-

多主元合金, 亦称为高熵合金, 作为一种新型合金材料, 因其优异的力学性能和热稳定性在多个领域展现出巨大的应用潜力. 本文采用分子动力学模拟方法, 以3种典型的体心立方结构多主元合金——TaWNbMo, TiZrNb和CoFeNiTi为研究对象, 系统研究了合金中的原子局域晶格畸变特征及其影响因素. 通过冯·米塞斯应变和体积应变作为描述符, 定量分析了合金中原子应变的分布及其与晶格畸变的关系. 研究结果表明, 晶格畸变越大, 冯·米塞斯应变和体积应变的分布范围越广, 且应变值显著增大. 进一步分析发现, 合金中的原子半径差异、化学短程有序结构以及温度均显著影响原子应变. 具体而言, 原子半径差异越大, 体积应变越大, 而化学短程有序结构的形成有助于减小晶格畸变和原子应变. 温度的升高则会导致晶格振动加剧, 从而增大原子应变. 本文的研究为理解高熵合金的微观力学行为提供了新的视角, 并为其在高温和极端环境下的应用设计提供了理论支持.Multi-principal element alloys (MPEAs), also known as high-entropy alloys (HEAs), are novel materials that have received significant attention due to their exceptional mechanical properties, thermal stability, and resistance to wear and corrosion. These alloys are typically composed of multiple principal elements in near-equal atomic proportions, forming solid solution phases such as face-centered cubic (FCC) or body-centered cubic (BCC) structures. Despite the promising applications, a more in-depth understanding of the atomic-level behavior, particularly, lattice distortion and atomic strain, is essential to better design and optimize these materials in extreme environments. This study focuses on systematically investigating the atomic-scale lattice distortion characteristics and their influence on atomic strain in three representative BCC-based MPEAs: TaWNbMo, TiZrNb, and CoFeNiTi. We utilize molecular dynamics (MD) simulations to explore the local atomic strain distributions in these alloys at various temperatures. Von Mises strain and volumetric strain are employed as key descriptors to quantify the atomic strain, providing a clear representation of how lattice distortion on an atomic scale influences the overall strain behavior. The study specifically addresses the effects of atomic radius differences, chemical short-range ordering, and temperature on the strain characteristics of the alloys. The results obtained indicate that an increase in lattice distortion corresponds to a broader distribution of von Mises strain and volumetric strain, with strain values significantly amplified. More precisely, alloys with larger atomic radius differences exhibit greater volumetric strain, reflecting the influence of atomic size disparity on strain distribution. Furthermore, the formation of chemical short-range order (CSRO) significantly mitigates lattice distortion and atomic strain. This finding highlights the importance of short-range atomic ordering in enhancing the stability of the alloy structures, thus potentially improving their mechanical properties. Temperature effects are also investigated, revealing that elevated temperature induces more intense atomic vibration, which in turn increases the atomic strain. The findings underscore the complex interplay between atomic-scale phenomena and macroscopic mechanical properties, offering new insights into the microscopic mechanical behavior of high-entropy alloys. This study contributes to a better understanding of the underlying mechanisms driving atomic strain and lattice distortion in MPEAs. The results provide valuable theoretical insights that can guide the design of high-performance alloys tailored for high-temperature and extreme environments. By addressing the key factors influencing atomic strain, such as atomic radius, chemical ordering, and temperature, this work lays the foundation for future research aimed at enhancing the mechanical performance of MPEAs in various industrial applications.

-

Keywords:

- multi-principal element alloys /

- lattice distortion /

- atomic strain /

- molecular dynamics simulations

[1] George E P, Raabe D, Ritchie R O 2019 Nat. Rev. Mater. 4 515

Google Scholar

Google Scholar

[2] George E P, Curtin W A, Tasan C C 2020 Acta Mater. 188 435

Google Scholar

Google Scholar

[3] Miracle D B 2017 J. Met. 69 2130

Google Scholar

Google Scholar

[4] Pickering E J, Jones N G 2016 Int. Mater. Rev. 61 183

Google Scholar

Google Scholar

[5] Ma E, Ding J 2025 J. Mater. Sci. Technol. 220 233

Google Scholar

Google Scholar

[6] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[7] Li Z M, Pradeep K G, Deng F, Paabe D, Tasan C C 2016 Nature 534 227

Google Scholar

Google Scholar

[8] Maresca F, Curtin W A 2020 Acta Mater. 182 235

Google Scholar

Google Scholar

[9] Gludovatz B, Hohenwarter A, Catoor D, Chang E H, George E P, Ritchie P O 2014 Science 345 1153

Google Scholar

Google Scholar

[10] Shi Y Z, Yang B, Liaw P K 2017 Metals 7 18

Google Scholar

Google Scholar

[11] Chen P Y, Lee C, Wang S Y, Seifi M, Lewandowski J J, Dahmen K A, Jia H L, Xie X, Chen B L, Yeh J W, Tsai C W, Yuan T, Liaw P K 2018 Sci. China-Technol. Sci. 61 168

Google Scholar

Google Scholar

[12] Kozelj P, Vrtnik S, Jelen A, Jazbec S, Jaglicic Z, Maiti S, Feuerbacher M, Steurer W, Dolinsek J 2014 Phys. Rev. Lett. 113 107001

Google Scholar

Google Scholar

[13] Su Z X, Ding J, Song M, Jiang L, Shi Tan, Li Z M, Wang S, Gao F, Ma E Lu C Y 2023 Acta Mater. 245 118662

Google Scholar

Google Scholar

[14] Zhang Z, Su Z, Zhang B, Yu Q, Ding J, Shi T, Lu C, Ritchie R O, Ma E 2023 Proc. Natl. Acad. Sci. 120 e2218673120

Google Scholar

Google Scholar

[15] Zhang Y, Zuo T, Tang T, Gao M, Dahmen K, Liaw K, Lu Z 2014 Prog. Mater. Sci. 61 1

Google Scholar

Google Scholar

[16] Kozak P, Sologubenko A, Steurer W 2015 Z Kristallogr Cryst Mater 230 55

Google Scholar

Google Scholar

[17] Zhang B, Zhang Z, Xun K, Asta M, Ding J, Ma E 2024 Proc. Natl. Acad. Sci. 121 e2314248121

Google Scholar

Google Scholar

[18] Miracle D B, Senkov O N 2017 Acta Mater. 122 448

Google Scholar

Google Scholar

[19] Fan Z, Wang H, Wu Y, Liu X J, Lu Z P 2017 Mater. Res. Lett. 5 187

Google Scholar

Google Scholar

[20] Yeh J W, Chang S Y, Hong Y D, Chen S K, Lin S J 2007 Mater. Chem. Phys. 103 41

Google Scholar

Google Scholar

[21] Tong C J, Chen Y L, Chen S K, Yeh J W, Shun T T, Tsau C H, Lin S J, Chang S Y 2005 Metall. Mater. Trans. A 36 881

Google Scholar

Google Scholar

[22] Tsai C W, Tsai M H, Yeh J W, Yang C C 2010 J. Alloys Compd. 490 160

Google Scholar

Google Scholar

[23] Yeh J W, Chen S K, Gan J Y, Lin S J, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Metall. Mater. Trans. A 35 2533

Google Scholar

Google Scholar

[24] 杨勇, 赫全锋 2021 金属学报 57 385

Google Scholar

Google Scholar

Yang Y, He Q F 2021 Acta Metall. Sin. 57 385

Google Scholar

Google Scholar

[25] Zou Y, Maiti S, Steurer W, Spolenak R 2014 Acta Mater. 65 85

Google Scholar

Google Scholar

[26] Santodonato L J, Zhang Y, Feygenson M, Parish C M, Gao M C, Weber R J, Neuefeind J C, Tang Z, Liaw P K 2015 Nat. Commun. 6 5964

Google Scholar

Google Scholar

[27] Toda-Caraballo I, Wr obel J S, Dudarev S L, Nguyen-Manh D, Rivera-Díaz-del-Castillo P E 2015 Acta Mater. 97 156

Google Scholar

Google Scholar

[28] Tian L Y, Hu Q M, Yang R, Zhao J, Johansson B, Vitos L 2015 J. Phys. Condens. Mat. 27 315702

Google Scholar

Google Scholar

[29] Chen B, Li S Z, Ding J, Ding X D, Sun J, Ma E 2023 Scr. Mater. 222 115048

Google Scholar

Google Scholar

[30] Tandoc C, Hu Y J, Qi L, Liaw P K 2023 npj Comput. Mater. 9 53

Google Scholar

Google Scholar

[31] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[32] Yin S, Zuo Y X, Abu-Odeh A, Zhang H, Li X G, Ding J, Ong S P, Asta M, Ritchie R 2021 Nat. Commun. 12 4873

Google Scholar

Google Scholar

[33] Chen B, Li S Z, Ding J, Ding X D, Sun J, Ma E 2020 Proc. Natl. Acad. Sci. 117 16199

Google Scholar

Google Scholar

[34] Stukowski A 2010 Model. Simul. Mater. Sc. 18 015012

Google Scholar

Google Scholar

[35] Wang J H, Li J, Yip S, Phillpot S, Wolf D 1995 Phys. Rev. B 52 12627

Google Scholar

Google Scholar

[36] Li J 2003 Model. Simul. Mater. Sci. Eng. 11 173

Google Scholar

Google Scholar

[37] Wang L, Ding J, Chen S S, Jin K, Zhang Q H, Cui J X, Wang B P, Chen B, Li T Y, Ren Y, Zheng S J, Ming K S, Lu W J, Hou J H, Sha G, Liang J, Wang L, Xue Y F, Ma E 2023 Nat. Mater. 22 950

Google Scholar

Google Scholar

[38] Zhang M, Zhang B Z, Ding J, Ma E 2025 Scripta Mater. 259 116559

Google Scholar

Google Scholar

[39] Ding J, Yu Q, Asta M, O. Ritchie R 2018 Proc. Natl. Acad. Sci. 115 8919

Google Scholar

Google Scholar

[40] Zhang F X, Zhao S J, Jin K, Xue H, Velisa G, Bei H, Huang R, Ko J Y P, Pagan D C, Neuefeind J C, Weber W J, Zhang Y W 2017 Phys. Rev. Lett. 118 205501

Google Scholar

Google Scholar

[41] Zhang R P, Zhao S T, Ding J, Chong Y, Jia T, Ophus C, Asta M, O. Ritchie R, Minor M A. 2020 Nature 581 283

Google Scholar

Google Scholar

[42] Xun K H, Zhang B Z, Wang Q, Zhang Z, Ding J, Ma E 2023 J. Mater. Sci. Technol. 135 221

Google Scholar

Google Scholar

[43] Chen B, Li S Z, Ding J, Ding X D, Sun J, Ma E 2024 Acta Mater. 272 119910

Google Scholar

Google Scholar

[44] He Q F, Wang J G, Chen H A, Ding Z Y, Zhou Z Q, Xiong L H, Luan J H, Pelletier J M, Qiao J C, Wang Q, Fan L L, Zeng Q S, Liu C T, Pao C W, Srolovitz D J, Yang Y 2022 Nature 602 251

Google Scholar

Google Scholar

[45] Tan Y Y, Chen Z J, Su M Y, Ding G, Jiang M Q, Xie Z C, Gong Y, Wu T, Wu Z H, Wang H Y, Dai L H 2022 J. Mater. Sci. Technol. 104 236

Google Scholar

Google Scholar

-

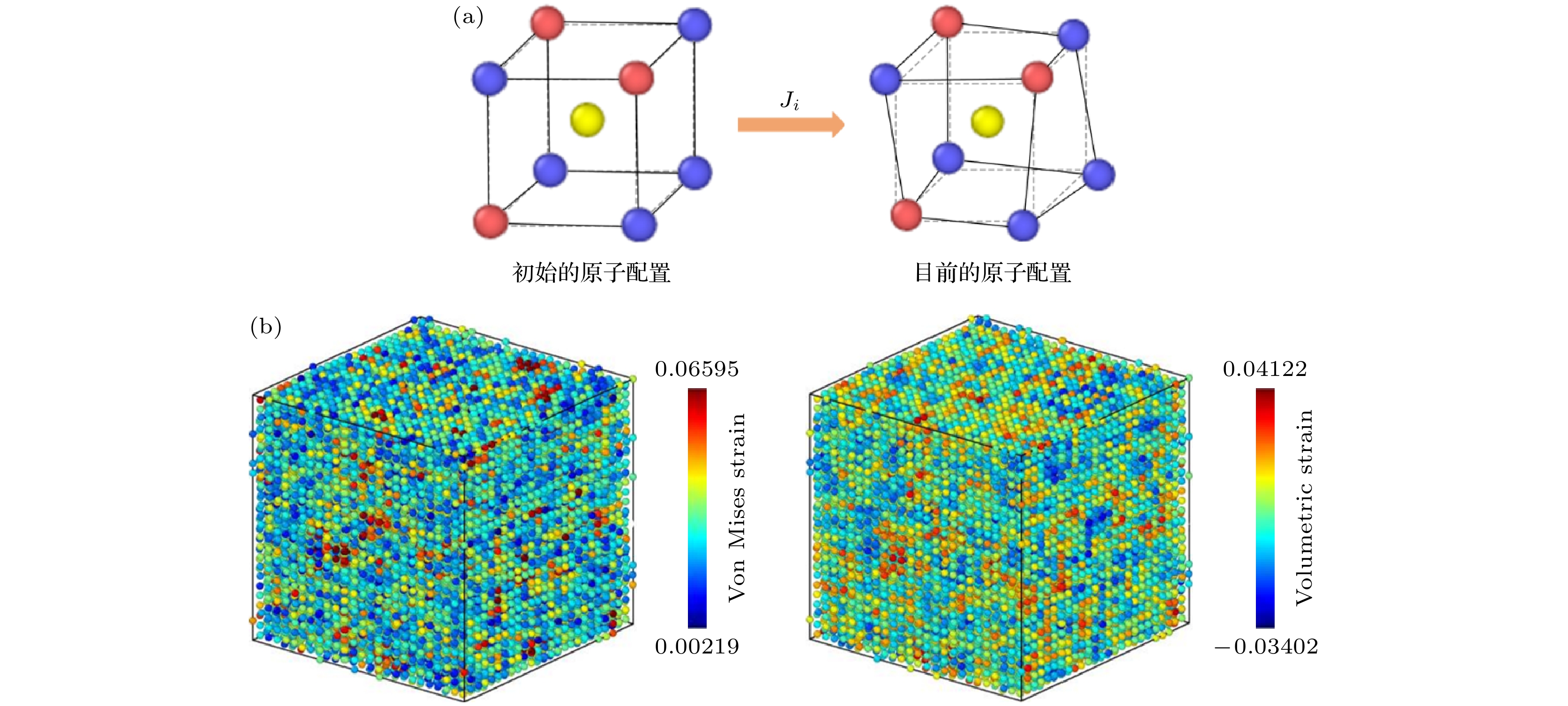

图 1 多主元合金中的晶格畸变及局域原子应变 (a)晶格畸变示意图, 局部仿射变换矩阵$ {J}_{i} $ 描述了初始与当前原子构型之间的转变; (b) 0 K下TiZrNb合金中的原子应变示例, 左图为每个原子的冯·米塞斯应变, 右图为每个原子的体积应变

Fig. 1. Lattice distortion and local atomic strain in multi-principal element alloys: (a) Schematic of lattice distortion, where the local affine transformation matrix $ {J}_{i} $ describes the transition from the initial to the current atomic configuration; (b) atomic strain distribution in the TiZrNb alloy at 0 K, the left panel displays the Von Mises strain for each atom, while the right panel shows the volumetric strain.

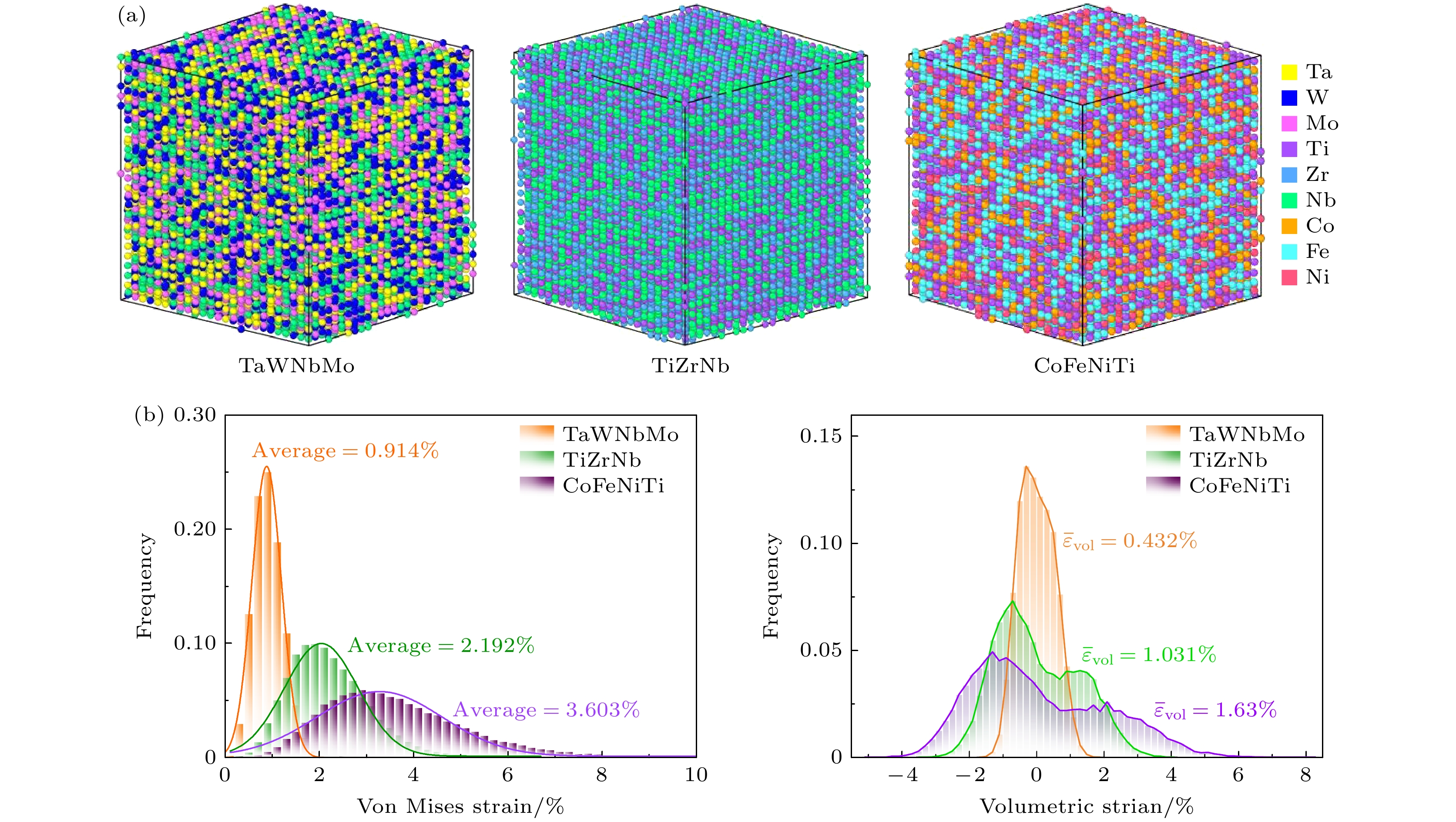

图 2 不同合金体系的三维原子分布模型及其原子应变的分布 (a) TaWNbMo, TiZrNb和CoFeNiTi的三维原子分布模型; (b) 3种合金体系的冯·米塞斯应变和体积应变的分布

Fig. 2. Three-dimensional atomic distribution models and atomic strain distributions in different alloy systems: (a) Three-dimensional atomic distribution models of TaWNbMo, TiZrNb, and CoFeNiTi; (b) distribution of Von Mises strain and volumetric strain for the three alloy systems.

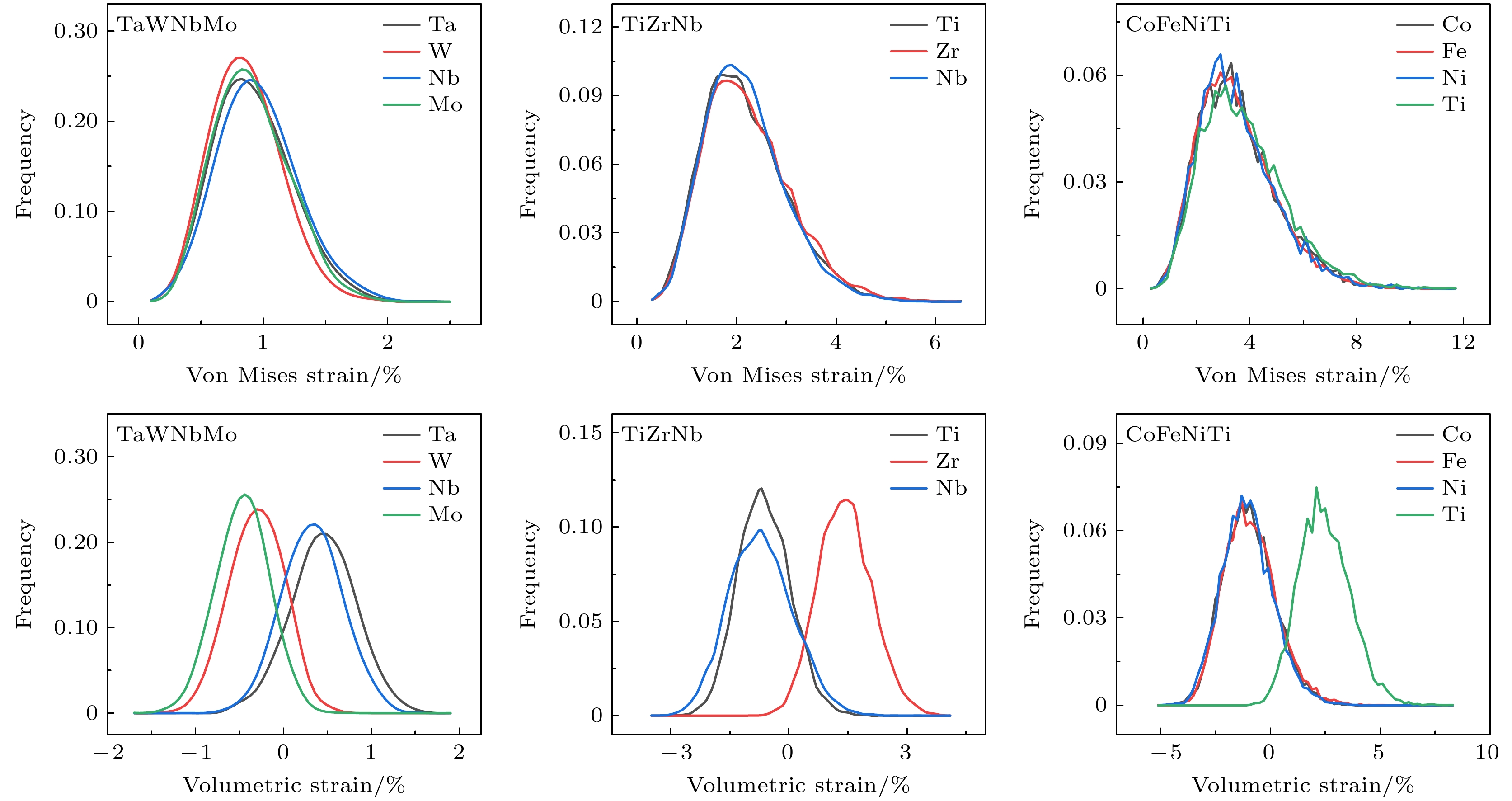

图 3 三种合金体系中不同组元的冯·米塞斯应变和体积应变的分布, 展示了TaWNbMo, TiZrNb和CoFeNiTi三种合金体系中不同组元的冯·米塞斯应变和体积应变的分布, 每种合金中的不同组元(Ta, W, Nb, Mo, Ti, Zr, Nb, 和Co, Fe, Ni, Ti)分别绘制了应变分布图, 上半部分为冯·米塞斯应变的分布, 下半部分为体积应变的分布, 不同颜色的曲线对应于不同的元素, 反映了各组元在合金中的应变特性差异

Fig. 3. Distribution of von Mises strain and volumetric strain for different elements in the TaWNbMo, TiZrNb, and CoFeNiTi alloy systems. The strain distributions for different elements (Ta, W, Nb, Mo, Ti, Zr, Nb, Co, Fe, Ni, Ti) in each alloy are shown. The upper part of the figure shows the distribution of von Mises strain, while the lower part shows the distribution of volumetric strain. The different colored curves represent different elements, reflecting the strain characteristics of each element in the alloy.

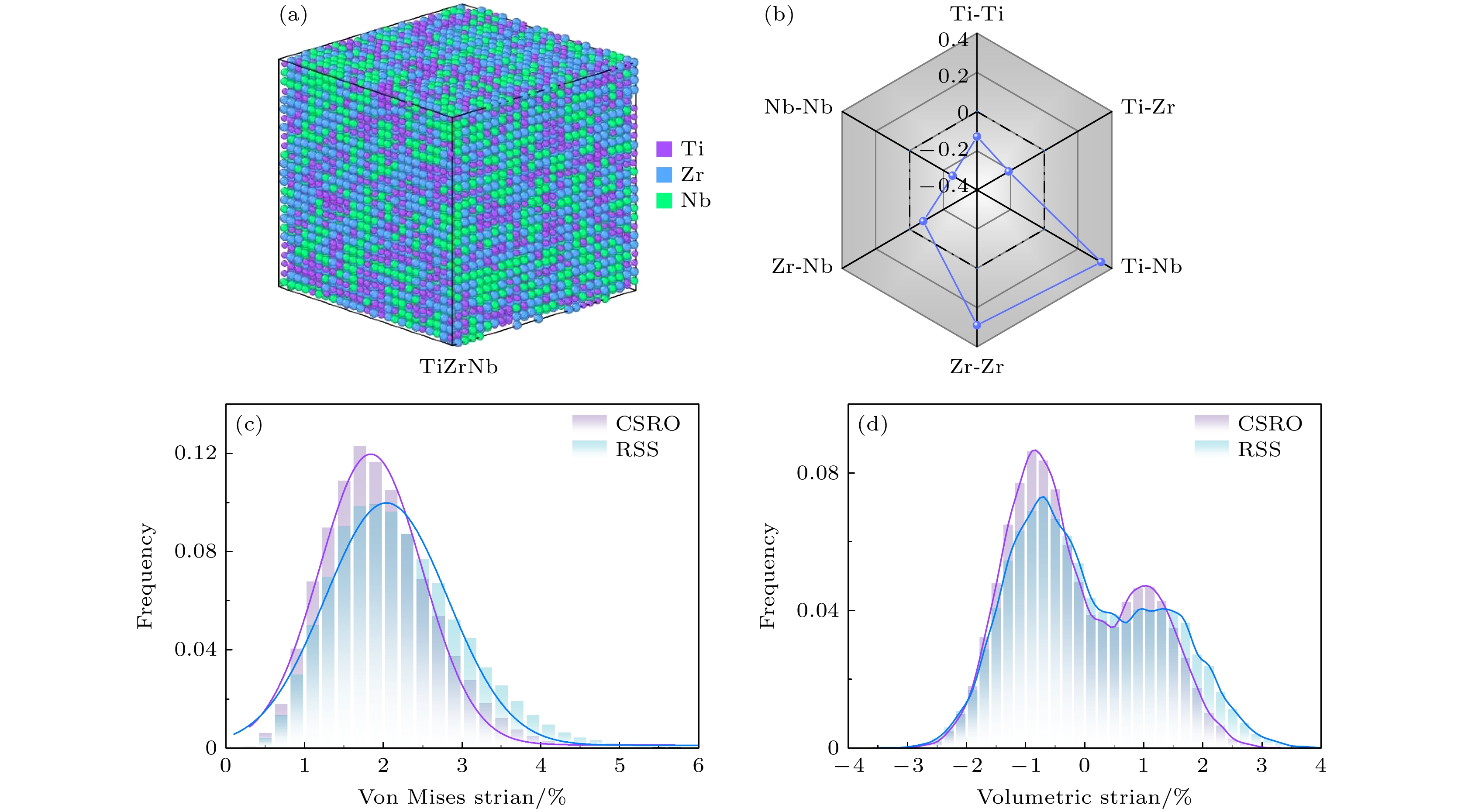

图 4 TiZrNb合金在800 K下的化学短程有序信息及其原子应变分布特征 (a)化学短程有序构型的三维原子分布模型; (b)不同原子对的Warren-Cowley参数, 展示了合金中各原子对之间的短程有序程度; (c)冯·米塞斯应变的频率分布, 分别为CSRO和RSS两种不同的化学短程有序状态下的应变分布; (d)体积应变的频率分布, 展示了不同原子对间的体积应变分布特征

Fig. 4. Chemical short-range order information and atomic strain distribution characteristics of TiZrNb alloy at 800 K: (a) Three-dimensional atomic distribution model of the chemical short-range ordered configuration; (b) Warren-Cowley parameters for different atomic pairs, showing the degree of short-range order between atomic pairs in the alloy; (c) distribution of von Mises strain, showing the strain distributions under CS0 and RSS short-range order configurations; (d) frequency distribution of volumetric strain, illustrating the volumetric strain characteristics between different atomic pairs.

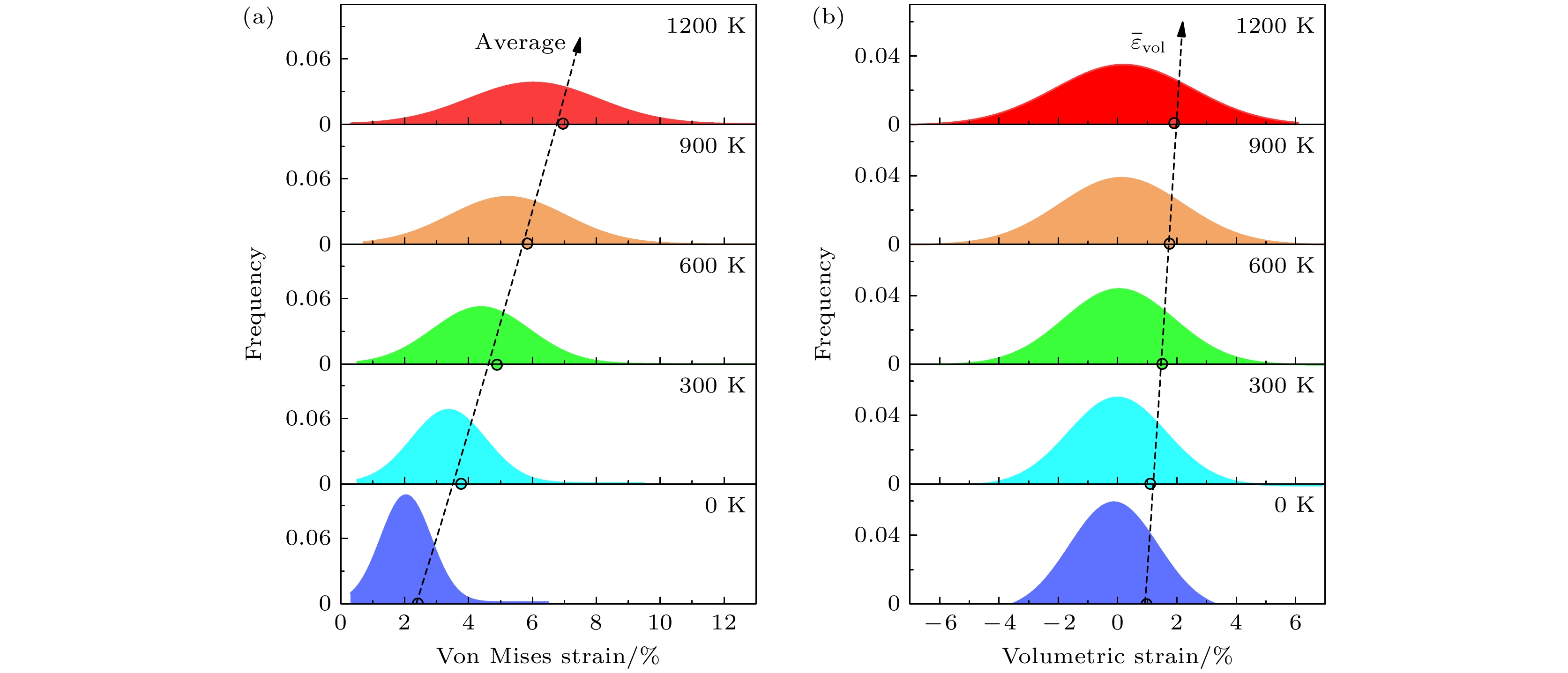

图 5 不同温度下TiZrNb合金的冯·米塞斯应变和体积应变频率分布图, 图中展示的温度范围从0—1200 K, 分别以不同颜色表示不同的温度状态 (a)冯·米塞斯应变的分布; (b)体积应变的分布

Fig. 5. Frequency distribution of von Mises strain and volumetric strain of TiZrNb alloy at various temperatures, ranging from 0 K to 1200 K: (a) Distribution of von Mises strain; (b) distribution of volumetric strain.

-

[1] George E P, Raabe D, Ritchie R O 2019 Nat. Rev. Mater. 4 515

Google Scholar

Google Scholar

[2] George E P, Curtin W A, Tasan C C 2020 Acta Mater. 188 435

Google Scholar

Google Scholar

[3] Miracle D B 2017 J. Met. 69 2130

Google Scholar

Google Scholar

[4] Pickering E J, Jones N G 2016 Int. Mater. Rev. 61 183

Google Scholar

Google Scholar

[5] Ma E, Ding J 2025 J. Mater. Sci. Technol. 220 233

Google Scholar

Google Scholar

[6] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[7] Li Z M, Pradeep K G, Deng F, Paabe D, Tasan C C 2016 Nature 534 227

Google Scholar

Google Scholar

[8] Maresca F, Curtin W A 2020 Acta Mater. 182 235

Google Scholar

Google Scholar

[9] Gludovatz B, Hohenwarter A, Catoor D, Chang E H, George E P, Ritchie P O 2014 Science 345 1153

Google Scholar

Google Scholar

[10] Shi Y Z, Yang B, Liaw P K 2017 Metals 7 18

Google Scholar

Google Scholar

[11] Chen P Y, Lee C, Wang S Y, Seifi M, Lewandowski J J, Dahmen K A, Jia H L, Xie X, Chen B L, Yeh J W, Tsai C W, Yuan T, Liaw P K 2018 Sci. China-Technol. Sci. 61 168

Google Scholar

Google Scholar

[12] Kozelj P, Vrtnik S, Jelen A, Jazbec S, Jaglicic Z, Maiti S, Feuerbacher M, Steurer W, Dolinsek J 2014 Phys. Rev. Lett. 113 107001

Google Scholar

Google Scholar

[13] Su Z X, Ding J, Song M, Jiang L, Shi Tan, Li Z M, Wang S, Gao F, Ma E Lu C Y 2023 Acta Mater. 245 118662

Google Scholar

Google Scholar

[14] Zhang Z, Su Z, Zhang B, Yu Q, Ding J, Shi T, Lu C, Ritchie R O, Ma E 2023 Proc. Natl. Acad. Sci. 120 e2218673120

Google Scholar

Google Scholar

[15] Zhang Y, Zuo T, Tang T, Gao M, Dahmen K, Liaw K, Lu Z 2014 Prog. Mater. Sci. 61 1

Google Scholar

Google Scholar

[16] Kozak P, Sologubenko A, Steurer W 2015 Z Kristallogr Cryst Mater 230 55

Google Scholar

Google Scholar

[17] Zhang B, Zhang Z, Xun K, Asta M, Ding J, Ma E 2024 Proc. Natl. Acad. Sci. 121 e2314248121

Google Scholar

Google Scholar

[18] Miracle D B, Senkov O N 2017 Acta Mater. 122 448

Google Scholar

Google Scholar

[19] Fan Z, Wang H, Wu Y, Liu X J, Lu Z P 2017 Mater. Res. Lett. 5 187

Google Scholar

Google Scholar

[20] Yeh J W, Chang S Y, Hong Y D, Chen S K, Lin S J 2007 Mater. Chem. Phys. 103 41

Google Scholar

Google Scholar

[21] Tong C J, Chen Y L, Chen S K, Yeh J W, Shun T T, Tsau C H, Lin S J, Chang S Y 2005 Metall. Mater. Trans. A 36 881

Google Scholar

Google Scholar

[22] Tsai C W, Tsai M H, Yeh J W, Yang C C 2010 J. Alloys Compd. 490 160

Google Scholar

Google Scholar

[23] Yeh J W, Chen S K, Gan J Y, Lin S J, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Metall. Mater. Trans. A 35 2533

Google Scholar

Google Scholar

[24] 杨勇, 赫全锋 2021 金属学报 57 385

Google Scholar

Google Scholar

Yang Y, He Q F 2021 Acta Metall. Sin. 57 385

Google Scholar

Google Scholar

[25] Zou Y, Maiti S, Steurer W, Spolenak R 2014 Acta Mater. 65 85

Google Scholar

Google Scholar

[26] Santodonato L J, Zhang Y, Feygenson M, Parish C M, Gao M C, Weber R J, Neuefeind J C, Tang Z, Liaw P K 2015 Nat. Commun. 6 5964

Google Scholar

Google Scholar

[27] Toda-Caraballo I, Wr obel J S, Dudarev S L, Nguyen-Manh D, Rivera-Díaz-del-Castillo P E 2015 Acta Mater. 97 156

Google Scholar

Google Scholar

[28] Tian L Y, Hu Q M, Yang R, Zhao J, Johansson B, Vitos L 2015 J. Phys. Condens. Mat. 27 315702

Google Scholar

Google Scholar

[29] Chen B, Li S Z, Ding J, Ding X D, Sun J, Ma E 2023 Scr. Mater. 222 115048

Google Scholar

Google Scholar

[30] Tandoc C, Hu Y J, Qi L, Liaw P K 2023 npj Comput. Mater. 9 53

Google Scholar

Google Scholar

[31] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[32] Yin S, Zuo Y X, Abu-Odeh A, Zhang H, Li X G, Ding J, Ong S P, Asta M, Ritchie R 2021 Nat. Commun. 12 4873

Google Scholar

Google Scholar

[33] Chen B, Li S Z, Ding J, Ding X D, Sun J, Ma E 2020 Proc. Natl. Acad. Sci. 117 16199

Google Scholar

Google Scholar

[34] Stukowski A 2010 Model. Simul. Mater. Sc. 18 015012

Google Scholar

Google Scholar

[35] Wang J H, Li J, Yip S, Phillpot S, Wolf D 1995 Phys. Rev. B 52 12627

Google Scholar

Google Scholar

[36] Li J 2003 Model. Simul. Mater. Sci. Eng. 11 173

Google Scholar

Google Scholar

[37] Wang L, Ding J, Chen S S, Jin K, Zhang Q H, Cui J X, Wang B P, Chen B, Li T Y, Ren Y, Zheng S J, Ming K S, Lu W J, Hou J H, Sha G, Liang J, Wang L, Xue Y F, Ma E 2023 Nat. Mater. 22 950

Google Scholar

Google Scholar

[38] Zhang M, Zhang B Z, Ding J, Ma E 2025 Scripta Mater. 259 116559

Google Scholar

Google Scholar

[39] Ding J, Yu Q, Asta M, O. Ritchie R 2018 Proc. Natl. Acad. Sci. 115 8919

Google Scholar

Google Scholar

[40] Zhang F X, Zhao S J, Jin K, Xue H, Velisa G, Bei H, Huang R, Ko J Y P, Pagan D C, Neuefeind J C, Weber W J, Zhang Y W 2017 Phys. Rev. Lett. 118 205501

Google Scholar

Google Scholar

[41] Zhang R P, Zhao S T, Ding J, Chong Y, Jia T, Ophus C, Asta M, O. Ritchie R, Minor M A. 2020 Nature 581 283

Google Scholar

Google Scholar

[42] Xun K H, Zhang B Z, Wang Q, Zhang Z, Ding J, Ma E 2023 J. Mater. Sci. Technol. 135 221

Google Scholar

Google Scholar

[43] Chen B, Li S Z, Ding J, Ding X D, Sun J, Ma E 2024 Acta Mater. 272 119910

Google Scholar

Google Scholar

[44] He Q F, Wang J G, Chen H A, Ding Z Y, Zhou Z Q, Xiong L H, Luan J H, Pelletier J M, Qiao J C, Wang Q, Fan L L, Zeng Q S, Liu C T, Pao C W, Srolovitz D J, Yang Y 2022 Nature 602 251

Google Scholar

Google Scholar

[45] Tan Y Y, Chen Z J, Su M Y, Ding G, Jiang M Q, Xie Z C, Gong Y, Wu T, Wu Z H, Wang H Y, Dai L H 2022 J. Mater. Sci. Technol. 104 236

Google Scholar

Google Scholar

计量

- 文章访问数: 2419

- PDF下载量: 133

- 被引次数: 0

下载:

下载: