-

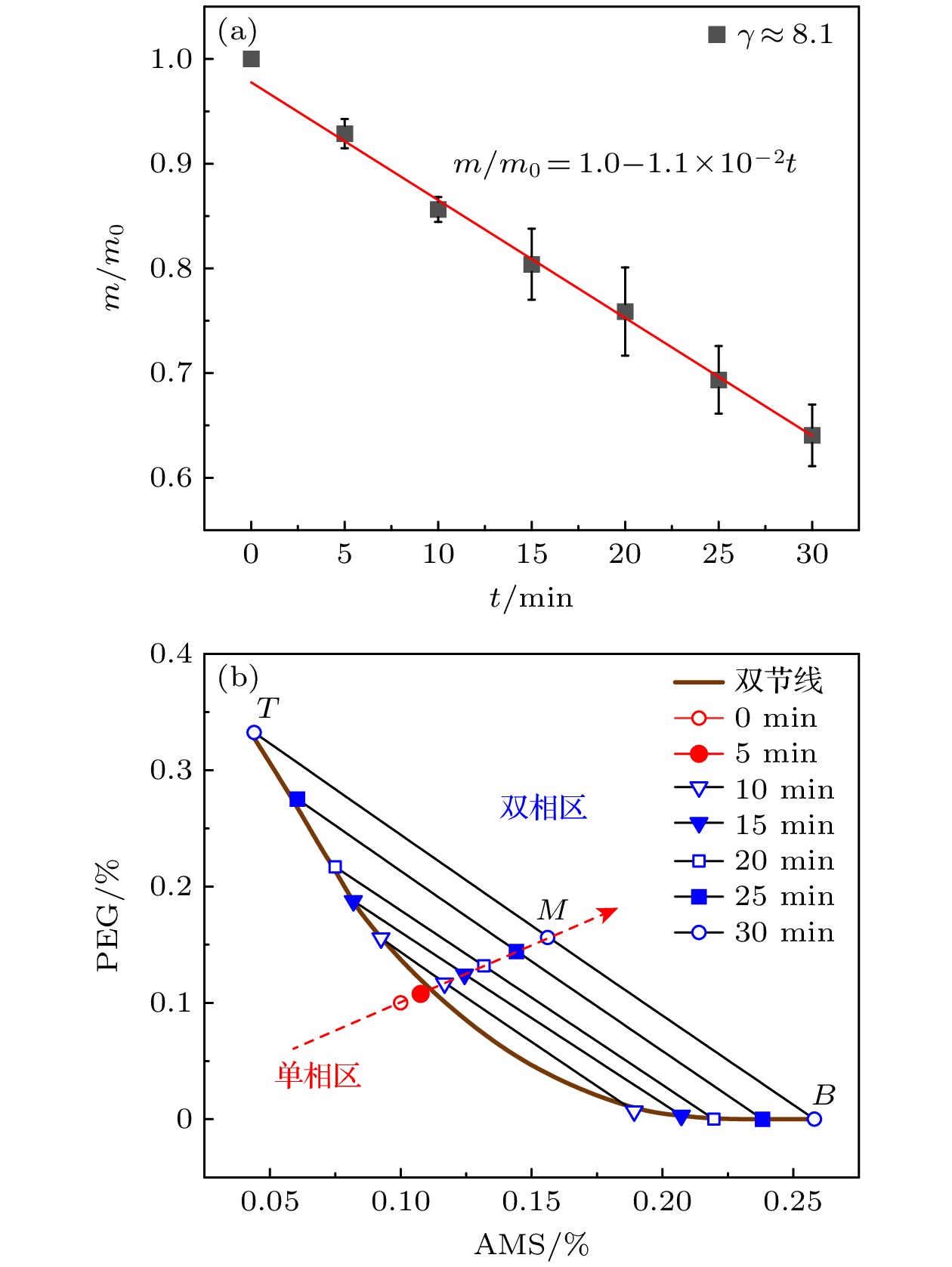

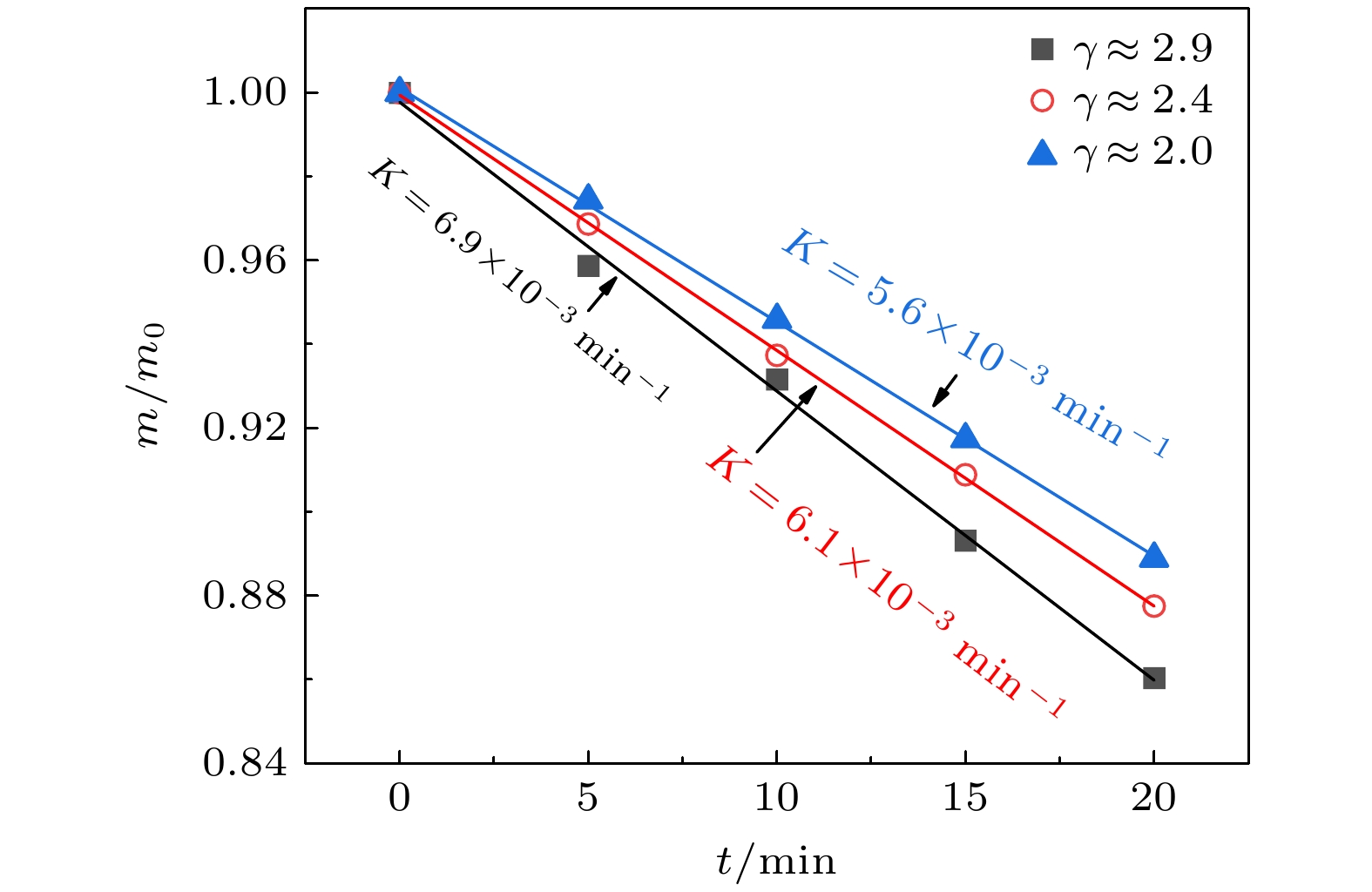

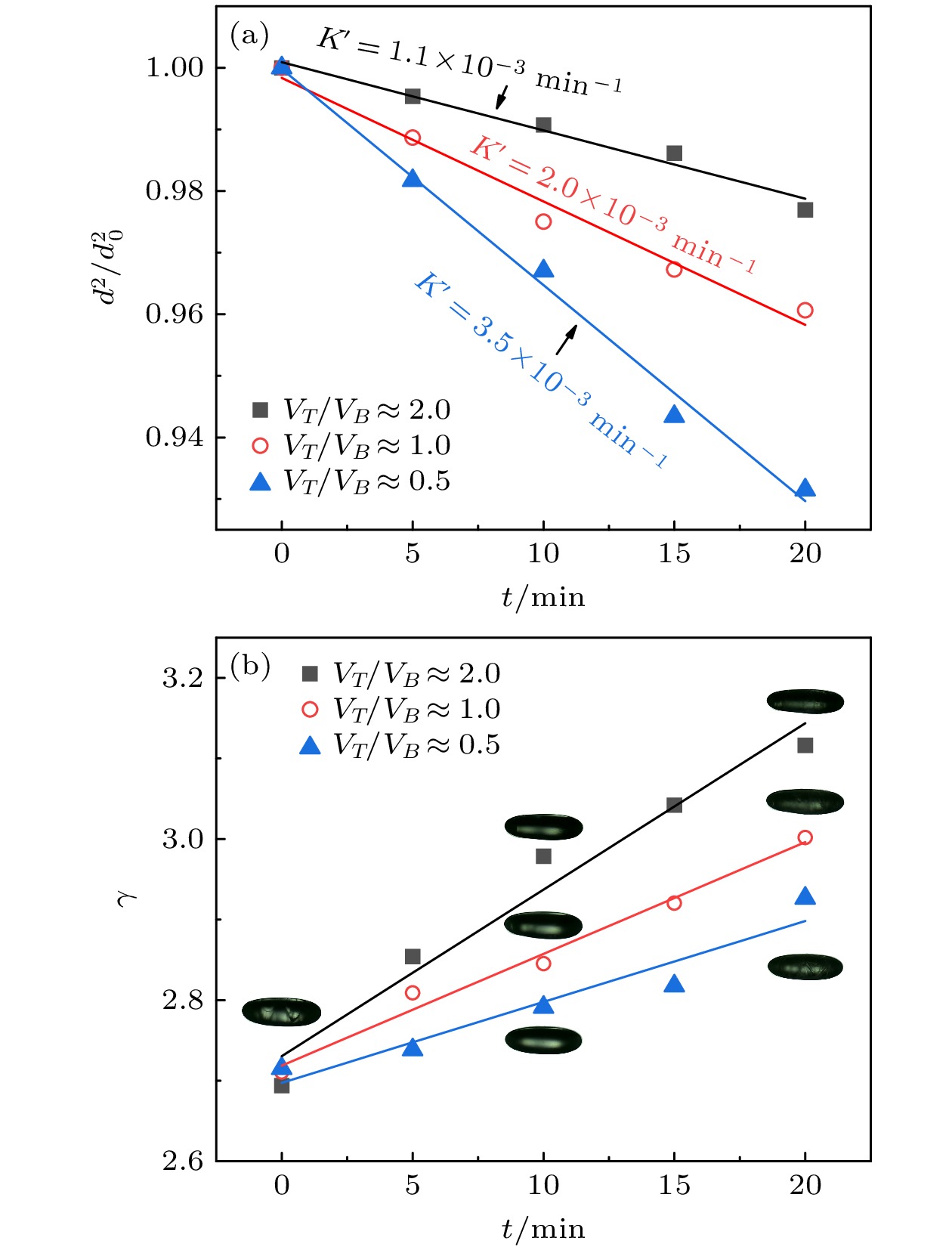

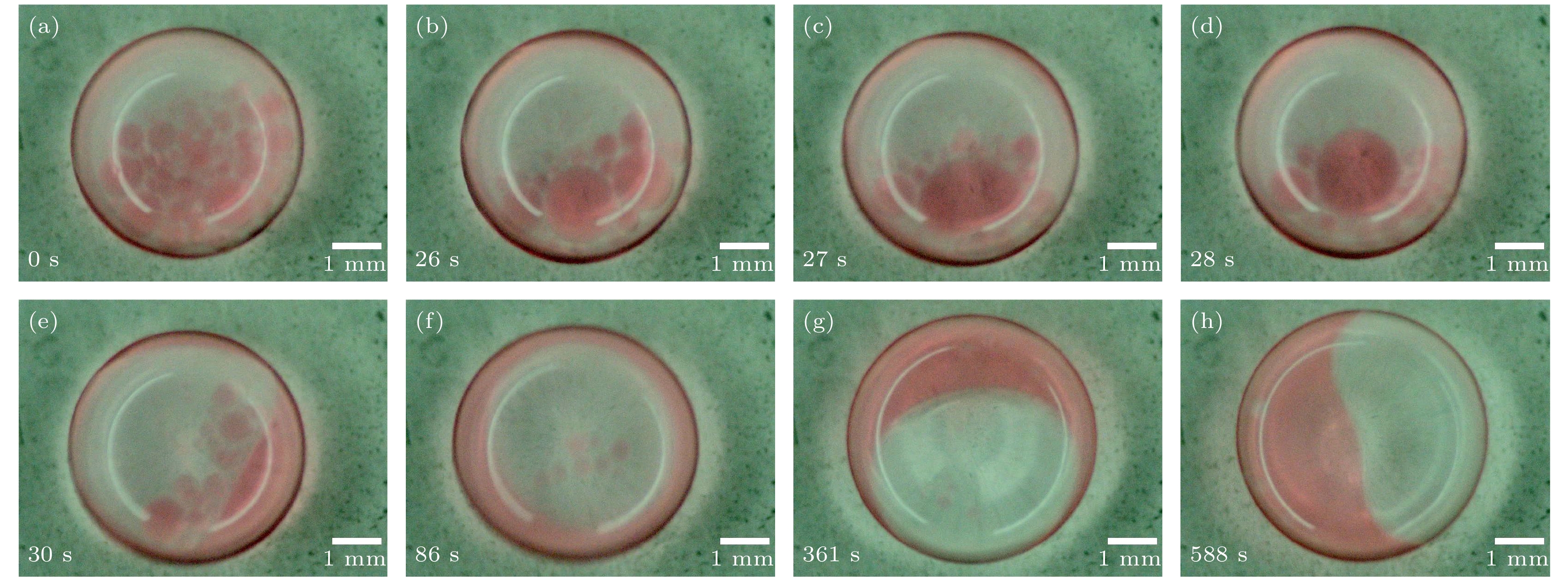

As a ground-based experimental method for simulating the containerless state in space, acoustic levitation provides excellent containerless and contact-free conditions for studying droplet dynamics, including droplet evaporation and phase separation. Meanwhile, the nonlinear effects of the acoustic field, such as acoustic radiation pressure and acoustic streaming, bring novel characteristics to the droplet evaporation process and phase separation process. In this work, the evaporation and phase separation of aqueous two-phase-system (ATPS) droplet composed of polyethylene glycol (PEG) and ammonium sulfate (AMS) are investigated by a single-axis acoustic levitator through the combination of image acquisition and processing technique. During the evaporation of the ATPS droplet, the square of its equatorial diameter,

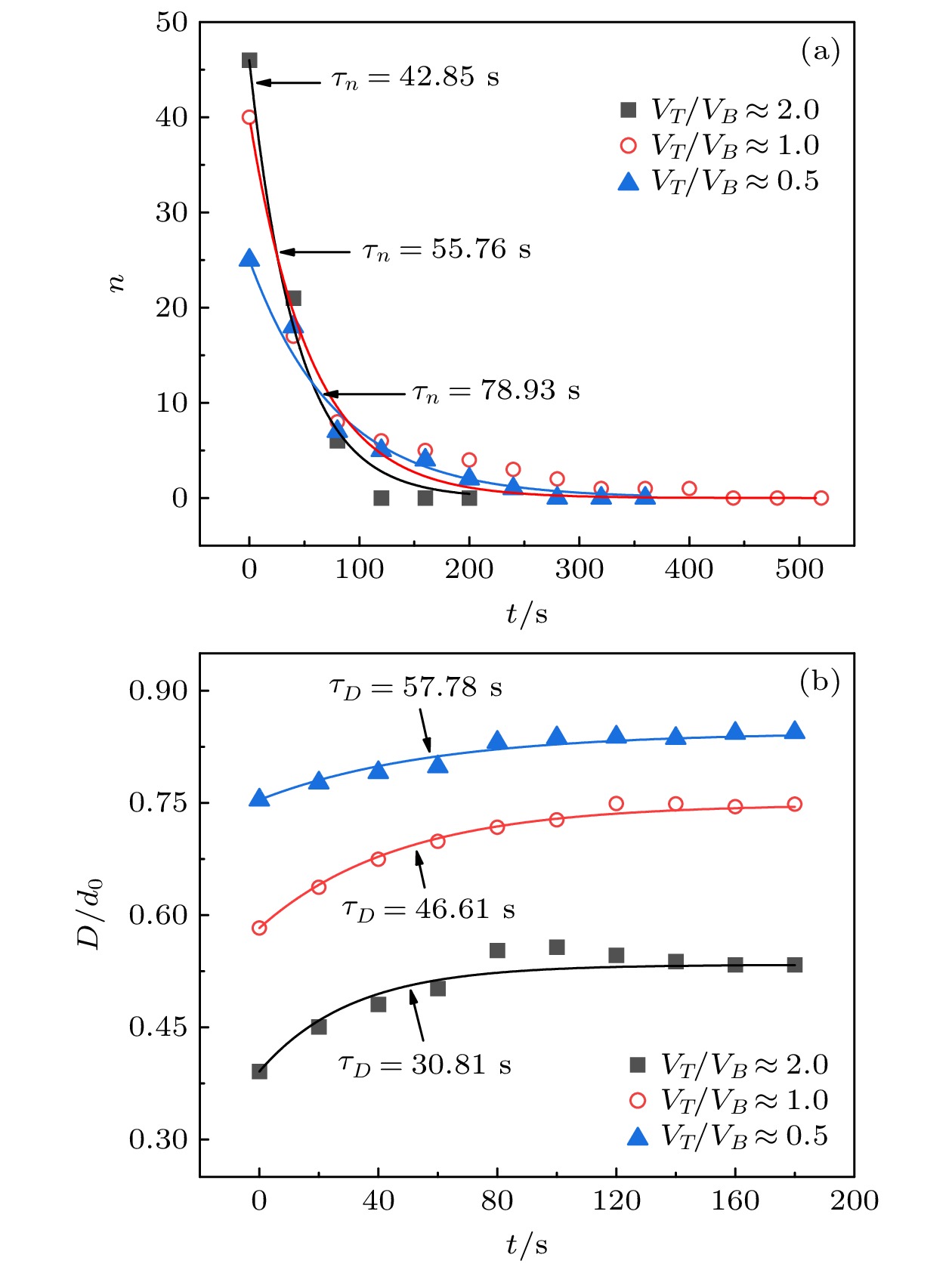

$ {d}^{2} $ , decreases linearly with time, and its aspect ratio,$ \gamma $ , increases linearly with time. The PEG-AMS droplet initially in the single-phase regime can enter into the two-phase regime as the water evaporates, resulting in phase separation. The phase separation of the acoustically levitated PEG-AMS ATPS droplet includes three stages: first, a large number of PEG-rich globules form inside the ATPS droplet, and then these PEG-rich globules collide, coagulate and migrate outward, and finally a horizontal layered structure of the whole droplet comes into being. The evaporation constant, the evolution of the PEG-rich globules and the AMS-rich phase area, are analyzed for ATPS droplets with different initial aspect ratios and different initial compositions. It is concluded that the greater the initial aspect ratio and the smaller the volume fraction of the PEG-rich phase, the faster the evaporation rate of the droplet is; the greater the initial aspect ratio and the lager the volume fraction of the PEG-rich phase, the faster the phase separation is. Numerical simulations show that the acoustically levitated droplets with a large aspect ratio are subjected to greater acoustic radiation pressure on the surface, and that the corresponding sound field is more intense and the acoustic streaming is stronger, which accelerates the evaporation and phase separation of the levitated droplets. These findings contribute to deepening our understanding of the motion characteristics, evaporation dynamics and phase separation of acoustically levitated droplets, and provide a foundation for studying the containerless preparation and processing the materials under acoustic levitation.[1] Andrade M A B, Pérez N, Adamowski J C 2018 Braz. J. Phys. 48 190

Google Scholar

Google Scholar

[2] Xie W J, Wei B 2001 Appl. Phys. Lett. 79 881

Google Scholar

Google Scholar

[3] Geng D L, Yan N, Xie W J, Lü Y J, Wei B B 2023 Adv. Mater. 35 2206464

Google Scholar

Google Scholar

[4] Andrade M A B, Marzo A, Adamowski J C 2020 Appl. Phys. Lett. 116 250501

Google Scholar

Google Scholar

[5] Ami Y B, Manela A 2021 J. Fluid Mech. 916 A24

Google Scholar

Google Scholar

[6] Polychronopoulos S, Memoli G 2020 Sci. Rep. 10 4254

Google Scholar

Google Scholar

[7] Combe N A, Donaldson D J 2017 J. Phys. Chem. A 121 7197

Google Scholar

Google Scholar

[8] Bunio L B, Wang J, Kannaiyan R, Gates I D 2022 Chem. Eng. Sci. 251 117441

Google Scholar

Google Scholar

[9] Inserra C, Regnault G, Cleve S, Mauger C, Blanc-Benon P 2021 J. Vis. Exp. 171 e62044

Google Scholar

Google Scholar

[10] Lu X L, Twiefel J, Ma Z C, Yu T T, Wallaschek J, Fischer P 2021 Adv. Sci. 8 2100888

Google Scholar

Google Scholar

[11] Xie W J, Wei B B 2004 Phys. Rev. E 70 046611

Google Scholar

Google Scholar

[12] Argyri S M, Evenäs L, Bordes R 2023 J. Colloid Interface Sci. 640 637

Google Scholar

Google Scholar

[13] 杜人君, 解文军 2011 60 114302

Google Scholar

Google Scholar

Du R J, Xie W J 2011 Acta Phys. Sin. 60 114302

Google Scholar

Google Scholar

[14] Tuckermann R, Puskar L, Zavabeti M, Sekine R, Mcnaughton D 2009 Anal. Bioanal. Chem. 394 1433

Google Scholar

Google Scholar

[15] Zaitone B A 2018 Int. J. Heat Mass Transf. 126 164

Google Scholar

Google Scholar

[16] Maruyama Y, Hasegawa K 2020 RSC Adv. 10 1870

Google Scholar

Google Scholar

[17] Brutin D, Starov V 2018 Chem. Soc. Rev. 47 558

Google Scholar

Google Scholar

[18] Junk M, Hinrichs J, Polt F, Fechner J, Pauer W 2020 Int. J. Heat Mass Transf. 149 119057

Google Scholar

Google Scholar

[19] Yarin A L, Brenn G, Kastner O, Rensink D, Tropea C 1999 J. Fluid Mech. 399 151

Google Scholar

Google Scholar

[20] Yarin A L, Brenn G, Rensink D 2002 Int. J. Heat Fluid Flow 23 471

Google Scholar

Google Scholar

[21] 翟薇, 王楠, 魏炳波 2007 56 2353

Google Scholar

Google Scholar

Zhai W, Wang N, Wei B B 2007 Acta Phys. Sin. 56 2353

Google Scholar

Google Scholar

[22] Hoven C V, Dang X D, Coffin R C, Peet J, Nguyen T Q, Bazan G C 2010 Adv. Mater. 22 E63

Google Scholar

Google Scholar

[23] Zhu J, Jiang L 2022 Langmuir 38 9043

Google Scholar

Google Scholar

[24] 齐玉, 曲昌荣, 王丽, 方腾 2014 63 046401

Google Scholar

Google Scholar

Qi Y, Qu C R, Wang L, Fang T 2014 Acta Phys. Sin. 63 046401

Google Scholar

Google Scholar

[25] 张鹏程, 方文玉, 鲍磊, 康文斌 2020 69 138701

Google Scholar

Google Scholar

Zhang P C, Fang W Y, Bao L, Kang W B 2020 Acta Phys. Sin. 69 138701

Google Scholar

Google Scholar

[26] Molino J V D, Marques D A V, Júnior A P, Mazzola P G, Gatti M S V 2013 Biotechnol. Prog. 29 1343

Google Scholar

Google Scholar

[27] Zhong Q C, Xie W J 2020 Appl. Phys. Lett. 116 224101

Google Scholar

Google Scholar

[28] Chao Y, Shum H C 2020 Chem. Soc. Rev. 49 114

Google Scholar

Google Scholar

[29] King L V 1934 Proc. Roy. Soc. A 147 212

Google Scholar

Google Scholar

[30] Huddleston J G, Willauer H D, Rogers R D 2003 J. Chem. Eng. Data 48 1230

Google Scholar

Google Scholar

-

图 5 液滴表面声辐射压分布与反射端-发射端间距H0的关系 (a) H0 = 34.1 mm时声场中的声辐射压分布; (b) 不同H0对应的液滴上下表面的声辐射压(空心符号和实心符号分别表示液滴上下表面)

Figure 5. Relationship between the acoustic radiation pressure on the droplet’s surface and the reflector-emitter distance H0: (a) Distribution of acoustic radiation pressure when H0 = 34.1 mm; (b) acoustic radiation pressure on the upper and lower surfaces of the droplets with different H0 (the open symbols indicate the data on the upper surface, and the solid symbols the lower surface).

表 1 三种成分的PEG-AMS双水相液体参数

Table 1. Parameters of three PEG-AMS ATPS liquids with different compositions.

序号 成分(质量分数)/% 上下相体积比$ {V}_{{{T}}}/{V}_{{{B}}} $ H2O PEG AMS ① 51 22 27 0.47 ② 47 32 21 0.96 ③ 43 43 14 2.08 表 2 声场模拟采用的物理参数

Table 2. Physical parameters for acoustic simulation.

参数 数值 注释 $ {H}_{0} $/mm 34—35 反射端-发射端间距 $ {R}_{0} $/mm 40 反射端曲率半径 $ {R}_{{\mathrm{b}}} $/mm 20 反射端截面半径 $ {R}_{{\mathrm{a}}} $/mm 12 发射端截面半径 $ {H}_{{\mathrm{s}}} $/mm 20 样品位置 $ {R}_{1} $/mm 2 液滴半长轴 $ {r}_{1} $/mm 1 液滴半短轴 $ {\rho }_{0} $/(kg·m–3) 1.293 空气密度 $ {c}_{0} $/(m·s–1) 340 空气中声速 $ {v}_{0} $/(m·s–1) 0.8916 发射端振动速度幅值 $ {f}_{0} $/kHz 22 超声波频率 表 3 H2O-10%PEG-10%AMS液滴蒸发过程中上、下相的成分变化

Table 3. Compositions of the top phase and bottom phase during evaporation of H2O-10%PEG-10%AMS droplet.

蒸发时间/min 液滴成分(质量分数)/% 上相成分 (质量分数)/% 下相成分(质量分数)/% H2O PEG AMS H2O PEG AMS H2O PEG AMS 0 80.0 10.0 10.0 — — — — — — 5 78.4 10.8 10.8 — — — — — — 10 76.6 11.7 11.7 75.2 15.6 9.2 80.4 0.7 18.9 15 75.2 12.4 12.4 73.0 18.8 8.2 79.0 0.3 20.7 20 73.6 13.2 13.2 70.8 21.7 7.5 78.0 0.0 22.0 25 71.2 14.4 14.4 66.5 27.5 6.0 76.2 0.0 23.8 30 68.8 15.6 15.6 62.4 33.2 4.4 74.2 0.0 25.8 -

[1] Andrade M A B, Pérez N, Adamowski J C 2018 Braz. J. Phys. 48 190

Google Scholar

Google Scholar

[2] Xie W J, Wei B 2001 Appl. Phys. Lett. 79 881

Google Scholar

Google Scholar

[3] Geng D L, Yan N, Xie W J, Lü Y J, Wei B B 2023 Adv. Mater. 35 2206464

Google Scholar

Google Scholar

[4] Andrade M A B, Marzo A, Adamowski J C 2020 Appl. Phys. Lett. 116 250501

Google Scholar

Google Scholar

[5] Ami Y B, Manela A 2021 J. Fluid Mech. 916 A24

Google Scholar

Google Scholar

[6] Polychronopoulos S, Memoli G 2020 Sci. Rep. 10 4254

Google Scholar

Google Scholar

[7] Combe N A, Donaldson D J 2017 J. Phys. Chem. A 121 7197

Google Scholar

Google Scholar

[8] Bunio L B, Wang J, Kannaiyan R, Gates I D 2022 Chem. Eng. Sci. 251 117441

Google Scholar

Google Scholar

[9] Inserra C, Regnault G, Cleve S, Mauger C, Blanc-Benon P 2021 J. Vis. Exp. 171 e62044

Google Scholar

Google Scholar

[10] Lu X L, Twiefel J, Ma Z C, Yu T T, Wallaschek J, Fischer P 2021 Adv. Sci. 8 2100888

Google Scholar

Google Scholar

[11] Xie W J, Wei B B 2004 Phys. Rev. E 70 046611

Google Scholar

Google Scholar

[12] Argyri S M, Evenäs L, Bordes R 2023 J. Colloid Interface Sci. 640 637

Google Scholar

Google Scholar

[13] 杜人君, 解文军 2011 60 114302

Google Scholar

Google Scholar

Du R J, Xie W J 2011 Acta Phys. Sin. 60 114302

Google Scholar

Google Scholar

[14] Tuckermann R, Puskar L, Zavabeti M, Sekine R, Mcnaughton D 2009 Anal. Bioanal. Chem. 394 1433

Google Scholar

Google Scholar

[15] Zaitone B A 2018 Int. J. Heat Mass Transf. 126 164

Google Scholar

Google Scholar

[16] Maruyama Y, Hasegawa K 2020 RSC Adv. 10 1870

Google Scholar

Google Scholar

[17] Brutin D, Starov V 2018 Chem. Soc. Rev. 47 558

Google Scholar

Google Scholar

[18] Junk M, Hinrichs J, Polt F, Fechner J, Pauer W 2020 Int. J. Heat Mass Transf. 149 119057

Google Scholar

Google Scholar

[19] Yarin A L, Brenn G, Kastner O, Rensink D, Tropea C 1999 J. Fluid Mech. 399 151

Google Scholar

Google Scholar

[20] Yarin A L, Brenn G, Rensink D 2002 Int. J. Heat Fluid Flow 23 471

Google Scholar

Google Scholar

[21] 翟薇, 王楠, 魏炳波 2007 56 2353

Google Scholar

Google Scholar

Zhai W, Wang N, Wei B B 2007 Acta Phys. Sin. 56 2353

Google Scholar

Google Scholar

[22] Hoven C V, Dang X D, Coffin R C, Peet J, Nguyen T Q, Bazan G C 2010 Adv. Mater. 22 E63

Google Scholar

Google Scholar

[23] Zhu J, Jiang L 2022 Langmuir 38 9043

Google Scholar

Google Scholar

[24] 齐玉, 曲昌荣, 王丽, 方腾 2014 63 046401

Google Scholar

Google Scholar

Qi Y, Qu C R, Wang L, Fang T 2014 Acta Phys. Sin. 63 046401

Google Scholar

Google Scholar

[25] 张鹏程, 方文玉, 鲍磊, 康文斌 2020 69 138701

Google Scholar

Google Scholar

Zhang P C, Fang W Y, Bao L, Kang W B 2020 Acta Phys. Sin. 69 138701

Google Scholar

Google Scholar

[26] Molino J V D, Marques D A V, Júnior A P, Mazzola P G, Gatti M S V 2013 Biotechnol. Prog. 29 1343

Google Scholar

Google Scholar

[27] Zhong Q C, Xie W J 2020 Appl. Phys. Lett. 116 224101

Google Scholar

Google Scholar

[28] Chao Y, Shum H C 2020 Chem. Soc. Rev. 49 114

Google Scholar

Google Scholar

[29] King L V 1934 Proc. Roy. Soc. A 147 212

Google Scholar

Google Scholar

[30] Huddleston J G, Willauer H D, Rogers R D 2003 J. Chem. Eng. Data 48 1230

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4387

- PDF Downloads: 343

- Cited By: 0

DownLoad:

DownLoad: