-

液滴撞击壁面是一种常见的现象, 减少撞击过程中液滴在壁面的驻留时间在很多应用中非常重要. 本文在对液滴撞击加热壁面的动力学过程的研究中, 发现了一种能够大幅减少液滴驻留时间的弹起模式, 即雾化弹起模式. 与液滴撞击壁面过程中的回缩弹起模式相比, 雾化弹起模式的液滴驻留时间能减少约40%. 与其他试图减少液滴驻留时间的手段相比, 本文中驻留时间的减少仅需加热壁面, 因此该方法容易实施而且非常可靠. 最后, 本文对雾化弹起模式下液滴驻留时间减少的机理进行了讨论, 提出了一个针对膜态沸腾区域雾化弹起模式发生条件的简化理论模型, 并得出了膜态沸腾区域液滴从雾化弹起模式到回缩弹起模式过渡边界的幂次关系, 该幂次关系与实验数据吻合良好. 此外, 该理论模型也能解释过渡沸腾区域两种弹起模式的过渡边界的变化规律.

-

关键词:

- 液滴撞击 /

- Leidenfrost效应 /

- 驻留时间 /

- 反弹

The impact of droplets on surfaces is a ubiquitous phenomenon, and reducing the droplet residence time is the aim of many studies because of the potential applications in self-cleaning, anti-icing, corrosion resistance, etc. This study identifies a mode of droplet bouncing (bouncing-with-spray) that can reduce the residence time significantly. And compared with the way of using complex microstructures on the substrate employed in previous studies, simply heating the substrate to reduce the residence time is novel and simple. The dimensionless residence time decreases down to about 40% compared with that from the traditional retraction-bouncing mode. The reduction in the residence time is due to the burst of vapor bubbles in the liquid film, which results in holes forming in the liquid film and consequently the liquid film recoiling from the holes. The reduction in the recoiling distance leads to the reduction in the recoiling time. Then a simplified theoretical model with considering the energy balance and the critical condition of the bubble burst is proposed. According to this theoretical model, a scaling law is proposed for the transition boundary between the retraction-bouncing mode and the bouncing-with-spray mode in the film boiling regime, and it accords well with our experimental data. This model can also explain the transition boundary between these two modes in the transition boiling regime.-

Keywords:

- droplet impact /

- Leidenfrost effect /

- residence time /

- bouncing

[1] 毕菲菲, 郭亚丽, 沈胜强, 陈觉先, 李熠桥 2012 61 184702

Google Scholar

Google Scholar

Bi F F, Guo Y L, Shen S Q, Chen J X, Li Y Q 2012 Acta Phys. Sin. 61 184702

Google Scholar

Google Scholar

[2] 马理强, 常建忠, 刘汉涛, 刘谋斌 2012 61 054701

Google Scholar

Google Scholar

Ma L Q, Chang J Z, Liu H T, Liu M B 2012 Acta Phys. Sin. 61 054701

Google Scholar

Google Scholar

[3] 沈胜强, 张洁珊, 梁刚涛 2015 64 134704

Google Scholar

Google Scholar

Shen S Q, Zhang J S, Liang G T 2015 Acta Phys. Sin. 64 134704

Google Scholar

Google Scholar

[4] Quéré D 2013 Annu. Rev. Fluid Mech. 45 197

Google Scholar

Google Scholar

[5] Bernardin J D, Stebbins C J, Mudawar I 1997 Int. J. Heat Mass Transfer 40 247

Google Scholar

Google Scholar

[6] Castanet G, Lienart T, Lemoine F 2009 Int. J. Heat Mass Transfer 52 670

Google Scholar

Google Scholar

[7] Bertola V 2015 Int. J. Heat Mass Transfer 85 430

Google Scholar

Google Scholar

[8] Breitenbach J, Roisman I V, Tropea C 2017 Phy. Rev. Fluids 2 074301

Google Scholar

Google Scholar

[9] Liang G T, Mudawar I 2017 Int. J. Heat Mass Transfer 106 103

Google Scholar

Google Scholar

[10] Tran T, Staat H J J, Prospeeretti A, Sun C, Lohse D 2012 Phys. Rev. Lett. 108 036101

Google Scholar

Google Scholar

[11] Nair H, Staat H J J, Tran T, van Houselt A, Prosperetti A, Lohse D, Sun C 2014 Soft Matter 10 2102

Google Scholar

Google Scholar

[12] Tran T, Staat H J J, Susarrey-Arce A, Foertsch T C, van Houselt A, Gardeniers H J G E, Prosperetti A, Lohse D, Sun C 2013 Soft Matter 9 3272

Google Scholar

Google Scholar

[13] Shirota M, van Limbeek M A J, Sun C, Prosperetti A, Lohse D 2016 Phys. Rev. Lett. 116 064501

Google Scholar

Google Scholar

[14] van Limbeek M A J, Hoefnagels P B J, Sun C, Lohse D 2017 Soft Matter 13 7514

Google Scholar

Google Scholar

[15] Richard D, Clanet C, Quéré D 2002 Nature 417 811

[16] Bird J C, Dhiman R, Kwon H M, Varanasi K K 2013 Nature 503 385

Google Scholar

Google Scholar

[17] Liu Y, Moevius L, Xu X, Qian T, Yeomans J M, Wang Z 2014 Nat. Phys. 10 515

Google Scholar

Google Scholar

[18] Liu Y, Andrew M, Li J, Yeomans J M, Wang Z 2015 Nat. Commun. 6 10034

Google Scholar

Google Scholar

[19] Yun S 2018 Soft Matter 14 4946

Google Scholar

Google Scholar

[20] Roisman I V, Horvat K, Tropea C 2006 Phys. Fluids 18 102104

Google Scholar

Google Scholar

[21] Rayleigh L 1879 Proc. Roy. Soc. London 29 71

Google Scholar

Google Scholar

[22] Biance A L, Chevy F, Clanet C, Lagubeau G, Quéré D 2006 J. Fluid Mech. 554 47

Google Scholar

Google Scholar

[23] Liang G T, Shen S Q, Guo Y L, Zhang J L 2016 Int. J. Heat Mass Transfer 100 48

Google Scholar

Google Scholar

[24] Biance A L, Pirat C, Ybert C 2011 Phys. Fluids 23 022104

Google Scholar

Google Scholar

[25] Eggers J, Fontelos M A, Josserand C, Zaleski S 2010 Phys. Fluids 22 062101

Google Scholar

Google Scholar

[26] Fedorchenko A I, Wang A B, Wang Y H 2005 Phys. Fluids 17 093104

Google Scholar

Google Scholar

[27] Labeish V G 1994 Exp. Therm. Fluid Sci. 8 181

Google Scholar

Google Scholar

[28] Antonimi C, Bernagozzi I, Jung S, Poilikakos D, Marengo M 2013 Phys. Rev. Lett. 111 014501

Google Scholar

Google Scholar

-

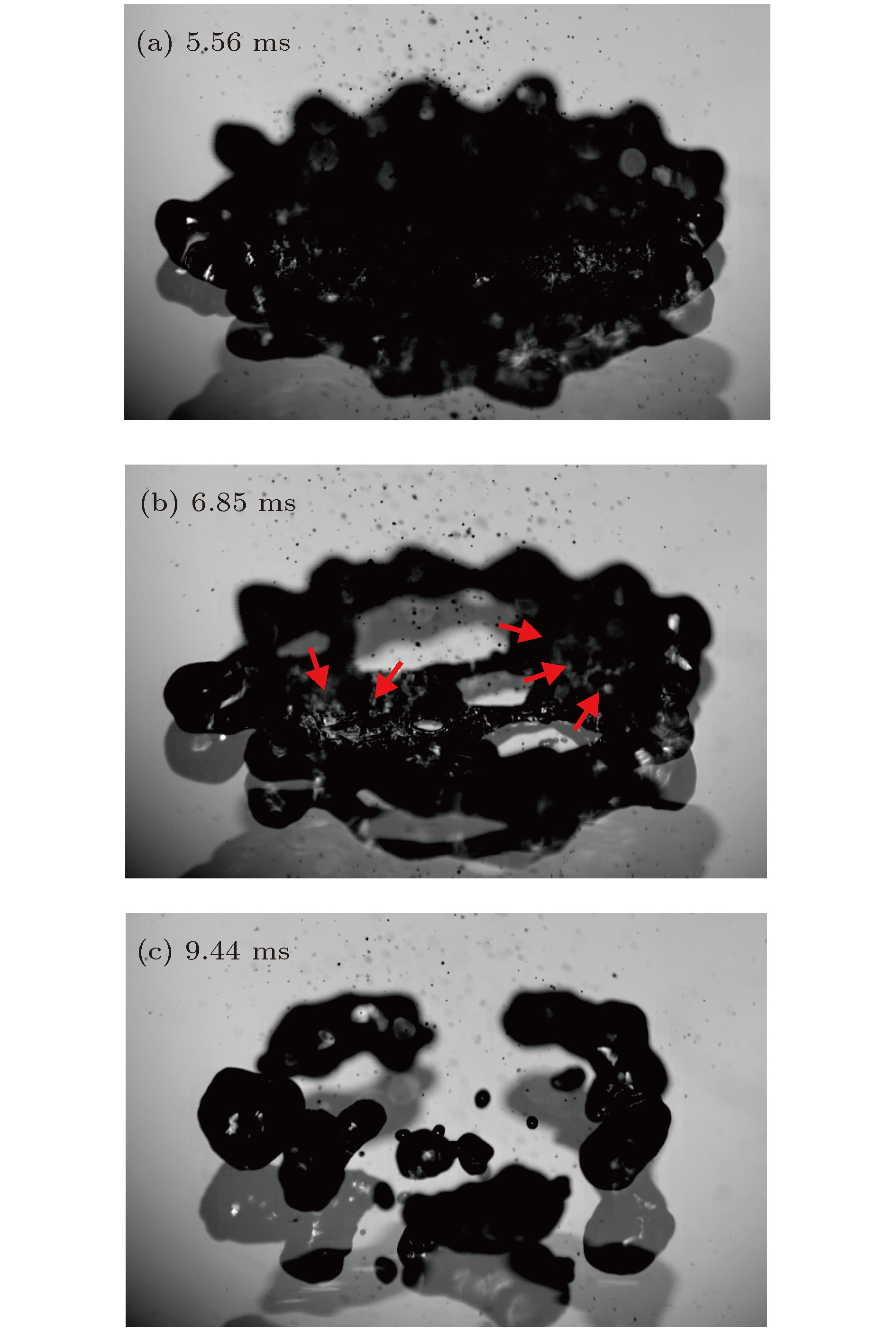

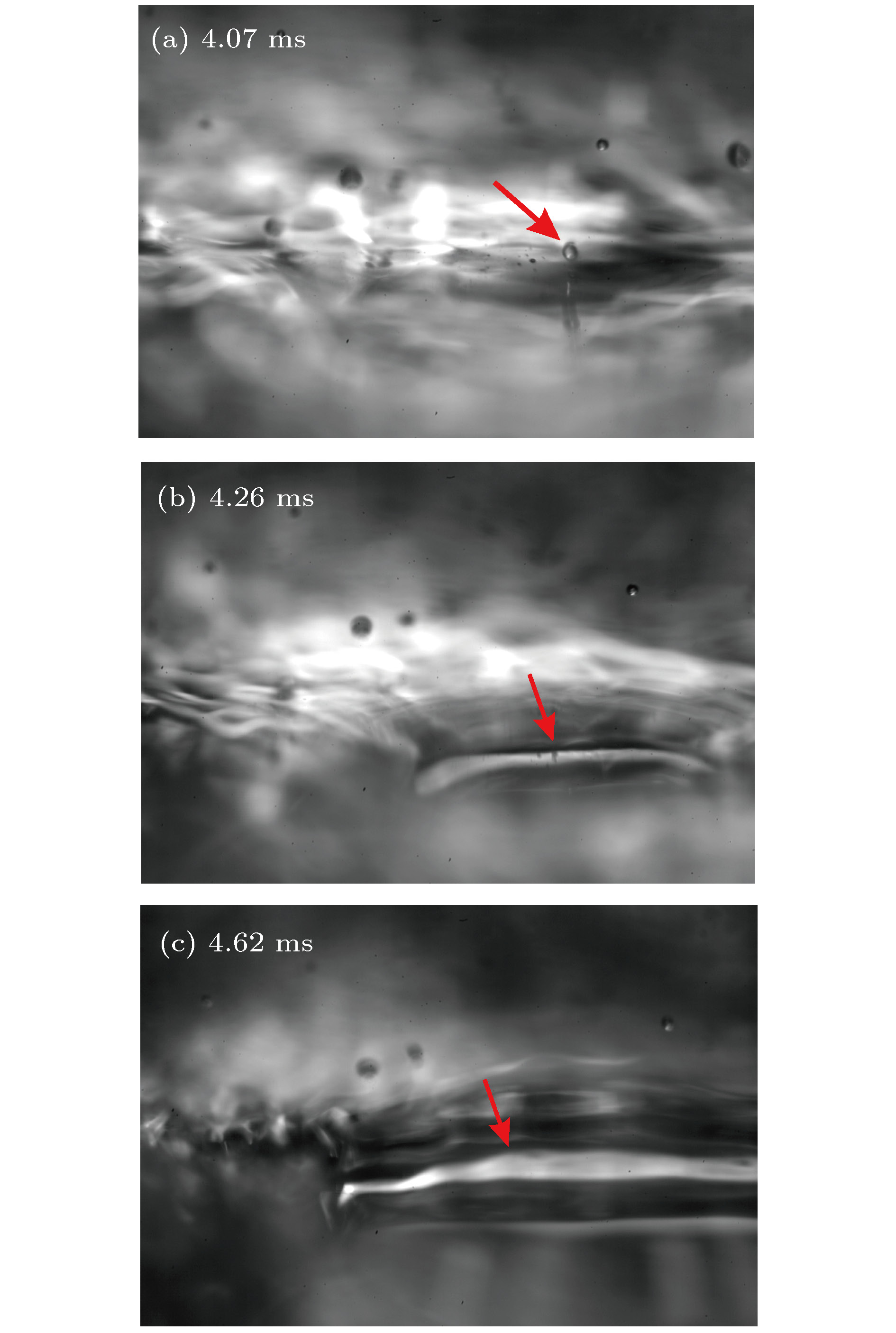

图 2 在3个沸腾区域水滴撞击加热壁面的形貌图, 子液滴的喷射如红色圆圈及箭头所示 (a)核态沸腾区域,

$We = 37$ ,$T = 260{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ ; (b)过渡沸腾区域回缩弹起模式,$We = 37$ ,$T = 380{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ ; (c)过渡沸腾区域雾化弹起模式, 其中(c1)为$We = 69$ ,$T = 380{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ , (c2)为$We = 105$ ,$T = 380{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ ; (d)膜态沸腾区域回缩弹起模式, 其中(d1)为$We = 25$ ,$T = 400{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ , (d2)为$We = 25$ ,$T = 440{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ ; (e)膜态沸腾区域雾化弹起模式, 其中(e1)为$We = 60$ ,$T = 440{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ , (e2)为$We = 129$ ,$T = 440{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ Fig. 2. Morphologies of water droplet impacting on heated surfaces in three boiling regimes, the red circles and arrows highlight the spray-like ejection of tiny droplets: (a) Nucleate boiling,

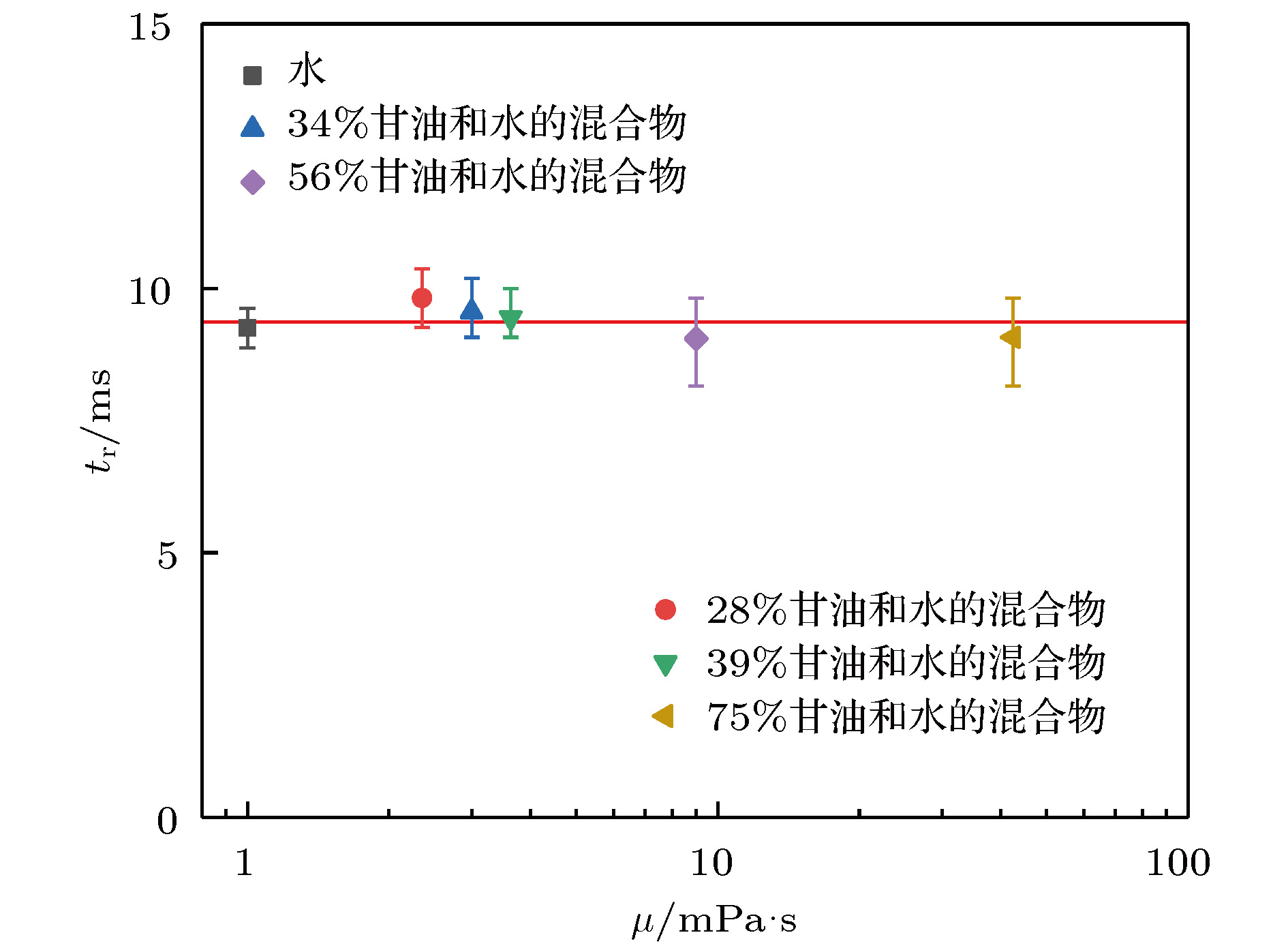

$We = 37$ and$T = 260{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ ; (b) retraction-bouncing mode in transition boiling regime,$We = 37$ and$T = 380{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ ; (c) bouncing-with-spray mode in transition boiling regime,$We = 69$ and$T = 380{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ for (c1), and$We = 105$ and$T = 380{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ for (c2); (d) retraction-bouncing mode in film boiling regime,$We = 25$ and$T = 400{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ for (d1), and$We = 25$ and$T = 440{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ for (d2); (e) bouncing-with-spray mode in film boiling regime,$We = 60$ and$T = 440{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ for (e1), and$We = 129$ and$T = 440{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} ^\circ {\rm C}$ for (e2).图 3 液体黏度对雾化弹起模式下驻留时间的影响(液滴直径为2.8 mm, 撞击速度为

$1.2{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rm m} \cdot {{\rm s}^{{\rm - 1}}}$ )Fig. 3. Effect of liquid viscosity on the residence time of the bouncing-with-spray mode. The droplet diameter is 2.8 mm, and the impact velocity is

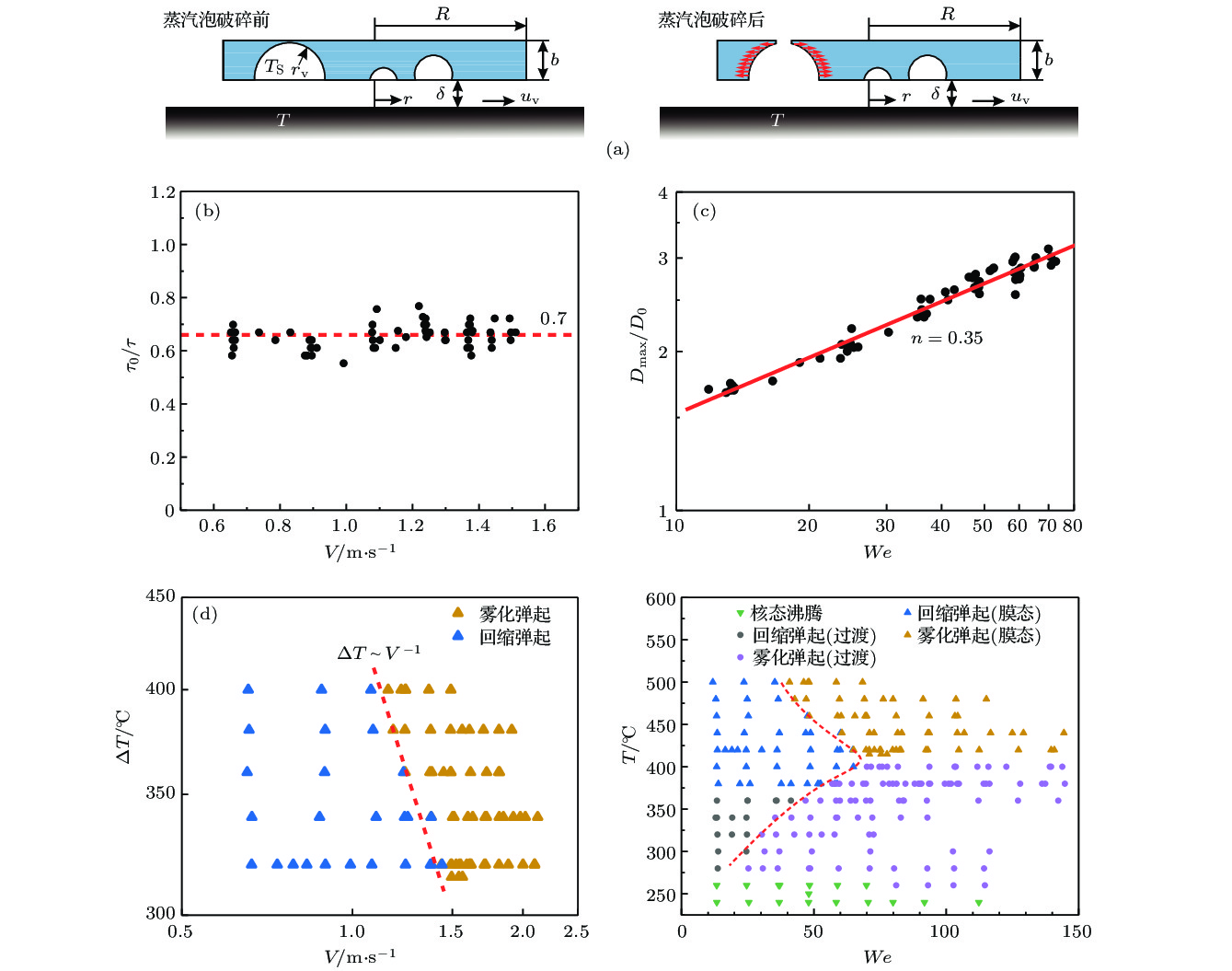

$1.2{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rm m} \cdot {{\rm s}^{{\rm - 1}}}$ .图 7 (a)蒸汽泡破碎理论模型的示意图; (b)采用液滴自由振荡周期无量纲化后的液滴最大铺展时间; (c)对数坐标下膜态沸腾区域水滴的无量纲最大铺展直径和撞击韦伯数的关系图,

${{{D_{\max }}} / {{D_0}}} \sim W{e^n}$ ; (d)对数坐标下水滴在膜态沸腾区域由回缩弹起到雾化弹起模式过渡的$\Delta T \sim {V^{ - 1}}$ 边界线, 液滴直径为2.2 mm; (e)水滴撞击加热硅片的相图及从回缩弹起到雾化弹起模式下的过渡, 图中红色虚线为示意, 液滴直径为2.2 mm, “过渡”为过渡腾区域, “膜态”指膜态沸腾区域Fig. 7. (a) Schematic diagram for the theoretical model for the burst of vapor bubbles; (b) the time of maximum spreading diameter of water droplets normalized by droplet free oscillation period; (c) log-log plot for the normalized maximal spreading diameter of water droplets versus We in the film boiling regime, showing

${{{D_{\max }}} / {{D_0}}} \sim W{e^n}$ ; (d) log-log plot for$\Delta T \sim {V^{ - 1}}$ boundary line between the retraction-bouncing mode and the bouncing-with-spray mode in the film boiling regime for water droplets, the droplet diameter is 2.2 mm; (e) regime map for a water droplet impacting on a heated silicon wafer and the transition between the retraction-bouncing mode and the bouncing-with-spray mode, the red dashed line is only for eye guidance, the droplet diameter is 2.2 mm.表 1 本实验中不同液体物性参数表

Table 1. Properties of the liquids used in this study.

液体种类 密度$\rho {\rm /kg} \cdot {{\rm m}^{{\rm - 3}}}$ 表面张力$\sigma /{\rm mN} \cdot {{\rm m}^{ - 1}}$ 动力黏度$\mu /{\rm mPa} \cdot {\rm s}$ 汽化潜热$\ell /{\rm kJ} \cdot {\rm k}{{\rm g}^{ - 1}}$ 水 998 72 1.00 2257 水 + 甘油(28 wt%) 1068 70 2.35 水 + 甘油(34 wt%) 1083 70 3.00 水 + 甘油(39 wt%) 1097 70 3.63 水 + 甘油(56 wt%) 1143 68 9.00 水 + 甘油(75 wt%) 1195 66 42.47 乙醇 790 22 1.07 853 -

[1] 毕菲菲, 郭亚丽, 沈胜强, 陈觉先, 李熠桥 2012 61 184702

Google Scholar

Google Scholar

Bi F F, Guo Y L, Shen S Q, Chen J X, Li Y Q 2012 Acta Phys. Sin. 61 184702

Google Scholar

Google Scholar

[2] 马理强, 常建忠, 刘汉涛, 刘谋斌 2012 61 054701

Google Scholar

Google Scholar

Ma L Q, Chang J Z, Liu H T, Liu M B 2012 Acta Phys. Sin. 61 054701

Google Scholar

Google Scholar

[3] 沈胜强, 张洁珊, 梁刚涛 2015 64 134704

Google Scholar

Google Scholar

Shen S Q, Zhang J S, Liang G T 2015 Acta Phys. Sin. 64 134704

Google Scholar

Google Scholar

[4] Quéré D 2013 Annu. Rev. Fluid Mech. 45 197

Google Scholar

Google Scholar

[5] Bernardin J D, Stebbins C J, Mudawar I 1997 Int. J. Heat Mass Transfer 40 247

Google Scholar

Google Scholar

[6] Castanet G, Lienart T, Lemoine F 2009 Int. J. Heat Mass Transfer 52 670

Google Scholar

Google Scholar

[7] Bertola V 2015 Int. J. Heat Mass Transfer 85 430

Google Scholar

Google Scholar

[8] Breitenbach J, Roisman I V, Tropea C 2017 Phy. Rev. Fluids 2 074301

Google Scholar

Google Scholar

[9] Liang G T, Mudawar I 2017 Int. J. Heat Mass Transfer 106 103

Google Scholar

Google Scholar

[10] Tran T, Staat H J J, Prospeeretti A, Sun C, Lohse D 2012 Phys. Rev. Lett. 108 036101

Google Scholar

Google Scholar

[11] Nair H, Staat H J J, Tran T, van Houselt A, Prosperetti A, Lohse D, Sun C 2014 Soft Matter 10 2102

Google Scholar

Google Scholar

[12] Tran T, Staat H J J, Susarrey-Arce A, Foertsch T C, van Houselt A, Gardeniers H J G E, Prosperetti A, Lohse D, Sun C 2013 Soft Matter 9 3272

Google Scholar

Google Scholar

[13] Shirota M, van Limbeek M A J, Sun C, Prosperetti A, Lohse D 2016 Phys. Rev. Lett. 116 064501

Google Scholar

Google Scholar

[14] van Limbeek M A J, Hoefnagels P B J, Sun C, Lohse D 2017 Soft Matter 13 7514

Google Scholar

Google Scholar

[15] Richard D, Clanet C, Quéré D 2002 Nature 417 811

[16] Bird J C, Dhiman R, Kwon H M, Varanasi K K 2013 Nature 503 385

Google Scholar

Google Scholar

[17] Liu Y, Moevius L, Xu X, Qian T, Yeomans J M, Wang Z 2014 Nat. Phys. 10 515

Google Scholar

Google Scholar

[18] Liu Y, Andrew M, Li J, Yeomans J M, Wang Z 2015 Nat. Commun. 6 10034

Google Scholar

Google Scholar

[19] Yun S 2018 Soft Matter 14 4946

Google Scholar

Google Scholar

[20] Roisman I V, Horvat K, Tropea C 2006 Phys. Fluids 18 102104

Google Scholar

Google Scholar

[21] Rayleigh L 1879 Proc. Roy. Soc. London 29 71

Google Scholar

Google Scholar

[22] Biance A L, Chevy F, Clanet C, Lagubeau G, Quéré D 2006 J. Fluid Mech. 554 47

Google Scholar

Google Scholar

[23] Liang G T, Shen S Q, Guo Y L, Zhang J L 2016 Int. J. Heat Mass Transfer 100 48

Google Scholar

Google Scholar

[24] Biance A L, Pirat C, Ybert C 2011 Phys. Fluids 23 022104

Google Scholar

Google Scholar

[25] Eggers J, Fontelos M A, Josserand C, Zaleski S 2010 Phys. Fluids 22 062101

Google Scholar

Google Scholar

[26] Fedorchenko A I, Wang A B, Wang Y H 2005 Phys. Fluids 17 093104

Google Scholar

Google Scholar

[27] Labeish V G 1994 Exp. Therm. Fluid Sci. 8 181

Google Scholar

Google Scholar

[28] Antonimi C, Bernagozzi I, Jung S, Poilikakos D, Marengo M 2013 Phys. Rev. Lett. 111 014501

Google Scholar

Google Scholar

计量

- 文章访问数: 10558

- PDF下载量: 152

- 被引次数: 0

下载:

下载: