-

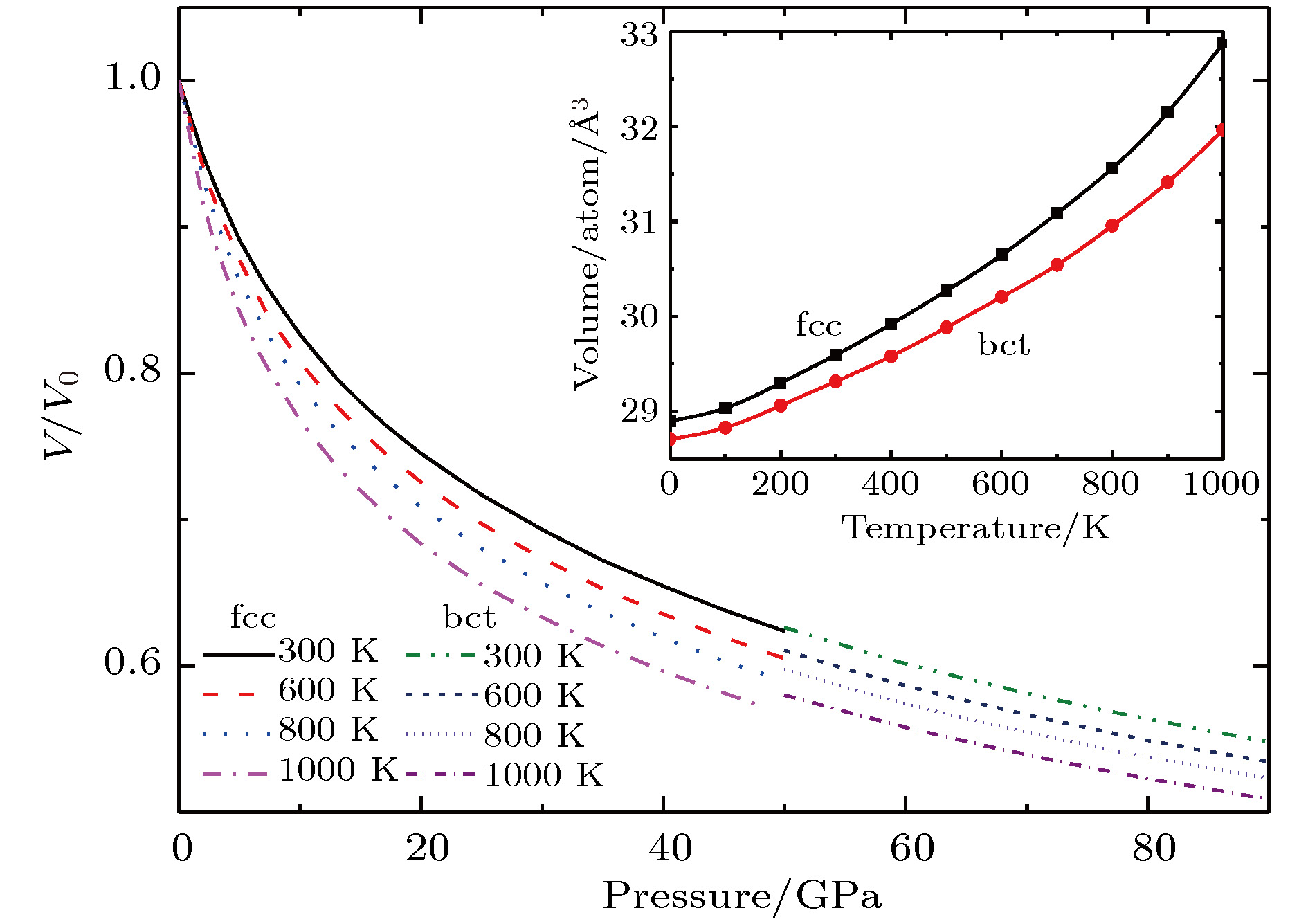

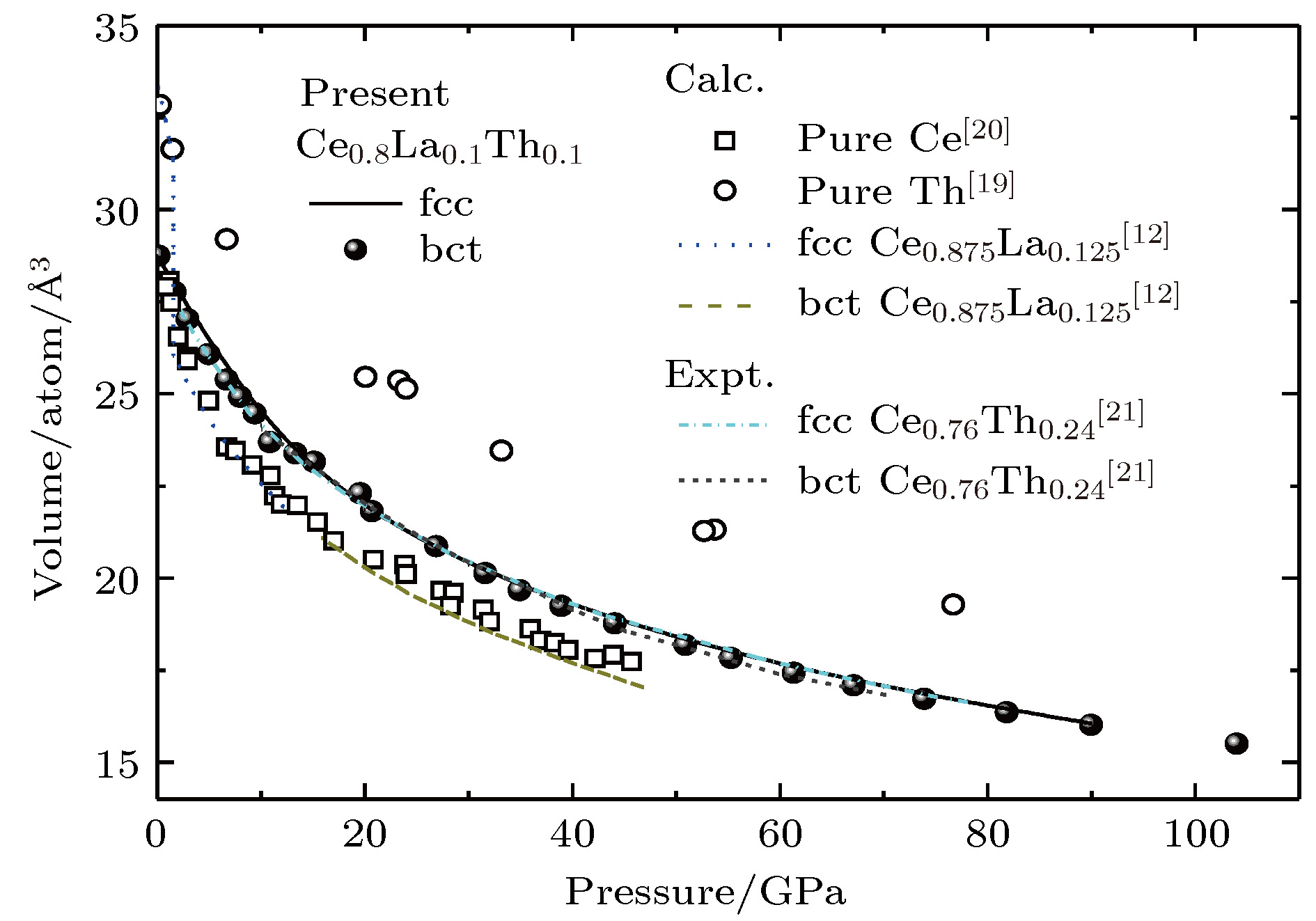

The lanthanide and actinide metals and alloys are of great interest in experimental and theoretical high-pressure research, because of the unique behavior of the f electrons under pressure and their delocalization and participation in bonding. Cerium (Ce) metal is the first lanthanide element with a 4f electron. It has a very complex phase diagram and displays intriguing physical and chemical properties. In addition, it is expected to be an excellent surrogate candidate for plutonium (Pu), one of the radioactive transuranic actinides with a 5f electron. The bulk properties and phase transformation characteristics of Ce-based alloys are similar to those of Pu and its compounds. Thus, the investigations of Ce-based alloys are necessary and can potentially advance the understanding of the behavior of Pu. In this work, the equation of state, phase transition, elastic and thermodynamic properties of Ce0.8La0.1Th0.1 alloy at high pressure are investigated by using first-principles calculations based on the density-functional theory. The structural properties of the Ce0.8La0.1Th0.1 alloy are in good agreement with the available experimental and theoretical data. The lattice constant a decreases with pressure increasing, while c shows an opposite variation. It is found that the lattice parameter c shows abnormal jump. And the critical volume is located at 20.1 Å3. The axial ratio jumps from a value of about

$\sqrt 2 $ (corresponding to the fcc structure) to a higher value, which indicates that the fcc-bct transition occurs. And the corresponding transition pressure is located at ~31.6 GPa. When the pressure rises to 34.9 GPa, the bct structure displays a saturated c/a axial ratio close to about 1.67. The Young's modulus E, shear modulus G and the Debye temperature of the fcc phase tend to be " softened” around the phase transition pressure. The vibrational free energy is obtained by using the quasi-harmonic Debye model. And then the thermodynamic properties including the thermal equation of state, heat capacity and entropy under high pressure and high temperature are also predicted successfully. The results show that the heat capacity and entropy increase rapidly with temperature increasing, and decrease with pressure increasing. The high pressure can suppress part of the anharmonicity caused by temperature.-

Keywords:

- Ce-based alloy /

- density functional theory /

- phase transformation /

- high pressure

[1] Bridgman P W 1927 Proc. Am. Acad.Arts Sci. 62 207

Google Scholar

Google Scholar

[2] Bridgman P W 1951 Proc. Am. Acad. Arts Sci. 79 149

Google Scholar

Google Scholar

[3] Bridgman P W 1954 Proc. Am. Acad. Arts Sci. 83 1

[4] Lanson A W, Tang T Y 1949 Phys. Rev. 76 301

Google Scholar

Google Scholar

[5] 潘昊, 胡晓棉, 吴子辉, 戴诚达, 吴强 2012 61 206401

Google Scholar

Google Scholar

Pan H, Hu X M, Wu Z H, Dai C D, Wu Q 2012 Acta Phys. Sin. 61 206401

Google Scholar

Google Scholar

[6] Hu C E, Zeng Z Y, Zhang L, Chen X T, Cai L C 2011 Physica B 406 669

Google Scholar

Google Scholar

[7] Lawson A C, Williams A, Wire M S 1988 J. Less-common Met. 142 177

Google Scholar

Google Scholar

[8] Lawrence J M, Thompson J D, Fisk Z, Smith J L, Batlogg B 1984 Phys. Rev. B 29 4017

Google Scholar

Google Scholar

[9] Drymiotis F, Singleton J, Harrison N, Lashley J C, Bangura A, Mielke C H, Balicas L, Fisk Z, Migliori A, Smith J L 2005 J. Phys.: Condens. Matter 17 L77

Google Scholar

Google Scholar

[10] Ruff J P C, Islam Z, Das R K, Nojiri H, Cooley J C, Mielke C H 2012 Phys. Rev. B 85 024104

Google Scholar

Google Scholar

[11] Hu C E, Zeng Z Y, Zhang L, Chen X R, Cai L C 2010 Solid State Commun. 150 2362

Google Scholar

Google Scholar

[12] Zeng Z Y, Hu C E, Li Z G, Zhang W, Cai L C 2015 J. Alloys Compd. 640 201

Google Scholar

Google Scholar

[13] Blanco M A, Francisco E, Luaña V 2004 Comput. Phys. Commun. 158 57

Google Scholar

Google Scholar

[14] Blanco M A, MartínPendás A, Francisco E, Recio J M, Franco R 1996 J. Mol. Struct.: Theochem 368 245

Google Scholar

Google Scholar

[15] Francisco E, Recio J M, Blanco M A, Pendás A M 1998 J. Phys. Chem. 102 1595

Google Scholar

Google Scholar

[16] Francisco E, Sanjurjo G, Blanco M A 2001 Phys. Rev. B 63 094107

Google Scholar

Google Scholar

[17] Flórez M, Recio J M, Francisco E, Blanco M A, Pendás A M 2002 Phys. Rev. B 66 144112

Google Scholar

Google Scholar

[18] 邓世杰, 赵宇宏, 侯华, 文志勤, 韩培德 2017 66 146101

Google Scholar

Google Scholar

Deng S J, Zhao H Y, Hou H, Wen Z Q, Han P D 2017 Acta Phys. Sin. 66 146101

Google Scholar

Google Scholar

[19] Vohra Y K, Holzapfel W B 1993 High Pressure Res. 11 223

Google Scholar

Google Scholar

[20] Olsen J S, Gerward L, Benedict U, Itié J P 1985 Physica B+C (Amsterdam)

133 129  Google Scholar

Google Scholar

[21] Gu G, Vohra Y K, Winand J M, Spirlet J C 1995 Scr. Metall. Mater. 32 2081

Google Scholar

Google Scholar

[22] Svane A 1996 Phys. Rev. B 53 4275

[23] Soderlind P, Eriksson O, Wills J M, Boring A M 1993 Phys. Rev. B 48 9306

Google Scholar

Google Scholar

[24] Koskenmaki D C, Gschneidner K A 1978 Handb. Phys. Chem. Rare Earths 1 337

Google Scholar

Google Scholar

[25] Gerward L, Olsen J S, Diffr P 1993 Powder Diffr. 8 127

Google Scholar

Google Scholar

[26] Decremps F, Antonangeli D, Amadon B, Schmerber G 2009 Phys. Rev. B 80 132103

Google Scholar

Google Scholar

[27] Lipp M J, Kono Y, Jenei Z, Cynn H, Aracne-Ruddle C, Park C, Kenney-Benson C, Evans W J 2013 J. Phys: Condens. Matter 25 34

-

图 1 体积随压强变化的规律(黑色实点为直接加压结构优化后的结果, 黑色实线为状态方程拟合结果), 并与已有的Ce[20], Th[19], Ce0.875La0.125[12]的计算值及Ce0.76Th0.24[21]实验值进行比较

Fig. 1. The EOS of fcc and bct Ce-La-Th together with the experimental data (the black solid point is the result of the structure optimization, the black solid line is the fitting result of the EOS), together with the experimental data for Ce0.76Th0.24[21] and the calculated results for Ce[20], Th[19], Ce0.875La0.125[12].

表 1 零温零压下fcc相Ce-La-Th合金的平衡体积(V0)及体积模量(B0)

Table 1. Equilibrium volume (V0) and bulk modulus (B0) of Ce-La-Th of fcc phase at 0 GPa and 0 K.

-

[1] Bridgman P W 1927 Proc. Am. Acad.Arts Sci. 62 207

Google Scholar

Google Scholar

[2] Bridgman P W 1951 Proc. Am. Acad. Arts Sci. 79 149

Google Scholar

Google Scholar

[3] Bridgman P W 1954 Proc. Am. Acad. Arts Sci. 83 1

[4] Lanson A W, Tang T Y 1949 Phys. Rev. 76 301

Google Scholar

Google Scholar

[5] 潘昊, 胡晓棉, 吴子辉, 戴诚达, 吴强 2012 61 206401

Google Scholar

Google Scholar

Pan H, Hu X M, Wu Z H, Dai C D, Wu Q 2012 Acta Phys. Sin. 61 206401

Google Scholar

Google Scholar

[6] Hu C E, Zeng Z Y, Zhang L, Chen X T, Cai L C 2011 Physica B 406 669

Google Scholar

Google Scholar

[7] Lawson A C, Williams A, Wire M S 1988 J. Less-common Met. 142 177

Google Scholar

Google Scholar

[8] Lawrence J M, Thompson J D, Fisk Z, Smith J L, Batlogg B 1984 Phys. Rev. B 29 4017

Google Scholar

Google Scholar

[9] Drymiotis F, Singleton J, Harrison N, Lashley J C, Bangura A, Mielke C H, Balicas L, Fisk Z, Migliori A, Smith J L 2005 J. Phys.: Condens. Matter 17 L77

Google Scholar

Google Scholar

[10] Ruff J P C, Islam Z, Das R K, Nojiri H, Cooley J C, Mielke C H 2012 Phys. Rev. B 85 024104

Google Scholar

Google Scholar

[11] Hu C E, Zeng Z Y, Zhang L, Chen X R, Cai L C 2010 Solid State Commun. 150 2362

Google Scholar

Google Scholar

[12] Zeng Z Y, Hu C E, Li Z G, Zhang W, Cai L C 2015 J. Alloys Compd. 640 201

Google Scholar

Google Scholar

[13] Blanco M A, Francisco E, Luaña V 2004 Comput. Phys. Commun. 158 57

Google Scholar

Google Scholar

[14] Blanco M A, MartínPendás A, Francisco E, Recio J M, Franco R 1996 J. Mol. Struct.: Theochem 368 245

Google Scholar

Google Scholar

[15] Francisco E, Recio J M, Blanco M A, Pendás A M 1998 J. Phys. Chem. 102 1595

Google Scholar

Google Scholar

[16] Francisco E, Sanjurjo G, Blanco M A 2001 Phys. Rev. B 63 094107

Google Scholar

Google Scholar

[17] Flórez M, Recio J M, Francisco E, Blanco M A, Pendás A M 2002 Phys. Rev. B 66 144112

Google Scholar

Google Scholar

[18] 邓世杰, 赵宇宏, 侯华, 文志勤, 韩培德 2017 66 146101

Google Scholar

Google Scholar

Deng S J, Zhao H Y, Hou H, Wen Z Q, Han P D 2017 Acta Phys. Sin. 66 146101

Google Scholar

Google Scholar

[19] Vohra Y K, Holzapfel W B 1993 High Pressure Res. 11 223

Google Scholar

Google Scholar

[20] Olsen J S, Gerward L, Benedict U, Itié J P 1985 Physica B+C (Amsterdam)

133 129  Google Scholar

Google Scholar

[21] Gu G, Vohra Y K, Winand J M, Spirlet J C 1995 Scr. Metall. Mater. 32 2081

Google Scholar

Google Scholar

[22] Svane A 1996 Phys. Rev. B 53 4275

[23] Soderlind P, Eriksson O, Wills J M, Boring A M 1993 Phys. Rev. B 48 9306

Google Scholar

Google Scholar

[24] Koskenmaki D C, Gschneidner K A 1978 Handb. Phys. Chem. Rare Earths 1 337

Google Scholar

Google Scholar

[25] Gerward L, Olsen J S, Diffr P 1993 Powder Diffr. 8 127

Google Scholar

Google Scholar

[26] Decremps F, Antonangeli D, Amadon B, Schmerber G 2009 Phys. Rev. B 80 132103

Google Scholar

Google Scholar

[27] Lipp M J, Kono Y, Jenei Z, Cynn H, Aracne-Ruddle C, Park C, Kenney-Benson C, Evans W J 2013 J. Phys: Condens. Matter 25 34

计量

- 文章访问数: 16323

- PDF下载量: 160

- 被引次数: 0

下载:

下载: