-

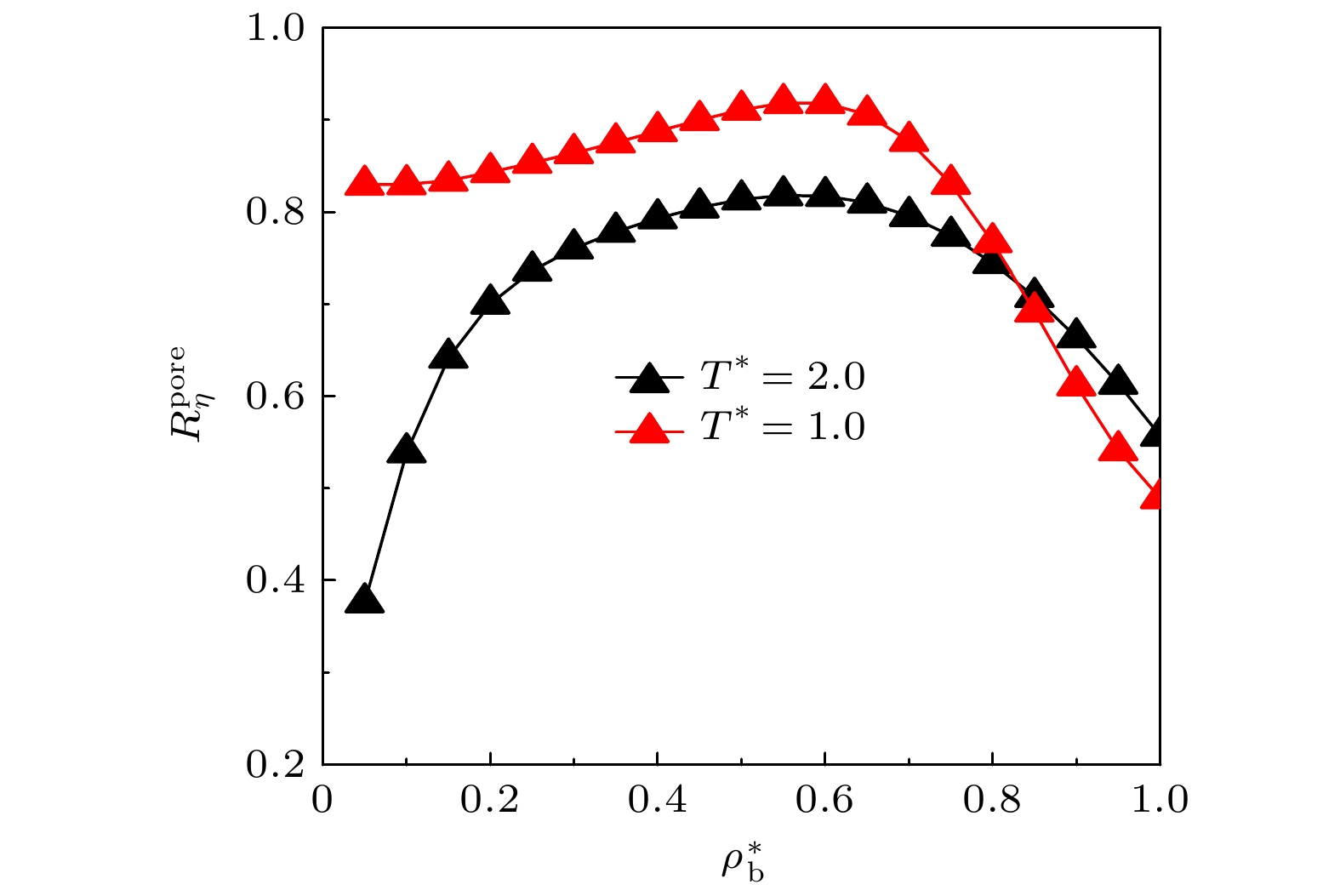

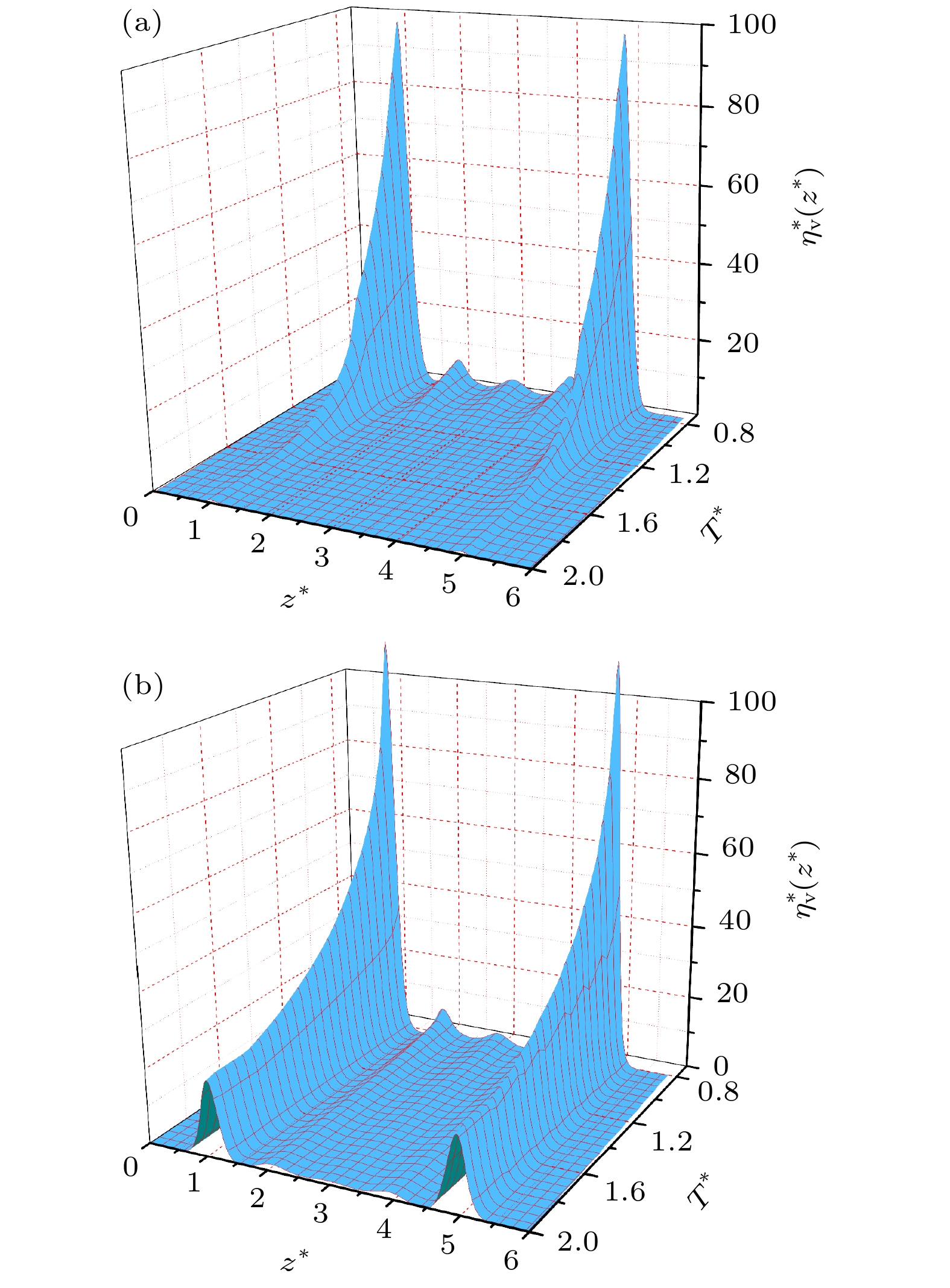

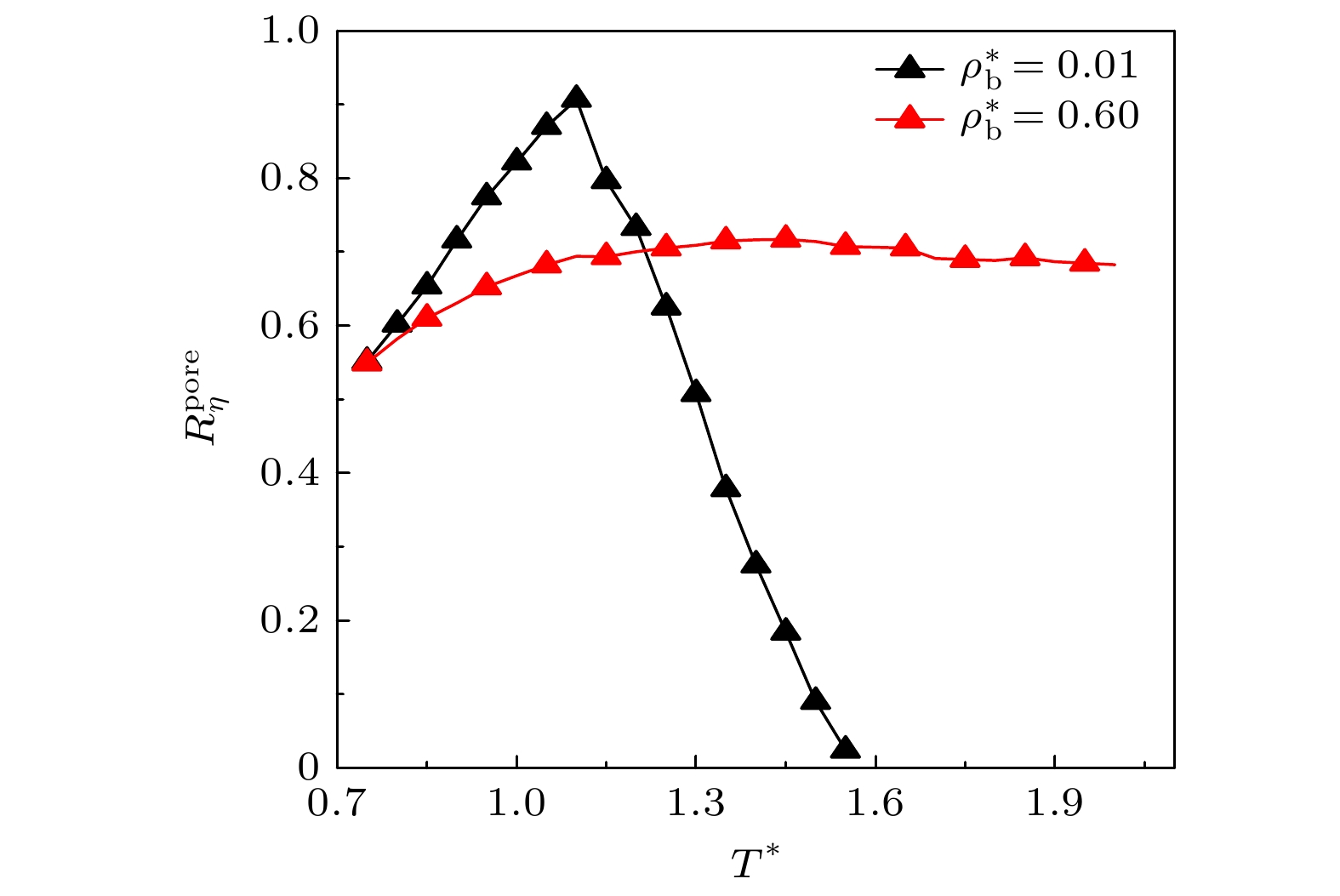

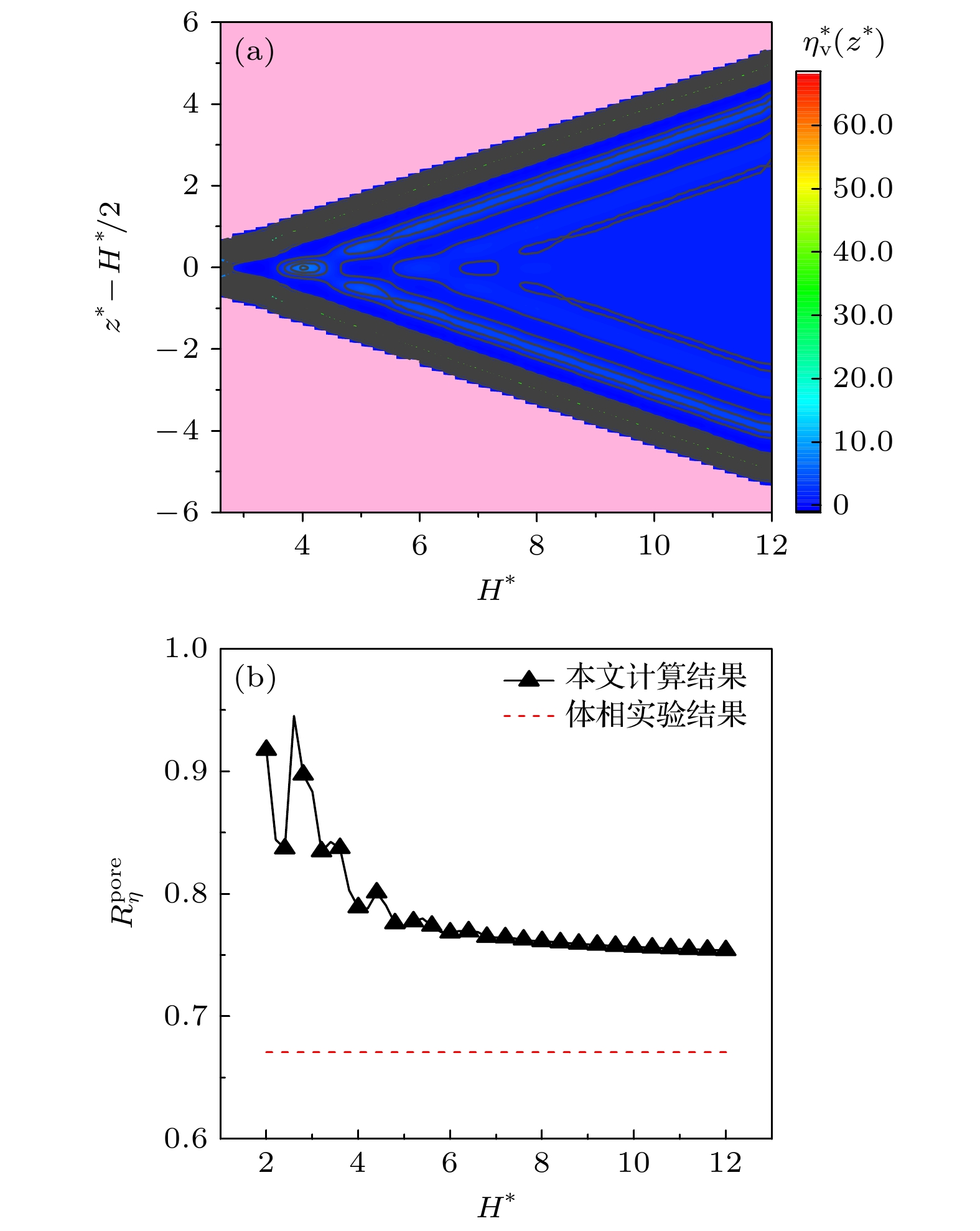

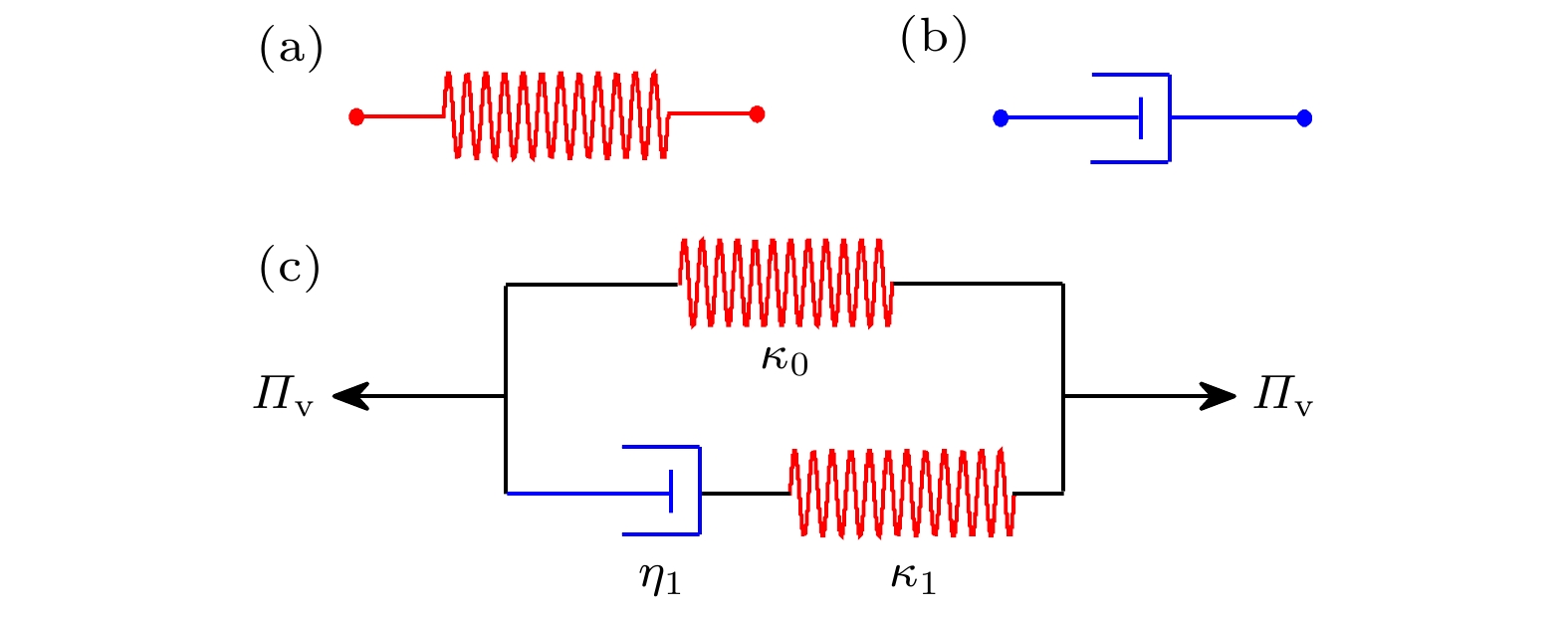

基于黏弹力学中的Maxwell弛豫理论, 提出一种新颖的、可用于计算非均匀体积黏度的理论方法. 该方法通过体相流体的黏性和弹性特征来计算体系的局域弛豫时间, 进而结合体系的局域弛豫模量来计算体积黏度的非均匀分布. 作为应用, 计算了受限于平行狭缝中的Lennard-Jones流体的非均匀体积黏度, 系统地研究了体密度、温度、缝宽和吸附强度等因素对体积黏度的影响. 结果表明, 上述因素的变化均可显著地调制狭缝中流体的体积黏度. 其中, 体密度和吸附强度的增大均有益于体积黏度的增强, 而温度的升高将则会削弱其体积黏度. 此外, 毛细凝聚的发生也对受限流体的体积黏度具有显著的调制作用.Volume viscosity is one of the most important and fundamental parameters in hydrodynamics. It measures the momentum loss caused by a volume deformation rather than shape deformation. So it is closely related to numerous phenomena in fluid dynamics. However, most of the existing related researches focus on the bulk fluids, but there is still a lack of in-depth understanding of the bulk viscosity of inhomogeneous fluids. In this work, a novel theoretical method is proposed for the inhomogeneous volume viscosity in the framework of Maxwell viscoelastic theory. In this proposal, the local relaxation time is calculated by using the viscous and elastic properties of the bulk fluids. Accordingly, the inhomogeneous volume viscosity can be obtained by combining the calculations of the local relaxation time and the local relaxation modulus. It is advantageous in the theoretical sense over the conventional LADM, because it takes into account the underlying correlation much better. On the one hand, the local infinite-frequency modulus is more accurate. On the other hand, by using an appropriate weight function to calculate the weight, the correlation effect can be better considered . As an application, the volume viscosity of the confined Lennard-Jones fluid in slit pore is investigated, and the influences of bulk density, temperature, pore width and adsorption strength are calculated and analyzed. The results indicate that these factors can significantly modulate the volume viscosity of the confined fluid. Specifically, the positive correlation between the volume viscosity and the local density leads to the oscillation of viscosity profile in the pore. Besides, the occurrence of capillary condensation in the cases of lower density and lower temperature makes the inhomogeneous viscosity rather different from that of bulk gaseous phase. Further, this study shows that the inhomogeneous volume viscosity usually increases with temperature decreasing, or with adsorption strength increasing. This is again the result of its dependence on the fluid structure in the pore. Furthermore, the influence of pore width on the inhomogeneous volume viscosity indicates that the excluded volume plays a decisive role. This can be attributed to the fact that it exerts a direct influence on the deformation of the fluid. Moreover, comparison between the volume and shear viscosity is also conducted and analyzed. In general, this study can be beneficial to deepening the understanding of volume viscosity in the confined fluids, and can provide reliable theoretical support for studying related issues in hydrodynamics.

-

Keywords:

- inhomogeneous fluid /

- volume viscosity /

- local relaxation time /

- mechanical modulus

[1] Stephan K, Lucas K D 1979 Viscosities of Dense Fluids (New York: Plenum

[2] Richardson S M 1989 Fluid Mechanics (New York: Hemisphere Publishing Corporation

[3] Dhont J K G 1996 An Introduction to Dynamics of Colloids (Amsterdam: Elsevier Science

[4] Cerbelaud M, Laganapan A M, Ala-Nissila T, Ferrandod R, Videcoq A 2017 Soft Matter 13 3909

Google Scholar

Google Scholar

[5] Zabaloy M S, Machado J M V, Macedo E A 2001 Int. J. Thermophys. 22 829

Google Scholar

Google Scholar

[6] Duque-Zumajo D, de la Torre J A, Español P 2020 J. Chem. Phys. 152 174108

Google Scholar

Google Scholar

[7] Zhang J F, Todd B D, Travis K P 2004 J. Chem. Phys. 121 10778

Google Scholar

Google Scholar

[8] 钱祖文 2012 61 134301

Google Scholar

Google Scholar

Qian Z W 2012 Acta Phys. Sin. 61 134301

Google Scholar

Google Scholar

[9] Stokes G G 1845 Trans. Cambridge Philos. Soc. 8 287

[10] Bhola S, Sengupta T K 2019 Phys. Fluids 31 096101

Google Scholar

Google Scholar

[11] Rahimzadeh A, Rutsch M, Kupnik M, Klitzing R 2021 Langmuir 37 5854

Google Scholar

Google Scholar

[12] Chen S, Wang X N, Wang J C, Wan M P, Li H, Chen S Y 2019 Phys. Fluids 31 085115

Google Scholar

Google Scholar

[13] Bhatia A B 1967 Ultrasonic Absorption: An Introduction to the Theory of Sound Absorption and Dispersion in Gases, Liquids, and Solids (New York: Oxford University Press

[14] Emanuel G 1990 Phys. Fluids A 2 2252

Google Scholar

Google Scholar

[15] Meier K, Laesecke A, Kabelac S 2005 J. Chem. Phys. 122 014513

Google Scholar

Google Scholar

[16] Zhang Y, Otani A, Maginn E J 2015 J. Chem. Theory Comput. 11 3537

Google Scholar

Google Scholar

[17] Sharma B, Kumar R, Gupta P, Pareek S, Singh A 2022 Phys. Fluids 34 057104

Google Scholar

Google Scholar

[18] Heyes D M, Pieprzyk S, Brańka A C 2022 J. Chem. Phys. 157 114502

Google Scholar

Google Scholar

[19] Hoover W G, Ladd A J C, Hickman R B, Holian B L 1980 Phys. Rev. A 21 1756

Google Scholar

Google Scholar

[20] Sharma B, Kumar R 2019 Phys. Rev. E 100 013309

Google Scholar

Google Scholar

[21] Palla P L, Pierleoni C, Ciccotti G 2008 Phys. Rev. E 78 021204

Google Scholar

Google Scholar

[22] Rah K, Eu B C 1999 Phys. Rev. Lett. 83 4566

Google Scholar

Google Scholar

[23] Okumura H, Yonezawa F 2002 J. Chem. Phys. 116 7400

Google Scholar

Google Scholar

[24] Gelb L D, Gubbins K E, Radhakrishnan R, Sliwinska-Bartkowiak M 1999 Rep. Prog. Phys. 62 1573

Google Scholar

Google Scholar

[25] Yu Y X, Gao G H, Wang X L 2006 J. Phys. Chem. B 110 14418

Google Scholar

Google Scholar

[26] Zhao S L, Liu Y, Chen X Q, Lu Y X, Liu H L, Hu Y 2015 Adv. Chem. Eng. 47 1

Google Scholar

Google Scholar

[27] Mittal J, Truskett T M, Errington J R, Hummer G 2008 Phys. Rev. Lett. 100 145901

Google Scholar

Google Scholar

[28] Banks H T, Hu S H, Kenz Z R 2011 Adv. Appl. Math. Mech. 3 1

Google Scholar

Google Scholar

[29] Bitsanis I, Vanderlick T K, Tirrell M, Davis H T 1988 J. Chem. Phys. 89 3152

Google Scholar

Google Scholar

[30] Hoang H, Galliero G 2012 Phys. Rev. E 86 021202

Google Scholar

Google Scholar

[31] Hoang H, Galliero G 2013 J. Phys. Condens. Matter 25 485001

Google Scholar

Google Scholar

[32] Heyes D M 1984 J. Chem. Soc. Faraday Trans. II 80 1363

Google Scholar

Google Scholar

[33] Zwanzig R, Mountain R D 1965 J. Chem. Phys. 43 4464

Google Scholar

Google Scholar

[34] Sun Z L, Kang Y S, Kang Y M 2019 Ind. Eng. Chem. Res. 58 15637

Google Scholar

Google Scholar

[35] Johnson J K, Zollweg J A, Gubbins K E 1993 Mol. Phys. 78 591

Google Scholar

Google Scholar

[36] Yu Y X, Wu J Z 2002 J. Chem. Phys. 117 10156

Google Scholar

Google Scholar

[37] Liu Y, Liu H L, Hu Y, Jiang J W 2010 J. Phys. Chem. B 114 2820

Google Scholar

Google Scholar

[38] Sun Z L, Kang Y S, Li S T 2022 J. Phys. Chem. B 126 8010

Google Scholar

Google Scholar

[39] Sun Z L, Kang Y S, Li S T 2023 Chem. Eng. Sci. 277 118847

Google Scholar

Google Scholar

[40] Goyal I, Zaheri A H M, Srivastava S, Tankeshwar K 2013 Phys. Chem. Liq. 55 595

Google Scholar

Google Scholar

[41] Jaeger F, Matar O K, Müller E A 2018 J. Chem. Phys. 148 174504

Google Scholar

Google Scholar

[42] Cowan J A, Leech J W 1981 Can. J. Phys. 59 1280

[43] Paeßens M 2003 J. Chem. Phys. 118 10287

Google Scholar

Google Scholar

-

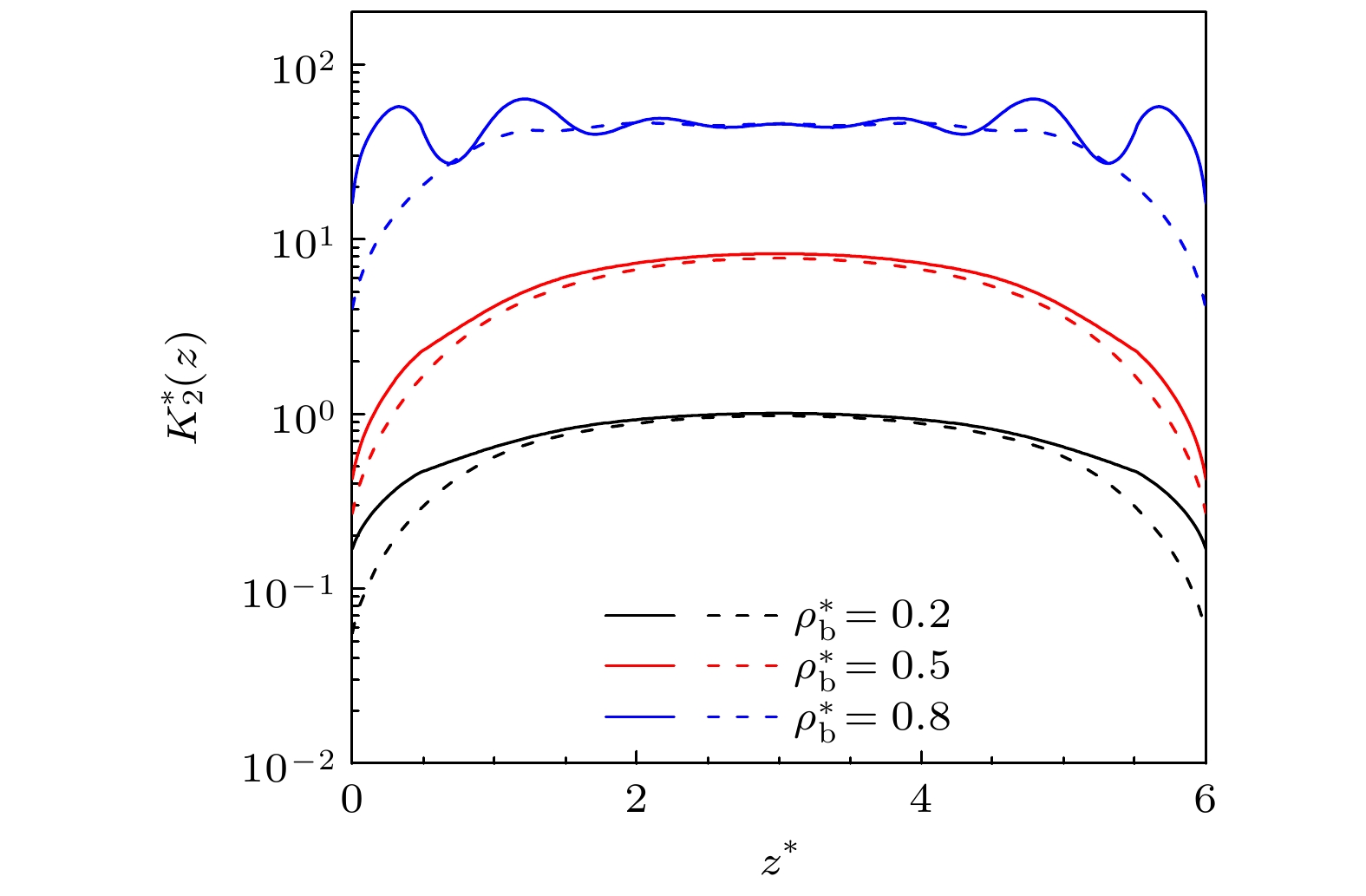

图 2 狭缝中LJ流体的局域弛豫模量的分布. 图中实线为$ {K}_{2}\left(z\right) $的结果, 虚线为$ {K}_{\infty }^{{\mathrm{b}}}\left(\bar{\rho }\left(z\right)\right)-{K}_{0}^{{\mathrm{b}}}\left(\bar{\rho }\left(z\right)\right) $的结果. 计算中的参数取为$ {T}^{*}=1.5 $, $ {H}^{*}=6.0 $. 此外, 约化模量$ {K}_{2}^{*}={K}_{2}{\sigma }^{3}/\varepsilon $

Fig. 2. Profiles of the local relaxation modulus of LJ fluid in slits. In the figure, the solid and dashed lines stand for the results of $ {K}_{2}\left(z\right) $ and $ {K}_{\infty }^{{\mathrm{b}}}\left(\bar{\rho }\left(z\right)\right)-{K}_{0}^{{\mathrm{b}}}\left(\bar{\rho }\left(z\right)\right) $, respectively. In the calculations, the parameters are set as $ {T}^{*}=1.5 $, $ {H}^{*}=6.0 $. In addition, the modulus is reduced as $ {K}_{2}^{*}={K}_{2}{\sigma }^{3}/\varepsilon $.

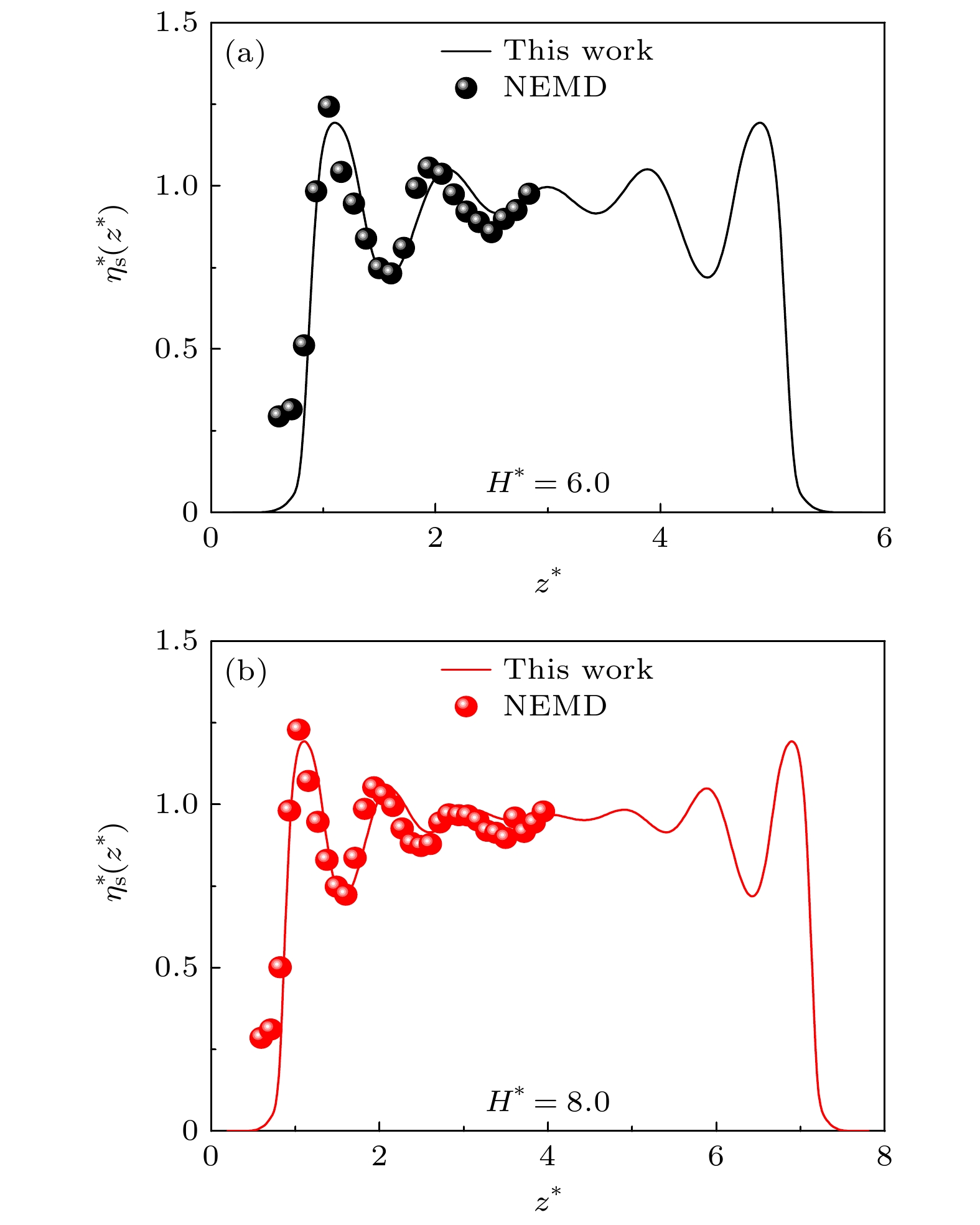

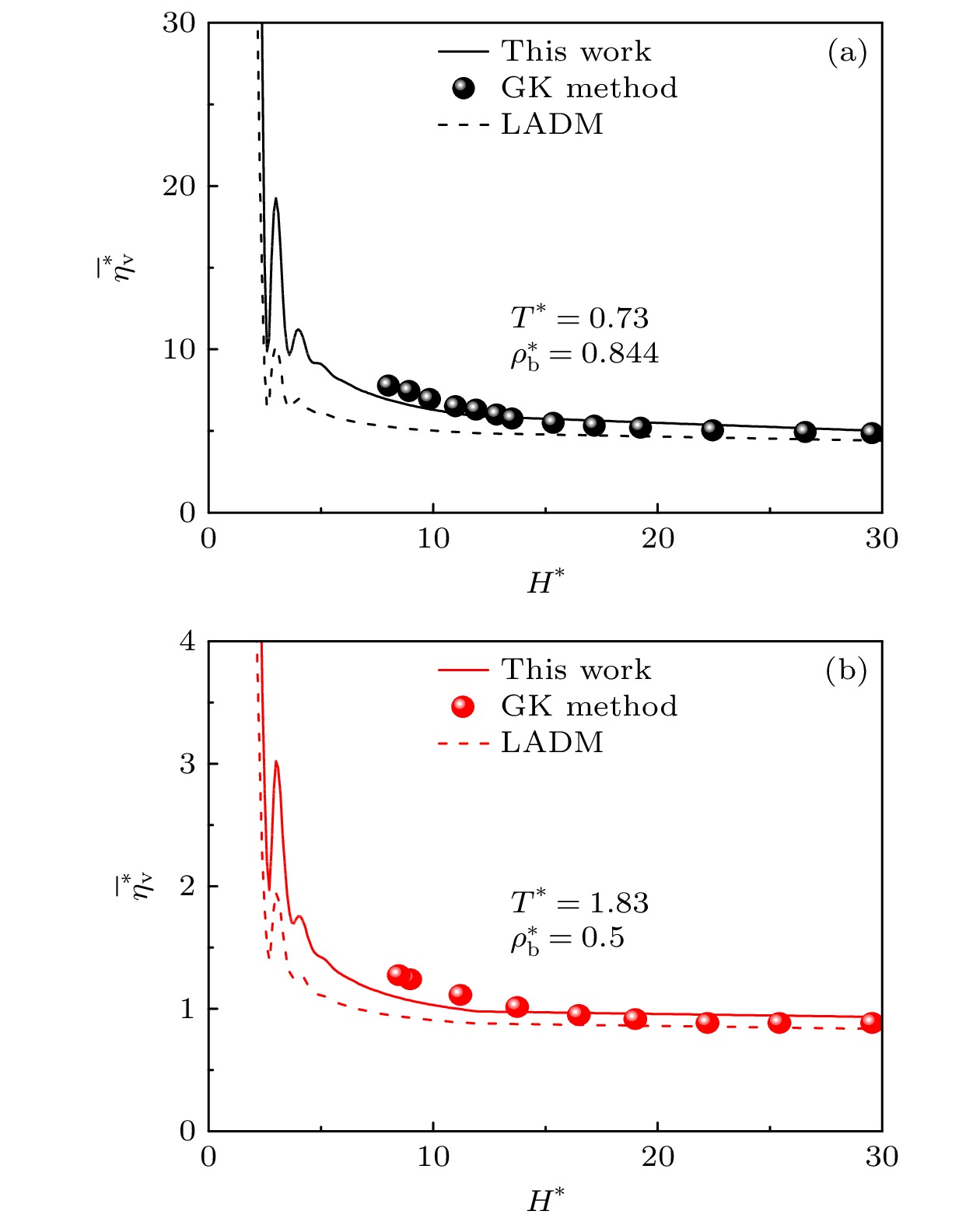

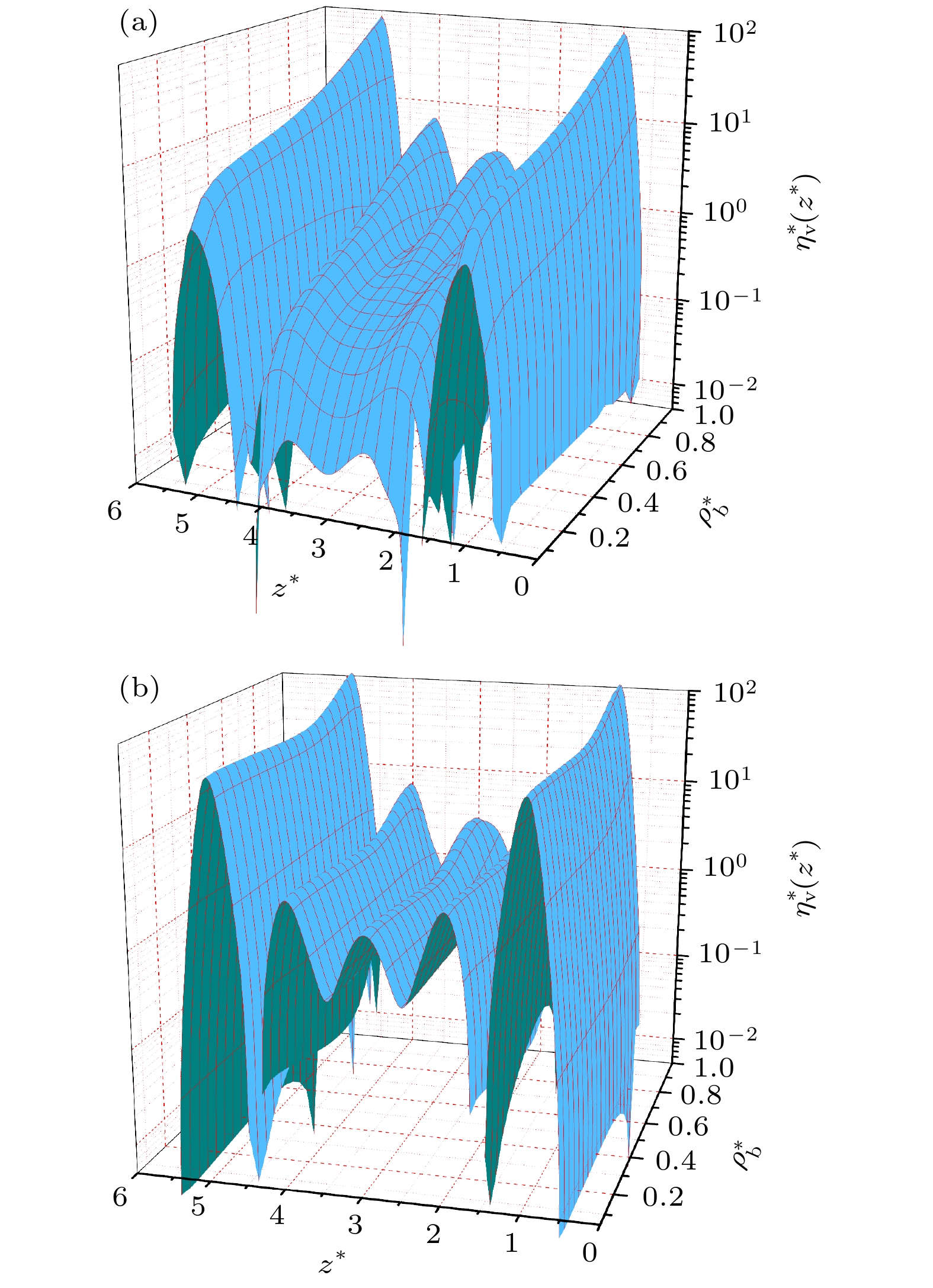

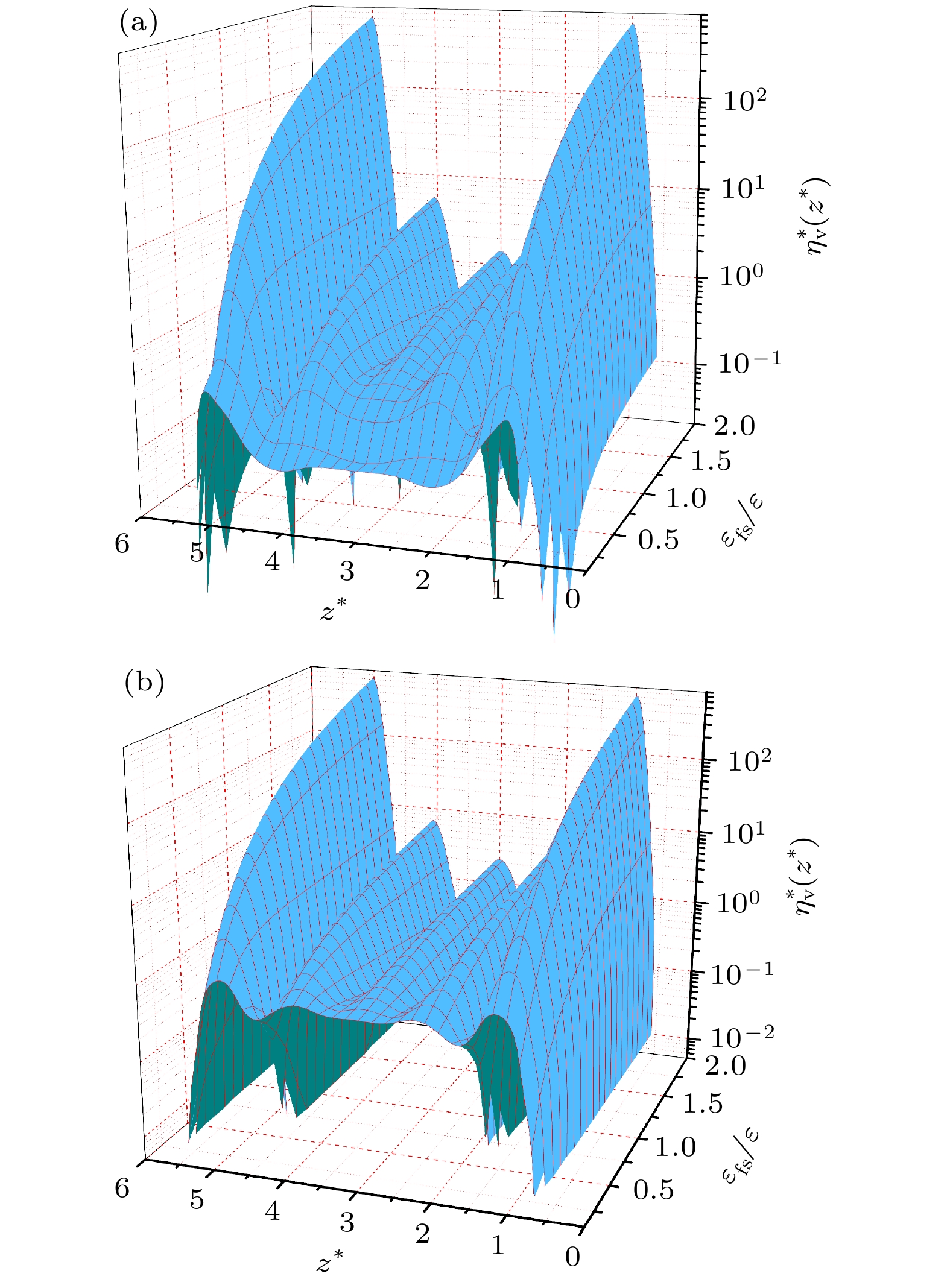

图 5 在$ {H}^{*}=6.0 $情况下, 体积黏度$ {\eta }_{{\mathrm{v}}}^{*}\left({z}^{*}\right) $随体密度的变化 (a) $ {T}^{*}=2.0 $; (b) $ {T}^{*}=1.0 $

Fig. 5. Influence of bulk density on the volume viscosity $ {\eta }_{{\mathrm{v}}}^{*}\left({z}^{*}\right) $ under the condition of $ {H}^{*}=6.0 $: (a) $ {T}^{*}=2.0; $ (b) $ {T}^{*}=1.0 $.

图 7 在$ {H}^{*}=6.0 $情况下, 体积黏度$ {\eta }_{{\mathrm{v}}}^{*}\left({z}^{*}\right) $随温度的变化 (a) $ {\rho }_{{\mathrm{b}}}^{*}=0.01; $ (b) $ {\rho }_{{\mathrm{b}}}^{*}=0.6 $.

Fig. 7. Influence of temperature on the volume viscosity $ {\eta }_{{\mathrm{v}}}^{*}\left({z}^{*}\right) $ under the condition of $ {H}^{*}=6.0: $ (a) $ {\rho }_{{\mathrm{b}}}^{*}=0.01 $; (b) $ {\rho }_{{\mathrm{b}}}^{*}=0.6 $.

图 9 在$ {T}^{*}=1.5 $和$ {\rho }_{{\mathrm{b}}}^{*}=0.8 $条件下, (a) 体积黏度$ {\eta }_{{\mathrm{v}}}^{*}\left({z}^{*}\right) $随缝宽的变化; (b) 比值$ {R}_{\eta }^{{\mathrm{p}}{\mathrm{o}}{\mathrm{r}}{\mathrm{e}}} $随缝宽的变化. 图(b)中虚线为同一条件下体相液态的实验结果[40]

Fig. 9. Influence of pore width on (a) the volume viscosity $ {\eta }_{{\mathrm{v}}}^{*}\left({z}^{*}\right) $ and (b) the ratio $ {R}_{\eta }^{{\mathrm{p}}{\mathrm{o}}{\mathrm{r}}{\mathrm{e}}} $, under the conditions of $ {T}^{*}=1.5 $ and $ {\rho }_{{\mathrm{b}}}^{*}=0.8 $. The dashed line in panel (b) denotes the experimental result[40] under the same conditions.

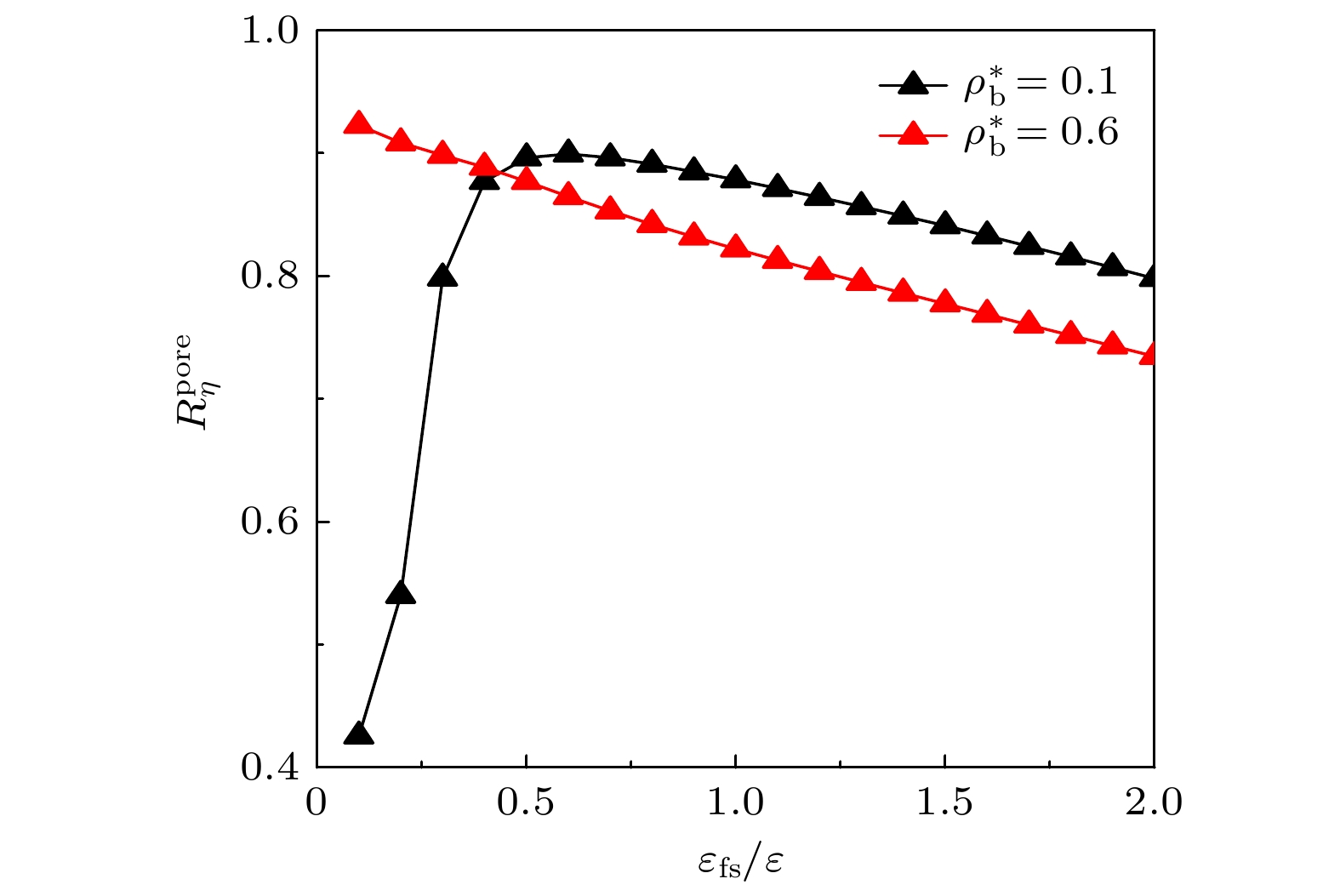

图 10 在$ {H}^{*}=6.0 $情况下, 体积黏度$ {\eta }_{{\mathrm{v}}}^{*}\left({z}^{*}\right) $随吸附势强度的变化 (a) $ {\rho }_{{\mathrm{b}}}^{*}=0.1 $; (b) $ {\rho }_{{\mathrm{b}}}^{*}=0.6 $

Fig. 10. Influence of adsorption strength on the volume viscosity $ {\eta }_{{\mathrm{v}}}^{*}\left({z}^{*}\right) $ under the condition of $ {H}^{*}=6.0 $: (a) $ {\rho }_{{\mathrm{b}}}^{*}= $$ 0.1 $; (b) $ {\rho }_{{\mathrm{b}}}^{*}=0.6 $.

-

[1] Stephan K, Lucas K D 1979 Viscosities of Dense Fluids (New York: Plenum

[2] Richardson S M 1989 Fluid Mechanics (New York: Hemisphere Publishing Corporation

[3] Dhont J K G 1996 An Introduction to Dynamics of Colloids (Amsterdam: Elsevier Science

[4] Cerbelaud M, Laganapan A M, Ala-Nissila T, Ferrandod R, Videcoq A 2017 Soft Matter 13 3909

Google Scholar

Google Scholar

[5] Zabaloy M S, Machado J M V, Macedo E A 2001 Int. J. Thermophys. 22 829

Google Scholar

Google Scholar

[6] Duque-Zumajo D, de la Torre J A, Español P 2020 J. Chem. Phys. 152 174108

Google Scholar

Google Scholar

[7] Zhang J F, Todd B D, Travis K P 2004 J. Chem. Phys. 121 10778

Google Scholar

Google Scholar

[8] 钱祖文 2012 61 134301

Google Scholar

Google Scholar

Qian Z W 2012 Acta Phys. Sin. 61 134301

Google Scholar

Google Scholar

[9] Stokes G G 1845 Trans. Cambridge Philos. Soc. 8 287

[10] Bhola S, Sengupta T K 2019 Phys. Fluids 31 096101

Google Scholar

Google Scholar

[11] Rahimzadeh A, Rutsch M, Kupnik M, Klitzing R 2021 Langmuir 37 5854

Google Scholar

Google Scholar

[12] Chen S, Wang X N, Wang J C, Wan M P, Li H, Chen S Y 2019 Phys. Fluids 31 085115

Google Scholar

Google Scholar

[13] Bhatia A B 1967 Ultrasonic Absorption: An Introduction to the Theory of Sound Absorption and Dispersion in Gases, Liquids, and Solids (New York: Oxford University Press

[14] Emanuel G 1990 Phys. Fluids A 2 2252

Google Scholar

Google Scholar

[15] Meier K, Laesecke A, Kabelac S 2005 J. Chem. Phys. 122 014513

Google Scholar

Google Scholar

[16] Zhang Y, Otani A, Maginn E J 2015 J. Chem. Theory Comput. 11 3537

Google Scholar

Google Scholar

[17] Sharma B, Kumar R, Gupta P, Pareek S, Singh A 2022 Phys. Fluids 34 057104

Google Scholar

Google Scholar

[18] Heyes D M, Pieprzyk S, Brańka A C 2022 J. Chem. Phys. 157 114502

Google Scholar

Google Scholar

[19] Hoover W G, Ladd A J C, Hickman R B, Holian B L 1980 Phys. Rev. A 21 1756

Google Scholar

Google Scholar

[20] Sharma B, Kumar R 2019 Phys. Rev. E 100 013309

Google Scholar

Google Scholar

[21] Palla P L, Pierleoni C, Ciccotti G 2008 Phys. Rev. E 78 021204

Google Scholar

Google Scholar

[22] Rah K, Eu B C 1999 Phys. Rev. Lett. 83 4566

Google Scholar

Google Scholar

[23] Okumura H, Yonezawa F 2002 J. Chem. Phys. 116 7400

Google Scholar

Google Scholar

[24] Gelb L D, Gubbins K E, Radhakrishnan R, Sliwinska-Bartkowiak M 1999 Rep. Prog. Phys. 62 1573

Google Scholar

Google Scholar

[25] Yu Y X, Gao G H, Wang X L 2006 J. Phys. Chem. B 110 14418

Google Scholar

Google Scholar

[26] Zhao S L, Liu Y, Chen X Q, Lu Y X, Liu H L, Hu Y 2015 Adv. Chem. Eng. 47 1

Google Scholar

Google Scholar

[27] Mittal J, Truskett T M, Errington J R, Hummer G 2008 Phys. Rev. Lett. 100 145901

Google Scholar

Google Scholar

[28] Banks H T, Hu S H, Kenz Z R 2011 Adv. Appl. Math. Mech. 3 1

Google Scholar

Google Scholar

[29] Bitsanis I, Vanderlick T K, Tirrell M, Davis H T 1988 J. Chem. Phys. 89 3152

Google Scholar

Google Scholar

[30] Hoang H, Galliero G 2012 Phys. Rev. E 86 021202

Google Scholar

Google Scholar

[31] Hoang H, Galliero G 2013 J. Phys. Condens. Matter 25 485001

Google Scholar

Google Scholar

[32] Heyes D M 1984 J. Chem. Soc. Faraday Trans. II 80 1363

Google Scholar

Google Scholar

[33] Zwanzig R, Mountain R D 1965 J. Chem. Phys. 43 4464

Google Scholar

Google Scholar

[34] Sun Z L, Kang Y S, Kang Y M 2019 Ind. Eng. Chem. Res. 58 15637

Google Scholar

Google Scholar

[35] Johnson J K, Zollweg J A, Gubbins K E 1993 Mol. Phys. 78 591

Google Scholar

Google Scholar

[36] Yu Y X, Wu J Z 2002 J. Chem. Phys. 117 10156

Google Scholar

Google Scholar

[37] Liu Y, Liu H L, Hu Y, Jiang J W 2010 J. Phys. Chem. B 114 2820

Google Scholar

Google Scholar

[38] Sun Z L, Kang Y S, Li S T 2022 J. Phys. Chem. B 126 8010

Google Scholar

Google Scholar

[39] Sun Z L, Kang Y S, Li S T 2023 Chem. Eng. Sci. 277 118847

Google Scholar

Google Scholar

[40] Goyal I, Zaheri A H M, Srivastava S, Tankeshwar K 2013 Phys. Chem. Liq. 55 595

Google Scholar

Google Scholar

[41] Jaeger F, Matar O K, Müller E A 2018 J. Chem. Phys. 148 174504

Google Scholar

Google Scholar

[42] Cowan J A, Leech J W 1981 Can. J. Phys. 59 1280

[43] Paeßens M 2003 J. Chem. Phys. 118 10287

Google Scholar

Google Scholar

计量

- 文章访问数: 3322

- PDF下载量: 64

- 被引次数: 0

下载:

下载: