-

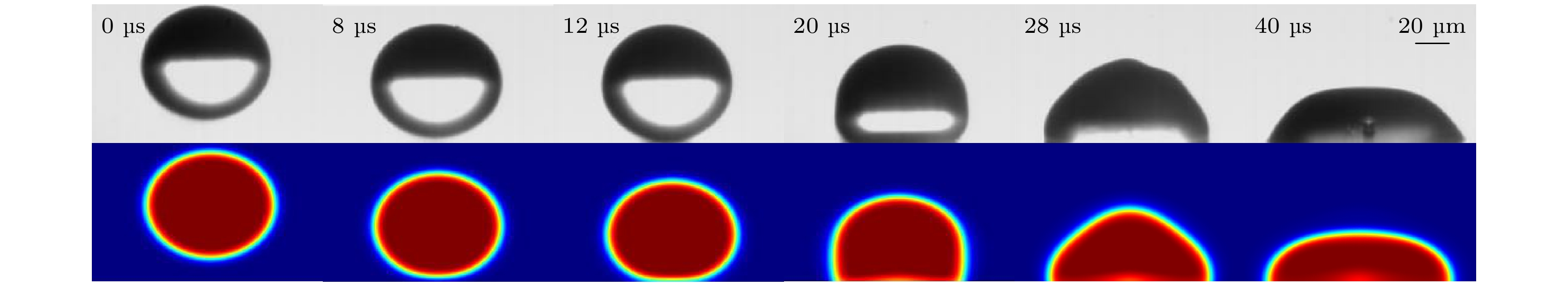

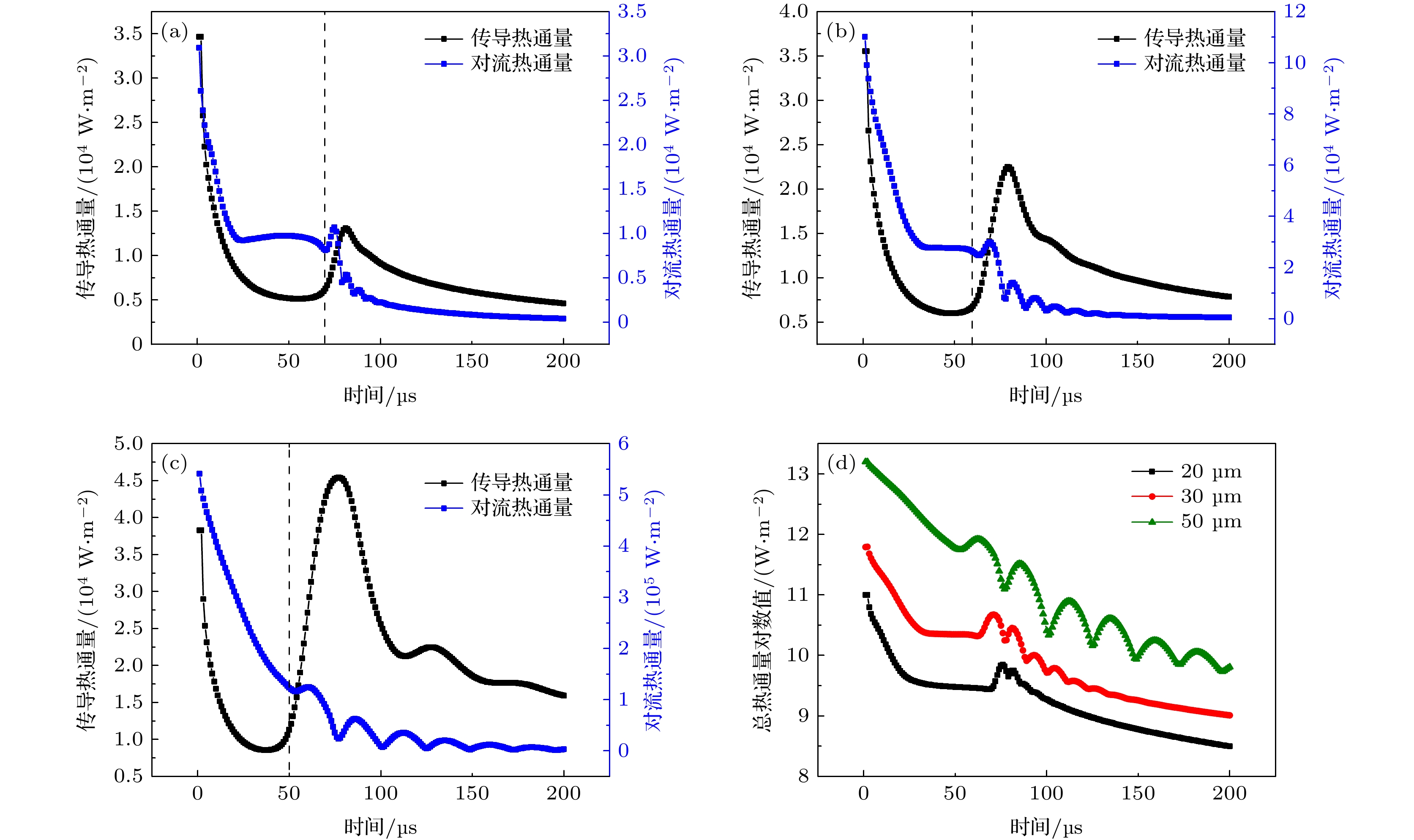

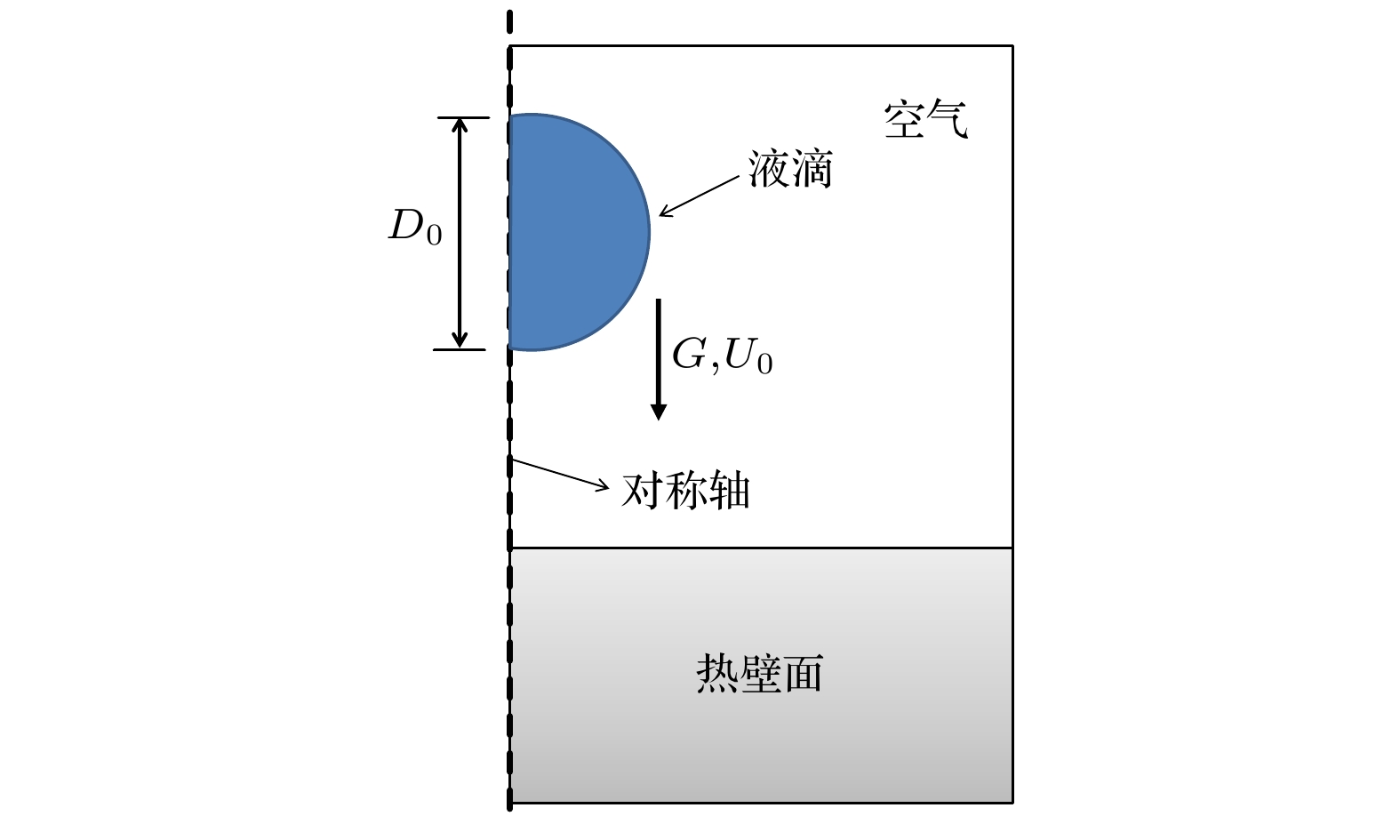

小液滴撞击壁面现象在喷雾冷却等领域都有广泛应用. 为研究小液滴(微米)撞击热壁面(非沸腾区)传热过程, 建立了二维液滴撞壁瞬态模型, 并采用相场方法对小液滴换热过程中对流热通量和导热热通量的大小进行了对比. 研究结果表明: 液滴撞击壁面初期形成“冷斑”, 有利于小液滴与壁面的传热; 小液滴撞击壁面过程中热通量峰值存在于三相接触点附近, 数量级在105—106 W/m2; 小液滴撞击壁面过程中受壁面浸润性和液滴尺寸对传导热通量的影响较为显著, 而速度和液滴尺寸对对流热通量的影响较为显著; 大多数情况下, 小液滴撞击壁面传导热通量数量级在103—105 W/m2, 对流热通量数量级在104—106 W/m2, 对流热通量大于传导热通量, 在整个换热过程中占据主导地位.The phenomenon of small droplets impacting on the wall is widely used in fields such as spray cooling. In recent years, the research on the behavior of droplets impacting on a wall has been extensively concerned by scholars. However, current research mainly focuses on the flow and heat transfer characteristics of large droplets (millimeters) impacting on a hot wall. Since the dynamic and thermodynamic characteristics of small droplets (micrometers) impacting on the hot wall are significantly different from those of large droplets, the research on the behavior of small droplets impacting on the hot wall will further facilitate the understanding of the heat transfer mechanism. In order to study the heat transfer process of small droplets impacting on the hot wall (non-boiling zone), a two-dimensional transient model of droplets impacting on the wall is established, and the phase field method is used to analyze the convective heat flux and heat conduction heat flux in the heat transfer process of small droplets. The effect of velocity, wettability and droplet size on the heat transfer characteristics of droplets impacting on the wall are explored. The simulation results show that the phase field method is feasible in studying the behavior of small droplets impacting on the wall. Furthermore, the research results show that the initial stage of droplet impacting on the wall is “cold spot”, which is conducive to the heat transfer between the small droplet and the wall. The peak heat flux during the small droplet impacting on the wall is near the three-phase contact point, and it is on the order of 105–106 W/m2. The influence of wall wettability and droplet size on the conductive heat flux during the small droplets impacting on the wall are more significant, while velocity and droplet size have a significant influence on convective heat flux. In most cases, the conduction heat flux of small droplets impacting on the wall is about 103–105 W/m2, and the convective heat flux is about 104–106 W/m2. The convective heat flux is larger than the conduction heat flux, and it plays a dominant role in the whole process of heat transfer. The above conclusions are helpful in enriching the heat transfer mechanism of small droplets impacting on the hot wall, and implementing the spray cooling and other technologies.

-

Keywords:

- small droplet /

- impact surface /

- heat transfer characteristics /

- phase field method

[1] Horacek B, Kiger K T, Kim J 2005 Int. J. Heat Mass Transfer 48 1425

Google Scholar

Google Scholar

[2] Pais M R, Chow L C, Mahefkey E T 1992 Int. J. Heat Transfer 114 211

Google Scholar

Google Scholar

[3] Opoku R, Kizito J P 2020 RINENG 6 100

Google Scholar

Google Scholar

[4] Yang Y, Yang L, Du X, Yang Y 2019 Appl. Therm. Eng. 163 114401

Google Scholar

Google Scholar

[5] Yang H, Rong L, Liu X, Liu L, Fan M, Pei N 2020 Energy Rep. 6 906

Google Scholar

Google Scholar

[6] Hajidavalloo E, Eghtedari H 2010 Int. J. Refrig. 33 982

Google Scholar

Google Scholar

[7] Zhang C, Liu H 2016 Phys. Fluids. 28 062107

Google Scholar

Google Scholar

[8] Zhang Q, Zhu W B 2021 J. Propul. Technol 1 (accepted)

[9] Visser C W, Tagawa Y, Sun C, Lohse D 2012 Soft Matter 8 10732

Google Scholar

Google Scholar

[10] Yarin A L, Weiss D A 1995 J. Fluid Mech. 283 141

Google Scholar

Google Scholar

[11] Pasandideh-Fard M, Aziz S D, Chandra S, Mostaghimi J 2001 Int. J. Heat Fluid Fl. 22 201

Google Scholar

Google Scholar

[12] Lee J, Kim J, Kiger K T 2001 Int. J. Heat Fluid Fl. 22 188

Google Scholar

Google Scholar

[13] Hase M, Weigand B 2004 Int. J. Numer. Method. H. 14 85

Google Scholar

Google Scholar

[14] Berberovic E, Roisman I V, Jakirlic S, Tropea C 2011 Int. J. Heat Fluid Fl. 32 785

Google Scholar

Google Scholar

[15] 叶学民, 李永康, 李春曦 2016 23 234701

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. sin. 23 234701

Google Scholar

Google Scholar

[16] Guggilla G, Narayanaswamy R, Pattamatta A 2019 Exp. Therm. Fluid Sci. 110 109916

Google Scholar

Google Scholar

[17] Gelissen E J, Geld C W M, Baltussen M W, Kuerten J G M 2019 Int. J. Multiphase Flow 123 103173

Google Scholar

Google Scholar

[18] 黄龙, 刘昭亮, 王玉洁 2020 制冷与空调 34 283

Google Scholar

Google Scholar

Huang L, Liu Z L, Wang Y J 2020 Refrig. Air-Cond. 34 283

Google Scholar

Google Scholar

[19] Cahn J W 1961 Acta Metall. Sin 9 795

Google Scholar

Google Scholar

[20] Van D, Dirkjan B, Le C C 2004 Phys. Fluids 16 3403

Google Scholar

Google Scholar

-

图 5 壁面不同位置热流密度分布, 与固液界面垂直距离分别为 (a) 0 μm, (b) 10 μm, (c) 20 μm, (d) 30 μm, (e) 40 μm, (f) 50 μm, (g)具体位置示意图

Fig. 5. The heat flux distribution at different positions on the wall, the vertical distances from the solid-liquid interface are respectively (a) 0 μm, (b) 10 μm, (c) 20 μm, (d) 30 μm, (e) 40 μm, (f) 50 μm, (g) Specific location diagram

-

[1] Horacek B, Kiger K T, Kim J 2005 Int. J. Heat Mass Transfer 48 1425

Google Scholar

Google Scholar

[2] Pais M R, Chow L C, Mahefkey E T 1992 Int. J. Heat Transfer 114 211

Google Scholar

Google Scholar

[3] Opoku R, Kizito J P 2020 RINENG 6 100

Google Scholar

Google Scholar

[4] Yang Y, Yang L, Du X, Yang Y 2019 Appl. Therm. Eng. 163 114401

Google Scholar

Google Scholar

[5] Yang H, Rong L, Liu X, Liu L, Fan M, Pei N 2020 Energy Rep. 6 906

Google Scholar

Google Scholar

[6] Hajidavalloo E, Eghtedari H 2010 Int. J. Refrig. 33 982

Google Scholar

Google Scholar

[7] Zhang C, Liu H 2016 Phys. Fluids. 28 062107

Google Scholar

Google Scholar

[8] Zhang Q, Zhu W B 2021 J. Propul. Technol 1 (accepted)

[9] Visser C W, Tagawa Y, Sun C, Lohse D 2012 Soft Matter 8 10732

Google Scholar

Google Scholar

[10] Yarin A L, Weiss D A 1995 J. Fluid Mech. 283 141

Google Scholar

Google Scholar

[11] Pasandideh-Fard M, Aziz S D, Chandra S, Mostaghimi J 2001 Int. J. Heat Fluid Fl. 22 201

Google Scholar

Google Scholar

[12] Lee J, Kim J, Kiger K T 2001 Int. J. Heat Fluid Fl. 22 188

Google Scholar

Google Scholar

[13] Hase M, Weigand B 2004 Int. J. Numer. Method. H. 14 85

Google Scholar

Google Scholar

[14] Berberovic E, Roisman I V, Jakirlic S, Tropea C 2011 Int. J. Heat Fluid Fl. 32 785

Google Scholar

Google Scholar

[15] 叶学民, 李永康, 李春曦 2016 23 234701

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. sin. 23 234701

Google Scholar

Google Scholar

[16] Guggilla G, Narayanaswamy R, Pattamatta A 2019 Exp. Therm. Fluid Sci. 110 109916

Google Scholar

Google Scholar

[17] Gelissen E J, Geld C W M, Baltussen M W, Kuerten J G M 2019 Int. J. Multiphase Flow 123 103173

Google Scholar

Google Scholar

[18] 黄龙, 刘昭亮, 王玉洁 2020 制冷与空调 34 283

Google Scholar

Google Scholar

Huang L, Liu Z L, Wang Y J 2020 Refrig. Air-Cond. 34 283

Google Scholar

Google Scholar

[19] Cahn J W 1961 Acta Metall. Sin 9 795

Google Scholar

Google Scholar

[20] Van D, Dirkjan B, Le C C 2004 Phys. Fluids 16 3403

Google Scholar

Google Scholar

计量

- 文章访问数: 9516

- PDF下载量: 182

- 被引次数: 0

下载:

下载: