-

Organic-inorganic hybrid perovskite solar cell devices have received wide attention because of their high efficiency, and interface problem is one of the key problems in the preparation of perovskite solar cells. An efficient double-layered ethylene diamine tetraacetic acid (EDTA)/SnO2 composite structure, the ultrathin EDTA layer in contact with ITO electrode and an SnO2 layer interfaced with the perovskite, is developed as an electron-transport layer (ETL) in the preparation of perovskite solar cells. It is interesting that the surface morphology of the top SnO2 side of the composite ETL can be finely adjusted by tuning the underneath EDTA layer. These control the nucleation process in crystallization of the perovskite layer and adjust carrier extraction process between the electron transport and perovskite layers. High performance perovskite solar cells having a certified power conversion efficiency of 20.2% with negligible hysteresis are achieved.

-

Keywords:

- perovskite solar cells /

- interface modification /

- EDTA /

- crystallization

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] https://www.nrel.gov/pv/cell-efficiency.html [2022-2-14]

[3] Snaith H J, Abate A, Ball J M, Eperon G E, Leijtens T, Noel N K, Stranks S D, Wang J T-W, Wojciechowski K, Zhang W 2014 J. Phys. Chem. Lett. 5 1511

Google Scholar

Google Scholar

[4] Kim H S, Jang I H, Ahn N, Choi M, Guerrero A, Bisquert J, Park N G 2015 J. Phys. Chem. Lett. 6 4633

Google Scholar

Google Scholar

[5] Dong Q, Wang M, Zhang Q, Chen F, Zhang S, Bian J, Ma T, Wang L, Shi Y 2017 Nano Energy 38 358

Google Scholar

Google Scholar

[6] Li W, Zhang W, Van Reenen S, Sutton R J, Fan J, Haghighirad A A, Johnston M B, Wang L, Snaith H J 2016 Energy Environ. Sci. 9 490

Google Scholar

Google Scholar

[7] Yang J, Siempelkamp B D, Mosconi E, De Angelis F, Kelly T L 2015 Chem. Mater. 27 4229

Google Scholar

Google Scholar

[8] Dong Q, Shi Y, Wang K, Li Y, Wang S, Zhang H, Xing Y, Du Y, Bai X, Ma T 2015 J. Phys. Chem. C 119 10212

[9] Jiang Q, Chu Z, Wang P, Yang X, Liu H, Wang Y, Yin Z, Wu J, Zhang X, You J 2017 Adv. Mater. 29 1703852

Google Scholar

Google Scholar

[10] Sun M, Liang C, Zhang H, Ji C, Sun F, You F, Jing X, He Z 2018 J. Mater. Chem. A 6 24793

Google Scholar

Google Scholar

[11] Jiang Q, Zhao Y, Zhang X, Yang X, Chen Y, Chu Z, Ye Q, Li X, Yin Z, You J 2019 Nat. Photonics 13 460

Google Scholar

Google Scholar

[12] Jiang Q, Zhang L, Wang H, Yang X, Meng J, Liu H, Yin Z, Wu J, Zhang X, You J 2016 Nat. Energy 2 16177

[13] Yang G, Tao H, Qin P, Ke W, Fang G 2016 J. Mater. Chem. A 4 3970

Google Scholar

Google Scholar

[14] Wang F, Zhang Y, Yang M, Du J, Xue L, Yang L, Fan L, Sui Y, Yang J, Zhang X 2019 Nano Energy 63 103825

Google Scholar

Google Scholar

[15] Ke W, Xiao C, Wang C, Saparov B, Duan H S, Zhao D, Xiao Z, Schulz P, Harvey S P, Liao W, Meng W, Yu Y, Cimaroli A J, Jiang C-S, Zhu K, Al-Jassim M, Fang G, Mitzi D B, Yan Y 2016 Adv. Mater. 28 5214

Google Scholar

Google Scholar

[16] Yang G, Wang C, Lei H, Zheng X, Qin P, Xiong L, Zhao X, Yan Y, Fang G 2017 J. Mater. Chem. A 5 1658

Google Scholar

Google Scholar

[17] Ma J, Yang G, Qin M, Zheng X, Lei H, Chen C, Chen Z, Guo Y, Han H, Zhao X, Fang G 2017 Adv. Sci. 4 1700031

Google Scholar

Google Scholar

[18] Li N, Niu X, Pei F, Liu H, Cao Y, Liu Y, Xie H, Gao Y, Chen Q, Mo F, Zhou H 2019 Sol. RRL 4 1900217

[19] Hafer E, Holzgrabe U, Kraus K, Adams K, Hook J M, Diehl B 2020 Magnetic Resonance in Chemistry 58 653

Google Scholar

Google Scholar

[20] Li X, Liu X, Zhang W, Wang H-Q, Fang J 2017 Chem. Mater. 29 4176

Google Scholar

Google Scholar

[21] Yang D, Yang R, Wang K, Wu C, Zhu X, Feng J, Ren X, Fang G, Priya S, Liu S 2018 Nat. Commun. 9 3239

Google Scholar

Google Scholar

[22] Li X, Zhang W, Wang X, Wu Y, Gao F, Fang J 2015 J. Mater. Chem. A 3 504

Google Scholar

Google Scholar

[23] Li X, Zhang W, Wang X, Gao F, Fang J 2014 ACS Appl. Mater. Interfaces 6 20569

Google Scholar

Google Scholar

[24] Pham H T, Duong T, Rickard W D A, Kremer F, Weber K J, Wong-Leung J 2019 J. Phys. Chem. C 123 26718

Google Scholar

Google Scholar

[25] Xie L Q, Chen L, Nan Z A, Lin H X, Wang T, Zhan D P, Yan J W, Mao B W, Tian Z Q 2017 J. Am. Chem. Soc. 139 3320

Google Scholar

Google Scholar

[26] Turren-Cruz S-H, Hagfeldt A, Saliba M 2018 Science 362 449

Google Scholar

Google Scholar

[27] Warren B E 1990 X-Ray Diffraction (Second Edition) (New York: Dover Publication)

[28] Guo Z, He Z, Sun M, Zhang H, Xu Y, Li X, Liang C, Jing X 2018 Polymer 153 398

Google Scholar

Google Scholar

[29] Mitchell G R, Windle A H 1982 Polymer 23 1269

Google Scholar

Google Scholar

[30] Zhao L, Li Q, Hou C-H, Li S, Yang X, Wu J, Zhang S, Hu Q, Wang Y, Zhang Y, Jiang Y, Jia S, Shyue J-J, Russell T P, Gong Q, Hu X, Zhu R 2022 J. Am. Chem. Soc. 144 1700

Google Scholar

Google Scholar

[31] Tauc J 1968 Mater. Res. Bull. 3 37

Google Scholar

Google Scholar

[32] Son D-Y, Lee J-W, Choi Y J, Jang I-H, Lee S, Yoo P J, Shin H, Ahn N, Choi M, Kim D, Park N-G 2016 Nat. Energy 1 16081

Google Scholar

Google Scholar

[33] Kim M, Kim G-H, Lee T K, Choi I W, Choi H W, Jo Y, Yoon Y J, Kim J W, Lee J, Huh D, Lee H, Kwak S K, Kim J Y, Kim D S 2019 Joule 3 2179

Google Scholar

Google Scholar

[34] Chen S, Wen X, Huang S, Huang F, Cheng Y-B, Green M, Ho-Baillie A 2017 Sol. RRL 1 1600001

Google Scholar

Google Scholar

-

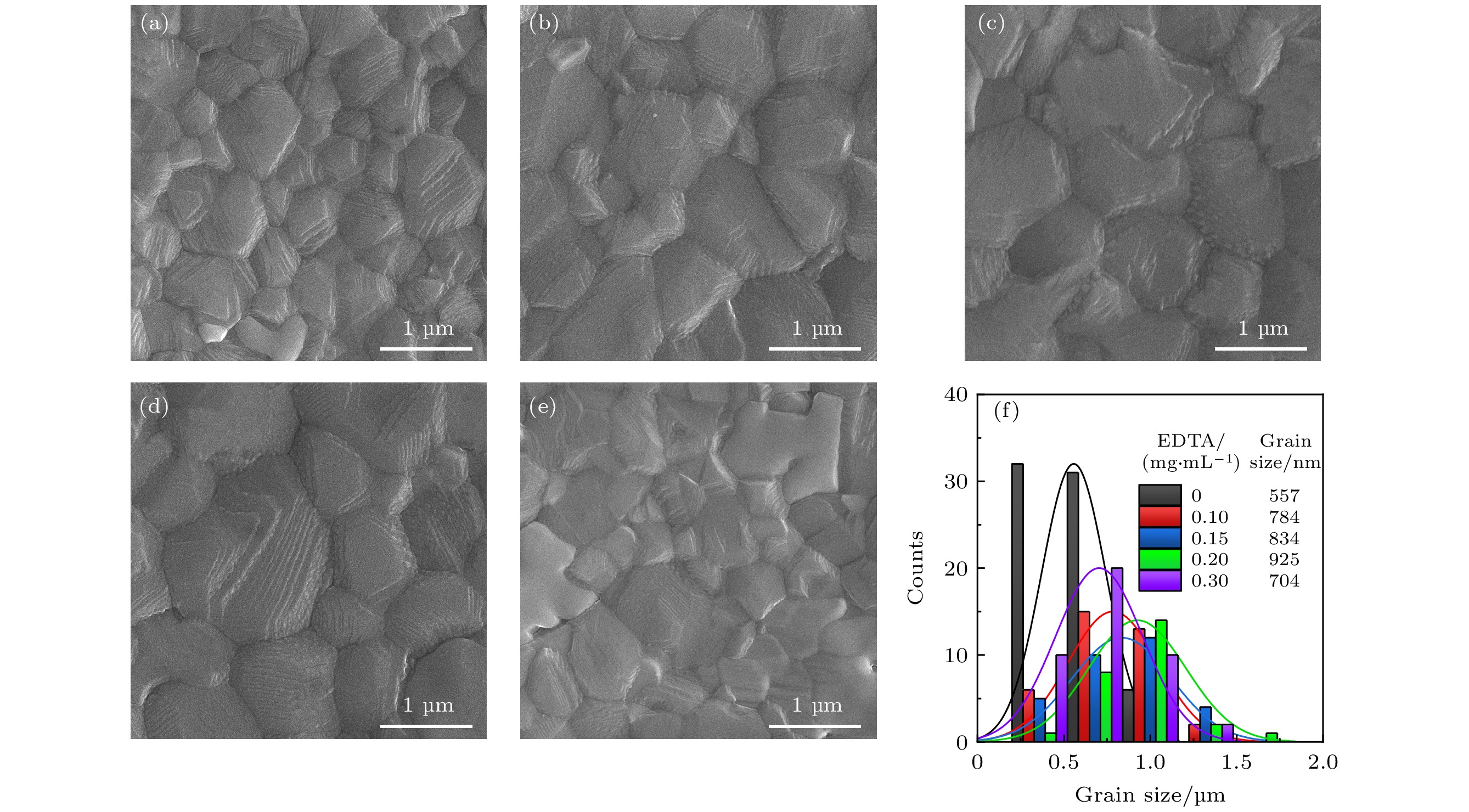

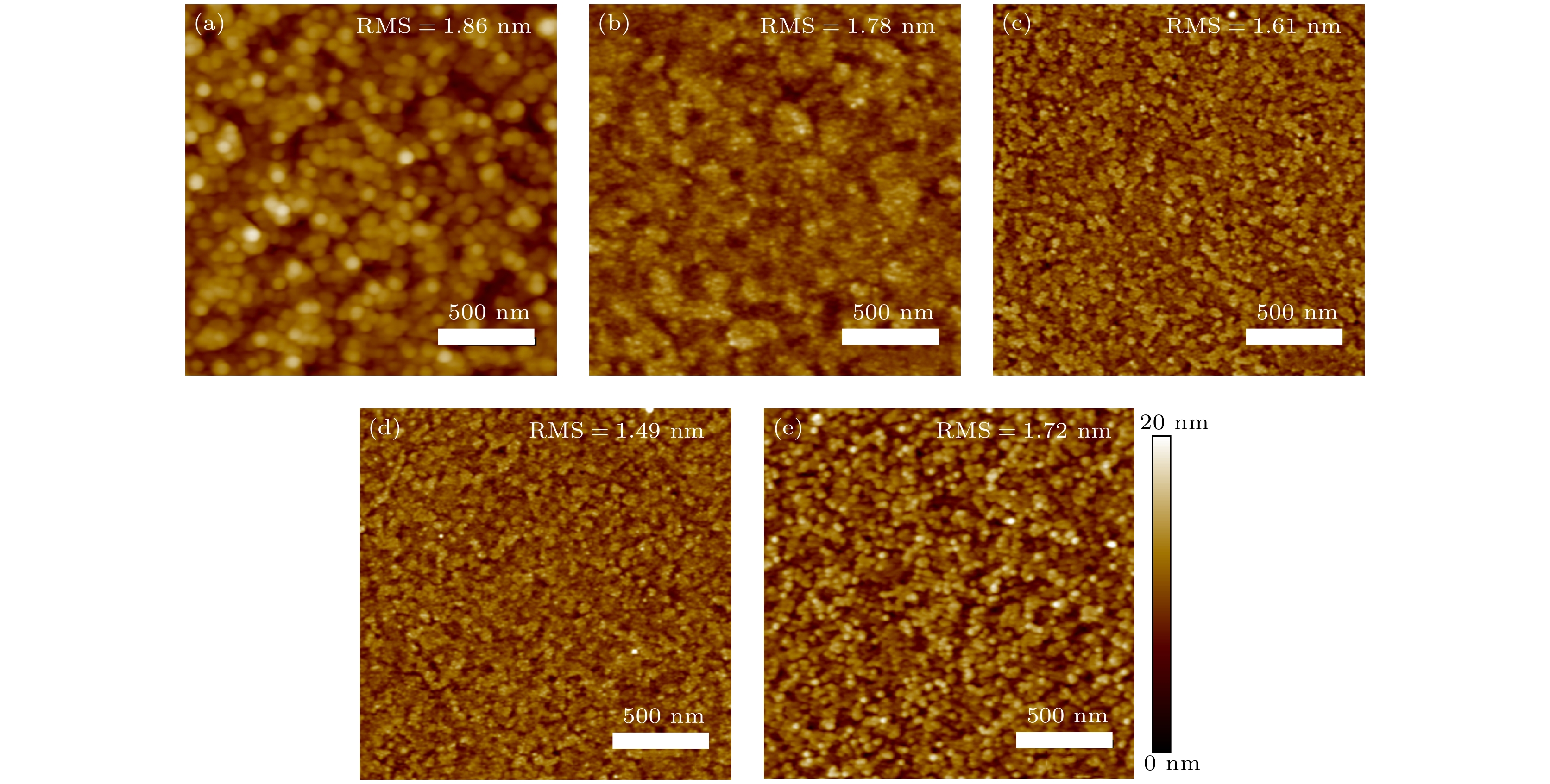

图 3 在不同EDTA溶液浓度的双层EDTA/SnO2复合ETL上制备的钙钛矿薄膜样品的SEM图像 (a) 无EDTA (b) 0.1 mg/mL (c) 0.15 mg/mL (d) 0.2 mg/mL (e) 0.3 mg/mL. (f)使用Image-Pro软件根据(a)—(e)进行计算得出的粒径分布

Figure 3. SEM top surface images of perovskite film specimens fabricated on double-layered EDTA/SnO2 composite ETLs with different EDTA precursors: (a) No EDTA; (b) 0.1 mg/mL; (c) 0.15 mg/mL; (d) 0.2 mg/mL; (e) 0.3 mg/mL; (f) particle size distribution calculated according to (a)–(e) using Image-Pro software.

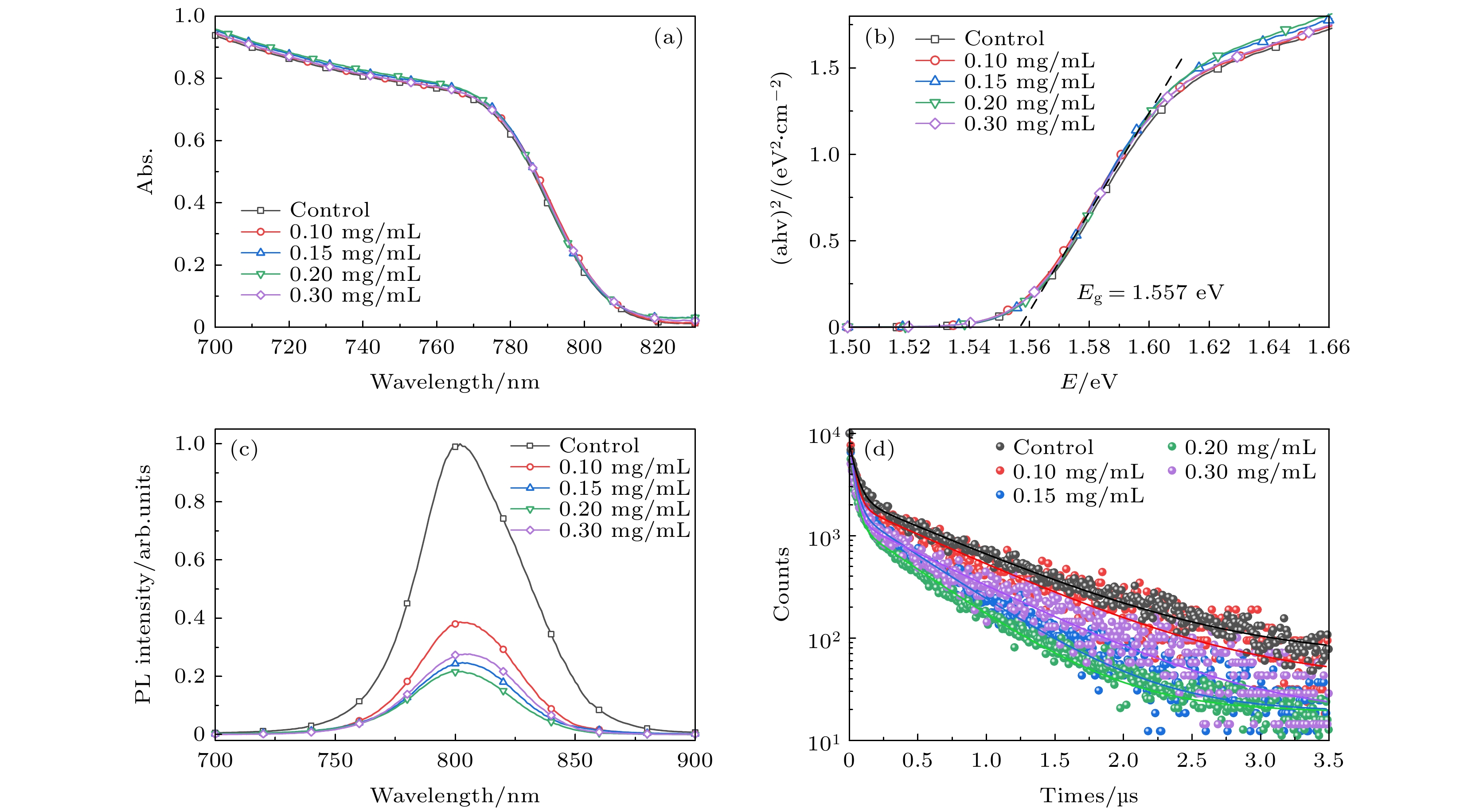

图 6 在使用不同浓度的EDTA前驱体溶液的EDTA/SnO2复合ETL上制备的钙钛矿薄膜的 (a)吸收光谱; (b) Tauc-Plot图分析光学带隙(Eg); (c)稳态PL光谱(479 nm激发); (d) TRPL光谱(800 nm监测)

Figure 6. (a) Absorbance spectra, (b) Tauc plot to analyze optical band gap (Eg), (c) steady-state PL spectra (excited at 479 nm), and (d) TRPL spectra (excited at 479 nm and monitored at 800 nm) of perovskite films with different concentration of EDTA precursors.

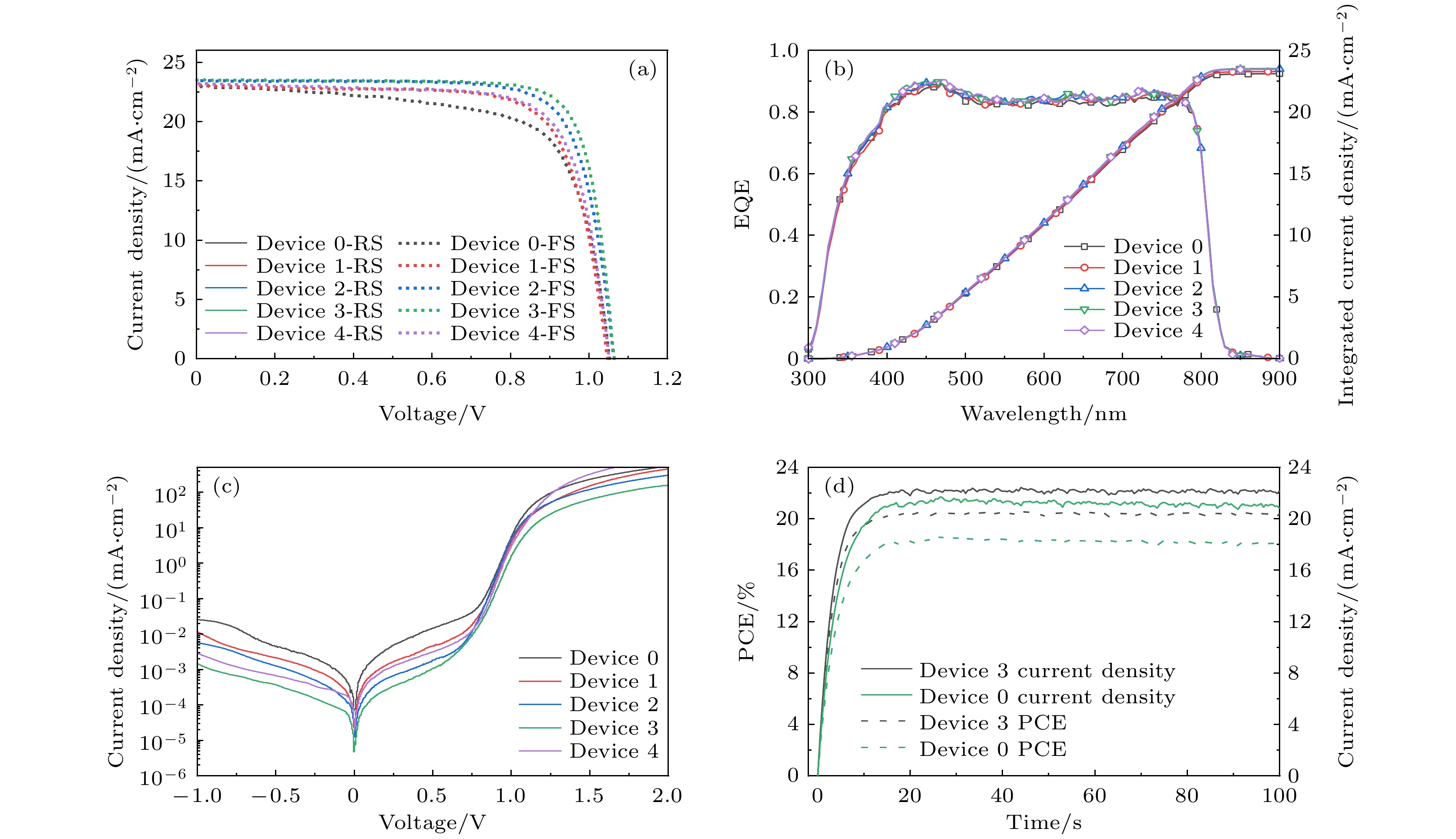

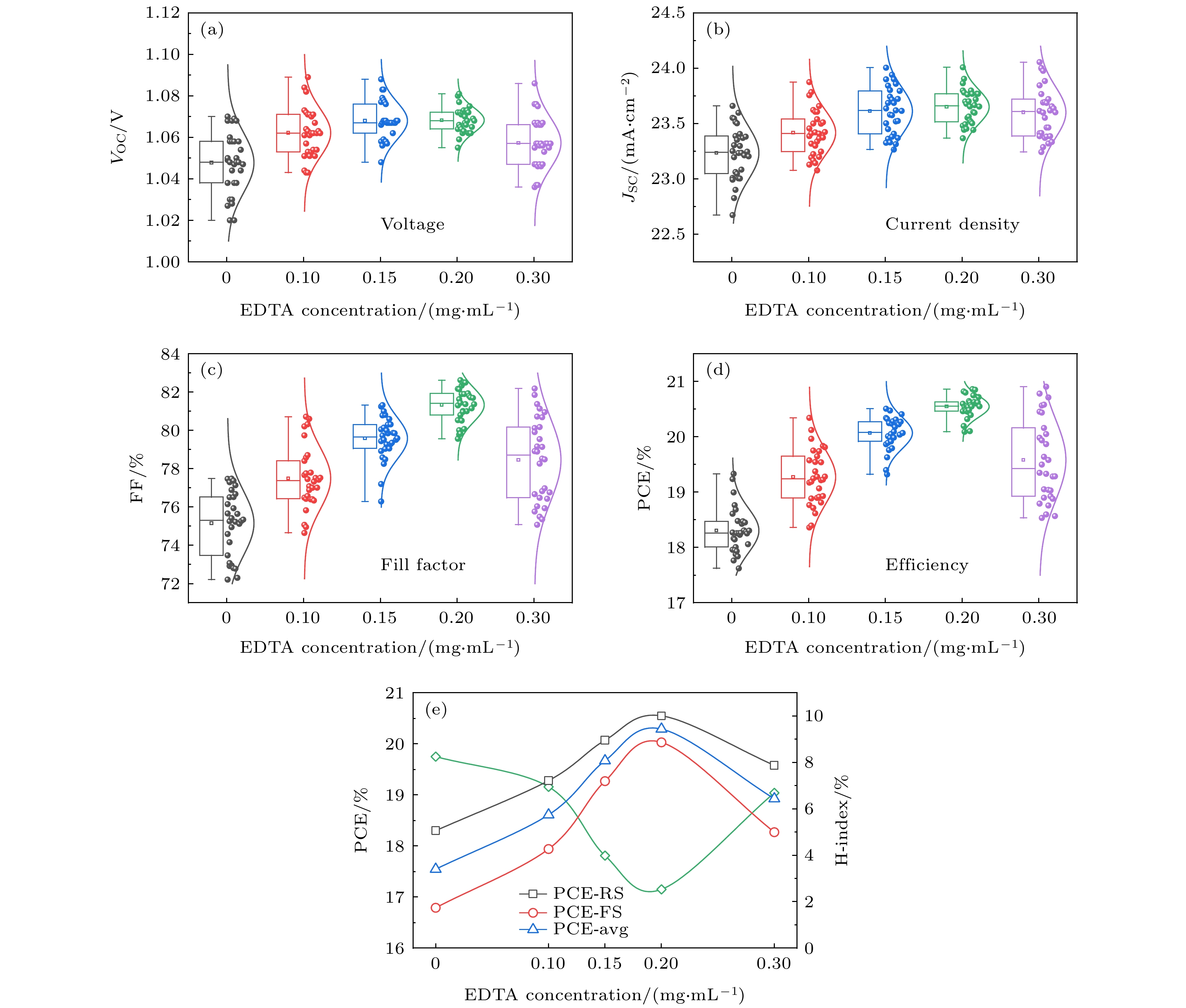

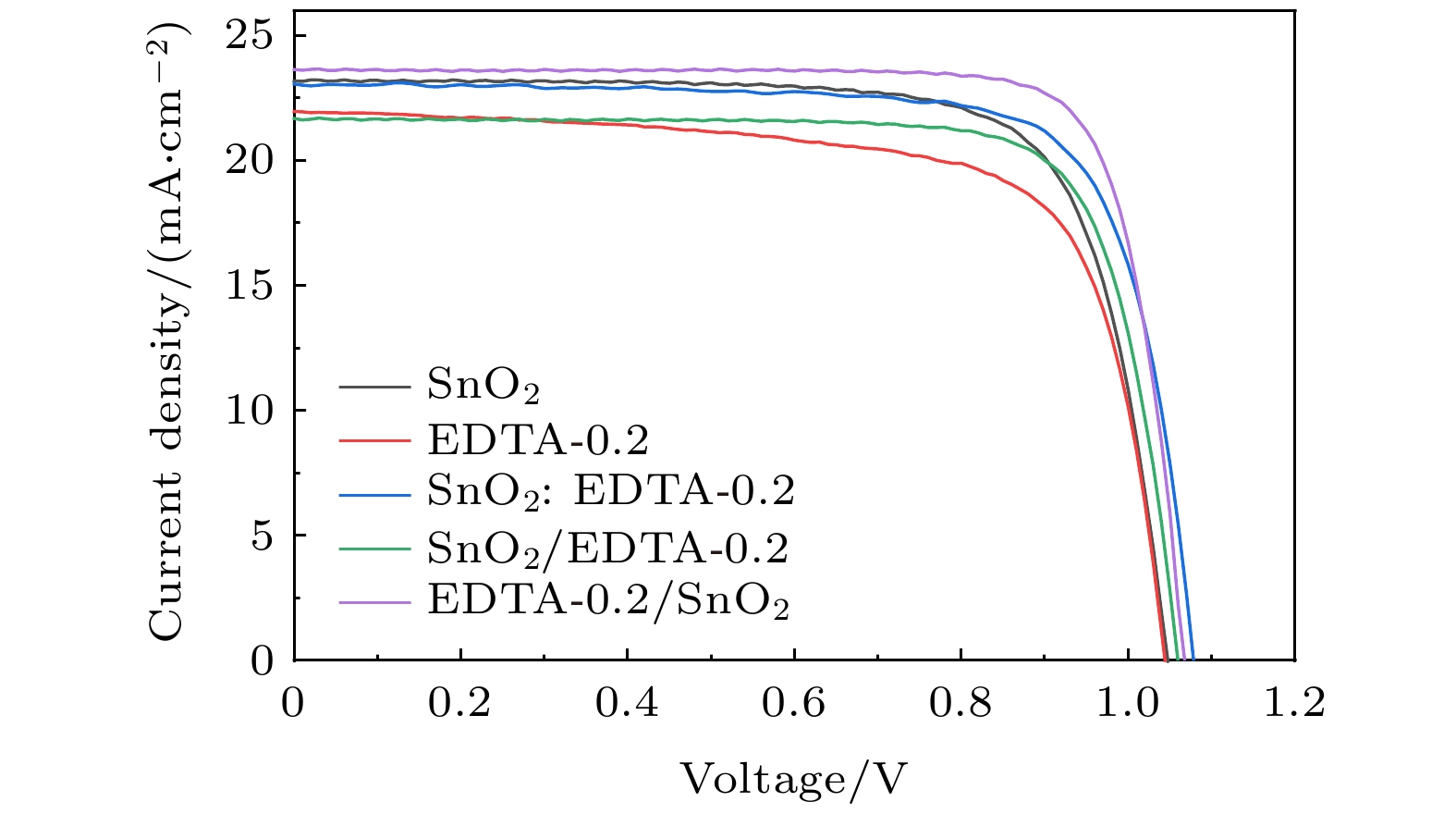

图 7 使用不同厚度的EDTA中间层构成的EDTA/SnO2复合ETL的PSCs的性能 (a) J-V特性曲线; (b) EQE光谱; (c) 暗电流曲线以及(d) Device 0和3稳定在最大功率点处输出功率和光电流测量

Figure 7. Performance of PSCs: (a) J-V characteristics under a standard solar illumination; (b) EQE spectra; (c) J-V characteristics under darkness measured from Device 0 to Device 4, and (d) Stabilized PCEs and J at the maximum power point measured from Device 0 and Device 3.

表 1 用不同方法使用EDTA制备ETL的器件的光伏参数表

Table 1. Photovoltaic parameters derived from J-V measurements of devices prepared with different ways of using EDTA.

(ITO)/ETL VOC/

VJSC/

(mA·cm–2)FF

/%PCE

/%SnO2 1.047 23.20 75.42 18.32 EDTA(0.2 mg/mL) 1.044 21.97 71.63 16.43 SnO2: EDTAa 1.077 23.07 76.67 19.05 SnO2/EDTA (0.2 mg/mL) 1.059 23.55 78.59 18.05 EDTA (0.2 mg/mL)/SnO2 1.068 23.65 81.37 20.55 a 溶液中SnO2∶EDTA质量比为133.5∶1. 表 2 EDTA/SnO2表面钙钛矿薄膜的结晶特性

Table 2. The crystallization of the perovskite films on top of the EDTA/SnO2 surface.

EDTA

concentration/

(mg·ML–1)Perovskite films SEM X-ray diffraction Grain size/

nm2θ at (100)/

(°)Intensity

at (100)∆L at (100)/

nm0 557 14.00 0.543 516 0.1 784 14.00 0.671 765 0.15 834 14.00 0.839 811 0.2 925 14.00 1.000 888 0.3 704 14.00 0.756 664 表 3 由沉积在纯SnO2表面或EDTA/SnO2复合表面的钙钛矿薄膜的TRPL光谱的双指数拟合得到的衰减时间

Table 3. Decay times obtained by a biexponential fit of TRPL spectra from perovskite films deposited on a pure SnO2 surface or on EDTA/SnO2 composite surfaces.

EDTA

concentration/

(mg·mL–1)τ1/ns A1/% a τ2/ns A2/% a τavg/ns 0 48.7 70.2 745.4 29.8 652.3 0.1 38.3 78.1 710.9 21.9 602.4 0.15 36.8 78.1 484.4 21.9 389.0 0.2 33.8 81.3 465.5 18.7 361.9 0.3 35.3 80.9 659.6 19.1 544.6 aAi is the fraction of τi component. 表 4 在标准太阳模拟光源下由J-V测量得到的PSCs详细光伏参数表

Table 4. Photovoltaic parameters derived from J-V measurements of devices prepared with different based on reverse and forward scans under standard illumination.

Devices Scan direction VOC/V JSC/

(mA·cm–2)FF/% PCE/% H-index/

%RP/Ω RS/

ΩDevice 0 RS 1.047 23.20 75.35 18.3 8.25 3757 3.64 (control) FS 1.052 23.03 69.32 16.79 Device 1 RS 1.062 23.42 77.53 19.28 6.95 4409 3.26 FS 1.047 23.12 74.12 17.94 Device 2 RS 1.068 23.61 79.60 20.07 3.99 4683 3.02 FS 1.063 23.41 77.42 19.27 Device 3 RS 1.068 23.65 81.37 20.55 2.53 5537 2.88 FS 1.064 23.48 80.18 20.03 Device 4 RS 1.057 23.60 78.49 19.58 6.69 5135 3.19 FS 1.051 23.22 74.88 18.27 -

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] https://www.nrel.gov/pv/cell-efficiency.html [2022-2-14]

[3] Snaith H J, Abate A, Ball J M, Eperon G E, Leijtens T, Noel N K, Stranks S D, Wang J T-W, Wojciechowski K, Zhang W 2014 J. Phys. Chem. Lett. 5 1511

Google Scholar

Google Scholar

[4] Kim H S, Jang I H, Ahn N, Choi M, Guerrero A, Bisquert J, Park N G 2015 J. Phys. Chem. Lett. 6 4633

Google Scholar

Google Scholar

[5] Dong Q, Wang M, Zhang Q, Chen F, Zhang S, Bian J, Ma T, Wang L, Shi Y 2017 Nano Energy 38 358

Google Scholar

Google Scholar

[6] Li W, Zhang W, Van Reenen S, Sutton R J, Fan J, Haghighirad A A, Johnston M B, Wang L, Snaith H J 2016 Energy Environ. Sci. 9 490

Google Scholar

Google Scholar

[7] Yang J, Siempelkamp B D, Mosconi E, De Angelis F, Kelly T L 2015 Chem. Mater. 27 4229

Google Scholar

Google Scholar

[8] Dong Q, Shi Y, Wang K, Li Y, Wang S, Zhang H, Xing Y, Du Y, Bai X, Ma T 2015 J. Phys. Chem. C 119 10212

[9] Jiang Q, Chu Z, Wang P, Yang X, Liu H, Wang Y, Yin Z, Wu J, Zhang X, You J 2017 Adv. Mater. 29 1703852

Google Scholar

Google Scholar

[10] Sun M, Liang C, Zhang H, Ji C, Sun F, You F, Jing X, He Z 2018 J. Mater. Chem. A 6 24793

Google Scholar

Google Scholar

[11] Jiang Q, Zhao Y, Zhang X, Yang X, Chen Y, Chu Z, Ye Q, Li X, Yin Z, You J 2019 Nat. Photonics 13 460

Google Scholar

Google Scholar

[12] Jiang Q, Zhang L, Wang H, Yang X, Meng J, Liu H, Yin Z, Wu J, Zhang X, You J 2016 Nat. Energy 2 16177

[13] Yang G, Tao H, Qin P, Ke W, Fang G 2016 J. Mater. Chem. A 4 3970

Google Scholar

Google Scholar

[14] Wang F, Zhang Y, Yang M, Du J, Xue L, Yang L, Fan L, Sui Y, Yang J, Zhang X 2019 Nano Energy 63 103825

Google Scholar

Google Scholar

[15] Ke W, Xiao C, Wang C, Saparov B, Duan H S, Zhao D, Xiao Z, Schulz P, Harvey S P, Liao W, Meng W, Yu Y, Cimaroli A J, Jiang C-S, Zhu K, Al-Jassim M, Fang G, Mitzi D B, Yan Y 2016 Adv. Mater. 28 5214

Google Scholar

Google Scholar

[16] Yang G, Wang C, Lei H, Zheng X, Qin P, Xiong L, Zhao X, Yan Y, Fang G 2017 J. Mater. Chem. A 5 1658

Google Scholar

Google Scholar

[17] Ma J, Yang G, Qin M, Zheng X, Lei H, Chen C, Chen Z, Guo Y, Han H, Zhao X, Fang G 2017 Adv. Sci. 4 1700031

Google Scholar

Google Scholar

[18] Li N, Niu X, Pei F, Liu H, Cao Y, Liu Y, Xie H, Gao Y, Chen Q, Mo F, Zhou H 2019 Sol. RRL 4 1900217

[19] Hafer E, Holzgrabe U, Kraus K, Adams K, Hook J M, Diehl B 2020 Magnetic Resonance in Chemistry 58 653

Google Scholar

Google Scholar

[20] Li X, Liu X, Zhang W, Wang H-Q, Fang J 2017 Chem. Mater. 29 4176

Google Scholar

Google Scholar

[21] Yang D, Yang R, Wang K, Wu C, Zhu X, Feng J, Ren X, Fang G, Priya S, Liu S 2018 Nat. Commun. 9 3239

Google Scholar

Google Scholar

[22] Li X, Zhang W, Wang X, Wu Y, Gao F, Fang J 2015 J. Mater. Chem. A 3 504

Google Scholar

Google Scholar

[23] Li X, Zhang W, Wang X, Gao F, Fang J 2014 ACS Appl. Mater. Interfaces 6 20569

Google Scholar

Google Scholar

[24] Pham H T, Duong T, Rickard W D A, Kremer F, Weber K J, Wong-Leung J 2019 J. Phys. Chem. C 123 26718

Google Scholar

Google Scholar

[25] Xie L Q, Chen L, Nan Z A, Lin H X, Wang T, Zhan D P, Yan J W, Mao B W, Tian Z Q 2017 J. Am. Chem. Soc. 139 3320

Google Scholar

Google Scholar

[26] Turren-Cruz S-H, Hagfeldt A, Saliba M 2018 Science 362 449

Google Scholar

Google Scholar

[27] Warren B E 1990 X-Ray Diffraction (Second Edition) (New York: Dover Publication)

[28] Guo Z, He Z, Sun M, Zhang H, Xu Y, Li X, Liang C, Jing X 2018 Polymer 153 398

Google Scholar

Google Scholar

[29] Mitchell G R, Windle A H 1982 Polymer 23 1269

Google Scholar

Google Scholar

[30] Zhao L, Li Q, Hou C-H, Li S, Yang X, Wu J, Zhang S, Hu Q, Wang Y, Zhang Y, Jiang Y, Jia S, Shyue J-J, Russell T P, Gong Q, Hu X, Zhu R 2022 J. Am. Chem. Soc. 144 1700

Google Scholar

Google Scholar

[31] Tauc J 1968 Mater. Res. Bull. 3 37

Google Scholar

Google Scholar

[32] Son D-Y, Lee J-W, Choi Y J, Jang I-H, Lee S, Yoo P J, Shin H, Ahn N, Choi M, Kim D, Park N-G 2016 Nat. Energy 1 16081

Google Scholar

Google Scholar

[33] Kim M, Kim G-H, Lee T K, Choi I W, Choi H W, Jo Y, Yoon Y J, Kim J W, Lee J, Huh D, Lee H, Kwak S K, Kim J Y, Kim D S 2019 Joule 3 2179

Google Scholar

Google Scholar

[34] Chen S, Wen X, Huang S, Huang F, Cheng Y-B, Green M, Ho-Baillie A 2017 Sol. RRL 1 1600001

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 11851

- PDF Downloads: 202

- Cited By: 0

DownLoad:

DownLoad: