283

Google Scholar

Google Scholar

[64] Isheim D, Kolli R P, Fine M E, Seidman D N 2006 Scr. Mater. 55 35

Google Scholar

Google Scholar

[65] Russell K C, Brown L M 1972 Acta Metall. 20 969

Google Scholar

Google Scholar

[66] Hahn S I, Hwang S J 2009 J. Alloys Compd. 483 207

Google Scholar

Google Scholar

[67] Dinsdale A T 1991 Calphad 15 317

Google Scholar

Google Scholar

[68] Liu X Y, Wang G, Hu Y, Ji Y Z, Rong Y M, Hu Y Z, Chen L Q 2021 Mater. Sci. Eng., A. 814 141223

Google Scholar

Google Scholar

计量

- 文章访问数: 10015

- PDF下载量: 198

- 被引次数: 0

下载:

下载: