-

The electron transport layer is very important for the device efficiency and stability of perovskite solar cells. Tin dioxide is a common electron transport layer in high-efficiency solar cells and has good carrier extraction and transport capability. However, using the solution method to prepare tin dioxide, a large number of defects are generated on its surface during high-temperature annealing in air, which can degrade the electrical properties of the film, so the solution method is not conducive to preparing large-area film. In this paper, the reactive plasma deposition method is used to prepare tin dioxide thin film, and the performance of the thin film is optimized by adjusting the glow discharge time and working current. The film is applied to small-area N-I-P type perovskite solar cells, the efficiency reaching to 21.24%. The hysteresis of the device is improved by introducing stannous isooctanoate and tin dioxide as a double electron transport layer, the open circuit voltage of the solar cell increases from 1.11 to 1.15 V, the efficiency rises from 21.27% to 22.15%, and the hysteresis factor decreases from 24.04% to 3.69%. This work presents a new preparation method and effective optimization strategy to prepare tin dioxide electron transport layer, which will promote the development of planar heterojunction perovskite solar cells and provide a new research idea for preparing high-efficiency and stable perovskite solar cells.

-

Keywords:

- reactive plasma deposition /

- tin dioxide electron transport layer /

- perovskite solar cells /

- hysteresis

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Jeong J, Kim M, Seo J, et al. 2021 Nature 592 381

Google Scholar

Google Scholar

[3] Jiang Q, Tong J, Xian Y, et al. 2022 Nature 611 278

Google Scholar

Google Scholar

[4] Best research-cell efficiencies https://www.nrel.gov/pv/cell-efficiency.html. [2023-6-1]

[5] Roose B, Baena J P C, Gödel K C, Graetzel M, Hagfeldt A, Steiner U, Abate A 2016 Nano Energy 30 517

Google Scholar

Google Scholar

[6] Jiang Q, Zhang X W, You J B 2018 Small 14 1801154

Google Scholar

Google Scholar

[7] Min H, Lee D Y, Kim J, et al. 2021 Nature 598 444

Google Scholar

Google Scholar

[8] Park S Y, Zhu K 2022 Adv. Mater. 34 2110438

Google Scholar

Google Scholar

[9] Shi L, Lin H 2011 Langmuir 27 3977

Google Scholar

Google Scholar

[10] Xi J, Wu Z, Jiao B, et al. 2017 Adv. Mater. 29 1606964

Google Scholar

Google Scholar

[11] Yang D, Yang R, Wang K, Wu C, Zhu X, Feng J, Ren X, Fang G, Priya S, Liu S 2018 Nat. Commun. 9 3239

Google Scholar

Google Scholar

[12] Yang F, Liu J, Wang X, et al. 2019 ACS Appl. Mater. Interfaces 11 15680

Google Scholar

Google Scholar

[13] Wang F, Yang M, Zhang Y, Yang L, Fan L, Lv S, Liu X, Han D, Yang J 2019 Adv. Sci. 6 1801170

Google Scholar

Google Scholar

[14] Dong Q, Zhu C, Chen M, et al. 2021 Nat. Commun. 12 973

Google Scholar

Google Scholar

[15] Sun Y F, Liu S B, Meng F L, Liu J Y, Jin Z, Kong L T, Liu J H 2012 Sensors (Basel) 12 2610

Google Scholar

Google Scholar

[16] Kozhushner M A, Bodneva V L, Oleynik I I, Belysheva T V, Ikim M I, Trakhtenberg L I 2017 J. Phys. Chem. C 121 6940

Google Scholar

Google Scholar

[17] Ma J, Zheng X, Lei H, Ke W, Chen C, Chen Z, Yang G, Fang G 2017 Sol. RRL 1 1700118

Google Scholar

Google Scholar

[18] Guo Y, Yin X, Liu J, Chen W, Wen S, Que M, Xie H, Yang Y, Que W, Gao B 2019 Org. Electron. 65 207

Google Scholar

Google Scholar

[19] Bai G, Wu Z, Li J, Bu T, Li W, Li W, Huang F, Zhang Q, Cheng Y B, Zhong J 2019 Sol. Energy 183 306

Google Scholar

Google Scholar

[20] Zimmermann I, Provost M, Mejaouri S, Al Atem M, Blaizot A, Duchatelet A, Collin S, Rousset J 2022 ACS Appl. Mater. Interfaces 14 11636

Google Scholar

Google Scholar

[21] Porte Y, Maller R, Faber H, AlShareef H N, Anthopoulos T D, McLachlan M A 2016 J. Mater. Chem. C 4 758

Google Scholar

Google Scholar

[22] 杜荣池, 王广才, 张晓丹, 张迎春, 赵颖 2017 真空与低温 23 136

Google Scholar

Google Scholar

Du R C, Wang G C, Zhang X D, Zhang Y C, Zhao Y 2017 Vacuum and Cryogenics 23 136

Google Scholar

Google Scholar

[23] Li F, Shen Z, Weng Y, Lou Q, Chen C, Shen L, Guo W, Li G 2020 Adv. Funct. Mater. 30 2004933

Google Scholar

Google Scholar

[24] Le Corre V M, Duijnstee E A, El Tambouli O, Ball J M, Snaith H J, Lim J, Koster L J A 2021 ACS Energy Lett. 6 1087

Google Scholar

Google Scholar

-

图 1 (a) 基于不同厚度RPD-SnO2薄膜的钙钛矿太阳电池的最佳J-V曲线; (b) 基于厚度分别为12.43, 17.91和27.82 nm的RPD-SnO2薄膜的钙钛矿太阳电池的EQE和积分电流曲线

Figure 1. (a) Optimum J-V curves of perovskite solar cells based on RPD-SnO2 films with different thicknesses; (b) EQE and integrated current density curves of perovskite solar cells based on RPD-SnO2 films with thicknesses of 12.43, 17.91 and 27.82 nm.

图 2 (a) 不同工作电流下制备的SnO2薄膜的厚度和生长速率; (b) 不同工作电流下制备的SnO2薄膜的光学透过率; (c) 不同工作电流下制备的SnO2薄膜的吸收光谱, 插图为通过吸收光谱得到的Tauc图

Figure 2. (a) Thickness and growth rate of SnO2 films prepared under different working currents; (b) optical transmittance of SnO2 thin films prepared under different working currents; (c) absorption spectra of SnO2 thin films prepared under different working currents, the inset is the Tauc diagram obtained from the absorption spectra.

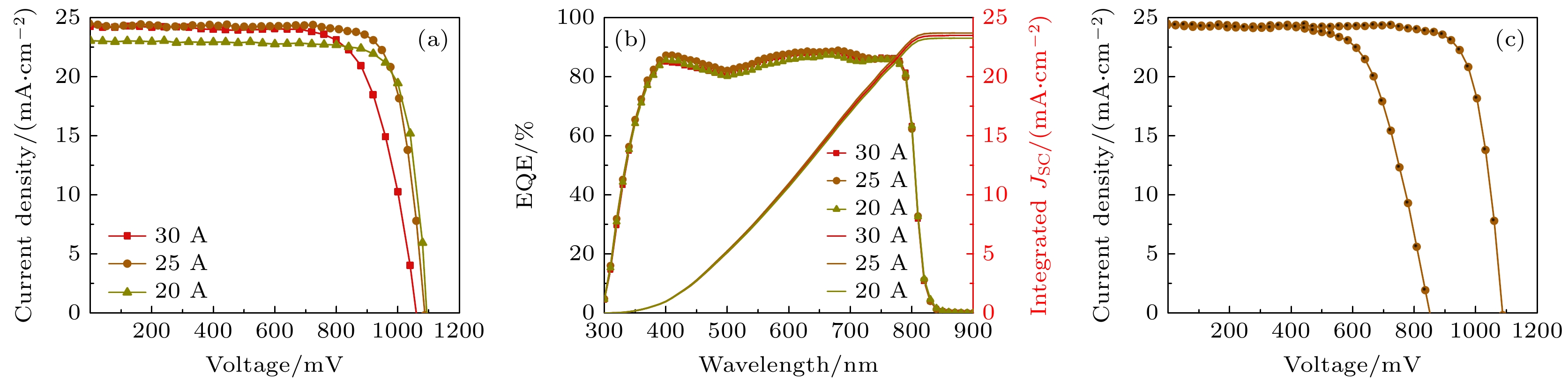

图 5 (a) 基于不同工作电流下制备的SnO2薄膜的器件最佳J-V曲线; (b) EQE和积分电流密度曲线; (c) 基于25 A-SnO2的钙钛矿太阳电池的J-V曲线

Figure 5. (a) Optimal J-V curves of devices based on SnO2 thin films prepared under different working currents; (b) EQE and integrated current density curves; (c) J-V curves of perovskite solar cells based on 25 A-SnO2.

图 6 (a) RPD-SnO2和RPD-SnO2+CSCO的Tauc图; (b) RPD-SnO2和RPD-SnO2+CSCO的起始能量的UPS扫描以及截止能量边; (c) RPD-SnO2和RPD-SnO2+CSCO的能带结构示意图

Figure 6. (a) UPS scans of onset energy and cutoff energy edges of RPD-SnO2 and RPD-SnO2+CSCO; (b) Tauc plots of RPD-SnO2 and RPD-SnO2+CSCO; (c) schematic diagram of energy band structures of RPD-SnO2 and RPD-SnO2+CSCO.

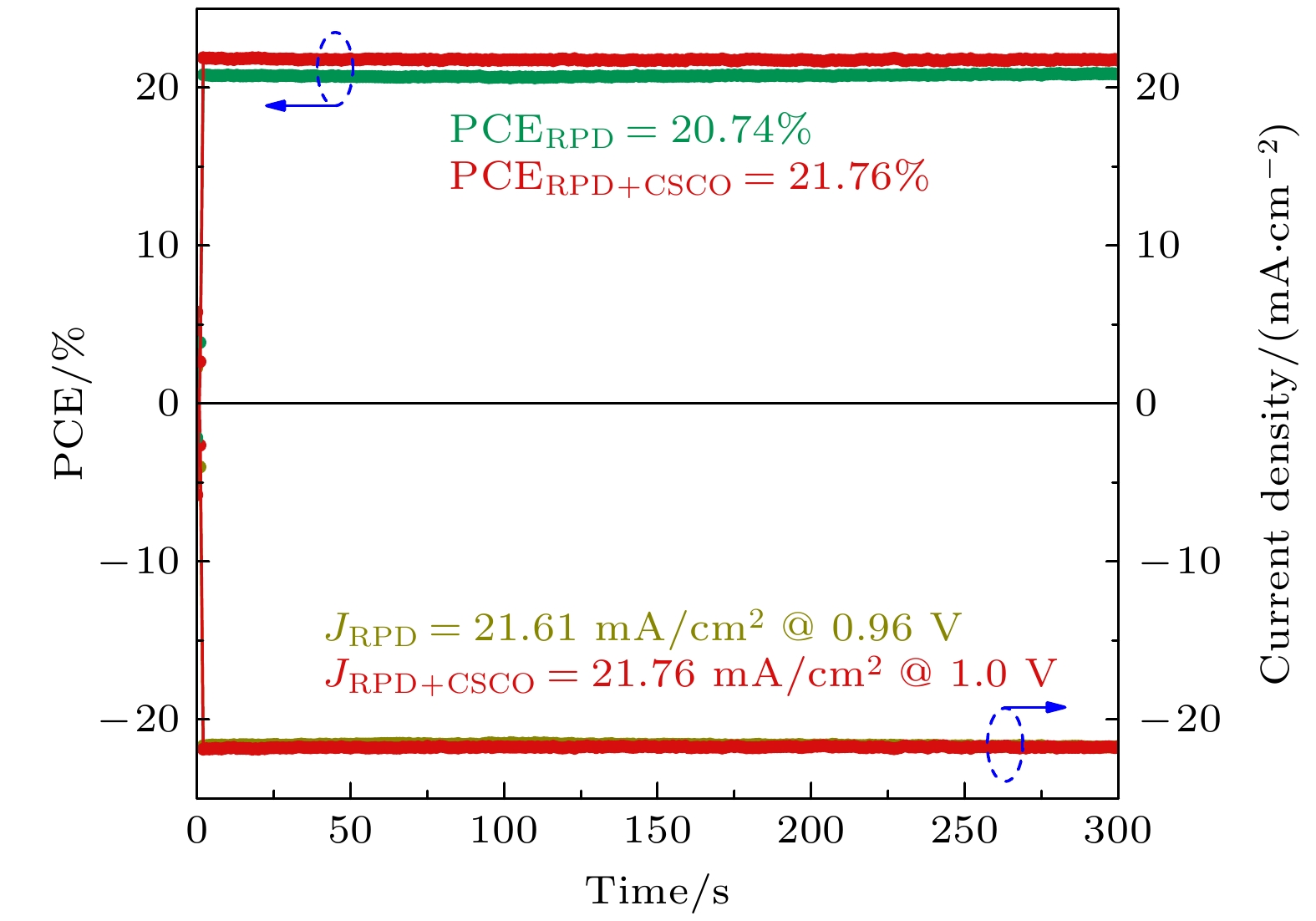

图 7 (a) 不同ETLs制备的器件反向和正向扫描J-V曲线; (b) 对应器件的EQE和积分电流密度曲线; (c) 基于ITO/ETLs/FA1–xMAxPbI3/PCBM/Au结构的纯电子器件的SCLC; (d) 从 15个器件获得的迟滞系数箱体图

Figure 7. (a) Reverse and forward scan J-V curves of devices prepared by different ETLs; (b) EQE and integrated current density curves of corresponding devices; (c) SCLC of pure electrons devices based on ITO/ETLs/FA1–xMAxPbI3/PCBM/Au structure; (d) hysteresis coefficient box plot obtained from 15 devices.

表 1 使用双指数函数拟合基于不同工作电流制备的SnO2作为衬底的钙钛矿的TPRL曲线参数

Table 1. Parameters of TPRL curves of perovskite based SnO2 substrate prepared under different working currents fitted by double exponential function.

Samples A1 $ {\tau }_{1} $/ns A2 $ {\tau }_{2} $/ns RPD-30 A-SnO2 664.42 44.50 1249.27 172.17 RPD-25 A-SnO2 747.38 36.52 1120.05 198.19 RPD-20 A- SnO2 689.05 37.83 1193.30 164.57 表 2 基于不同ETLs的钙钛矿太阳电池的最佳器件性能参数

Table 2. Optimal device performance parameters for perovskite solar cells based on different ETLs.

Device JSC/(mA·cm–2) VOC/mV FF/% PCE/% Integrated JSC/(mA·cm–2) RPD-SnO2 23.36 1112 81.85 21.27 24.07 CSCO 23.21 1147 81.13 21.61 24.37 RPD-SnO2+CSCO 23.91 1147 80.72 22.15 24.67 -

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Jeong J, Kim M, Seo J, et al. 2021 Nature 592 381

Google Scholar

Google Scholar

[3] Jiang Q, Tong J, Xian Y, et al. 2022 Nature 611 278

Google Scholar

Google Scholar

[4] Best research-cell efficiencies https://www.nrel.gov/pv/cell-efficiency.html. [2023-6-1]

[5] Roose B, Baena J P C, Gödel K C, Graetzel M, Hagfeldt A, Steiner U, Abate A 2016 Nano Energy 30 517

Google Scholar

Google Scholar

[6] Jiang Q, Zhang X W, You J B 2018 Small 14 1801154

Google Scholar

Google Scholar

[7] Min H, Lee D Y, Kim J, et al. 2021 Nature 598 444

Google Scholar

Google Scholar

[8] Park S Y, Zhu K 2022 Adv. Mater. 34 2110438

Google Scholar

Google Scholar

[9] Shi L, Lin H 2011 Langmuir 27 3977

Google Scholar

Google Scholar

[10] Xi J, Wu Z, Jiao B, et al. 2017 Adv. Mater. 29 1606964

Google Scholar

Google Scholar

[11] Yang D, Yang R, Wang K, Wu C, Zhu X, Feng J, Ren X, Fang G, Priya S, Liu S 2018 Nat. Commun. 9 3239

Google Scholar

Google Scholar

[12] Yang F, Liu J, Wang X, et al. 2019 ACS Appl. Mater. Interfaces 11 15680

Google Scholar

Google Scholar

[13] Wang F, Yang M, Zhang Y, Yang L, Fan L, Lv S, Liu X, Han D, Yang J 2019 Adv. Sci. 6 1801170

Google Scholar

Google Scholar

[14] Dong Q, Zhu C, Chen M, et al. 2021 Nat. Commun. 12 973

Google Scholar

Google Scholar

[15] Sun Y F, Liu S B, Meng F L, Liu J Y, Jin Z, Kong L T, Liu J H 2012 Sensors (Basel) 12 2610

Google Scholar

Google Scholar

[16] Kozhushner M A, Bodneva V L, Oleynik I I, Belysheva T V, Ikim M I, Trakhtenberg L I 2017 J. Phys. Chem. C 121 6940

Google Scholar

Google Scholar

[17] Ma J, Zheng X, Lei H, Ke W, Chen C, Chen Z, Yang G, Fang G 2017 Sol. RRL 1 1700118

Google Scholar

Google Scholar

[18] Guo Y, Yin X, Liu J, Chen W, Wen S, Que M, Xie H, Yang Y, Que W, Gao B 2019 Org. Electron. 65 207

Google Scholar

Google Scholar

[19] Bai G, Wu Z, Li J, Bu T, Li W, Li W, Huang F, Zhang Q, Cheng Y B, Zhong J 2019 Sol. Energy 183 306

Google Scholar

Google Scholar

[20] Zimmermann I, Provost M, Mejaouri S, Al Atem M, Blaizot A, Duchatelet A, Collin S, Rousset J 2022 ACS Appl. Mater. Interfaces 14 11636

Google Scholar

Google Scholar

[21] Porte Y, Maller R, Faber H, AlShareef H N, Anthopoulos T D, McLachlan M A 2016 J. Mater. Chem. C 4 758

Google Scholar

Google Scholar

[22] 杜荣池, 王广才, 张晓丹, 张迎春, 赵颖 2017 真空与低温 23 136

Google Scholar

Google Scholar

Du R C, Wang G C, Zhang X D, Zhang Y C, Zhao Y 2017 Vacuum and Cryogenics 23 136

Google Scholar

Google Scholar

[23] Li F, Shen Z, Weng Y, Lou Q, Chen C, Shen L, Guo W, Li G 2020 Adv. Funct. Mater. 30 2004933

Google Scholar

Google Scholar

[24] Le Corre V M, Duijnstee E A, El Tambouli O, Ball J M, Snaith H J, Lim J, Koster L J A 2021 ACS Energy Lett. 6 1087

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6853

- PDF Downloads: 186

- Cited By: 0

DownLoad:

DownLoad: