-

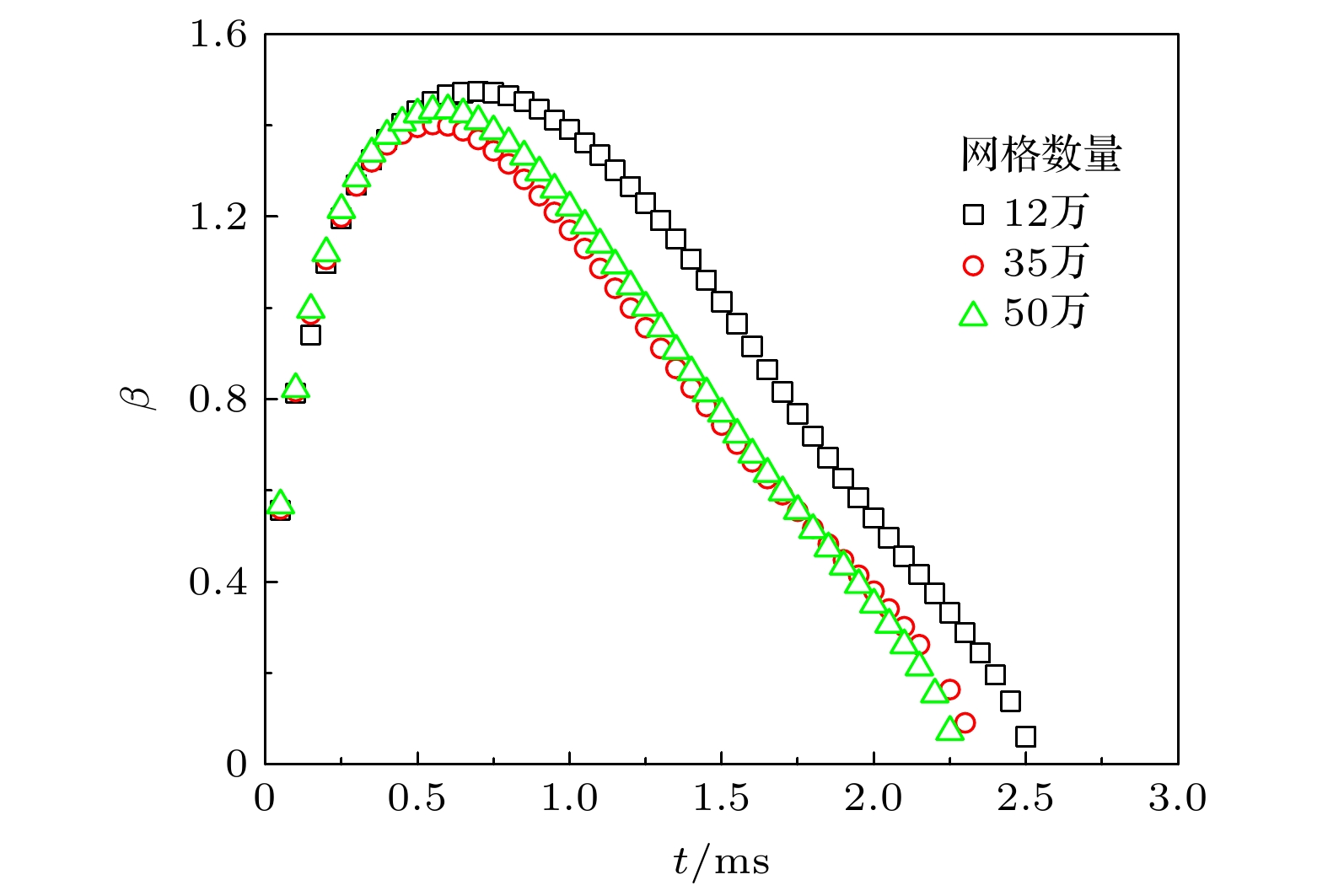

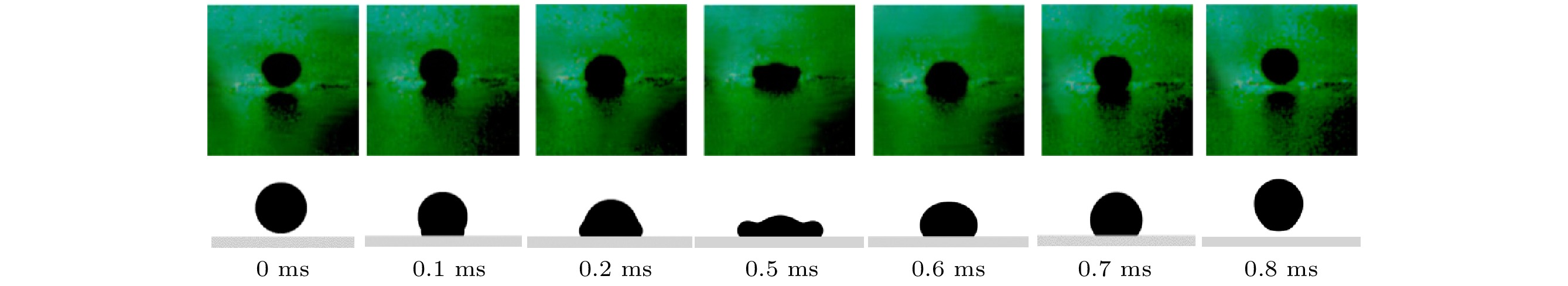

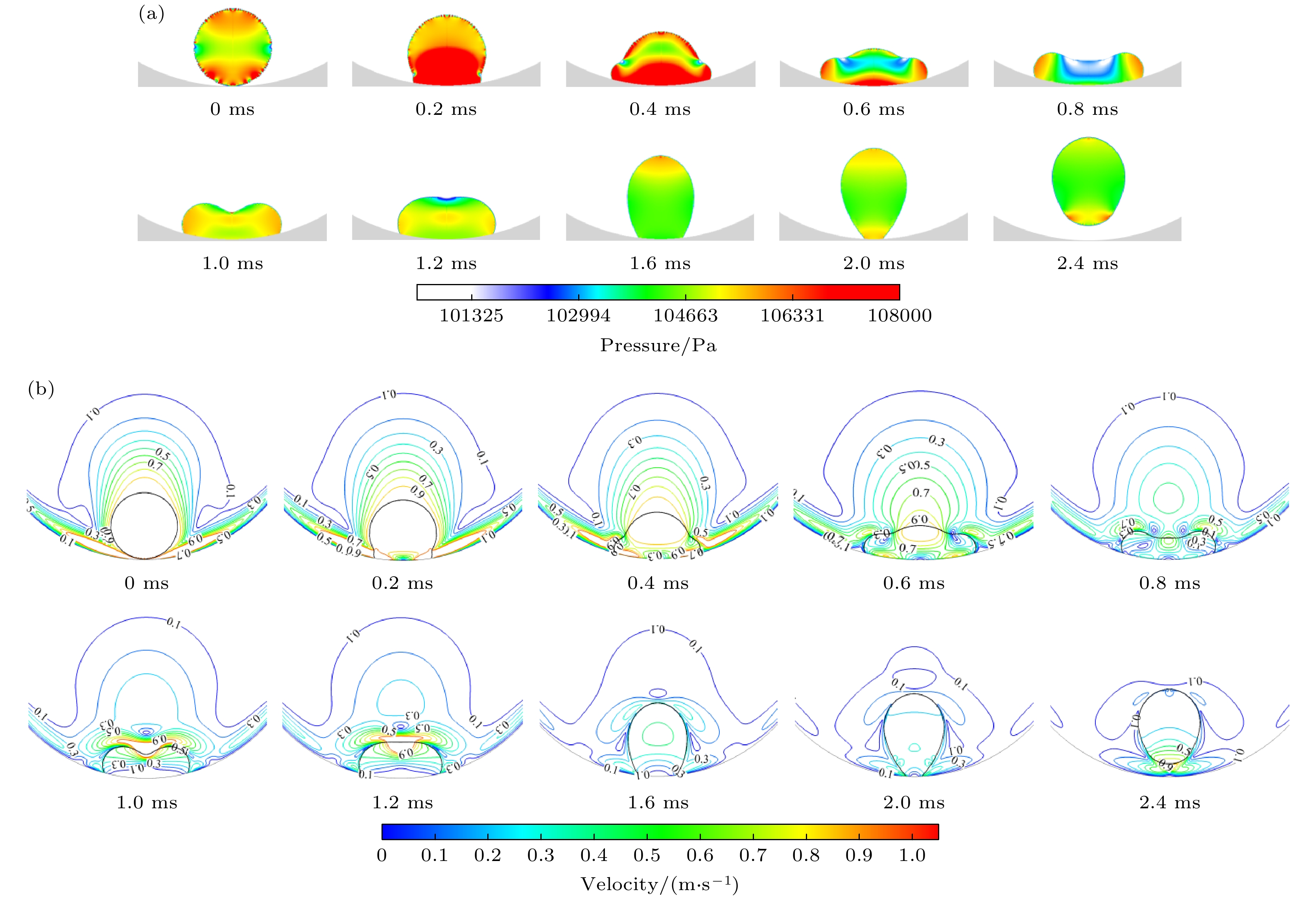

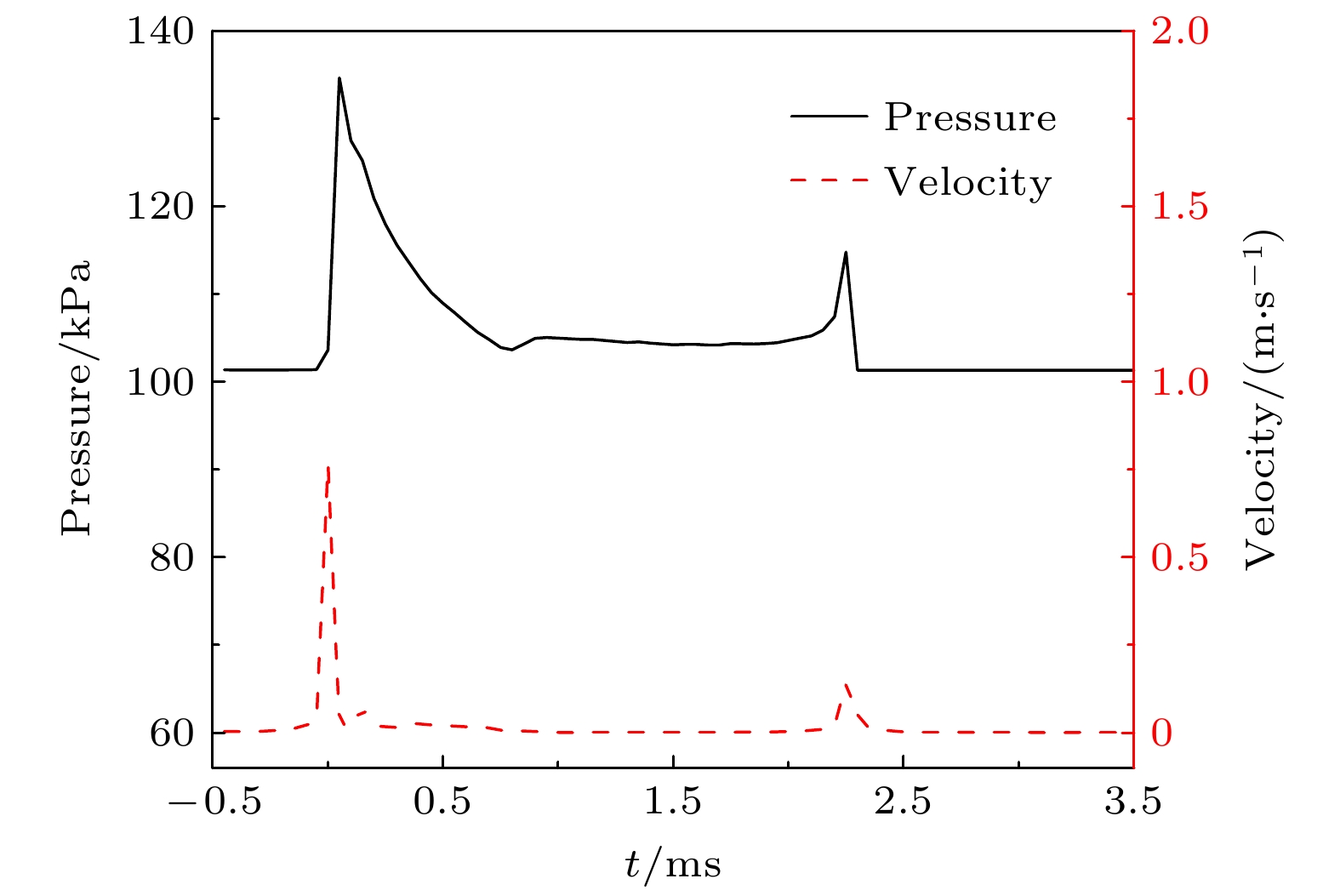

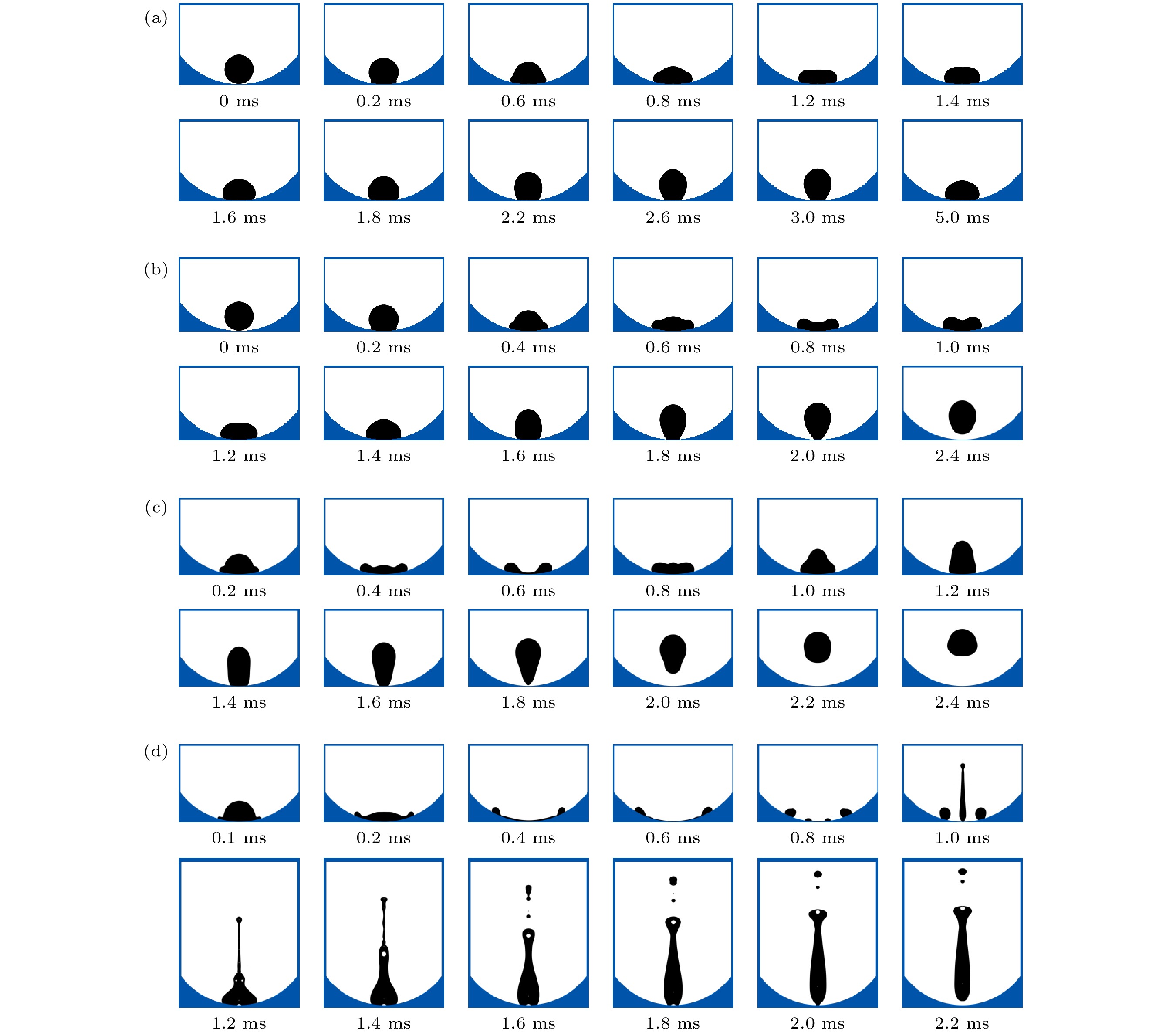

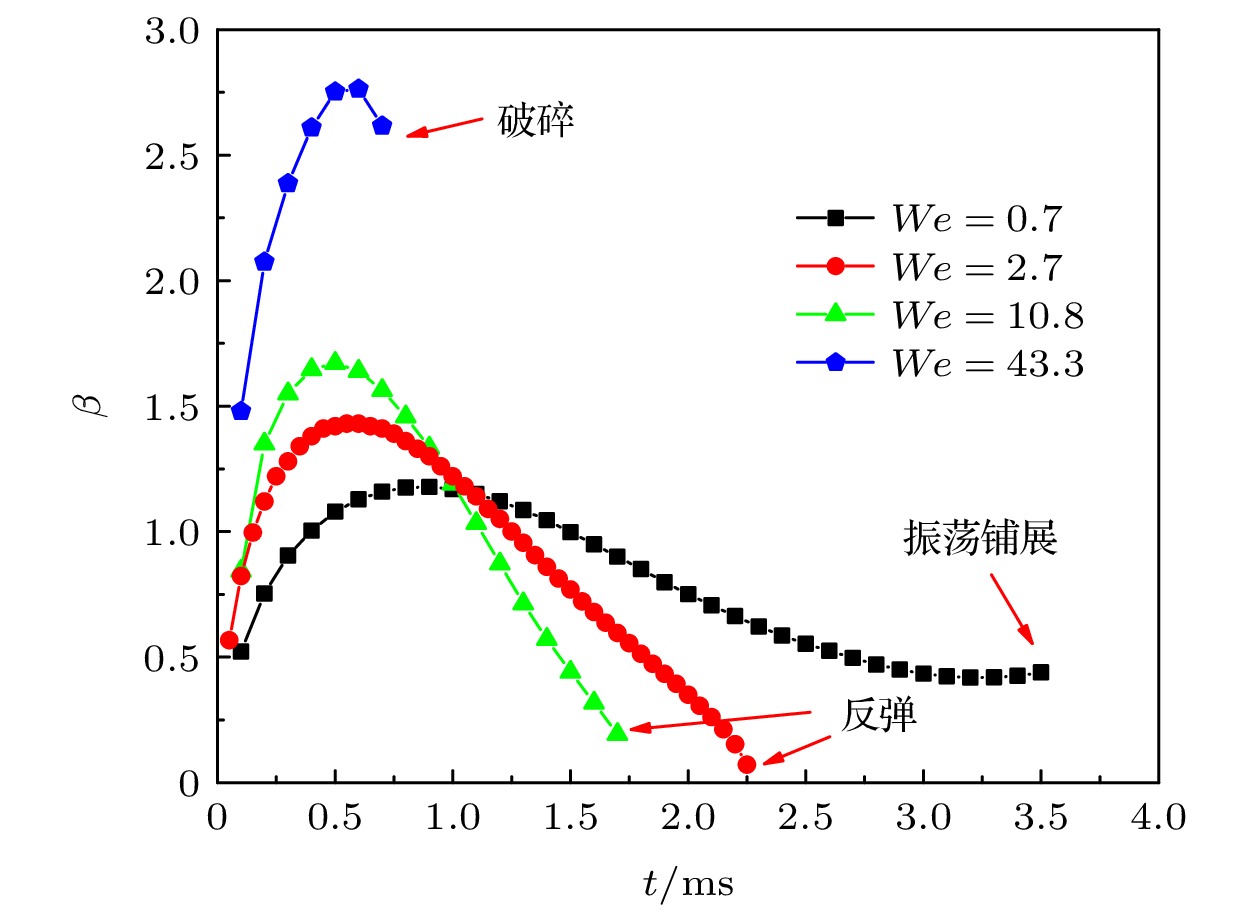

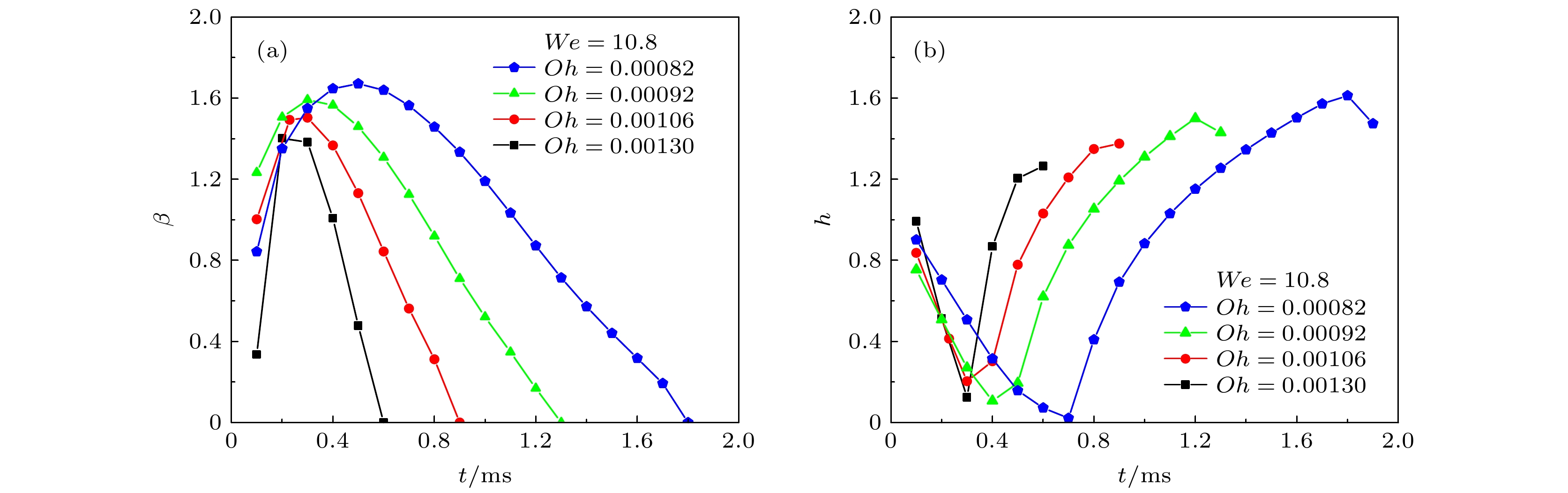

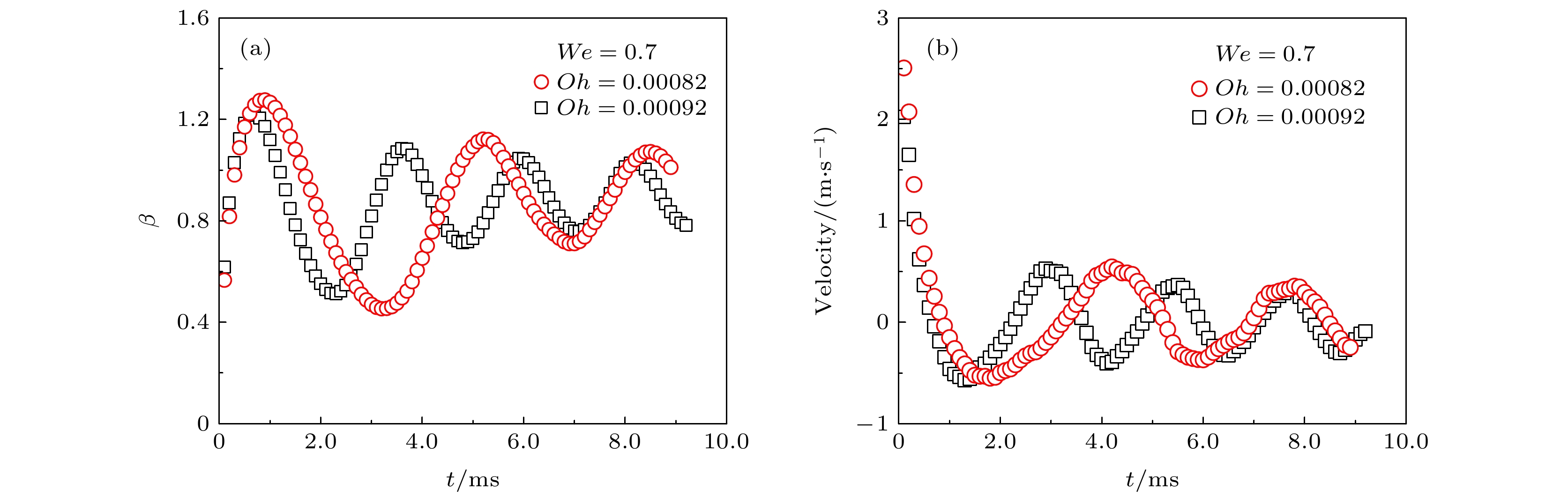

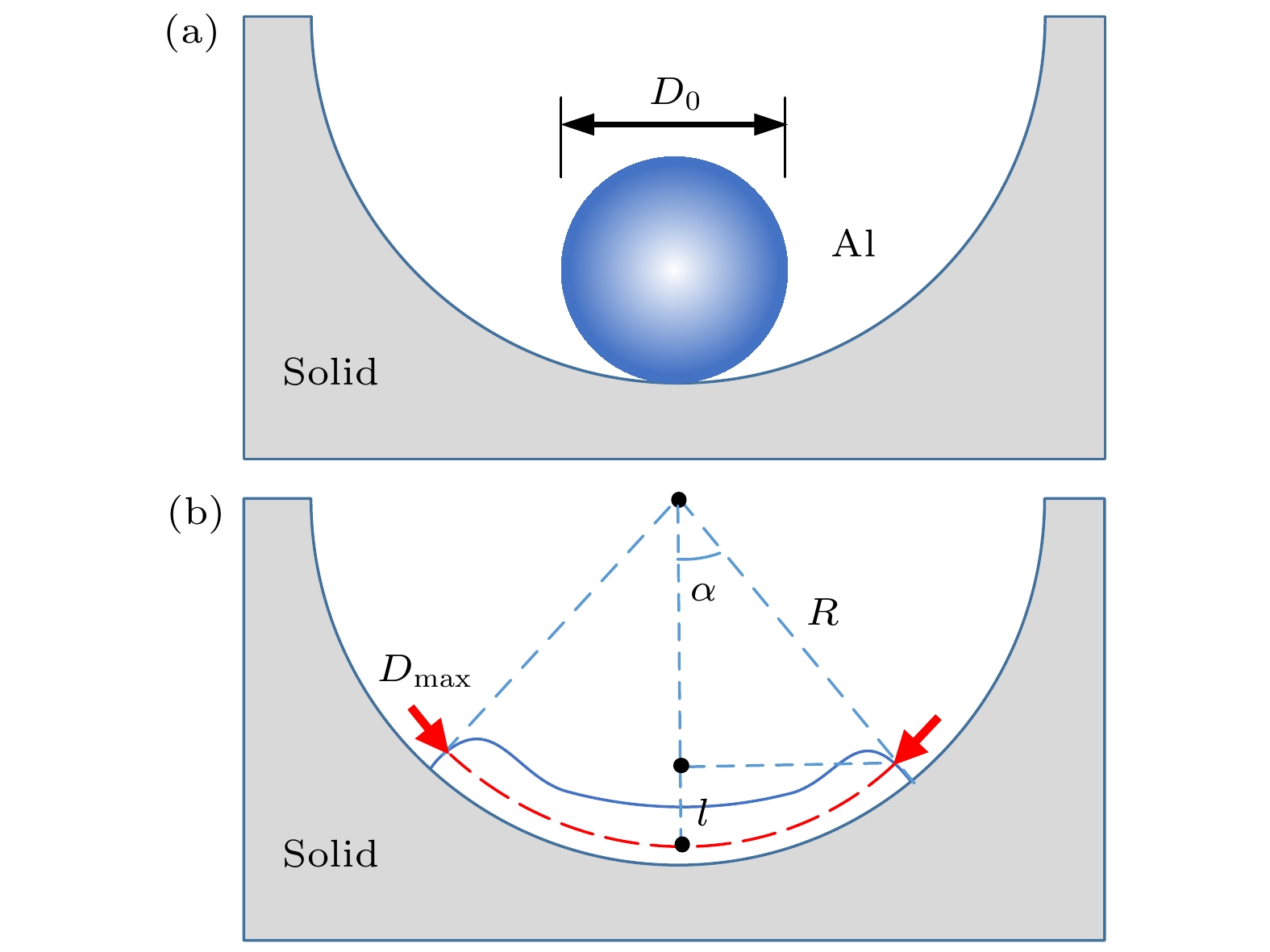

In order to reveal the mechanism of reaction between aluminum droplet and curved wall, a numerical calculation model based on the volume of fluid method of aluminum droplet impacting curved wall is established. By analyzing the influence law of Weber number, Ohnesorge number and wall curvature on the process of droplet impacting the wall, the spreading characteristics and flow mechanism of droplet on curved surface are studied. The results show that the flow characteristics of aluminum droplets after impacting the wall are affected not only by inertial force, surface tension, and viscous force, but also by the structure of the wall. The behavior patterns of the droplets contain adhesion, rebound and splash under different Weber numbers. Because energy dissipation is produced in both spreading process and retracting process, the retracting speed of droplet is always less than its spreading speed. During the flow of the droplet, there are two pressure peaks and velocity peaks at the contact point, while the two peaks appear respectively at the moment when the droplet impacts the wall and when the droplet is about to rebound. In the behavioral mode of rebound, as Ohnesorge number increases, the maximum spreading diameter of the droplet gradually decreases, and the contact time is shorter. In the behavioral mode of adhesion, the spreading radius of the droplets is of oscillatory decay. Within the same period, the maximum spreading coefficient of the larger-Ohnesorge number droplets is smaller, and the decay rate is faster and the oscillation period is shorter. With the increase of wall curvature, the maximum spreading coefficient of droplet increases and that on the plane is the minimum. Based on the calculation results, the empirical formula is revised. Compared with the previous formula, it can well predict the maximum spreading coefficient on the curved surface, whose average error is within 3%. Further, according to the conservation of energy, theoretical models which predict the maximum spreading coefficients when droplets impact a curved and plate wall are also established. Compared with the scenario on the plane, the spreading coefficient of droplet on the curved surface is related to not only the motion parameters of droplet and the wettability of wall surface, but also the ratio of wall curvature to droplet curvature. More importantly, the new theoretical model takes into account the coupling effects of Weber number, Reynolds number, curvature ratio and contact angle, so it has stronger applicability and better robustness. The research results in this work will provide the theoretical basis for practical engineering application.

-

Keywords:

- aluminum droplet /

- curved surface /

- volume of fluid method /

- prediction model

[1] Yi H, Qi L, Luo J, Zhang D, Li H, Hou X 2018 Int. J. Mach. Tools Manuf. 130–131 1

[2] 李涛 2020 博士学位论文 (济南: 山东大学)

Li T 2020 Ph. D. Dissertation (Jinan: Shandong University) (in Chinese)

[3] Rioboo R, Tropea C, Marengo M 2001 Atomization Sprays 11 155

Google Scholar

Google Scholar

[4] Rioboo R, Marengo M, Tropea C 2002 Exp. Fluids 33 112

Google Scholar

Google Scholar

[5] Mundo C, Sommerfeld M, Tropea C 1994 Int. J. Multiphase Flow 21 151

[6] Stanton D W, Rutland C J 1996 SAE Trans. 105 960628

[7] Xu H T, Liu Y C, He P, Wang H Q 1998 J. Fluids Eng. 120 593

Google Scholar

Google Scholar

[8] Attané P, Girard F, Morin V 2007 Phys. Fluids 19 12101

Google Scholar

Google Scholar

[9] 宋云超 2013 博士学位论文 (北京: 北京交通大学)

Song Y C 2013 Ph. D. Dissertation (Beijing: Beijing Jiaotong University) (in Chinese)

[10] 李大树 2015 博士学位论文 (北京: 中国石油大学)

Li D S 2015 Ph. D. Dissertation (Beijing: China University of Petroleum) (in Chinese)

[11] 陈石, 王辉, 沈胜强, 梁刚涛 2013 62 204702

Google Scholar

Google Scholar

Chen S, Wang H, Shen S Q, Liang G T 2013 Acta Phys. Sin. 62 204702

Google Scholar

Google Scholar

[12] 梁刚涛, 郭亚丽, 沈胜强 2013 62 024705

Google Scholar

Google Scholar

Liang G T, Guo Y L, Shen S Q 2013 Acta Phys. Sin. 62 024705

Google Scholar

Google Scholar

[13] 黄虎, 洪宁, 梁宏, 施保昌, 柴振华 2013 62 084702

Google Scholar

Google Scholar

Huang H, Hong N, Liang H, Shi B C, Chai Z H 2013 Acta Phys. Sin. 62 084702

Google Scholar

Google Scholar

[14] 武冠杰 2019 博士学位论文 (西安: 西北工业大学)

Wu G J 2019 Ph. D. Dissertation (Xi’an: Northwestern Polytechnical University) (in Chinese)

[15] Pasandideh-Fard M, Chandra S, Mostaghimi J 2002 Int. J. Heat Mass Transfer 45 2229

Google Scholar

Google Scholar

[16] 尚超, 阳倦成, 张杰, 倪明玖 2019 力学学报 51 380

Google Scholar

Google Scholar

Shang C, Yang Q C, Zhang J, Ni M J 2019 J. Theor. Appl. Mech. 51 380

Google Scholar

Google Scholar

[17] Dou Y, Luo J, Qi L, Lian H, Huang J 2021 J. Mater. Process. Technol. 297 117268

Google Scholar

Google Scholar

[18] Li C, Wu G, Li M, Hu C, Wei J 2020 Aerosp. Sci. Technol. 97 105639

Google Scholar

Google Scholar

[19] Assael M J, Kakosimos K, Banish R M, Brillo J, Egry I, Brooks R, Quested P N, Mills K C, Nagashima A, Sato Y, Wakeham W A 2006 J. Phys. Chem. Ref. Data 35 285

Google Scholar

Google Scholar

[20] Sarou-Kanian V, Millot F, Rifflet J C 2003 Int. J. Thermophys. 24 277

Google Scholar

Google Scholar

[21] Wu G J, Ren Q B, Fu Y, Liu Y M, Hu C B 2018 J. Solid Rocket Technol. 41 677

[22] Brackbill J U, Kothe D B, Zemach C 1992 J. Comput. Phys. 100 335

Google Scholar

Google Scholar

[23] Balla M, Kumar Tripathi M, Sahu K C 2019 Phys. Rev. E 99 23107

Google Scholar

Google Scholar

[24] 唐鹏博, 王关晴, 王路, 石中玉, 李源, 徐江荣 2020 69 024702

Google Scholar

Google Scholar

Tang P B, Wang G Q, Wang L, Shi Z Y, Li Y, Xu J R 2020 Acta Phys. Sin. 69 024702

Google Scholar

Google Scholar

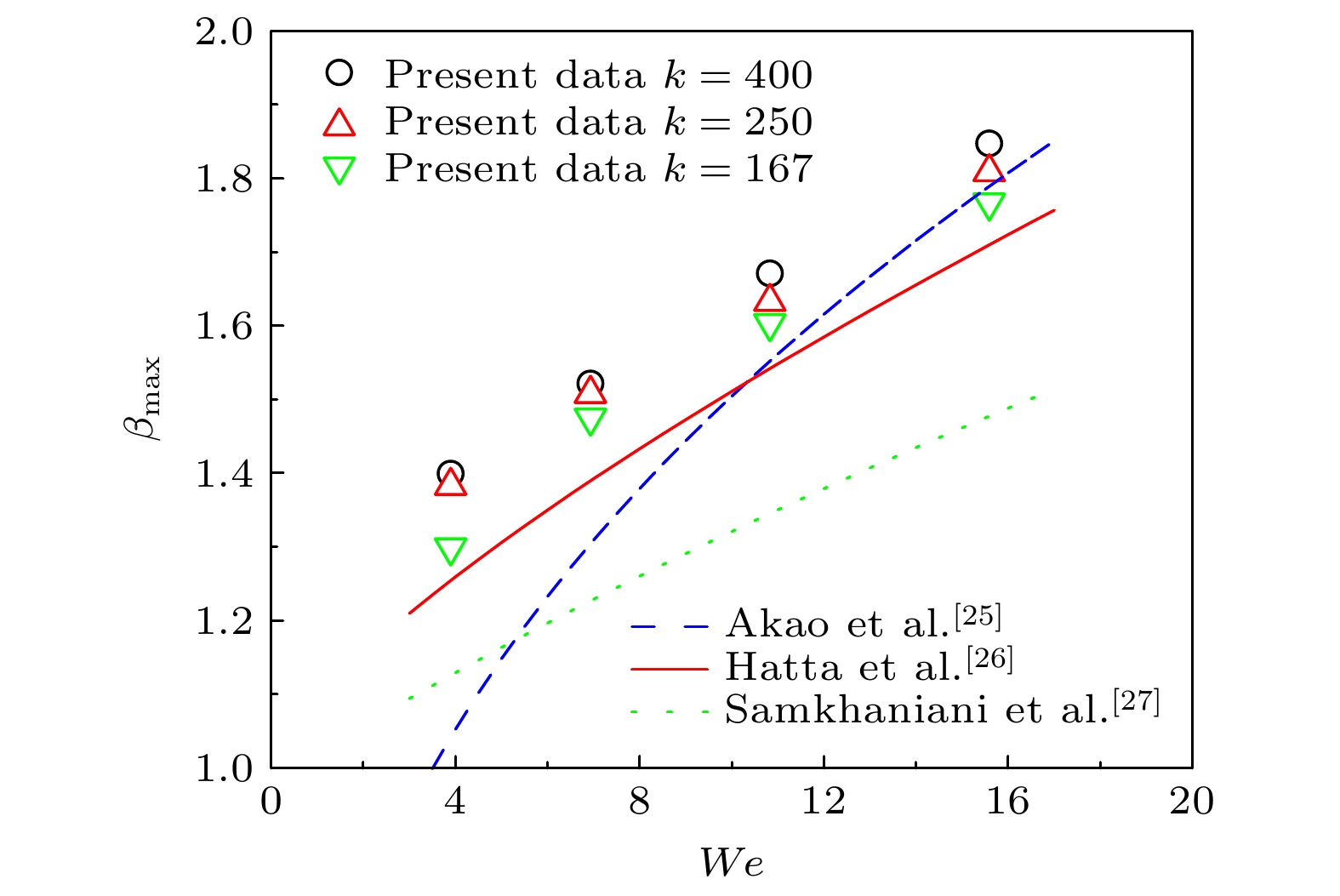

[25] Akao F, Araki K, Mori S, Moriyama A 1980 Trans. ISIJ 20 737

Google Scholar

Google Scholar

[26] Hatta N, Fujimoto H, Takuda H, Kinoshita K, Takahashi O 1995 ISIJ Int. 35 50

Google Scholar

Google Scholar

[27] Samkhaniani N, Stroh A, Holzinger M, Marschall H, Frohnapfel B, Wörner M 2021 Int. J. Heat Mass Transfer 180 121777

Google Scholar

Google Scholar

[28] Chandra S, Avedisian C T 1991 Proc. R. Soc. London, Ser. A 432 13

Google Scholar

Google Scholar

[29] Pasandideh-Fard M, Qiao Y M, Chandra S, Mostaghimi J 1996 Phys. Fluids 8 650

Google Scholar

Google Scholar

-

表 1 主要物性参数

Table 1. Main physical properties.

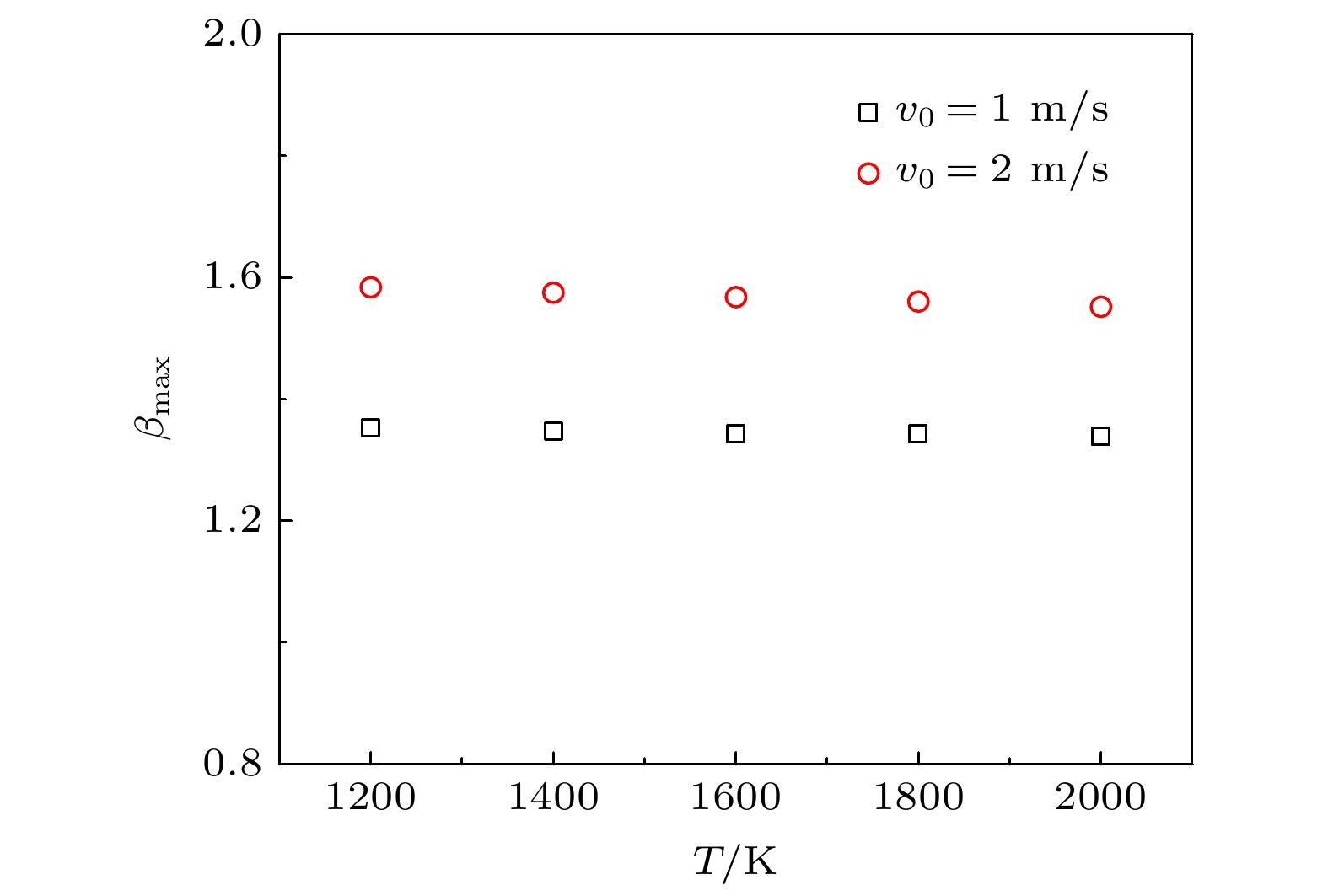

参数 数值 单位 温度 1000 K 压力 101325 Pa 液滴密度 2357 kg/m3 液滴黏度 1.178×10–3 Pa/s 表面张力 0.871 N/m 接触角 161 (°) 表 2 铝液滴物性参数随温度的变化

Table 2. Physical parameters properties of aluminum droplets at different temperatures.

温度/K 密度/

(kg·m–3)黏度/

(10–3 Pa·s–1)表面张力/

(N·m–1)1200 2294 0.865 0.834 1400 2232 0.694 0.797 1600 2170 0.589 0.760 1800 2108 0.518 0.723 2000 2046 0.467 0.686 表 3 铺展过程的特征参数

Table 3. Characteristic parameters of the spreading process.

k $ {\beta }_{\mathrm{m}\mathrm{a}\mathrm{x}} $ $ {h}_{\mathrm{m}\mathrm{i}\mathrm{n}} $ t1/ms t2/ms tmax/ms 0 1.394 0.192 0.6 0.9 2.3 167 1.411 0.242 0.6 0.8 2.2 250 1.418 0.257 0.6 0.8 2.2 400 1.433 0.281 0.6 0.8 2.3 表 4 预测模型的相对误差

Table 4. Relative error of prediction model

k ε Re We Relative error/% Hatta模型 Samkhaniani模型 Eq. (7) Eq.(32) 167 0.083 2401 3.54 3.45 33.91 1.27 24.54 167 0.083 3201 6.30 5.80 54.13 0.36 18.45 167 0.083 4001 9.84 3.83 74.51 1.18 18.42 167 0.083 4801 14.17 3.23 87.61 1.06 16.95 250 0.125 2401 3.54 9.29 29.48 2.83 20.53 250 0.125 3201 6.30 7.84 50.37 0.29 15.69 250 0.125 4001 9.84 5.54 68.87 1.49 14.75 250 0.125 4801 14.17 5.46 85.67 1.28 15.92 400 0.2 2401 3.54 10.35 24.34 1.59 16.06 400 0.2 3201 6.30 8.67 49.43 1.836 15.33 400 0.2 4001 9.84 7.73 67.43 1.60 14.19 400 0.2 4801 14.17 7.45 79.43 0.97 12.52 -

[1] Yi H, Qi L, Luo J, Zhang D, Li H, Hou X 2018 Int. J. Mach. Tools Manuf. 130–131 1

[2] 李涛 2020 博士学位论文 (济南: 山东大学)

Li T 2020 Ph. D. Dissertation (Jinan: Shandong University) (in Chinese)

[3] Rioboo R, Tropea C, Marengo M 2001 Atomization Sprays 11 155

Google Scholar

Google Scholar

[4] Rioboo R, Marengo M, Tropea C 2002 Exp. Fluids 33 112

Google Scholar

Google Scholar

[5] Mundo C, Sommerfeld M, Tropea C 1994 Int. J. Multiphase Flow 21 151

[6] Stanton D W, Rutland C J 1996 SAE Trans. 105 960628

[7] Xu H T, Liu Y C, He P, Wang H Q 1998 J. Fluids Eng. 120 593

Google Scholar

Google Scholar

[8] Attané P, Girard F, Morin V 2007 Phys. Fluids 19 12101

Google Scholar

Google Scholar

[9] 宋云超 2013 博士学位论文 (北京: 北京交通大学)

Song Y C 2013 Ph. D. Dissertation (Beijing: Beijing Jiaotong University) (in Chinese)

[10] 李大树 2015 博士学位论文 (北京: 中国石油大学)

Li D S 2015 Ph. D. Dissertation (Beijing: China University of Petroleum) (in Chinese)

[11] 陈石, 王辉, 沈胜强, 梁刚涛 2013 62 204702

Google Scholar

Google Scholar

Chen S, Wang H, Shen S Q, Liang G T 2013 Acta Phys. Sin. 62 204702

Google Scholar

Google Scholar

[12] 梁刚涛, 郭亚丽, 沈胜强 2013 62 024705

Google Scholar

Google Scholar

Liang G T, Guo Y L, Shen S Q 2013 Acta Phys. Sin. 62 024705

Google Scholar

Google Scholar

[13] 黄虎, 洪宁, 梁宏, 施保昌, 柴振华 2013 62 084702

Google Scholar

Google Scholar

Huang H, Hong N, Liang H, Shi B C, Chai Z H 2013 Acta Phys. Sin. 62 084702

Google Scholar

Google Scholar

[14] 武冠杰 2019 博士学位论文 (西安: 西北工业大学)

Wu G J 2019 Ph. D. Dissertation (Xi’an: Northwestern Polytechnical University) (in Chinese)

[15] Pasandideh-Fard M, Chandra S, Mostaghimi J 2002 Int. J. Heat Mass Transfer 45 2229

Google Scholar

Google Scholar

[16] 尚超, 阳倦成, 张杰, 倪明玖 2019 力学学报 51 380

Google Scholar

Google Scholar

Shang C, Yang Q C, Zhang J, Ni M J 2019 J. Theor. Appl. Mech. 51 380

Google Scholar

Google Scholar

[17] Dou Y, Luo J, Qi L, Lian H, Huang J 2021 J. Mater. Process. Technol. 297 117268

Google Scholar

Google Scholar

[18] Li C, Wu G, Li M, Hu C, Wei J 2020 Aerosp. Sci. Technol. 97 105639

Google Scholar

Google Scholar

[19] Assael M J, Kakosimos K, Banish R M, Brillo J, Egry I, Brooks R, Quested P N, Mills K C, Nagashima A, Sato Y, Wakeham W A 2006 J. Phys. Chem. Ref. Data 35 285

Google Scholar

Google Scholar

[20] Sarou-Kanian V, Millot F, Rifflet J C 2003 Int. J. Thermophys. 24 277

Google Scholar

Google Scholar

[21] Wu G J, Ren Q B, Fu Y, Liu Y M, Hu C B 2018 J. Solid Rocket Technol. 41 677

[22] Brackbill J U, Kothe D B, Zemach C 1992 J. Comput. Phys. 100 335

Google Scholar

Google Scholar

[23] Balla M, Kumar Tripathi M, Sahu K C 2019 Phys. Rev. E 99 23107

Google Scholar

Google Scholar

[24] 唐鹏博, 王关晴, 王路, 石中玉, 李源, 徐江荣 2020 69 024702

Google Scholar

Google Scholar

Tang P B, Wang G Q, Wang L, Shi Z Y, Li Y, Xu J R 2020 Acta Phys. Sin. 69 024702

Google Scholar

Google Scholar

[25] Akao F, Araki K, Mori S, Moriyama A 1980 Trans. ISIJ 20 737

Google Scholar

Google Scholar

[26] Hatta N, Fujimoto H, Takuda H, Kinoshita K, Takahashi O 1995 ISIJ Int. 35 50

Google Scholar

Google Scholar

[27] Samkhaniani N, Stroh A, Holzinger M, Marschall H, Frohnapfel B, Wörner M 2021 Int. J. Heat Mass Transfer 180 121777

Google Scholar

Google Scholar

[28] Chandra S, Avedisian C T 1991 Proc. R. Soc. London, Ser. A 432 13

Google Scholar

Google Scholar

[29] Pasandideh-Fard M, Qiao Y M, Chandra S, Mostaghimi J 1996 Phys. Fluids 8 650

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8634

- PDF Downloads: 130

- Cited By: 0

DownLoad:

DownLoad: