-

The mCBP and CBP are two kinds of isomers containing carbazole groups and often used as the device hosts for fluorescence and phosphorescence emission. However, there are little studies on the microscopic mechanisms of exciplex-type devices based on mCBP or CBP. In this paper, the isomers of mCBP and CBP are used as donors and the PO-T2T is selected as an acceptor. The two kinds of exciplex-based devices are fabricated according to a mass ratio of 1∶1, which are respectively referred to as device 1 (Dev. 1) and device 2 (Dev. 2). Their magneto-electroluminescence (MEL) curves are measured at different working temperatures and various injection currents. It is found that the low field effects of the MEL curves from Dev. 1 are dominated by the B-mediated reverse intersystem crossing (RISC) process at room temperature, and as the operational temperature decreases, the MEL line-shapes change gradually from RISC to the intersystem crossing (ISC) process. Conversely, the low field effects of the MEL curves of Dev. 2 are governed by the B-mediated ISC process at room temperature, and the ISC process first weakens then strengthens with temperature decreasing. The high field effects of the MEL curves of Dev. 1 and Dev. 2 are both dominated by the B-mediated triplet-charge annihilation (TQA) process at room temperature, but those of Dev. 2 at 20 K present the B-mediated triplet-triplet annihilation (TTA) process. The completely opposite low-field line-shapes of MEL traces from Dev. 1 and Dev. 2 can be attributed to their different structures of mCBP and CBP, which lead to the higher and lower triplet state exciton energy, respectively. The higher triplet exciton energy of the mCBP donor causes the triplet exciplex energy to be confined effectively, which promotes the RISC process (EX1 ← EX3) in Dev.1. Contrarily, the lower triplet exciton energy of the CBP donor causes the triplet exciplex to experience an energy loss process (EX3 → T1, CBP) , resulting in the suppressed RISC process in Dev. 2. Consequently, the overlapped effects of the ISC process of polaron pairs and the RISC process of exciplex in Dev. 2 under the action of external magnetic field display the ISC-determined process at room temperature. Moreover, the temperature-dependent change in the microscopic process of Dev. 1 such as the conversion from RISC to ISC is because decreasing temperature is not conducive to the occurrence of the RISC process of exciplex states due to its endothermic property. The low-temperature TTA process occurring in Dev. 2 is due to the suppressed energy loss process of triplet exciplex via the Dexter energy transfer from the triplet exciplex to the triplet exciton of CBP donor. In addition, when the mass ratio of mCBP donor to PO-T2T acceptor varies from 1∶4 to 1∶1 to 4∶1, the RISC process of MEL curves of devices turns stronger and stronger, which is because the devices tend more to balance, favoring the RISC process. A higher external quantum efficiency is obtained in the mCBP:PO-T2T host than in the CBP:PO-T2T host when fluorescent guest material of TBRb is used as a dopant in these two exciplex-based devices, which verifies the importance of the effective confinement of triplet exciplex energy in improving the luminescence efficiency. Note that via the MEL detection technology, the current- and temperature-dependent microscopic processes and their reasonable interpretations and device performances from exciplex-based devices with the isomers of mCBP and CBP as donors have not been reported in the literature. This work provides experimental and theoretical references for fabricating the high-efficiency exciplex-based organic light-emitting devices.

-

Keywords:

- exciplex /

- magneto-electroluminescence /

- triplet state energy /

- reverse intersystem crossing

[1] Goushi K, Adachi C 2012 Appl. Phys. Lett. 101 023306

Google Scholar

Google Scholar

[2] Goushi K, Yoshida K, Sato K, Adachi C 2012 Nat. Photonics 6 253

Google Scholar

Google Scholar

[3] Kim K H, Yoo S J, Kim J J 2016 ACS Chem. Mater. 28 1936

Google Scholar

Google Scholar

[4] Zhao X, Tang X T, Pan R H, Xu J, Qu F L, Xiong Z H 2019 J. Mater. Chem. C 7 10841

Google Scholar

Google Scholar

[5] Yuan P S, Qiao X F, Yan D H, Ma D G 2018 J. Mater. Chem. C 6 5721

Google Scholar

Google Scholar

[6] Schrögel P, Langer N, Schildknecht C, Wagenblast G, Lennartz C, Strohriegl P 2011 Org. Electron. 12 2047

Google Scholar

Google Scholar

[7] Bagnich SA, Rudnick A, Schroegel P, Strohriegl P, Köhler A 2015 Philos. Trans. R. Soc. London, Ser. A 373 20140446

Google Scholar

Google Scholar

[8] 张勇, 刘亚莉, 焦威, 陈林, 熊祖洪 2012 61 117106

Google Scholar

Google Scholar

Zhang Y, Liu Y L, Jiao W, Chen L, Xiong Z H 2012 Acta Phys. Sin. 61 117106

Google Scholar

Google Scholar

[9] Crooker S A, Liu F, Kelley M R, Martinez N J D, Nie W, Mohite A, Nayyar I H, Tretiak S, Smith D L, Ruden P P 2014 Appl. Phys. Lett. 105 153304

Google Scholar

Google Scholar

[10] Peng Q M, Li W J, Zhang S T, Chen P, Li F, Ma Y G 2013 Adv. Opt. Mater. 1 362

Google Scholar

Google Scholar

[11] Xiang J, Chen Y B, Yuan D, Jia W Y, Zhang Q M, Xiong Z H 2016 Appl. Phys. Lett. 109 103301

Google Scholar

Google Scholar

[12] Chen Y B, Jia W Y, Xiang J, Yuan D, Chen Q S, Chen L X, Xiong Z H 2016 Org. Electron. 39 207

Google Scholar

Google Scholar

[13] Choi W H, Tan G P, Sit W Y, Ho C L, Chan C Y H, Xu W W, Wong W Y, So S K 2015 Org. Electron. 24 7

Google Scholar

Google Scholar

[14] Kim J M, Lee C H, Kim J J 2017 Appl. Phys. Lett. 111 203301

Google Scholar

Google Scholar

[15] Ying S A, Pang P Y, Zhang S A, Sun Q, Dai Y F, Qiao X F, Yang D Z, Chen J S, Ma D G 2019 ACS Appl. Mater. Interfaces 11 31078

Google Scholar

Google Scholar

[16] 管胜婕, 周林箭, 沈成梅, 张勇 2020 69 167101

Google Scholar

Google Scholar

Guan S J, Zhou L J, Shen C M, Zhang Y 2020 Acta Phys. Sin. 69 167101

Google Scholar

Google Scholar

[17] Uoyama H, Goushi K, Shizu K, Nomura H, Adachi C 2012 Nature 492 234

Google Scholar

Google Scholar

[18] Tang X T, Hu Y Q, Jia W Y, Pan R H, Deng J Q, Deng J Q, He Z H, Xiong Z H 2018 ACS Appl. Mater. Interfaces 10 1948

Google Scholar

Google Scholar

[19] 汤仙童, 邓军权, 胡叶倩, 潘睿亨, 邓金秋, 熊祖洪 2017 中国科学: 技术科学 47 946

Google Scholar

Google Scholar

Tang X T, Deng J Q, Hu Y Q, Pan R H, Deng J Q, Xiong Z H 2017 Sci. Sin. Technol. 47 946

Google Scholar

Google Scholar

[20] 汤仙童, 许静, 邓金秋, 潘睿亨, 胡叶倩, 熊祖洪, 陈晓莉 2018 中国科学: 物理学 力学 天文学 48 117001

Google Scholar

Google Scholar

Tang X T, Xu J, Deng J Q, Pan R H, Hu Y Q, Xiong Z H, Chen X L 2018 Sci. Sin-Phys. Mech. Astron. 48 117001

Google Scholar

Google Scholar

[21] Zhang T Y, Chu B, Li W L, Su Z S, Peng Q M, Zhao B, Luo Y S, Jin F M, Yan X W, Gao Y, Wu H R, Zhang F, Fan D, Wang J B 2014 ACS Appl. Mater. Interfaces 6 11907

Google Scholar

Google Scholar

[22] Zhu L P, Xu K, Wang Y P, Chen J S, Ma D G 2015 Front. Optoelectron. 8 439

Google Scholar

Google Scholar

[23] Song W, Lee J Y, Cho Y J, Yu H, Aziz H, Lee K M 2018 Adv. Sci. 5 1700608

Google Scholar

Google Scholar

[24] Desai P, Shakya P, Kreouzis T, Gillin W P 2007 Phys. Rev. B 75 094423

Google Scholar

Google Scholar

[25] Zhao X, Tang X T, Zhu H Q, Ma C H, Wang Y, Ye S N, Tu L Y, Xiong Z H 2021 ACS Appl. Electron. Mater. 3 3034

Google Scholar

Google Scholar

[26] Kim H B, Kim J J 2020 Phys. Rev. Appl. 13 024006

Google Scholar

Google Scholar

[27] Bagnich S A, Niedermeier U, Melzer C, Sarfert W, von Seggern H 2009 J. Appl. Phys. 106 113702

Google Scholar

Google Scholar

[28] Chen D C, Xie G Z, Cai X Y, Liu M, Cao Y, Su S J 2016 Adv. Mater. 28 239

Google Scholar

Google Scholar

[29] 陈秋松, 袁德, 贾伟尧, 陈历相, 邹越, 向杰, 陈颖冰, 张巧明, 熊祖洪 2015 64 177801

Google Scholar

Google Scholar

Chen Q S, Yuan D, Jia W Y, Chen L X, Zou Y, Xiang J, Chen Y B, Zhang Q M, Xiong Z H 2015 Acta Phys. Sin. 64 177801

Google Scholar

Google Scholar

[30] Kim K H, Moon C K, Sun J W, Sim B, Kim J J 2015 Adv. Opt. Mater. 3 895

Google Scholar

Google Scholar

[31] Kim H G, Kim K H, Kim J J 2017 Adv. Mater. 29 1702159

Google Scholar

Google Scholar

[32] Tang X T, Pan R H, Zhao X, Jia W Y, Wang Y, Ma C H, Tu L Y, Xiong Z H 2020 Adv. Funct. Mater. 30 2005765

Google Scholar

Google Scholar

-

图 1 (a) 器件1和器件2的能级排布结构; (b) mCBP和CBP的化学分子结构; (c) mCBP, PO-T2T和mCBP:PO-T2T的归一化PL谱以及器件1的归一化EL谱; (d) CBP, PO-T2T和CBP:PO-T2T的归一化PL谱以及器件2的归一化EL谱

Figure 1. (a) Energy level structures of device 1 and device 2; (b) the chemical structures of mCBP and CBP molecules; (c) normalized PL spectra of mCBP, PO-T2T, and mCBP:PO-T2T and normalized EL spectrum of device 1; (d) normalized PL spectra of CBP, PO-T2T, and CBP:PO-T2T and normalized EL spectrum of device 2.

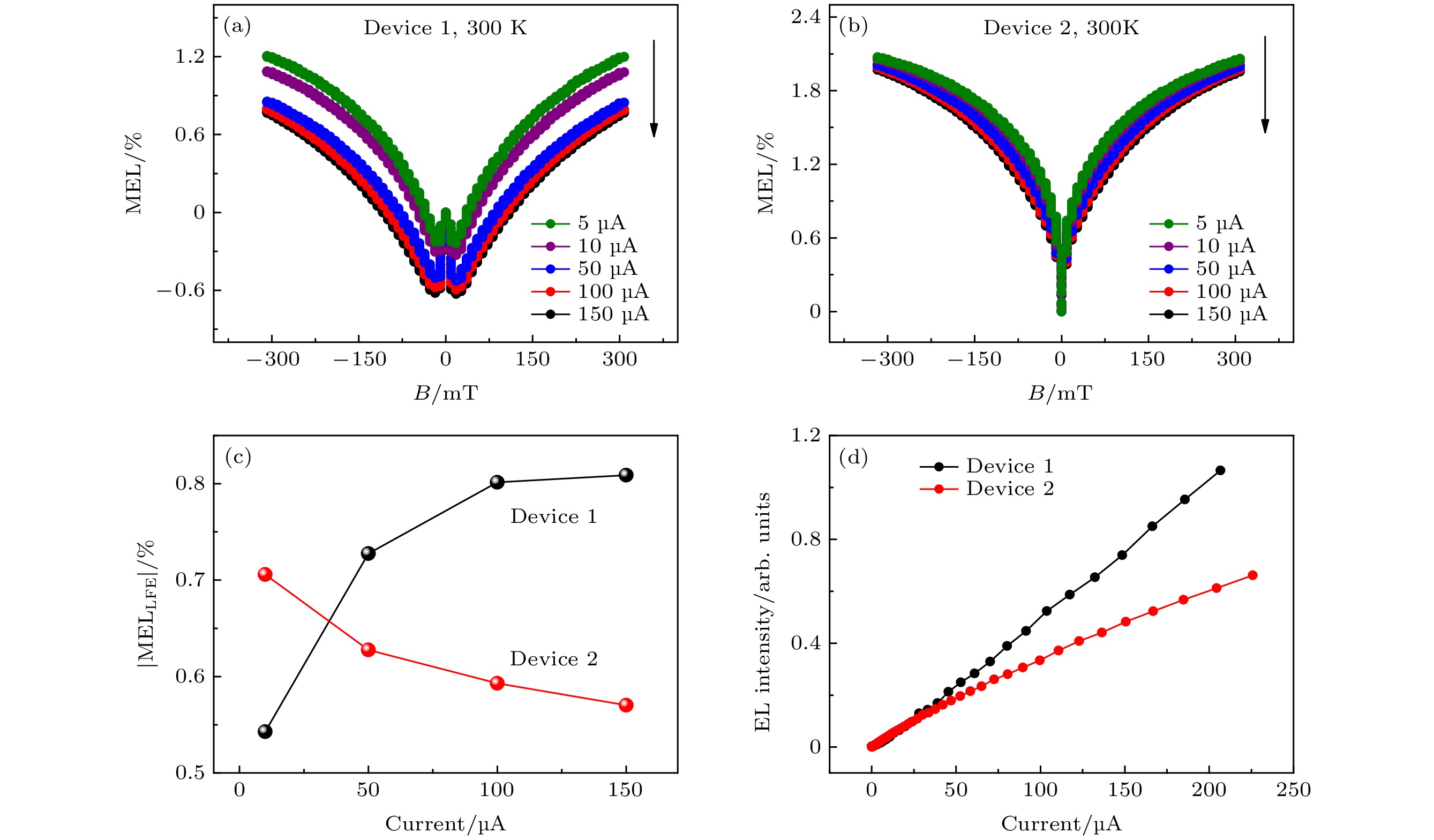

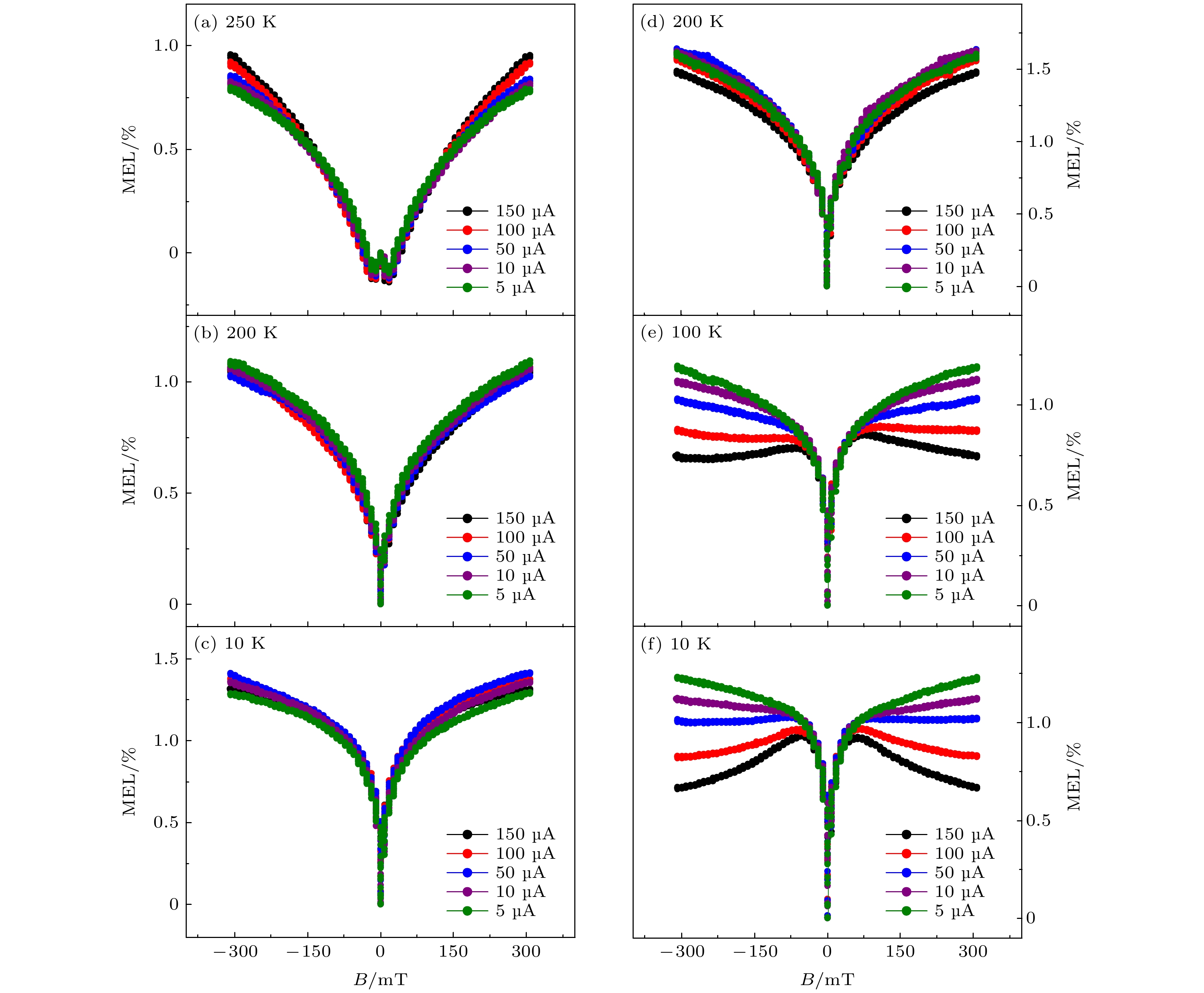

图 2 (a) 室温300 K下器件1在不同注入电流时的MEL曲线; (b) 室温300 K下器件2在不同注入电流时的MEL曲线; (c) 器件1和器件2的MELLFE幅值随电流的变化关系; (d) 器件1和器件2的电致发光强度随电流的变化曲线

Figure 2. (a) The MEL curves of device 1 acquired at different injection currents at 300 K; (b) the MEL curves of device 2 obtained at different injection currents at 300 K; (c) MELLFE magnitudes of device 1 and device 2 at different injection currents; (d) electroluminescence intensity-current curves of device 1 and device 2.

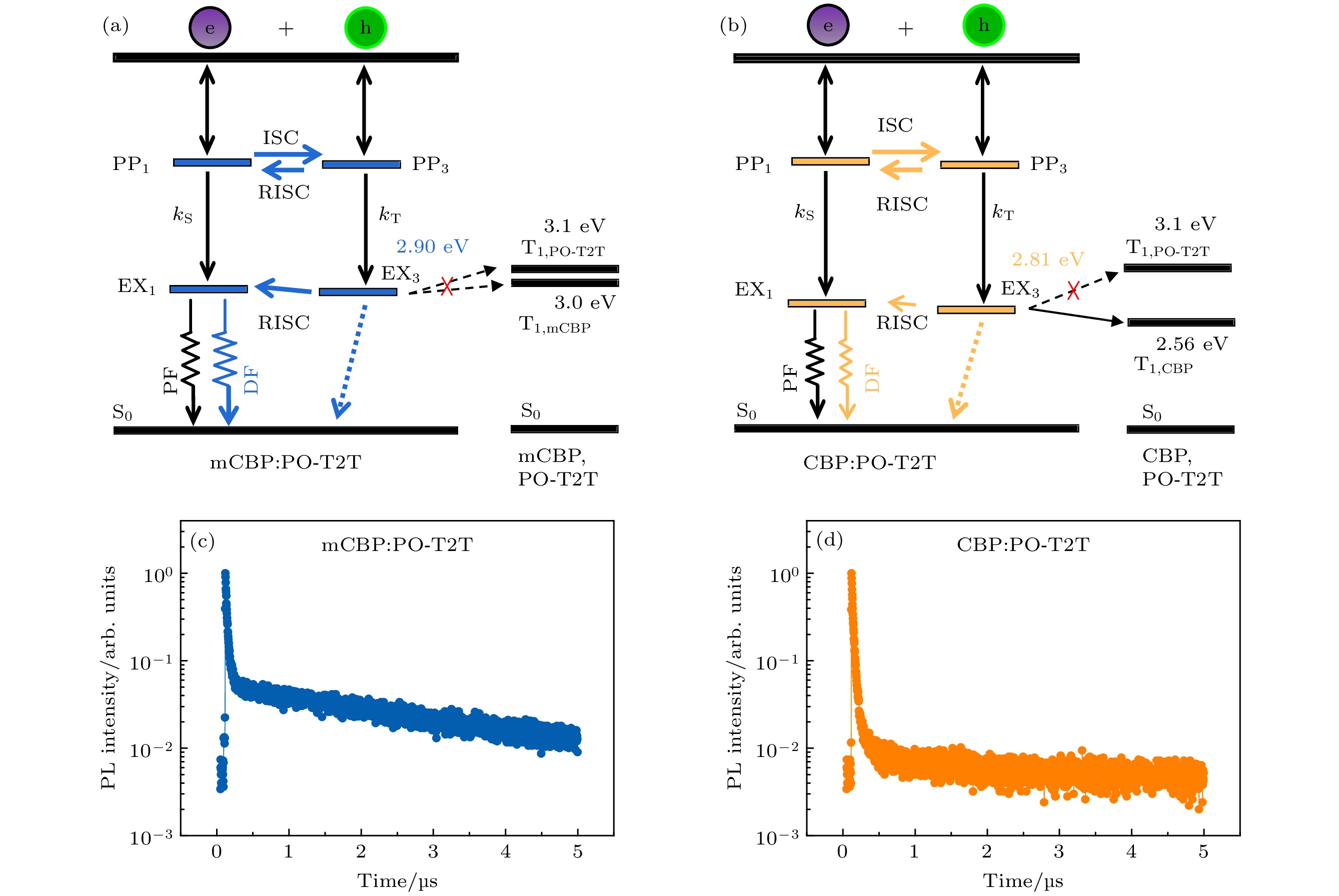

图 3 (a) 器件1的微观机理图; (b) 器件2的微观机理图; (c) 薄膜mCBP:PO-T2T的瞬态PL衰减曲线, 激发波长和监测波长分别是340 nm和488 nm; (d) 薄膜CBP:PO-T2T的瞬态PL衰减曲线, 激发波长和监测波长分别是340 nm和491 nm

Figure 3. (a) Microscopic mechanisms in device 1; (b) microscopic mechanisms in device 2; (c) transient PL decay curves of mCBP:PO-T2T film, the wavelengths of excitation and detection are 340 nm and 488 nm, respectively; (d) transient PL decay curves of CBP:PO-T2T film, the wavelengths of excitation and detection are 340 nm and 491 nm, respectively.

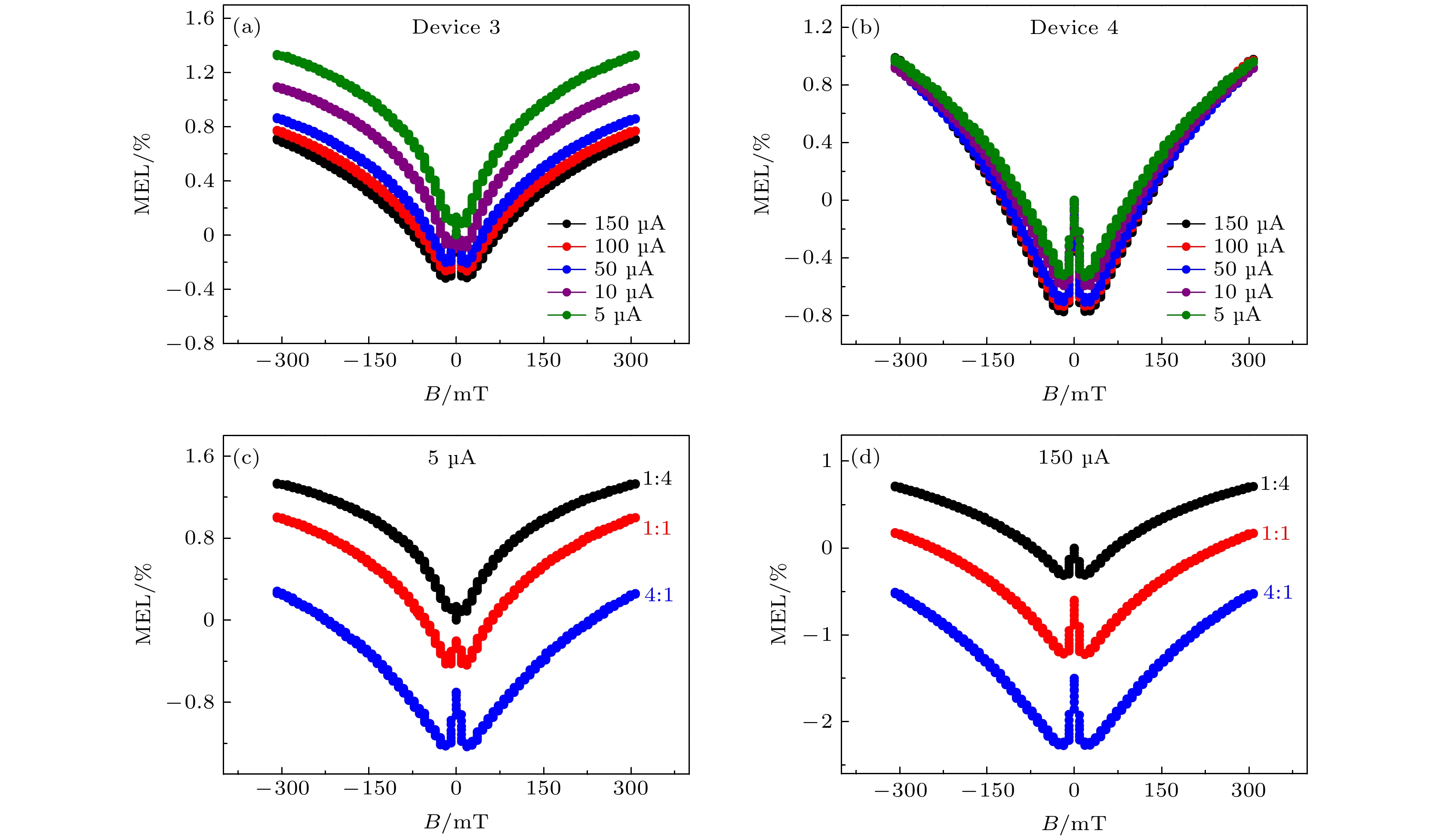

图 5 (a) 室温下器件3在不同注入电流时的MEL曲线; (b) 室温下器件4在不同注入电流时的MEL曲线; (c) 室温下电流为5 μA时器件3 (1:4)、器件1 (1:1)和器件4 (4:1)的MEL曲线; (d) 室温下电流为150 μA时器件3、器件1和器件4的MEL曲线

Figure 5. (a) The room temperature MEL curves of device 3 at different injection currents; (b) the room temperature MEL curves of device 4 at different injection currents; (c) the room temperature MEL curves of device 3 (1:4), device 1 (1:1), and device 4 (4:1) at 5 μA; (d) the room temperature MEL curves of device 3, device 1, and device 4 at 150 μA.

图 6 (a) 器件5和器件6的能级结构; (b) 器件5和器件6的电流效率-亮度特性曲线; (c) 器件5和器件6的归一化EL谱和TBRb的分子结构; (d) 器件5和器件6的EQE-亮度特性曲线

Figure 6. (a) Energy level structures of devices 5 and 6; (b) current efficiency-luminance characteristics of devices 5 and 6; (c) normalized EL spectra of devices 5 and 6 and molecular structure of TBRb; (d) EQE-luminance characteristics of devices 5 and 6.

-

[1] Goushi K, Adachi C 2012 Appl. Phys. Lett. 101 023306

Google Scholar

Google Scholar

[2] Goushi K, Yoshida K, Sato K, Adachi C 2012 Nat. Photonics 6 253

Google Scholar

Google Scholar

[3] Kim K H, Yoo S J, Kim J J 2016 ACS Chem. Mater. 28 1936

Google Scholar

Google Scholar

[4] Zhao X, Tang X T, Pan R H, Xu J, Qu F L, Xiong Z H 2019 J. Mater. Chem. C 7 10841

Google Scholar

Google Scholar

[5] Yuan P S, Qiao X F, Yan D H, Ma D G 2018 J. Mater. Chem. C 6 5721

Google Scholar

Google Scholar

[6] Schrögel P, Langer N, Schildknecht C, Wagenblast G, Lennartz C, Strohriegl P 2011 Org. Electron. 12 2047

Google Scholar

Google Scholar

[7] Bagnich SA, Rudnick A, Schroegel P, Strohriegl P, Köhler A 2015 Philos. Trans. R. Soc. London, Ser. A 373 20140446

Google Scholar

Google Scholar

[8] 张勇, 刘亚莉, 焦威, 陈林, 熊祖洪 2012 61 117106

Google Scholar

Google Scholar

Zhang Y, Liu Y L, Jiao W, Chen L, Xiong Z H 2012 Acta Phys. Sin. 61 117106

Google Scholar

Google Scholar

[9] Crooker S A, Liu F, Kelley M R, Martinez N J D, Nie W, Mohite A, Nayyar I H, Tretiak S, Smith D L, Ruden P P 2014 Appl. Phys. Lett. 105 153304

Google Scholar

Google Scholar

[10] Peng Q M, Li W J, Zhang S T, Chen P, Li F, Ma Y G 2013 Adv. Opt. Mater. 1 362

Google Scholar

Google Scholar

[11] Xiang J, Chen Y B, Yuan D, Jia W Y, Zhang Q M, Xiong Z H 2016 Appl. Phys. Lett. 109 103301

Google Scholar

Google Scholar

[12] Chen Y B, Jia W Y, Xiang J, Yuan D, Chen Q S, Chen L X, Xiong Z H 2016 Org. Electron. 39 207

Google Scholar

Google Scholar

[13] Choi W H, Tan G P, Sit W Y, Ho C L, Chan C Y H, Xu W W, Wong W Y, So S K 2015 Org. Electron. 24 7

Google Scholar

Google Scholar

[14] Kim J M, Lee C H, Kim J J 2017 Appl. Phys. Lett. 111 203301

Google Scholar

Google Scholar

[15] Ying S A, Pang P Y, Zhang S A, Sun Q, Dai Y F, Qiao X F, Yang D Z, Chen J S, Ma D G 2019 ACS Appl. Mater. Interfaces 11 31078

Google Scholar

Google Scholar

[16] 管胜婕, 周林箭, 沈成梅, 张勇 2020 69 167101

Google Scholar

Google Scholar

Guan S J, Zhou L J, Shen C M, Zhang Y 2020 Acta Phys. Sin. 69 167101

Google Scholar

Google Scholar

[17] Uoyama H, Goushi K, Shizu K, Nomura H, Adachi C 2012 Nature 492 234

Google Scholar

Google Scholar

[18] Tang X T, Hu Y Q, Jia W Y, Pan R H, Deng J Q, Deng J Q, He Z H, Xiong Z H 2018 ACS Appl. Mater. Interfaces 10 1948

Google Scholar

Google Scholar

[19] 汤仙童, 邓军权, 胡叶倩, 潘睿亨, 邓金秋, 熊祖洪 2017 中国科学: 技术科学 47 946

Google Scholar

Google Scholar

Tang X T, Deng J Q, Hu Y Q, Pan R H, Deng J Q, Xiong Z H 2017 Sci. Sin. Technol. 47 946

Google Scholar

Google Scholar

[20] 汤仙童, 许静, 邓金秋, 潘睿亨, 胡叶倩, 熊祖洪, 陈晓莉 2018 中国科学: 物理学 力学 天文学 48 117001

Google Scholar

Google Scholar

Tang X T, Xu J, Deng J Q, Pan R H, Hu Y Q, Xiong Z H, Chen X L 2018 Sci. Sin-Phys. Mech. Astron. 48 117001

Google Scholar

Google Scholar

[21] Zhang T Y, Chu B, Li W L, Su Z S, Peng Q M, Zhao B, Luo Y S, Jin F M, Yan X W, Gao Y, Wu H R, Zhang F, Fan D, Wang J B 2014 ACS Appl. Mater. Interfaces 6 11907

Google Scholar

Google Scholar

[22] Zhu L P, Xu K, Wang Y P, Chen J S, Ma D G 2015 Front. Optoelectron. 8 439

Google Scholar

Google Scholar

[23] Song W, Lee J Y, Cho Y J, Yu H, Aziz H, Lee K M 2018 Adv. Sci. 5 1700608

Google Scholar

Google Scholar

[24] Desai P, Shakya P, Kreouzis T, Gillin W P 2007 Phys. Rev. B 75 094423

Google Scholar

Google Scholar

[25] Zhao X, Tang X T, Zhu H Q, Ma C H, Wang Y, Ye S N, Tu L Y, Xiong Z H 2021 ACS Appl. Electron. Mater. 3 3034

Google Scholar

Google Scholar

[26] Kim H B, Kim J J 2020 Phys. Rev. Appl. 13 024006

Google Scholar

Google Scholar

[27] Bagnich S A, Niedermeier U, Melzer C, Sarfert W, von Seggern H 2009 J. Appl. Phys. 106 113702

Google Scholar

Google Scholar

[28] Chen D C, Xie G Z, Cai X Y, Liu M, Cao Y, Su S J 2016 Adv. Mater. 28 239

Google Scholar

Google Scholar

[29] 陈秋松, 袁德, 贾伟尧, 陈历相, 邹越, 向杰, 陈颖冰, 张巧明, 熊祖洪 2015 64 177801

Google Scholar

Google Scholar

Chen Q S, Yuan D, Jia W Y, Chen L X, Zou Y, Xiang J, Chen Y B, Zhang Q M, Xiong Z H 2015 Acta Phys. Sin. 64 177801

Google Scholar

Google Scholar

[30] Kim K H, Moon C K, Sun J W, Sim B, Kim J J 2015 Adv. Opt. Mater. 3 895

Google Scholar

Google Scholar

[31] Kim H G, Kim K H, Kim J J 2017 Adv. Mater. 29 1702159

Google Scholar

Google Scholar

[32] Tang X T, Pan R H, Zhao X, Jia W Y, Wang Y, Ma C H, Tu L Y, Xiong Z H 2020 Adv. Funct. Mater. 30 2005765

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9142

- PDF Downloads: 189

- Cited By: 0

DownLoad:

DownLoad: