-

Diamond/graphene composite three-dimensional electrode has attracted extensive attention because of its low background current, wide potential window from diamond component, and high electrochemical activity from graphite component. In this work, by using the hot wire chemical vapor deposition method, nano diamonds are embedded in the vertical graphene sheet on the surface of single particle layer of nano diamond by regulating the short-term growth time to form a composite three-dimensional electrode. The results show that the electrode exhibits a wide potential window (3.59 V) and a very low background current (1.27 mA/cm2) when nano-diamond crystals grow on the top of the vertical graphene sheet. The composite structure of nano-diamond crystals coated with graphite on the top of the graphene sheet is the key to broadening the potential window and reducing the background current. With the increase of growth time, the vertical graphene sheet grows and nano-diamond grains are embedded into the lamellae, and a novel nano-diamond/graphene composite vertical lamellae structure is constructed. The ordered graphite structure increases the electrochemical active area to 677.19 μC/cm2 and the specific capacitance to 627.34 μF/cm2. The increase of graphite components makes the potential window narrow, and the embedded nano-diamond crystals effectively reduce the background current. This study provides a new method for preparing three-dimensional nanodiamond/graphene composite electrodes by hot wire chemical vapor deposition, and provides a new idea for fully exploiting the synergistic effect of diamond/graphene composite films.

-

Keywords:

- nano-diamond /

- vertical graphene /

- electrode /

- electrochemical properties

[1] Lesiak B, Kövér L, Tóth J, Zemek J, Jiricek P, Kromka A, Rangam N 2018 Appl. Surf. Sci. 452 223

Google Scholar

Google Scholar

[2] Zhai Z, Huang N, Jiang X 2022 Curr. Opin. Electrochem. 32 100884

Google Scholar

Google Scholar

[3] Chen C K, He Z, Xu A, Li X, Jiang M, Xu T, Yan B, Hu X 2021 Funct. Diamond 1 117

Google Scholar

Google Scholar

[4] 胡衡, 胡晓君, 白博文, 陈小虎 2012 61 148101

Google Scholar

Google Scholar

Hu H, Hu X J, Bai B W, Chen X H 2012 Acta Phys. Sin. 61 148101

Google Scholar

Google Scholar

[5] 潘金平, 胡晓君, 陆利平, 印迟 2010 59 7410

Google Scholar

Google Scholar

Pan J P, Hu X J, Lu L P, Yin C 2010 Acta Phys. Sin. 59 7410

Google Scholar

Google Scholar

[6] 胡晓君, 李荣斌, 沈荷生, 何贤昶, 邓 文, 罗里熊 2004 53 2014

Google Scholar

Google Scholar

Hu X J, Li R B, Shen H S, He X C, Deng W, Luo L X 2004 Acta Phys. Sin. 53 2014

Google Scholar

Google Scholar

[7] Yang N, Yu S, Macpherson J V, Einaga Y, Zhao H, Zhao G, Swain G M, Jiang X 2019 Chem. Soc. Rev. 48 157

Google Scholar

Google Scholar

[8] Gao F, Nebel C E 2016 ACS Appl. Mater. Interfaces 8 28244

Google Scholar

Google Scholar

[9] Watanabe T, Honda Y, Kanda K, Einaga Y 2014 Phys. Status Solidi A 211 2709

Google Scholar

Google Scholar

[10] Sun Y, Wu Q, Xu Y, Bai H, Li C, Shi G 2011 J. Mater. Chem. 21 7154

Google Scholar

Google Scholar

[11] Wei M, Terashima C, Lv M, Fujishima A, Gu Z Z 2009 Chem. Commun. 24 3624

Google Scholar

Google Scholar

[12] 蒋梅燕, 朱政杰, 陈成克, 李晓, 胡晓君 2019 68 148101

Google Scholar

Google Scholar

Jiang M Y, Zhu Z J, Chen C K, Li X, Hu X J 2019 Acta Phys. Sin. 68 148101

Google Scholar

Google Scholar

[13] 王锐, 胡晓君 2014 63 148102

Google Scholar

Google Scholar

Wang R, Hu X J 2014 Acta Phys. Sin. 63 148102

Google Scholar

Google Scholar

[14] Sobaszek M, Siuzdak K, Ryl J, Sawczak M, Gupta S, Carrizosa S B, Ficek M, Dec B, Darowicki K, Bogdanowicz R 2017 J. Phys. Chem. C 121 20821

Google Scholar

Google Scholar

[15] Shen A, Zou Y, Wang Q, Dryfe R A W, Huang X, Dou S, Dai L, Wang S 2014 Angew. Chem. Int. Ed. 53 10804

Google Scholar

Google Scholar

[16] Kamata T, Kato D, Ida H, Niwa O 2014 Diamond Relat. Mater. 49 25

Google Scholar

Google Scholar

[17] Garcia-Segura S, Vieira dos Santos E, Martínez Huitle C A 2015 Electrochem. Commun. 59 52

Google Scholar

Google Scholar

[18] Ayres Z J, Borrill A J, Newland J C, Newton M E, Macpherson Julie. V 2016 Anal. Chem. 88 974

Google Scholar

Google Scholar

[19] Cobb S J, Ayres Z J, Macpherson J V 2018 Annu. Rev. Anal. Chem. 11 463

Google Scholar

Google Scholar

[20] Vlasov I, Lebedev O I, Ralchenko V G, Goovaerts E, Bertoni G, Van Tendeloo G, Konov V I 2007 Adv. Mater. 19 4058

Google Scholar

Google Scholar

[21] Arenal R, Bruno P, Miller D J, Bleuel M, Lal J, Gruen D M 2007 Phys. Rev. B 75 195431

Google Scholar

Google Scholar

[22] Sankaran K J, Kurian J, Chen H C, Dong C L, Lee C Y, Tai N H, Lin I N 2012 J. Phys. D:Appl. Phys. 45 365303

Google Scholar

Google Scholar

[23] Shang N, Papakonstantinou P, Wang P, Zakharov A, Palnitkar U, Lin I N, Chu M, Stamboulis A 2009 ACS Nano 3 1032

Google Scholar

Google Scholar

[24] Shalini J, Sankaran K J, Dong C L, Lee C Y, Tai N H, Lin I N 2013 Nanoscale 5 1159

Google Scholar

Google Scholar

[25] Shalini J, Lin Y C, Chang T H, Sankaran K J, Chen H C, Lin I N, Lee C Y, Tai N H 2013 Electrochim. Acta 92 9

Google Scholar

Google Scholar

[26] Zhai Z, Huang N, Yang B, Wang C, Liu L, Qiu J, Shi D, Yuan Z, Lu Z, Song H, Zhou M, Chen B, Jiang X 2019 J. Phys. Chem. C 123 6018

Google Scholar

Google Scholar

[27] Yu S, Sankaran K J, Korneychuk S, Verbeeck J, Haenen K, Jiang X, Yang N 2019 Nanoscale 11 17939

Google Scholar

Google Scholar

[28] 邢丽丹, 谢启明, 李伟善 2020 69 228205

Google Scholar

Google Scholar

Xing L D, Xie Q M, Li W S 2020 Acta Phys. Sin. 69 228205

Google Scholar

Google Scholar

[29] Wu, Yang 2002 Nano Lett. 2 355

Google Scholar

Google Scholar

[30] Tzeng Y, Chen W L, Wu C, Lo J Y, Li C Y 2013 Carbon 53 120

Google Scholar

Google Scholar

[31] Banerjee D, Sankaran K J, Deshmukh S, Ficek M, Bhattacharya G, Ryl J, Phase D M, Gupta M, Bogdanowicz R, Lin I N, Kanjilal A, Haenen K, Roy S S 2019 J. Phys. Chem. C 123 15458

Google Scholar

Google Scholar

[32] Zhai Z, Leng B, Yang N, Yang B, Liu L, Huang N, Jiang X 2019 Small 15 1901527

Google Scholar

Google Scholar

[33] Zhou M, Zhai Z, Liu L, Zhang C, Yuan Z, Lu Z, Chen B, Shi D, Yang B, Wei Q, Huang N, Jiang X 2021 Appl. Surf. Sci. 551 149418

Google Scholar

Google Scholar

[34] Jiang M Y, Ma W C, Han S J, Chen C K, Fan D, Li X, Hu X J 2020 J. Appl. Phys. 127 015301

Google Scholar

Google Scholar

[35] Jiang M Y, Zhang Z Q, Chen C K, Ma W C, Han S J, Li X, Lu S H, Hu X J 2020 Carbon 168 536

Google Scholar

Google Scholar

[36] Jiang M Y, Chen C K, Wang P, Guo D F, Han S J, Li X, Lu S H, Hu X J. 2022 PNAS 119 2201451119

Google Scholar

Google Scholar

[37] Chen C K, Fan D, Xu H J, Jiang M Y, Li X, Lu S H, Ke C C, Hu X J. 2022 Carbon 196 466

Google Scholar

Google Scholar

[38] 胡晓君, 仰宗春 2015 中国专利 ZL 201510149374.4 [2017-04-12]

Hu X J, Yang Z C 2015 Chin. Patent ZL 201510149374.4 [2017-04-12]

[39] Klauser F, Steinmüller Nethl D, Kaindl R, Bertel E, Memmel N 2010 Chem. Vap. Deposition 16 127

Google Scholar

Google Scholar

[40] Malard L M, Pimenta M A, Dresselhaus G, Dresselhaus M S 2009 Phys. Rep. 473 51

Google Scholar

Google Scholar

[41] Cançado L G, Jorio A, Ferreira E H M, Stavale F, Achete C A, Capaz R B, Moutinho M V O, Lombardo A, Kulmala T S, Ferrari A C 2011 Nano Lett. 11 3190

Google Scholar

Google Scholar

[42] Shimada T, Sugai T, Fantini C, Souza M, Cançado L G, Jorio A, Pimenta M A, Saito R, Grüneis A, Dresselhaus G, Dresselhaus M S, Ohno Y, Mizutani T, Shinohara H 2005 Carbon 43 1049

Google Scholar

Google Scholar

[43] Ferrari A C, Robertson J. Resonant 2001 Phys. Rev. B 64 075414

Google Scholar

Google Scholar

[44] Vora H, Moravec T J 1981 J. Appl. Phys. 52 6151

Google Scholar

Google Scholar

[45] Konyashin I, Frost D J, Sidorenko D, Orekhov A, Obraztsova E A, Sviridova T A 2020 Diamond Relat. Mater. 109 108017

Google Scholar

Google Scholar

-

图 1 不同生长时间下复合薄膜的FESEM形貌和截面图, 内插图为对应样品的静态水接触角图 (a), (e), (i) 1.5 min; (b), (f), (j) 2 min; (c), (g), (k) 2.5 min; (d), (h), (l) 3 min

Figure 1. FESEM images for frontal and cross-sectional morphologies of composite films under different growth times, the inset images show the static water contact angle diagram from the corresponding samples under different growth times: (a), (e), (i) 1.5 min; (b), (f), (j) 2 min; (c), (g), (k) 2.5 min; (d), (h), (l) 3 min.

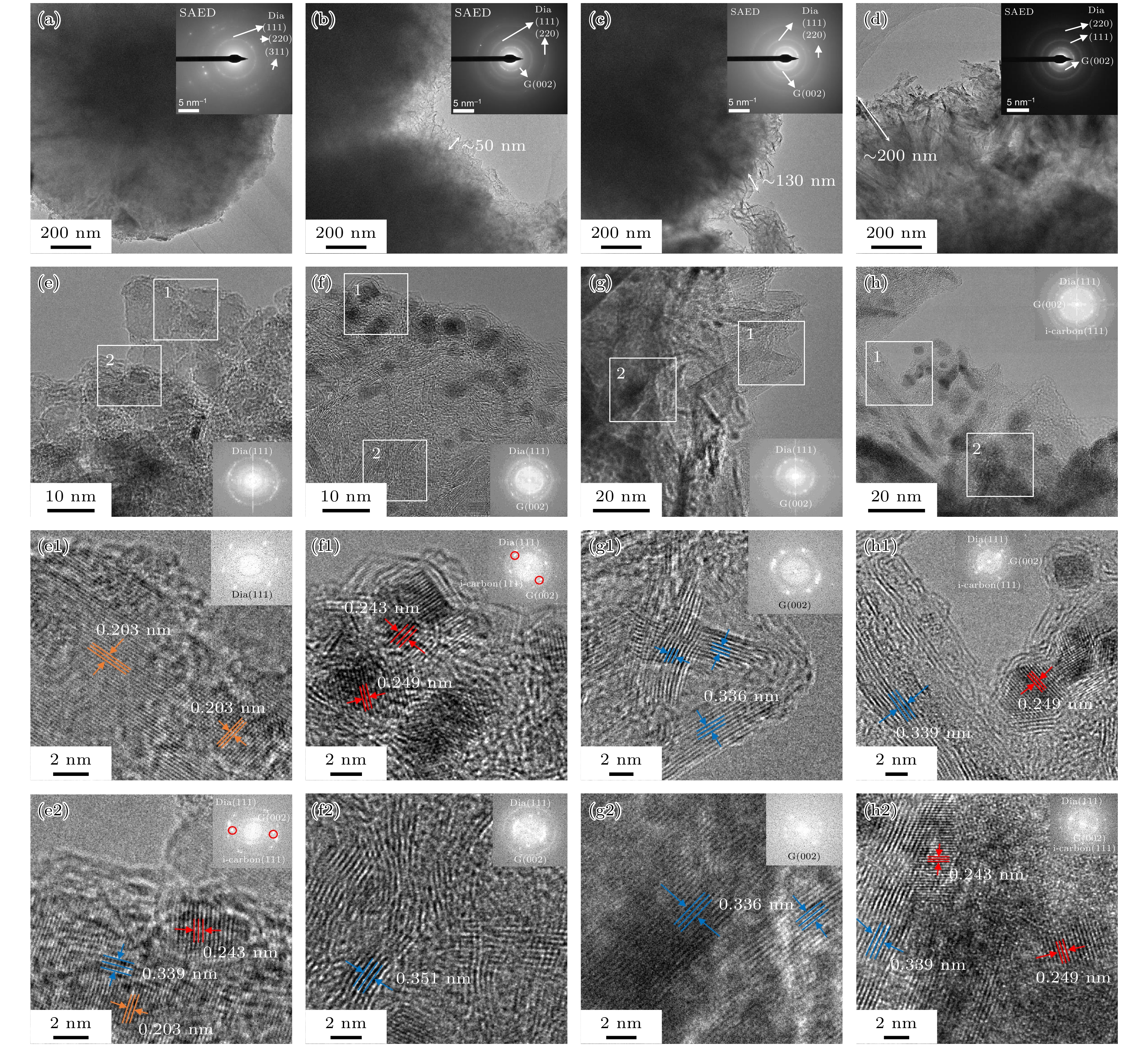

图 3 不同生长时间样品的低倍, 高倍和对应白框选定区域的放大图, 及其对应区域的FFT图 (a), (e) 1.5 min; (b), (f) 2 min; (c), (g) 2.5 min; (d), (h) 3 min. (e1)—(h1), (e2)—(h2) 图(e)—(h)中对白框选定区域的放大图以及其相应的对应区域的FFT图

Figure 3. The low- and high-magnificent TEM images with inset corresponding FFTs from samples under different growth times: (a), (e) 1.5 min; (b), (f) 2 min; (c), (g) 2.5 min; (d), (h) 3 min. (e1)–(h1), (e2)–(h2) are enlarged images and corresponding FFTs of the selected areas in the corresponding white boxes in Figure (e)–(h).

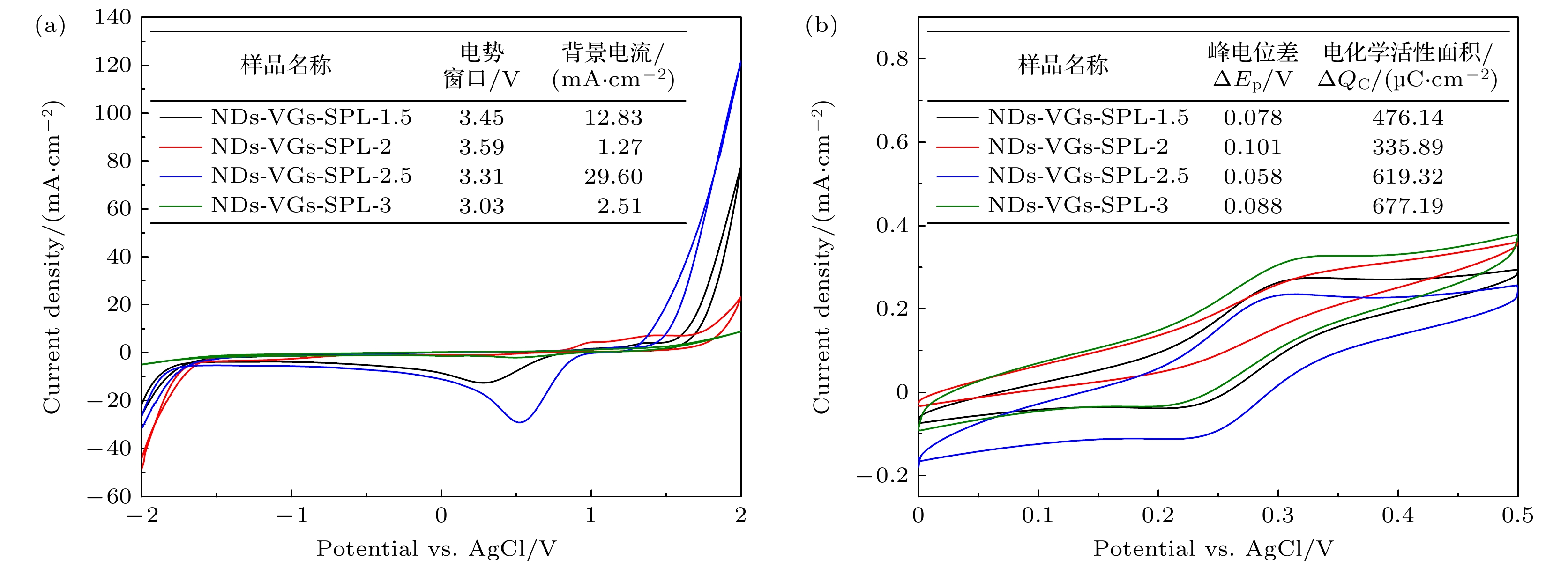

图 4 不同生长时间的NDs-VGs-SPL薄膜电极(a)在1 M KCl体系中的电势窗口和背景电流和(b)在 1 mM K3Fe(CN)6+1 M KCl 体系中以 100 mV/s 扫速下的循环伏安图. 图(a)和图(b)插入的表格列出了扫描速度为100 mV/s时的相应参数

Figure 4. Cyclic voltammetry curves for NDs-VGs-SPL electrodes in 1 M KCl solution (a) and in 1 mM K3Fe(CN)6+ 1 M KCl solution (b). The inset tables are their corresponding parameters under the scanning rate of 100 mV/s.

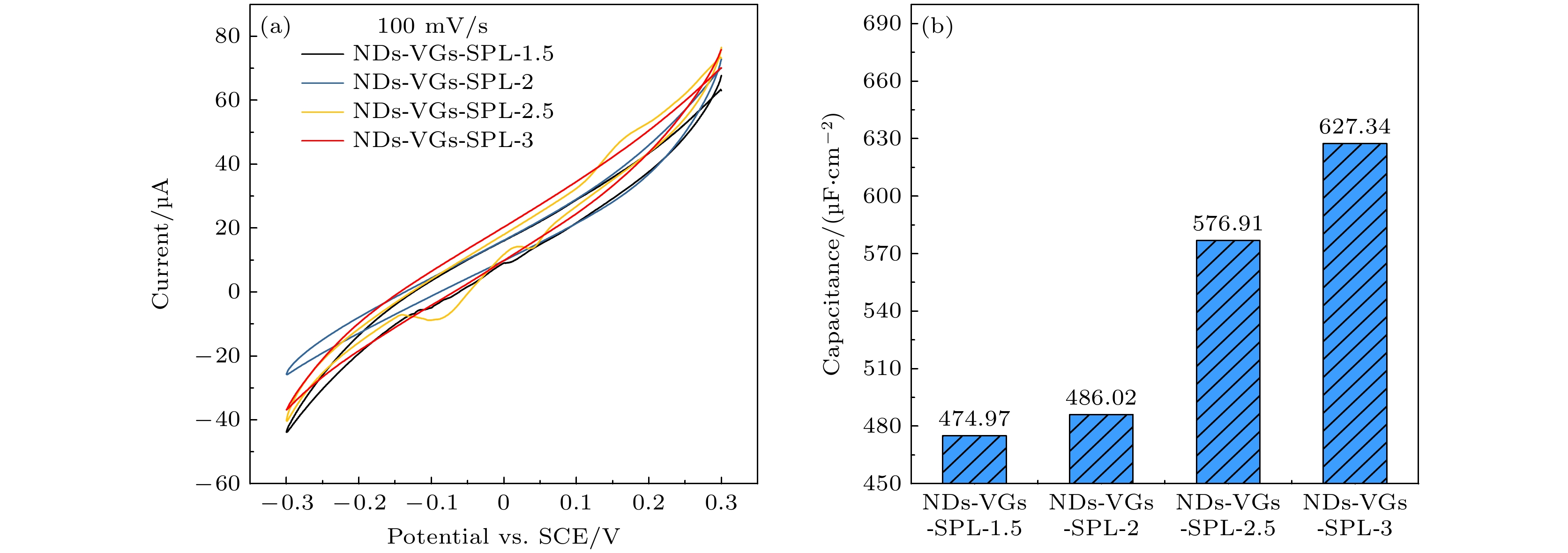

图 5 不同生长时间下复合薄膜电极在0.1—0.5 V/s扫描速率下1 mol/L KOH体系中的循环伏安曲线 (a) NDs-VGs-SPL-1.5; (b) NDs-VGs-SPL-2; (c) NDs-VGs-SPL-2.5; (d) NDs-VGs-SPL-3

Figure 5. Cyclic voltammetry curves for NDs-VGs-SPL electrodes of (a) NDs-VGs-SPL-1.5, (b) NDs-VGs-SPL-2, (c) NDs-VGs-SPL-2.5, (d) NDs-VGs-SPL-3 in 1 M KOH solution under the scanning rate of 0.1–0.5 V/s.

表 1 Raman光谱拟合结果汇总

Table 1. Summary of the data from the fitted Raman spectra.

样品 1332

/arb. unitsD'

/arb. unitsG

/arb. unitsFWHMG

/cm–1D'

/arb. units2D

/arb. unitsITPA/ISUM I2D/IG 1.5 min 0.22 0.58 0.43 90.56 — 0.17 0.44 0.40 2.0 min — 0.84 0.73 44.85 0.26 0.57 0.35 0.65 2.5 min — 0.85 0.48 34.12 0.22 0.31 0.30 0.63 3.0 min — 0.92 0.66 33.40 0.21 0.76 0.28 1.14 注: 表格中“—”符号表示Raman光谱中未检测到此峰位. -

[1] Lesiak B, Kövér L, Tóth J, Zemek J, Jiricek P, Kromka A, Rangam N 2018 Appl. Surf. Sci. 452 223

Google Scholar

Google Scholar

[2] Zhai Z, Huang N, Jiang X 2022 Curr. Opin. Electrochem. 32 100884

Google Scholar

Google Scholar

[3] Chen C K, He Z, Xu A, Li X, Jiang M, Xu T, Yan B, Hu X 2021 Funct. Diamond 1 117

Google Scholar

Google Scholar

[4] 胡衡, 胡晓君, 白博文, 陈小虎 2012 61 148101

Google Scholar

Google Scholar

Hu H, Hu X J, Bai B W, Chen X H 2012 Acta Phys. Sin. 61 148101

Google Scholar

Google Scholar

[5] 潘金平, 胡晓君, 陆利平, 印迟 2010 59 7410

Google Scholar

Google Scholar

Pan J P, Hu X J, Lu L P, Yin C 2010 Acta Phys. Sin. 59 7410

Google Scholar

Google Scholar

[6] 胡晓君, 李荣斌, 沈荷生, 何贤昶, 邓 文, 罗里熊 2004 53 2014

Google Scholar

Google Scholar

Hu X J, Li R B, Shen H S, He X C, Deng W, Luo L X 2004 Acta Phys. Sin. 53 2014

Google Scholar

Google Scholar

[7] Yang N, Yu S, Macpherson J V, Einaga Y, Zhao H, Zhao G, Swain G M, Jiang X 2019 Chem. Soc. Rev. 48 157

Google Scholar

Google Scholar

[8] Gao F, Nebel C E 2016 ACS Appl. Mater. Interfaces 8 28244

Google Scholar

Google Scholar

[9] Watanabe T, Honda Y, Kanda K, Einaga Y 2014 Phys. Status Solidi A 211 2709

Google Scholar

Google Scholar

[10] Sun Y, Wu Q, Xu Y, Bai H, Li C, Shi G 2011 J. Mater. Chem. 21 7154

Google Scholar

Google Scholar

[11] Wei M, Terashima C, Lv M, Fujishima A, Gu Z Z 2009 Chem. Commun. 24 3624

Google Scholar

Google Scholar

[12] 蒋梅燕, 朱政杰, 陈成克, 李晓, 胡晓君 2019 68 148101

Google Scholar

Google Scholar

Jiang M Y, Zhu Z J, Chen C K, Li X, Hu X J 2019 Acta Phys. Sin. 68 148101

Google Scholar

Google Scholar

[13] 王锐, 胡晓君 2014 63 148102

Google Scholar

Google Scholar

Wang R, Hu X J 2014 Acta Phys. Sin. 63 148102

Google Scholar

Google Scholar

[14] Sobaszek M, Siuzdak K, Ryl J, Sawczak M, Gupta S, Carrizosa S B, Ficek M, Dec B, Darowicki K, Bogdanowicz R 2017 J. Phys. Chem. C 121 20821

Google Scholar

Google Scholar

[15] Shen A, Zou Y, Wang Q, Dryfe R A W, Huang X, Dou S, Dai L, Wang S 2014 Angew. Chem. Int. Ed. 53 10804

Google Scholar

Google Scholar

[16] Kamata T, Kato D, Ida H, Niwa O 2014 Diamond Relat. Mater. 49 25

Google Scholar

Google Scholar

[17] Garcia-Segura S, Vieira dos Santos E, Martínez Huitle C A 2015 Electrochem. Commun. 59 52

Google Scholar

Google Scholar

[18] Ayres Z J, Borrill A J, Newland J C, Newton M E, Macpherson Julie. V 2016 Anal. Chem. 88 974

Google Scholar

Google Scholar

[19] Cobb S J, Ayres Z J, Macpherson J V 2018 Annu. Rev. Anal. Chem. 11 463

Google Scholar

Google Scholar

[20] Vlasov I, Lebedev O I, Ralchenko V G, Goovaerts E, Bertoni G, Van Tendeloo G, Konov V I 2007 Adv. Mater. 19 4058

Google Scholar

Google Scholar

[21] Arenal R, Bruno P, Miller D J, Bleuel M, Lal J, Gruen D M 2007 Phys. Rev. B 75 195431

Google Scholar

Google Scholar

[22] Sankaran K J, Kurian J, Chen H C, Dong C L, Lee C Y, Tai N H, Lin I N 2012 J. Phys. D:Appl. Phys. 45 365303

Google Scholar

Google Scholar

[23] Shang N, Papakonstantinou P, Wang P, Zakharov A, Palnitkar U, Lin I N, Chu M, Stamboulis A 2009 ACS Nano 3 1032

Google Scholar

Google Scholar

[24] Shalini J, Sankaran K J, Dong C L, Lee C Y, Tai N H, Lin I N 2013 Nanoscale 5 1159

Google Scholar

Google Scholar

[25] Shalini J, Lin Y C, Chang T H, Sankaran K J, Chen H C, Lin I N, Lee C Y, Tai N H 2013 Electrochim. Acta 92 9

Google Scholar

Google Scholar

[26] Zhai Z, Huang N, Yang B, Wang C, Liu L, Qiu J, Shi D, Yuan Z, Lu Z, Song H, Zhou M, Chen B, Jiang X 2019 J. Phys. Chem. C 123 6018

Google Scholar

Google Scholar

[27] Yu S, Sankaran K J, Korneychuk S, Verbeeck J, Haenen K, Jiang X, Yang N 2019 Nanoscale 11 17939

Google Scholar

Google Scholar

[28] 邢丽丹, 谢启明, 李伟善 2020 69 228205

Google Scholar

Google Scholar

Xing L D, Xie Q M, Li W S 2020 Acta Phys. Sin. 69 228205

Google Scholar

Google Scholar

[29] Wu, Yang 2002 Nano Lett. 2 355

Google Scholar

Google Scholar

[30] Tzeng Y, Chen W L, Wu C, Lo J Y, Li C Y 2013 Carbon 53 120

Google Scholar

Google Scholar

[31] Banerjee D, Sankaran K J, Deshmukh S, Ficek M, Bhattacharya G, Ryl J, Phase D M, Gupta M, Bogdanowicz R, Lin I N, Kanjilal A, Haenen K, Roy S S 2019 J. Phys. Chem. C 123 15458

Google Scholar

Google Scholar

[32] Zhai Z, Leng B, Yang N, Yang B, Liu L, Huang N, Jiang X 2019 Small 15 1901527

Google Scholar

Google Scholar

[33] Zhou M, Zhai Z, Liu L, Zhang C, Yuan Z, Lu Z, Chen B, Shi D, Yang B, Wei Q, Huang N, Jiang X 2021 Appl. Surf. Sci. 551 149418

Google Scholar

Google Scholar

[34] Jiang M Y, Ma W C, Han S J, Chen C K, Fan D, Li X, Hu X J 2020 J. Appl. Phys. 127 015301

Google Scholar

Google Scholar

[35] Jiang M Y, Zhang Z Q, Chen C K, Ma W C, Han S J, Li X, Lu S H, Hu X J 2020 Carbon 168 536

Google Scholar

Google Scholar

[36] Jiang M Y, Chen C K, Wang P, Guo D F, Han S J, Li X, Lu S H, Hu X J. 2022 PNAS 119 2201451119

Google Scholar

Google Scholar

[37] Chen C K, Fan D, Xu H J, Jiang M Y, Li X, Lu S H, Ke C C, Hu X J. 2022 Carbon 196 466

Google Scholar

Google Scholar

[38] 胡晓君, 仰宗春 2015 中国专利 ZL 201510149374.4 [2017-04-12]

Hu X J, Yang Z C 2015 Chin. Patent ZL 201510149374.4 [2017-04-12]

[39] Klauser F, Steinmüller Nethl D, Kaindl R, Bertel E, Memmel N 2010 Chem. Vap. Deposition 16 127

Google Scholar

Google Scholar

[40] Malard L M, Pimenta M A, Dresselhaus G, Dresselhaus M S 2009 Phys. Rep. 473 51

Google Scholar

Google Scholar

[41] Cançado L G, Jorio A, Ferreira E H M, Stavale F, Achete C A, Capaz R B, Moutinho M V O, Lombardo A, Kulmala T S, Ferrari A C 2011 Nano Lett. 11 3190

Google Scholar

Google Scholar

[42] Shimada T, Sugai T, Fantini C, Souza M, Cançado L G, Jorio A, Pimenta M A, Saito R, Grüneis A, Dresselhaus G, Dresselhaus M S, Ohno Y, Mizutani T, Shinohara H 2005 Carbon 43 1049

Google Scholar

Google Scholar

[43] Ferrari A C, Robertson J. Resonant 2001 Phys. Rev. B 64 075414

Google Scholar

Google Scholar

[44] Vora H, Moravec T J 1981 J. Appl. Phys. 52 6151

Google Scholar

Google Scholar

[45] Konyashin I, Frost D J, Sidorenko D, Orekhov A, Obraztsova E A, Sviridova T A 2020 Diamond Relat. Mater. 109 108017

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7489

- PDF Downloads: 105

- Cited By: 0

DownLoad:

DownLoad: