-

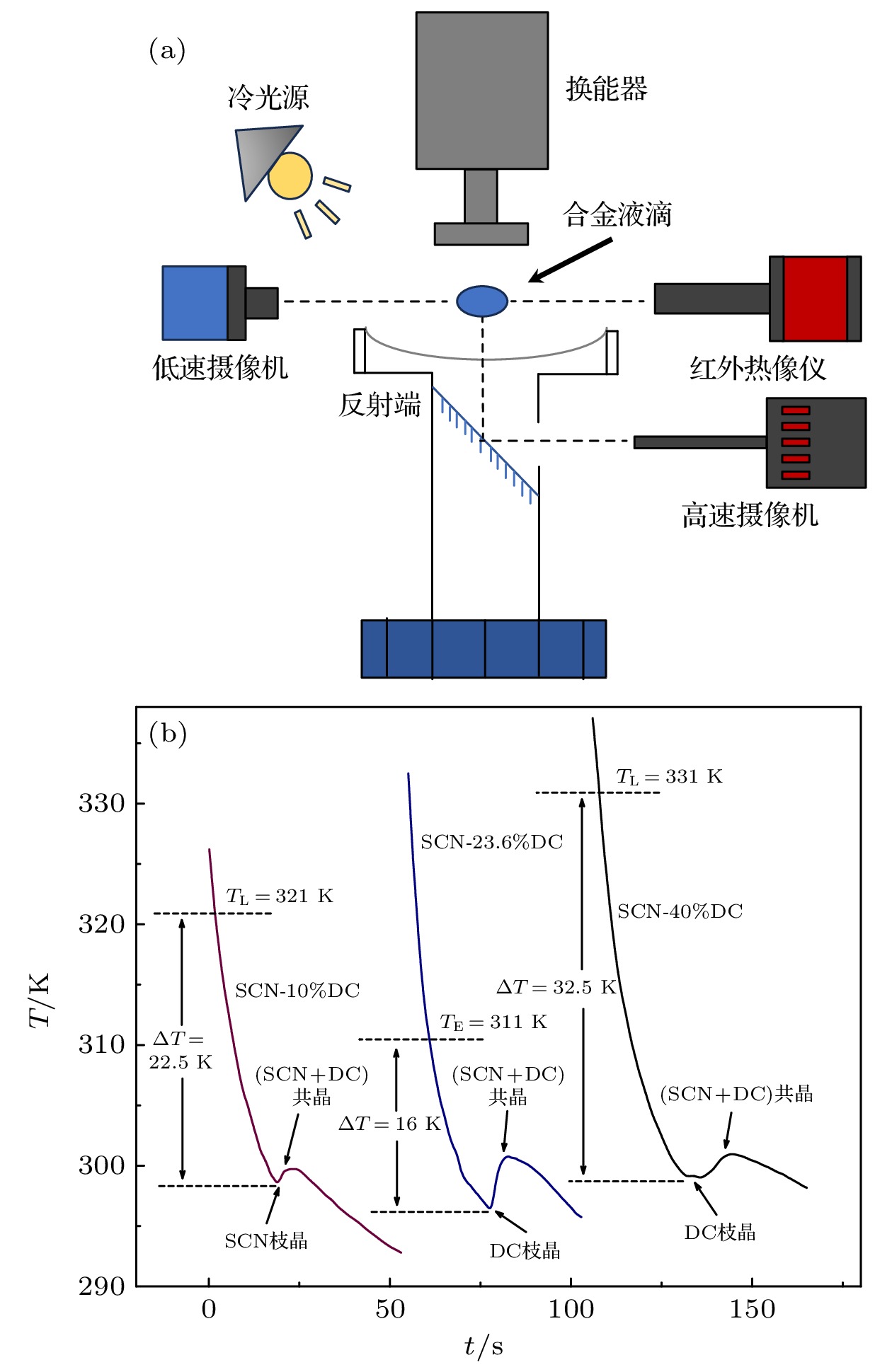

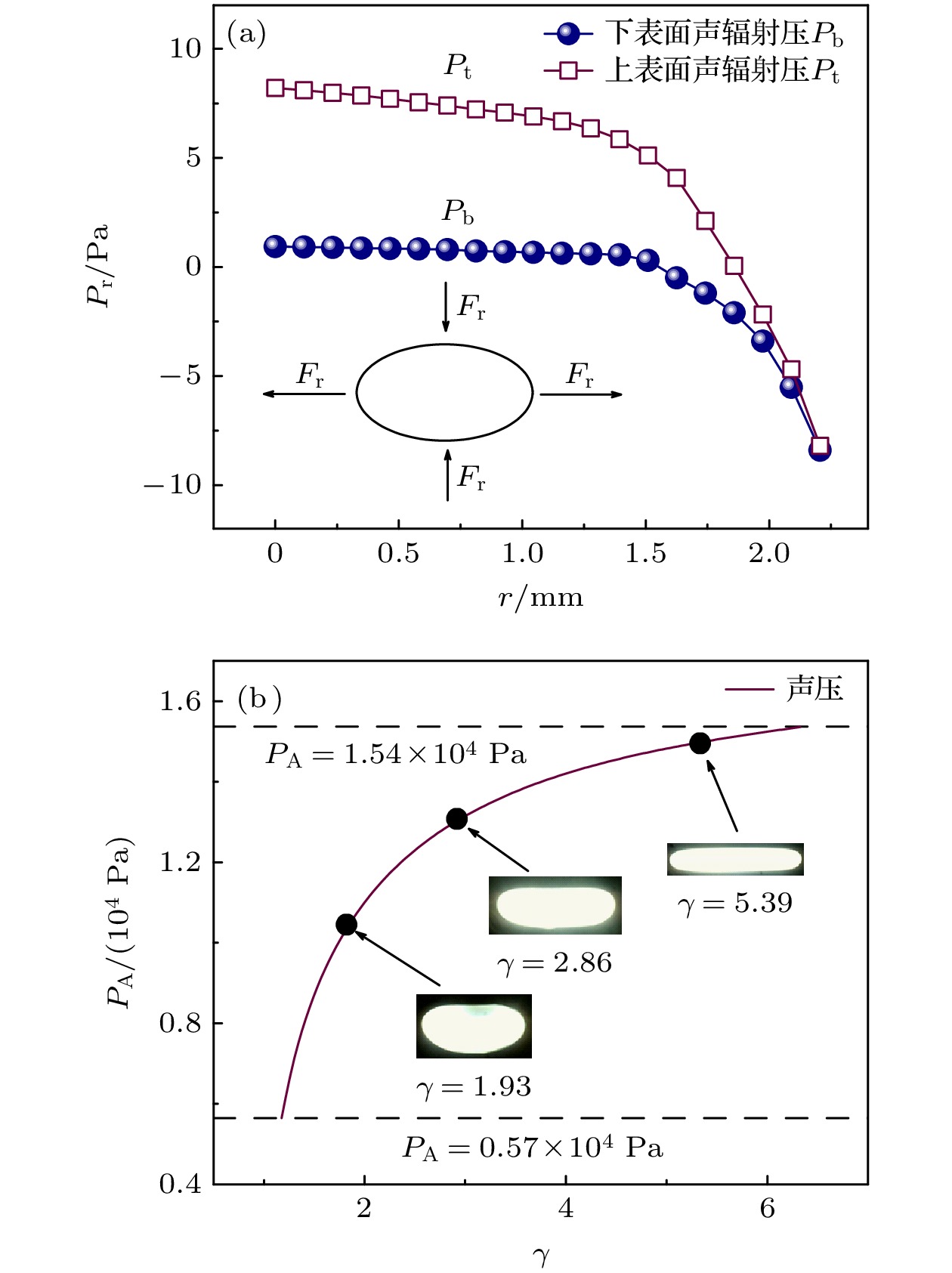

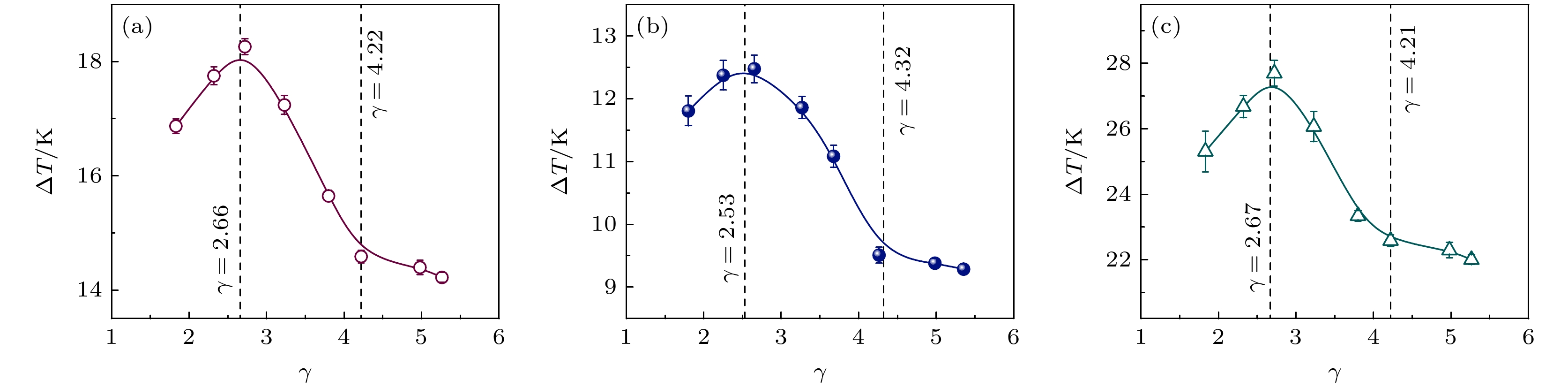

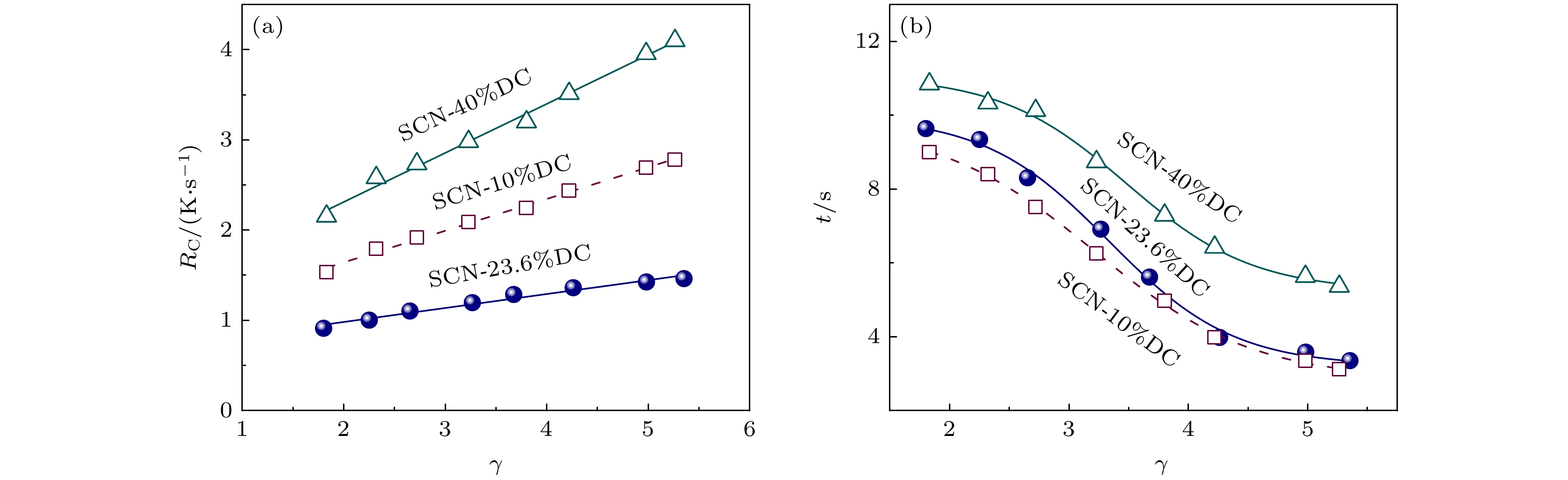

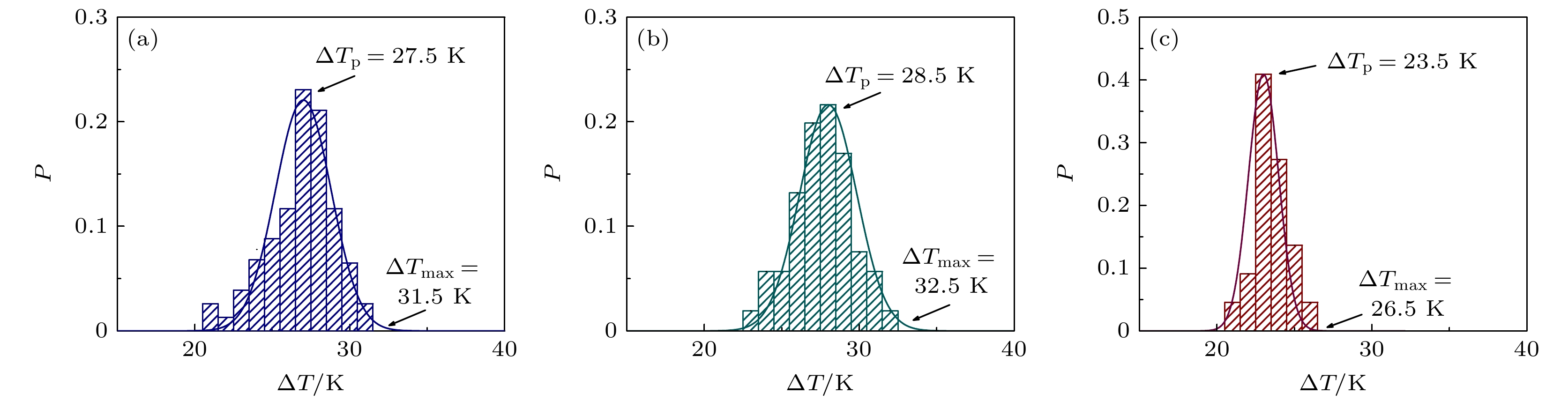

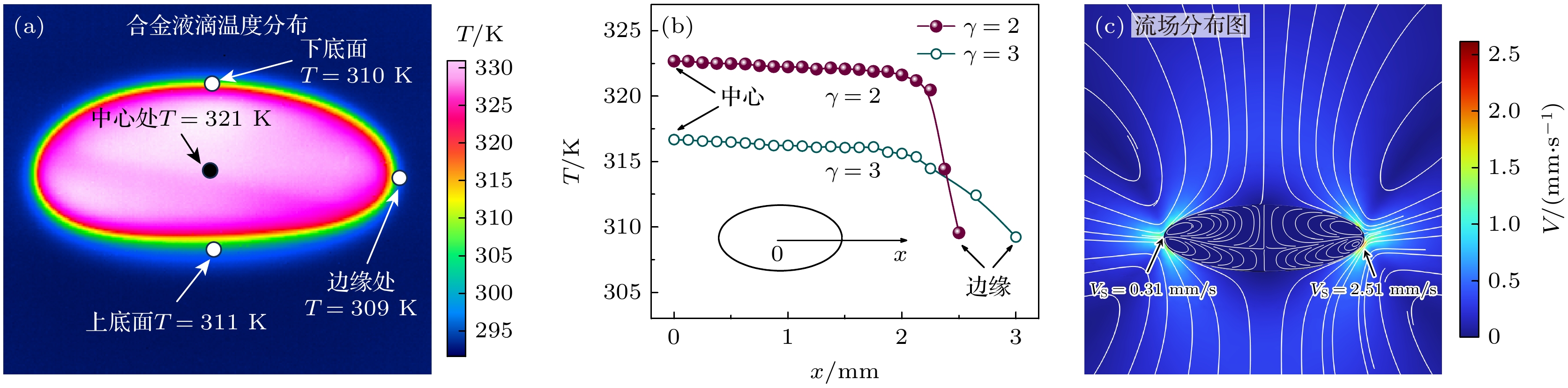

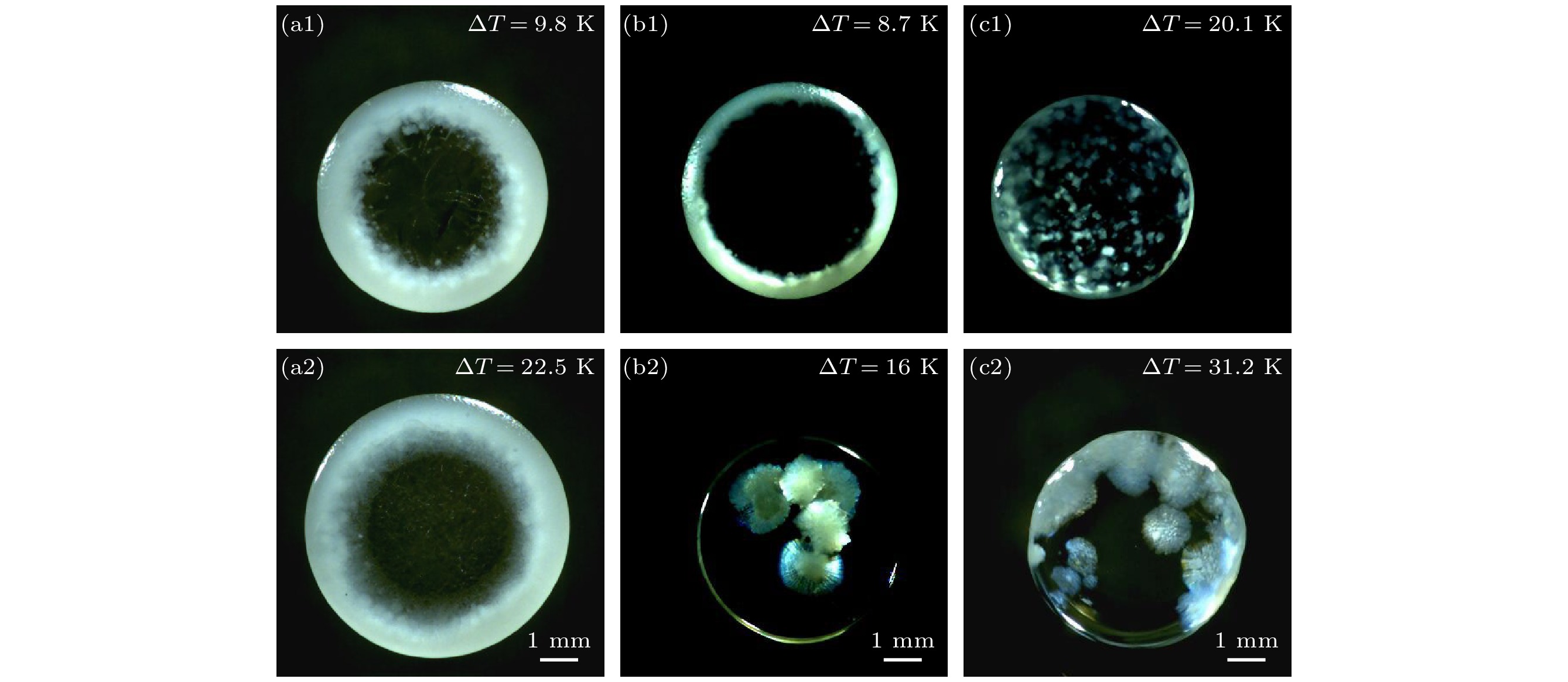

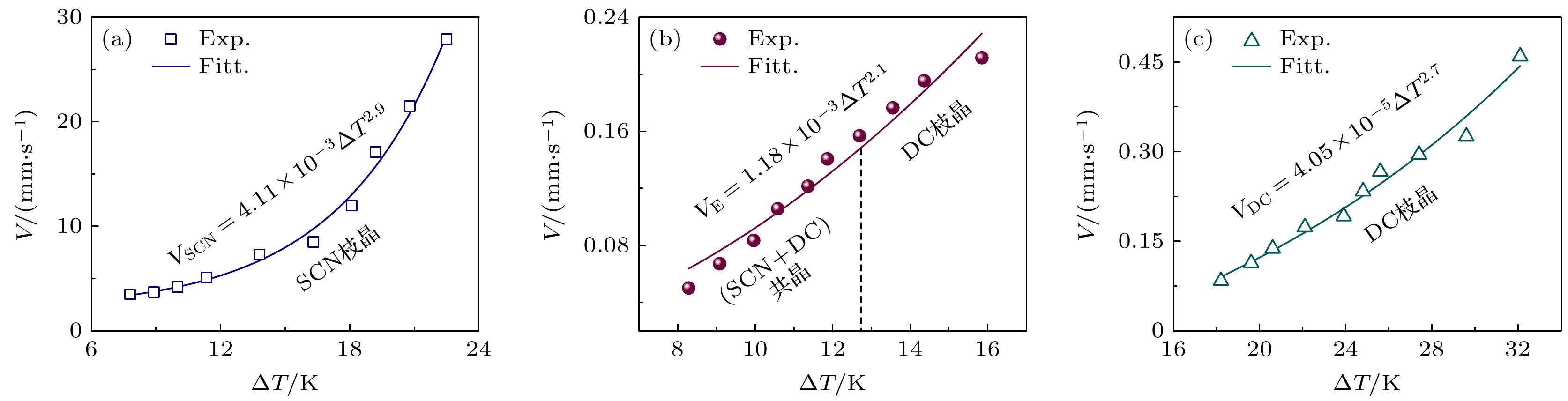

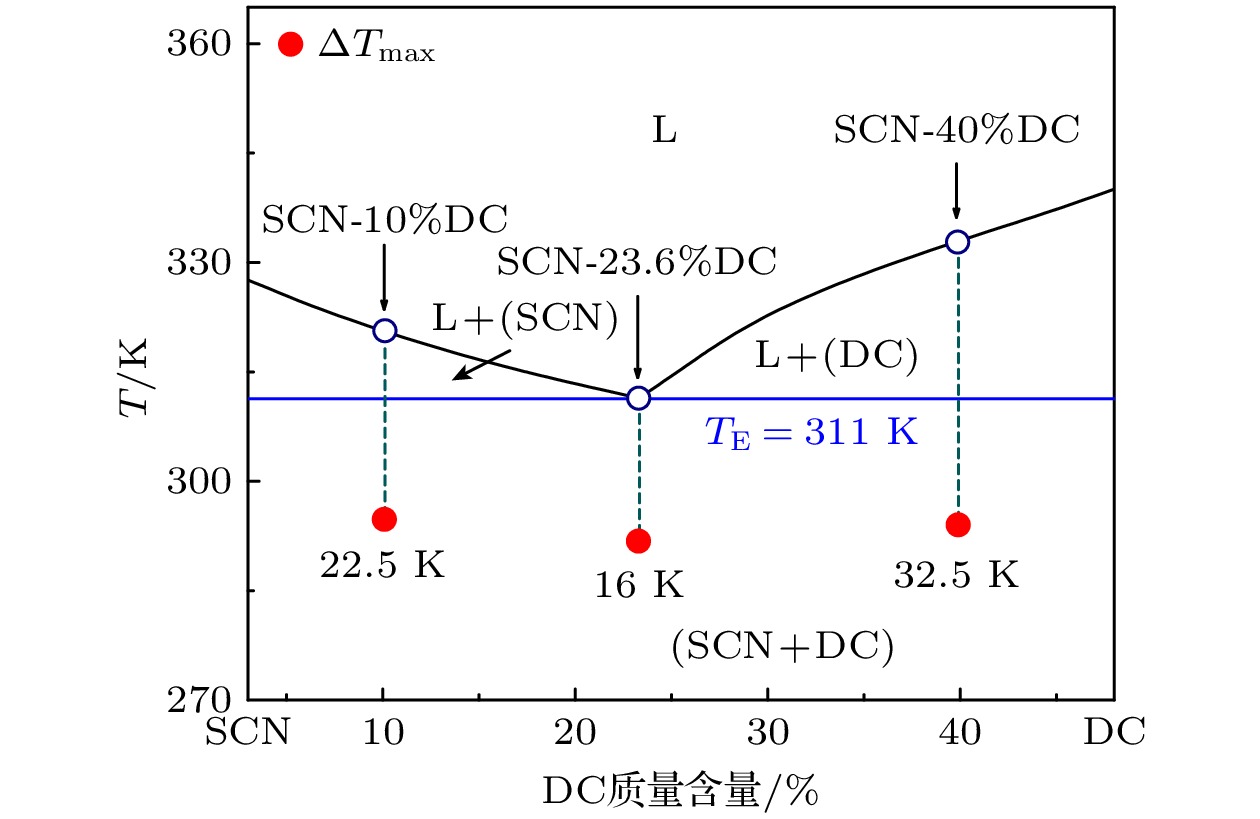

采用超声悬浮无容器处理技术, 并结合高速摄影实时分析方法, 研究了丁二腈-樟脑(SCN-DC)共晶型合金在不同声场条件下的液态过冷能力及其结晶过程. 实验发现, SCN-10%DC亚共晶、SCN-23.6%DC共晶和SCN-40%DC过共晶合金熔体获得的最大过冷度分别达22.5 K (0.07TL), 16 K (0.05TE)和32.5 K (0.1TL), 相应的晶体生长速度各为27.91, 0.21和0.45 mm/s. 随着声压的增强, 合金液滴的径厚比逐渐增大. 其过冷度随径厚比的增大先升高后逐渐降低, 最后基本保持不变. 强声场引起的表面形核率增加以及合金液滴振动是阻碍深过冷的主要因素.As an important and promising experimental method of simulating the containerless state in outer space, acoustic levitation provides excellent contact-free condition for investigating solidification process. Meanwhile, the radiation pressure and acoustic streaming caused by nonlinear effects bring various kinds of novel phenomena to crystallization kinetics. In this work, high-speed charge coupled device (CCD), low-speed camera and infrared thermal imager are used simultaneously to observe the crystallization process of acoustically levitated SCN-DC transparent alloys. The undercooling ability and solidification process of alloy droplets with different aspect ratios are explored in acoustic levitation state. For hypoeutectic SCN-10%DC, eutectic SCN-23.6%DC and hypereutectic SCN-40%DC alloys, the experimental maximum undercoolings reach 22.5 K (0.07TL), 16 K (0.05TE) and 32.5 K (0.1TL) and the corresponding crystal growth velocities are 27.91, 0.21 and 0.45 mm/s, respectively. In SCN-10%DC hypoeutectic alloy, the nucleation mode of SCN dendrite changes from edge nucleation into random nucleation with the increase of undercooling. For SCN-23.6%DC eutectic alloy, when the undercooling exceeds 12.6 K, DC dendrites preferentially nucleate and grow, and then the (SCN+DC) eutectic adheres to and grows on DC dendrites. Moreover, the growth interface of DC dendrites gradually changes from sharp into smooth within SCN-40%DC hypereutectic alloy as the undercooling degree rises. The undercooling distribution curve and nucleation probability variation trend versus aspect ratio are analyzed. It is found that as the aspect ratio increases, undercooling of alloy droplet first increases, then decreases, and finally remains almost unchanged. Further analysis shows that with the increase of aspect ratio, the cooling rate will rise and thus enhance the undercooling. However, the increase in surface nucleation rate and the droplet oscillation inhibits deep undercooling of alloy droplet. Therefore, the coupled effects of cooling rate, surface nucleation rate, and droplet oscillation determine the undercooling of the alloy. In the case of SCN-40% DC hypereutectic alloy, the acoustic streaming and surface oscillation arising from acoustic field are the main factors intensifying surface nucleation.

-

Keywords:

- acoustic levitation /

- SCN-DC alloy /

- nucleation /

- crystal growth

[1] Foresti D, Nabavi M, Klingauf M, Ferrari A, Poulikakos D 2013 Proc. Natl. Acad. Sci. U. S. A. 110 12549

Google Scholar

Google Scholar

[2] Xie W J, Cao C D, Lü Y J, Wei B 2002 Phys. Rev. Lett. 89 104304

Google Scholar

Google Scholar

[3] Doss M, Bänsch E 2022 Chem. Eng. Sci. 248 117149

Google Scholar

Google Scholar

[4] Zehnter S, Andrade M A B, Ament C 2021 J. Appl. Phys. 129 134901

Google Scholar

Google Scholar

[5] 秦修培, 耿德路, 洪振宇, 魏炳波 2017 66 124301

Google Scholar

Google Scholar

Qin X P, Geng D L, Hong Z Y, Wei B B 2017 Acta Phys. Sin. 66 124301

Google Scholar

Google Scholar

[6] Vieira S L, Andrade M A B 2020 J. Appl. Phys. 127 224901

Google Scholar

Google Scholar

[7] Andrade M A B, Bernassau A L, Adamowski J C 2016 Appl. Phys. Lett. 109 044101

Google Scholar

Google Scholar

[8] Nada B, Daniele F, Marko D, Majid N, Dimos P 2010 Appl. Phys. Lett. 97 161904

Google Scholar

Google Scholar

[9] 陈聪, 张若钦, 李锋, 李志远 2023 72 124302

Google Scholar

Google Scholar

Chen C, Zhang R Q, Li F, Li Z Y 2023 Acta Phys. Sin. 72 124302

Google Scholar

Google Scholar

[10] Wu B, Vansaders B, Lim M X, Jaeger H M 2023 Proc. Natl. Acad. Sci. U. S. A. 120 e2301625120

Google Scholar

Google Scholar

[11] Hosseinzadeh V A, Holt R G 2017 J. Appl. Phys. 121 174502

Google Scholar

Google Scholar

[12] Kremer J, Kilzer A, Petermann M 2018 Rev. Sci. Instrum. 89 015109

Google Scholar

Google Scholar

[13] Brillo J, Pommrich A I, Meyer A 2011 Phys. Rev. Lett. 107 165902

Google Scholar

Google Scholar

[14] Su Y, Mohr M, Wunderlich R K, Wang X D, Cao Q P, Zhang D X, Yang Y, Fecht H J, Jiang J Z 2020 J. Mol. Liq. 298 111992

Google Scholar

Google Scholar

[15] Mark P, Taketoshi H, Minoru E, Ivan E 1995 J. Cryst. 151 60

Google Scholar

Google Scholar

[16] Lü Y J, Wei B 2006 J. Chem. Phys. 125 144503

Google Scholar

Google Scholar

[17] Andrade M A B, Marzo A, Adamowski J C 2020 Appl. Phys. Lett. 116 250501

Google Scholar

Google Scholar

[18] 杜人君, 解文军 2011 60 114302

Google Scholar

Google Scholar

Du R J, Xie W J 2011 Acta Phys. Sin. 60 114302

Google Scholar

Google Scholar

[19] 王哲, 王发展, 王欣, 何银花, 马姗, 吴振 2014 63 076101

Google Scholar

Google Scholar

Wang Z, Wang F Z, Wang X, He Y H, Ma S, Wu Z 2014 Acta Phys. Sin. 63 076101

Google Scholar

Google Scholar

[20] Lü Y J, Xie W J, Wei B 2005 Appl. Phys. Lett. 87 184107

Google Scholar

Google Scholar

[21] Mauro N A, Vogt A J, Johnson M L, Bendert J C, Kelton K F 2013 Appl. Phys. Lett. 103 021904

Google Scholar

Google Scholar

[22] Mauro N A, Vogt A J, Johnson M L, Bendert J C, Soklaski R, Yang L, Kelton K F 2013 Acta Mater. 61 7411

Google Scholar

Google Scholar

[23] Wolfgang R, Joseph P, Allen C, Daniel D 2023 J. Acoust. Soc. Am. 154 1339

Google Scholar

Google Scholar

[24] Loops J H, Lima E B, Leão-Neto J P, Silva G T 2020 Phys. Rev. E 101 043102

Google Scholar

Google Scholar

[25] O’Connell R A, Sharratt W N, Cabral J T 2023 Phys. Rev. Lett. 131 218101

Google Scholar

Google Scholar

[26] Zsolt V, Arnold R, Jenő K, András R 2019 J. Cryst. 506 127

Google Scholar

Google Scholar

[27] Rodriguez J E, Kreischer C, Volkmann T, Matson D M 2017 Acta Mater. 122 431

Google Scholar

Google Scholar

[28] Ohsaka K, Trinh E H 1990 J. Cryst. 106 191

Google Scholar

Google Scholar

[29] Witusiewicz V T, Hecht U, Rex S 2013 J. Cryst. 375 84

Google Scholar

Google Scholar

[30] Lee C P, Wang T G 1993 J. Acoust. Soc. Am. 94 1099

Google Scholar

Google Scholar

[31] Xie W J, Wei B 2003 J. Appl. Phys. 93 3016

Google Scholar

Google Scholar

-

表 1 声场计算所需物理参数

Table 1. Physical parameters used for calculation

参数 单位 数值 超声频率 f kHz 22 发射端振幅 A μm 15 等效半径 $ {{R}}_{\text{s}} $ mm 4.15 重力加速度 g m/s2 9.8 介质密度 $ {\rho }_{0} $ kg/m3 1.29 介质黏度 $ {\eta}_{0} $ $ {10}^{-5}\text{ }\text{Pa∙s} $ 1.81 声速 $ {{c}}_{0} $ m/s 340 合金密度 $ {\rho }_{\text{s}} $ 103 kg/m3 1.02 合金表面张力 $ \sigma $ $ {10}^{-2}\text{\;}\text{N/m} $ 3.75 合金黏度 $ {\eta}_{\text{L}} $ $ {10}^{-3}\text{\;}\text{Pa∙s} $ 3.22 温度T K 293 -

[1] Foresti D, Nabavi M, Klingauf M, Ferrari A, Poulikakos D 2013 Proc. Natl. Acad. Sci. U. S. A. 110 12549

Google Scholar

Google Scholar

[2] Xie W J, Cao C D, Lü Y J, Wei B 2002 Phys. Rev. Lett. 89 104304

Google Scholar

Google Scholar

[3] Doss M, Bänsch E 2022 Chem. Eng. Sci. 248 117149

Google Scholar

Google Scholar

[4] Zehnter S, Andrade M A B, Ament C 2021 J. Appl. Phys. 129 134901

Google Scholar

Google Scholar

[5] 秦修培, 耿德路, 洪振宇, 魏炳波 2017 66 124301

Google Scholar

Google Scholar

Qin X P, Geng D L, Hong Z Y, Wei B B 2017 Acta Phys. Sin. 66 124301

Google Scholar

Google Scholar

[6] Vieira S L, Andrade M A B 2020 J. Appl. Phys. 127 224901

Google Scholar

Google Scholar

[7] Andrade M A B, Bernassau A L, Adamowski J C 2016 Appl. Phys. Lett. 109 044101

Google Scholar

Google Scholar

[8] Nada B, Daniele F, Marko D, Majid N, Dimos P 2010 Appl. Phys. Lett. 97 161904

Google Scholar

Google Scholar

[9] 陈聪, 张若钦, 李锋, 李志远 2023 72 124302

Google Scholar

Google Scholar

Chen C, Zhang R Q, Li F, Li Z Y 2023 Acta Phys. Sin. 72 124302

Google Scholar

Google Scholar

[10] Wu B, Vansaders B, Lim M X, Jaeger H M 2023 Proc. Natl. Acad. Sci. U. S. A. 120 e2301625120

Google Scholar

Google Scholar

[11] Hosseinzadeh V A, Holt R G 2017 J. Appl. Phys. 121 174502

Google Scholar

Google Scholar

[12] Kremer J, Kilzer A, Petermann M 2018 Rev. Sci. Instrum. 89 015109

Google Scholar

Google Scholar

[13] Brillo J, Pommrich A I, Meyer A 2011 Phys. Rev. Lett. 107 165902

Google Scholar

Google Scholar

[14] Su Y, Mohr M, Wunderlich R K, Wang X D, Cao Q P, Zhang D X, Yang Y, Fecht H J, Jiang J Z 2020 J. Mol. Liq. 298 111992

Google Scholar

Google Scholar

[15] Mark P, Taketoshi H, Minoru E, Ivan E 1995 J. Cryst. 151 60

Google Scholar

Google Scholar

[16] Lü Y J, Wei B 2006 J. Chem. Phys. 125 144503

Google Scholar

Google Scholar

[17] Andrade M A B, Marzo A, Adamowski J C 2020 Appl. Phys. Lett. 116 250501

Google Scholar

Google Scholar

[18] 杜人君, 解文军 2011 60 114302

Google Scholar

Google Scholar

Du R J, Xie W J 2011 Acta Phys. Sin. 60 114302

Google Scholar

Google Scholar

[19] 王哲, 王发展, 王欣, 何银花, 马姗, 吴振 2014 63 076101

Google Scholar

Google Scholar

Wang Z, Wang F Z, Wang X, He Y H, Ma S, Wu Z 2014 Acta Phys. Sin. 63 076101

Google Scholar

Google Scholar

[20] Lü Y J, Xie W J, Wei B 2005 Appl. Phys. Lett. 87 184107

Google Scholar

Google Scholar

[21] Mauro N A, Vogt A J, Johnson M L, Bendert J C, Kelton K F 2013 Appl. Phys. Lett. 103 021904

Google Scholar

Google Scholar

[22] Mauro N A, Vogt A J, Johnson M L, Bendert J C, Soklaski R, Yang L, Kelton K F 2013 Acta Mater. 61 7411

Google Scholar

Google Scholar

[23] Wolfgang R, Joseph P, Allen C, Daniel D 2023 J. Acoust. Soc. Am. 154 1339

Google Scholar

Google Scholar

[24] Loops J H, Lima E B, Leão-Neto J P, Silva G T 2020 Phys. Rev. E 101 043102

Google Scholar

Google Scholar

[25] O’Connell R A, Sharratt W N, Cabral J T 2023 Phys. Rev. Lett. 131 218101

Google Scholar

Google Scholar

[26] Zsolt V, Arnold R, Jenő K, András R 2019 J. Cryst. 506 127

Google Scholar

Google Scholar

[27] Rodriguez J E, Kreischer C, Volkmann T, Matson D M 2017 Acta Mater. 122 431

Google Scholar

Google Scholar

[28] Ohsaka K, Trinh E H 1990 J. Cryst. 106 191

Google Scholar

Google Scholar

[29] Witusiewicz V T, Hecht U, Rex S 2013 J. Cryst. 375 84

Google Scholar

Google Scholar

[30] Lee C P, Wang T G 1993 J. Acoust. Soc. Am. 94 1099

Google Scholar

Google Scholar

[31] Xie W J, Wei B 2003 J. Appl. Phys. 93 3016

Google Scholar

Google Scholar

计量

- 文章访问数: 2692

- PDF下载量: 62

- 被引次数: 0

下载:

下载: