-

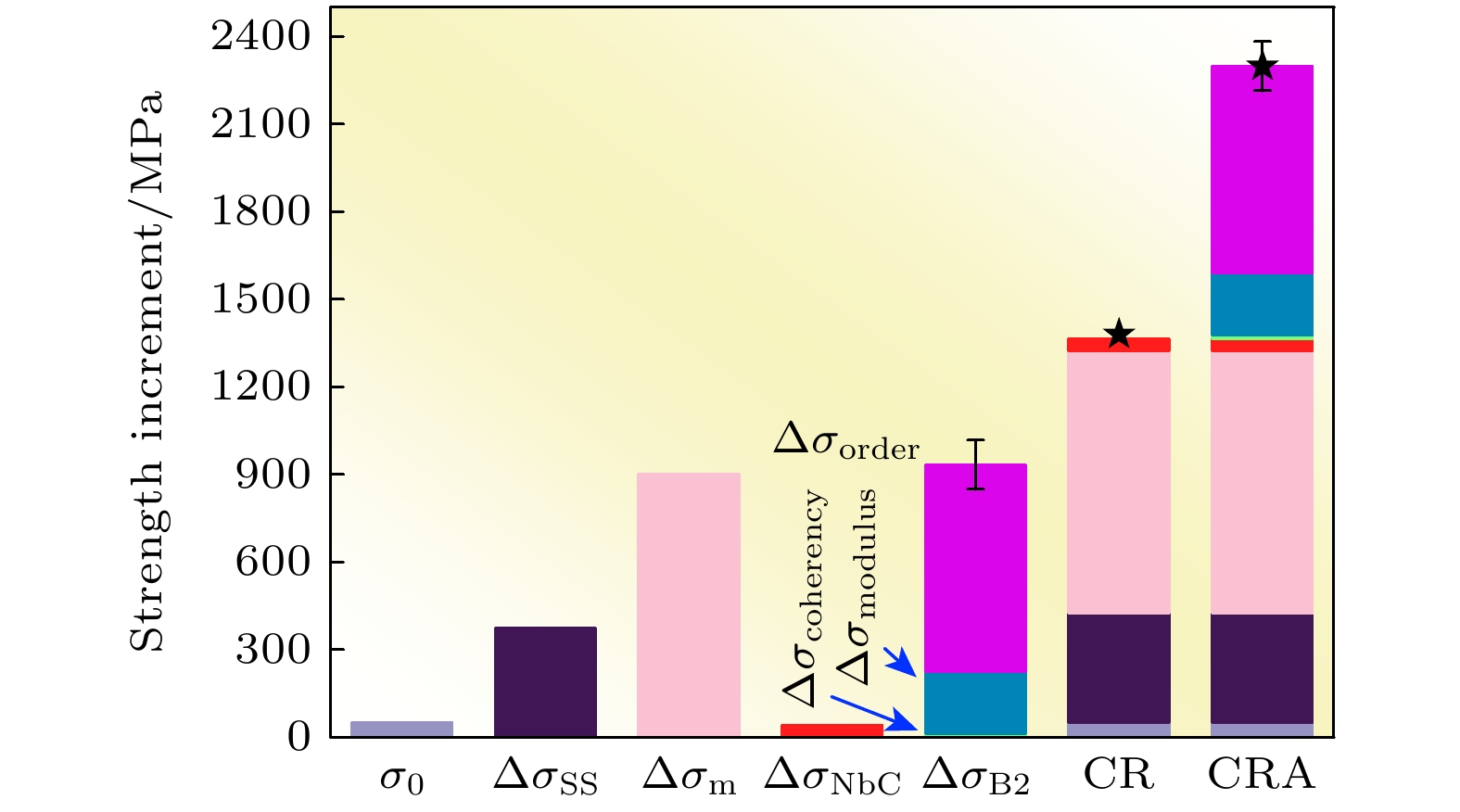

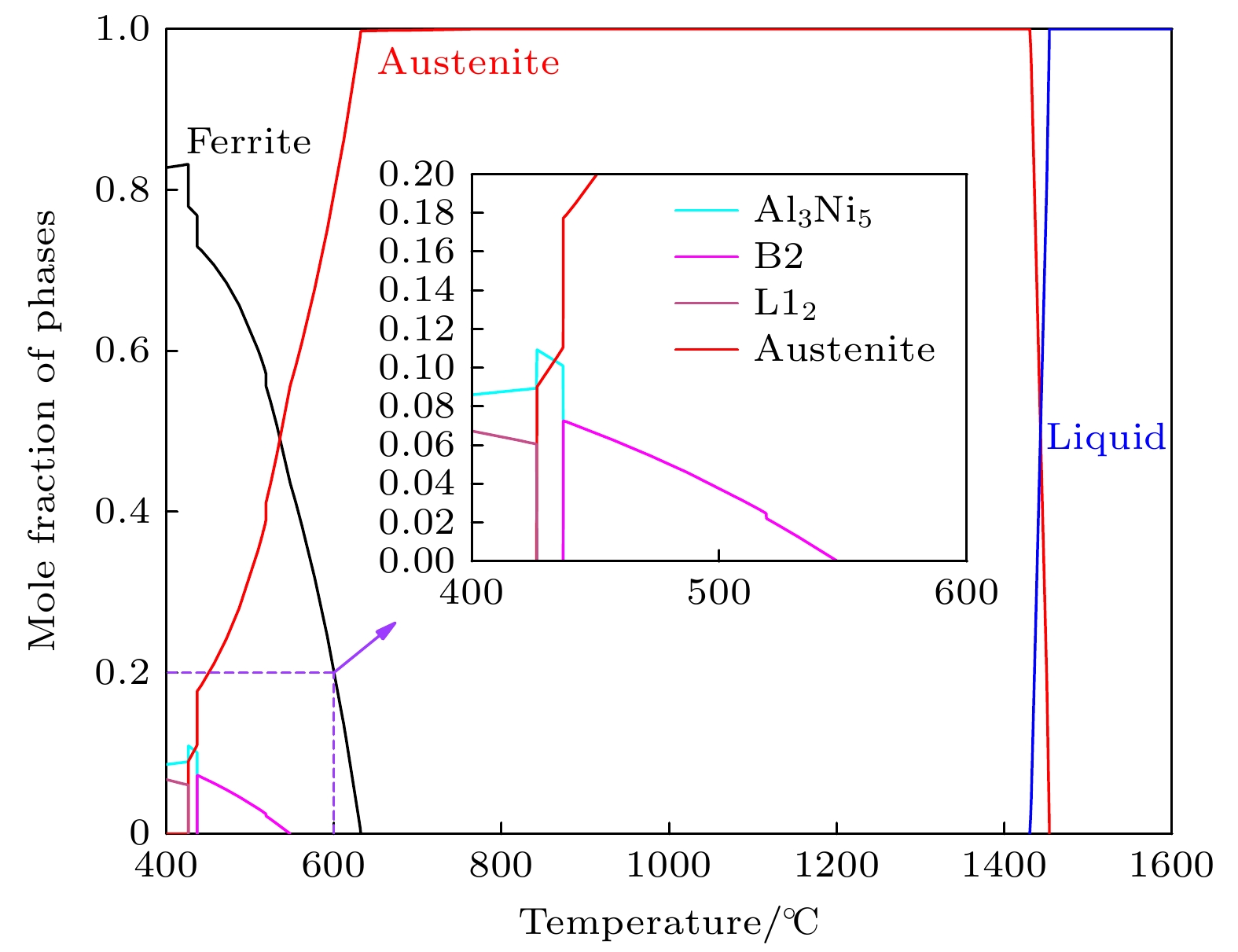

超高强度马氏体时效不锈钢同时拥有优异的强度及易加工等良好性能, 广泛应用于如飞机起落架等关键承载部件中. 然而, 由于析出的纳米粒子通常与体心立方(BCC)马氏体基体呈半共格或非共格关系, 传统马氏体时效不锈钢在追求超高强度的同时依然面临材料强韧性制衡这一难题. 本工作通过团簇式设计方法设计了一种新型共格析出强化的超高强度马氏体时效不锈钢(Fe-7.95Cr-13.47Ni-3.10Al-1.83Mo-0.03C-0.23Nb, 数字为各元素的质量百分含量). 实验结果表明, 该冷轧态不锈钢时效后马氏体组织晶粒破碎、拉长, 同时BCC马氏体基体中存在高密度位错(~1.8 × 10–3 nm–2)和大量的共格析出的B2-NiAl纳米粒子(< 5 nm). 力学性能方面, 该不锈钢在时效过程后表现出明显的时效硬化, 峰值时效硬度达到651 HV. 并且该不锈钢不仅具有极高的屈服强度(σYS = 2.3 GPa), 而且具有良好的断后延伸率(El = 3.6%), 表明实现了良好的强塑性匹配. 最后, 对该不锈钢的超高强度来源进行深入讨论, 发现该不锈钢的超高强度来自于各不同微观结构的强化作用. 本工作为进一步设计开发出高性能超高强度马氏体时效不锈钢提供了有价值的参考.Ultra-high strength maraging stainless steels possess many important applications such as in aircraft landing gears owing to their excellent strength and good process ability. However, traditional ultra-high strength maraging stainless steels are facing the challenge of balancing strength and ductility while pursuing ultra-high strength. This is mainly due to the semi-coherent or non-coherent relationship between the precipitated nanoparticles and the body-centered cubic (BCC) martensitic matrix. In this work, a novel ultra-high strength maraging stainless steel (Fe-7.95Cr-13.47Ni-3.10Al-1.83Mo-0.03C-0.23Nb, weight percent, %) is designed using a cluster formula approach. Alloy ingots are prepared by vacuum induction melting under an argon atmosphere, followed by hot rolling at 950 ℃ and multiple passes of cold rolling. Finally, the alloy is aged at 500 ℃ for 288 h. Microstructural characterizations of the alloy in different aging states are performed using electron backscatter diffraction (EBSD) and transmission electron microscope (TEM). As a result, the martensitic structure of the alloy is fragmented and elongated, with high-density dislocations (~1.8×10–3 nm–2) and a large number of coherent B2-NiAl nanoparticles (<5 nm) observed in the BCC martensitic matrix after cold rolling and aging. In terms of mechanical properties, the alloy exhibits significant age-hardening, with a peak-aged hardness of 651 HV after ageing treatment. It also demonstrates an extraordinarily high yield strength (σYS = 2.3 GPa) and a decent elongation (El = 3.6%), indicating a well-balanced strength-ductility property. Finally, the origins of the ultra-high strength in the novel alloy are discussed in depth, showing that the ultra-high strength of this stainless steel comes from the strengthening effect of different microstructures. This study provides valuable guidance for designing high-performance ultra-high strength maraging stainless steels.

-

Keywords:

- maraging stainless steel /

- ultra-high strength /

- coherent precipitation /

- strengthening mechanisms

[1] 杨柯, 牛梦超, 田家龙, 王威 2018 金属学报 54 1567

Google Scholar

Google Scholar

Yang K, Niu M C, Tian J L, Wang W 2018 Acta. Metall. Sin. 54 1567

Google Scholar

Google Scholar

[2] 罗海文, 沈国慧 2020 金属学报 56 494

Google Scholar

Google Scholar

Luo H W, Shen G H 2020 Acta. Metall. Sin. 56 494

Google Scholar

Google Scholar

[3] Sun W W, Marceau R K W, Styles M J, Barbier D, Hutchinson C R 2017 Acta Mater. 130 28

Google Scholar

Google Scholar

[4] Morris Jr J W 2017 Nat. Mater. 16 787

Google Scholar

Google Scholar

[5] Yang J R, Yu T H, Wang C H 2006 Mater. Sci. Eng. A 438 276

[6] Shi X H, Zeng W D, Zhao Q Y, Peng W W, Kang C 2016 J. Alloys. Compd. 679 184

Google Scholar

Google Scholar

[7] Wert D E, DiSabella R P 2006 Adv. Mater. Process. 164 34

[8] Ifergane S, Pinkas M, Barkayc Z, Brosh E, Ezersky V, Beeri O, Eliaz N 2017 Mater. Charact. 127 129

Google Scholar

Google Scholar

[9] Floreen S 1968 Metall. Rev. 13 115

Google Scholar

Google Scholar

[10] Tewari R, Mazumder S, Batra I S, Dey G K, Banerjee S 2000 Acta Mater. 48 1187

Google Scholar

Google Scholar

[11] Xu W, Rivera-Díaz-del-Castillo P E J, Yan W, Yang K, San Martín D, Kestens L A I, van der Zwaag S 2010 Acta Mater. 58 4067

Google Scholar

Google Scholar

[12] Qi L, Jin Y C, Zhao Y H, Yang X M, Zhao H, Han P D 2015 J. Alloys. Compd. 621 383

Google Scholar

Google Scholar

[13] Moshka O, Pinkas M., Brosh E, Ezersky V, Meshi L 2015 Mater. Sci. Eng. A 638 232

Google Scholar

Google Scholar

[14] 周倩青, 翟玉春 2009 金属学报 45 1249

Google Scholar

Google Scholar

Zhou Q Q, Zhai Y C 2009 Acta Metall. Sin. 45 1249

Google Scholar

Google Scholar

[15] Hättestrand M, Nilsson J O, Stiller K, Liu P, Andersson M 2004 Acta Mater. 52 1023

Google Scholar

Google Scholar

[16] Ghosh A, Das S, Chatterjee S 2008 Mater. Sci. Eng. A 486 152

Google Scholar

Google Scholar

[17] Mahmoudi A, Zamanzad Ghavidel M R, Hossein Nedjad S, Heidarzadeh A, Nili Ahmadabadi M 2011 Mater. Charact. 62 976

Google Scholar

Google Scholar

[18] Leitner H, Schnitzer R, Schober M, Zinner S 2011 Acta Mater. 59 5012

Google Scholar

Google Scholar

[19] Vaithyanathan V, Chen L Q 2002 Acta Mater. 50 4061

Google Scholar

Google Scholar

[20] Li H, Liu Y, Liu B 2022 Mater. Sci. Eng. A 842 143099

Google Scholar

Google Scholar

[21] Niu M C, Zhou G, Wang W, Shahzad M B, Shan Y Y, Yang K 2019 Acta Mater. 179 296

Google Scholar

Google Scholar

[22] Wan J Q, Ruan H H, Ding Z Y, Kong L B 2023 Scr. Mater. 226 115224

Google Scholar

Google Scholar

[23] Li K, Yu B, Misra R D K, Han G, Liu S, Shang C J 2018 Mater. Sci. Eng. A 715 485

[24] Ooi S W, Hill P, Rawson M, Bhadeshia H K D H 2013 Mater. Sci. Eng. A 564 485

Google Scholar

Google Scholar

[25] Liu T Q, Cao Z X, Wang H, Wu G L, Jin J J, Cao W Q 2020 Scr. Mater. 178 285

Google Scholar

Google Scholar

[26] Li Y C, Yan W, J. D. Cotton, G. J. Ryan, Shen Y F, Wang W, Shan Y Y, Yang K 2015 Mater. Des. 82 56

Google Scholar

Google Scholar

[27] Hedströma P, Baghsheikhi S, Liu P, Odqvist J 2012 Mater. Sci. Eng. A 534 552

Google Scholar

Google Scholar

[28] Li J L, Zhang J Q, Li Z, Wang Q, Dong C, Xu F, Sun L X, Liaw P K 2024 J. Mater. Sci. Technol. 186 174

Google Scholar

Google Scholar

[29] Zhang J X, Wang J C, Harada H, Koizumi Y 2005 Acta Mater. 53 4623

Google Scholar

Google Scholar

[30] Wang Z H, Wang Q, Niu B, Dong C, Zhang H W, Zhang H F, Liaw P K 2021 Mater. Res. Lett. 9 458

Google Scholar

Google Scholar

[31] Jiang S H, Wang H, Wu Y, Liu X J, Chen H H, Yao M J, Gault B, Ponge D, Raabe D, Hirata A, Chen M W, Wang Y D, Lu Z P 2017 Nature 544 460

Google Scholar

Google Scholar

[32] Zhou B C, Liu S F, Wu H H, Luan J H, Guo J M, Yang T, Jiao Z B 2023 Mater. Des. 234 112341

Google Scholar

Google Scholar

[33] Liang Y J, Wang L J, Wen Y R, Cheng B Y, Wu Q L, Cao T Q, Xiao Q, Xue Y F, Sha G, Wang Y D, Ren Y, Li X Y, Wang L, Wang F C, Cai H N 2018 Nat. Commun. 9 4063

Google Scholar

Google Scholar

[34] Hong H L, Wang Q, Dong C, Liaw P K 2014 Sci. Rep. 4 7065

Google Scholar

Google Scholar

[35] Pang C, Jiang B B, Shi Y, Wang Q, Dong C 2015 J. Alloys. Compd. 652 63

Google Scholar

Google Scholar

[36] Wang Z H, Niu B, Wang Q, Dong C, Jie J C, Wang T M, Nieh T G 2021 J. Mater. Sci. Technol. 93 60

Google Scholar

Google Scholar

[37] Calderon H A, Fine M E, Weertman J R 1987 Metall. Trans. A 19 1135

[38] Vo N Q, Liebscher C H, Rawlings M J S, Asta M, Dunand D C 2014 Acta Mater. 71 89

Google Scholar

Google Scholar

[39] Czyryca E J 1993 Key Eng. Mater. 84 491

[40] Wen D H, Wang Q, Jiang B B, Zhang C, Li X N, Chen G Q, Tang R, Zhang R Q, Dong C, P. K. Liaw 2018 Mater. Sci. Eng. A 719 27

Google Scholar

Google Scholar

[41] Bailey N 1993 Welding Steels without Hydrogen Cracking (Cambridge: Woodhead Publishing) p69

[42] Briant C L, Banerji S K 1978 Int. Metal. Rev. 23 164

[43] Hosford W F 2005 Mechanical Behavior of Materials (New York: Cambridge University Press) p16

[44] Leitner H, Schober M, Schnitzer R 2010 Acta Mater. 58 1261

Google Scholar

Google Scholar

[45] 毕正绪 2014 特钢技术 20 11

Google Scholar

Google Scholar

Bi Z X 2014 Special Steel Technol. 20 11

Google Scholar

Google Scholar

[46] Galindo-Nava E I, Rivera-Díaz-del-Castillo P E J 2015 Acta Mater. 98 81

Google Scholar

Google Scholar

[47] Galindo-Nava E I, Rainforth W M, Rivera-Díaz-del-Castillo P E J 2016 Acta Mater. 117 270

Google Scholar

Google Scholar

[48] Rivera-Díaz-del-Castillo P E J, Hayashi K, Galindo-Nava E I 2013 Mater. Sci. Technol. 29 1206

Google Scholar

Google Scholar

[49] Fleischer R L 1961 Acta Matall. 9 966

Google Scholar

Google Scholar

[50] Lide D R 2008 CRC Handbook of Chemistry and Physics (Boca Raton: CRC Press) pp12–10

[51] Morito S, Yoshida H, Maki T, Huang X 2006 Mater. Sci. Eng. A 438 237

[52] Su J, Raabe D, Li Z M 2019 Acta Mater. 163 40

Google Scholar

Google Scholar

[53] Kocks U F, Mecking H 2003 Prog. Mater Sci. 48 171

Google Scholar

Google Scholar

[54] Nembach E 1997 Mater. Sci. Technol. 3 329

[55] Gladman T 1999 Mater. Sci. J. 15 30

[56] Argon A 2007 Strengthening Mechanisms in Crystal Plasticity (Oxford: Oxford University Press) p74

[57] P. M. Kelley 1973 Int. Metall. Rev. 18 31

Google Scholar

Google Scholar

[58] A. Kelly, R. B. Nicholson 1971 Strengthening Methods in Crystals (London: Elsevier) p37

[59] T. Hong, A. J. Freeman 1991 Phys. Rev. B Condens. Matter. 43 6446

Google Scholar

Google Scholar

-

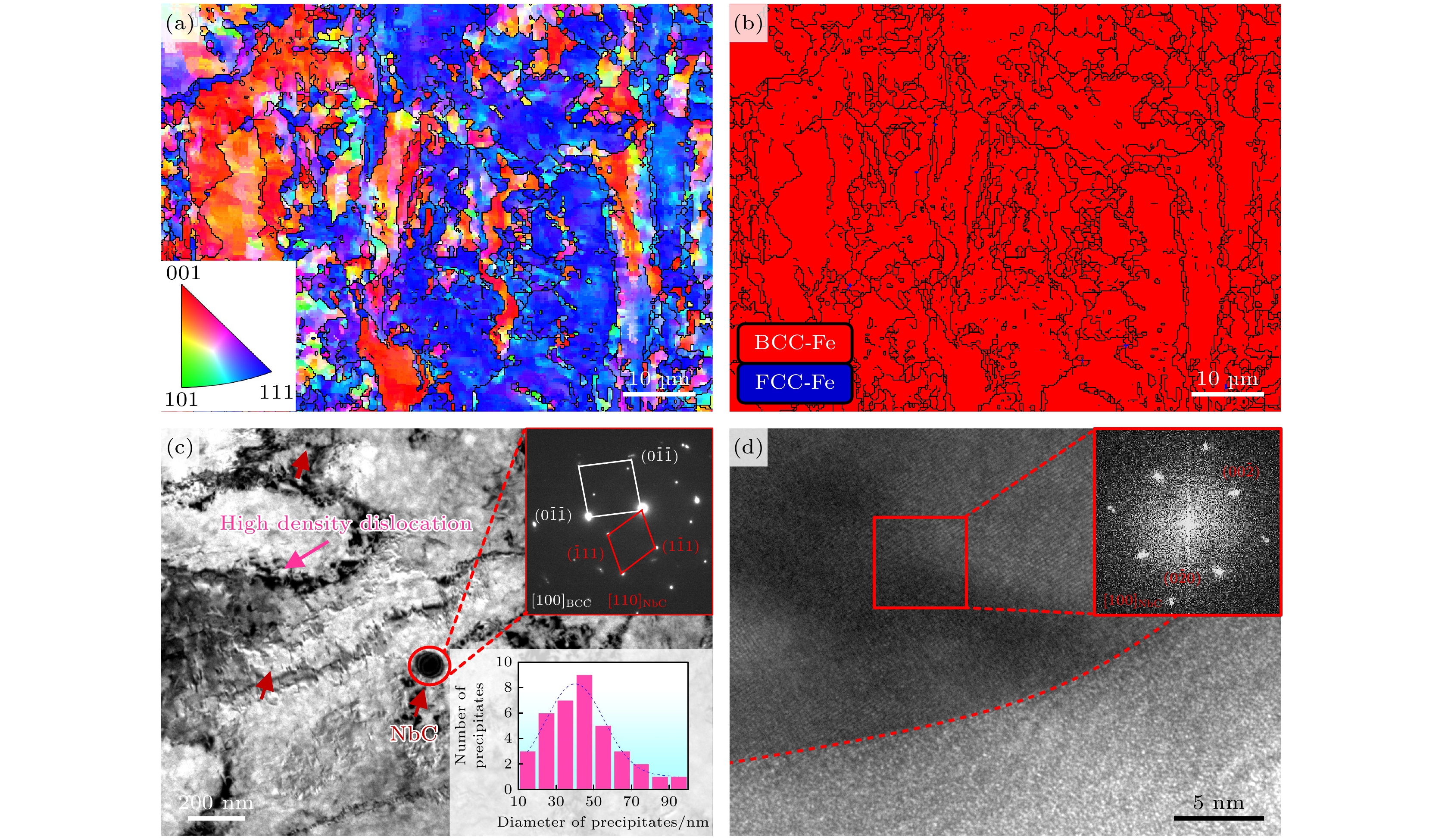

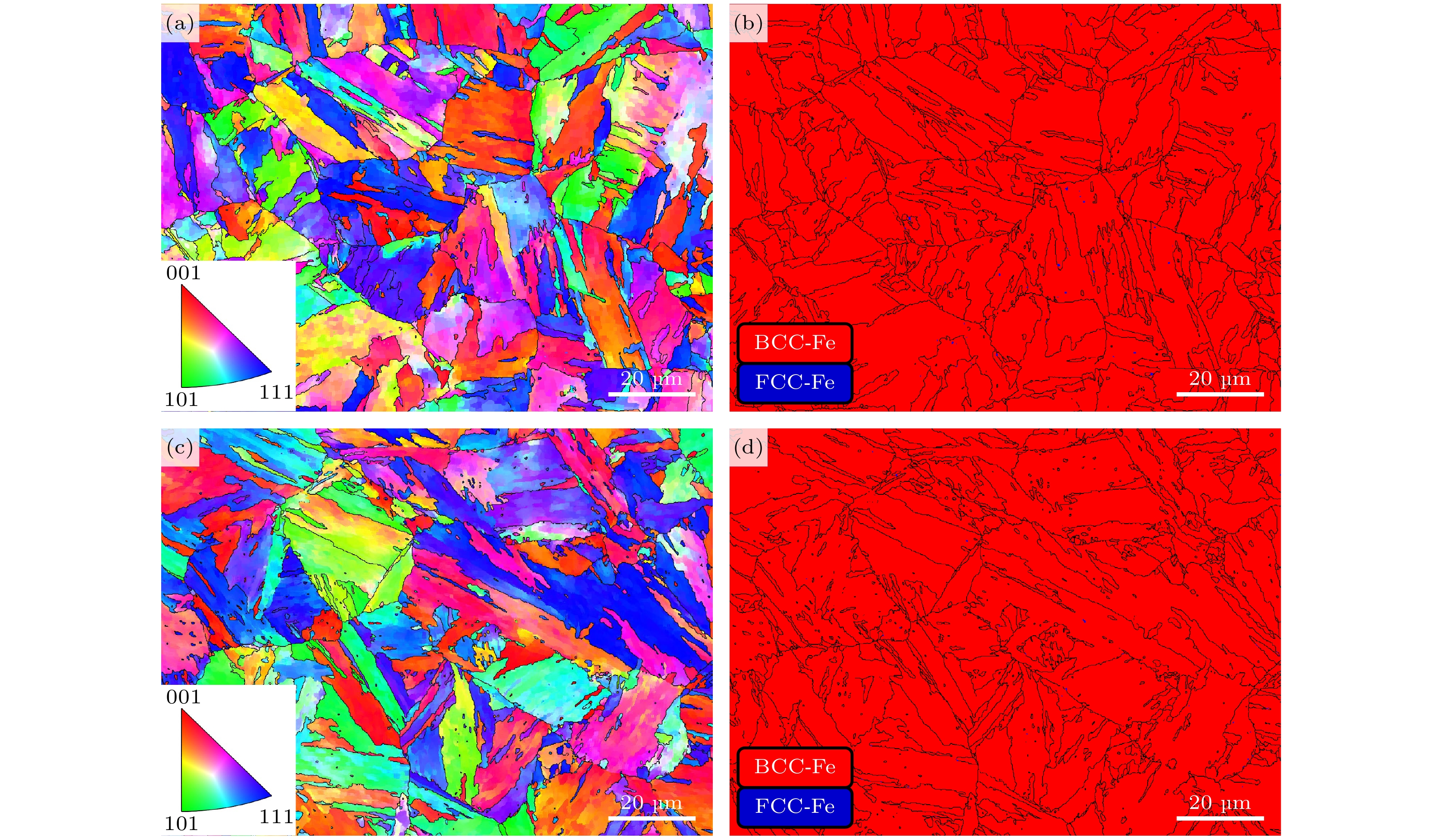

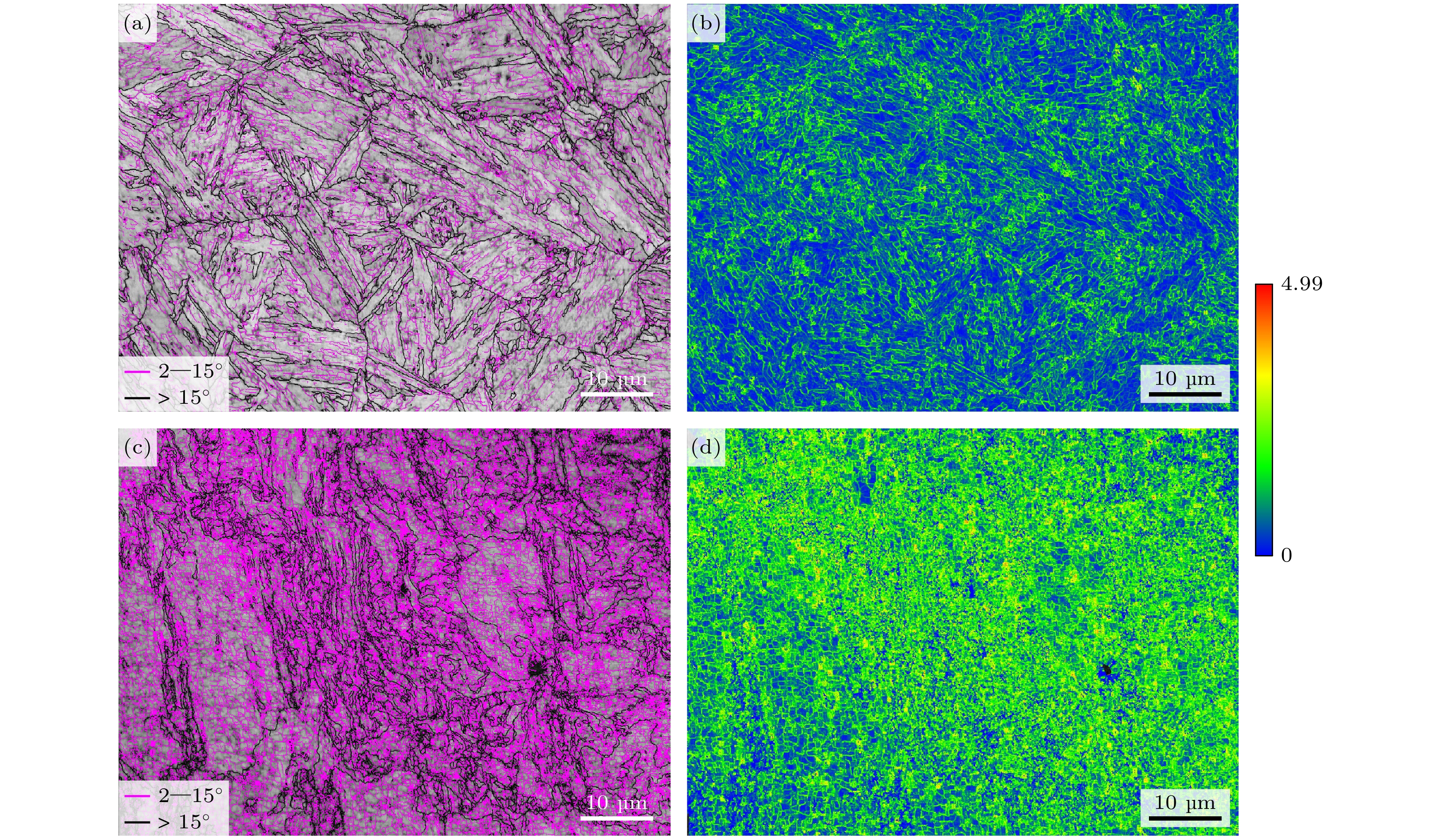

图 2 合金冷轧态(CR)的EBSD反极图(IPF)和相分布图(a), (b); 冷轧态合金TEM明场像及其对应的SAED花样(c); HRTEM图像及其对应的FTT图像(d)

Fig. 2. EBSD IPF image and phase image of the designed alloy after cold-rolling (CR) treatment (a), (b); TEM bright-field (BF) image and corresponding SAED patterns (c) and High-resolution TEM image and its FTT pattern (d) of CR.

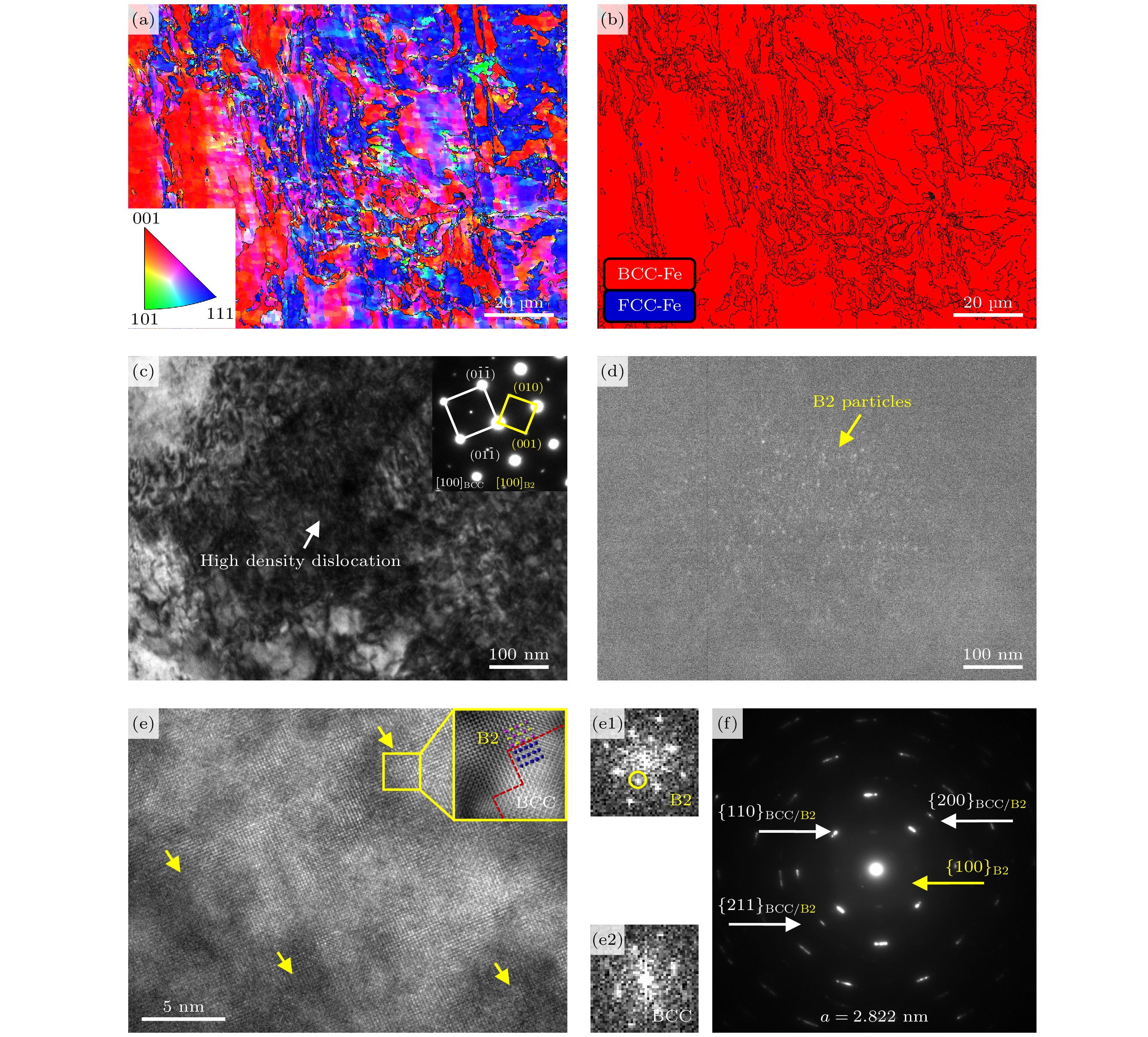

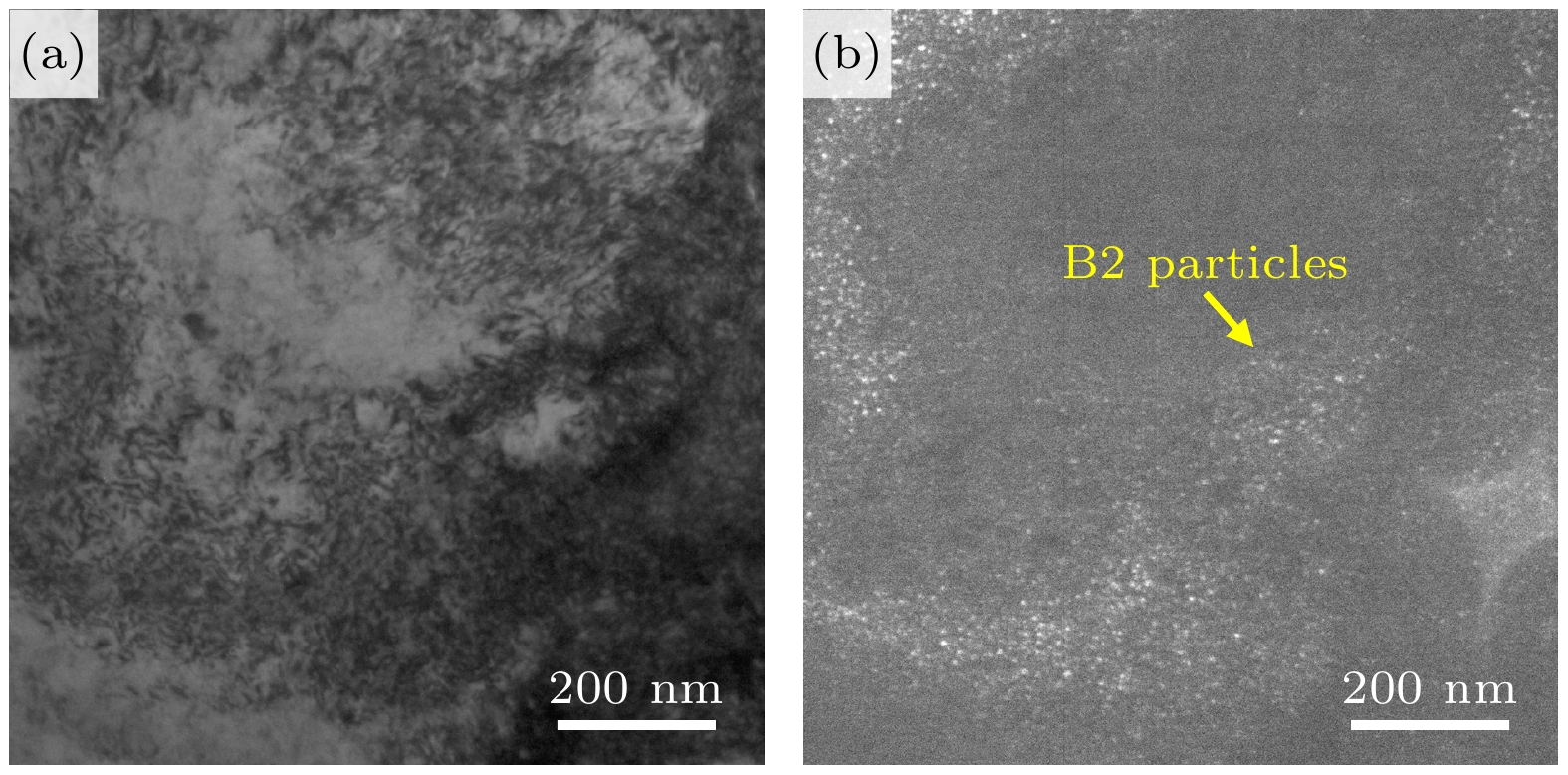

图 3 12 h时效后CRA合金的微观结构 合金冷轧+时效态(CRA)的EBSD反极图(IPF)和相分布图(a), (b); CRA合金TEM明场、暗场像及其对应的SAED花样(c), (d); CRA合金HRTEM图像及其对应的FTT图像(e), (e1), (e2), 以及衍射环图像(f)

Fig. 3. Microstructures of 12 h-aged CRA alloys: EBSD IPF image and phase image of the CRA alloy (a), (b); TEM bright-field (BF) image and corresponding SAED patterns (c), TEM DF image (d); HRTEM image and its FTT patterns (e), (e1), (e2), and diffraction ring (f) of the CRA alloy.

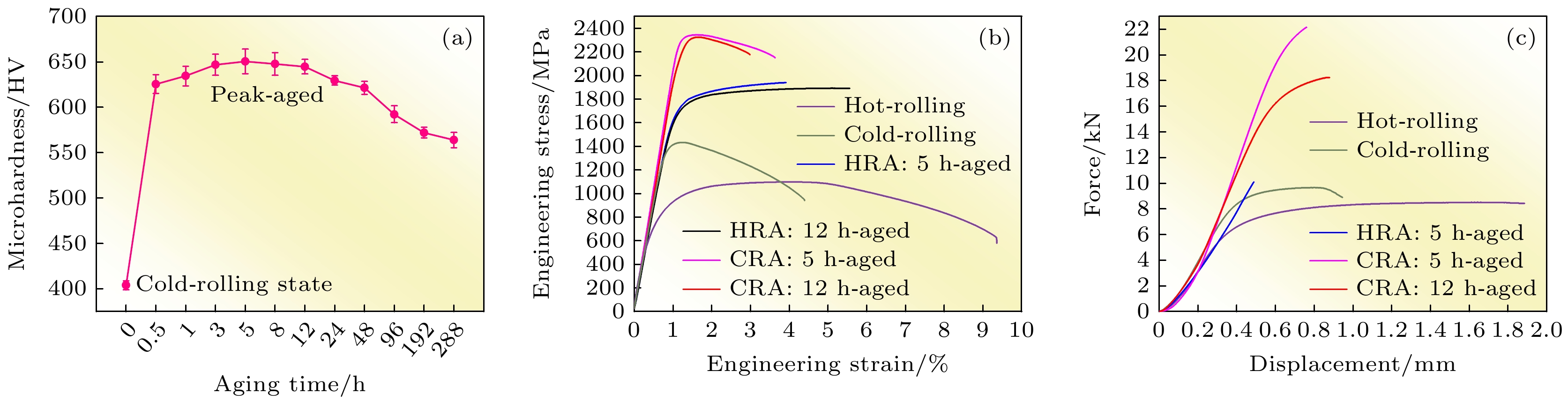

图 7 CRA合金在500 ℃时效时显微硬度随时效时间的变化(a), 不同热处理状态下合金在室温拉伸下的工程应力-应变曲线(b)和室温三点弯曲下的载荷-位移曲线(c)

Fig. 7. Variation tendency of microhardness of the CRA alloy with aging time at 500℃ (a), room-temperature engineering stress-strain tensile curves of the current alloy at different heat-treated (b), and 3-points bending test of the current alloy at different heat-treated (c).

表 1 不同热处理状态下设计合金以及18 Ni(300)[45]的H, σYS, σUTS, El, 极限弯曲载荷(FB), 及极限弯曲角度(θB)

Table 1. Mechanical properties of the current stainless steel at different heat-treated states and the 18 Ni(300) steel[45], including microhardness (H), yield strength (σYS), ultimate tensile strength (σUTS), elongation to fracture (El), ultimate bending force (FB), and ultimate bending angle (θB).

States H/HV σYS/MPa σUTS/MPa El/% FB/kN θB/(°) HR 326±10 787 1100 9.3 8.5 35.5 CR 404±5 1408 1432 4.4 9.7 14.9 HRA: 5 h-aged 573±6 1704 1940 3.9 10.1 9.7 CRA: 5 h-aged 645±6 2326 2344 3.6 22.2 15.4 CRA: 12 h-aged 641±8 2254 2324 3.0 18.2 17.9 18 Ni(300) — 2000 2050 7.0 — — -

[1] 杨柯, 牛梦超, 田家龙, 王威 2018 金属学报 54 1567

Google Scholar

Google Scholar

Yang K, Niu M C, Tian J L, Wang W 2018 Acta. Metall. Sin. 54 1567

Google Scholar

Google Scholar

[2] 罗海文, 沈国慧 2020 金属学报 56 494

Google Scholar

Google Scholar

Luo H W, Shen G H 2020 Acta. Metall. Sin. 56 494

Google Scholar

Google Scholar

[3] Sun W W, Marceau R K W, Styles M J, Barbier D, Hutchinson C R 2017 Acta Mater. 130 28

Google Scholar

Google Scholar

[4] Morris Jr J W 2017 Nat. Mater. 16 787

Google Scholar

Google Scholar

[5] Yang J R, Yu T H, Wang C H 2006 Mater. Sci. Eng. A 438 276

[6] Shi X H, Zeng W D, Zhao Q Y, Peng W W, Kang C 2016 J. Alloys. Compd. 679 184

Google Scholar

Google Scholar

[7] Wert D E, DiSabella R P 2006 Adv. Mater. Process. 164 34

[8] Ifergane S, Pinkas M, Barkayc Z, Brosh E, Ezersky V, Beeri O, Eliaz N 2017 Mater. Charact. 127 129

Google Scholar

Google Scholar

[9] Floreen S 1968 Metall. Rev. 13 115

Google Scholar

Google Scholar

[10] Tewari R, Mazumder S, Batra I S, Dey G K, Banerjee S 2000 Acta Mater. 48 1187

Google Scholar

Google Scholar

[11] Xu W, Rivera-Díaz-del-Castillo P E J, Yan W, Yang K, San Martín D, Kestens L A I, van der Zwaag S 2010 Acta Mater. 58 4067

Google Scholar

Google Scholar

[12] Qi L, Jin Y C, Zhao Y H, Yang X M, Zhao H, Han P D 2015 J. Alloys. Compd. 621 383

Google Scholar

Google Scholar

[13] Moshka O, Pinkas M., Brosh E, Ezersky V, Meshi L 2015 Mater. Sci. Eng. A 638 232

Google Scholar

Google Scholar

[14] 周倩青, 翟玉春 2009 金属学报 45 1249

Google Scholar

Google Scholar

Zhou Q Q, Zhai Y C 2009 Acta Metall. Sin. 45 1249

Google Scholar

Google Scholar

[15] Hättestrand M, Nilsson J O, Stiller K, Liu P, Andersson M 2004 Acta Mater. 52 1023

Google Scholar

Google Scholar

[16] Ghosh A, Das S, Chatterjee S 2008 Mater. Sci. Eng. A 486 152

Google Scholar

Google Scholar

[17] Mahmoudi A, Zamanzad Ghavidel M R, Hossein Nedjad S, Heidarzadeh A, Nili Ahmadabadi M 2011 Mater. Charact. 62 976

Google Scholar

Google Scholar

[18] Leitner H, Schnitzer R, Schober M, Zinner S 2011 Acta Mater. 59 5012

Google Scholar

Google Scholar

[19] Vaithyanathan V, Chen L Q 2002 Acta Mater. 50 4061

Google Scholar

Google Scholar

[20] Li H, Liu Y, Liu B 2022 Mater. Sci. Eng. A 842 143099

Google Scholar

Google Scholar

[21] Niu M C, Zhou G, Wang W, Shahzad M B, Shan Y Y, Yang K 2019 Acta Mater. 179 296

Google Scholar

Google Scholar

[22] Wan J Q, Ruan H H, Ding Z Y, Kong L B 2023 Scr. Mater. 226 115224

Google Scholar

Google Scholar

[23] Li K, Yu B, Misra R D K, Han G, Liu S, Shang C J 2018 Mater. Sci. Eng. A 715 485

[24] Ooi S W, Hill P, Rawson M, Bhadeshia H K D H 2013 Mater. Sci. Eng. A 564 485

Google Scholar

Google Scholar

[25] Liu T Q, Cao Z X, Wang H, Wu G L, Jin J J, Cao W Q 2020 Scr. Mater. 178 285

Google Scholar

Google Scholar

[26] Li Y C, Yan W, J. D. Cotton, G. J. Ryan, Shen Y F, Wang W, Shan Y Y, Yang K 2015 Mater. Des. 82 56

Google Scholar

Google Scholar

[27] Hedströma P, Baghsheikhi S, Liu P, Odqvist J 2012 Mater. Sci. Eng. A 534 552

Google Scholar

Google Scholar

[28] Li J L, Zhang J Q, Li Z, Wang Q, Dong C, Xu F, Sun L X, Liaw P K 2024 J. Mater. Sci. Technol. 186 174

Google Scholar

Google Scholar

[29] Zhang J X, Wang J C, Harada H, Koizumi Y 2005 Acta Mater. 53 4623

Google Scholar

Google Scholar

[30] Wang Z H, Wang Q, Niu B, Dong C, Zhang H W, Zhang H F, Liaw P K 2021 Mater. Res. Lett. 9 458

Google Scholar

Google Scholar

[31] Jiang S H, Wang H, Wu Y, Liu X J, Chen H H, Yao M J, Gault B, Ponge D, Raabe D, Hirata A, Chen M W, Wang Y D, Lu Z P 2017 Nature 544 460

Google Scholar

Google Scholar

[32] Zhou B C, Liu S F, Wu H H, Luan J H, Guo J M, Yang T, Jiao Z B 2023 Mater. Des. 234 112341

Google Scholar

Google Scholar

[33] Liang Y J, Wang L J, Wen Y R, Cheng B Y, Wu Q L, Cao T Q, Xiao Q, Xue Y F, Sha G, Wang Y D, Ren Y, Li X Y, Wang L, Wang F C, Cai H N 2018 Nat. Commun. 9 4063

Google Scholar

Google Scholar

[34] Hong H L, Wang Q, Dong C, Liaw P K 2014 Sci. Rep. 4 7065

Google Scholar

Google Scholar

[35] Pang C, Jiang B B, Shi Y, Wang Q, Dong C 2015 J. Alloys. Compd. 652 63

Google Scholar

Google Scholar

[36] Wang Z H, Niu B, Wang Q, Dong C, Jie J C, Wang T M, Nieh T G 2021 J. Mater. Sci. Technol. 93 60

Google Scholar

Google Scholar

[37] Calderon H A, Fine M E, Weertman J R 1987 Metall. Trans. A 19 1135

[38] Vo N Q, Liebscher C H, Rawlings M J S, Asta M, Dunand D C 2014 Acta Mater. 71 89

Google Scholar

Google Scholar

[39] Czyryca E J 1993 Key Eng. Mater. 84 491

[40] Wen D H, Wang Q, Jiang B B, Zhang C, Li X N, Chen G Q, Tang R, Zhang R Q, Dong C, P. K. Liaw 2018 Mater. Sci. Eng. A 719 27

Google Scholar

Google Scholar

[41] Bailey N 1993 Welding Steels without Hydrogen Cracking (Cambridge: Woodhead Publishing) p69

[42] Briant C L, Banerji S K 1978 Int. Metal. Rev. 23 164

[43] Hosford W F 2005 Mechanical Behavior of Materials (New York: Cambridge University Press) p16

[44] Leitner H, Schober M, Schnitzer R 2010 Acta Mater. 58 1261

Google Scholar

Google Scholar

[45] 毕正绪 2014 特钢技术 20 11

Google Scholar

Google Scholar

Bi Z X 2014 Special Steel Technol. 20 11

Google Scholar

Google Scholar

[46] Galindo-Nava E I, Rivera-Díaz-del-Castillo P E J 2015 Acta Mater. 98 81

Google Scholar

Google Scholar

[47] Galindo-Nava E I, Rainforth W M, Rivera-Díaz-del-Castillo P E J 2016 Acta Mater. 117 270

Google Scholar

Google Scholar

[48] Rivera-Díaz-del-Castillo P E J, Hayashi K, Galindo-Nava E I 2013 Mater. Sci. Technol. 29 1206

Google Scholar

Google Scholar

[49] Fleischer R L 1961 Acta Matall. 9 966

Google Scholar

Google Scholar

[50] Lide D R 2008 CRC Handbook of Chemistry and Physics (Boca Raton: CRC Press) pp12–10

[51] Morito S, Yoshida H, Maki T, Huang X 2006 Mater. Sci. Eng. A 438 237

[52] Su J, Raabe D, Li Z M 2019 Acta Mater. 163 40

Google Scholar

Google Scholar

[53] Kocks U F, Mecking H 2003 Prog. Mater Sci. 48 171

Google Scholar

Google Scholar

[54] Nembach E 1997 Mater. Sci. Technol. 3 329

[55] Gladman T 1999 Mater. Sci. J. 15 30

[56] Argon A 2007 Strengthening Mechanisms in Crystal Plasticity (Oxford: Oxford University Press) p74

[57] P. M. Kelley 1973 Int. Metall. Rev. 18 31

Google Scholar

Google Scholar

[58] A. Kelly, R. B. Nicholson 1971 Strengthening Methods in Crystals (London: Elsevier) p37

[59] T. Hong, A. J. Freeman 1991 Phys. Rev. B Condens. Matter. 43 6446

Google Scholar

Google Scholar

计量

- 文章访问数: 3423

- PDF下载量: 233

- 被引次数: 0

下载:

下载: