-

Soft, thin, skin-integrated electronics, i.e. epidermal electronics, has become a hotspot in biomedical engineering and drawn great attention for their applications in health monitoring, disease diagnosis and therapies. However, soft powering system is still a challenge for epidermal electronics, since the thickness and weight of the existing flexible energy harvesting and storage devices are very hard to meet the requirements of epidermal electronics. Here we present a stretchable and flexible self-powering epidermal electronic device based on rubbery piezoelectric composites formed by a ternary blend of PDMS, lead zirconate titanate (PZT) and graphene. The mixed PZT rubber is soft, ultra-thin and light weight and intrinsically stretchable. By combining soft PDMS substrate and advanced mechanics designed interdigital electrodes/interconnects, a stretchable and skin-integrated device for tactile sensing is realized. The soft device can not only accurately measure a board range of force from 2.84 kPa to 11.72 kPa but also exhibit great flexibility that can maintain stable performance under various mechanical deformations, such as bending, stretching and twisting. On-skin demonstration tests reveal that this self-powering device can clearly distinguish the differences among mechanical stimulations such as touching, poking, tapping and hitting. Furthermore, the self-powering nature of these devices allows energy to be harvested from daily body actives, for instance, hard touching by hand can lighten up to 15 light-emitting diodes.

-

Keywords:

- piezoelectric materials /

- graphene /

- flexible electronics /

- wearable devices

[1] Yu X, Wang H, Ning X, et al. 2018 Nat. Biomed. Eng. 2 165

Google Scholar

Google Scholar

[2] Koo J, MacEwan M R, Kang S K, et al. 2018 Nat. Med. 24 1830

Google Scholar

Google Scholar

[3] Ray T R, Choi J, Bandodkar A J, et al. 2019 Chem. Rev. 119 5461

Google Scholar

Google Scholar

[4] Wang C, Wang C, Huang Z, et al. 2018 Adv. Mater. 30 1801368

Google Scholar

Google Scholar

[5] Carlson A, Bowen A M, Huang Y, et al. 2012 Adv. Mater. 24 5284

Google Scholar

Google Scholar

[6] Sim K, Chen S, Li Z, et al. 2019 Nat. Electron. 2 471

Google Scholar

Google Scholar

[7] Liu Y, Xu Y, Avila R, et al. 2019 Nanotechnology 30 414001

Google Scholar

Google Scholar

[8] Rogers J A, Nuzzo R G 2005 Mater. Today 8 50

[9] Widlund T, Yang S, Hsu Y Y, et al. 2014 Int. J. Solids Struct. 51 4026

Google Scholar

Google Scholar

[10] Wang B, Bao S, Vinnikova S, et al. 2017 npj Flex. Electron. 1 1

Google Scholar

Google Scholar

[11] Xie Z, Ji B, Huo Q 2018 J. Appl. Mech. Trans. ASME 85 045001

Google Scholar

Google Scholar

[12] Chen H, Zhu F, Jang K I, et al. 2018 J. Mech. Phys. Solids 120 199

Google Scholar

Google Scholar

[13] Guo Q, Koo J, Xie Z, et al. 2019 Adv. Funct. Mater. 29 1905451

Google Scholar

Google Scholar

[14] Xie Z, Avila R, Huang Y, et al. 2019 Adv. Mater. 32 1902767

[15] Webb R C, Bonifas A P, Behnaz A, et al. 2013 Nat. Mater. 12 938

Google Scholar

Google Scholar

[16] Yang J, Shi R, Lou Z, et al. 2019 Small 15 1902801

Google Scholar

Google Scholar

[17] Boutry C M, Beker L, Kaizawa Y, et al. 2019 Nat. Biomed. Eng. 3 47

Google Scholar

Google Scholar

[18] Wang C C, Li X, Hu H, et al. 2018 Nat. Biomed. Eng. 2 687

Google Scholar

Google Scholar

[19] Ma Y, Choi J, Hourlier-Fargette A, et al. 2018 Proc. Natl. Acad. Sci. U. S. A. 115 11144

Google Scholar

Google Scholar

[20] Liu Y, Zhao L, Avila R, et al. 2020 Mater. Today Phys. 13 100199

Google Scholar

Google Scholar

[21] Wang Y, Qiu Y, Ameri S K, et al. 2018 npj Flex. Electron. 2 1

Google Scholar

Google Scholar

[22] Torrente-Rodríguez R M, Tu J, Yang Y, et al. 2020 Matter 2 921

Google Scholar

Google Scholar

[23] Kim S B, Lee K H, Raj M S, et al. 2018 Small 14 1802876

Google Scholar

Google Scholar

[24] Bandodkar A J, Gutruf P, Choi J, et al. 2019 Sci. Adv. 5 eaav3294

Google Scholar

Google Scholar

[25] Goni O, Lee S, Jin H, et al. 2020 PNAS 117 7063

Google Scholar

Google Scholar

[26] Lee K H, Ni X, Lee J H J Y, et al. 2019 Nat. Biomed. Eng. 4 148

[27] Liu Y, Norton J J S, Qazi R, et al. 2016 Sci. Adv. 2 e1601185

Google Scholar

Google Scholar

[28] Shin G, Gomez A M, Al-Hasani R, et al. 2017 Neuron 93 509

Google Scholar

Google Scholar

[29] Gutruf P, Rogers J A 2018 Curr. Opin. Neurobiol. 50 42

[30] Park S Il, Brenner D S, Shin G, et al. 2015 Nat. Biotechnol. 33 1280

Google Scholar

Google Scholar

[31] Chung H U, Kim B H, Lee J Y, et al. 2019 Science (80-.) 363 eaau0780

Google Scholar

Google Scholar

[32] Hong Y J, Jeong H, Cho K W, et al. 2019 Adv. Funct. Mater. 29 1808247

Google Scholar

Google Scholar

[33] Huang Z, Hao Y, Li Y, et al. 2018 Nat. Electron. 1 473

Google Scholar

Google Scholar

[34] Yu X, Xie Z, Yu Y, et al. 2019 Nature 575 473

Google Scholar

Google Scholar

[35] Liu Y, Wang L, Zhao L, et al. 2020 Adv. Electron. Mater. 6 1901174

Google Scholar

Google Scholar

[36] Liu Y, Zhao L, Wang L, et al. 2019 Adv. Mater. Technol. 4 1900744

Google Scholar

Google Scholar

[37] Erturk A, Inman D J 2011 Chichester

[38] Lin Z H, Yang Y, Wu J M, et al. 2012 J. Phys. Chem. Lett. 3 3599

Google Scholar

Google Scholar

[39] Niu X, Jia W, Qian S, et al. 2019 ACS Sustain. Chem. Eng. 7 979

Google Scholar

Google Scholar

[40] Liu Y, Wang L, Zhao L, et al. 2020 InfoMat 2 318

Google Scholar

Google Scholar

[41] Jung J H, Lee M, Hong J Il, et al. 2011 ACS Nano 5 10041

Google Scholar

Google Scholar

[42] Kim K H, Lee K Y, Seo J S, et al. 2011 Small 7 2577

Google Scholar

Google Scholar

[43] Hwang G T, Park H, Lee J H, et al. 2014 Adv. Mater. 26 4880

Google Scholar

Google Scholar

[44] Park K Il, Son J H, Hwang G T, et al. 2014 Adv. Mater. 26 2514

Google Scholar

Google Scholar

[45] Dagdeviren C, Yang B D, Su Y, et al. 2014 Proc. Natl. Acad. Sci. U. S. A. 111 1927

Google Scholar

Google Scholar

[46] Arumugam V, Naresh M D, Sanjeevi R 1994 J. Biosci. 19 307

Google Scholar

Google Scholar

-

图 1 柔性压电皮肤电子器件 (a) 器件结构图; (b) 蛇纹线结构叉指电极整体、细节及其设计图; (c) 器件贴于皮肤表面的照片; (d) 对器件分别进行纵向、横向拉伸及扭转、弯曲变形的照片; (e) 三元压电橡胶表面形貌的SEM图像; (f) SEM图像范围内C, Si, O, Pb, Zr, Ti元素的能量色散X射线EDX分布图

Figure 1. The flexible piezoelectric epidermal electronic device: (a) Explosive view of the structure of the device; (b) overall and detailed photos of the serpentine structured interdigital electrodes and the design; (c) photograph showing the device attached to the skin; (d) photographs showing the device under longitudinal and latitudinal stretching, twisting and bending, respectively; (e) the SEM image of the surface morphology of the graphene/PZT/PDMS ternary piezoelectric rubber; (f) energy dispersive X-ray spectroscopy (EDX) images illustrating the distribution of C, Si, O, Pb, Zr and Ti.

图 2 压电器件在1 Hz撞击频率下随撞击压力变化的电学性能 (a) 不同撞击压力下开路电压输出的实时测量值; (b) 以压力为变量的开路电压平均峰值曲线, 内插图为1 kPa及以下的小数量级压力下(虚线框内部分)的开路电压输出曲线放大图; (c) 不同撞击压力下短路电流输出的实时测量值; (d) 以压力为变量的短路电流平均峰值曲线, 内插图为1 kPa及以下的小数量级压力下(虚线框内部分)的短路电流输出曲线放大图

Figure 2. Electrical performance of the piezoelectric device with varying applied pressure under a hitting frequency of 1 Hz: (a) Real-time measured open-circuit voltage output under varying applied pressure; (b) average peak open-circuit voltage as a function of pressure (inset: OC voltage output at about 1 kPa pressure and below); (c) real-time measured short-circuit current output under varying applied pressure; (d) average peak short-circuit current as a function of pressure (inset: SC current output at about 1 kPa pressure and below).

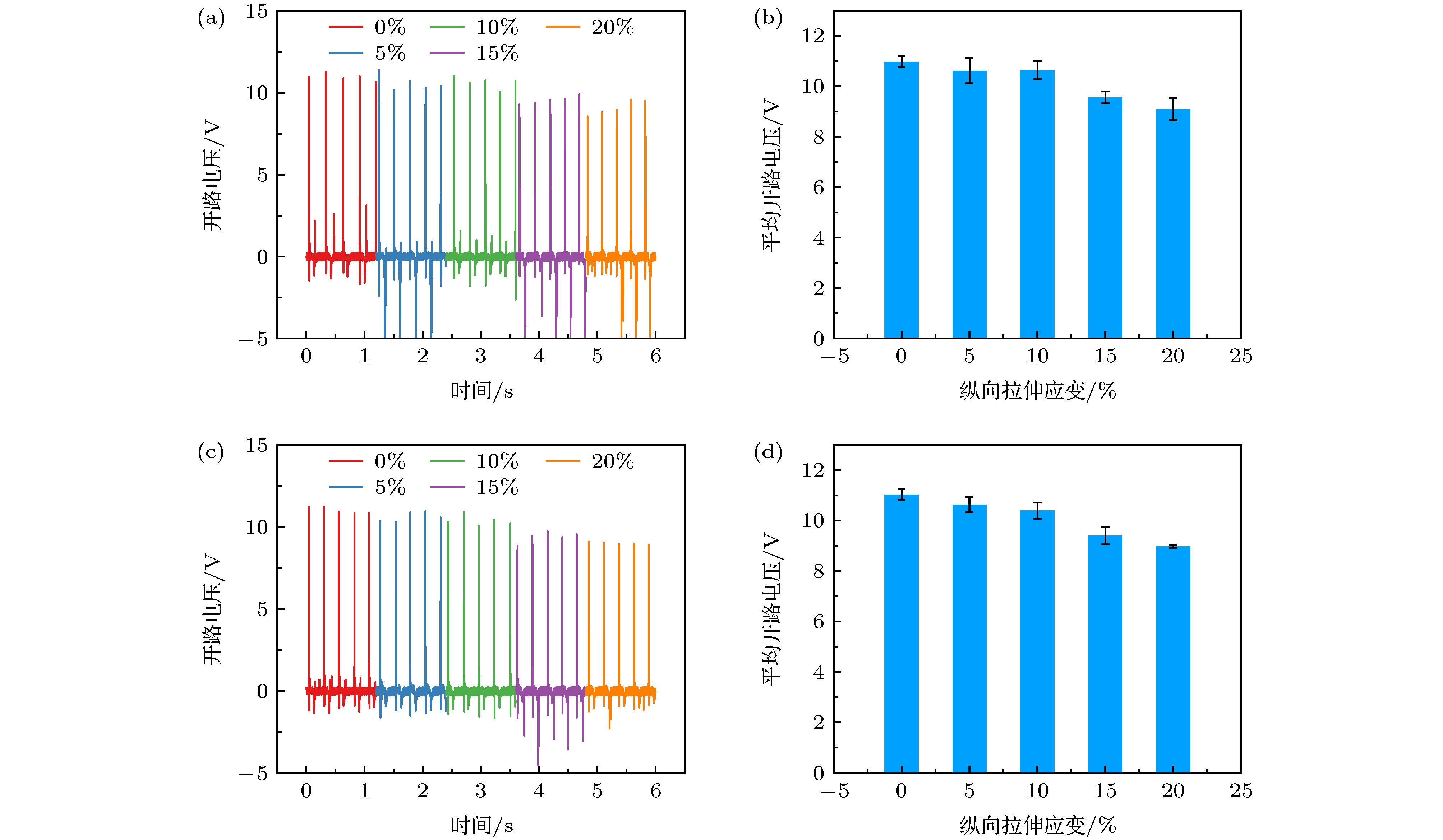

图 3 压电器件在纵向以及横向不同拉伸应变下, 在同一撞击压力((23.17 ± 1.76) kPa)下的电学性能 (a) 纵向拉伸下的开路电压输出实时测量值; (b) 纵向拉伸下的开路电压平均峰值统计图; (c) 横向拉伸下的开路电压输出实时测量值; (d) 横向拉伸下的开路电压平均峰值统计图

Figure 3. Electrical performance of the piezoelectric device with identical applied pressure ((23.17 ± 1.76) kPa) under varying longitu-dinal and latitudinal stretching strain: (a) Real-time measured open-circuit voltage output under varying longitudinal stretching strain; (b) average peak open-circuit voltage as a function of longitudinal strain; (c) real-time measured open-circuit voltage output under varying latitudinal strain; (d) average peak open-circuit voltage as a function of latitudinal strain.

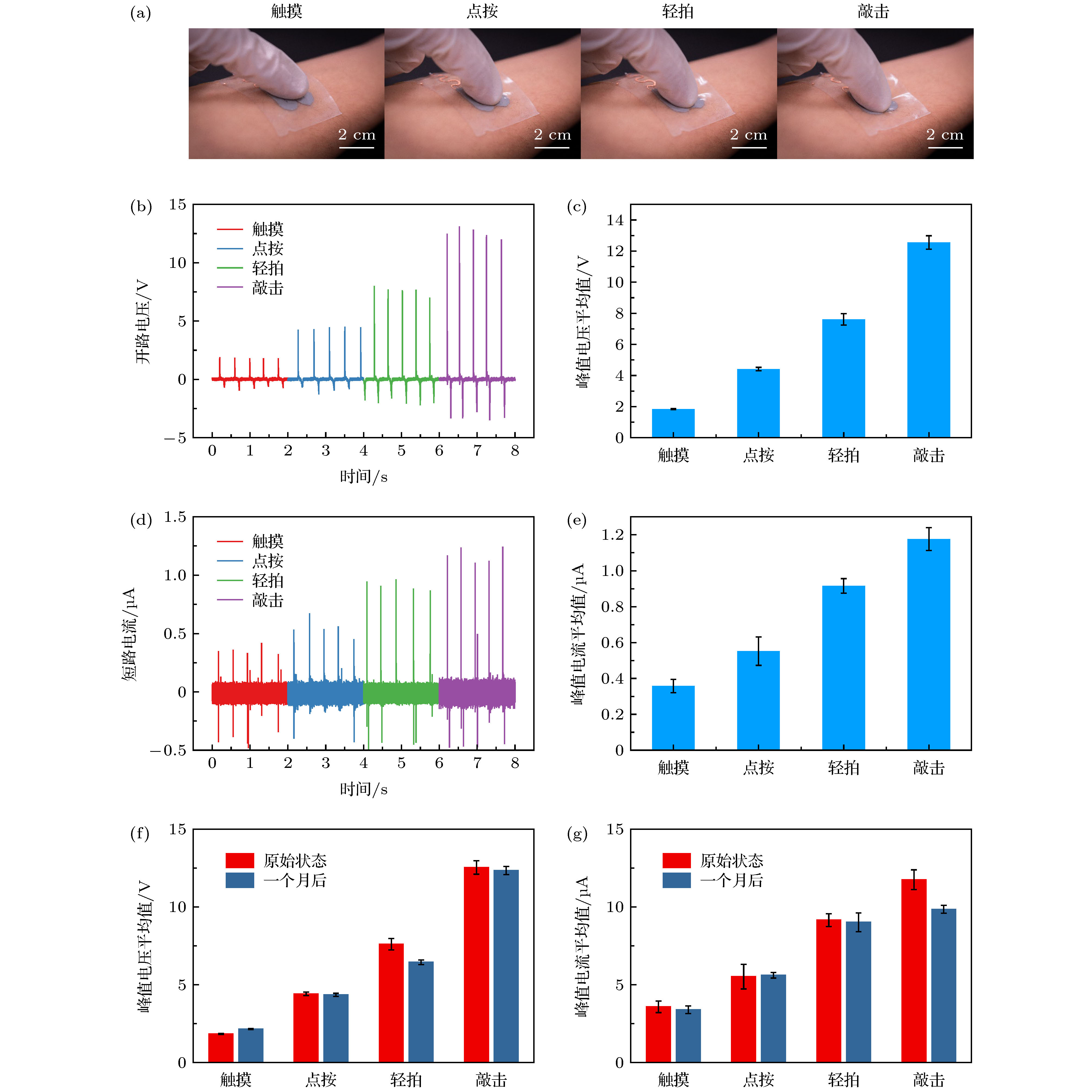

图 4 压电器件贴于人体表面实际测试时的电学性能 (a) 4种不同力度的接触方式: 触摸、点按、轻拍、敲击; (b) 开路电压输出的实时测量值; (c) 开路电压平均峰值统计图; (d) 短路电流输出的实时测量值; (e) 短路电流平均峰值统计图; (f) 器件经历长时间后的触觉传感开路电压与原始性能的对比; (g)器件经历长时间后的触觉传感短路电流与原始性能的对比

Figure 4. Electrical performance of the piezoelectric device when attached to human skin: (a) Photos of four different contact method: touching, poking, tapping and hitting; (b) real-time measured open-circuit voltage outputs; (c) average peak open-circuit voltages; (d) real-time measured short-circuit current outputs; (e) average peak short-circuit currents; (f) comparison between open-circuit voltage outputs of devices in original state and after one-month use when used for tactile sensing; (g) comparison between short-circuit current outputs of devices in original state and after one-month use when used for tactile sensing.

图 5 压电器件输出电能为15个LED灯泡供电测试 (a), (b) 在手指与压电器件分离时, LED灯灭; (c), (d) 手指敲打压电器件瞬间, 15个LED灯泡全部亮起

Figure 5. Demonstration test of supplying energy for 15 LED bulbs only by the piezoelectric device: (a), (b) LEDs are blacked out when fingers lift off from the device; (c), (d) 15 LEDs are all lighten up at the moment fingers hit the device.

-

[1] Yu X, Wang H, Ning X, et al. 2018 Nat. Biomed. Eng. 2 165

Google Scholar

Google Scholar

[2] Koo J, MacEwan M R, Kang S K, et al. 2018 Nat. Med. 24 1830

Google Scholar

Google Scholar

[3] Ray T R, Choi J, Bandodkar A J, et al. 2019 Chem. Rev. 119 5461

Google Scholar

Google Scholar

[4] Wang C, Wang C, Huang Z, et al. 2018 Adv. Mater. 30 1801368

Google Scholar

Google Scholar

[5] Carlson A, Bowen A M, Huang Y, et al. 2012 Adv. Mater. 24 5284

Google Scholar

Google Scholar

[6] Sim K, Chen S, Li Z, et al. 2019 Nat. Electron. 2 471

Google Scholar

Google Scholar

[7] Liu Y, Xu Y, Avila R, et al. 2019 Nanotechnology 30 414001

Google Scholar

Google Scholar

[8] Rogers J A, Nuzzo R G 2005 Mater. Today 8 50

[9] Widlund T, Yang S, Hsu Y Y, et al. 2014 Int. J. Solids Struct. 51 4026

Google Scholar

Google Scholar

[10] Wang B, Bao S, Vinnikova S, et al. 2017 npj Flex. Electron. 1 1

Google Scholar

Google Scholar

[11] Xie Z, Ji B, Huo Q 2018 J. Appl. Mech. Trans. ASME 85 045001

Google Scholar

Google Scholar

[12] Chen H, Zhu F, Jang K I, et al. 2018 J. Mech. Phys. Solids 120 199

Google Scholar

Google Scholar

[13] Guo Q, Koo J, Xie Z, et al. 2019 Adv. Funct. Mater. 29 1905451

Google Scholar

Google Scholar

[14] Xie Z, Avila R, Huang Y, et al. 2019 Adv. Mater. 32 1902767

[15] Webb R C, Bonifas A P, Behnaz A, et al. 2013 Nat. Mater. 12 938

Google Scholar

Google Scholar

[16] Yang J, Shi R, Lou Z, et al. 2019 Small 15 1902801

Google Scholar

Google Scholar

[17] Boutry C M, Beker L, Kaizawa Y, et al. 2019 Nat. Biomed. Eng. 3 47

Google Scholar

Google Scholar

[18] Wang C C, Li X, Hu H, et al. 2018 Nat. Biomed. Eng. 2 687

Google Scholar

Google Scholar

[19] Ma Y, Choi J, Hourlier-Fargette A, et al. 2018 Proc. Natl. Acad. Sci. U. S. A. 115 11144

Google Scholar

Google Scholar

[20] Liu Y, Zhao L, Avila R, et al. 2020 Mater. Today Phys. 13 100199

Google Scholar

Google Scholar

[21] Wang Y, Qiu Y, Ameri S K, et al. 2018 npj Flex. Electron. 2 1

Google Scholar

Google Scholar

[22] Torrente-Rodríguez R M, Tu J, Yang Y, et al. 2020 Matter 2 921

Google Scholar

Google Scholar

[23] Kim S B, Lee K H, Raj M S, et al. 2018 Small 14 1802876

Google Scholar

Google Scholar

[24] Bandodkar A J, Gutruf P, Choi J, et al. 2019 Sci. Adv. 5 eaav3294

Google Scholar

Google Scholar

[25] Goni O, Lee S, Jin H, et al. 2020 PNAS 117 7063

Google Scholar

Google Scholar

[26] Lee K H, Ni X, Lee J H J Y, et al. 2019 Nat. Biomed. Eng. 4 148

[27] Liu Y, Norton J J S, Qazi R, et al. 2016 Sci. Adv. 2 e1601185

Google Scholar

Google Scholar

[28] Shin G, Gomez A M, Al-Hasani R, et al. 2017 Neuron 93 509

Google Scholar

Google Scholar

[29] Gutruf P, Rogers J A 2018 Curr. Opin. Neurobiol. 50 42

[30] Park S Il, Brenner D S, Shin G, et al. 2015 Nat. Biotechnol. 33 1280

Google Scholar

Google Scholar

[31] Chung H U, Kim B H, Lee J Y, et al. 2019 Science (80-.) 363 eaau0780

Google Scholar

Google Scholar

[32] Hong Y J, Jeong H, Cho K W, et al. 2019 Adv. Funct. Mater. 29 1808247

Google Scholar

Google Scholar

[33] Huang Z, Hao Y, Li Y, et al. 2018 Nat. Electron. 1 473

Google Scholar

Google Scholar

[34] Yu X, Xie Z, Yu Y, et al. 2019 Nature 575 473

Google Scholar

Google Scholar

[35] Liu Y, Wang L, Zhao L, et al. 2020 Adv. Electron. Mater. 6 1901174

Google Scholar

Google Scholar

[36] Liu Y, Zhao L, Wang L, et al. 2019 Adv. Mater. Technol. 4 1900744

Google Scholar

Google Scholar

[37] Erturk A, Inman D J 2011 Chichester

[38] Lin Z H, Yang Y, Wu J M, et al. 2012 J. Phys. Chem. Lett. 3 3599

Google Scholar

Google Scholar

[39] Niu X, Jia W, Qian S, et al. 2019 ACS Sustain. Chem. Eng. 7 979

Google Scholar

Google Scholar

[40] Liu Y, Wang L, Zhao L, et al. 2020 InfoMat 2 318

Google Scholar

Google Scholar

[41] Jung J H, Lee M, Hong J Il, et al. 2011 ACS Nano 5 10041

Google Scholar

Google Scholar

[42] Kim K H, Lee K Y, Seo J S, et al. 2011 Small 7 2577

Google Scholar

Google Scholar

[43] Hwang G T, Park H, Lee J H, et al. 2014 Adv. Mater. 26 4880

Google Scholar

Google Scholar

[44] Park K Il, Son J H, Hwang G T, et al. 2014 Adv. Mater. 26 2514

Google Scholar

Google Scholar

[45] Dagdeviren C, Yang B D, Su Y, et al. 2014 Proc. Natl. Acad. Sci. U. S. A. 111 1927

Google Scholar

Google Scholar

[46] Arumugam V, Naresh M D, Sanjeevi R 1994 J. Biosci. 19 307

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 16496

- PDF Downloads: 534

- Cited By: 0

DownLoad:

DownLoad: