-

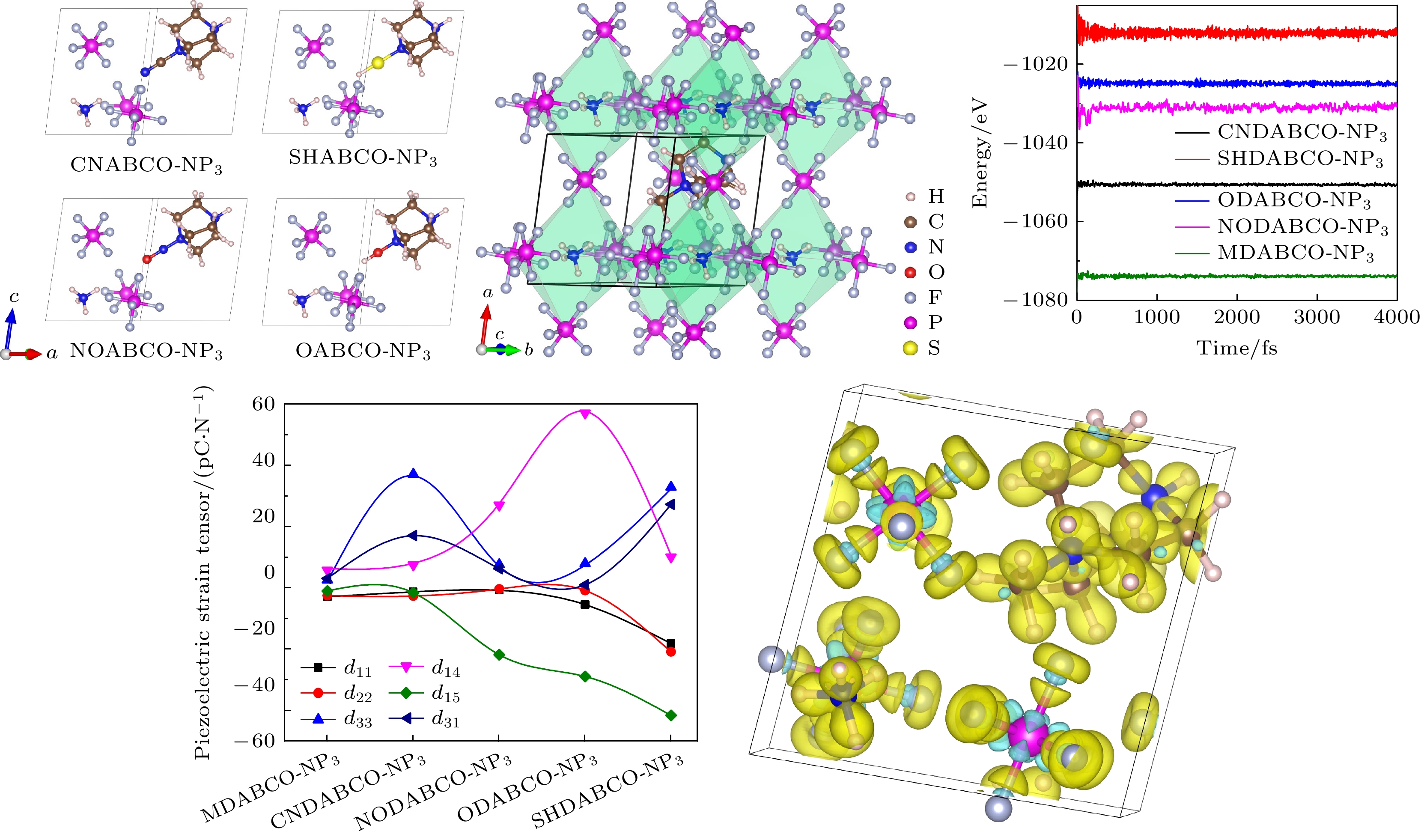

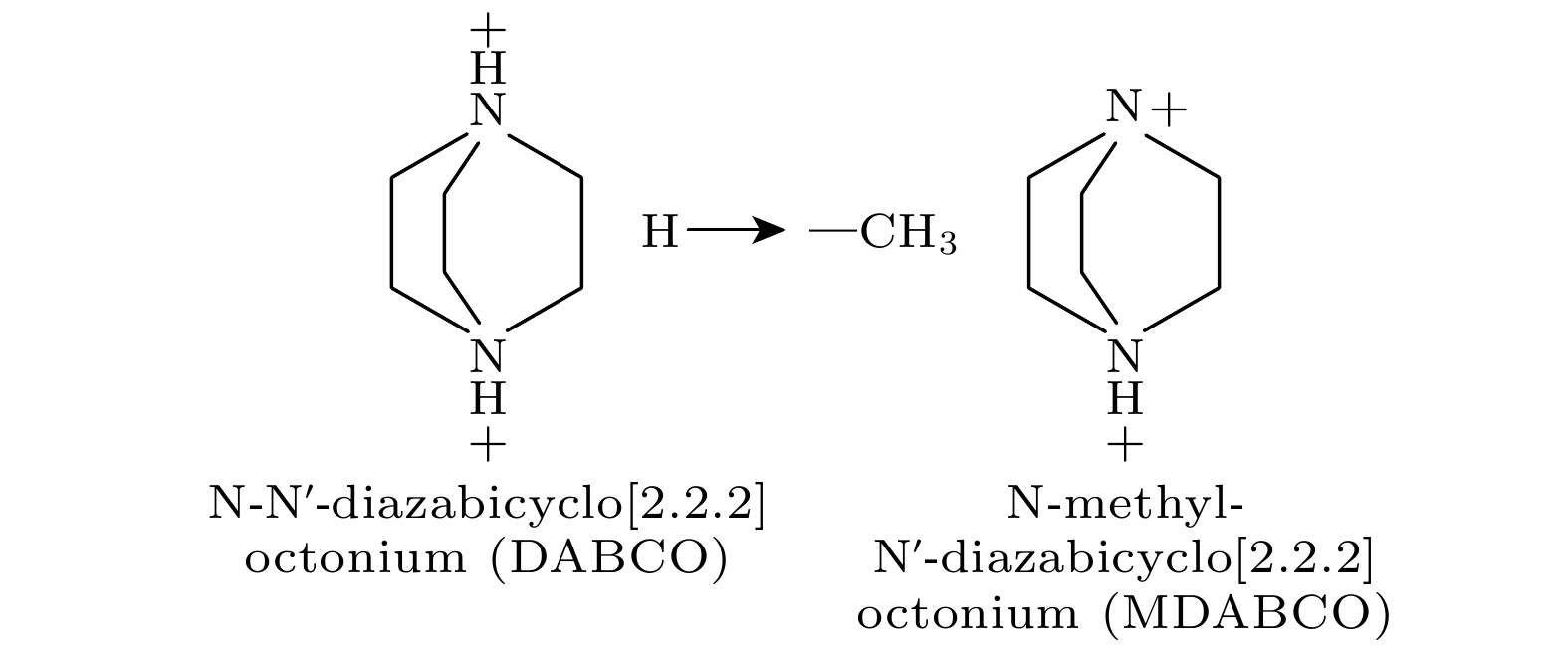

Organic ferroelectrics are desirable for the applications in the field of wearable electronics due to their eco-friendly process-ability, mechanical flexibility, low processing temperatures, and lightweight. In this work, we use five organic groups as substitution for organic cation and study the effects of organic cations on the structural stability, electronic structure, mechanical properties and spontaneous polarization of metal-free perovskite A-NH4-(PF6)3 (A = MDABCO, CNDABCO, ODABCO, NODABCO, SHDABCO) through first-principles calculations. Firstly, the stabilities of the five materials are calculated by molecular dynamics simulations, and the energy values of all systems are negative and stable after 500 fs, which demonstrates the stabilities of the five materials at 300 K. The electronic structure calculation shows that the organic perovskite materials have wide band gap with a value of about 7.05 eV. The valence band maximum (VBM) and Cconduction band minimum (CBM) are occupied by different elements, which is conductive to the separation of electrons and holes. We find that organic cations have an important contribution to the spontaneous polarization of materials, with a contribution rate over 50%. The presence of hydrogen atoms in the substituting groups (MDABCO, ODABCO) enhances the hydrogen bond interaction between the organic cations and

${\rm PF}_6^- $ and increases the displacement of the organic cation, resulting in an increase in the contribution of the polarization of the organic cation to the total polarization. In addition, we observe large piezoelectric strain components, the calculated value of d33 is 36.5 pC/N for CNDABCO-NH4-(PF6)3, 32.3 pC/N for SHNDABCO-NH4-(PF6)3, which is larger than the known value of d33 of MDABCO-NH4-I3(14pC/N). The calculated value of d14 is 57.5 pC/N for ODABCO-NH4-(PF6)3, 27.5 pC/N for NODABCO-NH4-(PF6)3. These components are at a high level among known organic perovskite materials and comparable to many known inorganic crystals. The large value of d14 is found to be closely related to the large value of elastic compliance tensor s44. The analysis of Young’s modulus and bulk’s modulus shows that these organic perovskite materials have good ductility. These results indicate that these organic materials are excellent candidates for future environmentally friendly piezoelectric materials.-

Keywords:

- metal-free perovskites /

- first-principles calculations /

- piezoelectricity /

- spontaneous polarization

[1] Kieslich G, Sun S J, Cheetham A K 2014 Chem. Sci. 5 4712

Google Scholar

Google Scholar

[2] Sessolo M, Bolink H J 2011 Adv. Mater. 23 1829

Google Scholar

Google Scholar

[3] Bechmann R 2005 J. Acoust. Soc. Am. 28 347

Google Scholar

Google Scholar

[4] Haertling G H 1999 J. Am. Cera. Soc. 82 797

Google Scholar

Google Scholar

[5] Zhao Y X, Zhu K 2016 Chem. Soc. Rev. 45 655

Google Scholar

Google Scholar

[6] Mischenko A S, Zhang Q, Scott J F, Whatmore R W, Mathur N D 2006 Science 311 1270

Google Scholar

Google Scholar

[7] Peña M A, Fierro J 2001 Chem. Rev. 101 1981

Google Scholar

Google Scholar

[8] 郑隆立, 齐世超, 王春明, 石磊, 2019 68 147701

Google Scholar

Google Scholar

Zheng L L, Qi S C, Wang C M, Shi L 2019 Acta Phys. Sin. 68 147701

Google Scholar

Google Scholar

[9] Neaten J B, Ederer C, Waghmare U V, Spaldin N A, Rabe K M 2005 Phys. Rev. B 71 14111

Google Scholar

Google Scholar

[10] Lebeugle D, Colson D, Forget A, Viret M 2007 Appl. Phys. Lett. 91 22907

Google Scholar

Google Scholar

[11] Palkar V R, Kundaliya D C, Malik S K 2003 J. Appl. Phys. 93 4337

Google Scholar

Google Scholar

[12] Gao W X, Chang L, Ma H, You L, Yin J, Liu J M, Liu Z G, Wang J L, Yuan G L 2015 NPG Asia Mater. 7 e189

Google Scholar

Google Scholar

[13] Xu W J, Kopyl S, Kholkin A, Rocha J 2019 Coordin. Chem. Rev. 387 398

Google Scholar

Google Scholar

[14] Nandi P, Topwal D, Park N G, Shin H 2020 J. Phys. D: Appl. Phys. 53 493002

Google Scholar

Google Scholar

[15] Köhnen E, Jost M, Morales-Vilches A B, Tockhorn P, Al-Ashouri A, Macco B, Kegelmann L, Korte L, Rech B, Schlatmann R, Stannowski B, Albrecht S 2019 Sustain. Energ. Fuels 3 1995

Google Scholar

Google Scholar

[16] Sahli F, Werner J, Kamino B A, Bräuninger M, Monnard R, Paviet-Salomon B, Barraud L, Ding L, Diaz Leon J J, Sacchetto D, Cattaneo G, Despeisse M, Boccard M, Nicolay S, Jeangros Q, Niesen B, Ballif C 2018 Nat. Mater. 17 820

Google Scholar

Google Scholar

[17] Yang W S, Park B, Jung E H, Jeon N J, Kim Y C, Lee D U, Shin S S, Seo J, Kim E K, Noh J H, Seok S I 2017 Science 356 1376

Google Scholar

Google Scholar

[18] Yun J S, Park C K, Jeong Y H, Cho J H, Paik J, Yoon S H, Hwang K 2016 Nanomater. Nanotechno. 6 20

Google Scholar

Google Scholar

[19] Ye H Y, Tang Y Y, Li P F, Liao W Q, Gao J X, Hua X N, Cai H, Shi P P, You Y M, Xiong R G 2018 Science 361 151

Google Scholar

Google Scholar

[20] Fu D W, Cai H L, Liu Y M, Ye Q, Zhang W, Zhang Y, Chen X Y, Giovannetti G, Capone M, Li J Y, Xiong R G 2013 Science 339 425

Google Scholar

Google Scholar

[21] Wang H, Liu H H, Zhang Z Y, Liu Z H, Lv Z L, Li T W, Ju W W, Li H S, Cai X W, Han H 2019 npj Comput. Mater 5 17

Google Scholar

Google Scholar

[22] Wu H S, Wei S, Chen S W, Pan H C, Pan W P, Huang S, Tsai M, Yang P 2022 Adv. Sci. 9 2105974

Google Scholar

Google Scholar

[23] Choi H S, Li S N, Park I, Liew W H, Zhu Z Y, Kwon K C, Wang L, Oh I, Zheng S S, Su C L, Xu Q H, Yao K, Pan F, Loh K P 2022 Nat. Commun. 13 794

Google Scholar

Google Scholar

[24] Sun M J, Zheng C, Gao Y, Johnston A, Najarian A M, Wang P X, Voznyy O, Hoogland S, Sargent E H 2021 Adv. Mater. 33 2006368

Google Scholar

Google Scholar

[25] Kasel T W, Deng Z Y, Mroz A M, Hendon C H, Butler K T, Canepa P 2019 Chem. Sci. 10 8187

Google Scholar

Google Scholar

[26] Kresse, Furthmuller 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[27] Kresse, Hafner 1994 Phys. Review. B 49 14251

Google Scholar

Google Scholar

[28] Kresse, Hafner 1993 Phys. Review. B 47 558

Google Scholar

Google Scholar

[29] Spaldin N A 2012 J. Solid State Chem. 195 2

Google Scholar

Google Scholar

[30] Li Z Z, Li Z H, Peng G Q, Shi C, Wang H X, Ding S Y, Wang Q, Liu Z T, Jin Z W 2023 Adv. Mater. 35 2300480

Google Scholar

Google Scholar

[31] King-Smith R D, Vanderbilt D 1993 Phys. Rev. B 48 4442

Google Scholar

Google Scholar

[32] Vanderbilt D, King-Smith R D 1993 Phys. Rev. B 47 1651

Google Scholar

Google Scholar

[33] Wang X M, Yan Y F 2022 arXiv: 2206.11137v1 [cond-mat. mtrl-sci]

[34] Singh J, Kaur H, Singh G, Tripathi S K 2021 Mater. Today Energy 21 100820

Google Scholar

Google Scholar

[35] Al-Qaisi S, Rai D P, Haq B U, Ahmed R, Vu T V, Khuili M, Tahir S A, Alhashim H H 2021 Mater. Chem. Phys. 258 123945

Google Scholar

Google Scholar

[36] Kiely E, Zwane R, Fox R, Reilly A M, Guerin S 2021 CrystEngComm 23 5697

Google Scholar

Google Scholar

[37] Mouhat F, Coudert F 2014 Phys. Rev. B 90 224104

Google Scholar

Google Scholar

[38] Haid S, Bouadjemi B, Houari M, Matougui M, Lantri T, Bentata S, Aziz Z 2019 Solid State Commun. 294 29

Google Scholar

Google Scholar

[39] Birch F 1938 J. Appl. Phys. 9 279

Google Scholar

Google Scholar

[40] Kholil M I, Bhuiyan M T H 2020 Solid State Commun. 322 114053

Google Scholar

Google Scholar

[41] Crisler D F, Cupal J J, Moore A R 1968 P. IEEE 56 225

Google Scholar

Google Scholar

[42] Weis R S, Gaylord T K 1985 Appl. Phys. A 37 191

Google Scholar

Google Scholar

[43] Joffe H, Berlincourt D, Krueger H, Shiozawa L 1960 14th Annual Symposium on Frequency Control Atlantic City, NJ, USA May 21–June 2 1960 p19

[44] Vanderbilt D, Hamann D R, Wu X F 2005 Phys. Rev. B 72 35105

Google Scholar

Google Scholar

[45] X Y H 1991 Ferroelectric Materials and Their Applications (Netherlands: Amsterdam

[46] Li F L, Tian S W, Wu G D, Jiang C, Wu F P, Zhao X 2019 Symposium on Piezoelectrcity, Acoustic Waves and Device Applications Shijiazhuang, China, November 1–4, 2019 p1

[47] Guy I L, Muensit S, Goldys E M 1999 Appl. Phys. Lett. 75 4133

Google Scholar

Google Scholar

[48] Irzhak D, Roshchupkin D, Fahrtdinov R 2012 Proceedings of ISAF-ECAPD-PFM 2012 Aveiro, Portugal, July 9–13 2012 p1

-

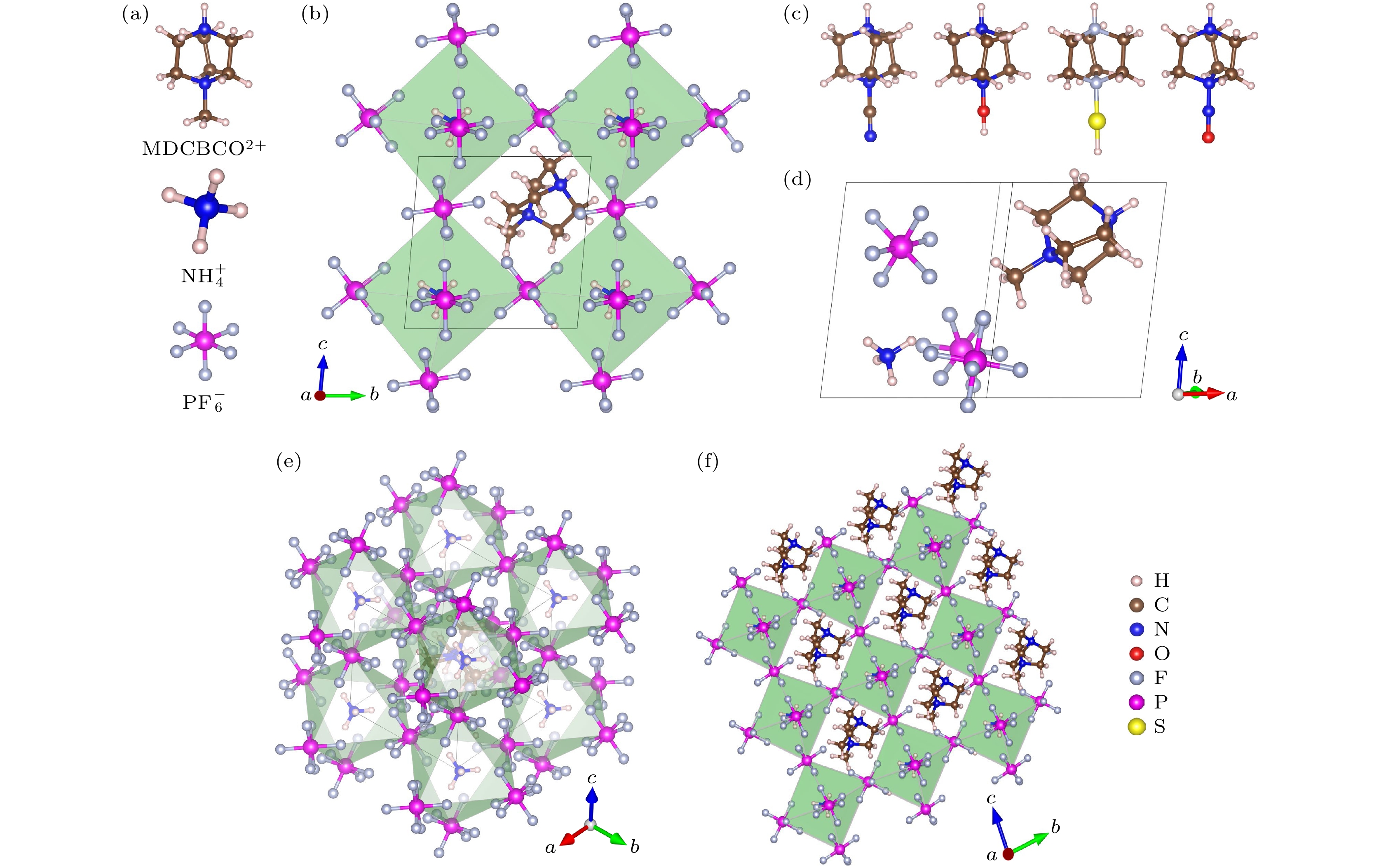

图 2 (a) MDABCO2+, ${\mathrm{NH}}_4^+ $, ${\text{PF}}_6^ - $结构示意图; (b) 沿a轴观察的MDABCO-NP3的原胞; (c) 不同基团取代之后的阳离子; (d) MDABCO-NP3的原胞; (e)沿着[111]方向观察到的MDABCO-NP3的原胞; (f) 沿a轴观察的MDABCO-NP3的晶胞

Figure 2. (a) Structures of MDABCO2+, ${\mathrm{NH}}_4^+ $, ${\text{PF}}_6^ - $ components; (b) the primitive cell of MDABCO-NP3 viewed along the a-axis; (c) cations substituted with different functionalities; (d) the primitive cell of MDABCO-NP3; (e) the primitive cell of MDABCO-NP3 viewed along [111] direction; (f) the unit cell of MDABCO-NP3 viewed along a-axis.

图 4 (a) 5种材料的总态密度; (b)—(f)分别为NODABCO-NP3, SHDABCO-NP3, ODABCO-NP3, CNDABCO-NP3, MDABCO-NP3的投影态密度 ; 费米能级设置为0 eV

Figure 4. (a) Total density of states for A-NP3; (b)–(f) projected density of states of (b) NODABCO-NP3, (c) SHDABCO-NP3, (d) ODABCO-NP3, (e) CNDABCO-NP3, (f) MDABCO-NP3. Fermi level is set to zero.

图 5 –R3到+R3结构的转变过程 (a) –R3铁电相 (λ = –1)结构; (b)中间相变结构(λ =0); (c) +R3铁电相(λ = 1)结构; (d) 类反铁电($ {\lambda }' = -1$)结构

Figure 5. Transformation of –R3 to +R3 structure: (a) –R3 ferroelectric phase (λ = –1) structure; (b) intermediate phase transition structure (λ = 0); (c) +R3 ferroelectric phase (λ = 1) structure; (d) quasi-antiferroelectric phase structure ($ {\lambda }' =-1$).

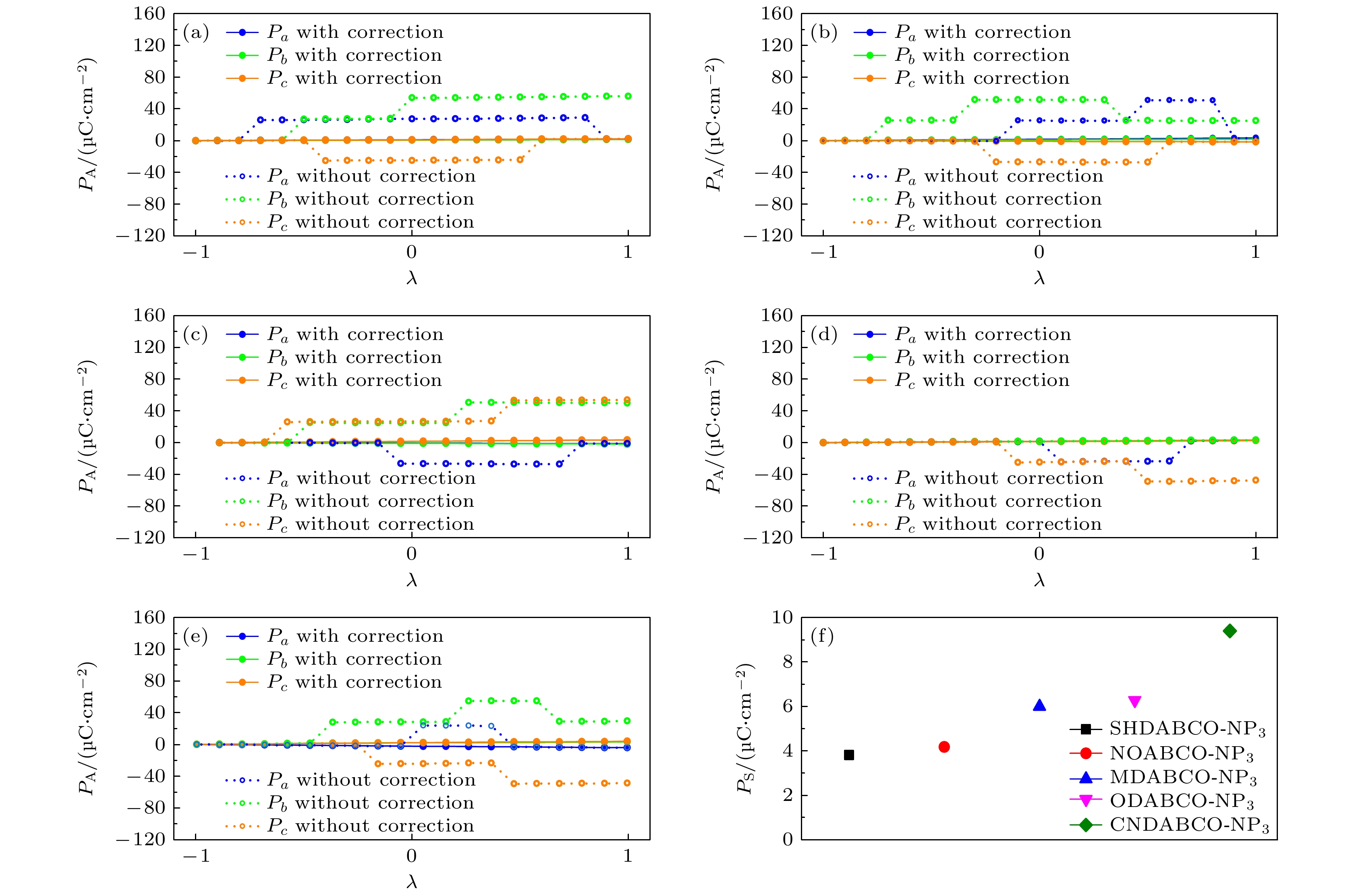

图 6 计算的(a) MDABCO-NP3, (b) SHDABCO-NP3, (c) NODABCO-NP3, (d) ODABCO- NP3, (e) CNDABCO-NP3的经极化量子数修正的和未修正的极化值; (f) 5种材料总的极化值

Figure 6. Calculated polarization value of (a) MDABCO-NP3, (b) SHDABCO-NP3, (c) NODABCO-NP3, (d) ODABCO-NP3, (e) CNDABCO-NP3 with and without correction for polarization quantum; (f) the total polarization values of five materials.

表 1 采用PBE和PBE+D3方法优化后的A-NP3的晶格结构参数

Table 1. Structural optimization of A-NP3 by using PBE and PBE+D3 methods.

Material Method a/Å α/(°) V/Å3 MDABCO-NP3 PBE 7.89(0.57%) 84.91(0.06%) 485.51 PBE+D3 7.73(–1.46%) 84.55(–0.36%) 478.25 Exp 7.84 84.86 496.46 SHDABCO-NP3 PBE 7.93 83.84 489.86 PBE+D3 7.74 83.18 483.46 NODABCO-NP3 PBE 7.95 83.74 493.15 PBE+D3 7.84 81.25 485.65 ODABCO-NP3 PBE 7.85 85.2 478.75 PBE+D3 7.75 83.65 475.21 CNDABCO-NP3 PBE 10.58 85.21 477.19 PBE+D3 9.28 83.48 486.48 表 2 A位阳离子的极化PA (μC/cm2)和材料的总极化PS (μC/cm2)及阳离子的极化对总极化的贡献PA/PS

Table 2. Polarization of A-site cations (PA) and total polarization of materials (PS) and the contribution of cation polarization to total polarization (PA/PS).

Materials PA PS PA/PS SHDABCO-NP3 2.4 3.8 0.64 NODABCO-NP3 2.6 4.2 0.63 ODABCO-NP3 4.3 6.0 0.71 MDABCO-NP3 4.3 6.3 0.68 CNDABCO-NP3 5.7 9.4 0.61 表 3 计算的A-NP3的弹性刚度张量Cij、体积模量B、剪切模量G、杨氏模量E (GPa)、皮尤比(B/G)和泊松比$ \nu $

Table 3. Calculated elastic tensor coefficients Cij , bulk modulu B, shear modulu G, Young’s modulu E(GPa), Pugh’s and Poisson’s ratios of A-NP3.

Materials C11 C33 C44 C12 C13 C14 C25 B G E B/G ν MDABCO-NP3 32.9 15.9 8.2 15.9 16.3 0.8 0.1 21.4 8.2 21.8 2.6 0.3 ODABCO-NP3 21.9 7.2 6.7 7.2 14.4 0.2 0.4 18.4 3.6 10.2 2.8 0.3 CNDABCO-NP3 35.2 19.4 6.6 19.4 22.8 0.6 1.3 25.7 6.7 18.4 4.0 0.4 SHDABCO-NP3 32.4 21.8 8.6 21.8 24.1 4.8 4.4 25.9 7.3 20.1 4.1 0.4 NODABCO-NP3 36.2 19.7 4.4 19.7 19.7 0.3 0.4 25.0 5.9 16.5 4.5 0.4 表 7 代表性无机、有机压电体对CNDABCO-NP3和SHDABCO-NP3的压电分量d33的对比.

Table 7. Comparison of piezoelectric component d33 of representative inorganic, organic piezoelectrics to CNDABCO-NP3 and SHDABCO-NP3.

表 8 代表性无机、有机压电体对MDABCO-NP3, NODABCO-NP3 和ODABCO-NP3的压电分量d14的对比

Table 8. Comparison of piezoelectric component d14 of representative inorganic, organic piezoelectrics to MDABCO-NP3, NODABCO-NP3 and ODABCO-NP3.

表 4 A-NP3的压电应变张量dij (pC/N)

Table 4. Piezoelectric strain tensor dij of A-NP3 (pC/N).

Materials d11 d22 d33 d14 d15 d31 MDABCO-NP3 –2.9 –2.6 2.0 –6.3 –1.0 3.0 ODABCO-NP3 –5.5 –0.9 7.4 –57.5 –28.9 0.9 CNDABCO-NP3 –1.3 –2.7 36.5 –7.9 –1.6 17.0 SHDABCO-NP3 –18.2 –20.9 32.3 –10.6 –41.6 27.2 NODABCO-NP3 –0.8 –0.4 7.1 27.5 –21.8 6.18 表 5 A-NP3的压电应力张量eij (C/m2)

Table 5. Piezoelectric stress tensor eij of A-NP3 (C/m2).

Materials e11 e22 e33 e14 e15 e31 MDABCO-NP3 –3.5 –3.0 2.4 4.5 –0.6 4.9 ODABCO-NP3 –2.1 –0.5 3.5 8.1 –1.7 9.9 CNDABCO-NP3 –1.9 –4.7 34.7 4.7 –0.8 9.7 SHDABCO-NP3 –5.2 –6.6 7.3 4.3 –21.9 6.5 NODABCO-NP3 –1.6 –0.5 10.5 8.9 –10.7 16.8 表 6 A-NP3的柔性刚度张量sij (10–12 m/N).

Table 6. Elastic compliance tensor sij of A-NP3 (10–12 m/N).

Materials s11 s33 s44 s12 s13 s14 s25 MDABCO-NP3 48.8 49.8 130.3 –16.8 –16.7 3.2 0.6 ODABCO-NP3 38.4 57.2 247.3 –9.0 –17.6 18 45.5 CNDABCO-NP3 56.9 85.4 157.3 –8.8 –35.7 –5.5 13.3 SHDABCO-NP3 124.7 142.4 218.9 –37.0 –79.2 –60.1 5.0 NODABCO-NP3 46.8 51.2 199.0 –16.6 –17.2 17.1 19.9 -

[1] Kieslich G, Sun S J, Cheetham A K 2014 Chem. Sci. 5 4712

Google Scholar

Google Scholar

[2] Sessolo M, Bolink H J 2011 Adv. Mater. 23 1829

Google Scholar

Google Scholar

[3] Bechmann R 2005 J. Acoust. Soc. Am. 28 347

Google Scholar

Google Scholar

[4] Haertling G H 1999 J. Am. Cera. Soc. 82 797

Google Scholar

Google Scholar

[5] Zhao Y X, Zhu K 2016 Chem. Soc. Rev. 45 655

Google Scholar

Google Scholar

[6] Mischenko A S, Zhang Q, Scott J F, Whatmore R W, Mathur N D 2006 Science 311 1270

Google Scholar

Google Scholar

[7] Peña M A, Fierro J 2001 Chem. Rev. 101 1981

Google Scholar

Google Scholar

[8] 郑隆立, 齐世超, 王春明, 石磊, 2019 68 147701

Google Scholar

Google Scholar

Zheng L L, Qi S C, Wang C M, Shi L 2019 Acta Phys. Sin. 68 147701

Google Scholar

Google Scholar

[9] Neaten J B, Ederer C, Waghmare U V, Spaldin N A, Rabe K M 2005 Phys. Rev. B 71 14111

Google Scholar

Google Scholar

[10] Lebeugle D, Colson D, Forget A, Viret M 2007 Appl. Phys. Lett. 91 22907

Google Scholar

Google Scholar

[11] Palkar V R, Kundaliya D C, Malik S K 2003 J. Appl. Phys. 93 4337

Google Scholar

Google Scholar

[12] Gao W X, Chang L, Ma H, You L, Yin J, Liu J M, Liu Z G, Wang J L, Yuan G L 2015 NPG Asia Mater. 7 e189

Google Scholar

Google Scholar

[13] Xu W J, Kopyl S, Kholkin A, Rocha J 2019 Coordin. Chem. Rev. 387 398

Google Scholar

Google Scholar

[14] Nandi P, Topwal D, Park N G, Shin H 2020 J. Phys. D: Appl. Phys. 53 493002

Google Scholar

Google Scholar

[15] Köhnen E, Jost M, Morales-Vilches A B, Tockhorn P, Al-Ashouri A, Macco B, Kegelmann L, Korte L, Rech B, Schlatmann R, Stannowski B, Albrecht S 2019 Sustain. Energ. Fuels 3 1995

Google Scholar

Google Scholar

[16] Sahli F, Werner J, Kamino B A, Bräuninger M, Monnard R, Paviet-Salomon B, Barraud L, Ding L, Diaz Leon J J, Sacchetto D, Cattaneo G, Despeisse M, Boccard M, Nicolay S, Jeangros Q, Niesen B, Ballif C 2018 Nat. Mater. 17 820

Google Scholar

Google Scholar

[17] Yang W S, Park B, Jung E H, Jeon N J, Kim Y C, Lee D U, Shin S S, Seo J, Kim E K, Noh J H, Seok S I 2017 Science 356 1376

Google Scholar

Google Scholar

[18] Yun J S, Park C K, Jeong Y H, Cho J H, Paik J, Yoon S H, Hwang K 2016 Nanomater. Nanotechno. 6 20

Google Scholar

Google Scholar

[19] Ye H Y, Tang Y Y, Li P F, Liao W Q, Gao J X, Hua X N, Cai H, Shi P P, You Y M, Xiong R G 2018 Science 361 151

Google Scholar

Google Scholar

[20] Fu D W, Cai H L, Liu Y M, Ye Q, Zhang W, Zhang Y, Chen X Y, Giovannetti G, Capone M, Li J Y, Xiong R G 2013 Science 339 425

Google Scholar

Google Scholar

[21] Wang H, Liu H H, Zhang Z Y, Liu Z H, Lv Z L, Li T W, Ju W W, Li H S, Cai X W, Han H 2019 npj Comput. Mater 5 17

Google Scholar

Google Scholar

[22] Wu H S, Wei S, Chen S W, Pan H C, Pan W P, Huang S, Tsai M, Yang P 2022 Adv. Sci. 9 2105974

Google Scholar

Google Scholar

[23] Choi H S, Li S N, Park I, Liew W H, Zhu Z Y, Kwon K C, Wang L, Oh I, Zheng S S, Su C L, Xu Q H, Yao K, Pan F, Loh K P 2022 Nat. Commun. 13 794

Google Scholar

Google Scholar

[24] Sun M J, Zheng C, Gao Y, Johnston A, Najarian A M, Wang P X, Voznyy O, Hoogland S, Sargent E H 2021 Adv. Mater. 33 2006368

Google Scholar

Google Scholar

[25] Kasel T W, Deng Z Y, Mroz A M, Hendon C H, Butler K T, Canepa P 2019 Chem. Sci. 10 8187

Google Scholar

Google Scholar

[26] Kresse, Furthmuller 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[27] Kresse, Hafner 1994 Phys. Review. B 49 14251

Google Scholar

Google Scholar

[28] Kresse, Hafner 1993 Phys. Review. B 47 558

Google Scholar

Google Scholar

[29] Spaldin N A 2012 J. Solid State Chem. 195 2

Google Scholar

Google Scholar

[30] Li Z Z, Li Z H, Peng G Q, Shi C, Wang H X, Ding S Y, Wang Q, Liu Z T, Jin Z W 2023 Adv. Mater. 35 2300480

Google Scholar

Google Scholar

[31] King-Smith R D, Vanderbilt D 1993 Phys. Rev. B 48 4442

Google Scholar

Google Scholar

[32] Vanderbilt D, King-Smith R D 1993 Phys. Rev. B 47 1651

Google Scholar

Google Scholar

[33] Wang X M, Yan Y F 2022 arXiv: 2206.11137v1 [cond-mat. mtrl-sci]

[34] Singh J, Kaur H, Singh G, Tripathi S K 2021 Mater. Today Energy 21 100820

Google Scholar

Google Scholar

[35] Al-Qaisi S, Rai D P, Haq B U, Ahmed R, Vu T V, Khuili M, Tahir S A, Alhashim H H 2021 Mater. Chem. Phys. 258 123945

Google Scholar

Google Scholar

[36] Kiely E, Zwane R, Fox R, Reilly A M, Guerin S 2021 CrystEngComm 23 5697

Google Scholar

Google Scholar

[37] Mouhat F, Coudert F 2014 Phys. Rev. B 90 224104

Google Scholar

Google Scholar

[38] Haid S, Bouadjemi B, Houari M, Matougui M, Lantri T, Bentata S, Aziz Z 2019 Solid State Commun. 294 29

Google Scholar

Google Scholar

[39] Birch F 1938 J. Appl. Phys. 9 279

Google Scholar

Google Scholar

[40] Kholil M I, Bhuiyan M T H 2020 Solid State Commun. 322 114053

Google Scholar

Google Scholar

[41] Crisler D F, Cupal J J, Moore A R 1968 P. IEEE 56 225

Google Scholar

Google Scholar

[42] Weis R S, Gaylord T K 1985 Appl. Phys. A 37 191

Google Scholar

Google Scholar

[43] Joffe H, Berlincourt D, Krueger H, Shiozawa L 1960 14th Annual Symposium on Frequency Control Atlantic City, NJ, USA May 21–June 2 1960 p19

[44] Vanderbilt D, Hamann D R, Wu X F 2005 Phys. Rev. B 72 35105

Google Scholar

Google Scholar

[45] X Y H 1991 Ferroelectric Materials and Their Applications (Netherlands: Amsterdam

[46] Li F L, Tian S W, Wu G D, Jiang C, Wu F P, Zhao X 2019 Symposium on Piezoelectrcity, Acoustic Waves and Device Applications Shijiazhuang, China, November 1–4, 2019 p1

[47] Guy I L, Muensit S, Goldys E M 1999 Appl. Phys. Lett. 75 4133

Google Scholar

Google Scholar

[48] Irzhak D, Roshchupkin D, Fahrtdinov R 2012 Proceedings of ISAF-ECAPD-PFM 2012 Aveiro, Portugal, July 9–13 2012 p1

Catalog

Metrics

- Abstract views: 3724

- PDF Downloads: 135

- Cited By: 0

DownLoad:

DownLoad: