-

Amorphous alloys have become a research hotpot in the field of materials science due to their unique long-range disordered structure and excellent physical properties. However, the complex microstructural evolution and electronic transport mechanisms of amorphous alloys under thermal effects still need in depth investigating. In this work, Ni40Fe35B15Si7P3 and Ni50Fe25B15Si7P3 amorphous alloy ribbons are prepared by the melt-spinning technique, and the as-cast samples are subjected to annealing treatments within the supercooled liquid region. The results show that annealing within the supercooled liquid region enhances the short-range order, reduces the free volume, and increases the atomic packing density of the alloys. The volume fractions of the local quasi-crystalline clusters in the annealed samples increase to 26%-34%. Furthermore, the increases in scattering centers and the release of internal stresses induced by the supercooled liquid region annealing lead to an increase in the electrical resistivity of the alloys. Specifically, the resistivity of the Ni40Fe35B15Si7P3 alloy increases from 131.8 μΩ·cm to 217.0 μΩ·cm, a increase of 64.6%. Under an applied magnetic field, the deflection of electron trajectories due to the Lorentz force and the magnetostriction effect further increases the resistivity of the alloys. Additionally, thermal activation releases the bound electrons and enhances their scattering, resulting in an increase in the carrier concentration and a decrease in the carrier mobility of the annealed alloys. This study demonstrates that annealing can effectively control the short-range order and free volume distribution of amorphous alloys, thereby influencing their electronic transport properties. The findings provide an experimental basis for designing high-performance amorphous alloy electronic devices.

-

Keywords:

- Ni-Fe-based amorphous alloys /

- annealing /

- short-range order /

- electrical properties

[1] Wang W H 2012 Prog. Mater. Sci. 57 487

Google Scholar

Google Scholar

[2] Inoue A, Takeuchi A 2011 Acta Mater. 59 2243

Google Scholar

Google Scholar

[3] Wu Y, Bei H, Wang Y L, Lu Z P, George E P, Gao Y F 2015 Int. J. Plasticity 71 136

Google Scholar

Google Scholar

[4] 王壮, 金凡, 李伟, 阮嘉艺, 王龙飞, 吴雪莲, 张义坤, 袁晨晨 2024 73 217101

Google Scholar

Google Scholar

Wang Z, Jin F, Li W, Ruan J Y, Wang L F, Wu X L, Zhang Y K, Yuan C C 2024 Acta Phys. Sin. 73 217101

Google Scholar

Google Scholar

[5] Lu W B, He M F, Yu D, Xie X M, Wang H, Wang S, Yuan C G, Chen A 2021 Mater. Design 210 110027

Google Scholar

Google Scholar

[6] Chen M 2011 Npg Asia Mater. 3 82

Google Scholar

Google Scholar

[7] Shen P P, Yuan F S, Zhou H B, Hu J, Sun B A 2023 J. Alloy. Compd. 44 169168

Google Scholar

Google Scholar

[8] Li X, Ren Q, Xu G J, Zhao A C, Duan L 2024 J. Mater. Sci-Mater. El. 35 564

Google Scholar

Google Scholar

[9] Nai J W, Kang J X, Guo L 2015 Sci. China Mater. 58 44

Google Scholar

Google Scholar

[10] Yao Y G, Kleinman L, MacDonald A H, Sinova J, Jungwirth T, Wang D S, Wang E G, Niu Q 2004 Phys. Rev. Lett. 92 037204

Google Scholar

Google Scholar

[11] Liu W J, Zhang H X, Shi J A, Wang Z C, Song C, Wang X R, Chen N 2016 Nat. Commun. 7 13497

Google Scholar

Google Scholar

[12] Wu M, Lou H B, Tse J S, Liu H Y, Pan Y M, Takahama K, Matsuoka T, Shimizu K, Jiang J Z 2016 Phys. Rev. B 94 054201

Google Scholar

Google Scholar

[13] Zhang Y Q, Zhou L Y, Tao S Y, Jiao Y Z, Li J F, Zheng K M, Hu Y C, Fang K X, Song C, Zhong X Y 2021 Sci. China Mater. 64 2305

Google Scholar

Google Scholar

[14] He S Y, Li Y G, Liu L, Jiang Y, Feng J J, Zhu W, Zhang J Y, Dong Z R, Deng Y, Luo J, Zhang W Q, Chen G 2020 Sci. Adv. 6 eaaz8423

Google Scholar

Google Scholar

[15] Mo S, Zeng J, Zhang H, Wu Y N, Liu T, Ni H W 2023 J. Mater. Sci. Technol. 143 189

Google Scholar

Google Scholar

[16] Li X S, Su F C, Zhou J, Mao Y C, Yang J M, Xue Z Y, Ke H B, Sun B A, Wang W H, Bai H Y 2024 Intermetallics 166 108201

Google Scholar

Google Scholar

[17] Ma H J, Wei W Q, Bao W K, Shen X B, Wang C C, Wang W M 2020 Rare. Metal Mat. Eng. 49 2904 [马海健, 魏文庆, 鲍文科, 神祥博, 王长春, 王伟民 2020 稀有金属材料与工程 49 2904]

Google Scholar

Google Scholar

Ma H J, Wei W Q, Bao W K, Shen X B, Wang C C, Wang W M 2020 Rare. Metal Mat. Eng. 49 2904

Google Scholar

Google Scholar

[18] Tong X, Zhang Y, Wang Y C, Liang X Y, Zhang K, Zhang F, Cai Y F, Ke H B, Wang G, Shen J, Makino A, Wang W H 2022 J. Mater. Sci. Technol. 96 233

Google Scholar

Google Scholar

[19] Jia J L, Wu Y, Shi L X, Wang R B, Guo W H, Bu H T, Shao Y, Chen N, Yao K F 2024 Mater. 17 1447

Google Scholar

Google Scholar

[20] Zhang L K, Liu L M, Zhang R, Chen D, Ma G Z, Ye C G 2023 Mater. Res. Express 10 055201

Google Scholar

Google Scholar

[21] Liu B B, Liu C Y, Jiang X, Zhen S Y, You L, Ye F 2021 Intermetallics 137 107283

Google Scholar

Google Scholar

[22] Cao C C, Zhu L, Meng Y, Zhai X B, Wang Y G 2018 J. Magn. Magn. Mater. 456 274

Google Scholar

Google Scholar

[23] Wang C, Tang Y, Ouyang X P, Wang H K 2025 Mat. Sci. Eng. A 924 147843

Google Scholar

Google Scholar

[24] Zhang S, Wei C, Yang L, Lv J W, Zhang H R, Shi Z L, Zhang X Y, Ma M Z. 2022 Mat. Sci. Eng. A 840 142978

Google Scholar

Google Scholar

[25] 吴渊, 宋温丽, 周捷, 曹迪, 王辉, 刘雄军, 吕昭平 2017 66 176111

Google Scholar

Google Scholar

Wu Y, Song W L, Zhou J, Cao D, Wang H, Liu X J, Lü Z P 2017 Acta Phys. Sin. 66 176111

Google Scholar

Google Scholar

[26] Pan J, Duan F H 2021 Acta Metall. Sin. 57 439 [潘杰, 段峰辉 2021 金属学报 57 439]

Google Scholar

Google Scholar

Pan J, Duan F H 2021 Acta Metall. Sin. 57 439

Google Scholar

Google Scholar

[27] 张志英, 汤迦南, 余杰, 王旭东, 黄罗超, 邹俊文, 唐浩, 张继康, 陈亚涛, 程东鹏 2018 中国腐蚀与防护学报 38 478

Google Scholar

Google Scholar

Zhang Z Y, Tang J N, Yu J, Wang X D, Huang L C, Zhou J W, Tang H, Zhang J K, Chen Y T, Cheng D P 2018 J. Chin. Soc. Corros. Prot. 38 478

Google Scholar

Google Scholar

[28] Teusner M, Mata J, Sharma N 2022 Curr. Opin. Electroche. 34 100990

Google Scholar

Google Scholar

[29] 刘文胜, 刘书华, 马运柱, 张佳佳, 叶晓珊 2015 稀有金属材料与工程 44 2459

Liu W S, Liu S H, Ma Y Z, Zhang J J, Ye X S 2015 Rare Met. Mater. Eng. 44 2459

[30] Ström P, Primetzhofer D 2021 Nucl. Mater. Energy 27 100979

Google Scholar

Google Scholar

[31] 陈仙, 王炎武, 王晓艳, 安书董, 王小波, 赵玉清 2014 63 246801

Google Scholar

Google Scholar

Chen X, Wang Y W, Wang X Y, An S D, Wang X B, Zhao Y Q 2014 Acta Phys. Sin. 63 246801

Google Scholar

Google Scholar

[32] Wang Q, Liu C T, Yang Y, Liu J B, Dong Y D, Lu J 2014 Sci. Rep-Uk. 4 4648

Google Scholar

Google Scholar

[33] Wang Q, Liu C T, Yang Y, Dong Y D, Lu J 2011 Phys. Rev. Lett. 106 215505

Google Scholar

Google Scholar

[34] Ezzat S S, Mani P D, Khaniya A, Kaden W, Gall D, Barmak K, Coffey K R 2019 J. Vac. Sci. Technol. A 37 031516

Google Scholar

Google Scholar

[35] Guo Y M, Wang X C, Li X, Zhang T 2023 Mater. Lett. 336 133890

Google Scholar

Google Scholar

[36] Yao X, Wang L Y, Shuai C J, Gao C D 2025 Mater. Lett. 384 138127

Google Scholar

Google Scholar

[37] 张广平, 李孟林, 吴细毛, 李春和, 罗雪梅 2014 材料研究学报 28 81

Google Scholar

Google Scholar

Zhang G P, Li M L, Wu X M, Li C H, Luo X M 2014 Chin. J. Mater. Res. 28 81

Google Scholar

Google Scholar

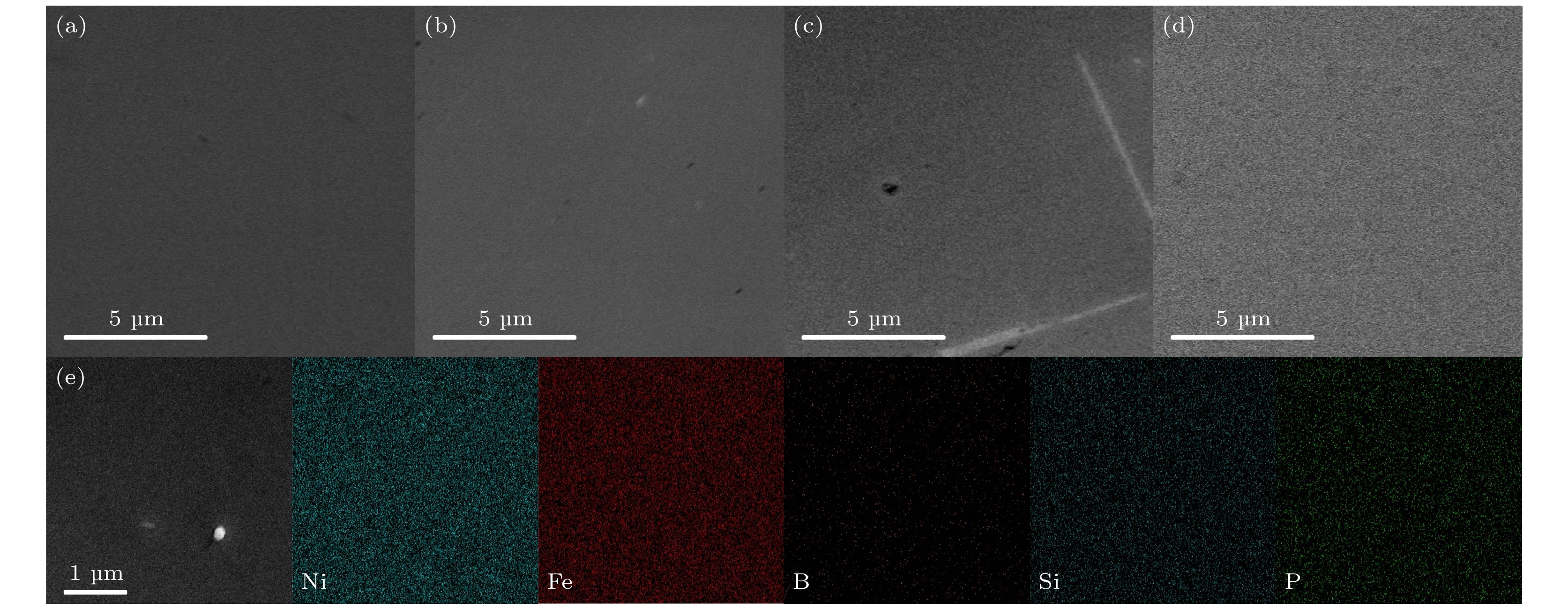

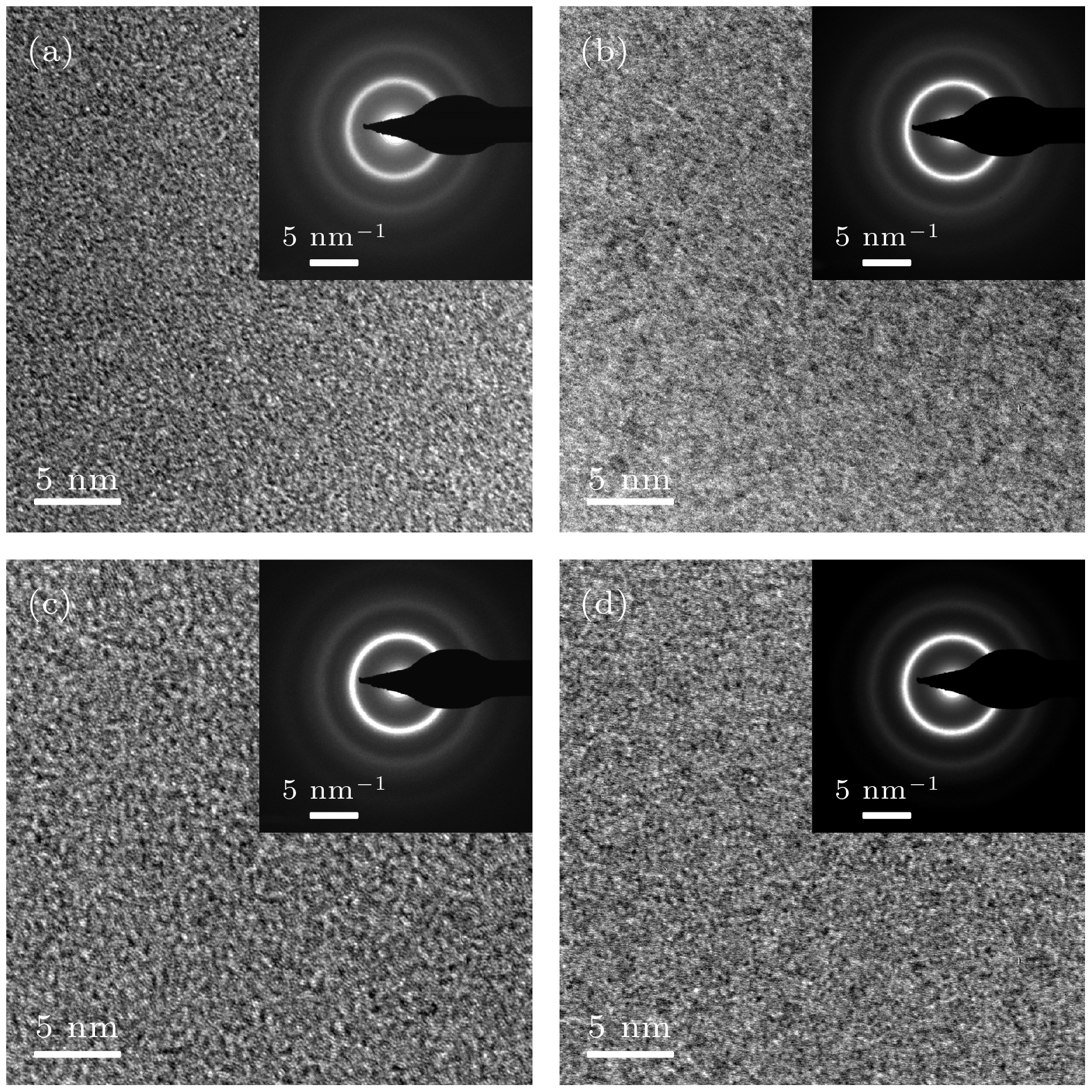

-

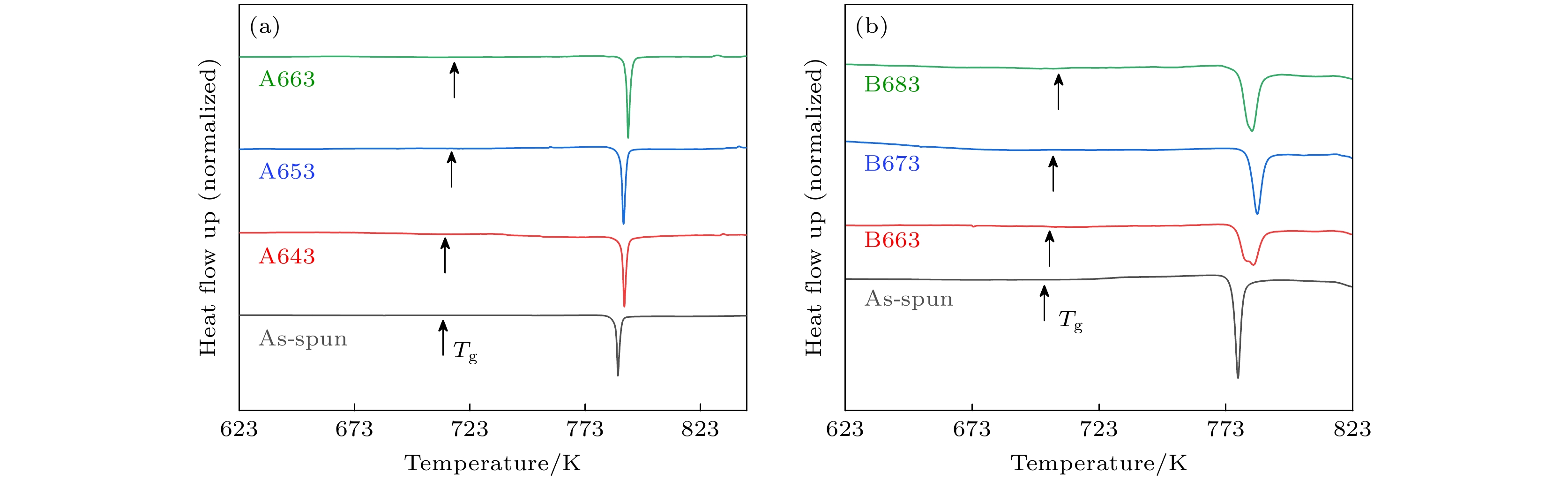

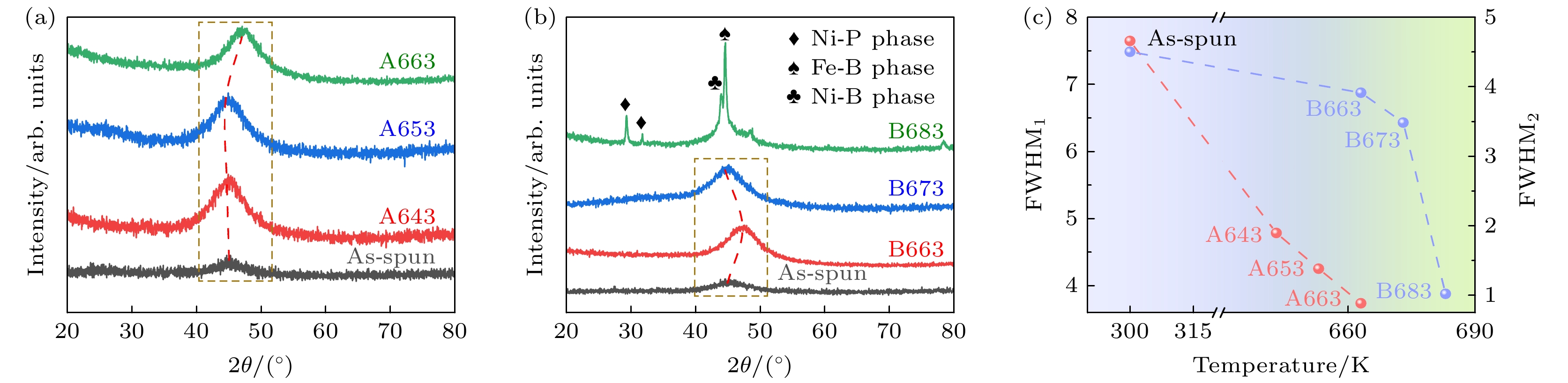

图 1 (a) Ni40Fe35B15Si7P3和(b) Ni50Fe25B15Si7P3合金退火前后的XRD图; (c) Ni40Fe35B15Si7P3和Ni50Fe25B15Si7P3合金退火前后的FWHM数值

Figure 1. (a) XRD patterns of Ni40Fe35B15Si7P3 and (b) Ni50Fe25B15Si7P3 alloys before and after annealing; (c) FWHM of Ni40Fe35B15Si7P3 and Ni50Fe25B15Si7P3 alloys before and after annealing.

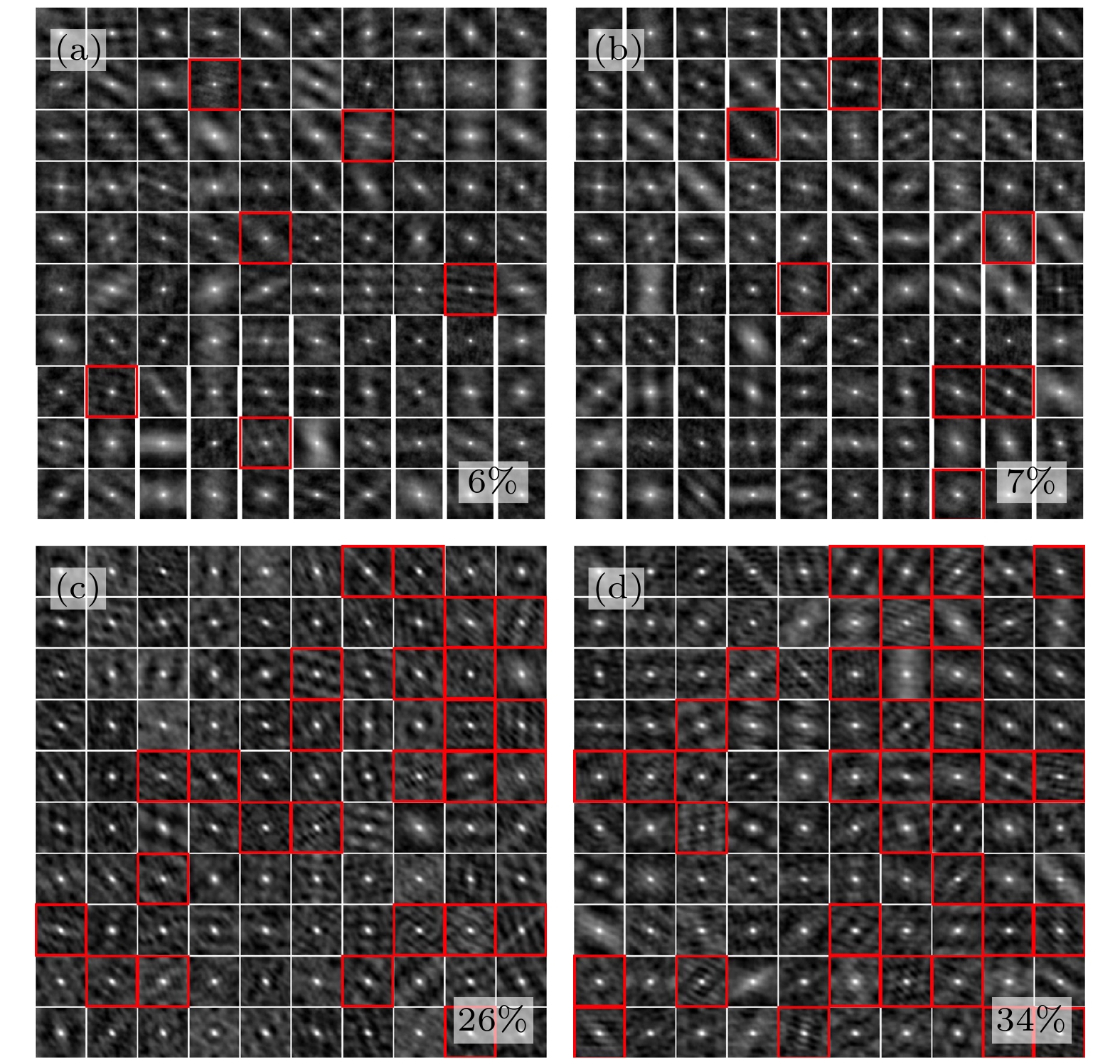

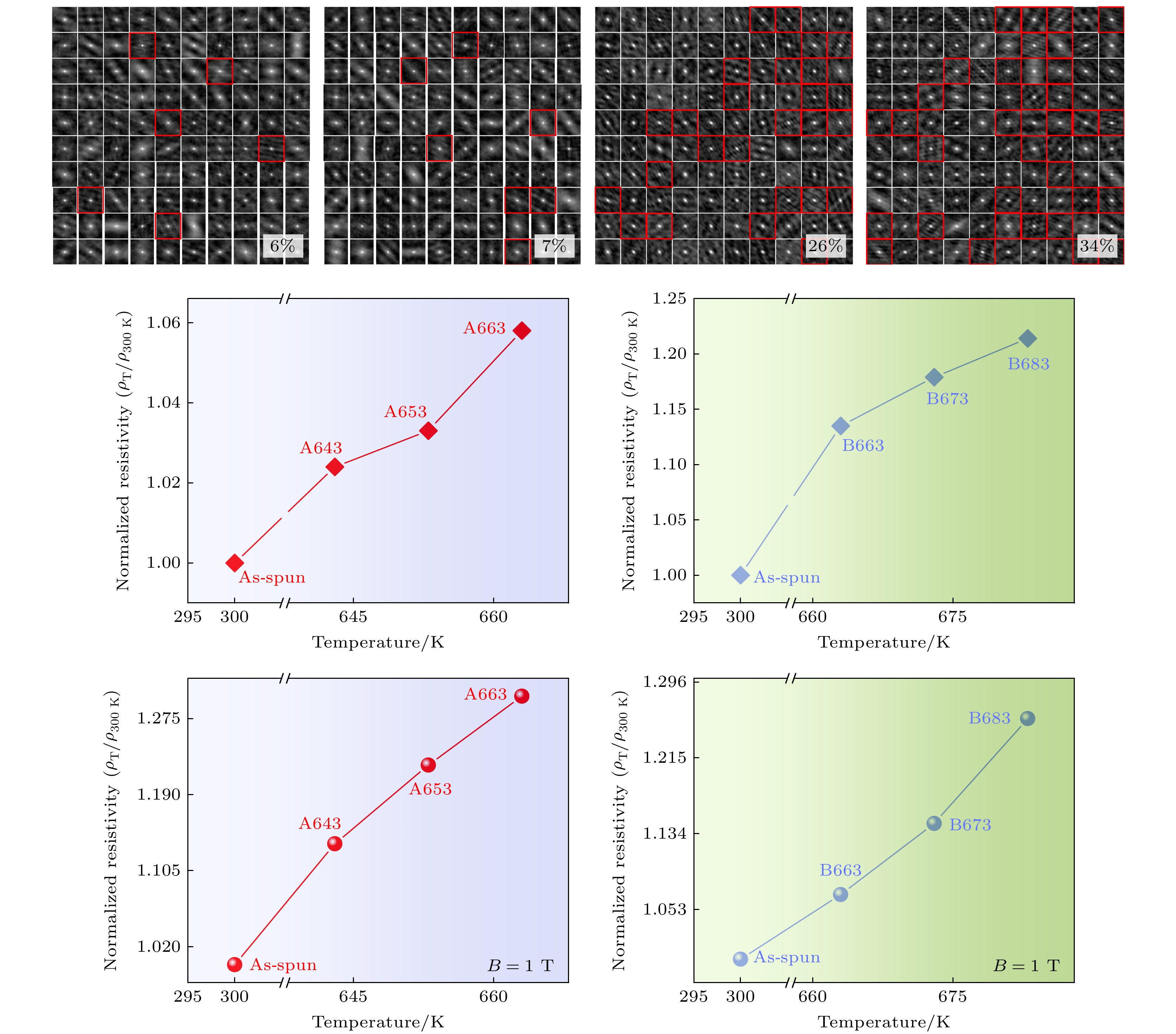

图 5 (a) Ni40Fe35B15Si7P3, (b) Ni50Fe25B15Si7P3, (c) A653, (d) B673合金TEM图的2D自相关映射图, 出现清晰条纹的图用红色方框标记, 对应局域类晶体结构

Figure 5. 2D autocorrelation mapping of the TEM images of (a) Ni40Fe35B15Si7P3, (b) Ni50Fe25B15Si7P3, (c)A653, (d) B673alloys before and after annealing, with clearly defined striped patterns marked by red squares, corresponding to the local quasi-crystalline structures.

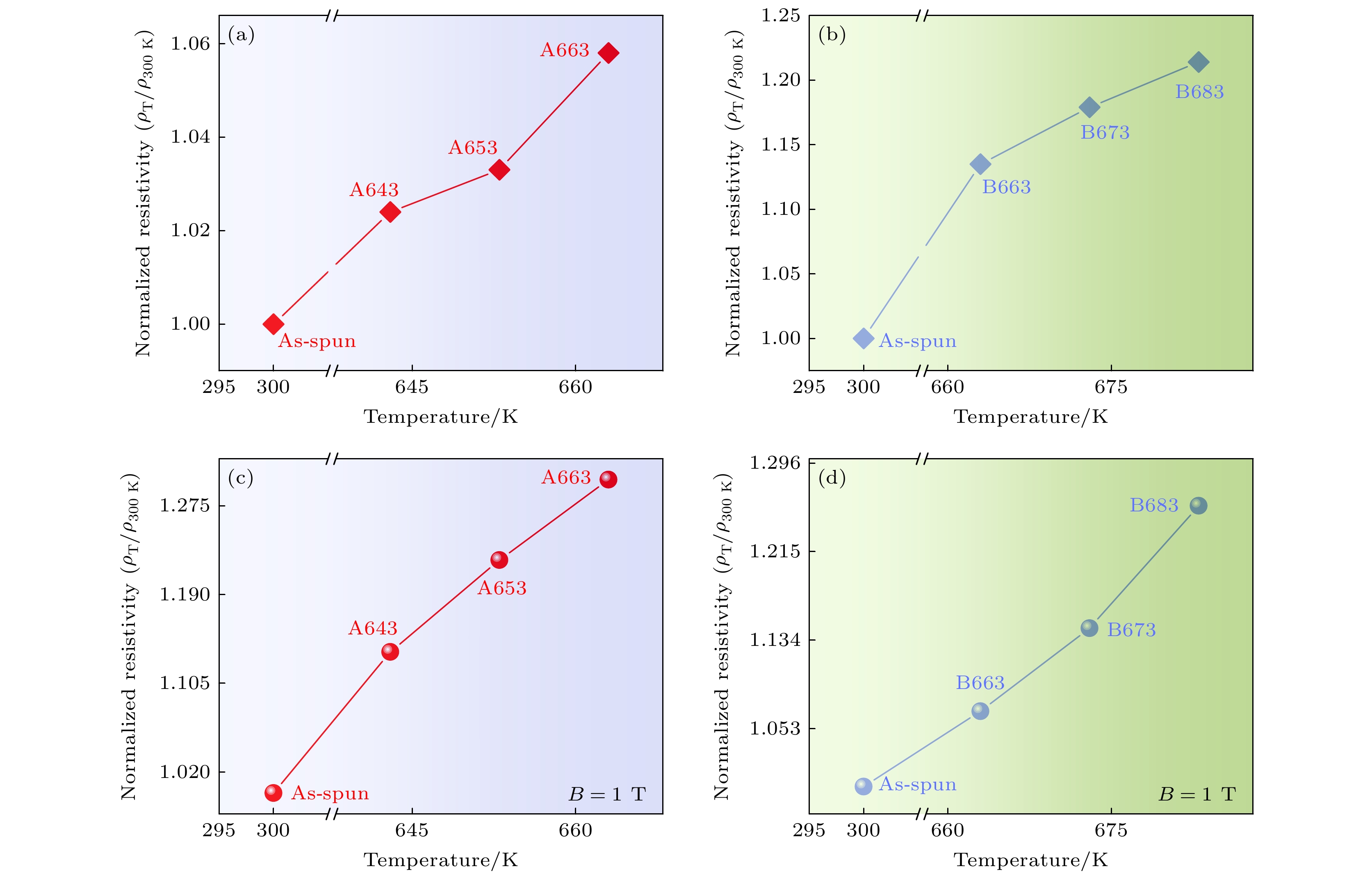

图 6 (a) Ni40Fe35B15Si7P3和(b) Ni50Fe25B15Si7P3合金退火前后的归一化电阻率(ρT/ρ300 K)曲线图; (c) Ni40Fe35B15Si7P3和(d) Ni50Fe25B15Si7P3合金在1 T磁场下退火前后的归一化电阻率(ρH/ρ300 K)曲线图

Figure 6. Normalized resistivity (ρT/ρ300 K) curves of (a) Ni40Fe35B15Si7P3 and (b) Ni50Fe25B15Si7P3 alloys before and after annealing; normalized resistivity (ρH/ρ300 K) of (c) Ni40Fe35B15Si7P3 and (d) Ni50Fe25B15Si7P3 alloys before and after annealing under a 1 T magnetic field.

表 1 Ni40Fe35B15Si7P3和Ni50Fe25B15Si7P3合金退火前后的热力学参数

Table 1. Thermodynamic parameters of Ni40Fe35B15Si7P3 and Ni50Fe25B15Si7P3 alloys before and after annealing.

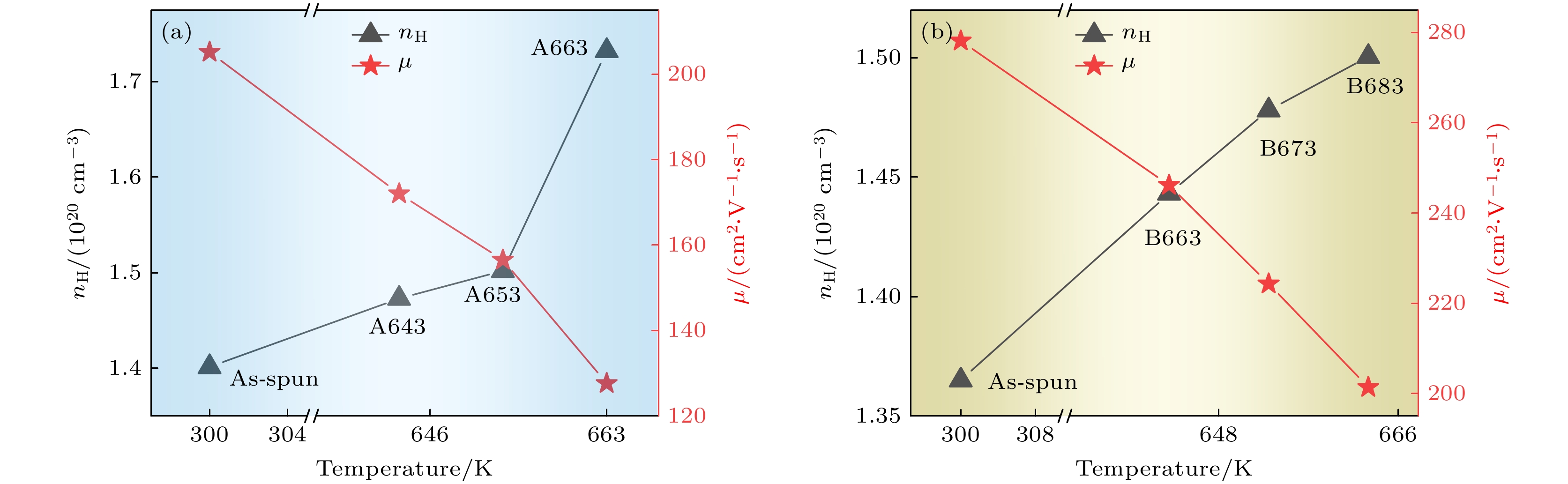

Ni40Fe35B15Si7P3 Tg/K Ni50Fe25B15Si7P3 Tg/K As-spun 711.25 As-spun 702.13 A643 712.97 B663 703.56 A653 714.12 B673 704.96 A663 715.56 B683 706.05 表 2 Ni40Fe35B15Si7P3和Ni50Fe25B15Si7P3合金退火前后的霍尔参数

Table 2. Hall parameters of of Ni40Fe35B15Si7P3 and Ni50Fe25B15Si7P3 alloys before and after annealing.

Ni40Fe35B15Si7P3 nH/(1020 cm–3) μ/(cm2·V–1·s-1) RH/(103 cm3·C–1) Ni50Fe25B15Si7P3 nH/(1020 cm–3) μ/(cm2·V–1·s–1) RH/(103 cm3·C–1) As-spun 1.40 205.17 –44.53 As-spun 1.37 278.17 –45.71 A643 1.47 172.04 –42.36 B663 1.44 246.19 –43.24 A653 1.50 156.51 –41.54 B673 1.48 224.32 –42.22 A663 1.73 127.64 –36.02 B683 1.50 201.35 –41.59 -

[1] Wang W H 2012 Prog. Mater. Sci. 57 487

Google Scholar

Google Scholar

[2] Inoue A, Takeuchi A 2011 Acta Mater. 59 2243

Google Scholar

Google Scholar

[3] Wu Y, Bei H, Wang Y L, Lu Z P, George E P, Gao Y F 2015 Int. J. Plasticity 71 136

Google Scholar

Google Scholar

[4] 王壮, 金凡, 李伟, 阮嘉艺, 王龙飞, 吴雪莲, 张义坤, 袁晨晨 2024 73 217101

Google Scholar

Google Scholar

Wang Z, Jin F, Li W, Ruan J Y, Wang L F, Wu X L, Zhang Y K, Yuan C C 2024 Acta Phys. Sin. 73 217101

Google Scholar

Google Scholar

[5] Lu W B, He M F, Yu D, Xie X M, Wang H, Wang S, Yuan C G, Chen A 2021 Mater. Design 210 110027

Google Scholar

Google Scholar

[6] Chen M 2011 Npg Asia Mater. 3 82

Google Scholar

Google Scholar

[7] Shen P P, Yuan F S, Zhou H B, Hu J, Sun B A 2023 J. Alloy. Compd. 44 169168

Google Scholar

Google Scholar

[8] Li X, Ren Q, Xu G J, Zhao A C, Duan L 2024 J. Mater. Sci-Mater. El. 35 564

Google Scholar

Google Scholar

[9] Nai J W, Kang J X, Guo L 2015 Sci. China Mater. 58 44

Google Scholar

Google Scholar

[10] Yao Y G, Kleinman L, MacDonald A H, Sinova J, Jungwirth T, Wang D S, Wang E G, Niu Q 2004 Phys. Rev. Lett. 92 037204

Google Scholar

Google Scholar

[11] Liu W J, Zhang H X, Shi J A, Wang Z C, Song C, Wang X R, Chen N 2016 Nat. Commun. 7 13497

Google Scholar

Google Scholar

[12] Wu M, Lou H B, Tse J S, Liu H Y, Pan Y M, Takahama K, Matsuoka T, Shimizu K, Jiang J Z 2016 Phys. Rev. B 94 054201

Google Scholar

Google Scholar

[13] Zhang Y Q, Zhou L Y, Tao S Y, Jiao Y Z, Li J F, Zheng K M, Hu Y C, Fang K X, Song C, Zhong X Y 2021 Sci. China Mater. 64 2305

Google Scholar

Google Scholar

[14] He S Y, Li Y G, Liu L, Jiang Y, Feng J J, Zhu W, Zhang J Y, Dong Z R, Deng Y, Luo J, Zhang W Q, Chen G 2020 Sci. Adv. 6 eaaz8423

Google Scholar

Google Scholar

[15] Mo S, Zeng J, Zhang H, Wu Y N, Liu T, Ni H W 2023 J. Mater. Sci. Technol. 143 189

Google Scholar

Google Scholar

[16] Li X S, Su F C, Zhou J, Mao Y C, Yang J M, Xue Z Y, Ke H B, Sun B A, Wang W H, Bai H Y 2024 Intermetallics 166 108201

Google Scholar

Google Scholar

[17] Ma H J, Wei W Q, Bao W K, Shen X B, Wang C C, Wang W M 2020 Rare. Metal Mat. Eng. 49 2904 [马海健, 魏文庆, 鲍文科, 神祥博, 王长春, 王伟民 2020 稀有金属材料与工程 49 2904]

Google Scholar

Google Scholar

Ma H J, Wei W Q, Bao W K, Shen X B, Wang C C, Wang W M 2020 Rare. Metal Mat. Eng. 49 2904

Google Scholar

Google Scholar

[18] Tong X, Zhang Y, Wang Y C, Liang X Y, Zhang K, Zhang F, Cai Y F, Ke H B, Wang G, Shen J, Makino A, Wang W H 2022 J. Mater. Sci. Technol. 96 233

Google Scholar

Google Scholar

[19] Jia J L, Wu Y, Shi L X, Wang R B, Guo W H, Bu H T, Shao Y, Chen N, Yao K F 2024 Mater. 17 1447

Google Scholar

Google Scholar

[20] Zhang L K, Liu L M, Zhang R, Chen D, Ma G Z, Ye C G 2023 Mater. Res. Express 10 055201

Google Scholar

Google Scholar

[21] Liu B B, Liu C Y, Jiang X, Zhen S Y, You L, Ye F 2021 Intermetallics 137 107283

Google Scholar

Google Scholar

[22] Cao C C, Zhu L, Meng Y, Zhai X B, Wang Y G 2018 J. Magn. Magn. Mater. 456 274

Google Scholar

Google Scholar

[23] Wang C, Tang Y, Ouyang X P, Wang H K 2025 Mat. Sci. Eng. A 924 147843

Google Scholar

Google Scholar

[24] Zhang S, Wei C, Yang L, Lv J W, Zhang H R, Shi Z L, Zhang X Y, Ma M Z. 2022 Mat. Sci. Eng. A 840 142978

Google Scholar

Google Scholar

[25] 吴渊, 宋温丽, 周捷, 曹迪, 王辉, 刘雄军, 吕昭平 2017 66 176111

Google Scholar

Google Scholar

Wu Y, Song W L, Zhou J, Cao D, Wang H, Liu X J, Lü Z P 2017 Acta Phys. Sin. 66 176111

Google Scholar

Google Scholar

[26] Pan J, Duan F H 2021 Acta Metall. Sin. 57 439 [潘杰, 段峰辉 2021 金属学报 57 439]

Google Scholar

Google Scholar

Pan J, Duan F H 2021 Acta Metall. Sin. 57 439

Google Scholar

Google Scholar

[27] 张志英, 汤迦南, 余杰, 王旭东, 黄罗超, 邹俊文, 唐浩, 张继康, 陈亚涛, 程东鹏 2018 中国腐蚀与防护学报 38 478

Google Scholar

Google Scholar

Zhang Z Y, Tang J N, Yu J, Wang X D, Huang L C, Zhou J W, Tang H, Zhang J K, Chen Y T, Cheng D P 2018 J. Chin. Soc. Corros. Prot. 38 478

Google Scholar

Google Scholar

[28] Teusner M, Mata J, Sharma N 2022 Curr. Opin. Electroche. 34 100990

Google Scholar

Google Scholar

[29] 刘文胜, 刘书华, 马运柱, 张佳佳, 叶晓珊 2015 稀有金属材料与工程 44 2459

Liu W S, Liu S H, Ma Y Z, Zhang J J, Ye X S 2015 Rare Met. Mater. Eng. 44 2459

[30] Ström P, Primetzhofer D 2021 Nucl. Mater. Energy 27 100979

Google Scholar

Google Scholar

[31] 陈仙, 王炎武, 王晓艳, 安书董, 王小波, 赵玉清 2014 63 246801

Google Scholar

Google Scholar

Chen X, Wang Y W, Wang X Y, An S D, Wang X B, Zhao Y Q 2014 Acta Phys. Sin. 63 246801

Google Scholar

Google Scholar

[32] Wang Q, Liu C T, Yang Y, Liu J B, Dong Y D, Lu J 2014 Sci. Rep-Uk. 4 4648

Google Scholar

Google Scholar

[33] Wang Q, Liu C T, Yang Y, Dong Y D, Lu J 2011 Phys. Rev. Lett. 106 215505

Google Scholar

Google Scholar

[34] Ezzat S S, Mani P D, Khaniya A, Kaden W, Gall D, Barmak K, Coffey K R 2019 J. Vac. Sci. Technol. A 37 031516

Google Scholar

Google Scholar

[35] Guo Y M, Wang X C, Li X, Zhang T 2023 Mater. Lett. 336 133890

Google Scholar

Google Scholar

[36] Yao X, Wang L Y, Shuai C J, Gao C D 2025 Mater. Lett. 384 138127

Google Scholar

Google Scholar

[37] 张广平, 李孟林, 吴细毛, 李春和, 罗雪梅 2014 材料研究学报 28 81

Google Scholar

Google Scholar

Zhang G P, Li M L, Wu X M, Li C H, Luo X M 2014 Chin. J. Mater. Res. 28 81

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 1029

- PDF Downloads: 48

- Cited By: 0

DownLoad:

DownLoad: