-

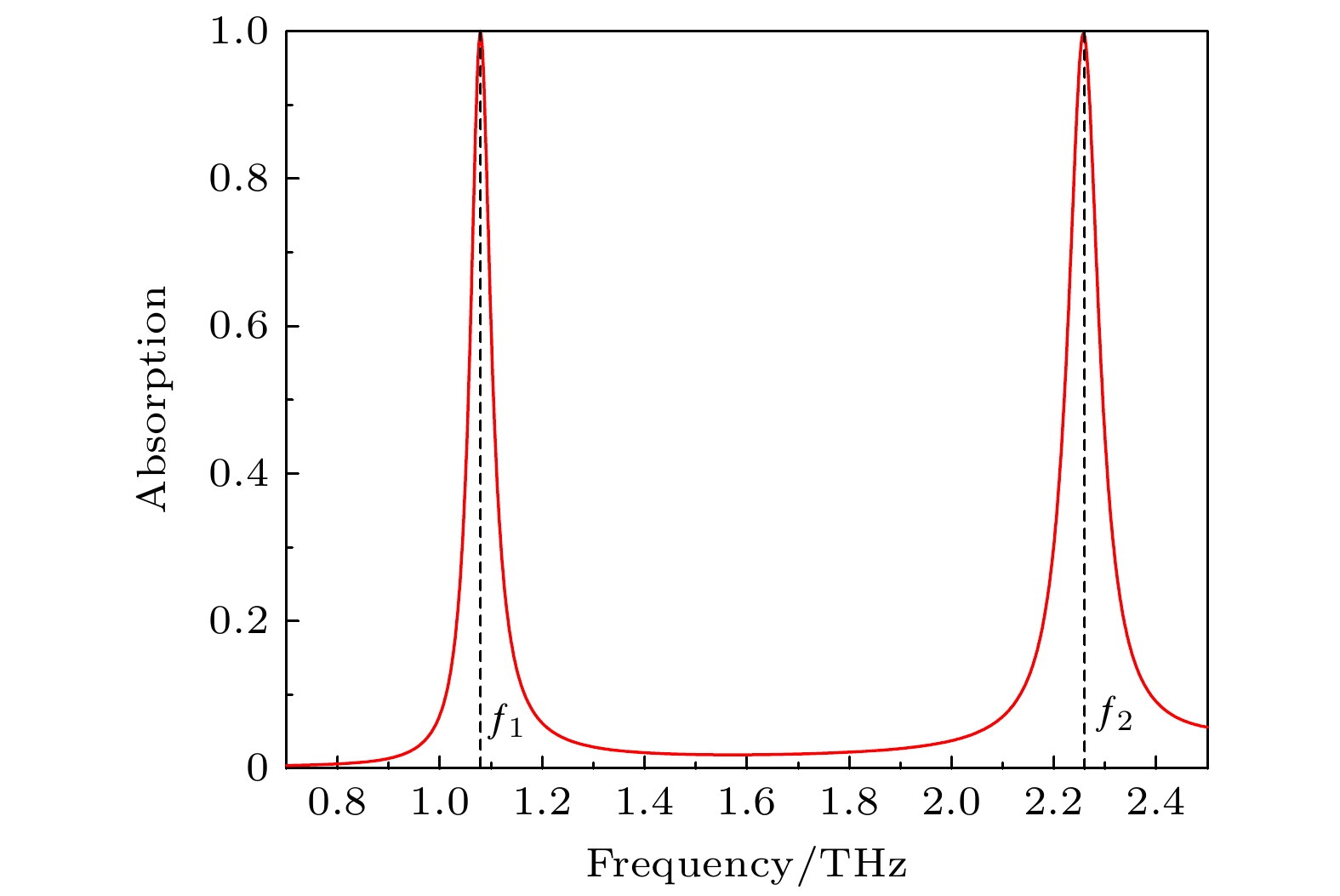

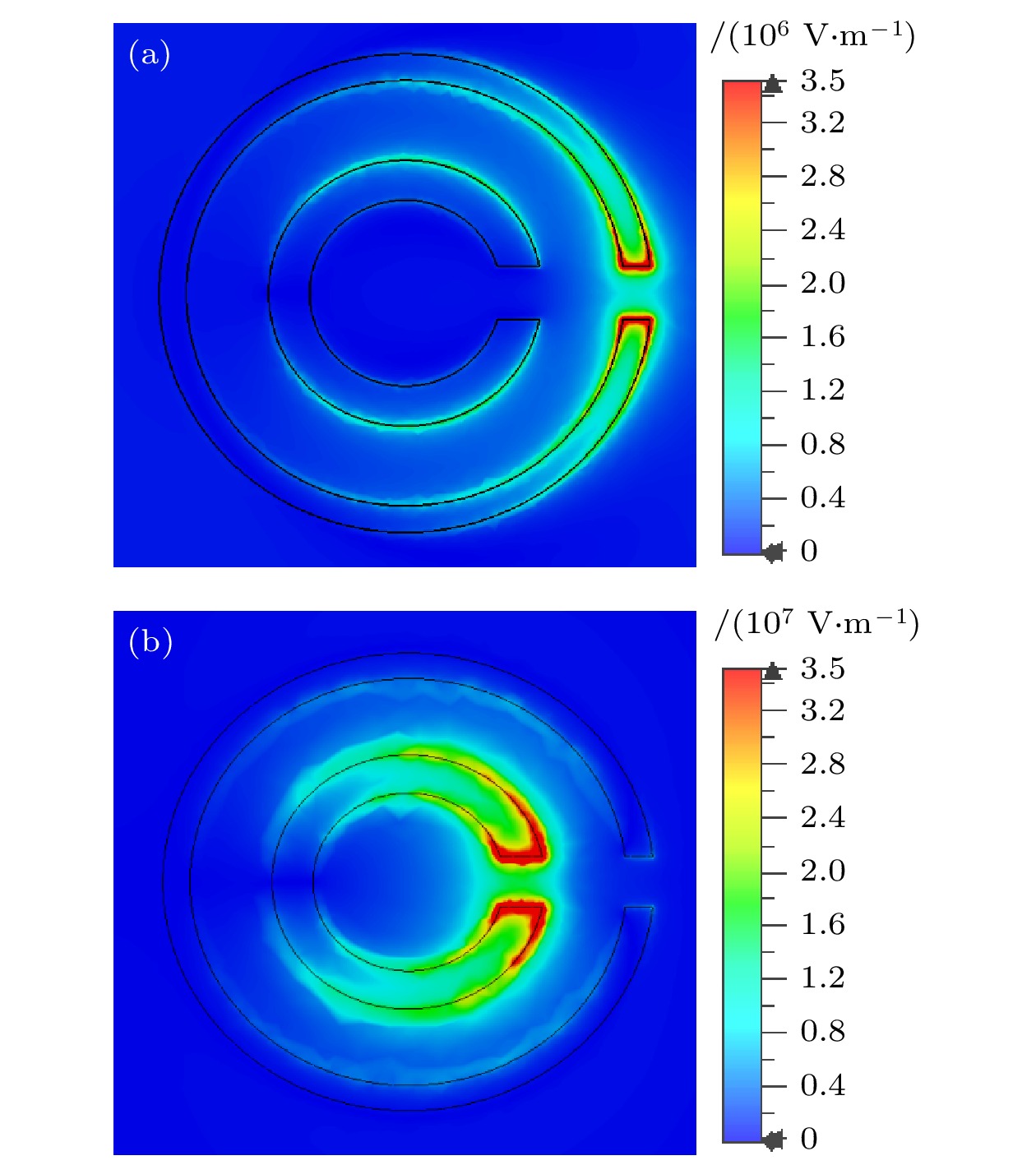

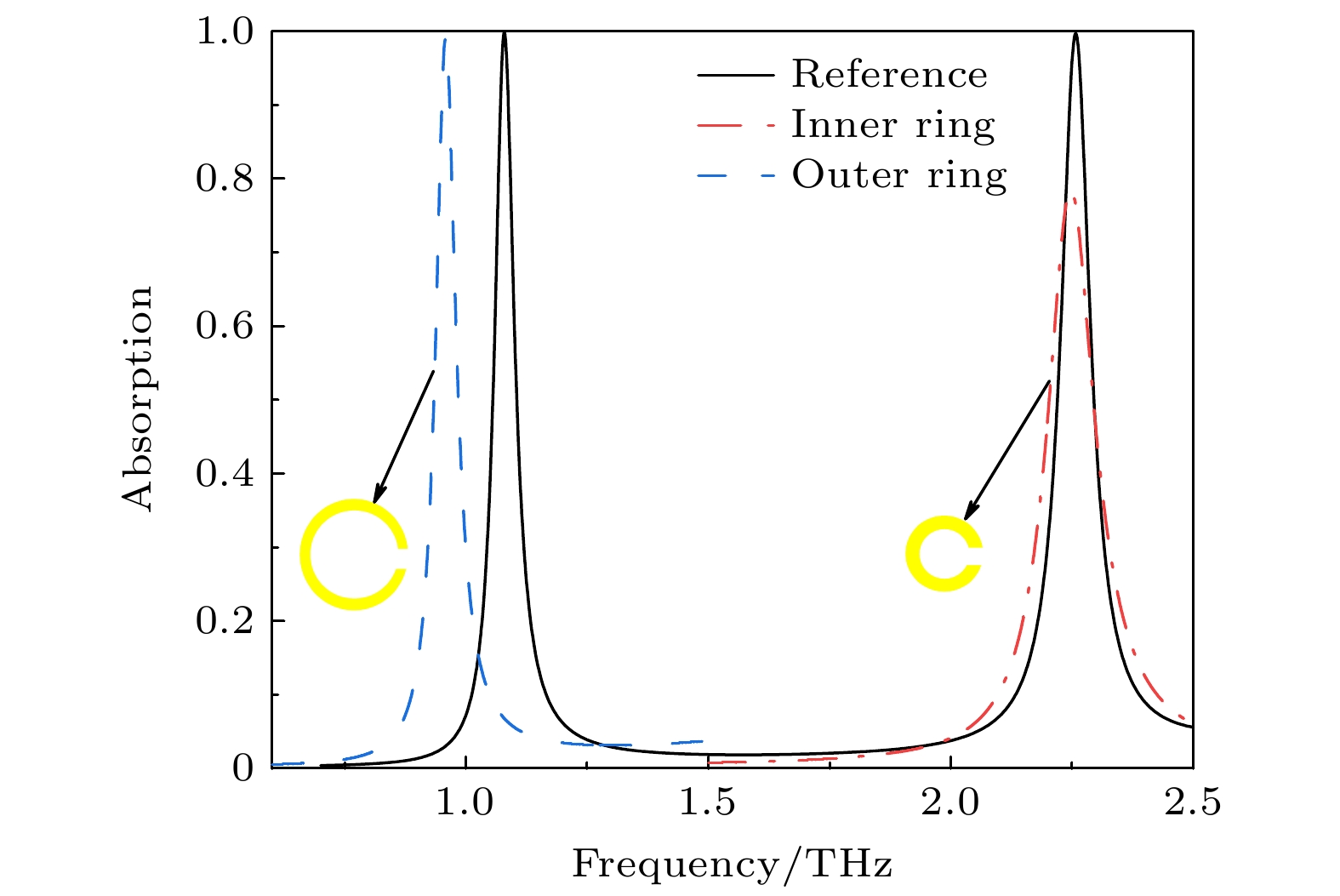

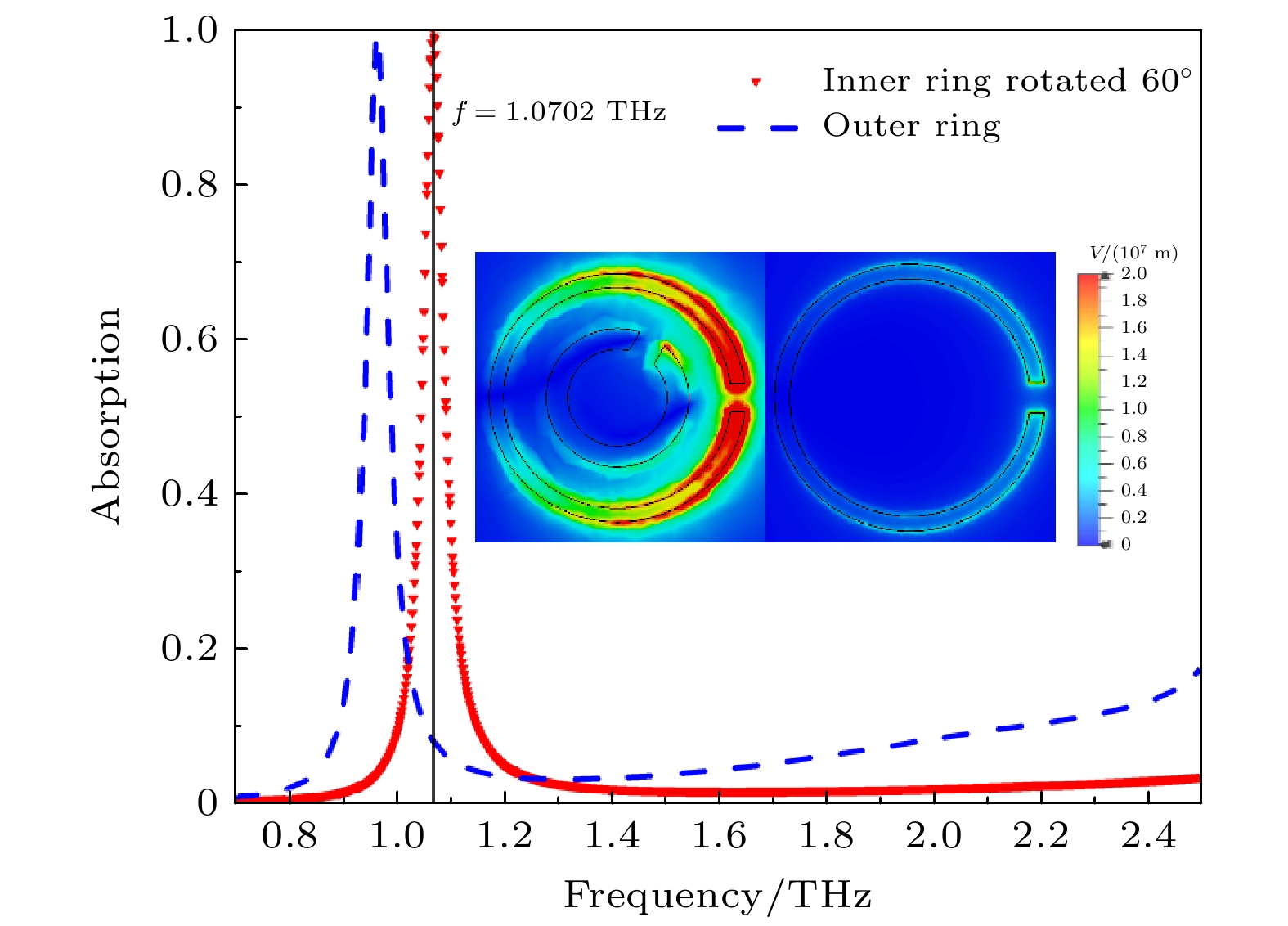

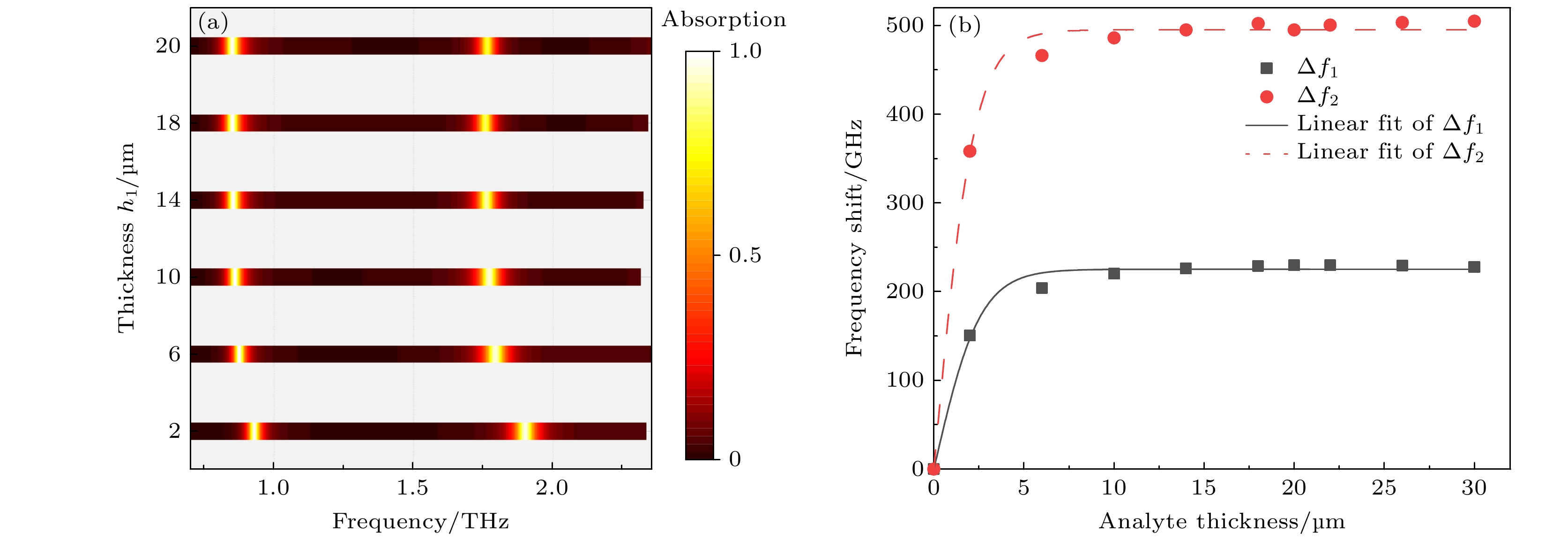

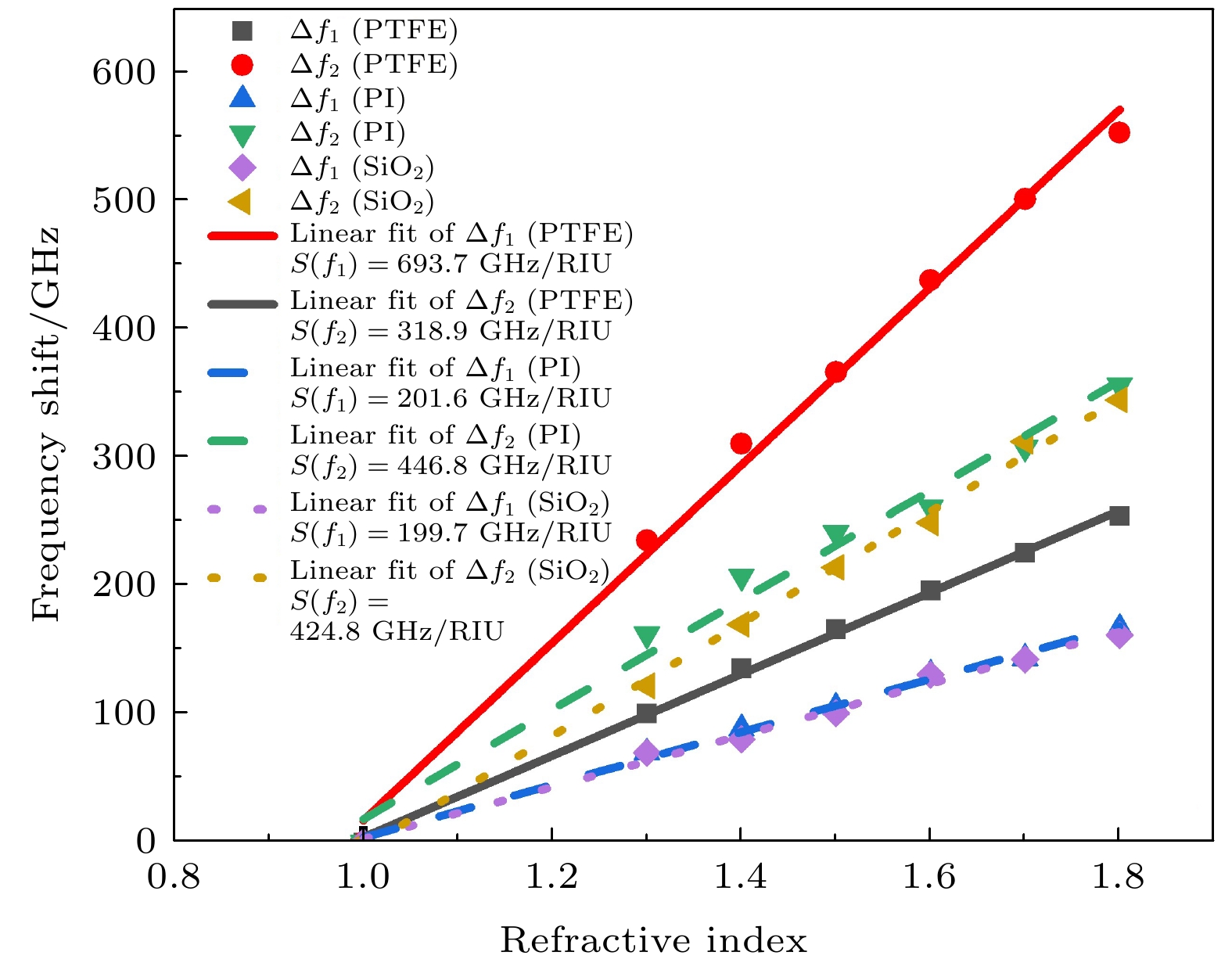

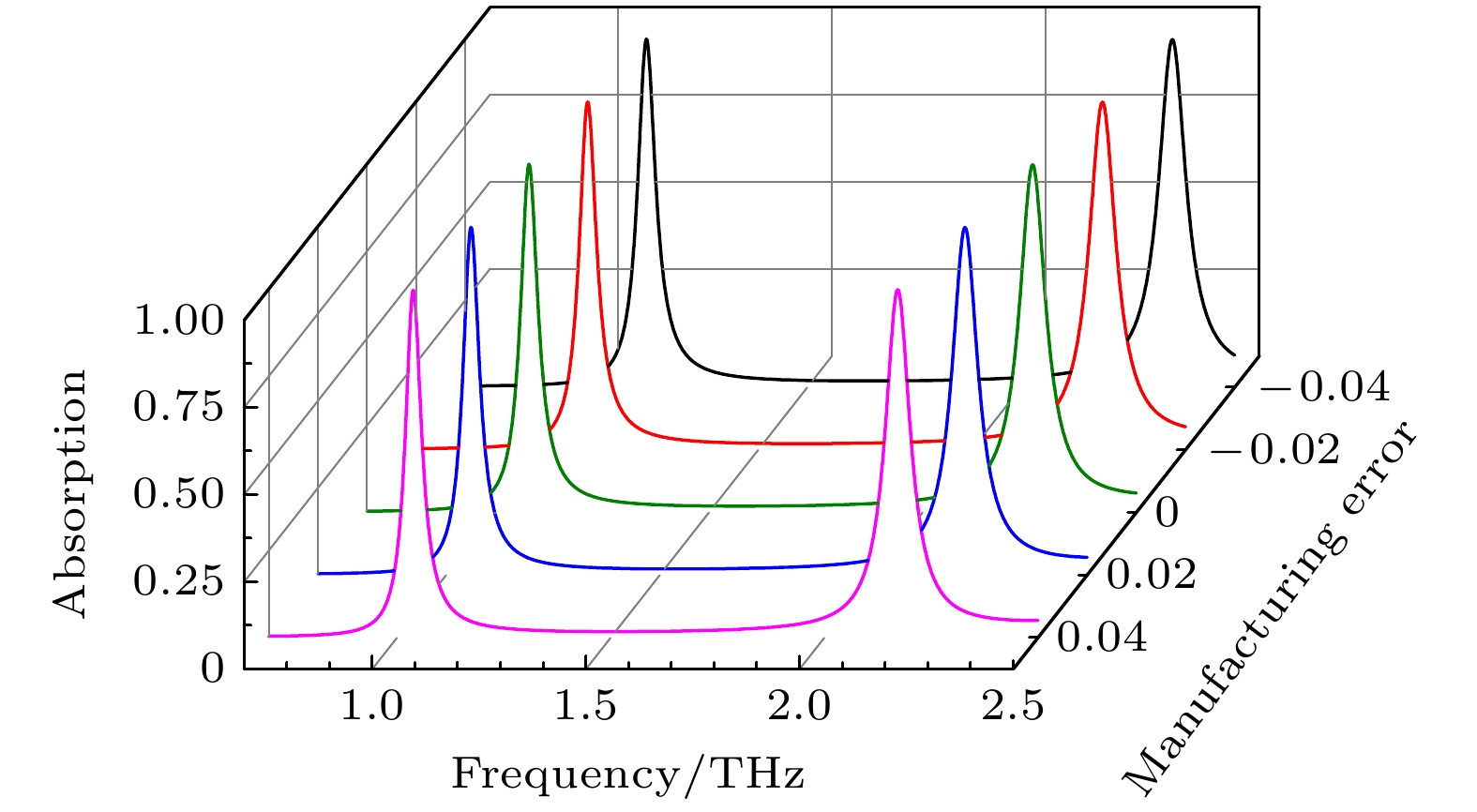

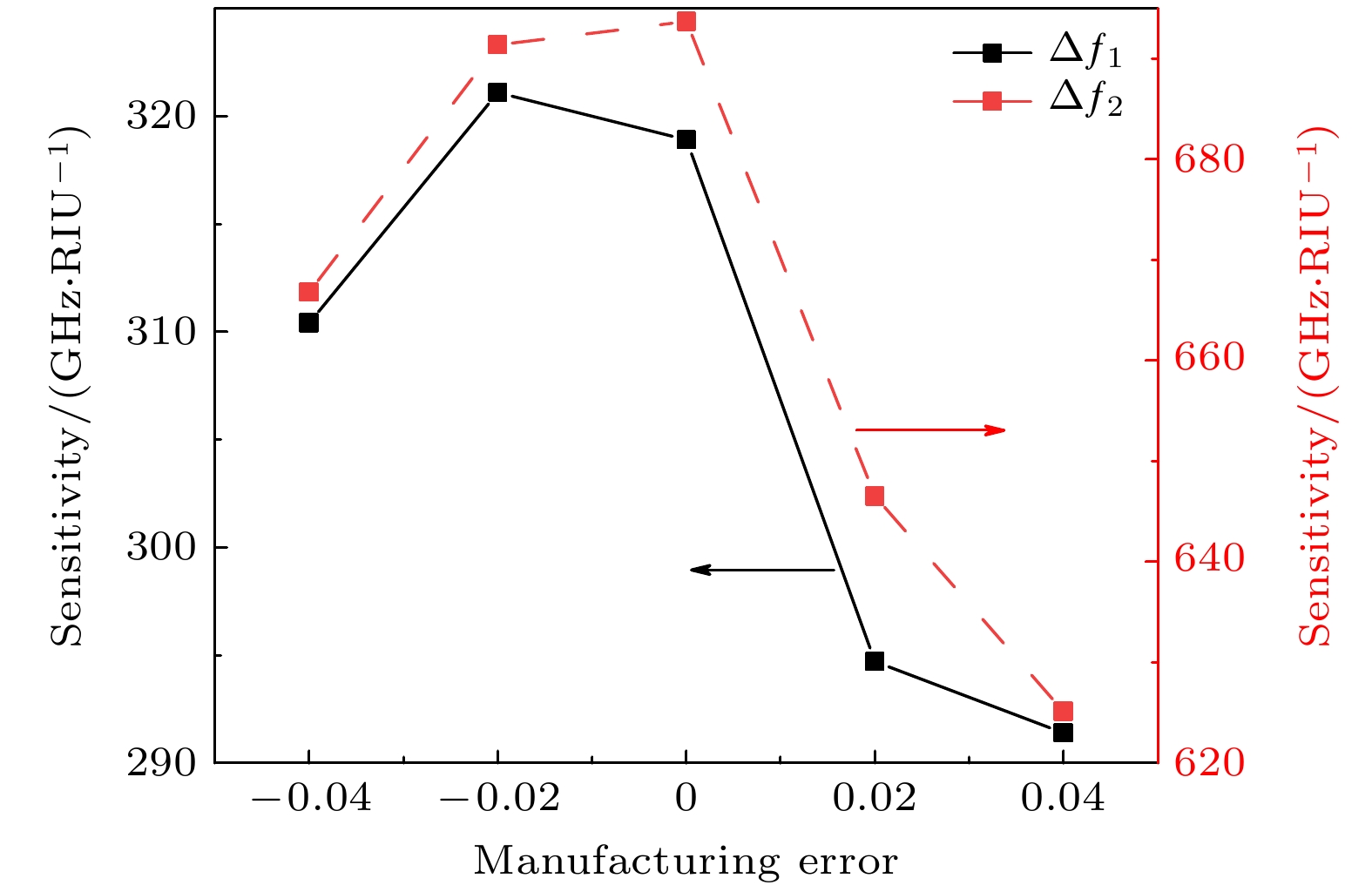

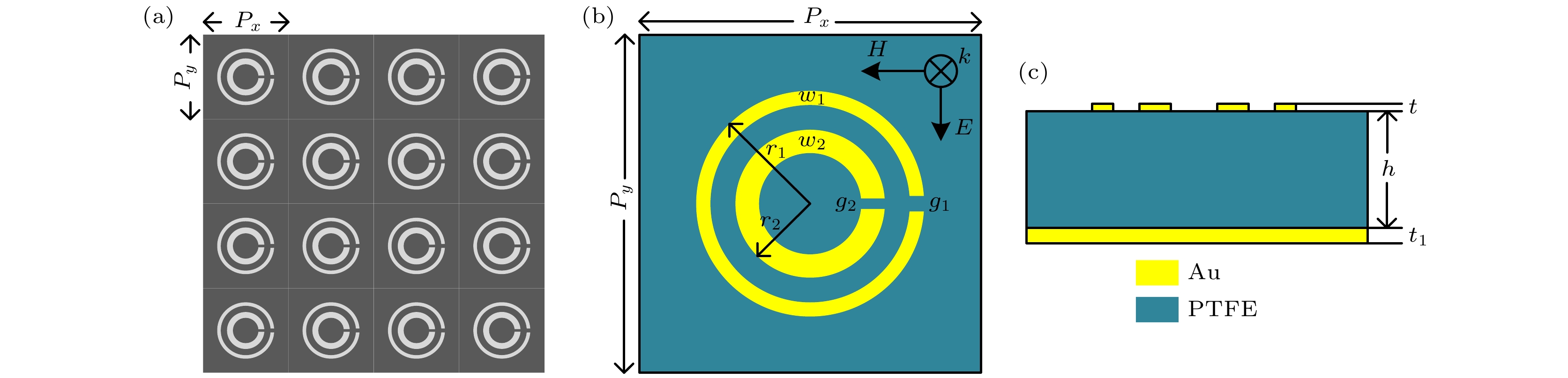

本文提出了一种用于生物样品检测的高灵敏度太赫兹折射率超材料吸波体传感器. 该传感器由2个同心开口金属环组成, 是一种多模谐振器. 传感器在0.7—2.5 THz频率范围内具有2个独立可调的工作频段, 即1.079 THz和2.271 THz, 可观测样品在太赫兹波段的不同电磁效应. 采用吸收特性、灵敏度等指标评估太赫兹传感器的性能, 自由空间中的吸收率超过99.9%, 具有较高的频率选择特性, 灵敏度达到693.7 GHz/RIU, 检测生物样品最小折射率变化量为0.004, 传感性能较好. 所提出的传感器使用低介电常数的柔性材料, 具有生物相容性、便携性等优点, 且在0°—60°斜入射角下及4%的制作误差内显示出高度稳定性. 此外, 通过乙醇-水混合物模拟实验, 验证了传感器的检测效果. 本文设计的传感器单元结构之间相互作用小、稳定、易制作, 能够显著增强光与物质之间相互作用, 在太赫兹高灵敏生物传感检测中具有广阔的应用前景.Terahertz metamaterial biosensor is a label-free affinity sensor that enhances the strength of the local electromagnetic field. It is extremely sensitive to changes in the dielectric constant of the surrounding environment, thereby providing a new method of detecting micro or trace biological samples. In this work, a highly sensitive terahertz refractive index metamaterial absorber sensor for detecting the biological sample is proposed. The sensor consists of two concentric open metal rings and is a multimode resonator. With two independent adjustable operating bands in a frequency range of 0.7–2.5 THz, i.e. 1.079 THz and 2.271 THz, the sensor can observe different electromagnetic effects of the sample in the terahertz band. We evaluate the performance of terahertz sensors with indicators such as absorption characteristics and sensitivity. The sensor possesses the absorption higher than 99.9% in free space. In addition, the large Q value indicates that the sensor provides high frequency selectivity characteristics. Especially, the sensitivity of the sensor achieves 693.7 GHz/RIU, with a minimum refractive index change of 0.004 for the detection of biological samples, which provides good sensing performance. In the proposed sensor, a flexible material with low dielectric constant is used, which has the advantages of biocompatibility and portability and shows high stability at the 0°–60° oblique incidence angle and within 4% fabrication error. Moreover, the detection effectiveness of the sensor is verified by simulation experiments with ethanol-water mixtures. The sensor units designed in this paper have small interactions among them, work stably and are easily fabricated The sensor can significantly enhance the interaction between light and matter and has broad application prospects in terahertz high-sensitivity biosensing detection.

-

Keywords:

- terahertz /

- metamaterials /

- absorbers /

- biosensors

[1] Alsharif M H, Albreem M, Solyman A, Kim S 2021 Comput. Mater. Con. 66 2831

Google Scholar

Google Scholar

[2] Ma A C, Zhong R B, Wu Z H, Wang Y Q, Yang L, Liang Z K, Fang Z, Liu S G 2020 Front. Phys. 8 584639

Google Scholar

Google Scholar

[3] Barnes M E, Daniell G J, Gow P, Apostolopoulos V 2014 J. Infrared. Millim. Te. 35 1030

Google Scholar

Google Scholar

[4] Zhou J, Zhang X, Huang G R, Yang X, Zhang Y, Zhan X Y, Tian H Y, Xiong Y, Wang Y X, Fu W L 2021 ACS Sensors 6 1884

Google Scholar

Google Scholar

[5] Bartels A, Cerna R, Kistner C, Thoma A, Hudert F, Janke C, Dekorsy T 2007 Rev. Sci. Instrum. 78 035107

Google Scholar

Google Scholar

[6] Sun X, Zhu G K, Hu J J, Jiang X, Liu Y 2019 J. Appl. Spectrosc. 86 661

Google Scholar

Google Scholar

[7] Wang L, Qi Z P, Li Z, Guo L 2021 Opt. Int. J. Light Electron. Opt. 239 166873

Google Scholar

Google Scholar

[8] Ahmadivand A, Gerislioglu B, Tomitaka A, Manickam P, Pala N 2018 Biomed. Opt. Express. 9 373

Google Scholar

Google Scholar

[9] Zheludev N I 2010 Science 328 582

Google Scholar

Google Scholar

[10] Shelby, R. A 2001 Ence. 292 77

Google Scholar

Google Scholar

[11] Kaina N, Lemoult F, Fink M, Lerosey G 2015 Nat. Int. J. Sci. 525 77

Google Scholar

Google Scholar

[12] Chen J B, Wang Y, Jia B H, Geng T, Li X P, Feng L, Qian W, Liang B M, Zhang X X, Gu M, Zhuang S L 2011 Nat. Photonics. 5 436

Google Scholar

Google Scholar

[13] Zhai S L, Zhao X P, Liu S, Shen F L, Li L L, Luo C R 2016 Sci. Rep. 6 465

Google Scholar

Google Scholar

[14] Wang G Q, Zhu F J, Lang T T, Liu J J, Hong Z, Qin J Y 2021 Nanoscale. Res. Lett. 16 109

Google Scholar

Google Scholar

[15] Chen L, Liao D G, Guo X G, Zhao J Y, Zhu Y M, Zhuang S L 2019 Front. Inform. Tech. El. 20 591

Google Scholar

Google Scholar

[16] Rezazadeh A, Soheilifar M R 2021 Optic. Quant. Electron. 53 555

Google Scholar

Google Scholar

[17] 庞慧中, 王鑫, 王俊林, 王宗利, 刘苏雅拉图, 田虎强 2021 70 321

Google Scholar

Google Scholar

Pang H Z, Wang X, Wang J L, Wang Z L, Liu S Y L T, Tian H Q 2021 Acta Phys. Sin. 70 321

Google Scholar

Google Scholar

[18] Chen Z Y, Qu F F, Wang Y, Nie P C 2021 Spectrochim. Acta. A. Mol. Biomol. Spectrosc. 263 120222

Google Scholar

Google Scholar

[19] Veeraselvam A, Mohammed G N A, Savarimuthu K, Sankararajan R 2021 Opt. Quant. Electron. 53 354

Google Scholar

Google Scholar

[20] Xu J J, Liao D G, Gupta M, Zhu Y M, Zhuang S L, Singh R, Chen L 2021 Adv. Opt. Mater. 9 2100024

Google Scholar

Google Scholar

[21] Shen Z L, Li S N, Xu Y F, Yin W, Zhang L Y, Chen X F 2021 Phys. Rev. Appl. 16 014066

Google Scholar

Google Scholar

[22] 王月娥, 李东霞, 李智, 胡放荣 2020 光谱学与光谱分析 40 1785

Google Scholar

Google Scholar

Wang Y E, Li D X, Li Z, Hu F R 2020 Spectrosc. Spec. Anal. 40 1785

Google Scholar

Google Scholar

[23] Jepsen P U, Merbold H 2010 J. Infrared. Millim. Te. 31 430

Google Scholar

Google Scholar

[24] Zhang C B, Xue T J, Zhang J, Liu L H, Xie J H, Wang G M, Yao J Q, Zhu W R, Ye X D 2021 Nanophotonics. 11 101

Google Scholar

Google Scholar

[25] 陈涛, 黄锋宇, 钟鑫, 蒋未杰, 张大鹏 2021 光子学报 50 131

Google Scholar

Google Scholar

Chen T, Huang F Y, Zhong X, Jiang W J, Zhang D P 2021 Acta Photonica Sin. 50 131

Google Scholar

Google Scholar

[26] Islam M S, Sultana J, Biabanifard M, Vafapour Z, Nine M J, Dinovitser A, Cordeiro C M B, Ng B W H, Abbott D 2020 Carbon. 158 559

Google Scholar

Google Scholar

[27] Saadeldin A S, Hameed M F O, Elkaramany E M A, Obayya S S A 2019 IEEE Sens. J. 19 7993

Google Scholar

Google Scholar

[28] 杨洁萍, 王民昌, 邓琥, 康莹, 李宗仁, 刘泉澄, 熊亮, 武志翔, 屈薇薇, 尚丽平 2021 光学学报 41 218

Yang J P, Wang M C, Deng H, Kang Y, Li Z R, Liu Q C, Xiong L, Wu Z X, Qu W W, Shang L P 2021 Acta Optica. Sin. 41 218

[29] Jepsen P U, Mller U, Merbold H 2007 Opt. Express. 15 14717

Google Scholar

Google Scholar

-

图 4 传感器在谐振频率处的电流分布 (a) f1处表面电流分布; (b) f2处表面电流分布; (c) f1处底板电流分布; (d) f2处底板电流分布

Fig. 4. The current distribution of the sensor at the resonance frequency: (a) Surface current distribution at f1; (b) surface current distribution at f2; (c) floor current distribution at f1; (d) floor current distribution at f2.

图 9 传感器几何参数变化吸收特性曲线. (a)外环半径r1; (b)外环开口间隙g1; (c)外环线宽w1; (d)内环半径r2; (e)内环开口间隙g2; (f)内环线宽w2

Fig. 9. Absorption characteristics curve with changes in sensor geometric parameters: (a) Outer ring radius r1; (b) outer ring opening gap g1; (c) outer ring line width w1; (d) inner ring radius r2; (e) inner ring opening gap g2; (f) inner ring line width w2.

图 10 (a), (b), (c)分别为不同周期P、不同衬底厚度、不同衬底材料的吸收特性曲线; (d)透射型传感器结构的传输特性曲线

Fig. 10. (a), (b), (c) are the absorption characteristic curves of different periods P, different substrate thicknesses, and different substrate materials; (d) transmission characteristic curves of the transmissive sensor structure.

表 1 单元结构的几何参数

Table 1. Geometric parameters of the unit structure.

参数 P h r1 w1 g1 r2 w2 g2 t t1 值/μm 80 20 18 2 4 10 3 4 0.2 0.5 表 2 所提出的传感器与参考文献中传感器对比

Table 2. Comparison of the proposed sensors with the sensors in the references.

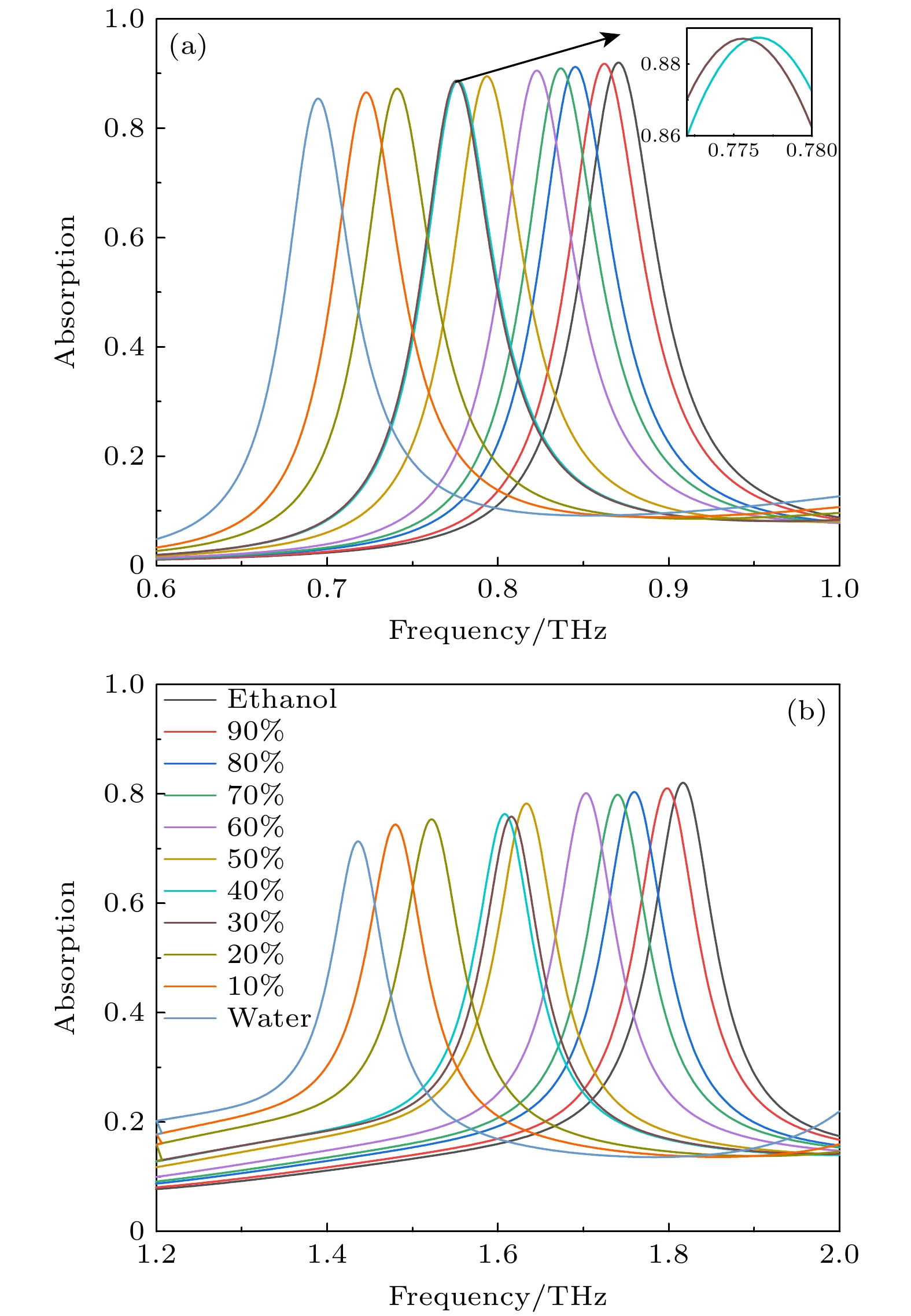

表 3 乙醇-水溶液不同浓度折射率

Table 3. Refractive indices of ethanol-water solutions at different concentrations.

Ethanol-water solution

concentration (%)ε' ε'' n 100 2.6 0.66 1.63 90 2.7 0.7 1.66 80 2.9 0.82 1.72 70 3 0.83 1.75 60 3.2 0.98 1.81 50 3.6 1.2 1.92 40 3.78 1.43 1.978 30 3.7 1.9 1.982 20 4.2 2.4 2.13 10 4.4 3.1 2.21 0 4.73 4.07 2.34 -

[1] Alsharif M H, Albreem M, Solyman A, Kim S 2021 Comput. Mater. Con. 66 2831

Google Scholar

Google Scholar

[2] Ma A C, Zhong R B, Wu Z H, Wang Y Q, Yang L, Liang Z K, Fang Z, Liu S G 2020 Front. Phys. 8 584639

Google Scholar

Google Scholar

[3] Barnes M E, Daniell G J, Gow P, Apostolopoulos V 2014 J. Infrared. Millim. Te. 35 1030

Google Scholar

Google Scholar

[4] Zhou J, Zhang X, Huang G R, Yang X, Zhang Y, Zhan X Y, Tian H Y, Xiong Y, Wang Y X, Fu W L 2021 ACS Sensors 6 1884

Google Scholar

Google Scholar

[5] Bartels A, Cerna R, Kistner C, Thoma A, Hudert F, Janke C, Dekorsy T 2007 Rev. Sci. Instrum. 78 035107

Google Scholar

Google Scholar

[6] Sun X, Zhu G K, Hu J J, Jiang X, Liu Y 2019 J. Appl. Spectrosc. 86 661

Google Scholar

Google Scholar

[7] Wang L, Qi Z P, Li Z, Guo L 2021 Opt. Int. J. Light Electron. Opt. 239 166873

Google Scholar

Google Scholar

[8] Ahmadivand A, Gerislioglu B, Tomitaka A, Manickam P, Pala N 2018 Biomed. Opt. Express. 9 373

Google Scholar

Google Scholar

[9] Zheludev N I 2010 Science 328 582

Google Scholar

Google Scholar

[10] Shelby, R. A 2001 Ence. 292 77

Google Scholar

Google Scholar

[11] Kaina N, Lemoult F, Fink M, Lerosey G 2015 Nat. Int. J. Sci. 525 77

Google Scholar

Google Scholar

[12] Chen J B, Wang Y, Jia B H, Geng T, Li X P, Feng L, Qian W, Liang B M, Zhang X X, Gu M, Zhuang S L 2011 Nat. Photonics. 5 436

Google Scholar

Google Scholar

[13] Zhai S L, Zhao X P, Liu S, Shen F L, Li L L, Luo C R 2016 Sci. Rep. 6 465

Google Scholar

Google Scholar

[14] Wang G Q, Zhu F J, Lang T T, Liu J J, Hong Z, Qin J Y 2021 Nanoscale. Res. Lett. 16 109

Google Scholar

Google Scholar

[15] Chen L, Liao D G, Guo X G, Zhao J Y, Zhu Y M, Zhuang S L 2019 Front. Inform. Tech. El. 20 591

Google Scholar

Google Scholar

[16] Rezazadeh A, Soheilifar M R 2021 Optic. Quant. Electron. 53 555

Google Scholar

Google Scholar

[17] 庞慧中, 王鑫, 王俊林, 王宗利, 刘苏雅拉图, 田虎强 2021 70 321

Google Scholar

Google Scholar

Pang H Z, Wang X, Wang J L, Wang Z L, Liu S Y L T, Tian H Q 2021 Acta Phys. Sin. 70 321

Google Scholar

Google Scholar

[18] Chen Z Y, Qu F F, Wang Y, Nie P C 2021 Spectrochim. Acta. A. Mol. Biomol. Spectrosc. 263 120222

Google Scholar

Google Scholar

[19] Veeraselvam A, Mohammed G N A, Savarimuthu K, Sankararajan R 2021 Opt. Quant. Electron. 53 354

Google Scholar

Google Scholar

[20] Xu J J, Liao D G, Gupta M, Zhu Y M, Zhuang S L, Singh R, Chen L 2021 Adv. Opt. Mater. 9 2100024

Google Scholar

Google Scholar

[21] Shen Z L, Li S N, Xu Y F, Yin W, Zhang L Y, Chen X F 2021 Phys. Rev. Appl. 16 014066

Google Scholar

Google Scholar

[22] 王月娥, 李东霞, 李智, 胡放荣 2020 光谱学与光谱分析 40 1785

Google Scholar

Google Scholar

Wang Y E, Li D X, Li Z, Hu F R 2020 Spectrosc. Spec. Anal. 40 1785

Google Scholar

Google Scholar

[23] Jepsen P U, Merbold H 2010 J. Infrared. Millim. Te. 31 430

Google Scholar

Google Scholar

[24] Zhang C B, Xue T J, Zhang J, Liu L H, Xie J H, Wang G M, Yao J Q, Zhu W R, Ye X D 2021 Nanophotonics. 11 101

Google Scholar

Google Scholar

[25] 陈涛, 黄锋宇, 钟鑫, 蒋未杰, 张大鹏 2021 光子学报 50 131

Google Scholar

Google Scholar

Chen T, Huang F Y, Zhong X, Jiang W J, Zhang D P 2021 Acta Photonica Sin. 50 131

Google Scholar

Google Scholar

[26] Islam M S, Sultana J, Biabanifard M, Vafapour Z, Nine M J, Dinovitser A, Cordeiro C M B, Ng B W H, Abbott D 2020 Carbon. 158 559

Google Scholar

Google Scholar

[27] Saadeldin A S, Hameed M F O, Elkaramany E M A, Obayya S S A 2019 IEEE Sens. J. 19 7993

Google Scholar

Google Scholar

[28] 杨洁萍, 王民昌, 邓琥, 康莹, 李宗仁, 刘泉澄, 熊亮, 武志翔, 屈薇薇, 尚丽平 2021 光学学报 41 218

Yang J P, Wang M C, Deng H, Kang Y, Li Z R, Liu Q C, Xiong L, Wu Z X, Qu W W, Shang L P 2021 Acta Optica. Sin. 41 218

[29] Jepsen P U, Mller U, Merbold H 2007 Opt. Express. 15 14717

Google Scholar

Google Scholar

计量

- 文章访问数: 9610

- PDF下载量: 271

- 被引次数: 0

下载:

下载: