-

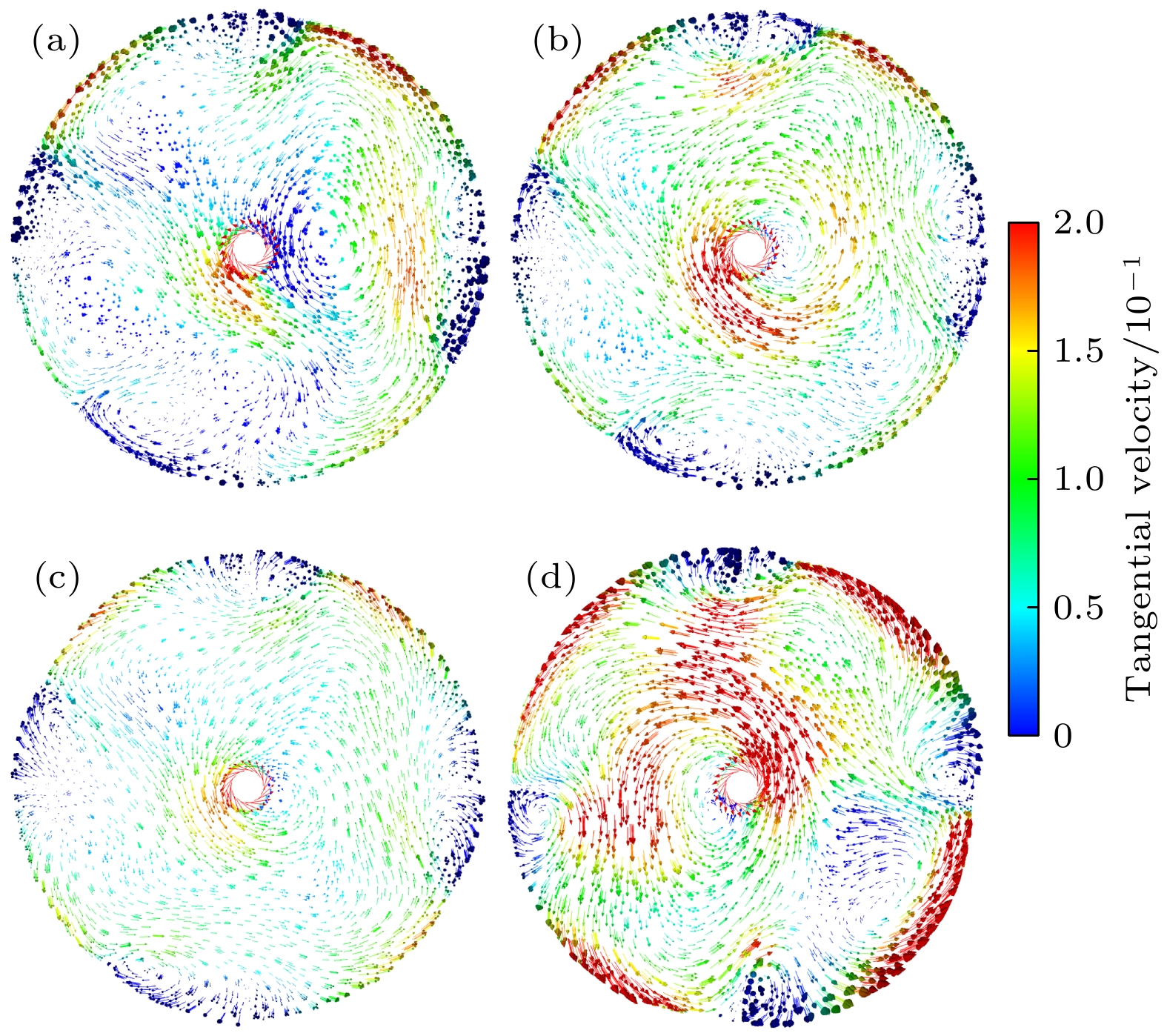

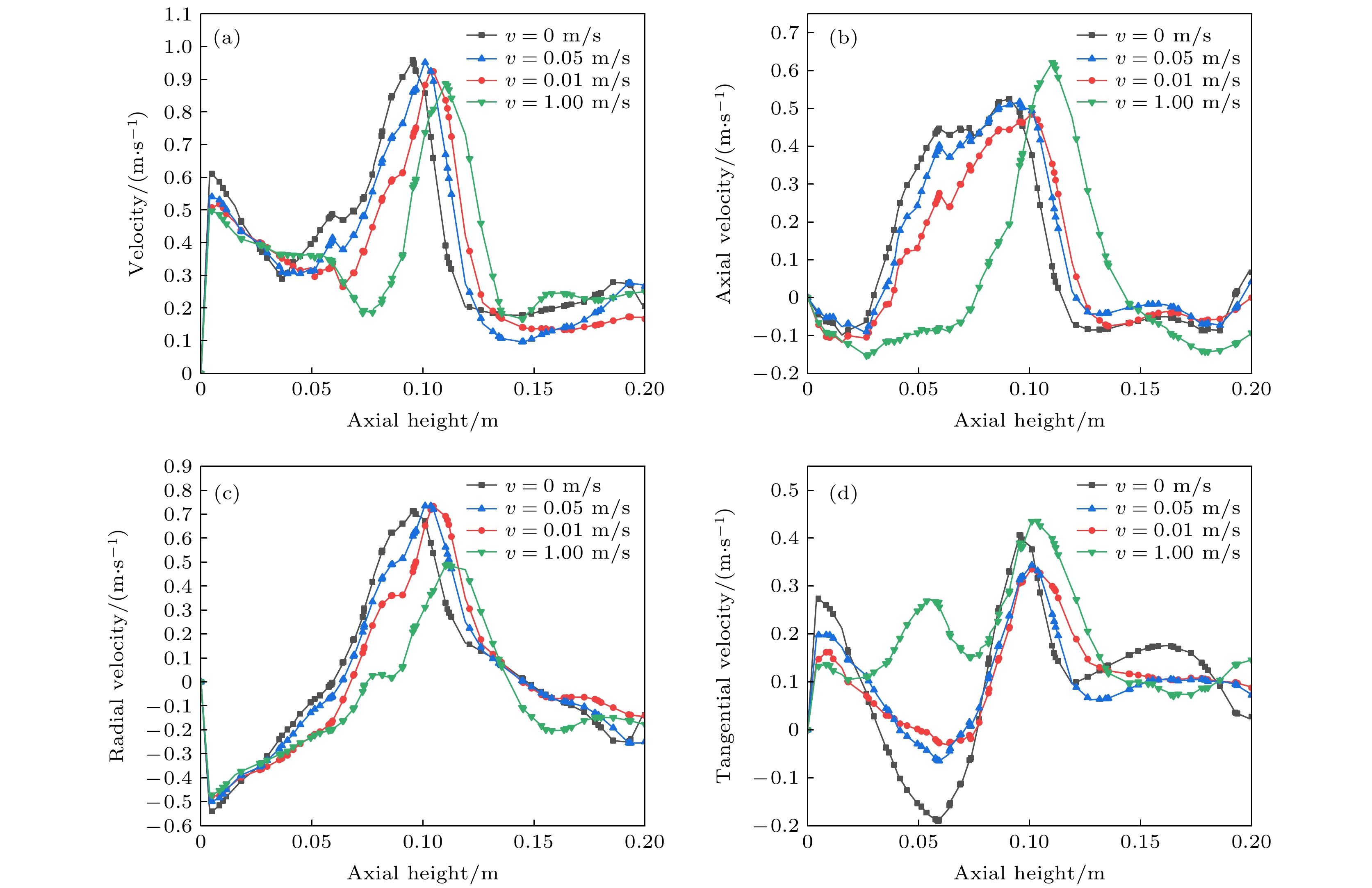

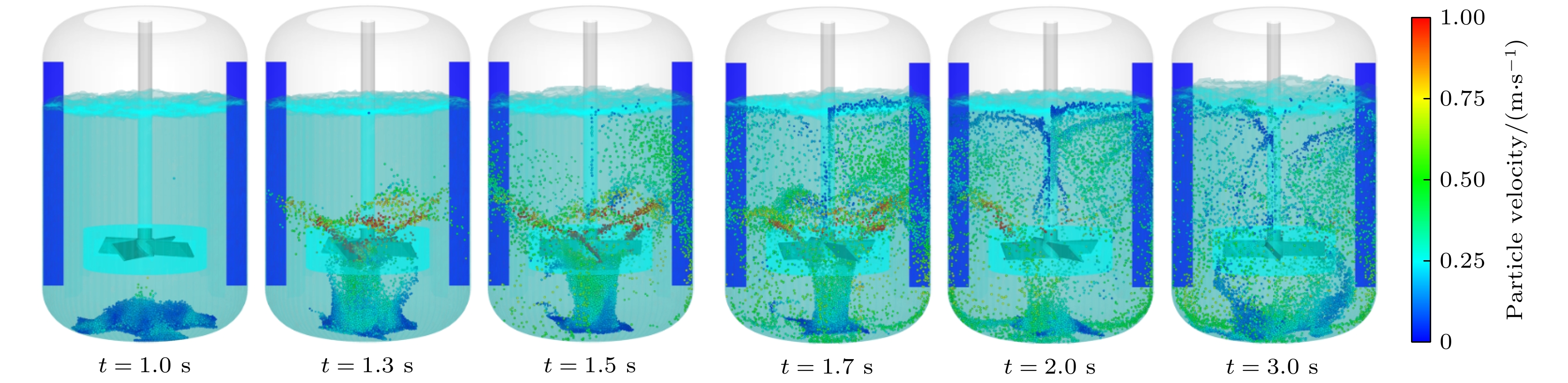

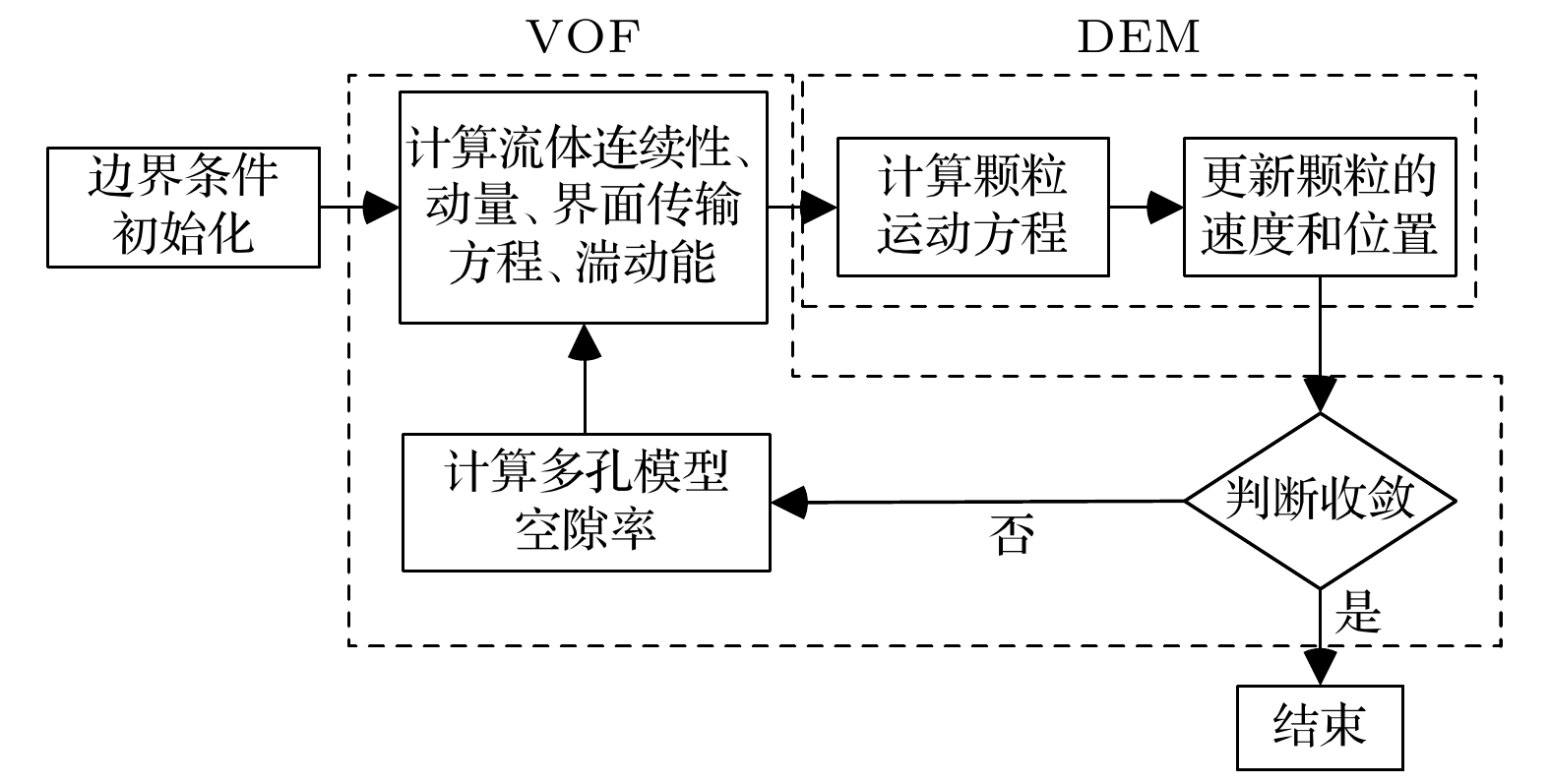

The mixing process of gas-liquid-solid three-phase flow is a complex multi-fluid-structure coupling dynamic problem. The relationship between the particle parameters and the physical spatial scale of the flow channel directly affects the calculation convergence. Numerical modeling and mesh processing of fluid-structure bidirectional interaction in the strong shear zone are difficult. Aiming at the above problems, a method of modeling and solving the gas-liquid-solid three-phase flow mixing is proposed. Based on the volume-of-fluid coupled with discrete-element-method model, a three-phase dynamic model considering particle motion is established. By solving the momentum equation, the bidirectional coupling of two-phase fluid and particle is realized. The user-defined function communication interface is developed independently to obtain the interaction force between fluid and particles, and a porous-interphase coupling solution is proposed to describe the trajectory of particles. Taking the mixing process of three-phase flow with strong shear for example, this method is used to study the influence of different aeration conditions on the free surface, velocity distribution and particle suspension characteristics in the physical space of the flow channel. The results show that strong shear and wall action can convert the tangential velocity of the fluid into axial and radial velocity; choosing an appropriate inflation velocity can eliminate the instability of the free surface and increasing the flow velocity of the fluid has a limited effect on the suspension of particles in some areas. The research results can provide a useful reference for studying the interaction mechanism of complex multiphase flow, and also provide technical support for the mixing production control of gas-liquid-solid three-phase particles.

-

Keywords:

- three-phase flow /

- solid particles /

- volume of fluid-discrete element method coupling /

- strong shear

[1] Delvigne F, Destain J, Thonart P 2005 Chem. Eng. J. 113 1

Google Scholar

Google Scholar

[2] Ge M, Ji S M, Tan D P, Cao H Q 2021 Int. J. Adv. Manuf. Tech. 114 3419

Google Scholar

Google Scholar

[3] Hosseini S, Patel D, Ein-Mozaffari F, Mehrvar M 2010 Ind. Eng. Chem. Res. 49 4426

Google Scholar

Google Scholar

[4] Wang S Y, Jiang X X, Wang R C, Wang X, Yang S W, Zhao J, Liu Y 2017 Adv. Powder Technol. 28 1611

Google Scholar

Google Scholar

[5] Panneerselvam R, Savithri S, Surender G D 2009 Ind. Eng. Chem. Res. 48 1611

Google Scholar

Google Scholar

[6] Li L, Tan D P, Yin Z C, Wang T, Fan X H, Wang R H 2021 Renew. Energy 175 887

Google Scholar

Google Scholar

[7] Li L, Tan D P, Wang T, Yin Z C, Fan X H, Wang R H 2021 Energy 216 119136

Google Scholar

Google Scholar

[8] Kasat G R, Khopkar A R, Ranade V V, Pandit A B 2008 Chem. Eng. Sci. 63 3877

Google Scholar

Google Scholar

[9] Qi H, Qin S K, Cheng Z C, Teng Q, Hong T, Xie Y 2021 J. Manuf. Processes 64 585

Google Scholar

Google Scholar

[10] Tan D P, Li L, Yin Z C, Li D F, Zhu Y L, Zheng S 2020 Int. J. Heat Mass Transfer 150 119250

Google Scholar

Google Scholar

[11] Alexander S, Alexander D, Markku N, Jan M, Falah A, Maximilian V B, Jochen S, Bernd E 2019 Chem. Eng. Sci. 196 37

Google Scholar

Google Scholar

[12] Musango L, John S, Lloyd M 2021 Powder Technol. 378 85

Google Scholar

Google Scholar

[13] Li L, Lu J F, Fang H, Yin Z C, Wang T, Wang R H, Fan X H, Zhao L J, Tan D P, Wan Y H 2020 IEEE Access 8 27649

Google Scholar

Google Scholar

[14] Han Y, Cundall P A 2013 Int. J. Numer. Anal. Methods Geomech. 37 10

Google Scholar

Google Scholar

[15] Bastien D, Juliane R, Louis F, Francois B, Bruno B 2021 Chem. Eng. Sci. 230 116137

Google Scholar

Google Scholar

[16] 邵婷, 胡银玉, 王文坦, 金涌, 程易 2013 中国化学工程学报 21 1069

Google Scholar

Google Scholar

Shao T, Hu Y Y, Wang W T, Jin Y, Cheng Y 2013 Chin. J. Chem. Eng. 21 1069

Google Scholar

Google Scholar

[17] Blais B, Lassaigne M, Goniva C, Fradette L 2016 J. Comput. Phys. 318 201

Google Scholar

Google Scholar

[18] Blais B, Bertrand F 2017 Chem. Eng. Res. Des. 118 270

Google Scholar

Google Scholar

[19] Blais B, Bertrand O, Fradette L, Bertrand F 2017 Chem. Eng. Res. Des. 123 388

Google Scholar

Google Scholar

[20] Xu W T, Tan Y B, Li M, Sun J L, Xie D, Liu Z 2020 Particuology 49 159

Google Scholar

Google Scholar

[21] Sun X, Sakai M 2015 Chem. Eng. Sci. 134 531

Google Scholar

Google Scholar

[22] Wu L, Gong M, Wang J T 2018 Ind. Eng. Chem. Res. 57 1714

Google Scholar

Google Scholar

[23] Kang Q Q, He D P, Zhao N, Feng X, Wang J T 2019 Chem. Eng. J. 386 122846

Google Scholar

Google Scholar

[24] 谭大鹏, 杨涛, 赵军, 计时鸣 2016 65 054701

Google Scholar

Google Scholar

Tan D P, Yang T, Zhao J, Ji S M 2016 Acta Phys. Sin. 65 054701

Google Scholar

Google Scholar

[25] 刘扬, 韩燕龙, 贾富国, 姚丽娜, 王会, 史宇菲 2015 64 114501

Google Scholar

Google Scholar

Liu Y, Han Y L, Jia F G, Yao L N, Wang H, Shi Y F 2015 Acta Phys. Sin. 64 114501

Google Scholar

Google Scholar

[26] Ergun S 1952 Chem. Eng. Prog. 48 89

Google Scholar

Google Scholar

[27] Ji S M, Xiao F Q, Tan D P 2010 Sci. China Technol. Sc. 53 100

Google Scholar

Google Scholar

[28] Saffman P G 1965 J. Fluid Mech. 22 385

Google Scholar

Google Scholar

[29] Tan D P, Ji S M, Fu Y Z 2016 Int. J. Adv. Manuf. Technol. 85 1261

Google Scholar

Google Scholar

[30] Li L, Qi H, Yin Z C, Li D F, Zhu Z L, Tangwarodomnukun V, Tan D P 2019 Powder Technol. 360 462

Google Scholar

Google Scholar

[31] Lu J F, Wang T, Li L, Yin Z C, Wang R H, Fan X H, Tan D P 2020 Processes 8 760

Google Scholar

Google Scholar

[32] Tamburini A, Cipollina A, Micale G, Brucato A, Ciofalo M 2012 Chem. Eng. J. 193 234

Google Scholar

Google Scholar

[33] Jahoda M, Tomaskova L, Mostek M 2009 Chem. Eng. Res. Des. 87 460

Google Scholar

Google Scholar

[34] Wang J J, Han Y, Gu X P, Feng L F, Hu G H 2013 AIChE J. 59 1066

Google Scholar

Google Scholar

[35] Xie L, Luo Z H 2017 Chem. Eng. Sci. 176 439

Google Scholar

Google Scholar

[36] Jovanovic A, Pezo M, Pezo L, Levic L 2014 Powder Technol. 266 240

Google Scholar

Google Scholar

-

表 1 流体和颗粒特性设置

Table 1. Characteristics settings of fluid and particle.

参数 值 空气密度 ${\rho _{\rm{a}}}$/(${\rm{kg}} \cdot {{\rm{m}}^{{ - 3}}}$) 1 空气黏度 ${\mu _{\rm{a}}}$/(${\rm{Pa}} \cdot {\rm{s}}$) 1 × 10–5 水密度 ${\rho _{\rm{w}}}$/(${\rm{kg}} \cdot {{\rm{m}}^{{ - 3}}}$) 1000 水黏度 ${\mu _{\rm{w}}}$/(${\rm{Pa}} \cdot {\rm{s}}$) 0.001 颗粒密度 ${\rho _{\rm{p}}}$/(${\rm{kg}} \cdot {{\rm{m}}^{{ - 3}}}$) 1100 颗粒直径 ${d_{\rm{p}}}$/mm 1 颗粒数目 ${n_{\rm{p}}}$ 10000 颗粒杨氏模量 ${Y_{\rm{P}}}$/${\rm{MPa}}$ 1 颗粒泊松比 ${\nu _{\rm{P}}}$ 0.25 壁面杨氏模量 ${Y_{\rm{w}}}$/${\rm{MPa}}$ 70000 壁面泊松比 ${\nu _{\rm{w}}}$ 0.3 滚动摩擦系数 ${\mu _{\rm{r}}}$ 0.01 静摩擦系数 ${\mu _{\rm{s}}}$ 0.5 恢复系数 ${e_{\rm{r}}}$ 0.5 搅拌桨速度 $\omega $/(${\rm r} \cdot {\rm min }^{ - 1 }$) 400 CFD时间步 $\Delta {t_{\rm{CFD}}}$/${\rm{s}}$ $2 \times {10^{ - 4}}$ DEM时间步 $\Delta {t_{\rm{DEM}}}$/${\rm{s}}$ $2 \times {10^{ - 5}}$ 耦合时间步 $\Delta {t_{{\rm{coupling}}}}$/${\rm{s}}$ $2 \times {10^{ - 4}}$ -

[1] Delvigne F, Destain J, Thonart P 2005 Chem. Eng. J. 113 1

Google Scholar

Google Scholar

[2] Ge M, Ji S M, Tan D P, Cao H Q 2021 Int. J. Adv. Manuf. Tech. 114 3419

Google Scholar

Google Scholar

[3] Hosseini S, Patel D, Ein-Mozaffari F, Mehrvar M 2010 Ind. Eng. Chem. Res. 49 4426

Google Scholar

Google Scholar

[4] Wang S Y, Jiang X X, Wang R C, Wang X, Yang S W, Zhao J, Liu Y 2017 Adv. Powder Technol. 28 1611

Google Scholar

Google Scholar

[5] Panneerselvam R, Savithri S, Surender G D 2009 Ind. Eng. Chem. Res. 48 1611

Google Scholar

Google Scholar

[6] Li L, Tan D P, Yin Z C, Wang T, Fan X H, Wang R H 2021 Renew. Energy 175 887

Google Scholar

Google Scholar

[7] Li L, Tan D P, Wang T, Yin Z C, Fan X H, Wang R H 2021 Energy 216 119136

Google Scholar

Google Scholar

[8] Kasat G R, Khopkar A R, Ranade V V, Pandit A B 2008 Chem. Eng. Sci. 63 3877

Google Scholar

Google Scholar

[9] Qi H, Qin S K, Cheng Z C, Teng Q, Hong T, Xie Y 2021 J. Manuf. Processes 64 585

Google Scholar

Google Scholar

[10] Tan D P, Li L, Yin Z C, Li D F, Zhu Y L, Zheng S 2020 Int. J. Heat Mass Transfer 150 119250

Google Scholar

Google Scholar

[11] Alexander S, Alexander D, Markku N, Jan M, Falah A, Maximilian V B, Jochen S, Bernd E 2019 Chem. Eng. Sci. 196 37

Google Scholar

Google Scholar

[12] Musango L, John S, Lloyd M 2021 Powder Technol. 378 85

Google Scholar

Google Scholar

[13] Li L, Lu J F, Fang H, Yin Z C, Wang T, Wang R H, Fan X H, Zhao L J, Tan D P, Wan Y H 2020 IEEE Access 8 27649

Google Scholar

Google Scholar

[14] Han Y, Cundall P A 2013 Int. J. Numer. Anal. Methods Geomech. 37 10

Google Scholar

Google Scholar

[15] Bastien D, Juliane R, Louis F, Francois B, Bruno B 2021 Chem. Eng. Sci. 230 116137

Google Scholar

Google Scholar

[16] 邵婷, 胡银玉, 王文坦, 金涌, 程易 2013 中国化学工程学报 21 1069

Google Scholar

Google Scholar

Shao T, Hu Y Y, Wang W T, Jin Y, Cheng Y 2013 Chin. J. Chem. Eng. 21 1069

Google Scholar

Google Scholar

[17] Blais B, Lassaigne M, Goniva C, Fradette L 2016 J. Comput. Phys. 318 201

Google Scholar

Google Scholar

[18] Blais B, Bertrand F 2017 Chem. Eng. Res. Des. 118 270

Google Scholar

Google Scholar

[19] Blais B, Bertrand O, Fradette L, Bertrand F 2017 Chem. Eng. Res. Des. 123 388

Google Scholar

Google Scholar

[20] Xu W T, Tan Y B, Li M, Sun J L, Xie D, Liu Z 2020 Particuology 49 159

Google Scholar

Google Scholar

[21] Sun X, Sakai M 2015 Chem. Eng. Sci. 134 531

Google Scholar

Google Scholar

[22] Wu L, Gong M, Wang J T 2018 Ind. Eng. Chem. Res. 57 1714

Google Scholar

Google Scholar

[23] Kang Q Q, He D P, Zhao N, Feng X, Wang J T 2019 Chem. Eng. J. 386 122846

Google Scholar

Google Scholar

[24] 谭大鹏, 杨涛, 赵军, 计时鸣 2016 65 054701

Google Scholar

Google Scholar

Tan D P, Yang T, Zhao J, Ji S M 2016 Acta Phys. Sin. 65 054701

Google Scholar

Google Scholar

[25] 刘扬, 韩燕龙, 贾富国, 姚丽娜, 王会, 史宇菲 2015 64 114501

Google Scholar

Google Scholar

Liu Y, Han Y L, Jia F G, Yao L N, Wang H, Shi Y F 2015 Acta Phys. Sin. 64 114501

Google Scholar

Google Scholar

[26] Ergun S 1952 Chem. Eng. Prog. 48 89

Google Scholar

Google Scholar

[27] Ji S M, Xiao F Q, Tan D P 2010 Sci. China Technol. Sc. 53 100

Google Scholar

Google Scholar

[28] Saffman P G 1965 J. Fluid Mech. 22 385

Google Scholar

Google Scholar

[29] Tan D P, Ji S M, Fu Y Z 2016 Int. J. Adv. Manuf. Technol. 85 1261

Google Scholar

Google Scholar

[30] Li L, Qi H, Yin Z C, Li D F, Zhu Z L, Tangwarodomnukun V, Tan D P 2019 Powder Technol. 360 462

Google Scholar

Google Scholar

[31] Lu J F, Wang T, Li L, Yin Z C, Wang R H, Fan X H, Tan D P 2020 Processes 8 760

Google Scholar

Google Scholar

[32] Tamburini A, Cipollina A, Micale G, Brucato A, Ciofalo M 2012 Chem. Eng. J. 193 234

Google Scholar

Google Scholar

[33] Jahoda M, Tomaskova L, Mostek M 2009 Chem. Eng. Res. Des. 87 460

Google Scholar

Google Scholar

[34] Wang J J, Han Y, Gu X P, Feng L F, Hu G H 2013 AIChE J. 59 1066

Google Scholar

Google Scholar

[35] Xie L, Luo Z H 2017 Chem. Eng. Sci. 176 439

Google Scholar

Google Scholar

[36] Jovanovic A, Pezo M, Pezo L, Levic L 2014 Powder Technol. 266 240

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 15481

- PDF Downloads: 475

- Cited By: 0

DownLoad:

DownLoad: