-

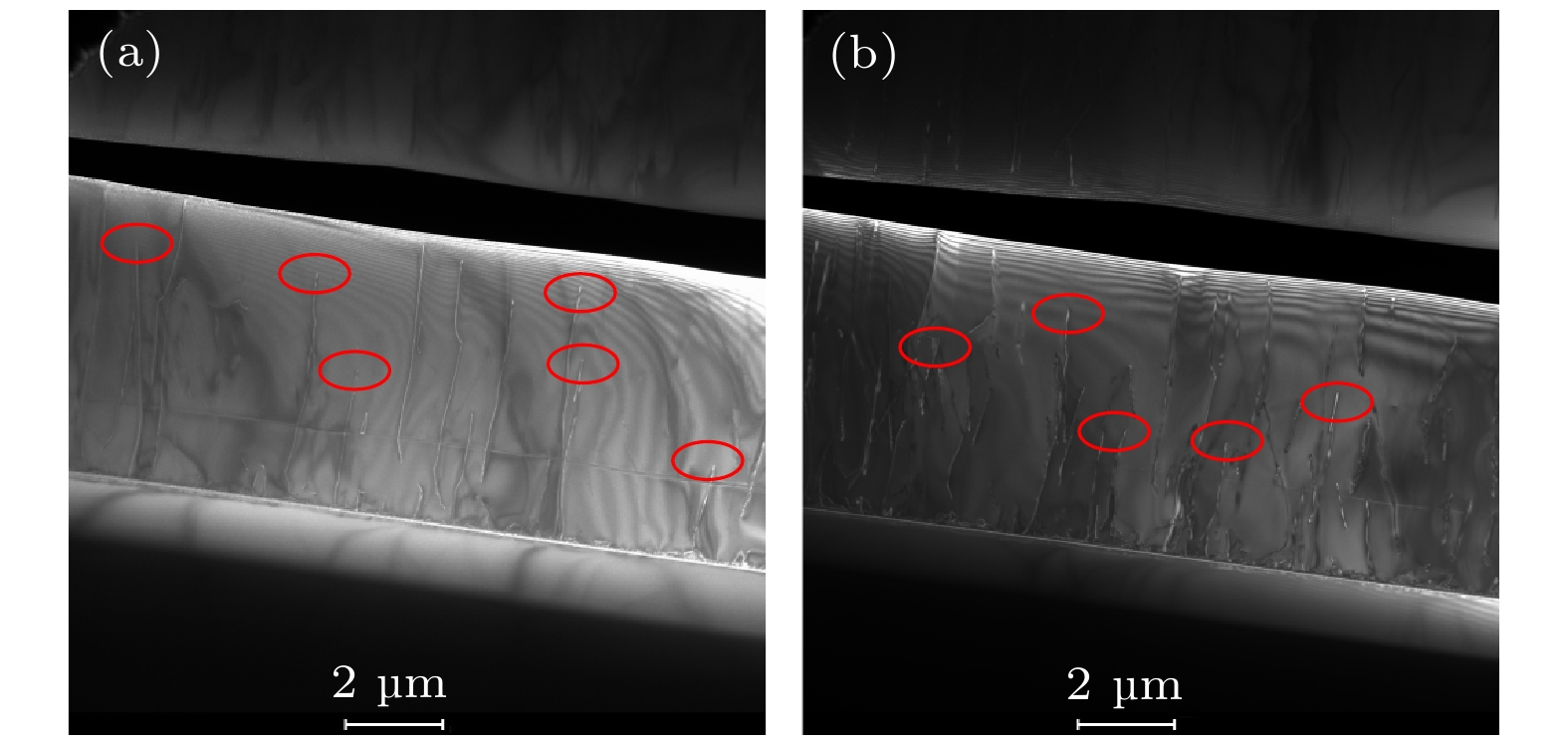

GaN materials are widely used in optoelectronic devices, high-power devices and high-frequency microwave devices because of their excellent characteristics, such as wide frequency band, high breakdown electric field, high thermal conductivity, and direct band gap. Owing to the large lattice mismatch and thermal mismatch brought by the heterogeneous epitaxy of GaN material, the GaN epitaxial layer will produce a great many dislocations in the growth process, resulting in the poor crystal quality of GaN material and the difficulty in further improving the device performance. Therefore, researchers have proposed the use of vicinal substrate to reduce the dislocation density of GaN material, but the dislocation annihilation mechanism in GaN film on vicinal substrate has not been sufficiently studied. Therefore, in this paper, GaN thin films are grown on vicinal sapphire substrates at different angles by using metal organic chemical vapor deposition technique. Atomic force microscope, high resolution X-ray diffractometer, photoluminescence testing, and transmission electron microscopy are used to analyze in detail the effects of vicinal substrates on GaN materials. The use of vicinal substrates can significantly reduce the dislocation density of GaN materials, but lead to degradation of their surface morphology morphologies. And the larger the substrate vicinal angle, the lower the dislocation density of the sample is. The dislocation density of the sample with a 5º bevel cut on the substrate is reduced by about one-third compared to that of the sample with a flat substrate. The special dislocation termination on the mitered substrate is observed by transmission electron microscopy, which is one of the main reasons for the reducing the dislocation density on the mitered substrate. The step merging on the vicinal sapphire substrate surface leads to both transverse growth and longitudinal growth of GaN in the growth process. The transverse growth region blocks the dislocations, resulting in an abrupt interruption of the dislocations during propagation, which in turn reduces the dislocation density. Based on the above phenomena, a model of GaN growth on vicinal substrate is proposed to explain the reason why the quality of GaN crystal can be improved by vicinal substrate. -

Keywords:

- vicinal sapphire substrates /

- GaN /

- dislocation termination /

- transmission electron microscope

[1] Morkoc H, Strite S, Gao G B, Lin M E, Sverdlov B, Burns M 1994 J. Appl. Phys. 76 1363

Google Scholar

Google Scholar

[2] Kneissl M, Seong T Y, Han J, Amano H 2019 Nat. Photonics 13 233

Google Scholar

Google Scholar

[3] 郭海君, 段宝兴, 袁嵩, 谢慎隆, 杨银堂 2017 66 167301

Google Scholar

Google Scholar

Guo H J, Duan B X, Yuan S, Xie S L, Yang Y T 2017 Acta Phys. Sin. 66 167301

Google Scholar

Google Scholar

[4] 武鹏, 张涛, 张进成, 郝跃 2022 71 158503

Google Scholar

Google Scholar

Wu P, Zhang T, Zhang J C, Hao Y 2022 Acta Phys. Sin. 71 158503

Google Scholar

Google Scholar

[5] Li G Q, Wang W L, Yang W J, Lin Y H, Wang H Y, Lin Z T, Zhou S Z 2016 Rep. Prog. Phys. 79 056501

Google Scholar

Google Scholar

[6] Jena D, Mishra U K 2002 Appl. Phys. Lett. 80 64

Google Scholar

Google Scholar

[7] 刘成, 李明, 文章, 顾钊源, 杨明超, 刘卫华, 韩传余, 张勇, 耿莉, 郝跃 2022 71 057301

Google Scholar

Google Scholar

Liu C, Li M, Wen Z, Gu Z Y, Yang M C, Liu W H, Han C Y, Zhang Y, Geng L, Hao Y 2022 Acta Phys. Sin. 71 057301

Google Scholar

Google Scholar

[8] Zhou S J, Zhao X Y, Du P, Zhang Z Q, Liu X, Liu S, Guo A 2022 Nanoscale 14 4887

Google Scholar

Google Scholar

[9] Kung P, Walker D, Hamilton N, Diaz J, Razeghi M 1999 Appl. Phys. Lett. 74 570

Google Scholar

Google Scholar

[10] Zhao Y, Xu S R, Feng L S, Peng R S, Fan X M, Du J J, Su H K, Zhang J C, Hao Y 2022 Mater. Sci. Semicond. Process. 143 106535

Google Scholar

Google Scholar

[11] Ni Y Q, He Z Y, Zhou D Q, Yao Y, Yang F, Zhou G L, Shen Z, Zhong J, Zhen Y, Zhang B J, Liu Y 2015 Superlattices Microstruct. 83 811

Google Scholar

Google Scholar

[12] Fatemi M, Wickenden A E, Koleske D D, Twigg M E, Freitas J A, Henry R L, Gorman R J 1998 Appl. Phys. Lett. 73 608

Google Scholar

Google Scholar

[13] Shen X Q, Shimizu M, Okumura H 2003 Jpn. J. Appl. Phys. 42 L1293

Google Scholar

Google Scholar

[14] Chang P C, Yu C L 2008 J. Electrochem. Soc. 155 H369

Google Scholar

Google Scholar

[15] Zhang H C, Sun Y, Song K, et al. 2022 Appl. Phys. Lett. 119 072104

Google Scholar

Google Scholar

[16] Fan X M, Bai J C, Xu S R, Zhang J C, Li P X, Peng R S, Zhao Y, Du J J, Shi X F, Hao Y 2018 Thin Solid Films 663 44

Google Scholar

Google Scholar

[17] Shen X Q, Matsuhata H, Okumura H 2005 Appl. Phys. Lett. 86 021912

Google Scholar

Google Scholar

[18] 林志宇, 张进成, 许晟瑞, 吕玲, 刘子扬, 马俊彩, 薛晓咏, 薛军帅, 郝跃 2012 61 186103

Google Scholar

Google Scholar

Lin Z Y, Zhang J C, Xu S R, Lü L, Liu Z Y, Ma J C, Xue X Y, Xue J S, Hao Y 2012 Acta Phys. Sin. 61 186103

Google Scholar

Google Scholar

[19] Chuang R W, Yu C L, Chang S J, Chang P C, Lin J C, Kuan T M 2007 J. Cryst. Growth 308 252

Google Scholar

Google Scholar

[20] Xu Z H, Zhang J C, Zhang Z F, Zhu Q W, Duan H T, Hao Y 2009 Chin. Phys. B 18 5457

Google Scholar

Google Scholar

[21] Sun H D, Mitra S, Subedi R C, et al. 2019 Adv. Funct. Mater. 29 1905445

Google Scholar

Google Scholar

[22] Zhang H C, Sun Y, Song K, Xing C, Yang L, Wang D H, Yu H B, Xiang X Q, Gao N, Xu G W, Sun H D, Long S B 2021 Appl. Phys. Lett. 119 072104

Google Scholar

Google Scholar

[23] Shen X Q, Furuta K, Nakamura N, Matsuhata H, Shimizu M, Okumura H 2007 J. Cryst. Growth 301 404

Google Scholar

Google Scholar

[24] Chierchia R, Bottcher T, Heinke H, Einfeldt S, Figge S, Hommel D 2003 J. Appl. Phys. 93 8918

Google Scholar

Google Scholar

[25] 郝跃, 张金风, 张进成 2013 氮化物宽禁带半导体材料与电子器件(北京: 科学出版社) 第25页

Hao Y, Zhang J F, Zhang J C 2013 Nitride Wide Bandgap Semiconductor Materials and Electronic Devices (Beijing: Science Press) p25

[26] Xu S R, Hao Y, Zhang J C, Jiang T, Yang L A, Lu X L, Lin Z Y 2013 Nano Lett. 13 3654

Google Scholar

Google Scholar

[27] Yu H B, Chen H, Li D S, Wang J, Xing Z G, Zheng X H, Huang Q, Zhou J M 2004 J. Cryst. Growth 266 455

Google Scholar

Google Scholar

[28] Lee J H, Lee D Y, Oh B W, Lee J H 2010 IEEE Trans. Electron Devices 57 157

Google Scholar

Google Scholar

[29] Kong B H, Sun Q, Han J, Lee I H, Cho H K 2012 Appl. Surf. Sci. 258 2522

Google Scholar

Google Scholar

[30] Pakula K, Baranowski J M, Borysiuk J 2007 Cryst. Res. Technol. 42 1176

Google Scholar

Google Scholar

[31] Tao H C, Xu S R, Zhang J C, Su H K, Gao Y, Zhang Y C, Zhou H, Hao Y 2023 Opt. Express 31 20850

Google Scholar

Google Scholar

-

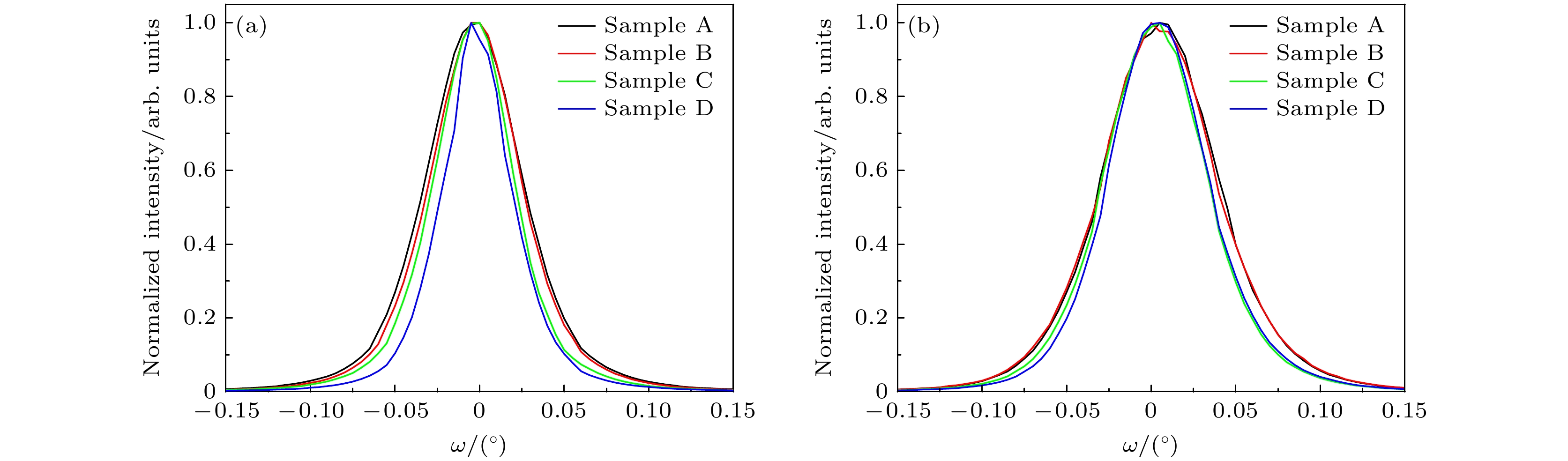

表 1 样品A, B, C, D的RC曲线FWHM值和位错密度

Table 1. FWHM values and dislocation density of RC curves of samples A, B, C and D.

样品 (002)面

FWHM值/('')(102)面

FWHM值/('')螺位错

密度/(107 cm–2)刃位错

密度/(108 cm–2)总位错

密度/(108 cm–2)Sample A 235 282 11.0 4.20 5.30 Sample B 221 274 9.76 3.97 4.94 Sample C 196 251 7.69 3.33 4.11 Sample D 165 240 5.47 3.07 3.62 -

[1] Morkoc H, Strite S, Gao G B, Lin M E, Sverdlov B, Burns M 1994 J. Appl. Phys. 76 1363

Google Scholar

Google Scholar

[2] Kneissl M, Seong T Y, Han J, Amano H 2019 Nat. Photonics 13 233

Google Scholar

Google Scholar

[3] 郭海君, 段宝兴, 袁嵩, 谢慎隆, 杨银堂 2017 66 167301

Google Scholar

Google Scholar

Guo H J, Duan B X, Yuan S, Xie S L, Yang Y T 2017 Acta Phys. Sin. 66 167301

Google Scholar

Google Scholar

[4] 武鹏, 张涛, 张进成, 郝跃 2022 71 158503

Google Scholar

Google Scholar

Wu P, Zhang T, Zhang J C, Hao Y 2022 Acta Phys. Sin. 71 158503

Google Scholar

Google Scholar

[5] Li G Q, Wang W L, Yang W J, Lin Y H, Wang H Y, Lin Z T, Zhou S Z 2016 Rep. Prog. Phys. 79 056501

Google Scholar

Google Scholar

[6] Jena D, Mishra U K 2002 Appl. Phys. Lett. 80 64

Google Scholar

Google Scholar

[7] 刘成, 李明, 文章, 顾钊源, 杨明超, 刘卫华, 韩传余, 张勇, 耿莉, 郝跃 2022 71 057301

Google Scholar

Google Scholar

Liu C, Li M, Wen Z, Gu Z Y, Yang M C, Liu W H, Han C Y, Zhang Y, Geng L, Hao Y 2022 Acta Phys. Sin. 71 057301

Google Scholar

Google Scholar

[8] Zhou S J, Zhao X Y, Du P, Zhang Z Q, Liu X, Liu S, Guo A 2022 Nanoscale 14 4887

Google Scholar

Google Scholar

[9] Kung P, Walker D, Hamilton N, Diaz J, Razeghi M 1999 Appl. Phys. Lett. 74 570

Google Scholar

Google Scholar

[10] Zhao Y, Xu S R, Feng L S, Peng R S, Fan X M, Du J J, Su H K, Zhang J C, Hao Y 2022 Mater. Sci. Semicond. Process. 143 106535

Google Scholar

Google Scholar

[11] Ni Y Q, He Z Y, Zhou D Q, Yao Y, Yang F, Zhou G L, Shen Z, Zhong J, Zhen Y, Zhang B J, Liu Y 2015 Superlattices Microstruct. 83 811

Google Scholar

Google Scholar

[12] Fatemi M, Wickenden A E, Koleske D D, Twigg M E, Freitas J A, Henry R L, Gorman R J 1998 Appl. Phys. Lett. 73 608

Google Scholar

Google Scholar

[13] Shen X Q, Shimizu M, Okumura H 2003 Jpn. J. Appl. Phys. 42 L1293

Google Scholar

Google Scholar

[14] Chang P C, Yu C L 2008 J. Electrochem. Soc. 155 H369

Google Scholar

Google Scholar

[15] Zhang H C, Sun Y, Song K, et al. 2022 Appl. Phys. Lett. 119 072104

Google Scholar

Google Scholar

[16] Fan X M, Bai J C, Xu S R, Zhang J C, Li P X, Peng R S, Zhao Y, Du J J, Shi X F, Hao Y 2018 Thin Solid Films 663 44

Google Scholar

Google Scholar

[17] Shen X Q, Matsuhata H, Okumura H 2005 Appl. Phys. Lett. 86 021912

Google Scholar

Google Scholar

[18] 林志宇, 张进成, 许晟瑞, 吕玲, 刘子扬, 马俊彩, 薛晓咏, 薛军帅, 郝跃 2012 61 186103

Google Scholar

Google Scholar

Lin Z Y, Zhang J C, Xu S R, Lü L, Liu Z Y, Ma J C, Xue X Y, Xue J S, Hao Y 2012 Acta Phys. Sin. 61 186103

Google Scholar

Google Scholar

[19] Chuang R W, Yu C L, Chang S J, Chang P C, Lin J C, Kuan T M 2007 J. Cryst. Growth 308 252

Google Scholar

Google Scholar

[20] Xu Z H, Zhang J C, Zhang Z F, Zhu Q W, Duan H T, Hao Y 2009 Chin. Phys. B 18 5457

Google Scholar

Google Scholar

[21] Sun H D, Mitra S, Subedi R C, et al. 2019 Adv. Funct. Mater. 29 1905445

Google Scholar

Google Scholar

[22] Zhang H C, Sun Y, Song K, Xing C, Yang L, Wang D H, Yu H B, Xiang X Q, Gao N, Xu G W, Sun H D, Long S B 2021 Appl. Phys. Lett. 119 072104

Google Scholar

Google Scholar

[23] Shen X Q, Furuta K, Nakamura N, Matsuhata H, Shimizu M, Okumura H 2007 J. Cryst. Growth 301 404

Google Scholar

Google Scholar

[24] Chierchia R, Bottcher T, Heinke H, Einfeldt S, Figge S, Hommel D 2003 J. Appl. Phys. 93 8918

Google Scholar

Google Scholar

[25] 郝跃, 张金风, 张进成 2013 氮化物宽禁带半导体材料与电子器件(北京: 科学出版社) 第25页

Hao Y, Zhang J F, Zhang J C 2013 Nitride Wide Bandgap Semiconductor Materials and Electronic Devices (Beijing: Science Press) p25

[26] Xu S R, Hao Y, Zhang J C, Jiang T, Yang L A, Lu X L, Lin Z Y 2013 Nano Lett. 13 3654

Google Scholar

Google Scholar

[27] Yu H B, Chen H, Li D S, Wang J, Xing Z G, Zheng X H, Huang Q, Zhou J M 2004 J. Cryst. Growth 266 455

Google Scholar

Google Scholar

[28] Lee J H, Lee D Y, Oh B W, Lee J H 2010 IEEE Trans. Electron Devices 57 157

Google Scholar

Google Scholar

[29] Kong B H, Sun Q, Han J, Lee I H, Cho H K 2012 Appl. Surf. Sci. 258 2522

Google Scholar

Google Scholar

[30] Pakula K, Baranowski J M, Borysiuk J 2007 Cryst. Res. Technol. 42 1176

Google Scholar

Google Scholar

[31] Tao H C, Xu S R, Zhang J C, Su H K, Gao Y, Zhang Y C, Zhou H, Hao Y 2023 Opt. Express 31 20850

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7006

- PDF Downloads: 234

- Cited By: 0

DownLoad:

DownLoad: