-

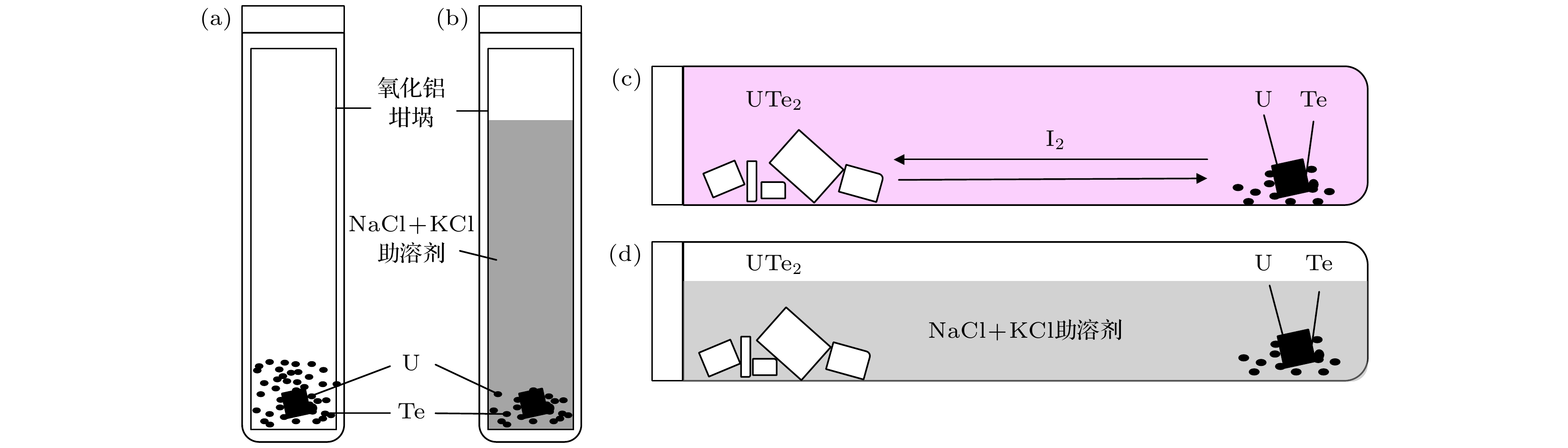

Heavy fermion compound UTe2, as a recently discovered unconventional superconductor, has received significant attention due to its potential spin-triplet superconducting pairing, high-field re-entrant superconducting phases, and unique quantum critical characteristics. However, experimental results of this system show significant changes and discrepancies, primarily due to difference in sample quality. The key unresolved issues include whether the system exhibits multi-component superconducting order parameters, whether time-reversal symmetry is spontaneously broken, and whether multiple field-induced superconducting phases share a common origin. These unsolved issues hinder an in-depth understanding of the intrinsic superconducting pairing mechanism in the UTe2 system. This paper reviews recent advances in single-crystal growth methods for UTe2, including chemical vapor transport (CVT), Te-flux, molten salt flux (MSF), and molten salt flux liquid transport (MSFLT). We systematically analyze how growth conditions influence superconductivity and crystal quality. Although the CVT method was initially employed in UTe2 studies, the samples grown by this method exhibit poor quality and significant compositional inhomogeneity, even in individual samples. Consequently, the CVT method has been progressively supplanted by the recently developed MSF method. In contrast, the MSF method and MSFLT method yield high-quality UTe2 single crystals with Tc achieving a value as high as 2.1 K and residual resistivity ratio (RRR) reaching up to 1000; however, the sample sizes are smaller than those grown by the CVT and Te-flux methods. Notably, MSF-grown samples occasionally contain magnetic impurities such as U7Te12, so careful screening is required in the sample collection process. The MSFLT combines the advantages of CVT and MSF methods to grow high-quality UTe2 single crystals while producing larger sample sizes than MSF. Our research findings highlight the importance of optimizing growth parameters such as Te/U ratio, temperature gradient, and cooling rate. For instance, lower growth temperature and precise control of the Te/U ratio can significantly enhance Tc and sample quality. Several controversies have been identified regarding high-quality MSF and MSFLT samples, including clarifying the single-component nature of the superconducting order parameter and confirming the absence of time-reversal symmetry breaking in optimized samples. This review underscores the pivotal role of advanced single-crystal growth techniques in advancing the study of UTe2. Future research should focus on utilizing these high-quality UTe2 samples grown by MSF and MSFLT methods to accurately determine superconducting order parameters, elucidate mechanisms behind high-field re-entrant superconducting phases, and explore topological properties, such as potential Majorana fermions. These efforts will deepen our understanding of unconventional superconductivity, spin fluctuations, and quantum critical phenomena in the UTe2 system. -

Keywords:

- UTe2 /

- unconventional superconductivity /

- chemical vapor transport method /

- molten salt flux method

[1] Ran S, Eckberg C, Ding Q P, Furukawa Y, Metz T, Saha S R, Liu I L, Zic M, Kim H, Paglione J 2019 Science 365 684

Google Scholar

Google Scholar

[2] Aoki D, Nakamura A, Honda F, Li D, Homma Y, Shimizu Y, Sato Y J, Knebel G, Brison J, Pourret A, Braithwaite D, Lapertot G, Niu Q, Vališka M, Harima H, Flouquet J 2019 J. Phys. Soc. Jpn. 88 043702

Google Scholar

Google Scholar

[3] Nakamine G, Kinjo K, Kitagawa S, Ishida K, Tokunaga Y, Sakai H, Kambe S, Nakamura A, Shimizu Y, Homma Y, Li D, Honda F, Aoki D 2021 Phys. Rev. B 103 L100503

Google Scholar

Google Scholar

[4] Fujibayashi H, Nakamine G, Kinjo K, Kitagawa S, Ishida K, Tokunaga Y, Sakai H, Kambe S, Nakamura A, Shimizu Y, Homma Y, Li D, Honda F, Aoki D 2022 J. Phys. Soc. Jpn. 91 043705

Google Scholar

Google Scholar

[5] 冉升, 焦琳 2021 中国科学: 物理学 力学 天文学) 51 047406

Google Scholar

Google Scholar

Ran S, Jiao L 2021 Sci. Sin. -Phys. Mech. Astron. 51 047406

Google Scholar

Google Scholar

[6] Ran S, Liu I, Eo Y S, Campbell D J, Neves P M, Fuhrman W T, Saha S R, Eckberg C, Kim H, Graf D, Balakirev F, Singleton J, Paglione J, Butch N P 2019 Nat. Phys. 15 1250

Google Scholar

Google Scholar

[7] Knebel G, Knafo W, Pourret A, Niu Q, Valiska M, Braithwaite D, Lapertot G, Nardone M, Zitouni A, Mishra S, Sheikin I, Seyfarth G, Brison J, Aoki D, Flouquet J 2019 J. Phys. Soc. Jpn. 88 063707

Google Scholar

Google Scholar

[8] Ikeda S, Sakai H, Aoki D, Homma Y, Yamamoto E, Nakamura A, Shiokawa Y, Haga Y, Onuki Y 2006 J. Phys. Soc. Jpn. 75 116

Google Scholar

Google Scholar

[9] Braithwaite D, Valiska M, Knebel G, Lapertot G, Brison J, Pourret A, Zhitomirsky M E, Flouquet J, Honda F, Aoki D 2019 Commun. Phys. 2 147

Google Scholar

Google Scholar

[10] Aoki D, Honda F, Knebel G, Braithwaite D, Nakamura A, Li D, Homma Y, Shimizu Y, Sato Y J, Brison J, Flouquet J 2020 J. Phys. Soc. Jpn. 89 053705

Google Scholar

Google Scholar

[11] Ran S, Kim H, Liu I, Saha S R, Hayes I, Metz T, Eo Y S, Paglione J, Butch N P 2020 Phys. Rev. B 101 140503

Google Scholar

Google Scholar

[12] Lin W, Campbell D J, Ran S, Liu I, Kim H, Nevidomskyy A H, Graf D, Butch N P, Paglione J 2020 npj Quantum Mater. 5 68

Google Scholar

Google Scholar

[13] Hayes I M, Wei D S, Metz T, Zhang J, Eo Y S, Ran S, Saha S R, Collini J, Butch N P, Agterberg D F, Kapitulnik A, Paglione J 2021 Science 373 797

Google Scholar

Google Scholar

[14] Thomas S M, Santos F B, Christensen M H, Asaba T, Ronning F, Thompson J D, Bauer E D, Fernandes R M, Fabbris G, Rosa P F S 2020 Sci. Adv. 6 eabc8709

Google Scholar

Google Scholar

[15] Aoki D, Brison J, Flouquet J, Ishida K, Knebel G, Tokunaga Y, Yanase Y 2022 J. Phys. Condens. Matter 34 243002

Google Scholar

Google Scholar

[16] Thomas S M, Stevens C, Santos F B, Fender S S, Bauer E D, Ronning F, Thompson J D, Huxley A, Rosa P F S 2021 Phys. Rev. B 104 224501

Google Scholar

Google Scholar

[17] Rosa P F S, Weiland A, Fender S S, Scott B L, Ronning F, Thompson J D, Bauer E D, Thomas S M 2022 Commun. Mater. 3 33

Google Scholar

Google Scholar

[18] Aoki D, Sakai H, Opletal P, Tokiwa Y, Ishizuka J, Yanase Y, Harima H, Nakamura A, Li D, Homma Y, Shimizu Y, Knebel G, Flouquet J, Haga Y 2022 J. Phys. Soc. Jpn. 91 083704

Google Scholar

Google Scholar

[19] Eaton A G, Weinberger T I, Popiel N J M, Wu Z, Hickey A J, Cabala A, Pospisil J, Prokleska J, Haidamak T, Bastien G, Opletal P, Sakai H, Haga Y, Nowell R, Benjamin S M, Sechovsky V, Lonzarich G G, Grosche F M, Valiska M 2024 Nat. Commun. 15 223

Google Scholar

Google Scholar

[20] Ajeesh M O, Bordelon M, Girod C, Mishra S, Ronning F, Bauer E D, Maiorov B, Thompson J D, Rosa P F S, Thomas S M 2023 Phys. Rev. X 13 041019

Google Scholar

Google Scholar

[21] Xu Y, Sheng Y, Yang Y 2019 Phys. Rev. Lett. 123 217002

Google Scholar

Google Scholar

[22] Stöwe K 1996 J. Solid. State. Chem. 127 202

Google Scholar

Google Scholar

[23] Ran S, Liu I L, Saha S R, Saraf P, Paglione J, Butch N P 2021 J. Vis. Exp. 173 e62563

Google Scholar

Google Scholar

[24] Jiao L, Howard S, Ran S, Wang Z, Rodriguez J O, Sigrist M, Wang Z, Butch N P, Madhavan V 2020 Nature 579 523

Google Scholar

Google Scholar

[25] Fujimori S, Kawasaki D, Takeda Y, Yamagami H, Nakamura A, Homma Y, Aoki D 2019 J. Phys. Soc. Jpn. 88 103701

Google Scholar

Google Scholar

[26] Miao L, Liu S, Xu Y, Kotta E C, Kang C, Ran S, Paglione J, Kotliar G, Butch N P, Denlinger J D, Wray L A 2020 Phys. Rev. Lett. 124 076401

Google Scholar

Google Scholar

[27] Cairns L P, Stevens C R, O'Neill C D, Huxley A 2020 J. Phys. Condens. Matter 32 415602

Google Scholar

Google Scholar

[28] Haga Y, Opletal P, Tokiwa Y, Yamamoto E, Tokunaga Y, Kambe S, Sakai H 2022 J. Phys. Condens. Matter 34 175601

Google Scholar

Google Scholar

[29] Yang C, Guo J, Cai S, Zhou Y, Sidorov V A, Huang C, Long S, Shi Y, Chen Q, Tan S, Wu Q, Coleman P, Xiang T, Sun L 2022 Phys. Rev. B 106 24503

Google Scholar

Google Scholar

[30] Frank C E, Lewin S K, Salas G S, Czajka P, Hayes I M, Yoon H, Metz T, Paglione J, Singleton J, Butch N P 2024 Nat. Commun. 15 3378

Google Scholar

Google Scholar

[31] Aoki D, Nakamura A, Honda F, Li D, Homma Y, Shimizu Y, Sato Y J, Knebel G, Brison J, Pourret A, Braithwaite D, Lapertot G, Niu Q, Vali Ka M, Harima H, Flouquet J 2020 Proceedings of the International Conference on Strongly Correlated Electron Systems (SCES2019) Okayama, Japan, September 23-28, 2019 011065

[32] Mineev V P 2022 J. Phys. Soc. Jpn. 91 074601

Google Scholar

Google Scholar

[33] Sundar S, Azari N, Goeks M R, Gheidi S, Abedi M, Yakovlev M, Dunsiger S R, Wilkinson J M, Blundell S J, Metz T E, Hayes I M, Saha S R, Lee S, Woods A J, Movshovich R, Thomas S M, Butch N P, Rosa P F S, Paglione J, Sonier J E 2023 Commun. Phys. 6 24

Google Scholar

Google Scholar

[34] Theuss F, Shragai A, Grissonnanche G, Hayes I M, Saha S R, Eo Y S, Suarez A, Shishidou T, Butch N P, Paglione J, Ramshaw B J 2024 Nat. Phys. 20 1124

Google Scholar

Google Scholar

[35] Yao S, Li T, Yue C, Xu X, Zhang B, Zhang C 2022 CrystEngComm 24 6262

Google Scholar

Google Scholar

[36] 谢东华, 赖新春, 谭世勇, 张文, 刘毅, 冯卫, 张云, 刘琴, 朱燮刚, 袁秉凯, 方运 2016 稀有金属材料与工程 45 2128

Xie D H, Lai X C, Tan S Y, Zhang W, Liu Y, Feng W, Zhang Y, Liu Q, Zhu X G, Yuan B K, Fang Y 2016 Rare Met. Mater. Eng. 45 2128

[37] Ji X, Liu Q, Feng W, Zhang Y, Chen Q, Liu Y, Hao Q, Wu J, Xue Z, Zhu X, Zhang Q, Luo X, Tan S, Lai X 2024 Phys. Rev. B 109 075158

Google Scholar

Google Scholar

[38] Sakai H, Opletal P, Tokiwa Y, Yamamoto E, Tokunaga Y, Kambe S, Haga Y 2022 Phys. Rev. Mater. 6 073401

Google Scholar

Google Scholar

[39] Bdey S, Savvin S N, Bourguiba N F, Núñez P 2022 J. Solid State Chem. 305 122644

Google Scholar

Google Scholar

[40] Kwon M J, Binh N V, Cho S, Shim S B, Ryu S H, Jung Y J, Nam W H, Cho J Y, Park J H 2024 Electron. Mater. Lett. 20 559

Google Scholar

Google Scholar

[41] Chen H, Singh S, Mei H, Ren G, Zhao B, Surendran M, Wang Y, Mishra R, Kats M A, Ravichandran J 2024 J. Mater. Res. 39 1901

Google Scholar

Google Scholar

[42] Matsumura H, Fujibayashi H, Kinjo K, Kitagawa S, Ishida K, Tokunaga Y, Sakai H, Kambe S, Nakamura A, Shimizu Y, Homma Y, Li D, Honda F, Aoki D 2023 J. Phys. Soc. Jpn. 92 063701

Google Scholar

Google Scholar

[43] Ishihara K, Roppongi M, Kobayashi M, Imamura K, Mizukami Y, Sakai H, Opletal P, Tokiwa Y, Haga Y, Hashimoto K, Shibauchi T 2023 Nat. Commun. 14 2966

Google Scholar

Google Scholar

[44] Azari N, Yakovlev M, Rye N, Dunsiger S R, Sundar S, Bordelon M M, Thomas S M, Thompson J D, Rosa P F S, Sonier J E 2023 Phys. Rev. Lett. 131 226504

Google Scholar

Google Scholar

[45] Ishihara K, Kobayashi M, Imamura K, Konczykowski M, Sakai H, Opletal P, Tokiwa Y, Haga Y, Hashimoto K, Shibauchi T 2023 Phys. Rev. Res. 5 L022002

Google Scholar

Google Scholar

[46] Vališka M, Haidamak T, Cabala A, Pospíšil J, Bastien G, Sechovský V, Prokleška J, Yanagisawa T, Opletal P, Sakai H, Haga Y, Miyata A, Gorbunov D, Zherlitsyn S 2024 Phys. Rev. Mater. 8 094415

Google Scholar

Google Scholar

[47] Broyles C, Rehfuss Z, Siddiquee H, Zhu J A, Zheng K, Nikolo M, Graf D, Singleton J, Ran S 2023 Phys. Rev. Lett. 131 036501

Google Scholar

Google Scholar

[48] Aoki D, Sheikin I, McCollam A, Ishizuka J, Yanase Y, Lapertot G, Flouquet J, Knebel G 2023 J. Phys. Soc. Jpn. 92 065002

Google Scholar

Google Scholar

[49] Weinberger T I, Wu Z, Graf D E, Skourski Y, Cabala A, Pospíšil J, Prokleška J, Haidamak T, Bastien G, Sechovský V, Lonzarich G G, Vališka M, Grosche F M, Eaton A G 2024 Phys. Rev. Lett. 132 266503

Google Scholar

Google Scholar

[50] Serrano K, Taxil P 1999 J. Appl. Electrochem. 29 497

Google Scholar

Google Scholar

[51] Opletal P, Sakai H, Haga Y, Tokiwa Y, Yamamoto E, Kambe S, Tokunaga Y 2023 J. Phys. Soc. Jpn. 92 034704

Google Scholar

Google Scholar

[52] Wu Z, Weinberger T I, Chen J, Cabala A, Chichinadze D V, Shaffer D, Pospíšil J, Prokleška J, Haidamak T, Bastien G, Sechovský V, Hickey A J, Mancera-Ugarte M J, Benjamin S, Graf D E, Skourski Y, Lonzarich G G, Vališka M, Grosche F M, Eaton A G 2024 Proc. Natl. Acad. Sci. U.S.A. 121 e2403067121

Google Scholar

Google Scholar

[53] Aoki D 2024 J. Phys. Soc. Jpn. 93 043703

Google Scholar

Google Scholar

[54] Tokiwa Y, Sakai H, Kambe S, Opletal P, Yamamoto E, Kimata M, Awaji S, Sasaki T, Yanase Y, Haga Y, Tokunaga Y 2023 Phys. Rev. B 108 144502

Google Scholar

Google Scholar

-

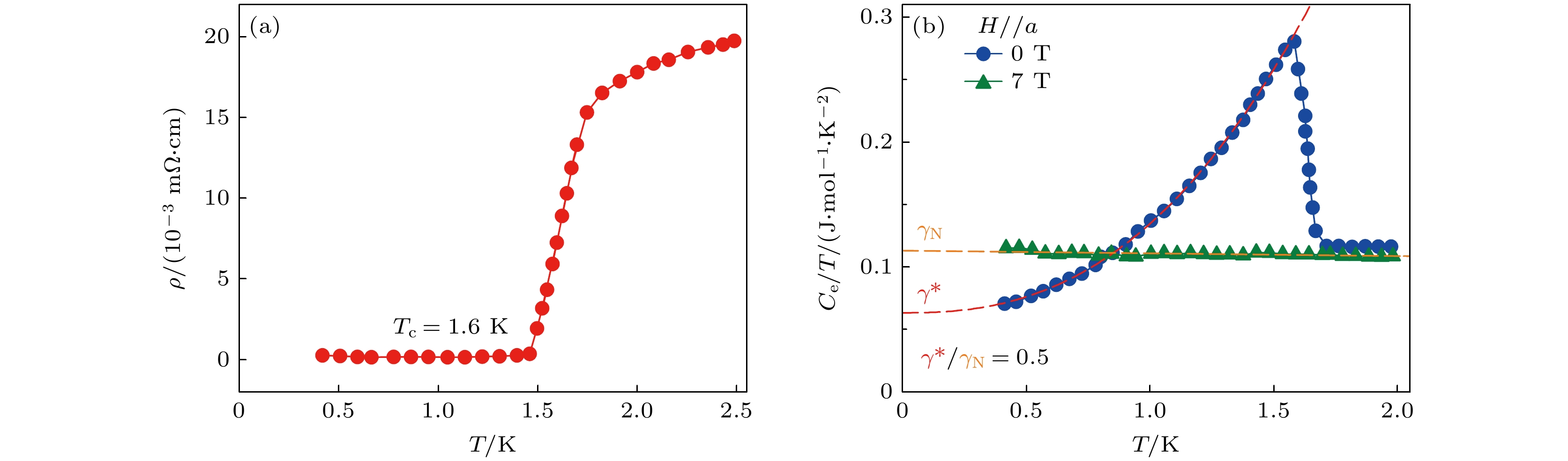

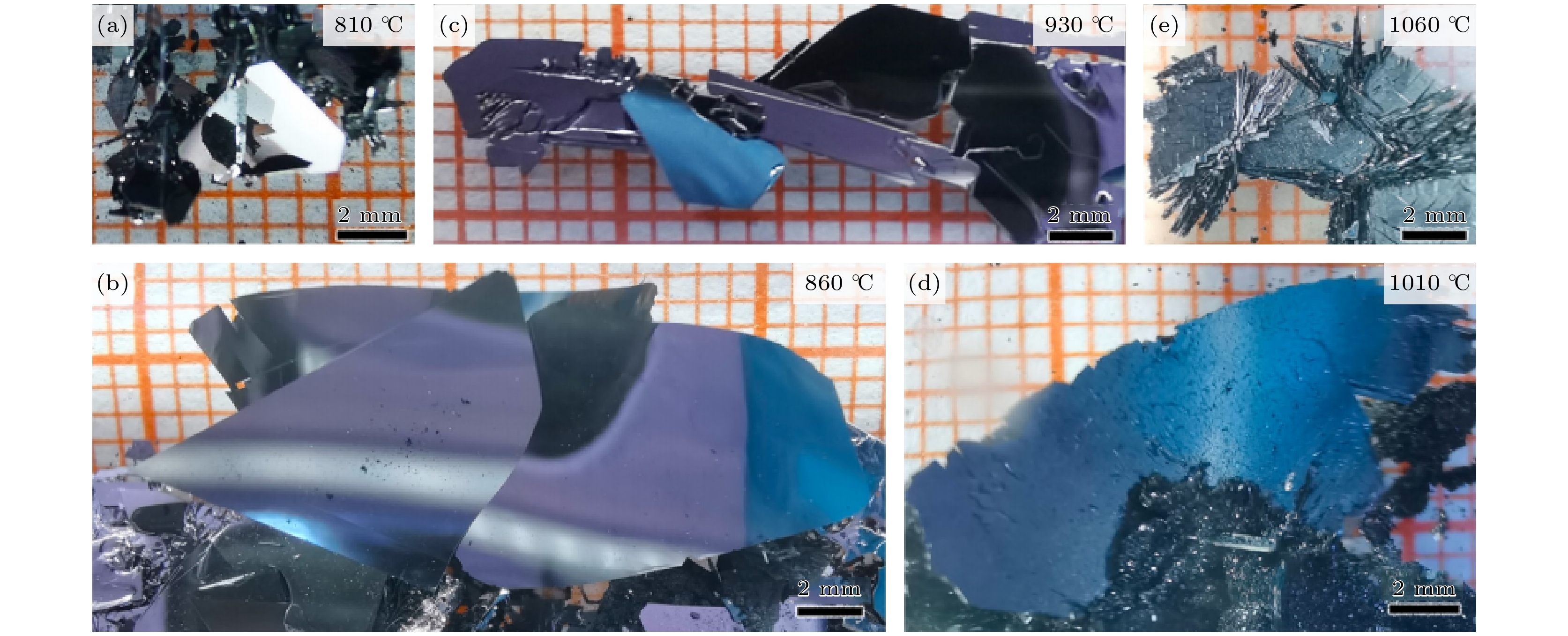

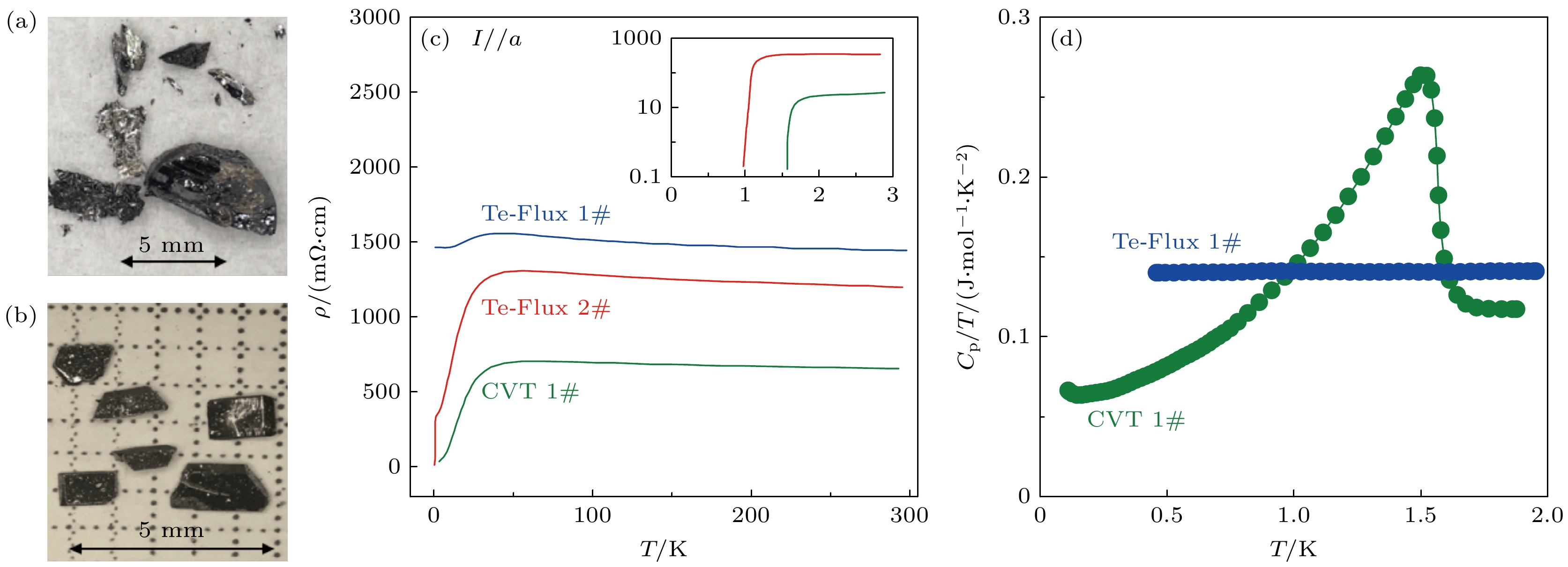

图 3 (a)不同起始原料摩尔比MTe/U样品的电阻率测量结果[27], 并与Ran等[1]和Hayes等[13]对比; (b) Tc = 2 K样品(C6)的比热测量结果, 插图为样品照片[27]

Figure 3. (a) Resistivity of samples with different initial molar ratios MTe/U [27] and comparison with those reported by Ran et al.[1] and Hayes et al. [13]; (b) specific heat data of sample C6 with Tc = 2 K, and the inset shows a sample image [27].

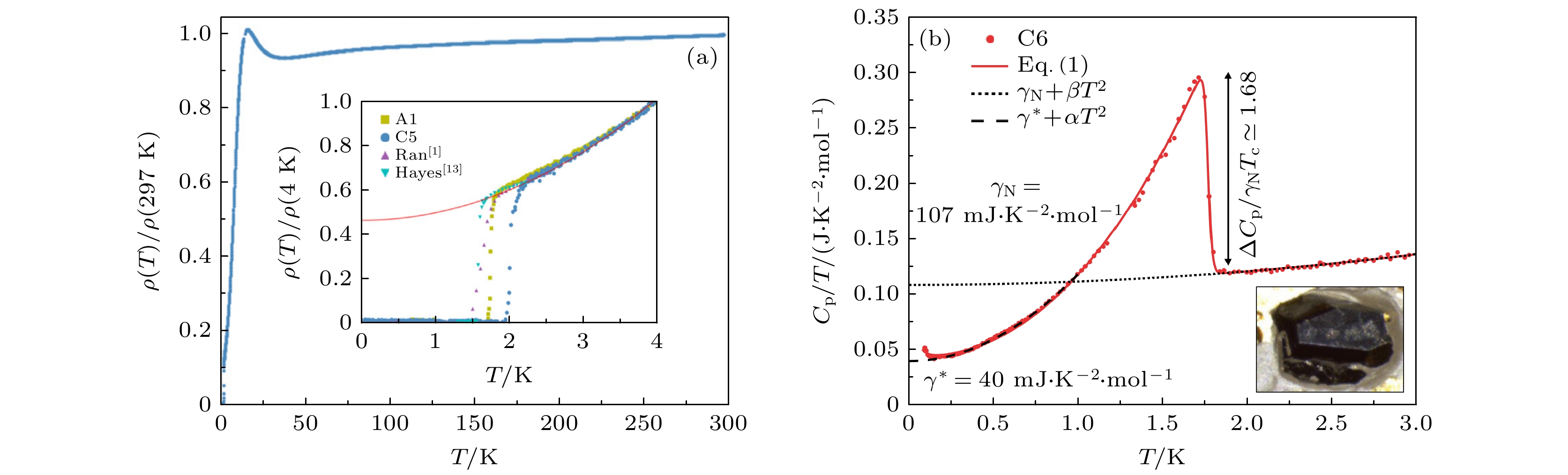

图 4 (a)不同生长温度获得UTe2样品的比热数据[17]; (b) 1060—1000 ℃温度梯度下生长的UTe2样品中测得Tc附近的极化Kerr角度演化[13]. 数据来源于文献[17,13]

Figure 4. (a) Specific heat data of UTe2 samples obtained at different growth temperatures [17]; (b) polar Kerr angle evolution near Tc in a UTe2 sample grown under a temperature gradient of 1060–1000 ℃[13]. The data are taken from Refs.[17,13].

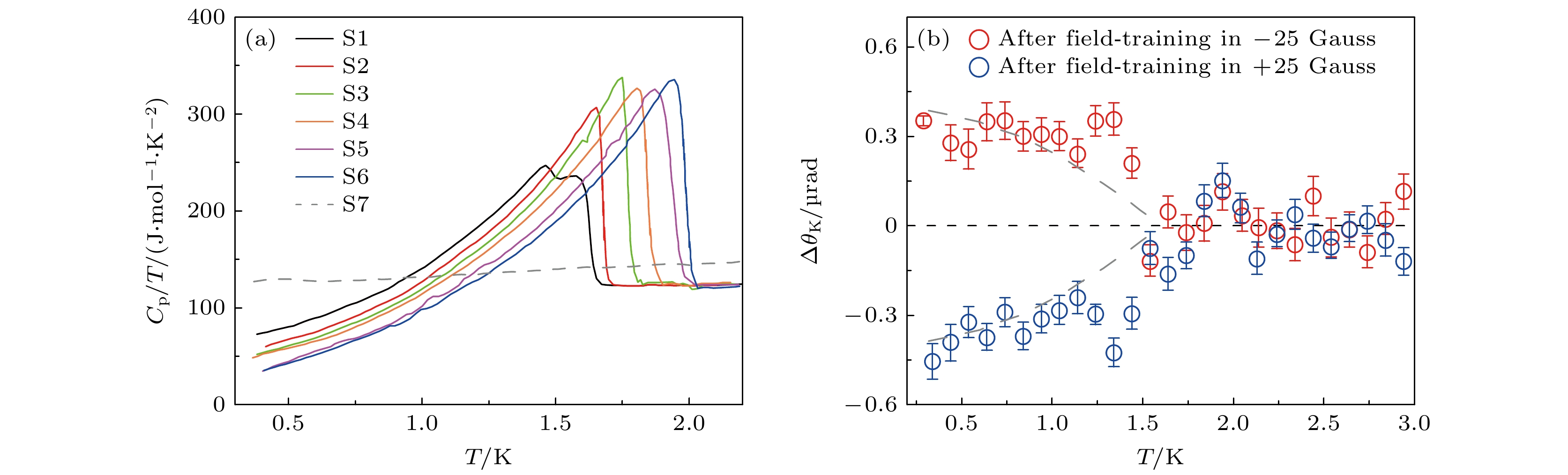

图 5 不同生长温度下获得UTe2样品的照片, 起始原料摩尔比MTe/U = 2, 标注为高温端温度 [35] (a) 810 ℃; (b) 860 ℃; (c) 930 ℃; (d) 1010 ℃; (e) 1060 ℃. 出自文献[35], 已获得授权

Figure 5. Photos of UTe2 samples obtained at different growth temperatures, with the molar ratio of the starting materials (MTe/U) set to 2, are labeled with the high-end temperatures [35]: (a) 810 ℃; (b) 860 ℃; (c) 930 ℃; (d) 1010 ℃; (e) 1060 ℃. Reproduced with permission from Ref.[35].

表 1 CVT起始原料摩尔比MTe/U对UTe2样品实际成分和Tc的影响[27]

Table 1. The impact of the molar ratio of MTe/U in CVT starting materials on the actual composition and Tc of UTe2 samples [27].

样品分组 起始原料

摩尔比MTe/UEDX测得的

MTe/U范围电阻率

测得的TcA 1.71 1.46—1.50 1.74 K B 2.14 1.79—2.06 无超导 C 1.85 1.72—1.87 2.00 K 表 2 CVT生长温度对UTe2单晶的Tc和样品质量的影响[17]

Table 2. Effect of CVT growth temperature on Tc and sample quality of UTe2 single crystals [17].

样品

编号生长

温度/℃比热

测得的

Tc/KRRR γ*/γN

(γN = 121

mJ·mol–1·K–1)s1 1060—1000 1.64

1.4830—40 0.54 s2 950—860 1.68 — 0.42 s3 925—835 1.77 — 0.36 s4 875—785 1.85 55 0.34 s5 825—735 1.95 70 0.21 s6 800—710 2.00 88 0.19 s7 775—685 No SC 2 — 表 3 MSF方法工艺参数对UTe2单晶Tc和样品质量的影响[38]

Table 3. Effect of MSF process parameters on the Tc and sample quality of UTe2 single crystals [38].

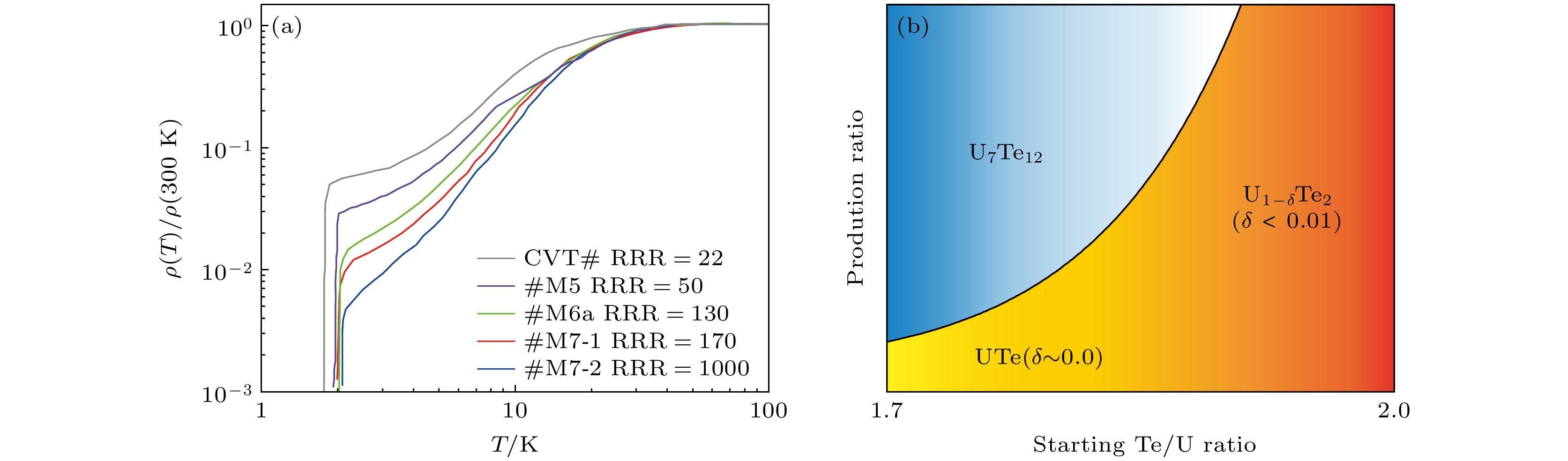

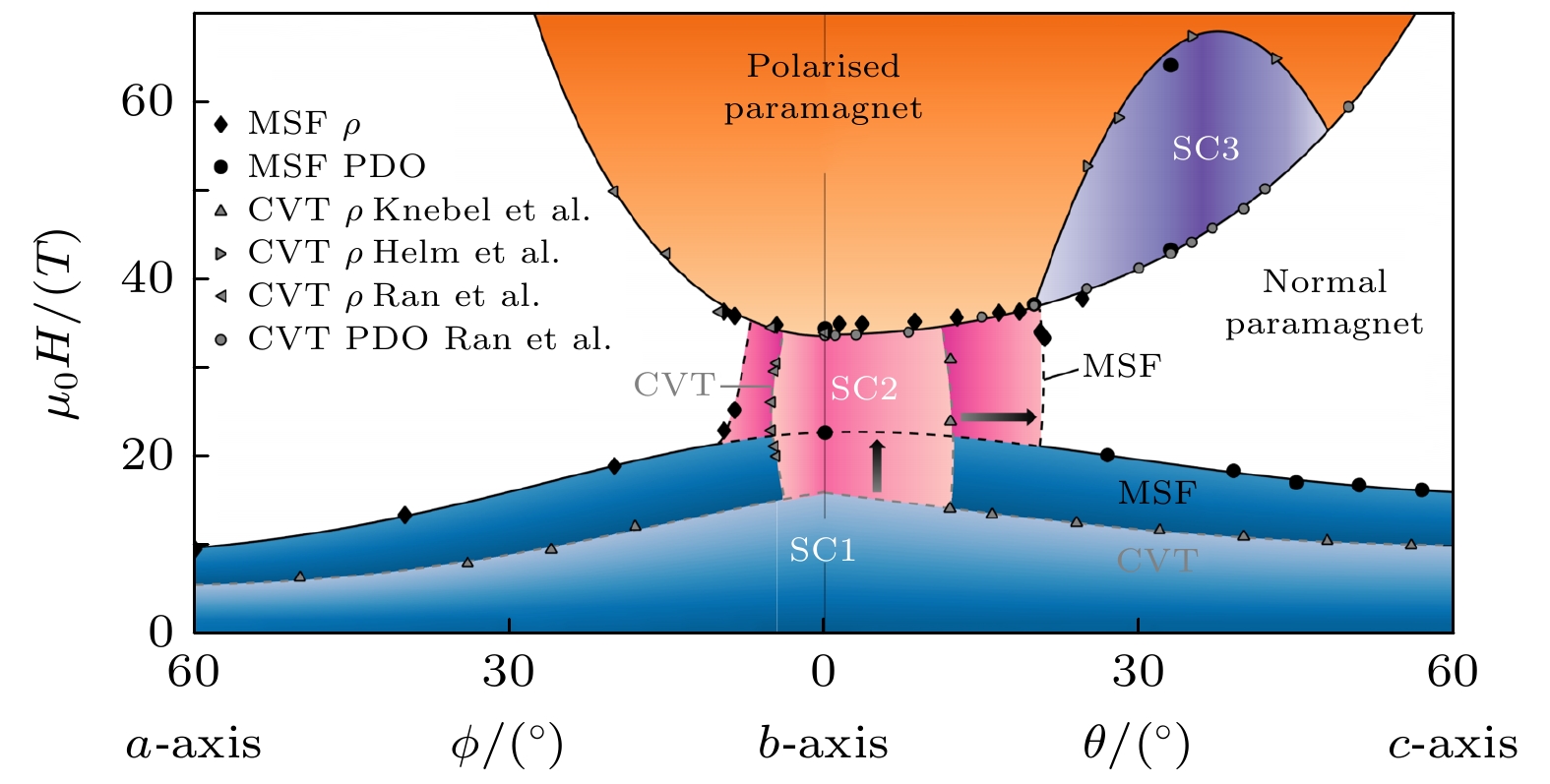

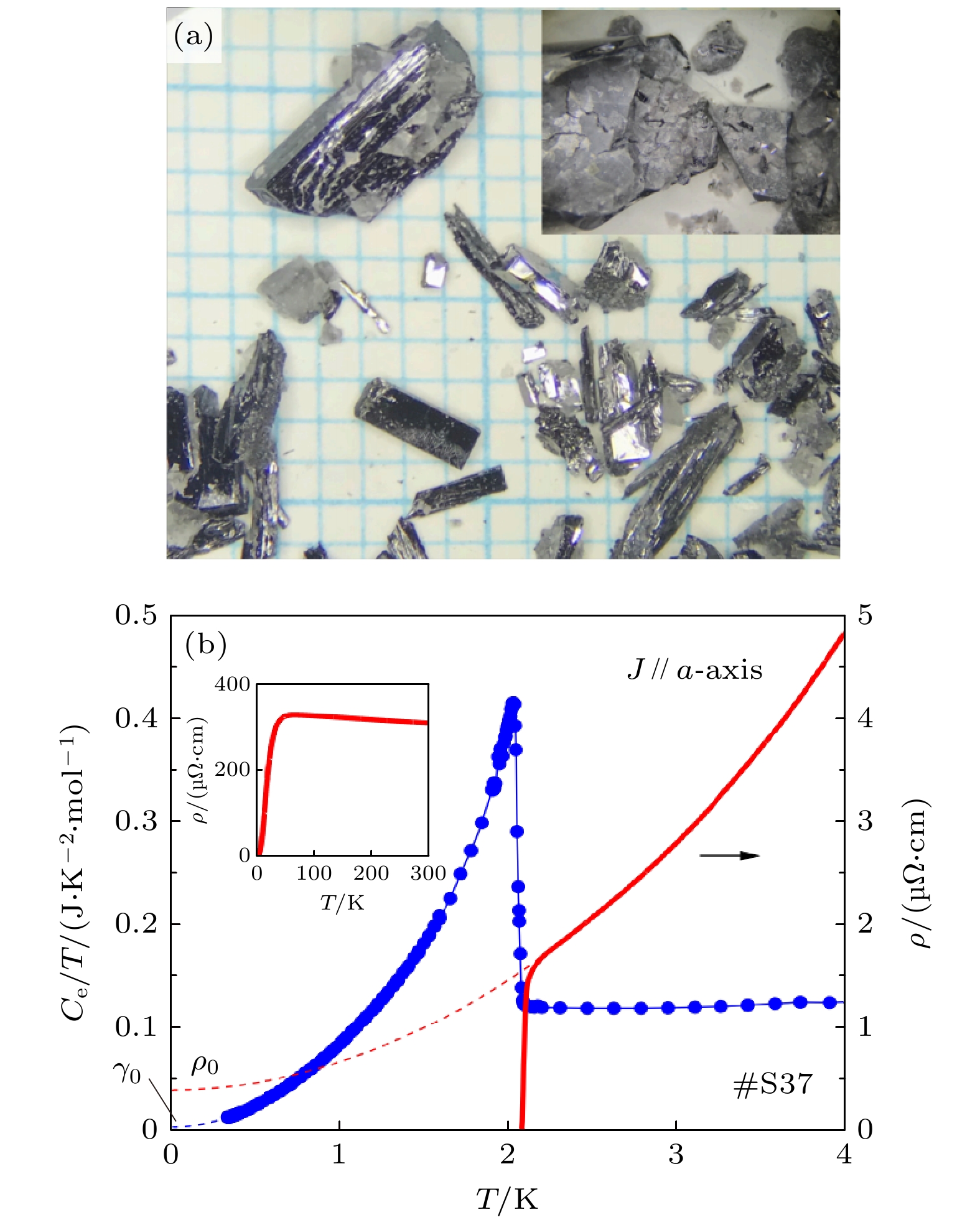

样品编号 原料比例 Tf/℃ Tc/K RRR 备注 MTe/U MSalt/U M1 2 29 650 1.7—1.8 40—60 M2 1.93 37 650 1.9—2.0 60—80 M3 1.92 36 650 1.95—2.0 30—40 M4 1.90 40 650 1.8—1.95 50—60 M5 1.90 67 650 1.9—2.05 50—60 M6 1.8 21 650 — — 产物为U7Te12 M6a 1.8 40 650 2.0—2.1 80—130 主要产物为U7Te12 M7 1.71 60 650 2.1 170—1000 主要产物为U7Te12 H1 2.0 48 700 1.6 11—12 离心去除盐 H2 1.95 42 700 1.75—1.9 35—60 L1 1.95 38 600 1.6—1.8 20—30 L2 1.90 44 600 2.1—2.2 65—70 聚集晶体 表 4 不同生长方法获得UTe2单晶的Tc和样品质量对比[53]

Table 4. Comparison of Tc and sample quality of UTe2 single crystals grown by different methods [53].

生长方法 原料比例MTe/U 助熔剂/输运剂 生长温度/℃ Tc/K RRR γ*/γN Te-flux 3.55 Te 1050 1.08 3.6 — CVT 2.00 I2 950—850 — 2.5 — CVT 1.50 I2 1050—990 1.65 14 0.61 CVT 1.40 I2 780—680 2.01 49 0.13 MSF 1.80 NaCl+KCl 950 <1.70 22 0.78 MSF 1.65 NaCl+KCl 950 2.06 220 0.046 MSFLT 1.50 NaCl+KCl 750—650 2.06 179 0.124 MSFLT 1.65 NaCl+KCl 750—650 2.09 800 0.034 表 5 不同生长方法的工艺特点与优缺点

Table 5. Process characteristics, advantages and disadvantages of different growth methods.

方法 最优的

工艺参数最佳的

超导样品影响因素 优点 缺点 CVT 原料比例MTe/U = 1.5

生长温度梯度800—710 ℃Tc = 2.0 K

RRR = 88原料比例MTe/U

生长温度梯度

输运剂类型与用量生长温度较低

样品尺寸大样品质量较差

成分均匀性差Te-flux 原料比例MTe/U = 3.55

生长温度1050 ℃

离心温度950 ℃Tc = 1.1 K

RRR = 4原料比例MTe/U

生长温度

降温速率工艺简单

样品产量高

样品尺寸大几乎不超导

样品质量差

生长温度高MSF 原料比例MTe/U = 1.71

原料比例MSalt/U = 60

生长温度950 ℃

退火温度650 ℃Tc = 2.1 K

RRR = 1000原料比例MTe/U

原料比例MSalt/U

退火温度;

降温速率

助熔剂盐的含水量样品质量高

生长温度较低产物伴随有磁性杂质

U7Te12 样品尺寸小MSFLT 原料比例MTe/U = 1.65

生长温度梯度750—670 ℃Tc = 2.09 K

RRR = 800原料比例MTe/U

助熔剂盐的含水量

生长温度梯度样品质量高

生长温度低样品尺寸较小 -

[1] Ran S, Eckberg C, Ding Q P, Furukawa Y, Metz T, Saha S R, Liu I L, Zic M, Kim H, Paglione J 2019 Science 365 684

Google Scholar

Google Scholar

[2] Aoki D, Nakamura A, Honda F, Li D, Homma Y, Shimizu Y, Sato Y J, Knebel G, Brison J, Pourret A, Braithwaite D, Lapertot G, Niu Q, Vališka M, Harima H, Flouquet J 2019 J. Phys. Soc. Jpn. 88 043702

Google Scholar

Google Scholar

[3] Nakamine G, Kinjo K, Kitagawa S, Ishida K, Tokunaga Y, Sakai H, Kambe S, Nakamura A, Shimizu Y, Homma Y, Li D, Honda F, Aoki D 2021 Phys. Rev. B 103 L100503

Google Scholar

Google Scholar

[4] Fujibayashi H, Nakamine G, Kinjo K, Kitagawa S, Ishida K, Tokunaga Y, Sakai H, Kambe S, Nakamura A, Shimizu Y, Homma Y, Li D, Honda F, Aoki D 2022 J. Phys. Soc. Jpn. 91 043705

Google Scholar

Google Scholar

[5] 冉升, 焦琳 2021 中国科学: 物理学 力学 天文学) 51 047406

Google Scholar

Google Scholar

Ran S, Jiao L 2021 Sci. Sin. -Phys. Mech. Astron. 51 047406

Google Scholar

Google Scholar

[6] Ran S, Liu I, Eo Y S, Campbell D J, Neves P M, Fuhrman W T, Saha S R, Eckberg C, Kim H, Graf D, Balakirev F, Singleton J, Paglione J, Butch N P 2019 Nat. Phys. 15 1250

Google Scholar

Google Scholar

[7] Knebel G, Knafo W, Pourret A, Niu Q, Valiska M, Braithwaite D, Lapertot G, Nardone M, Zitouni A, Mishra S, Sheikin I, Seyfarth G, Brison J, Aoki D, Flouquet J 2019 J. Phys. Soc. Jpn. 88 063707

Google Scholar

Google Scholar

[8] Ikeda S, Sakai H, Aoki D, Homma Y, Yamamoto E, Nakamura A, Shiokawa Y, Haga Y, Onuki Y 2006 J. Phys. Soc. Jpn. 75 116

Google Scholar

Google Scholar

[9] Braithwaite D, Valiska M, Knebel G, Lapertot G, Brison J, Pourret A, Zhitomirsky M E, Flouquet J, Honda F, Aoki D 2019 Commun. Phys. 2 147

Google Scholar

Google Scholar

[10] Aoki D, Honda F, Knebel G, Braithwaite D, Nakamura A, Li D, Homma Y, Shimizu Y, Sato Y J, Brison J, Flouquet J 2020 J. Phys. Soc. Jpn. 89 053705

Google Scholar

Google Scholar

[11] Ran S, Kim H, Liu I, Saha S R, Hayes I, Metz T, Eo Y S, Paglione J, Butch N P 2020 Phys. Rev. B 101 140503

Google Scholar

Google Scholar

[12] Lin W, Campbell D J, Ran S, Liu I, Kim H, Nevidomskyy A H, Graf D, Butch N P, Paglione J 2020 npj Quantum Mater. 5 68

Google Scholar

Google Scholar

[13] Hayes I M, Wei D S, Metz T, Zhang J, Eo Y S, Ran S, Saha S R, Collini J, Butch N P, Agterberg D F, Kapitulnik A, Paglione J 2021 Science 373 797

Google Scholar

Google Scholar

[14] Thomas S M, Santos F B, Christensen M H, Asaba T, Ronning F, Thompson J D, Bauer E D, Fernandes R M, Fabbris G, Rosa P F S 2020 Sci. Adv. 6 eabc8709

Google Scholar

Google Scholar

[15] Aoki D, Brison J, Flouquet J, Ishida K, Knebel G, Tokunaga Y, Yanase Y 2022 J. Phys. Condens. Matter 34 243002

Google Scholar

Google Scholar

[16] Thomas S M, Stevens C, Santos F B, Fender S S, Bauer E D, Ronning F, Thompson J D, Huxley A, Rosa P F S 2021 Phys. Rev. B 104 224501

Google Scholar

Google Scholar

[17] Rosa P F S, Weiland A, Fender S S, Scott B L, Ronning F, Thompson J D, Bauer E D, Thomas S M 2022 Commun. Mater. 3 33

Google Scholar

Google Scholar

[18] Aoki D, Sakai H, Opletal P, Tokiwa Y, Ishizuka J, Yanase Y, Harima H, Nakamura A, Li D, Homma Y, Shimizu Y, Knebel G, Flouquet J, Haga Y 2022 J. Phys. Soc. Jpn. 91 083704

Google Scholar

Google Scholar

[19] Eaton A G, Weinberger T I, Popiel N J M, Wu Z, Hickey A J, Cabala A, Pospisil J, Prokleska J, Haidamak T, Bastien G, Opletal P, Sakai H, Haga Y, Nowell R, Benjamin S M, Sechovsky V, Lonzarich G G, Grosche F M, Valiska M 2024 Nat. Commun. 15 223

Google Scholar

Google Scholar

[20] Ajeesh M O, Bordelon M, Girod C, Mishra S, Ronning F, Bauer E D, Maiorov B, Thompson J D, Rosa P F S, Thomas S M 2023 Phys. Rev. X 13 041019

Google Scholar

Google Scholar

[21] Xu Y, Sheng Y, Yang Y 2019 Phys. Rev. Lett. 123 217002

Google Scholar

Google Scholar

[22] Stöwe K 1996 J. Solid. State. Chem. 127 202

Google Scholar

Google Scholar

[23] Ran S, Liu I L, Saha S R, Saraf P, Paglione J, Butch N P 2021 J. Vis. Exp. 173 e62563

Google Scholar

Google Scholar

[24] Jiao L, Howard S, Ran S, Wang Z, Rodriguez J O, Sigrist M, Wang Z, Butch N P, Madhavan V 2020 Nature 579 523

Google Scholar

Google Scholar

[25] Fujimori S, Kawasaki D, Takeda Y, Yamagami H, Nakamura A, Homma Y, Aoki D 2019 J. Phys. Soc. Jpn. 88 103701

Google Scholar

Google Scholar

[26] Miao L, Liu S, Xu Y, Kotta E C, Kang C, Ran S, Paglione J, Kotliar G, Butch N P, Denlinger J D, Wray L A 2020 Phys. Rev. Lett. 124 076401

Google Scholar

Google Scholar

[27] Cairns L P, Stevens C R, O'Neill C D, Huxley A 2020 J. Phys. Condens. Matter 32 415602

Google Scholar

Google Scholar

[28] Haga Y, Opletal P, Tokiwa Y, Yamamoto E, Tokunaga Y, Kambe S, Sakai H 2022 J. Phys. Condens. Matter 34 175601

Google Scholar

Google Scholar

[29] Yang C, Guo J, Cai S, Zhou Y, Sidorov V A, Huang C, Long S, Shi Y, Chen Q, Tan S, Wu Q, Coleman P, Xiang T, Sun L 2022 Phys. Rev. B 106 24503

Google Scholar

Google Scholar

[30] Frank C E, Lewin S K, Salas G S, Czajka P, Hayes I M, Yoon H, Metz T, Paglione J, Singleton J, Butch N P 2024 Nat. Commun. 15 3378

Google Scholar

Google Scholar

[31] Aoki D, Nakamura A, Honda F, Li D, Homma Y, Shimizu Y, Sato Y J, Knebel G, Brison J, Pourret A, Braithwaite D, Lapertot G, Niu Q, Vali Ka M, Harima H, Flouquet J 2020 Proceedings of the International Conference on Strongly Correlated Electron Systems (SCES2019) Okayama, Japan, September 23-28, 2019 011065

[32] Mineev V P 2022 J. Phys. Soc. Jpn. 91 074601

Google Scholar

Google Scholar

[33] Sundar S, Azari N, Goeks M R, Gheidi S, Abedi M, Yakovlev M, Dunsiger S R, Wilkinson J M, Blundell S J, Metz T E, Hayes I M, Saha S R, Lee S, Woods A J, Movshovich R, Thomas S M, Butch N P, Rosa P F S, Paglione J, Sonier J E 2023 Commun. Phys. 6 24

Google Scholar

Google Scholar

[34] Theuss F, Shragai A, Grissonnanche G, Hayes I M, Saha S R, Eo Y S, Suarez A, Shishidou T, Butch N P, Paglione J, Ramshaw B J 2024 Nat. Phys. 20 1124

Google Scholar

Google Scholar

[35] Yao S, Li T, Yue C, Xu X, Zhang B, Zhang C 2022 CrystEngComm 24 6262

Google Scholar

Google Scholar

[36] 谢东华, 赖新春, 谭世勇, 张文, 刘毅, 冯卫, 张云, 刘琴, 朱燮刚, 袁秉凯, 方运 2016 稀有金属材料与工程 45 2128

Xie D H, Lai X C, Tan S Y, Zhang W, Liu Y, Feng W, Zhang Y, Liu Q, Zhu X G, Yuan B K, Fang Y 2016 Rare Met. Mater. Eng. 45 2128

[37] Ji X, Liu Q, Feng W, Zhang Y, Chen Q, Liu Y, Hao Q, Wu J, Xue Z, Zhu X, Zhang Q, Luo X, Tan S, Lai X 2024 Phys. Rev. B 109 075158

Google Scholar

Google Scholar

[38] Sakai H, Opletal P, Tokiwa Y, Yamamoto E, Tokunaga Y, Kambe S, Haga Y 2022 Phys. Rev. Mater. 6 073401

Google Scholar

Google Scholar

[39] Bdey S, Savvin S N, Bourguiba N F, Núñez P 2022 J. Solid State Chem. 305 122644

Google Scholar

Google Scholar

[40] Kwon M J, Binh N V, Cho S, Shim S B, Ryu S H, Jung Y J, Nam W H, Cho J Y, Park J H 2024 Electron. Mater. Lett. 20 559

Google Scholar

Google Scholar

[41] Chen H, Singh S, Mei H, Ren G, Zhao B, Surendran M, Wang Y, Mishra R, Kats M A, Ravichandran J 2024 J. Mater. Res. 39 1901

Google Scholar

Google Scholar

[42] Matsumura H, Fujibayashi H, Kinjo K, Kitagawa S, Ishida K, Tokunaga Y, Sakai H, Kambe S, Nakamura A, Shimizu Y, Homma Y, Li D, Honda F, Aoki D 2023 J. Phys. Soc. Jpn. 92 063701

Google Scholar

Google Scholar

[43] Ishihara K, Roppongi M, Kobayashi M, Imamura K, Mizukami Y, Sakai H, Opletal P, Tokiwa Y, Haga Y, Hashimoto K, Shibauchi T 2023 Nat. Commun. 14 2966

Google Scholar

Google Scholar

[44] Azari N, Yakovlev M, Rye N, Dunsiger S R, Sundar S, Bordelon M M, Thomas S M, Thompson J D, Rosa P F S, Sonier J E 2023 Phys. Rev. Lett. 131 226504

Google Scholar

Google Scholar

[45] Ishihara K, Kobayashi M, Imamura K, Konczykowski M, Sakai H, Opletal P, Tokiwa Y, Haga Y, Hashimoto K, Shibauchi T 2023 Phys. Rev. Res. 5 L022002

Google Scholar

Google Scholar

[46] Vališka M, Haidamak T, Cabala A, Pospíšil J, Bastien G, Sechovský V, Prokleška J, Yanagisawa T, Opletal P, Sakai H, Haga Y, Miyata A, Gorbunov D, Zherlitsyn S 2024 Phys. Rev. Mater. 8 094415

Google Scholar

Google Scholar

[47] Broyles C, Rehfuss Z, Siddiquee H, Zhu J A, Zheng K, Nikolo M, Graf D, Singleton J, Ran S 2023 Phys. Rev. Lett. 131 036501

Google Scholar

Google Scholar

[48] Aoki D, Sheikin I, McCollam A, Ishizuka J, Yanase Y, Lapertot G, Flouquet J, Knebel G 2023 J. Phys. Soc. Jpn. 92 065002

Google Scholar

Google Scholar

[49] Weinberger T I, Wu Z, Graf D E, Skourski Y, Cabala A, Pospíšil J, Prokleška J, Haidamak T, Bastien G, Sechovský V, Lonzarich G G, Vališka M, Grosche F M, Eaton A G 2024 Phys. Rev. Lett. 132 266503

Google Scholar

Google Scholar

[50] Serrano K, Taxil P 1999 J. Appl. Electrochem. 29 497

Google Scholar

Google Scholar

[51] Opletal P, Sakai H, Haga Y, Tokiwa Y, Yamamoto E, Kambe S, Tokunaga Y 2023 J. Phys. Soc. Jpn. 92 034704

Google Scholar

Google Scholar

[52] Wu Z, Weinberger T I, Chen J, Cabala A, Chichinadze D V, Shaffer D, Pospíšil J, Prokleška J, Haidamak T, Bastien G, Sechovský V, Hickey A J, Mancera-Ugarte M J, Benjamin S, Graf D E, Skourski Y, Lonzarich G G, Vališka M, Grosche F M, Eaton A G 2024 Proc. Natl. Acad. Sci. U.S.A. 121 e2403067121

Google Scholar

Google Scholar

[53] Aoki D 2024 J. Phys. Soc. Jpn. 93 043703

Google Scholar

Google Scholar

[54] Tokiwa Y, Sakai H, Kambe S, Opletal P, Yamamoto E, Kimata M, Awaji S, Sasaki T, Yanase Y, Haga Y, Tokunaga Y 2023 Phys. Rev. B 108 144502

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 3283

- PDF Downloads: 125

- Cited By: 0

DownLoad:

DownLoad: