-

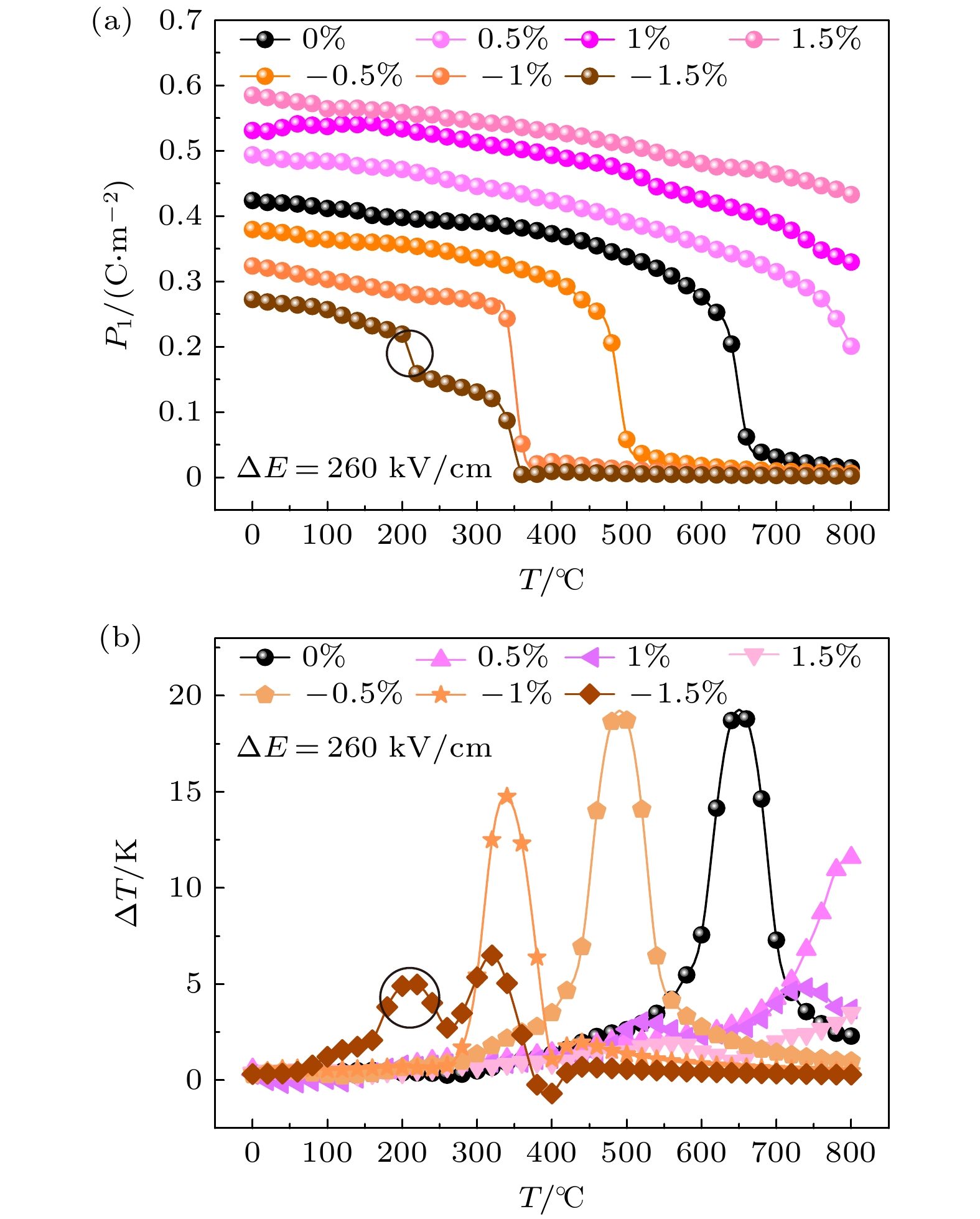

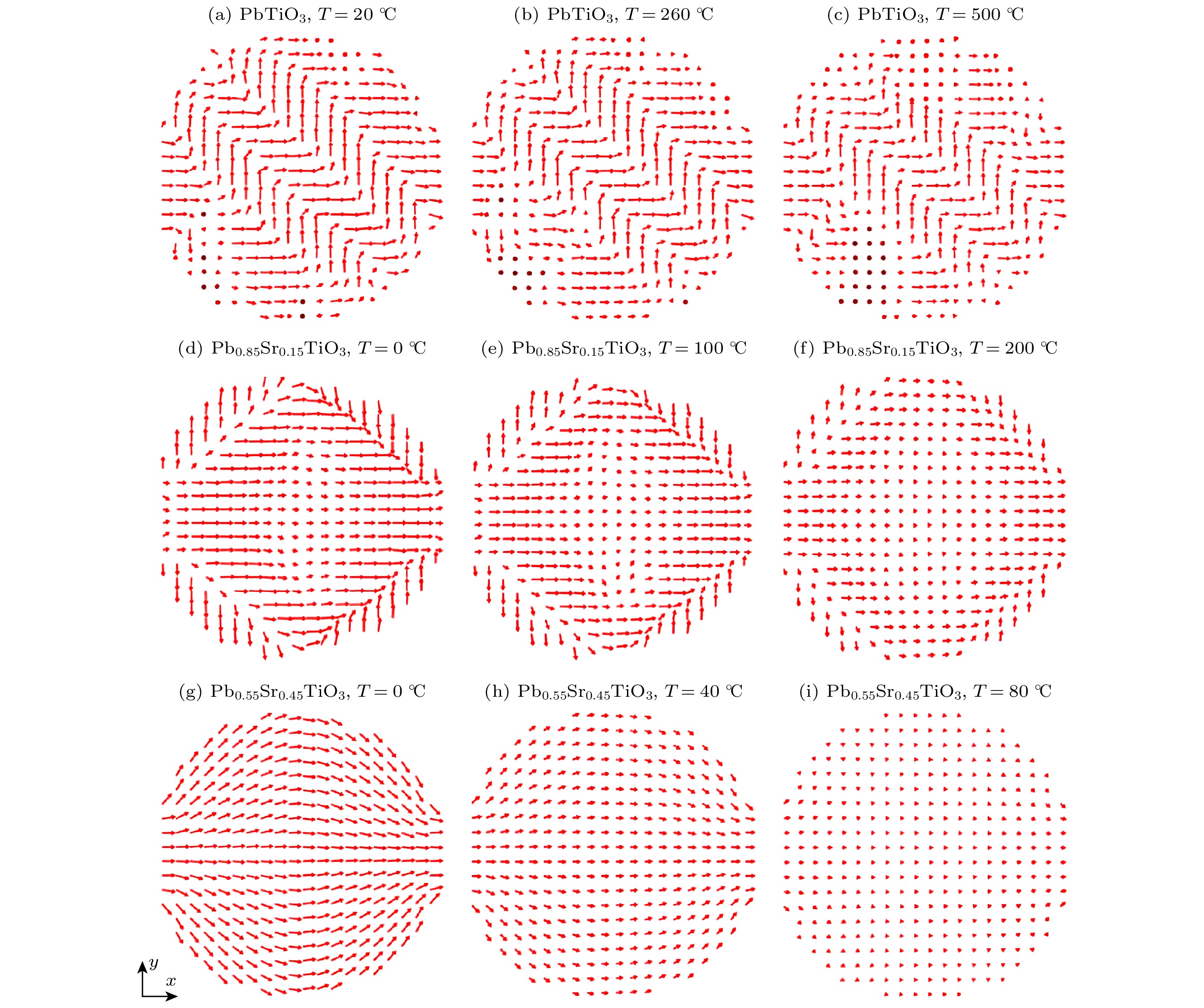

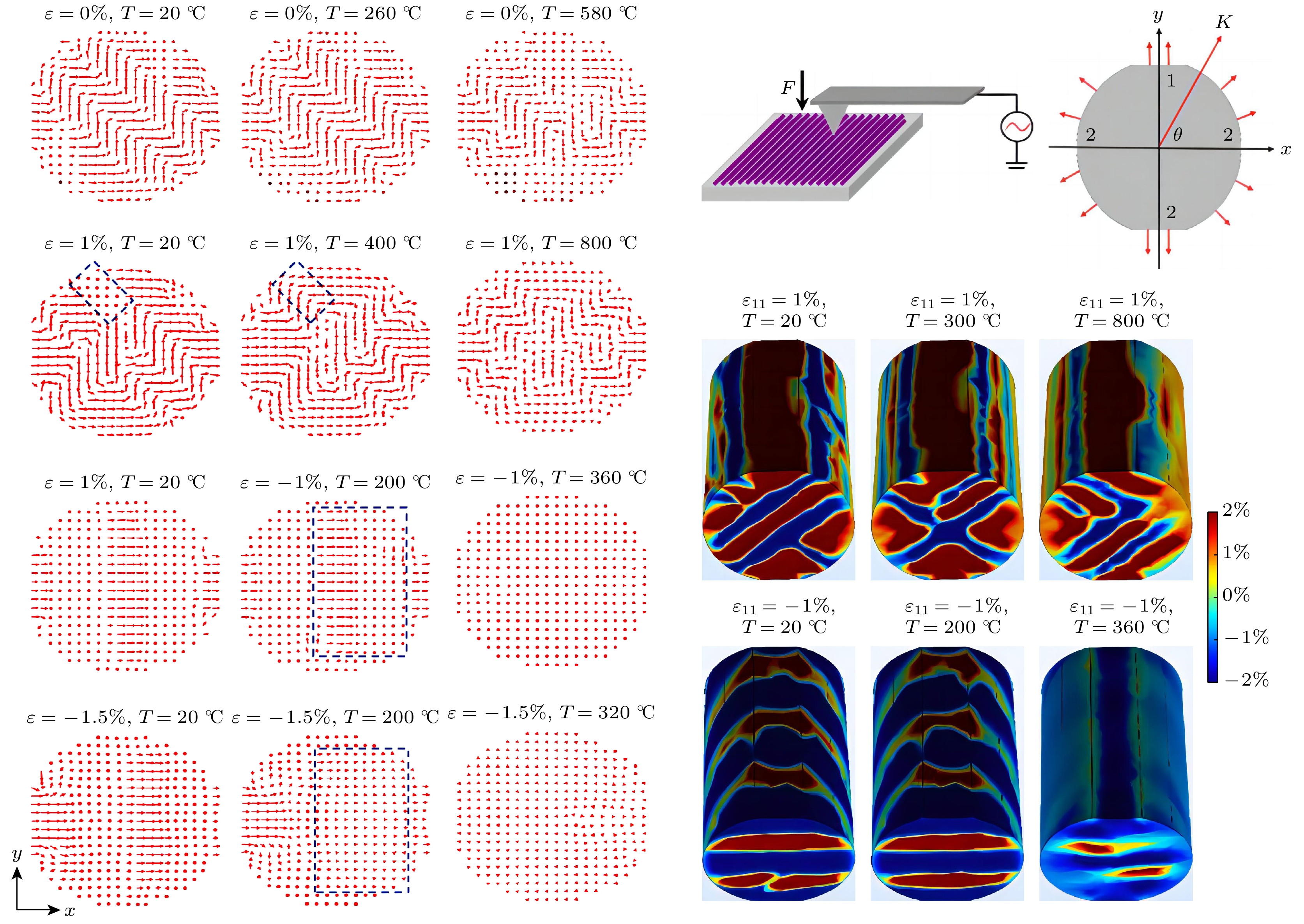

Composite films with ferroelectric nanowires serving as fillers, exhibit high adiabatic temperature change to meet the requirement for solid-state refrigeration, and their parallel-distributed filled nanowires are considered to be the key factor because their orientation is different from the orientation of the conventional perpendicularly distributed filled nanowires. However, the underlying mechanism of the electrocaloric effect of parallel-distributed nanowires has not been well understood. In this paper, a parallel-distributed PbTiO3 nanowire model is established to investigate the effects of surface stress and solid solution modification on their electrocaloric effects through phase field simulations. The results show that an adiabatic temperature change of 5 K can be obtained near 200 ℃ with 1.5% compressive stress under an electric field of 260 kV/cm. In order to further reduce its operating temperature, the electrocaloric effects of PST nanowires with different Sr contents are calculated, and it is found that the lower the doping amount of Sr, the higher the phase transition temperature of PST nanowires is. When the doping amount of Sr is 0.45, the phase transition temperature of the nanowires can be reduced to near 100 ℃, and an adiabatic temperature change of more than 8 K can be obtained under an electric field of 600 kV/cm. Even in the low-temperature interval from 50 to 100 ℃ the nanowires exhibit an adiabatic temperature change close to 8 K. The nanowires are also characterized by an adiabatic temperature change in a low-temperature interval from 50 to 100 ℃. At the same time, by combining the evolution of the simulated three-dimensional domain structure, it is revealed that the underlying mechanism of the change of the electrocaloric effect under surface stress and solid solution modification is due to different types of domain transformations. Finally, the combinations of components and surface stresses corresponding to the maximum value of the electrocaloric effect at different operating temperatures are discussed and analyzed. The present study provides useful theoretical guidance for developing solid-state refrigeration based on parallel-distributed ferroelectric nanowires.

-

Keywords:

- electrocaloric effect /

- nanowires /

- surface stress /

- solid solution modification

[1] Neese B, Chu B J, Lu S G, Wang Y, Furman E, Zhang Q M 2008 Science 321 821

Google Scholar

Google Scholar

[2] Valant M 2012 Prog. Mater. Sci. 57 980

Google Scholar

Google Scholar

[3] 汤卉, 牛翔, 杨志朋, 彭小草, 赵小波, 姚英邦, 陶涛, 梁波, 唐新桂, 鲁圣国 2022 71 147701

Google Scholar

Google Scholar

Tang H, Niu X, Yang Z P, Peng X C, Zhao X B, Yao Y B, Tao T, Liang B, Tang X G, Lu S G 2022 Acta Phys. Sin. 71 147701

Google Scholar

Google Scholar

[4] Mischenko A S, Zhang Q, Scott J F, Whatmore R W, Mathu D N, Lu S G, Zhang Q M 2006 Science 311 1270

Google Scholar

Google Scholar

[5] Kumar A, Kumar R, Singh K 2019 Phys. Status Solidi 216 1800786

Google Scholar

Google Scholar

[6] 白刚, 韩宇航, 高存法 2022 71 097701

Google Scholar

Google Scholar

Bai G, Han Y H, Gao C F 2022 Acta Phys. Sin. 71 097701

Google Scholar

Google Scholar

[7] Ren Y Q, Qi J, Yu H D, Zhang Z, Song R Q, Song W L, Yuan B, Wang T H, Ren W J, Zhang Z D, Tong X, Li B 2022 Nat. Commun. 13 2293

Google Scholar

Google Scholar

[8] Zhang G Z, Weng L X, Hu Z Y, Liu Y 2019 Adv. Mater. 31 1806642

Google Scholar

Google Scholar

[9] Chen Y Q, En Y F, Huang Y, Kong X D, Zheng X J, Lu Y D 2011 Appl. Phys. Lett. 99 203106

Google Scholar

Google Scholar

[10] Huang H B, Zhang G Z, Ma X Q, Liang D S, Wang J J, Liu Y, Wang Q, Chen L Q 2018 J. Am. Ceram. Soc. 101 1566

Google Scholar

Google Scholar

[11] Zhu J, Chen H Y, Hou X, Xu L R, Wu H P, Wang J 2019 J. Appl. Phys. 125 234101

Google Scholar

Google Scholar

[12] Xie B, Zhang H B, Zhang Q, Zang J D, Yang C, Wang Q P, Lia L Y, Jiang S L 2017 J. Mater. Chem. A 5 6070

Google Scholar

Google Scholar

[13] 陶巍, 李鹏飞, 王海山 2011 机电技术 34 85

Google Scholar

Google Scholar

Tao W, Li P F, Wang H S 2011 Mechatronic Technology 34 85

Google Scholar

Google Scholar

[14] 仰大勇, 蒋兴宇 2008 合成纤维 37 5

Google Scholar

Google Scholar

Yang D Y, Jiang X Y 2008 Synthetic Fibers 37 5

Google Scholar

Google Scholar

[15] 刘迪, 王静, 王俊升 2020 69 127801

Google Scholar

Google Scholar

Liu D, Wang J, Wang J S 2020 Acta Phys. Sin. 69 127801

Google Scholar

Google Scholar

[16] Liu D, Zhao R, Jafri H M, Wang J S, Huang H B 2019 Appl. Phys. Lett. 114 112903

Google Scholar

Google Scholar

[17] Haun M J, Furman E, Jang S J, Mckinstry H A, Cross L E 1987 J. Appl. Phys. 62 3331

Google Scholar

Google Scholar

[18] Li Y L, Choudhury S, Haeni J H, et al. 2006 Phys. Rev. B 73 184112

Google Scholar

Google Scholar

[19] Jain M, Majumder S B, Katiyar R S, Miranda F A, Van Keuls F W 2003 Appl. Phys. Lett. 821911

Google Scholar

Google Scholar

[20] Zhu J, Chen J X, Chen H Y, Wu H P, Chen S W, Hu P Y 2022 Mech. Adv. Mater. Struc. 29 3763

Google Scholar

Google Scholar

[21] Wang X Y, Chu R J, Dong Z C, Zhong C G, Huang Y Y, Min Y, Wang M, Zhou P X, Yuan G Q, Wei S N 2015 J. Alloys Compd. 649 261

Google Scholar

Google Scholar

[22] Hou X, Wu H P, Li H Y, Chen H Y, Wang J 2018 J. Phys. Condens. Matter. 30 465401

Google Scholar

Google Scholar

[23] Le V L, Hou X, Phan M H, Bui T Q, Wang J, Shimada T, Kitamura T, Dinh V H 2021 J. Phys. D Appl. Phys. 54 255307

Google Scholar

Google Scholar

[24] Le V L, Vu N L, Ha M T, Bui T Q, Le V T, Nguyen T G, Dinh V H 2020 J. Appl. Phys. 127 214103

Google Scholar

Google Scholar

-

-

[1] Neese B, Chu B J, Lu S G, Wang Y, Furman E, Zhang Q M 2008 Science 321 821

Google Scholar

Google Scholar

[2] Valant M 2012 Prog. Mater. Sci. 57 980

Google Scholar

Google Scholar

[3] 汤卉, 牛翔, 杨志朋, 彭小草, 赵小波, 姚英邦, 陶涛, 梁波, 唐新桂, 鲁圣国 2022 71 147701

Google Scholar

Google Scholar

Tang H, Niu X, Yang Z P, Peng X C, Zhao X B, Yao Y B, Tao T, Liang B, Tang X G, Lu S G 2022 Acta Phys. Sin. 71 147701

Google Scholar

Google Scholar

[4] Mischenko A S, Zhang Q, Scott J F, Whatmore R W, Mathu D N, Lu S G, Zhang Q M 2006 Science 311 1270

Google Scholar

Google Scholar

[5] Kumar A, Kumar R, Singh K 2019 Phys. Status Solidi 216 1800786

Google Scholar

Google Scholar

[6] 白刚, 韩宇航, 高存法 2022 71 097701

Google Scholar

Google Scholar

Bai G, Han Y H, Gao C F 2022 Acta Phys. Sin. 71 097701

Google Scholar

Google Scholar

[7] Ren Y Q, Qi J, Yu H D, Zhang Z, Song R Q, Song W L, Yuan B, Wang T H, Ren W J, Zhang Z D, Tong X, Li B 2022 Nat. Commun. 13 2293

Google Scholar

Google Scholar

[8] Zhang G Z, Weng L X, Hu Z Y, Liu Y 2019 Adv. Mater. 31 1806642

Google Scholar

Google Scholar

[9] Chen Y Q, En Y F, Huang Y, Kong X D, Zheng X J, Lu Y D 2011 Appl. Phys. Lett. 99 203106

Google Scholar

Google Scholar

[10] Huang H B, Zhang G Z, Ma X Q, Liang D S, Wang J J, Liu Y, Wang Q, Chen L Q 2018 J. Am. Ceram. Soc. 101 1566

Google Scholar

Google Scholar

[11] Zhu J, Chen H Y, Hou X, Xu L R, Wu H P, Wang J 2019 J. Appl. Phys. 125 234101

Google Scholar

Google Scholar

[12] Xie B, Zhang H B, Zhang Q, Zang J D, Yang C, Wang Q P, Lia L Y, Jiang S L 2017 J. Mater. Chem. A 5 6070

Google Scholar

Google Scholar

[13] 陶巍, 李鹏飞, 王海山 2011 机电技术 34 85

Google Scholar

Google Scholar

Tao W, Li P F, Wang H S 2011 Mechatronic Technology 34 85

Google Scholar

Google Scholar

[14] 仰大勇, 蒋兴宇 2008 合成纤维 37 5

Google Scholar

Google Scholar

Yang D Y, Jiang X Y 2008 Synthetic Fibers 37 5

Google Scholar

Google Scholar

[15] 刘迪, 王静, 王俊升 2020 69 127801

Google Scholar

Google Scholar

Liu D, Wang J, Wang J S 2020 Acta Phys. Sin. 69 127801

Google Scholar

Google Scholar

[16] Liu D, Zhao R, Jafri H M, Wang J S, Huang H B 2019 Appl. Phys. Lett. 114 112903

Google Scholar

Google Scholar

[17] Haun M J, Furman E, Jang S J, Mckinstry H A, Cross L E 1987 J. Appl. Phys. 62 3331

Google Scholar

Google Scholar

[18] Li Y L, Choudhury S, Haeni J H, et al. 2006 Phys. Rev. B 73 184112

Google Scholar

Google Scholar

[19] Jain M, Majumder S B, Katiyar R S, Miranda F A, Van Keuls F W 2003 Appl. Phys. Lett. 821911

Google Scholar

Google Scholar

[20] Zhu J, Chen J X, Chen H Y, Wu H P, Chen S W, Hu P Y 2022 Mech. Adv. Mater. Struc. 29 3763

Google Scholar

Google Scholar

[21] Wang X Y, Chu R J, Dong Z C, Zhong C G, Huang Y Y, Min Y, Wang M, Zhou P X, Yuan G Q, Wei S N 2015 J. Alloys Compd. 649 261

Google Scholar

Google Scholar

[22] Hou X, Wu H P, Li H Y, Chen H Y, Wang J 2018 J. Phys. Condens. Matter. 30 465401

Google Scholar

Google Scholar

[23] Le V L, Hou X, Phan M H, Bui T Q, Wang J, Shimada T, Kitamura T, Dinh V H 2021 J. Phys. D Appl. Phys. 54 255307

Google Scholar

Google Scholar

[24] Le V L, Vu N L, Ha M T, Bui T Q, Le V T, Nguyen T G, Dinh V H 2020 J. Appl. Phys. 127 214103

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 3817

- PDF Downloads: 115

- Cited By: 0

DownLoad:

DownLoad: