-

Simulation has become an important tool in materials science, it is a prerequisite to study the correlation between the structure and properties of materials, in that the structural characteristics of the system from the atomic coordinates output can be obtained by simulations. For simple (FCC, HCP, and BCC) crystals containing only 2-6 atoms, in the numerical analysis method, what needs to be determined is only the local characteristics of each atom. However, it is extremely computationally intensive to determine the cells containing tens or hundreds of atoms. The combination of numerical analysis and visualization is one of the methods to solve this kind of problem. In this work, Ni70Ag30 nanoparticles are simulated by molecular dynamics. It is found that the nanoparticles contain FCC crystals and a large number of complex topologically close-packed (TCP) structures. Using the analysis software based on the largest standard cluster analysis (LaSCA), the C15 phase of TCP atoms in nanoparticles is determined by topology configuration analysis and crystallography knowledge. The analytical ideas provide the algorithm logic fordeveloping the numerical recognition software for complex crystal structures in the future.

-

Keywords:

- Laves phase /

- LaSC /

- molecular dynamics simulation /

- rapid cooling

[1] Greer A L 1993 Nature 366 6453

[2] Li C, Li J C, Zhao M, Jiang Q 2009 J. Alloys Compd. 475 752

Google Scholar

Google Scholar

[3] Turchi P, Treglia G, Ducastelle F 1983 J. Phys. F:Met. Phys. 13 2543

Google Scholar

Google Scholar

[4] Hartsough L D 1974 J. Phys. Chem. Solids 35 1691

Google Scholar

Google Scholar

[5] Turchi P E A, Finel A 1992 Phys. Rev. B 46 702

Google Scholar

Google Scholar

[6] Moriarty J A 1994 Phys. Rev. B 49 12431

Google Scholar

Google Scholar

[7] Ye H Q, Zhu J 1989 Acta Cryst B 45 1

[8] Li D X, Kuo K H 1985 Philos. Mag. A 51 849

Google Scholar

Google Scholar

[9] Rehman H UR, Durst K, Neumeier S, Parsa A B, Kostka A, Eggeler G, Göken M 2015 Mater. Sci. Eng. A 634 202

Google Scholar

Google Scholar

[10] Rae C M F, Reed R C 2001 Acta Mater. 49 4113

Google Scholar

Google Scholar

[11] Kelchner C L, Plimpton S J, Hamilton J C 1998 Phys. Rev. B 58 11085

Google Scholar

Google Scholar

[12] Honeycutt J D, Andersen H C 1987 J. Phys. Chem. 91 4950

Google Scholar

Google Scholar

[13] Faken D, Jónsson H 1994 Comput. Mater. Sci. 2 279

Google Scholar

Google Scholar

[14] Wang S Y, Tian Z A, Dong K J, Xie Q 2021 J. Alloys Compd. 854 156983

Google Scholar

Google Scholar

[15] Mauro N A, Wessels V, Bendert J C, Klein S, Gangopadhyay A K, Kramer M J, Hao S G, Rustan G E, Kreyssig A, Goldman A I, Kelton K F 2011 Phys. Rev. B 83 184109

Google Scholar

Google Scholar

[16] Voronoi G. De Gruyter 1908 Journal für die reine und angewandte Mathematik (Crelles Journal) 134 198

[17] Xie Z C 2021 J. Mater. Res. 36 15

[18] Tian Z A, Liu R S, Dong K J, Yu A B 2011 EPL 96 36001

Google Scholar

Google Scholar

[19] Tian Z A, Dong K J, Yu A B 2015 Ann. Phys. 354 499

Google Scholar

Google Scholar

[20] Wu Z Z, Mo Y F, Lang L, Yu A B, Xie Q, Liu R S, Tian Z A 2018 Phys. Chem. Chem. Phys. 20 28088

Google Scholar

Google Scholar

[21] Lang L, Deng H Q, Tian Z A, Gao F, Hu W Y, Wen D D, Mo Y F 2019 J. Alloys Compd. 775 1184

Google Scholar

Google Scholar

[22] 栗晶晶, 田泽安 2020 低温 42 81

Li J J, Tian Z A 2020 Low. Temp. Phys. Lett. 42 81

[23] Mo Y F, Tian Z A, Lang L, Liu R S, Zhou L L, Hou Z Y, Peng P, Zhang T Y 2019 J. Non-Cryst. Solids 513 111

Google Scholar

Google Scholar

[24] Zhou L L, Tian Z A, Liang Y C, Mo Y F, Wang C J, Li F Z 2021 Phys. Chem. Chem. Phys. 23 25933

Google Scholar

Google Scholar

[25] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[26] Pan Z L, Borovikov V, Mendelev M I 2018 Modell. Simul. Mater. Sci. Eng. 26 075004

Google Scholar

Google Scholar

[27] Frank F C, Kasper J S 1958 Acta Crystallogr. 11 184

Google Scholar

Google Scholar

[28] Frank F C, Kasper J S 1959 Acta Crystallogr. 12 483

Google Scholar

Google Scholar

[29] Ahmed E, Akhter J I, Ahmad M 2004 Comput. Mater. Sci. 31 309

Google Scholar

Google Scholar

[30] Zheng Q, Xiao T, Tian Z A, Gao T H, Liang Y C, Chen Q, Xie Q 2021 Cryst. Growth Des 21 4746

Google Scholar

Google Scholar

[31] Pettifor D G, Seiser B, Margine E R, Kolmogorov A N, Drautz R 2013 Philos. Mag. 93 3907

Google Scholar

Google Scholar

[32] Zhu J H, Liu C T, Pike L M, Liaw P K 2002 Intermetallics 10 579

Google Scholar

Google Scholar

[33] Hajiw S, Pansu B, Sadoc J F 2015 ACS Nano 9 8116

Google Scholar

Google Scholar

[34] Kong Y Y, Duan Y H, Ma L S, Li R Y 2016 Mater. Res. Express 3 106505

Google Scholar

Google Scholar

[35] Ma L S, Duan Y Y, Li R 2017 Philos. Mag. 97 2406

Google Scholar

Google Scholar

-

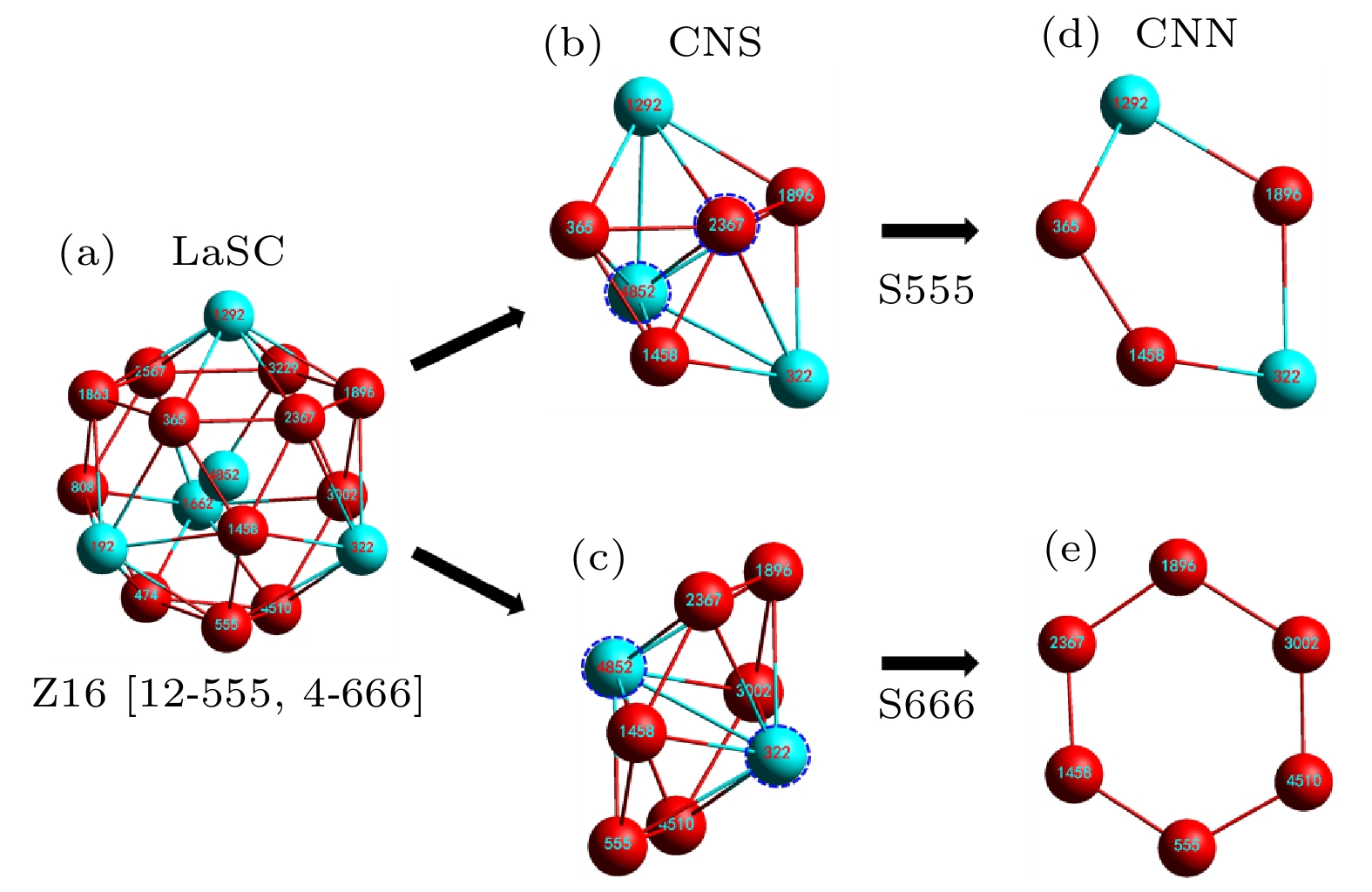

图 1 LaSC结构特征示例 (a)以一个中心原子(4852)和它的16个近邻原子组成的Z16[12-555, 4-666] LaSC; (b)S555由4852和2367组成的根原子对和5个CNN (d)组成; (c) S666由4852和322组成的根原子对及其6个CNN (e)组成

Figure 1. A sample for LaSC structural features: (a) a Z16[12-555, 4-666] LaSC composed of a central atom (labelled 4852) and 16 neighbors; (b) a S555 composed of a bonded reference pair (labelled 4852 and 2367) and 5 CNNs (d), a CNS of S666 (c) and its topology represented by 6 CNNs (e)

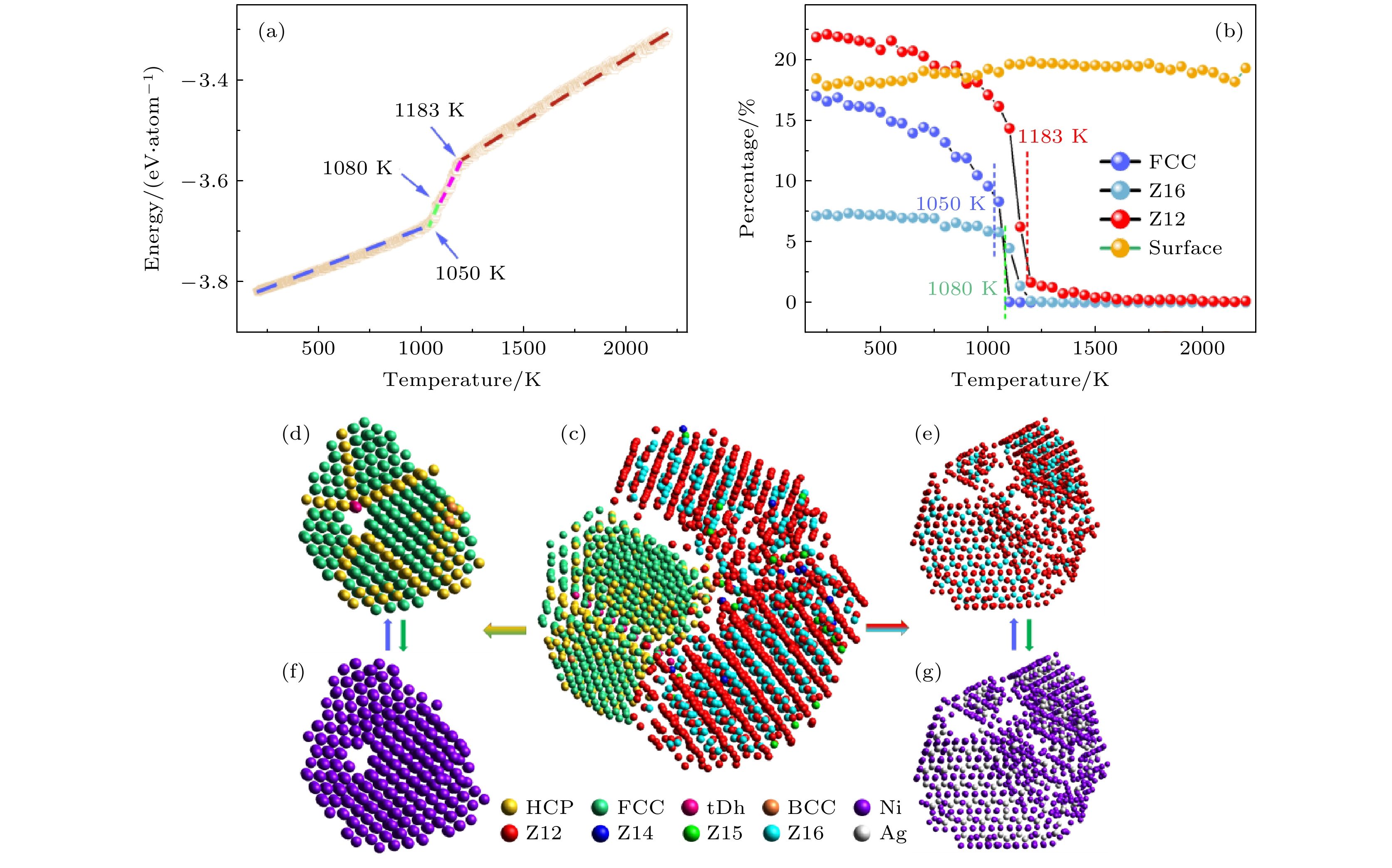

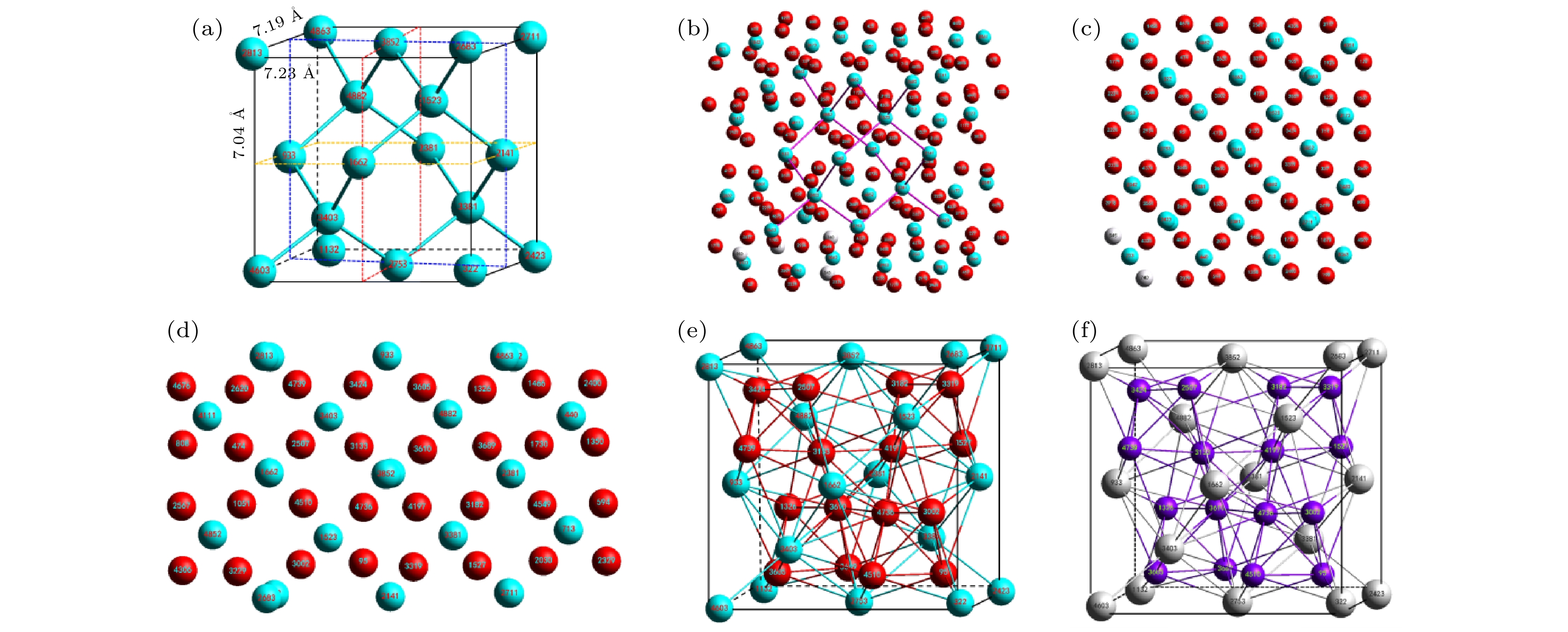

图 2 Ni70Ag30纳米液滴凝固过程中(a)平均原子势能和(b)原子数量百分比随温度的变化, 以及200 K时(c)纳米颗粒的结构分解, (d)FCC晶区和(e)TCP晶区. 对(d)和(e)中的晶区按原子元素分类得到(f)和(g)

Figure 2. (a)The average atomic potential energy and (b)atomic number percentage as a function of temperature for Ni70Ag30 nanoparticles. (c) The structural decomposition of nanoparticles, (d) FCC region and (e) TCP region at 200 K. The element-based color encoded versions (f) and (g) to the FCC and TCP regions, respectively.

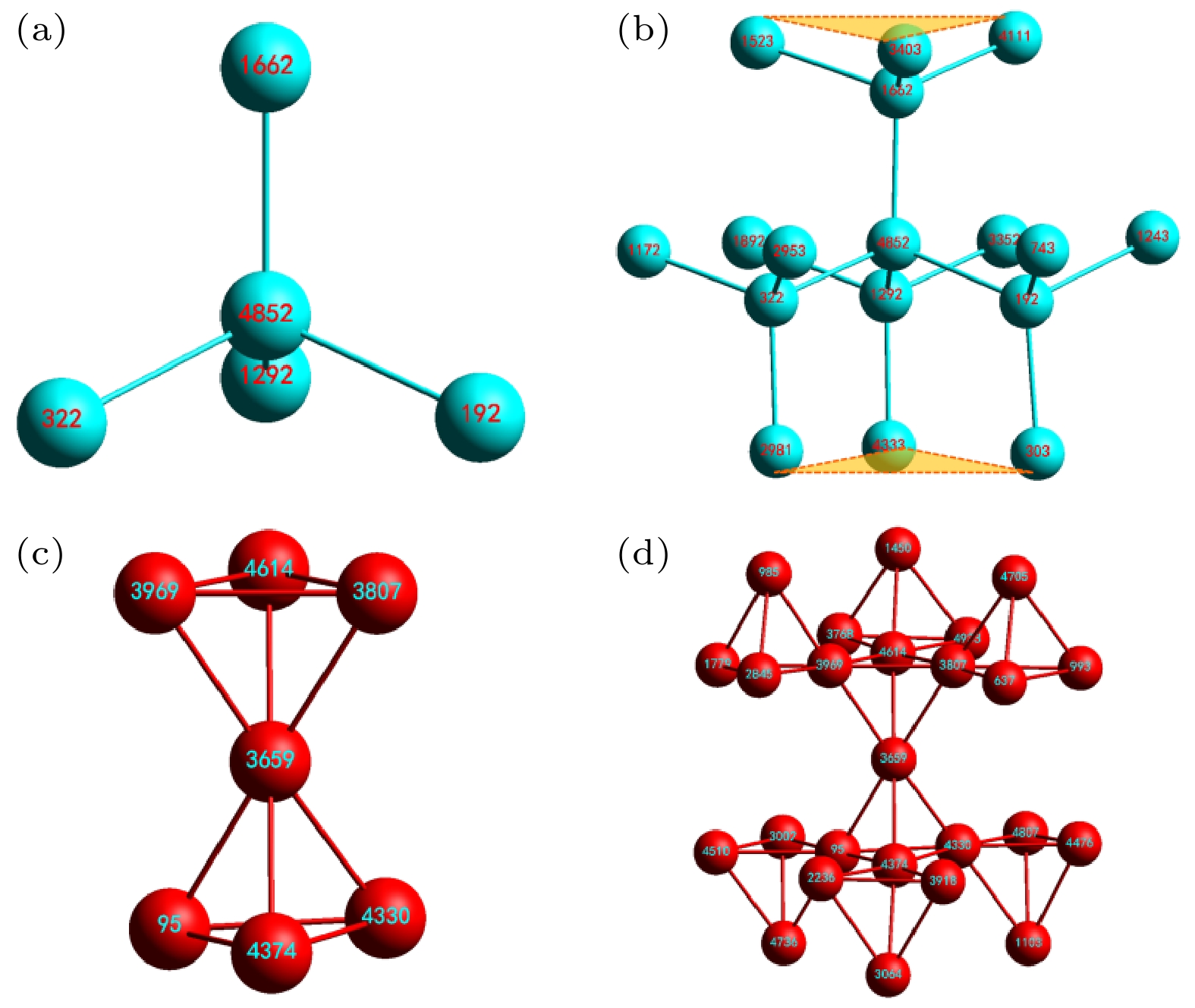

图 3 Z16和Z12原子的空间分布特征. Z16原子(4852)为中心, 包含(a)第一近邻和(b)第二近邻的结构; Z12原子(3659)为中心, 包含(c)第一近邻和(d)第二近邻的结构. 图(b)中两个黄色三角形相互平行但取向相反

Figure 3. The spatial distribution characteristics of Z16 and Z12 atoms. The structures composed of Z16 atoms, including (a) the nearest neighbors and (b) the second neighbors. The structures composed of Z12 atoms, including (c) the nearest neighbors and (d) the second neighbor. The two yellow triangles in panel (b) are parallel but opposite.

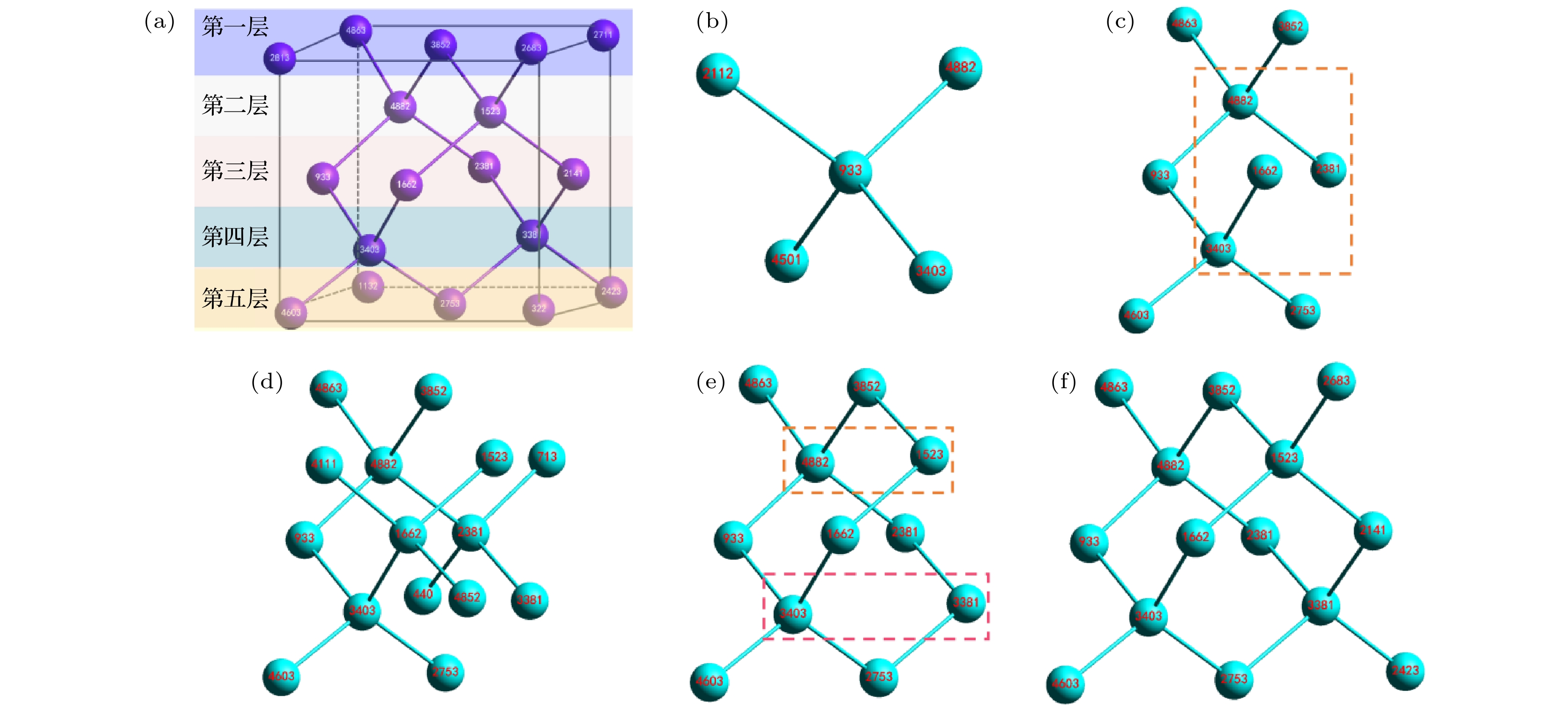

图 4 通过可视化软件的限定条件搜索功能, 确定由Z16原子构成的TCP晶体骨架结构的过程 (a)闪锌矿晶体结构及其分层特征; (b)原子933及其第一近邻; (c)原子4882和3403及其第一近邻; (d)原子4882, 3403, 1662和2381及其第一近邻; (e)从(d)中去掉不属于本晶胞的原子后的结构; (f)原子4882, 1523, 3403和3381及其第一近邻

Figure 4. A step-by-step three dimensional (3D) visualization for the identification of a periodic structural unit composed of Z16 atoms through search function with specific conditions (only Z16 atoms are considered) provided by the software: (a) Crystal structure of sphalerite and its layering characteristics with a Z16 atom labelled 933 being leftmost in the third layer; (b) an atom labelled 933 and its nearest neighbors; (c) two atoms {4882, 3403} and their nearest neighbors; (d) four atoms {4882, 3403, 1662, 2381} and their nearest neighbors; (e) the structure after removing atoms (not in the unit) from (d); (f) five atoms {4882, 1523, 3403, 3381} and their nearest neighbors.

图 5 寻找闪锌矿结构单元中的4个顶点原子(与内部原子不成键) (a) 第三层原子“933, 1662, 2381”所在平面; (b) 通过原子3852的截面; (c) 通过原子2753的截面. (b)和(c)中虚线框涉及的原子为图4(a)中的第一和第五层

Figure 5. Search for four vertex atoms in the sphalerite structural unit (not bonded to internal atoms): (a) The plane of the third layer atoms (933, 1662, 2381); (b), (c) the sections of 4852 and 2753 atoms respectively. The atoms involved in the dashed boxes in panels (b) and (c) are the first and fifth layers in Fig. 4(a).

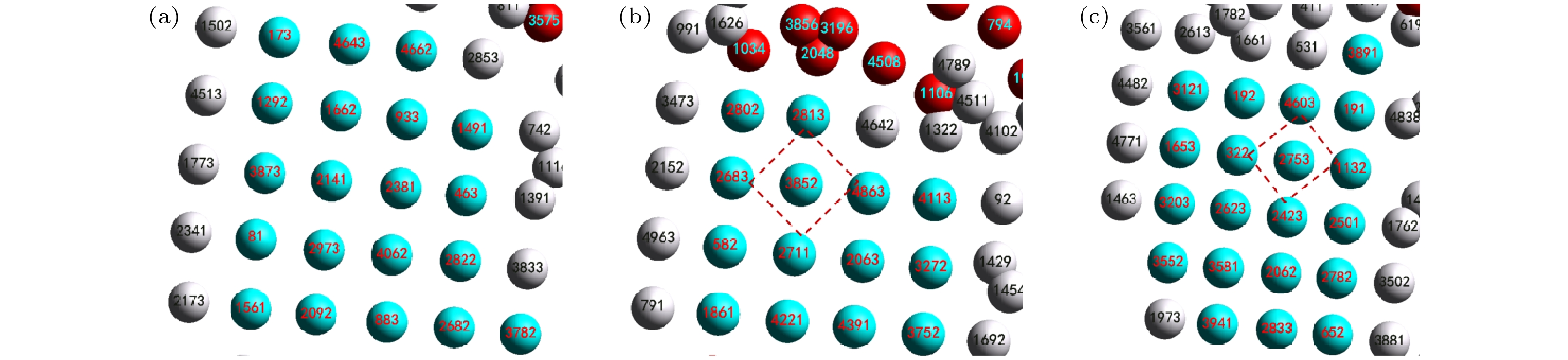

图 6 根据晶胞骨架两两正交的3个均分面交集获得晶胞完整结构的过程(a)晶胞骨架及3个均分面. (b)在晶胞骨架基础上, 一次“近邻搜索”得到的结构, 截取厚度d∈(0.5d0, 0.6d0), d0为晶格常数; 在图(b)上依次取(a)中红色虚线框截面得到(c), 取橙色虚线框截面得到(d), 取蓝色虚线框得到(e). (f)基于原子元素分类得到的晶胞. (a), (e), (f)中的黑色实线为人工添加, 以便观察, 不表示成键关系

Figure 6. The process of obtaining the complete structure of the cell is based on the intersection of three equipartition planes of the biorthogonal cell skeleton: (a) Cell skeleton and three equipartition planes. (b) The structure obtained by one "nearest neighbor search" based on the cytoskeleton; section thickness d∈(0.5d0, 0.6d0), where d0 is the lattice constant. In panel (b), atoms on the red, orange, and blue dashed boxes in panel (a) are taken for the section to obtain (c), (d) and (e). (f) Crystal cell based on classification of atomic elements. The solid black lines in panels (a), (e), and (f) are added manually for observation.

表 1 C15相中各原子的Wyckoff占位

Table 1. Wyckoff positions of atoms in the C15 phase.

Type Multiplicity Wyckoff letter Site symmetry Coordinates Z16 8 b $\bar{4}3m$ $\left(\dfrac{1}{2, }\dfrac{1}{2, }\dfrac{1}{2}\right)$ $\left(\dfrac{1}{4, }\dfrac{3}{4, }\dfrac{1}{4}\right)$ 8 a $\bar{4} 3m$ (0, 0, 0) $\left(\dfrac{3}{4, }\dfrac{1}{4, }\dfrac{3}{4}\right)$ Z12 16 d $.\bar{3}m$ $\left(\dfrac{5}{8, }\dfrac{5}{8, }\dfrac{5}{8}\right)\left(\dfrac{3}{8, }\dfrac{7}{8, }\dfrac{1}{8}\right)$ $\left(\dfrac{7}{8, }\dfrac{1}{8, }\dfrac{3}{8}\right)\left(\dfrac{1}{8, }\dfrac{3}{8, }\dfrac{7}{8}\right)$ 16 c $.\bar{3}m$ $\left(\dfrac{1}{8, }\dfrac{1}{8, }\dfrac{1}{8}\right)\left(\dfrac{7}{8, }\dfrac{3}{8, }\dfrac{5}{8}\right)$ $\left(\dfrac{3}{8, }\dfrac{5}{8, }\dfrac{7}{8}\right)\left(\dfrac{5}{8, }\dfrac{7}{8, }\dfrac{3}{8}\right)$ -

[1] Greer A L 1993 Nature 366 6453

[2] Li C, Li J C, Zhao M, Jiang Q 2009 J. Alloys Compd. 475 752

Google Scholar

Google Scholar

[3] Turchi P, Treglia G, Ducastelle F 1983 J. Phys. F:Met. Phys. 13 2543

Google Scholar

Google Scholar

[4] Hartsough L D 1974 J. Phys. Chem. Solids 35 1691

Google Scholar

Google Scholar

[5] Turchi P E A, Finel A 1992 Phys. Rev. B 46 702

Google Scholar

Google Scholar

[6] Moriarty J A 1994 Phys. Rev. B 49 12431

Google Scholar

Google Scholar

[7] Ye H Q, Zhu J 1989 Acta Cryst B 45 1

[8] Li D X, Kuo K H 1985 Philos. Mag. A 51 849

Google Scholar

Google Scholar

[9] Rehman H UR, Durst K, Neumeier S, Parsa A B, Kostka A, Eggeler G, Göken M 2015 Mater. Sci. Eng. A 634 202

Google Scholar

Google Scholar

[10] Rae C M F, Reed R C 2001 Acta Mater. 49 4113

Google Scholar

Google Scholar

[11] Kelchner C L, Plimpton S J, Hamilton J C 1998 Phys. Rev. B 58 11085

Google Scholar

Google Scholar

[12] Honeycutt J D, Andersen H C 1987 J. Phys. Chem. 91 4950

Google Scholar

Google Scholar

[13] Faken D, Jónsson H 1994 Comput. Mater. Sci. 2 279

Google Scholar

Google Scholar

[14] Wang S Y, Tian Z A, Dong K J, Xie Q 2021 J. Alloys Compd. 854 156983

Google Scholar

Google Scholar

[15] Mauro N A, Wessels V, Bendert J C, Klein S, Gangopadhyay A K, Kramer M J, Hao S G, Rustan G E, Kreyssig A, Goldman A I, Kelton K F 2011 Phys. Rev. B 83 184109

Google Scholar

Google Scholar

[16] Voronoi G. De Gruyter 1908 Journal für die reine und angewandte Mathematik (Crelles Journal) 134 198

[17] Xie Z C 2021 J. Mater. Res. 36 15

[18] Tian Z A, Liu R S, Dong K J, Yu A B 2011 EPL 96 36001

Google Scholar

Google Scholar

[19] Tian Z A, Dong K J, Yu A B 2015 Ann. Phys. 354 499

Google Scholar

Google Scholar

[20] Wu Z Z, Mo Y F, Lang L, Yu A B, Xie Q, Liu R S, Tian Z A 2018 Phys. Chem. Chem. Phys. 20 28088

Google Scholar

Google Scholar

[21] Lang L, Deng H Q, Tian Z A, Gao F, Hu W Y, Wen D D, Mo Y F 2019 J. Alloys Compd. 775 1184

Google Scholar

Google Scholar

[22] 栗晶晶, 田泽安 2020 低温 42 81

Li J J, Tian Z A 2020 Low. Temp. Phys. Lett. 42 81

[23] Mo Y F, Tian Z A, Lang L, Liu R S, Zhou L L, Hou Z Y, Peng P, Zhang T Y 2019 J. Non-Cryst. Solids 513 111

Google Scholar

Google Scholar

[24] Zhou L L, Tian Z A, Liang Y C, Mo Y F, Wang C J, Li F Z 2021 Phys. Chem. Chem. Phys. 23 25933

Google Scholar

Google Scholar

[25] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[26] Pan Z L, Borovikov V, Mendelev M I 2018 Modell. Simul. Mater. Sci. Eng. 26 075004

Google Scholar

Google Scholar

[27] Frank F C, Kasper J S 1958 Acta Crystallogr. 11 184

Google Scholar

Google Scholar

[28] Frank F C, Kasper J S 1959 Acta Crystallogr. 12 483

Google Scholar

Google Scholar

[29] Ahmed E, Akhter J I, Ahmad M 2004 Comput. Mater. Sci. 31 309

Google Scholar

Google Scholar

[30] Zheng Q, Xiao T, Tian Z A, Gao T H, Liang Y C, Chen Q, Xie Q 2021 Cryst. Growth Des 21 4746

Google Scholar

Google Scholar

[31] Pettifor D G, Seiser B, Margine E R, Kolmogorov A N, Drautz R 2013 Philos. Mag. 93 3907

Google Scholar

Google Scholar

[32] Zhu J H, Liu C T, Pike L M, Liaw P K 2002 Intermetallics 10 579

Google Scholar

Google Scholar

[33] Hajiw S, Pansu B, Sadoc J F 2015 ACS Nano 9 8116

Google Scholar

Google Scholar

[34] Kong Y Y, Duan Y H, Ma L S, Li R Y 2016 Mater. Res. Express 3 106505

Google Scholar

Google Scholar

[35] Ma L S, Duan Y Y, Li R 2017 Philos. Mag. 97 2406

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5660

- PDF Downloads: 70

- Cited By: 0

DownLoad:

DownLoad: