-

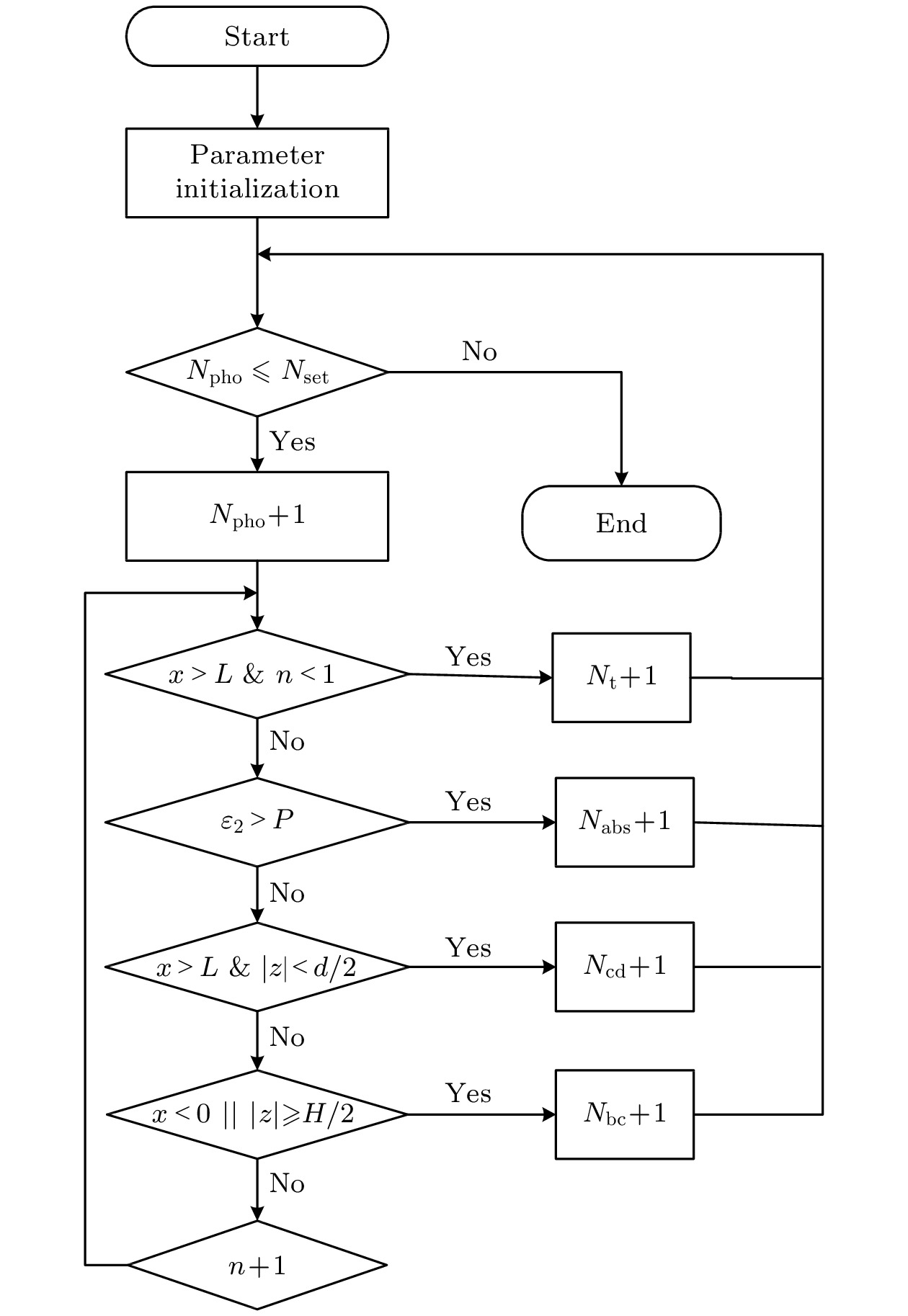

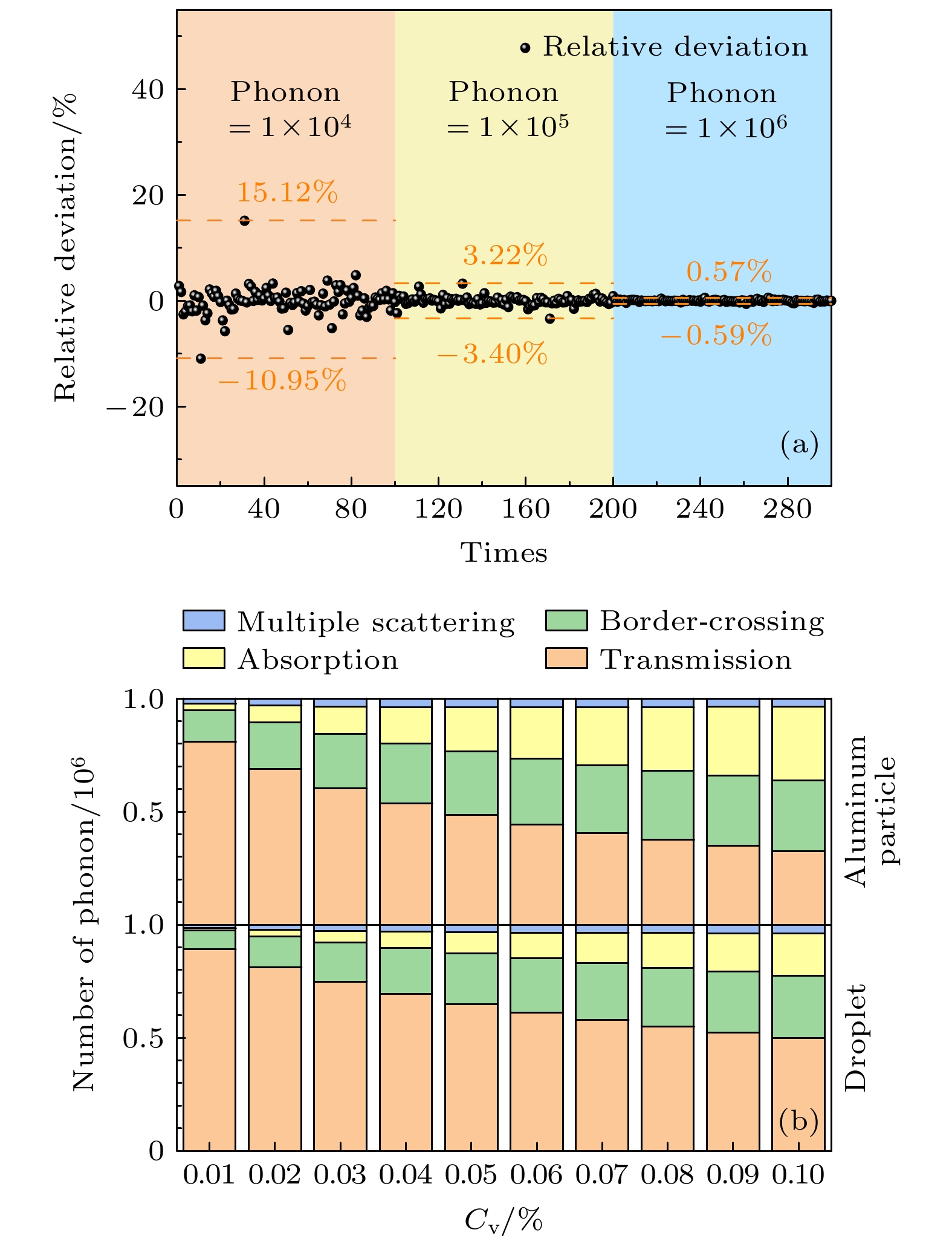

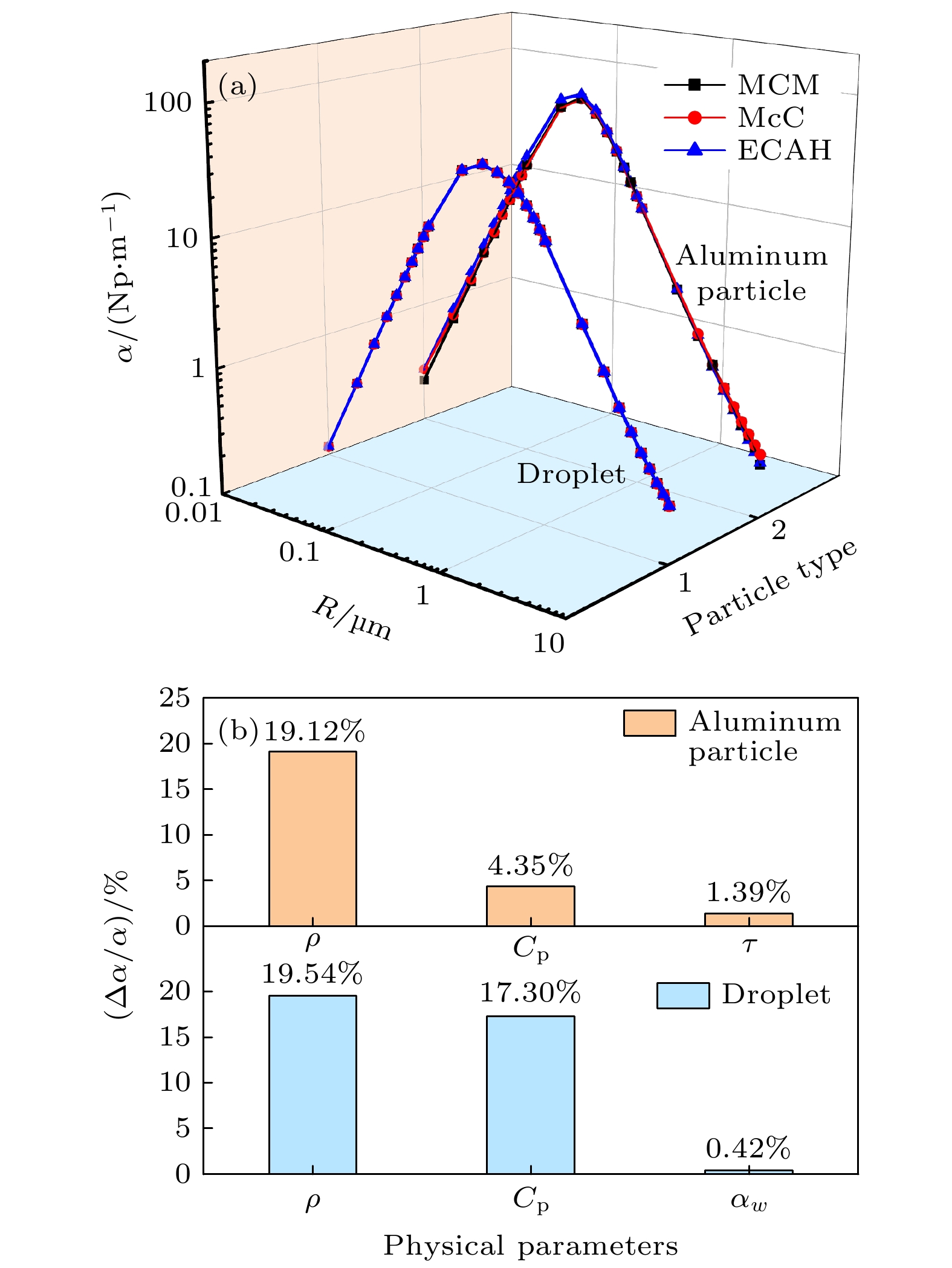

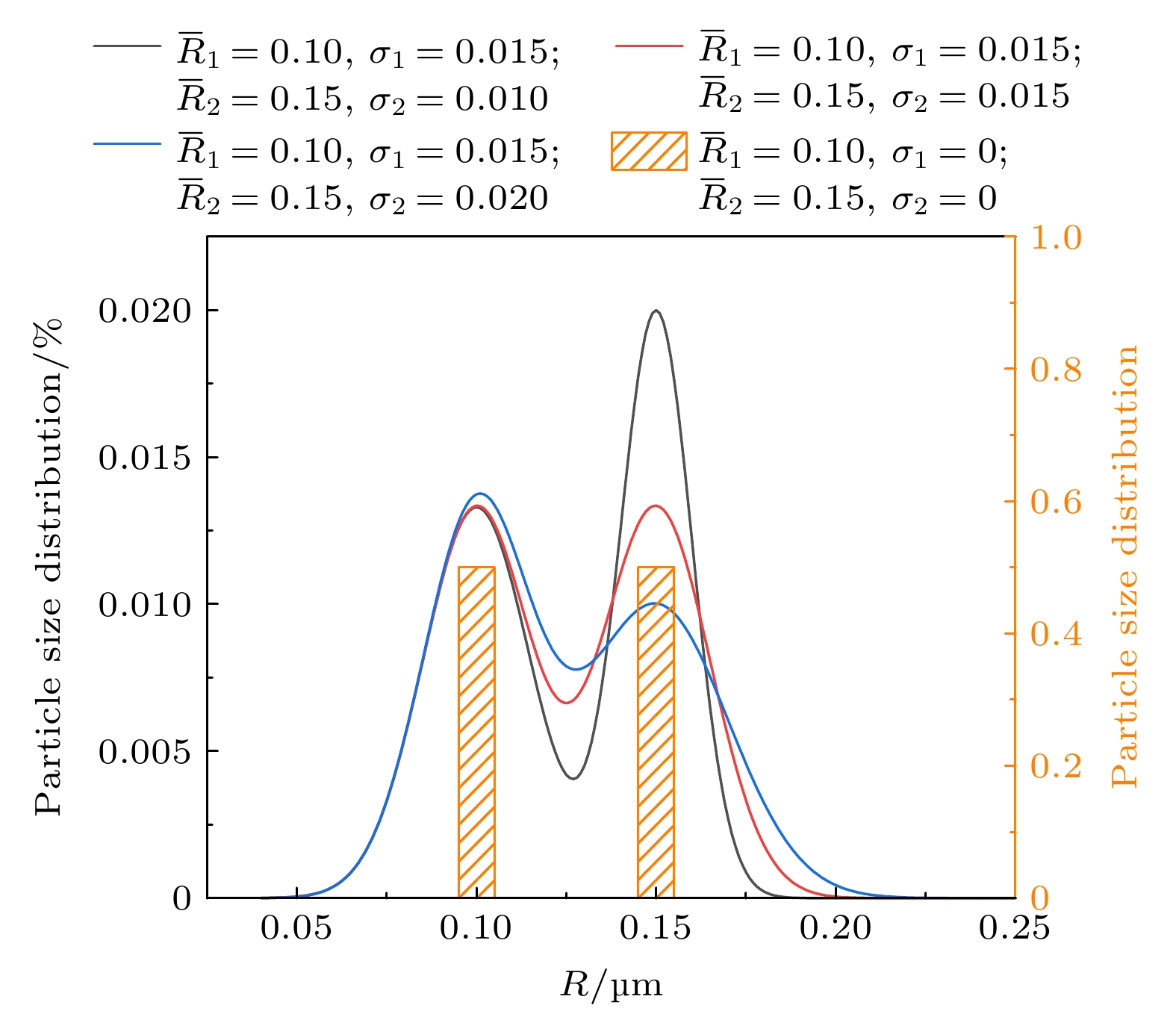

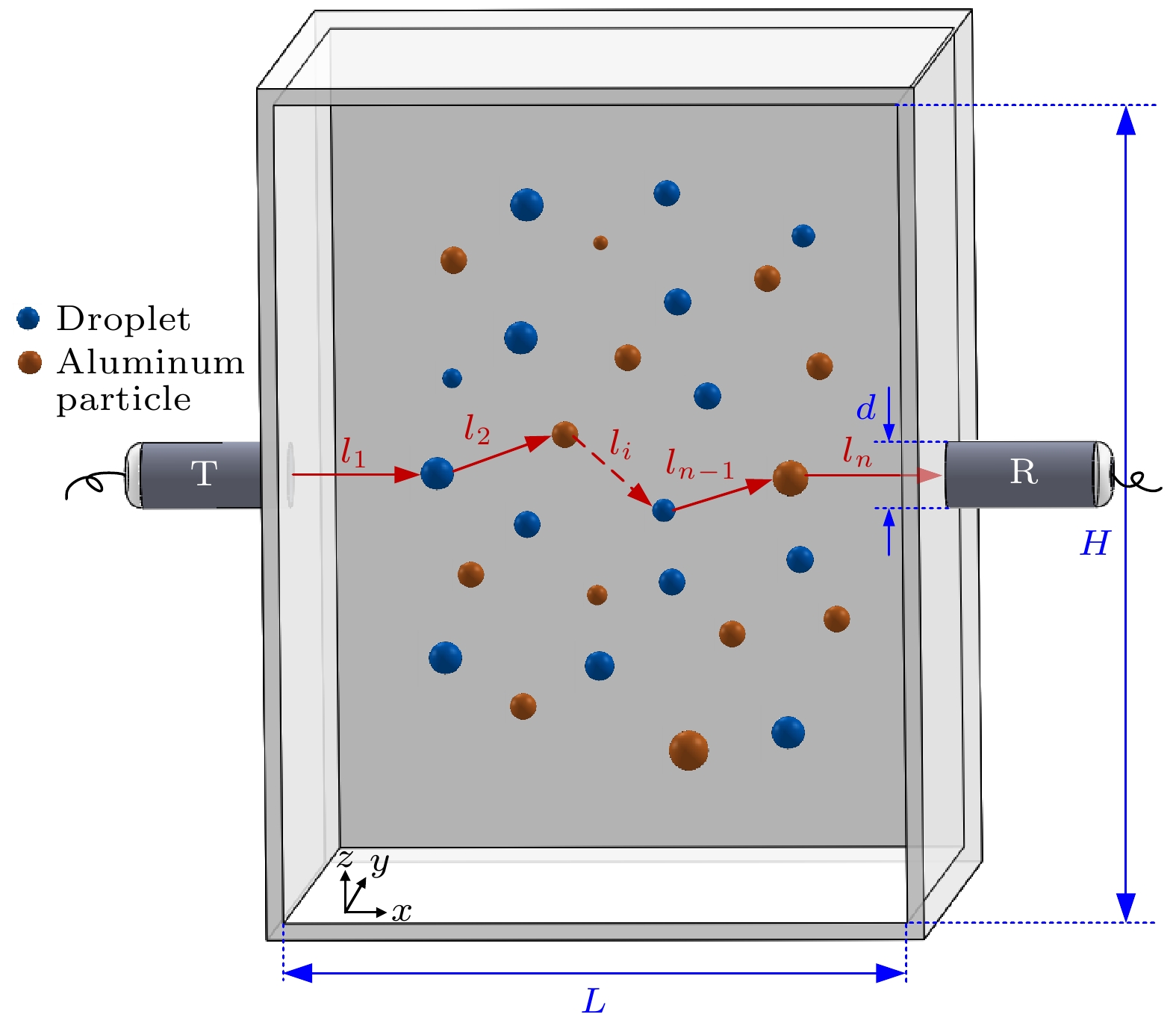

From the perspective of calculating ultrasonic absorption and scattering properties of individual solid particle and droplet, the ultrasonic wave is treated as discrete phonons. And by tracking their motion process and event statistics, a new prediction model of ultrasonic attenuation of spherical mixed particles in gaseous medium is established with Monte Carlo method. Considering the difference in physical properties between solid particles and liquid particles, the ultrasonic absorption characteristics of the two kinds of particles are obviously different, and when dimensionless particle size kR ≤ 1, the backscattering of particles is uniform and dominant, then the ultrasonic scattering pressures gradually transit from the dominant position of backscattering to the trend of forward enhancement with the increase of dimensionless particle size. The numerical simulation results for the system with a single particle type are compared with those from various standard models such as classical ECAH model and McC model, showing that they are in good agreement. Similarly, the results are then compared with experimental results, which accord with each other in general. After calculating and verifying the ultrasonic attenuation of aluminum particles and submicron droplets respectively in air, the method is extended to the three-phase monodisperse and polydisperse mixed particle system composed of aluminum particles and liquid droplets. In the three-phase system of gas-liquid-solid mixed particles, the particle type has a significant influence on ultrasonic attenuation, and the attenuation contribution of different particles against mixing ratio does not follow the linear gradient with the increase of volume concentration. For a polydisperse system, the ultrasonic attenuation spectrum is greatly affected by the average particle size, but it is insensitive to the width of particle size distribution. The numerical results also show that both the particle type and particle distribution size should be carefully take into account in the polydisperse system. Moreover, the MCM model can be further extended to non-spherical particles and combined with mathematical inversion to form the theoretical basis for the measurement of mixed particle system.

-

Keywords:

- Monte Carlo method /

- mixed particle three-phase system /

- polydisperse /

- ultrasonic attenuation

[1] 黄婷 2018 博士学位论文(成都: 西南石油大学)

Huang T 2018 Ph. D. Dissertation (Chengdu: Southwest Petroleum University) (in Chinese)

[2] 葛春亮, 蒋楠, 刘文榉, 厉雄峰, 李晨朗 2021 热力发电 50 103

Google Scholar

Google Scholar

Ge C L, Jing N, Liu W J, Li X F, Li C L 2021 Therm. Power Gener. 50 103

Google Scholar

Google Scholar

[3] 黄正梁, 王超, 李少硕, 杨遥, 孙婧元, 王靖岱, 阳永荣 2020 化工学报 71 274

Huang Z L, Wang C, Li S S, Yang Y, Sun J Y, Wang J D, Yang Y R 2020 J. Chem. Ind. Eng. 71 274

[4] 陶芳芳, 宁尚雷, 靳海波 2020 过程工程学报 20 371

Google Scholar

Google Scholar

Tao F F, Ning S L, Jin H B 2020 Chin. J. Process Eng. 20 371

Google Scholar

Google Scholar

[5] 万梓傲, 童永霞, 陈思井, 周金荣 2020 舰船电子工程 40 174

Google Scholar

Google Scholar

Wan Z A, Tong Y X, Chen S J, Zhou J R 2020 Ship Electron. Eng. 40 174

Google Scholar

Google Scholar

[6] Epstein P S, Carhart R R 1953 J. Acoust. Soc. Am. 25 553

Google Scholar

Google Scholar

[7] Allegra J R, Hawley S A 1972 J. Acoust. Soc. Am. 51 1545

Google Scholar

Google Scholar

[8] Mcclements D J, Hemar Y, Herrmann N 1999 J. Acoust. Soc. Am. 105 915

Google Scholar

Google Scholar

[9] Mcclements D J, Coupland J N 1996 Colloids Surf., A 117 161

Google Scholar

Google Scholar

[10] Mcclements D J 1992 J. Acoust. Soc. Am. 91 849

Google Scholar

Google Scholar

[11] Parker N G, Povey M J W 2012 Food Hydrocolloids Oxford 26 99

Google Scholar

Google Scholar

[12] Liu L 2009 Chem. Eng. Sci. 64 5036

Google Scholar

Google Scholar

[13] Dong L L, Su M X, Xue M H, Cai X S, Shang Z T 2007 AIP Conf. Proc. 914 654

Google Scholar

Google Scholar

[14] Wang Q, Attenborough K, Woodhead S 2000 J. Sound Vib. 236 781

Google Scholar

Google Scholar

[15] Wang Q, Attenborough K, Woodhead S 2001 Proc. Inst. Mech. Eng. Part E 215 133

Google Scholar

Google Scholar

[16] 杜娜, 苏明旭 2019 应用声学 38 980

Google Scholar

Google Scholar

Du N, Su M X 2019 J. Appl. Acoust. 38 980

Google Scholar

Google Scholar

[17] 侯森, 胡长青, 赵梅 2021 70 044301

Google Scholar

Google Scholar

Hou S, Hu C Q, Zhao M 2021 Acta Phys. Sin. 70 044301

Google Scholar

Google Scholar

[18] 陈时, 张迪, 王成会, 张引红 2019 68 074301

Google Scholar

Google Scholar

Chen S, Zhang D, Wang C H, Zhang Y H 2019 Acta Phys. Sin. 68 074301

Google Scholar

Google Scholar

[19] 郭盼盼, 苏明旭, 陈丽, 蔡小舒 2014 过程工程学报 14 562

Guo P P, Su M X, Chen L, Cai X S 2014 Chin. J. Process Eng. 14 562

[20] 李运思, 苏明旭, 杨荟楠, 凡凤仙, 蔡小舒 2017 声学学报 42 586

Google Scholar

Google Scholar

Li Y S, Su M X, Yang H N, Fan F X, Cai X S 2017 Acta. Acust. 42 586

Google Scholar

Google Scholar

[21] Huang B F, Fan F X, Li Y S, Su M X 2019 Ultrason. 94 218

Google Scholar

Google Scholar

[22] 冷坤, 章曦, 武文远, 龚艳春, 杨云涛 2018 物理与工程 28 74

Google Scholar

Google Scholar

Leng K, Zhang X, Wu W Y, Gong Y C, Yang Y T 2018 Phys. Eng. 28 74

Google Scholar

Google Scholar

[23] 王敏, 申玉清, 陈震宇, 徐鹏 2021 计算物理 38 623

Google Scholar

Google Scholar

Wang M, Shen Y Q, Chen Z Y, Xu P 2021 Chin. J. Comput. Phys. 38 623

Google Scholar

Google Scholar

[24] Hay A E, Mercer D G 1985 J. Acoust. Soc. Am. 78 1761

Google Scholar

Google Scholar

[25] Faran J J 1951 J. Acoust. Soc. Am. 23 405

Google Scholar

Google Scholar

[26] 冯若 1999 超声手册 (南京: 南京大学出版社) 第66页

Feng R 1999 Ultrasonic Handbook (Nanjing: Nanjing University Press) p66 (in Chinese)

[27] Wang M, Zheng D, Dong J, Hu J 2021 IEEE Trans. Instrum. Meas. 70 1

Google Scholar

Google Scholar

-

表 1 数值计算中介质和颗粒物性参数(25 ℃)

Table 1. Parameters in the numerical simulation (25 ℃)

密度

ρ/(kg·m–3)声速

c/(m·s–1)剪切模量

G/Pa比热容

cp/(J·kg–1·K–1)黏度

μ/(Pa·s)热膨胀

系数 β/K–1声吸收

系数 aw/(Np·m–1)空气 1.21 334.3 — 1004 1.81 × 10–4 3.661 × 10–4 1.7 × 10–11 液滴 1000 1497 — 4178.5 9.03 × 10–4 2.57 × 10–4 2.2 × 10–14 铝粉 3800 5000 2.63 × 1010 769 — 2.65 × 10–5 1.3 × 10–9 -

[1] 黄婷 2018 博士学位论文(成都: 西南石油大学)

Huang T 2018 Ph. D. Dissertation (Chengdu: Southwest Petroleum University) (in Chinese)

[2] 葛春亮, 蒋楠, 刘文榉, 厉雄峰, 李晨朗 2021 热力发电 50 103

Google Scholar

Google Scholar

Ge C L, Jing N, Liu W J, Li X F, Li C L 2021 Therm. Power Gener. 50 103

Google Scholar

Google Scholar

[3] 黄正梁, 王超, 李少硕, 杨遥, 孙婧元, 王靖岱, 阳永荣 2020 化工学报 71 274

Huang Z L, Wang C, Li S S, Yang Y, Sun J Y, Wang J D, Yang Y R 2020 J. Chem. Ind. Eng. 71 274

[4] 陶芳芳, 宁尚雷, 靳海波 2020 过程工程学报 20 371

Google Scholar

Google Scholar

Tao F F, Ning S L, Jin H B 2020 Chin. J. Process Eng. 20 371

Google Scholar

Google Scholar

[5] 万梓傲, 童永霞, 陈思井, 周金荣 2020 舰船电子工程 40 174

Google Scholar

Google Scholar

Wan Z A, Tong Y X, Chen S J, Zhou J R 2020 Ship Electron. Eng. 40 174

Google Scholar

Google Scholar

[6] Epstein P S, Carhart R R 1953 J. Acoust. Soc. Am. 25 553

Google Scholar

Google Scholar

[7] Allegra J R, Hawley S A 1972 J. Acoust. Soc. Am. 51 1545

Google Scholar

Google Scholar

[8] Mcclements D J, Hemar Y, Herrmann N 1999 J. Acoust. Soc. Am. 105 915

Google Scholar

Google Scholar

[9] Mcclements D J, Coupland J N 1996 Colloids Surf., A 117 161

Google Scholar

Google Scholar

[10] Mcclements D J 1992 J. Acoust. Soc. Am. 91 849

Google Scholar

Google Scholar

[11] Parker N G, Povey M J W 2012 Food Hydrocolloids Oxford 26 99

Google Scholar

Google Scholar

[12] Liu L 2009 Chem. Eng. Sci. 64 5036

Google Scholar

Google Scholar

[13] Dong L L, Su M X, Xue M H, Cai X S, Shang Z T 2007 AIP Conf. Proc. 914 654

Google Scholar

Google Scholar

[14] Wang Q, Attenborough K, Woodhead S 2000 J. Sound Vib. 236 781

Google Scholar

Google Scholar

[15] Wang Q, Attenborough K, Woodhead S 2001 Proc. Inst. Mech. Eng. Part E 215 133

Google Scholar

Google Scholar

[16] 杜娜, 苏明旭 2019 应用声学 38 980

Google Scholar

Google Scholar

Du N, Su M X 2019 J. Appl. Acoust. 38 980

Google Scholar

Google Scholar

[17] 侯森, 胡长青, 赵梅 2021 70 044301

Google Scholar

Google Scholar

Hou S, Hu C Q, Zhao M 2021 Acta Phys. Sin. 70 044301

Google Scholar

Google Scholar

[18] 陈时, 张迪, 王成会, 张引红 2019 68 074301

Google Scholar

Google Scholar

Chen S, Zhang D, Wang C H, Zhang Y H 2019 Acta Phys. Sin. 68 074301

Google Scholar

Google Scholar

[19] 郭盼盼, 苏明旭, 陈丽, 蔡小舒 2014 过程工程学报 14 562

Guo P P, Su M X, Chen L, Cai X S 2014 Chin. J. Process Eng. 14 562

[20] 李运思, 苏明旭, 杨荟楠, 凡凤仙, 蔡小舒 2017 声学学报 42 586

Google Scholar

Google Scholar

Li Y S, Su M X, Yang H N, Fan F X, Cai X S 2017 Acta. Acust. 42 586

Google Scholar

Google Scholar

[21] Huang B F, Fan F X, Li Y S, Su M X 2019 Ultrason. 94 218

Google Scholar

Google Scholar

[22] 冷坤, 章曦, 武文远, 龚艳春, 杨云涛 2018 物理与工程 28 74

Google Scholar

Google Scholar

Leng K, Zhang X, Wu W Y, Gong Y C, Yang Y T 2018 Phys. Eng. 28 74

Google Scholar

Google Scholar

[23] 王敏, 申玉清, 陈震宇, 徐鹏 2021 计算物理 38 623

Google Scholar

Google Scholar

Wang M, Shen Y Q, Chen Z Y, Xu P 2021 Chin. J. Comput. Phys. 38 623

Google Scholar

Google Scholar

[24] Hay A E, Mercer D G 1985 J. Acoust. Soc. Am. 78 1761

Google Scholar

Google Scholar

[25] Faran J J 1951 J. Acoust. Soc. Am. 23 405

Google Scholar

Google Scholar

[26] 冯若 1999 超声手册 (南京: 南京大学出版社) 第66页

Feng R 1999 Ultrasonic Handbook (Nanjing: Nanjing University Press) p66 (in Chinese)

[27] Wang M, Zheng D, Dong J, Hu J 2021 IEEE Trans. Instrum. Meas. 70 1

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5524

- PDF Downloads: 76

- Cited By: 0

DownLoad:

DownLoad: